Electromagnetic disc brake and traction machine provided with same

A technology of brakes and electro-magnetic disks, applied in the field of traction machines, can solve the problems of direct contact between the brake disks and the motor housing, difficulty in adjusting the brakes, etc., so as to eliminate low machining accuracy, avoid low machining accuracy, and reduce materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The electromagnetic disk brake of the present invention and the traction machine equipped with the electromagnetic disk brake will be described in detail below in conjunction with the accompanying drawings.

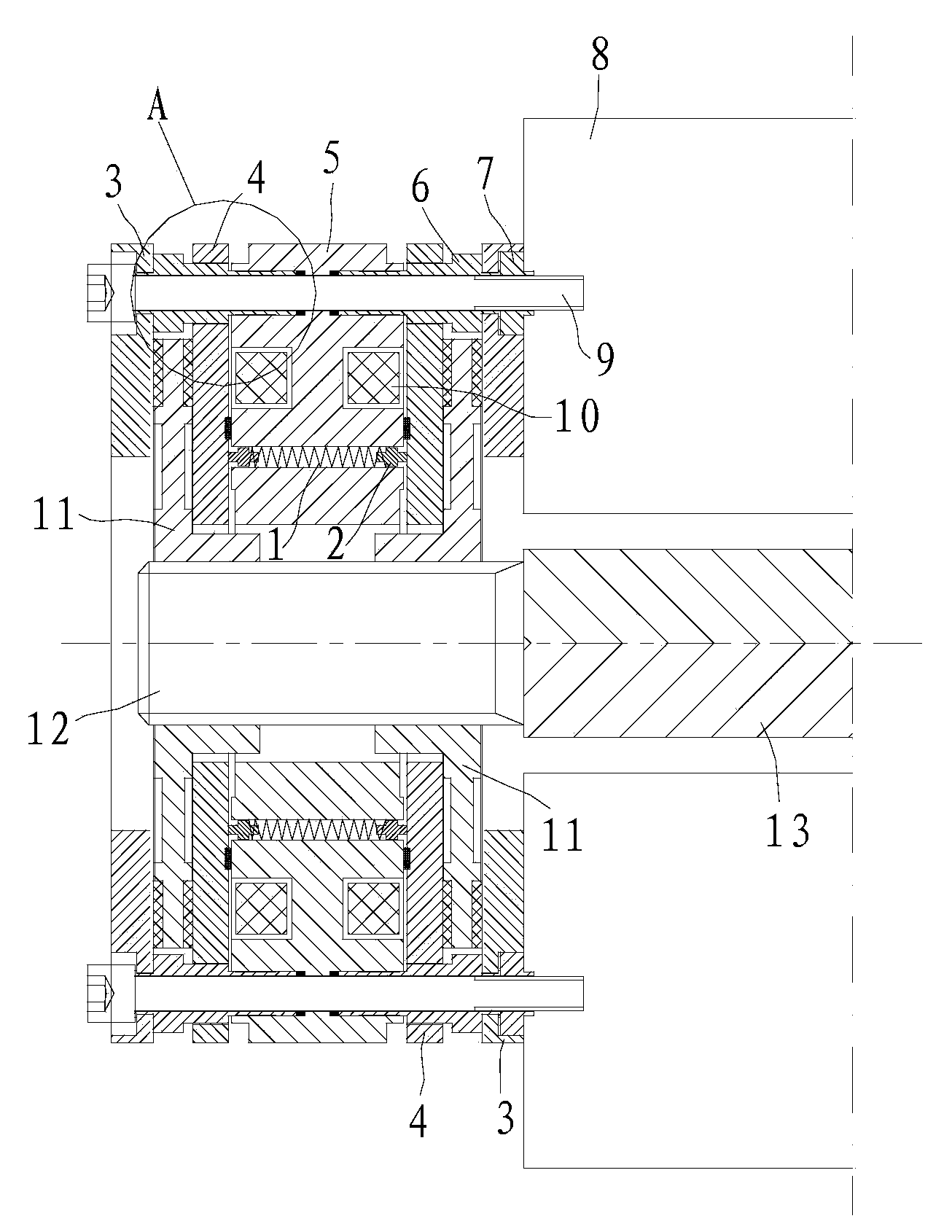

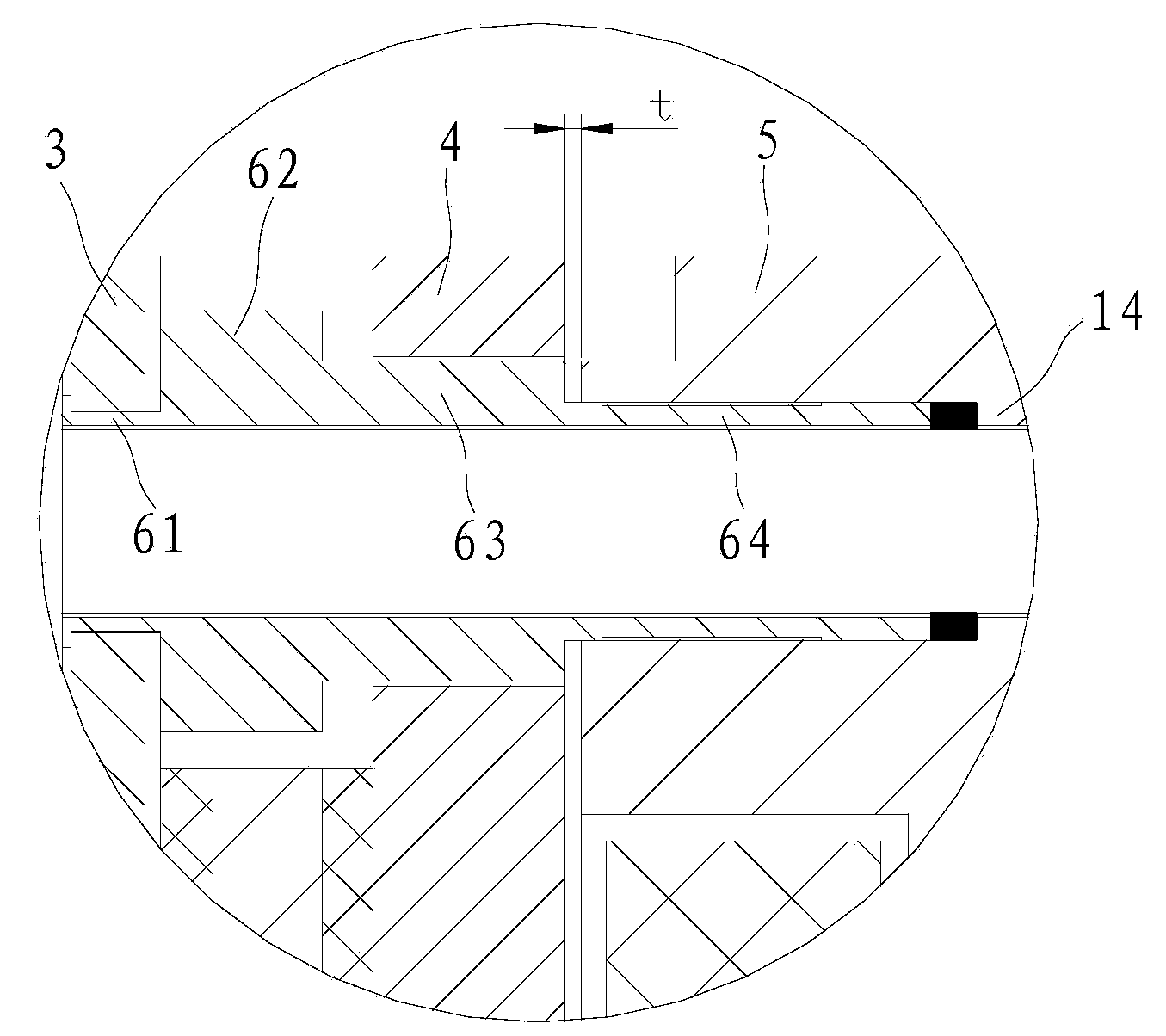

[0038] Such as figure 1 Shown, a kind of electromagnetic disk type brake comprises the static iron core 5 and moving iron core 4 that interact by electromagnetic force, and the brake disc 11 that is fixed with main shaft 13 (between the rotating shaft 12 of brake disc 11 and the main shaft 13 of motor fixedly connected by splines) and the brake plate 3 that cooperates with the moving iron core 4 to clamp the brake disc 11.

[0039] There are two moving iron cores 4 located on both sides of the static iron core 5 respectively, and two sets of brake discs 11 and brake plates 3 are arranged outside the corresponding moving iron cores 4 in turn.

[0040] There are two coil windings 10, and there are slots for accommodating the two coil windings 10 respectively. The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com