Method for manufacturing cable bridge elbow

A technology of cable bridge and manufacturing method, applied in the direction of electrical components, etc., to achieve the effect of ensuring the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

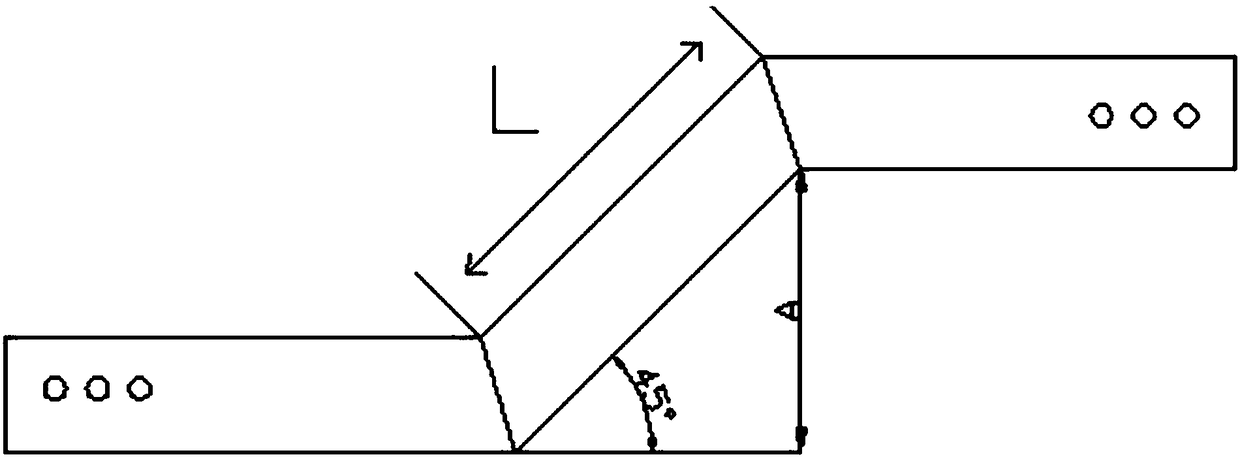

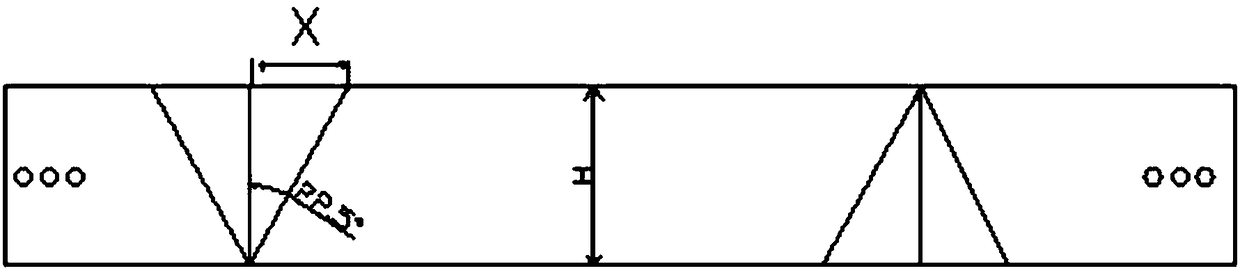

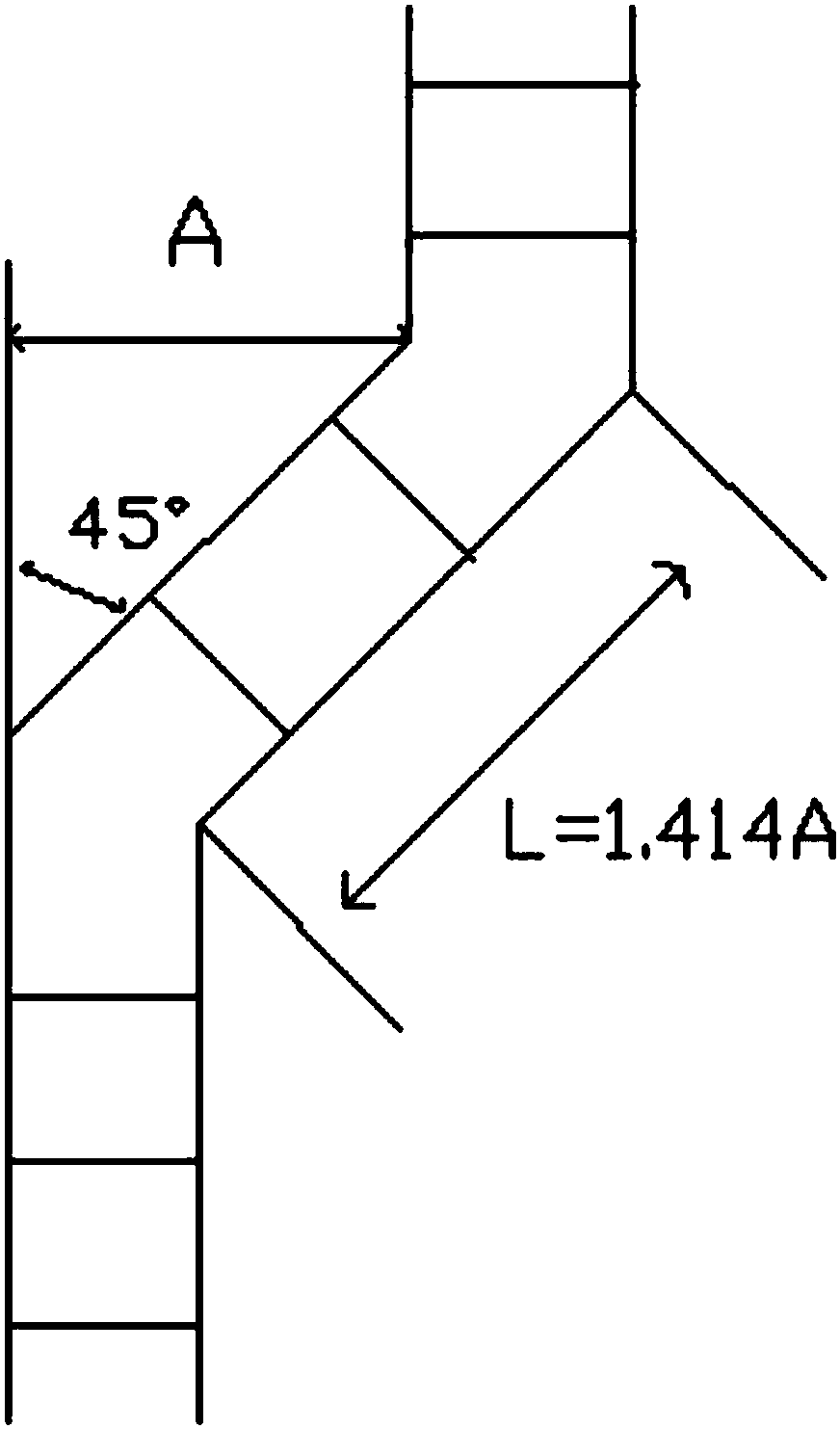

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as Figure 1 to Figure 3 As shown, the present invention provides a method for manufacturing a cable tray elbow, comprising:

[0018] 1) For the joints of the self-made cable tray elbow, jump bend and tee, spot welding is fixed on the inside first, and the burr coating is polished to ensure that the outside is flat, the gap is 5-10mm, and the saw edge is smooth and tidy;

[0019] 2) There is no wrong edge in the butt joint of the cable bridge elbow, so as to ensure that the welded joint is smooth and clean;

[0020] 3) When adding steel bars in the tray-type cable bridge, use ¢6-8MM round steel, and paint on the inside and outside;

[0021] 4) After the self-made tees and elbows of the multi-layer cable tray are installed, ensure that the knuckles are on a vertical unified straight line;

[0022] 5) After all the self-made elbows are made, apply anti-rus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com