Flotation pulp-mixing method and flotation pulp-mixing equipment capable of improving mineralization effect

A pulping and pulping technology, which is applied in flotation, solid separation, etc., can solve the problems of unable to quantitatively adjust the gas content of pulp, high ash content of clean coal, and low mineralization efficiency, so as to improve the pulping effect, promote agglomeration, The effect of increasing the apparent diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings.

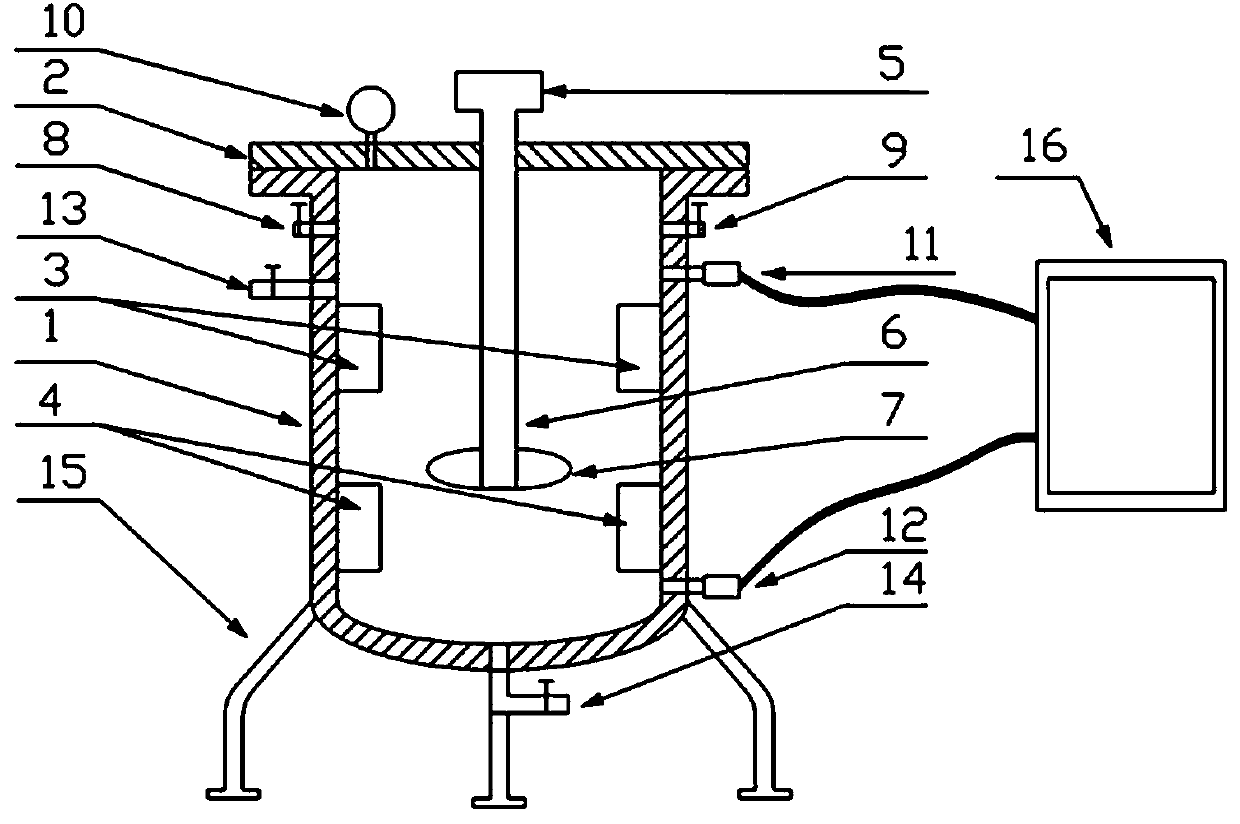

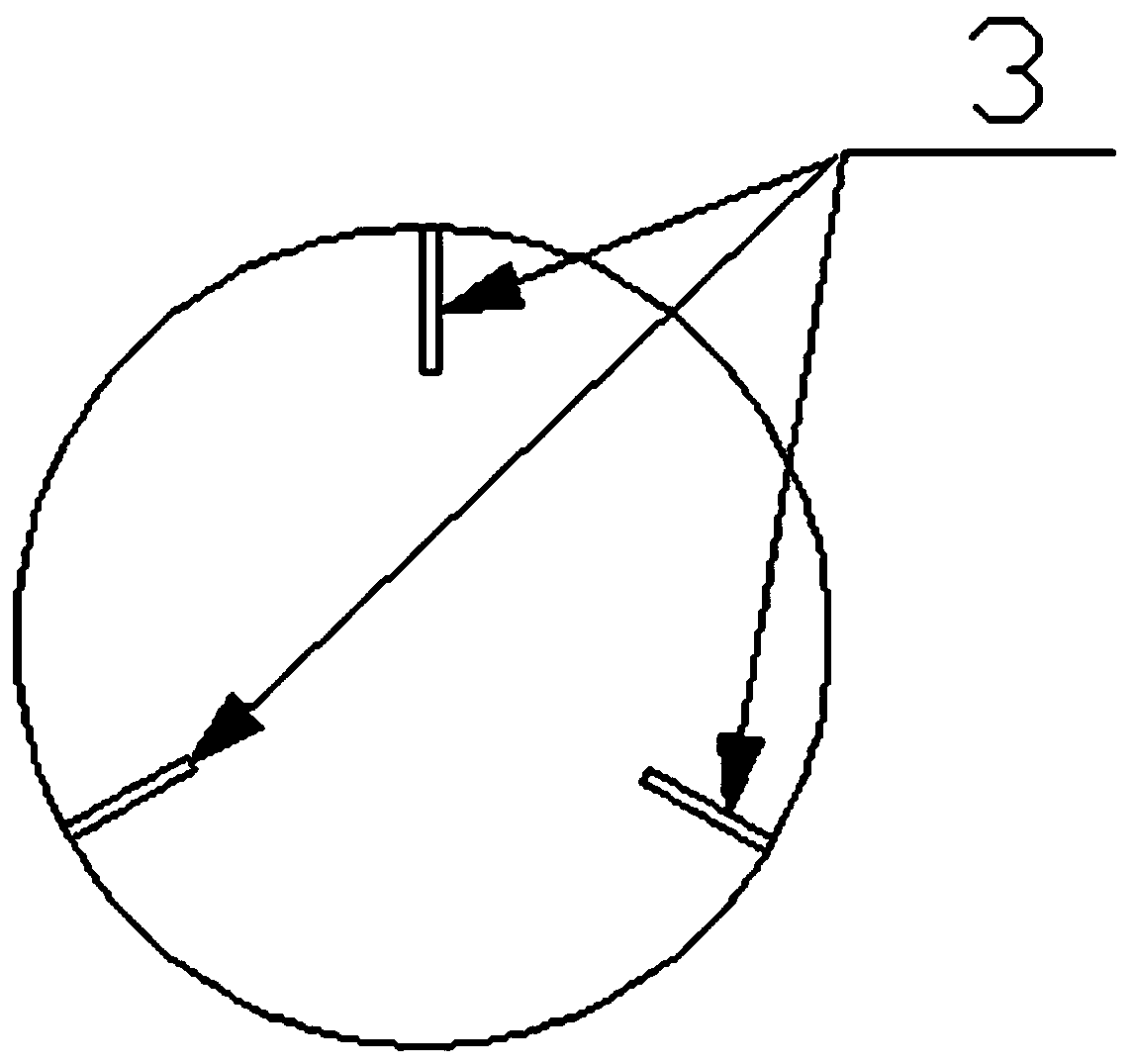

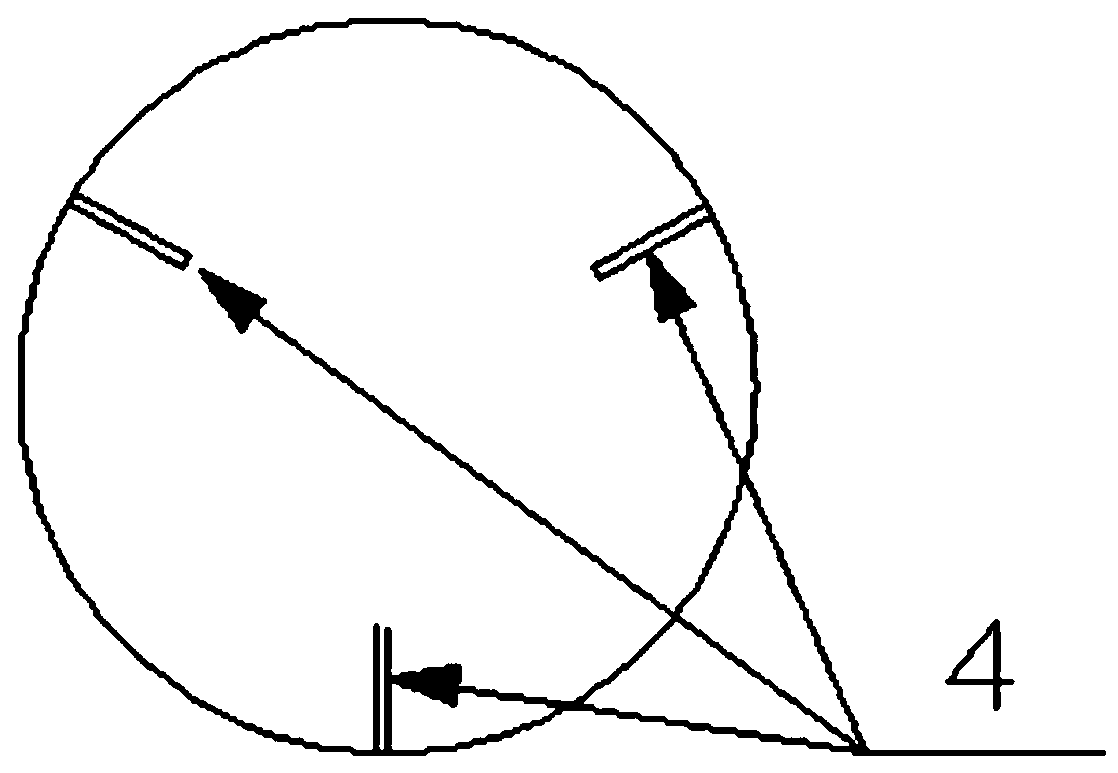

[0024] The present invention includes barrel body 1, sealing cover 2, upper baffle 3, lower baffle 4, stirring motor 5, stirring shaft 6, stirring impeller 7, suction valve 8, exhaust valve 9, pressure gauge 10, pressure sensor 11 And 12, material inlet 13, material outlet 14, support 15, processor 16. The sealing cover 2 is closely connected with the barrel body 1, the upper baffle plate 3 and the lower baffle plate 4 are evenly distributed and installed inside the barrel body 1, the stirring shaft 6 passes through the center of the sealing cover 2 and is connected to the external stirring motor 5, and the end of the stirring shaft 6 is connected to the The stirring impeller 7 is connected, the suction valve 8 and the exhaust valve 9 are installed on the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com