Method for manufacturing variable curvature cold bent pipe

A manufacturing method, technology of cold-bending pipes, applied in the field of mechanical product manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

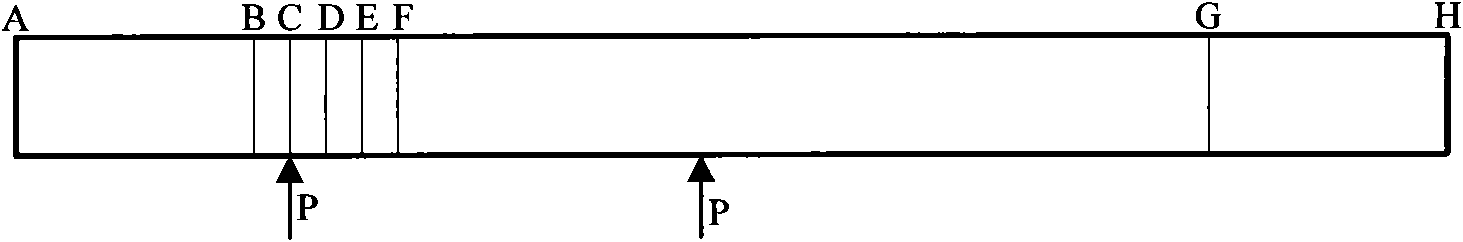

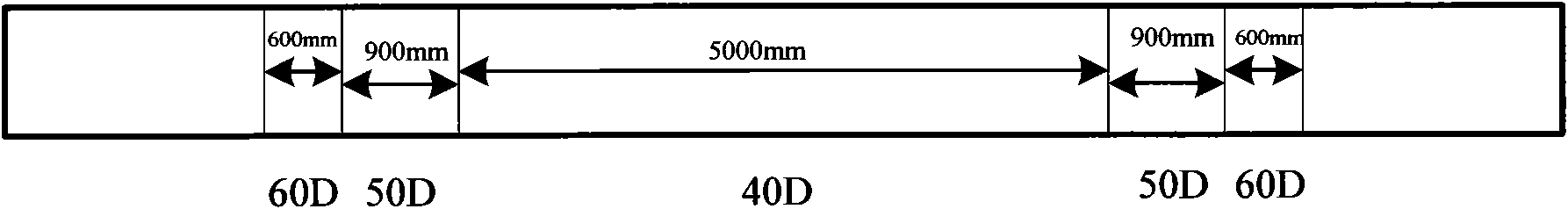

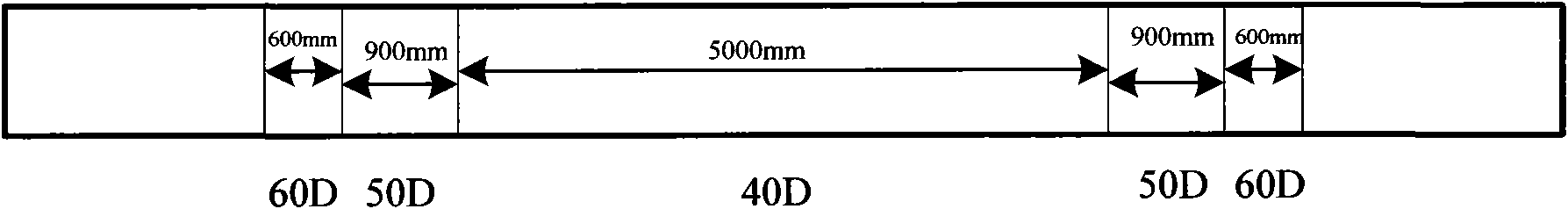

[0017] For example: to bend a steel pipe with a length of 12m and a diameter of 1016mm, and the straight pipe sections at both ends of the cold-bent pipe are both 2m long, so the effective bending length of the steel pipe is 8m. The variable curvature manufacturing process is used for bending. The commonly used cold-bent pipe construction specification stipulates that the radius of curvature is greater than 40D. Based on this, the 600mm pipe section near the pipe end is selected to be bent with a curvature radius of 60D. The adjacent 900mm pipe section Bending with a radius of curvature of 50D, and the middle section of the steel pipe with a radius of curvature of 40D, such as figure 2 shown.

[0018] use figure 2 In the variable curvature bending method shown, the bendable angle within the effective bending length of 8m is 10.2°, while the Φ1016mm cold-bent pipe for oil and gas transportation generally does not exceed 10°, so the variable-curvature cold-bend pipe and its m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com