Preparation method and application of ultra-micro silver-loading titanium dioxide photocatalyst

A technology of silver-loaded titanium dioxide and photocatalyst, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of long preparation time, low preparation efficiency, and silver loading. The problem of high content, to achieve the effect of good dispersibility, reduced compound rate, and low silver content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

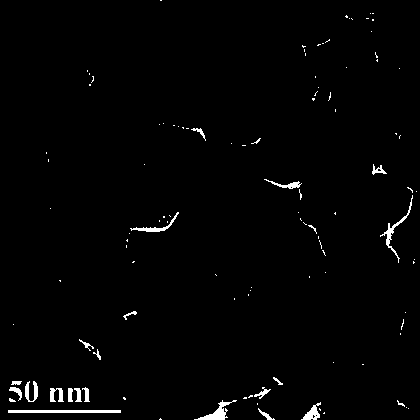

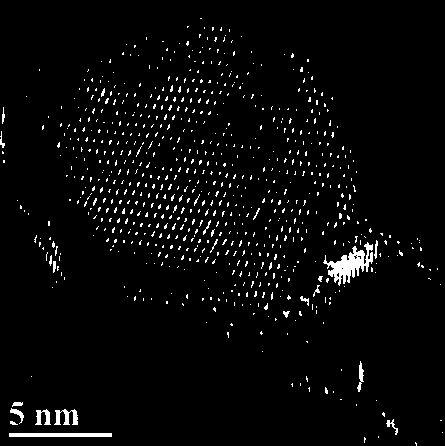

[0032] A preparation method of an ultra-trace amount of silver-loaded titanium dioxide photocatalyst, comprising the following steps:

[0033] A, mixing step, in the ethanol solution that is dissolved with titanium dioxide P25, add silver nitrate alcohol solution, the solution after mixing is placed in ultrasonic breaker and disperses;

[0034] B, photoreaction step, the solution after dispersion is poured in the quartz reactor, irradiates with 300W mercury lamp and feeds nitrogen to prevent the nano-state silver that reduction generates from being oxidized;

[0035] c. Drying step: Centrifuge the solution after the photoreaction, remove the supernatant, put the precipitate into a vacuum freeze dryer for freeze-drying, take it out after 36 hours of freeze-drying and grind it, and then obtain an ultra-trace amount of silver-loaded titanium dioxide photocatalyst .

[0036] In said step a, the ethanol solution having titanium dioxide P25 dissolved is obtained by dissolving titan...

Embodiment 1

[0058] A preparation method of an ultra-trace amount of silver-loaded titanium dioxide photocatalyst, comprising the following steps:

[0059] S1, mixing step

[0060] Dissolving p25: Add 0.8g of titanium dioxide P25 into a beaker, add 74mL of absolute ethanol, stir mechanically until completely dissolved;

[0061] Preparation of silver nitrate alcohol solution: Weigh 0.0126g of silver nitrate, add 100mL of absolute ethanol to dissolve, take 6ml of the above solution and add it dropwise to the P25 solution. The time is 30 minutes.

[0062] S2, photoreaction step

[0063] Add the solution obtained in the mixing step into a photochemical reaction quartz reactor, add a magnetic plastic rotor, and adjust the speed to 400r / min to make the solution more uniform. Adjust the power of the mercury lamp to 300W, and the irradiation time is 30min.

[0064] S3, drying step

[0065] The solution obtained in the photoreaction step was poured into a centrifuge tube, and the centrifuge sp...

Embodiment 2

[0068] A preparation method of an ultra-trace amount of silver-loaded titanium dioxide photocatalyst, comprising the following steps:

[0069] S1, mixing step

[0070] Dissolving p25: Add 0.8g of titanium dioxide P25 into a beaker, add 77mL of absolute ethanol, stir until completely dissolved;

[0071] Preparation of silver nitrate alcohol solution: Weigh 0.0126g of silver nitrate, add 100mL of absolute ethanol to dissolve, take 3ml of the above solution and add it dropwise to the P25 solution. for 30min.

[0072] S2, photoreaction step

[0073] Add the solution obtained in the mixing step into a photochemical reaction quartz reactor, add a magnetic plastic rotor, and adjust the speed to 400r / min to make the solution more uniform. Adjust the power of the mercury lamp to 300W and irradiate for 30min.

[0074] S3, drying step

[0075] The solution obtained in the photoreaction step was poured into a centrifuge tube, and the centrifuge speed was set to 7000 revolutions per m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com