Large thin-wall carbon fiber needling prefabricated body and preparation method thereof

A carbon fiber preform and carbon fiber technology, applied in the field of composite materials, can solve the problems of difficult to ensure dimensional accuracy and parallelism, reduce overall performance and stability, increase production costs, etc., to ensure process stability and preparation efficiency, improve uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

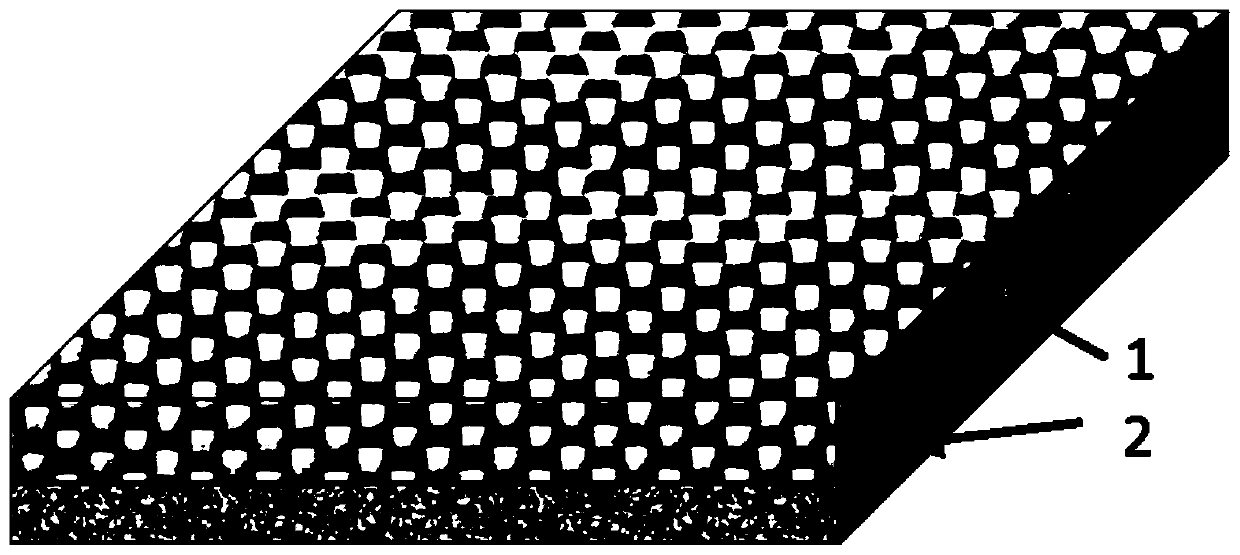

[0029] refer to figure 1 , a large thin-walled carbon fiber preform Y1, the carbon fiber needle-punched preform is a flat fabric with a specification of 800mm×500mm×4mm, and the volume density of the carbon fiber preform is required to be 0.45g / cm 3 . The needle-punched prefabricated body is composed of 16 structural unit layers, and each structural unit layer is composed of 1 layer of carbon fiber / PE fiber hybrid mesh tire and 1 layer of carbon fiber / PE fiber hybrid plain weave cloth. Among them, the density of the carbon fiber / PE fiber hybrid mesh tire is 50g / m 2 , wherein the content of PE fiber is 50wt%; the density of carbon fiber / PE hybrid plain weave is 250g / m 2 , wherein the content of PE fiber is 20wt%.

[0030] Prepare the carbon fiber preform Y1 as follows:

[0031] (1) Production of mixed fiber cloth and mixed fiber mesh

[0032] (1.1) Preparation of carbon fiber / PE fiber hybrid cloth:

[0033] 12K carbon fiber yarn is used as the warp yarn, 800D PE fiber yar...

