Shoemaking glue production equipment based on wheel transmission

A production equipment and wheel drive technology, which is applied to mixers, dissolvers, mixers and other directions with rotating stirring devices, can solve the problems of low stirring efficiency, difficult control, and high glue viscosity, so as to improve the stirring effect and avoid the dead angle of stirring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

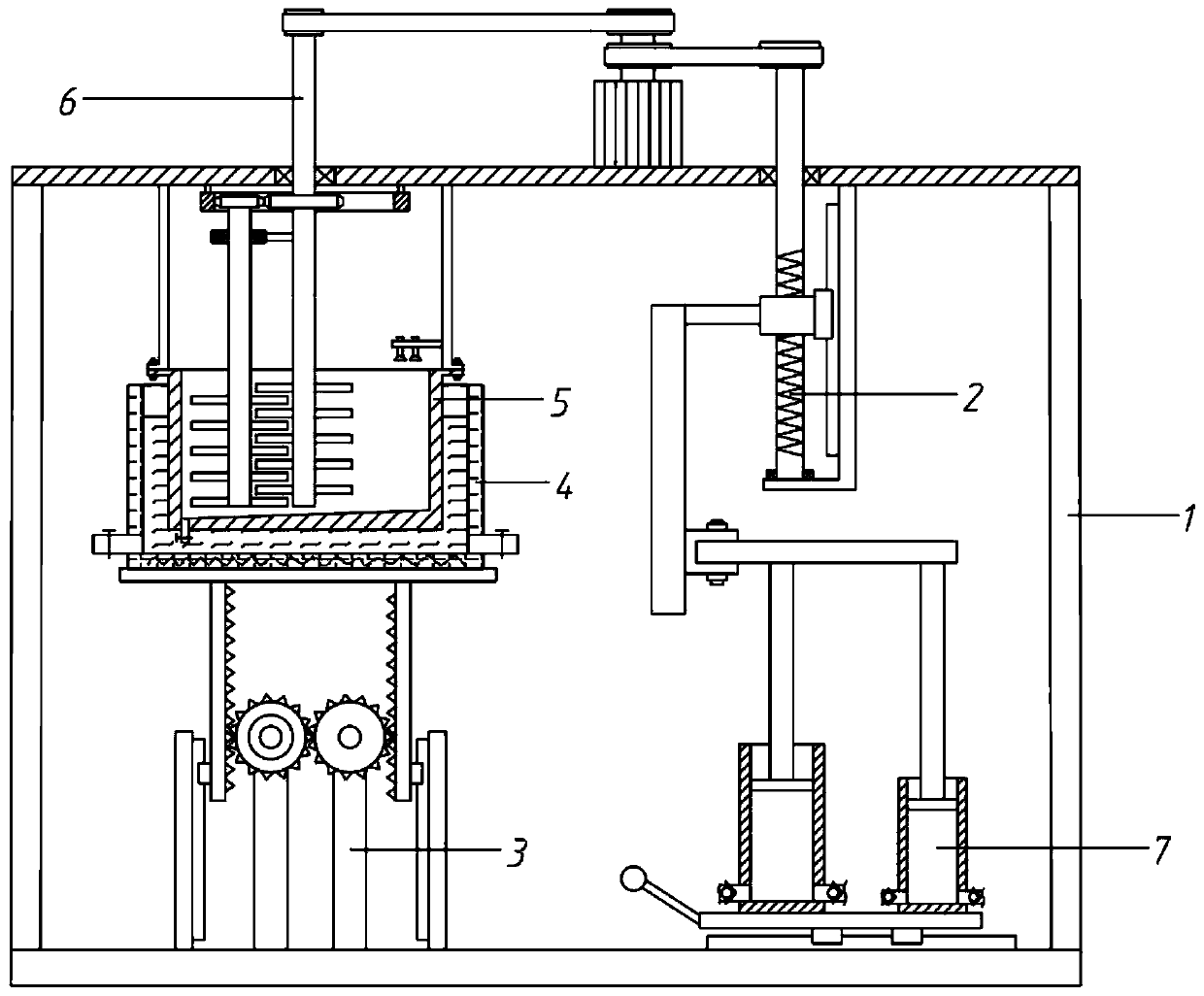

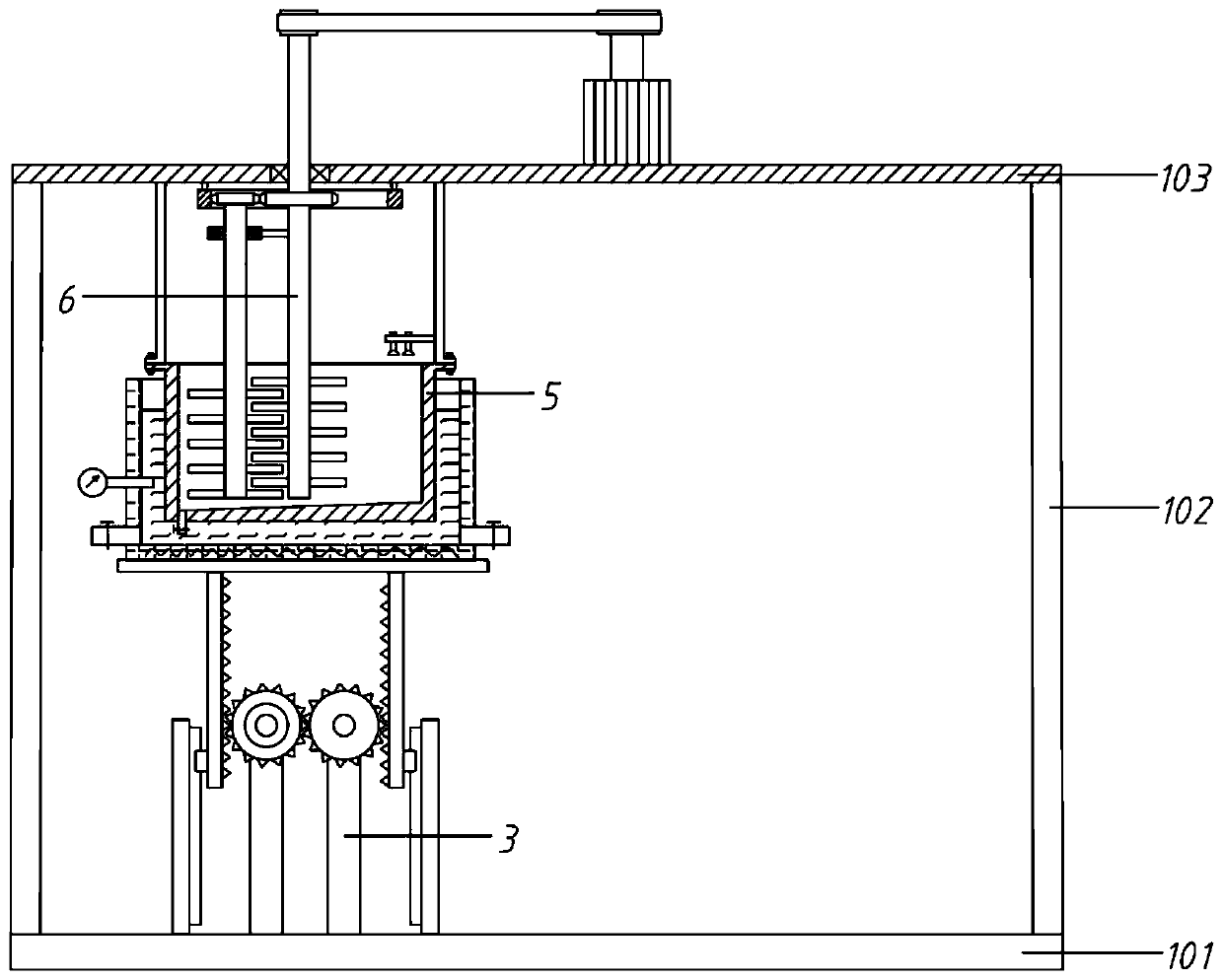

[0060] A wheel drive-based glue production equipment for shoemaking, including a frame 1, a mixing barrel 5, a water bath barrel 4, a lifting component 3, and a mixing component 6;

[0061] The frame 1 includes a bottom plate 101, a vertical plate 102 and a top plate 103, the top plate 103 is arranged above the bottom plate 101, and the corresponding left and right ends of the two are connected by the vertical plate 102;

[0062] The left part of the bottom plate 101 is provided with a lifting assembly 3, and the top of the lifting assembly 3 is provided with a water bath barrel 4; the top plate 103 downwardly corresponds to the water bath barrel 4 and is connected with a mixing barrel 5 through a three-type connecting rod 503; the mixing barrel 5 is provided with a stirring assembly 6.

Embodiment 2

[0064] A wheel drive-based glue production equipment for shoemaking, including a frame 1, a mixing barrel 5, a water bath barrel 4, a lifting component 3, and a mixing component 6;

[0065] The frame 1 includes a bottom plate 101, a vertical plate 102 and a top plate 103, the top plate 103 is arranged above the bottom plate 101, and the corresponding left and right ends of the two are connected by the vertical plate 102;

[0066] The left part of the bottom plate 101 is provided with a lifting assembly 3, and the top of the lifting assembly 3 is provided with a water bath barrel 4; the top plate 103 downwardly corresponds to the water bath barrel 4 and is connected with a mixing barrel 5 through a three-type connecting rod 503; the mixing barrel 5 is provided with a stirring assembly 6.