Embodiment 2

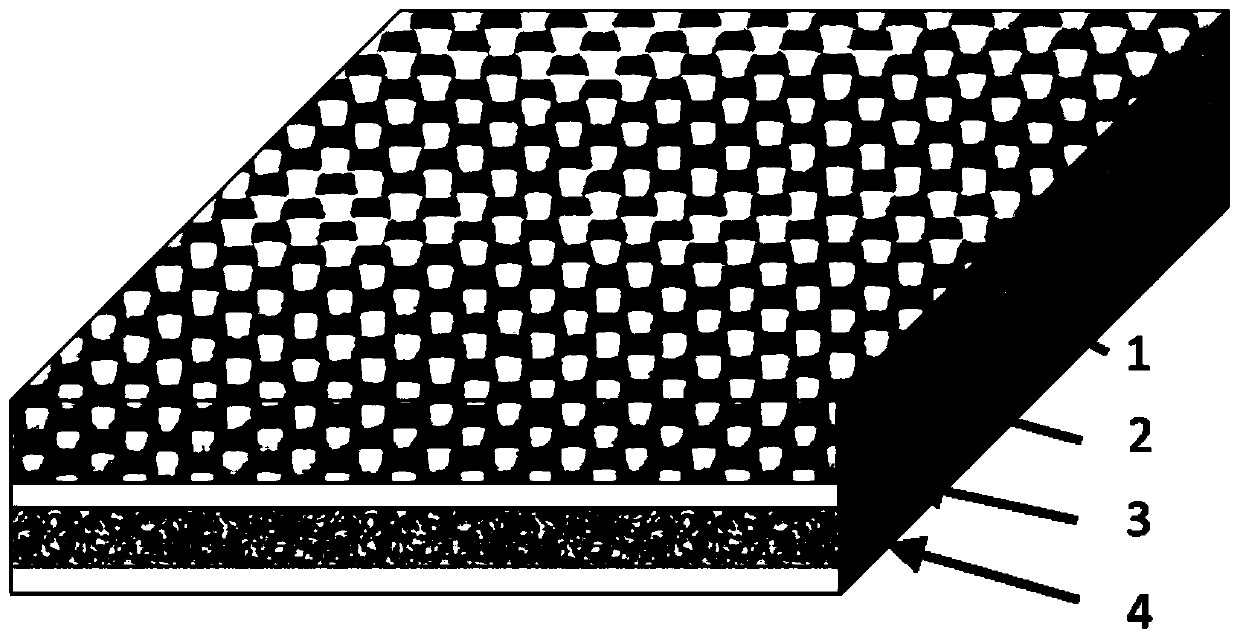

[0045] refer to figure 2 The last two layers of the unit layer, that is, 3 and 4 layers, a large thin-walled carbon fiber prefabricated body Y1, the carbon fiber needle-punched prefabricated body is a flat fabric with a specification of 500mm×500mm×2mm, and the volume density of carbon fiber is required to be 0.10g / cm 3 . The acupuncture prefabricated body is composed of 8 structural unit layers, and each structural unit layer is composed of 1 layer of carbon fiber mesh tire and 1 layer of PP film. Among them, the density of the carbon fiber net tire is 50g / m 2 , the thickness of the PP resin film is 0.1mm.

[0046] Prepare the carbon fiber preform Y1 as follows:

[0047] (1) Production of fiber mesh tires

[0048] Distribution The carbon fiber is chopped, the chopped length of the carbon fiber is 50mm, and after opening, carding and laying, the surface density is 50g / m 2 mixed fiber mesh tire;

[0049] (2) Preparation of structural unit layer

[0050]A layer of carbon...

Embodiment 3

[0058] refer to figure 2 , a large thin-walled carbon fiber preform Y3, the carbon fiber needle-punched preform is a cylindrical fabric with a length of 800mm, an inner diameter of 600mm, and a wall thickness of 2mm. The volume density of carbon fiber is required to be 0.80g / cm 3 . The acupuncture prefabricated body is composed of 4 structural unit layers, and each structural unit layer is composed of 2 layers of carbon fiber mesh, 2 layers of carbon fiber unidirectional cloth and 4 layers of PC film. Among them, the density of the carbon fiber mesh tire is 100g / m 2 , the density of carbon cloth is 300g / m 2 , PC film thickness is 0.05mm.

[0059] Prepare the carbon fiber preform Y3 as follows:

[0060] (1) Production of carbon fiber cloth and carbon fiber mesh

[0061] (1.1) Preparation of carbon cloth:

[0062] Use 12K carbon fiber yarn as the warp yarn and polyester yarn as the weft yarn binding yarn, weaving on the loom with an area density of 300g / m 2 carbon fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com