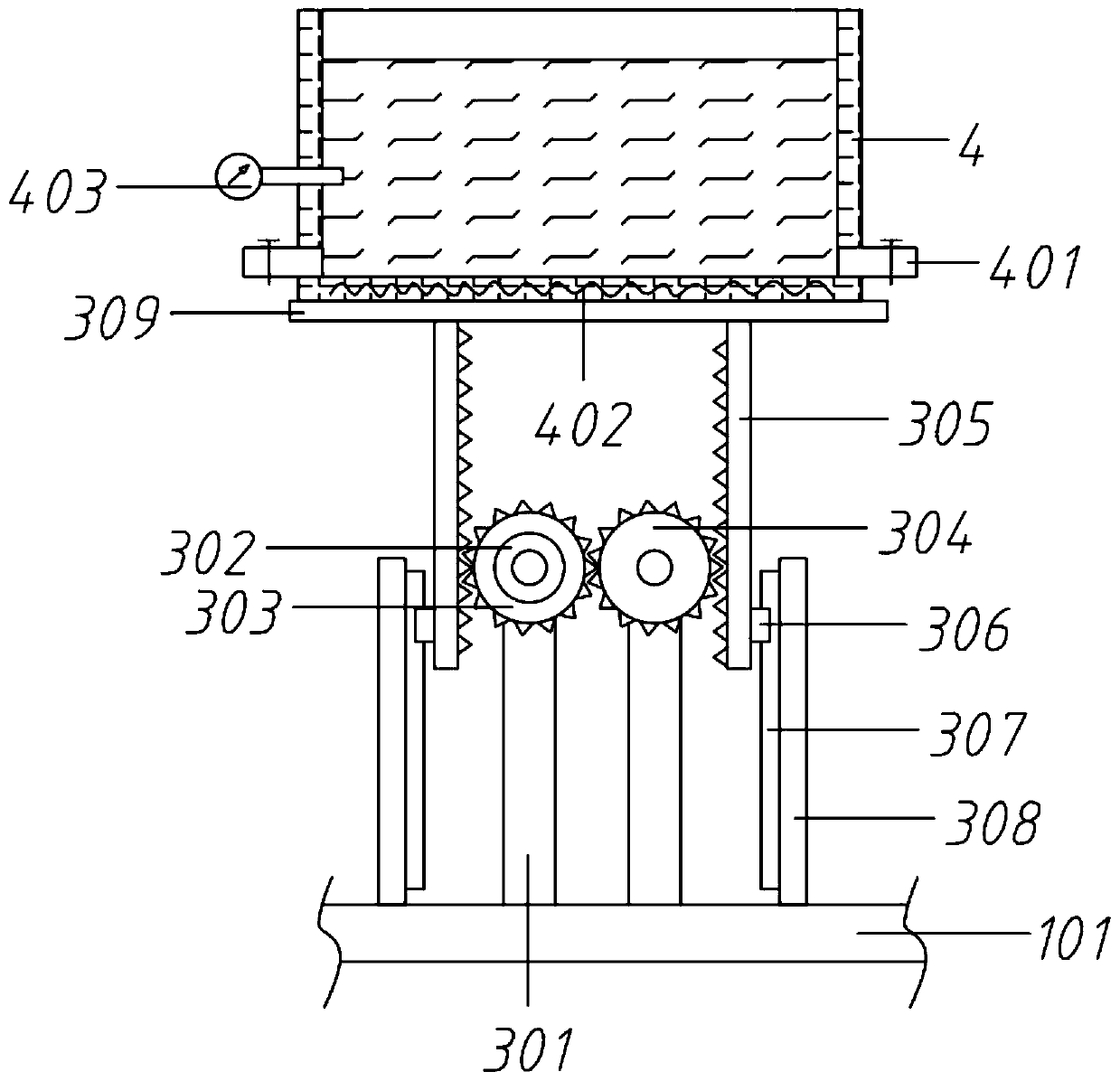

[0067] Among them, the lifting assembly 3 includes a mounting frame 301, a No. 1 servo motor 302, a No. 1 gear 303, a No. 2 gear 304, a rack 305, a No. 1 sliding block 306, a No. 1 slide rail 307, a ...

Embodiment 3

[0077] On the basis of Example 2,

[0078] The stirring assembly 6 also includes an outer ring gear 801, a driving gear 802, a driven gear 803, a four-category connecting rod 804, a supporting seat 805, and a driven shaft 806;

[0079] The outer gear ring 801 is fixed under the top plate 103, and the third rotating shaft 604 and the outer gear ring 801 are coaxial; the third rotating shaft 604 is equipped with a driving gear 802, and a driven gear 803 is arranged between the driving gear 802 and the outer gear 801 , The driven gear 803 meshes with the driving gear 802 and the outer ring gear 801; the side of the third rotating shaft 604 is also connected to a support base 805 through a four-category connecting rod 804; the driven gear 803 is downwardly connected with a driven shaft 806, The moving shaft 806 passes through and is rotatably connected to the support base 805 through a bearing; the driven shaft 806 extends into the mixing barrel 5, and the staggered mixing rod 605 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com