Patents

Literature

53results about How to "Eliminate stirring dead angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

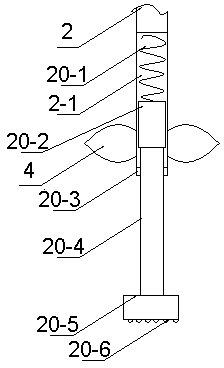

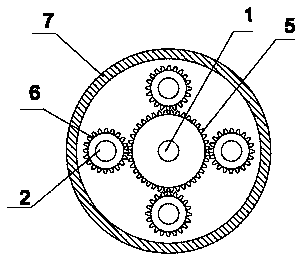

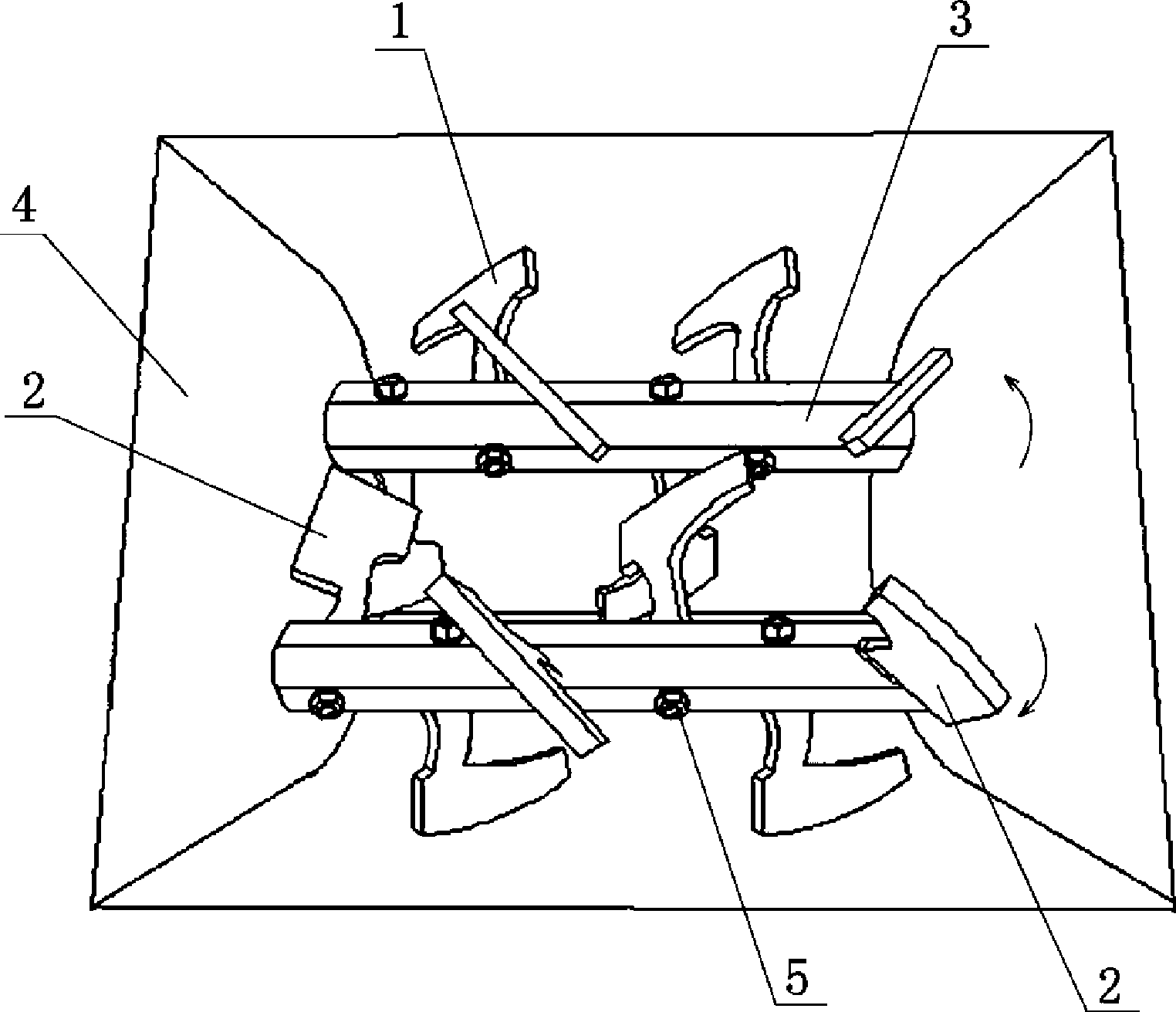

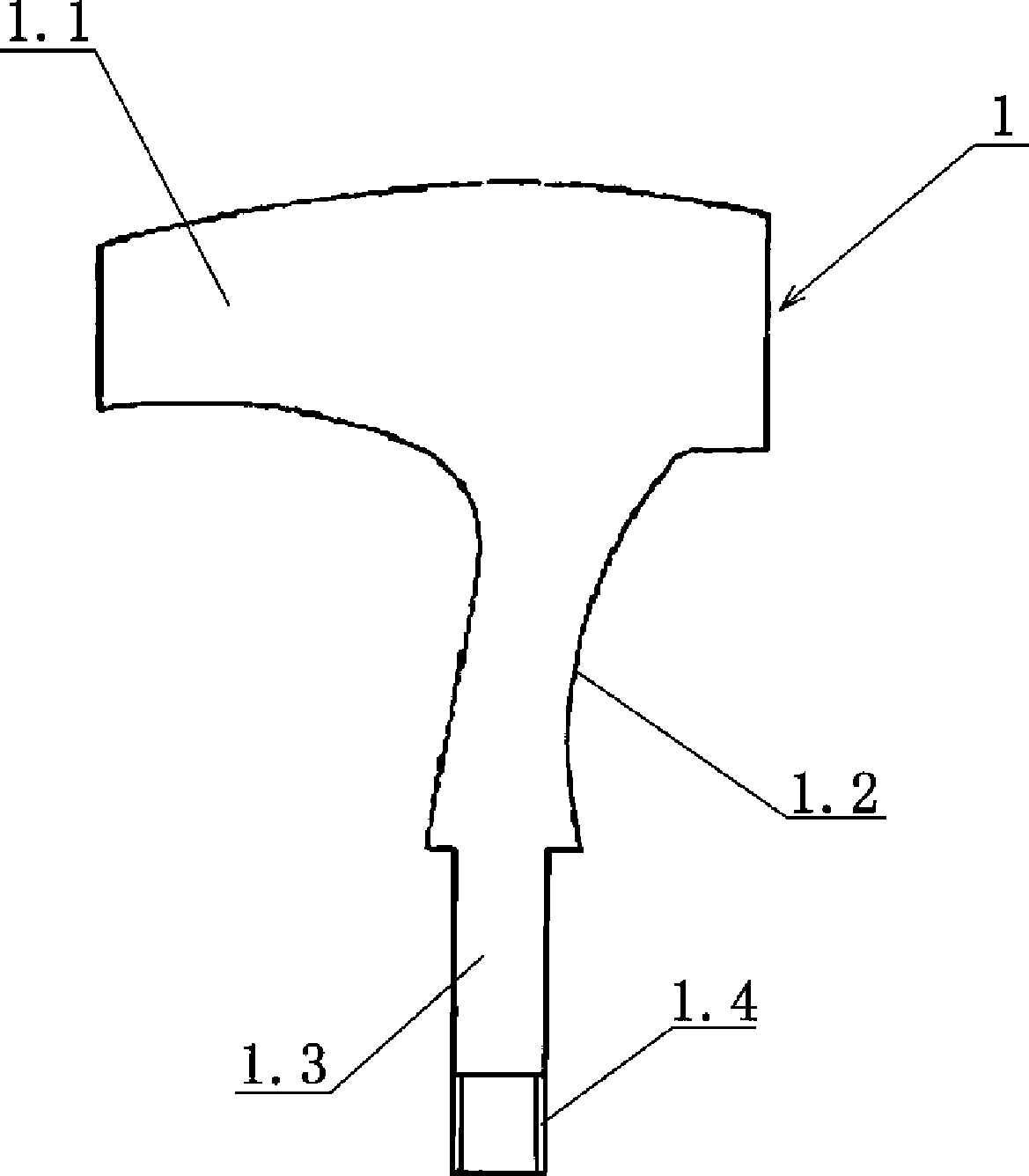

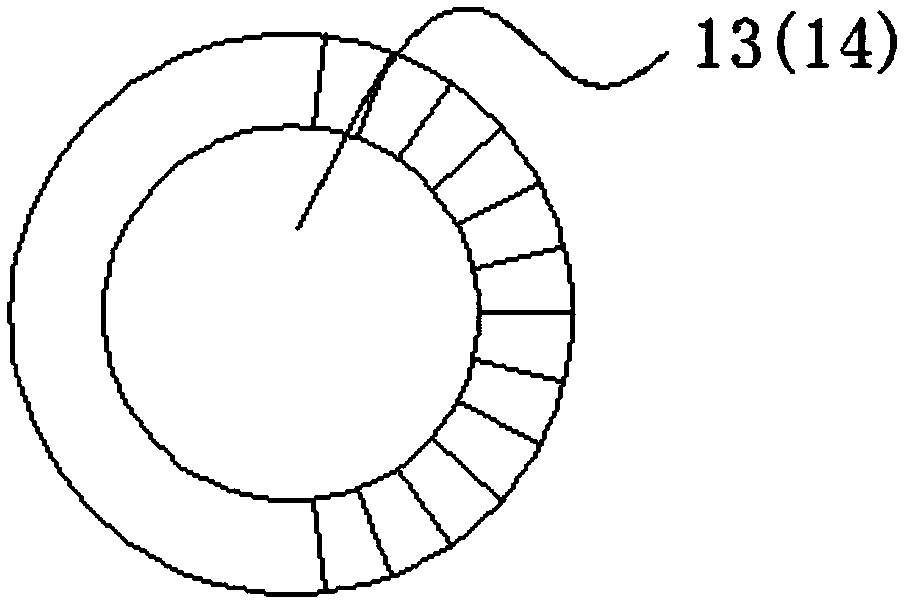

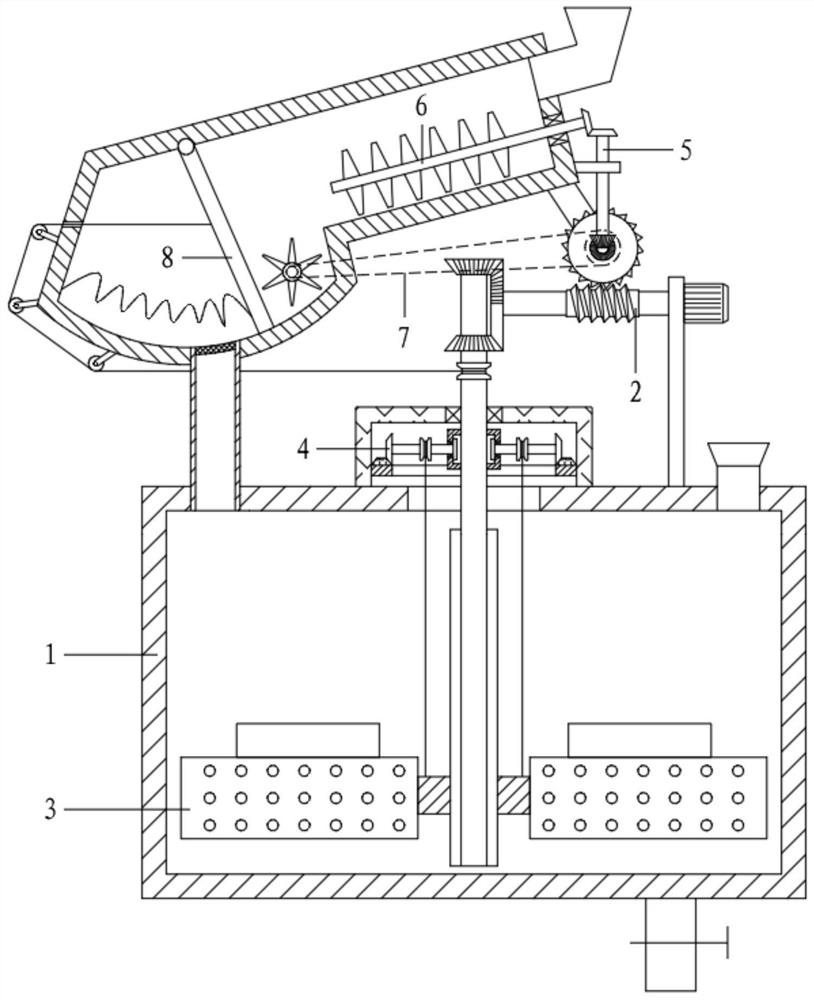

Multi-head printing ink mixing machine

ActiveCN103949175AAll-round three-dimensional mixingImprove stirring efficiencyRotary stirring mixersProcess engineeringPrinting ink

The invention relates to a multi-head printing ink mixing machine. The multi-head printing ink mixing machine comprises a mixing supporting device, a power device, a stirring device and a floating bottom-scraping device, wherein the power device and the stirring device are fixedly arranged on the mixing supporting device. The multi-head printing ink mixing machine is characterized in that the stirring device comprises a main stirring shaft, auxiliary stirring shafts, main stirring blades, auxiliary stirring blades, a gear box and a master gear and pinions, which are arranged in the gear box, wherein the gear box is fixedly arranged at the upper part of the main stirring shaft by a first bearing and a second bearing, the master gear is arranged at the center of the gear box and is fixedly connected with the main stirring shaft, the pinions are uniformly distributed at the periphery of the master gear, are meshed with the master gear and are fixed on the gear box by the auxiliary stirring shafts, and the main stirring blades and the auxiliary stirring blades are arranged on the main stirring shaft and the auxiliary stirring shafts, respectively. The multi-head printing ink mixing machine has the beneficial effects of solving the problems of low slurry stirring efficiency and poor slurry stirring effect.

Owner:烟台市裕同印刷包装有限公司

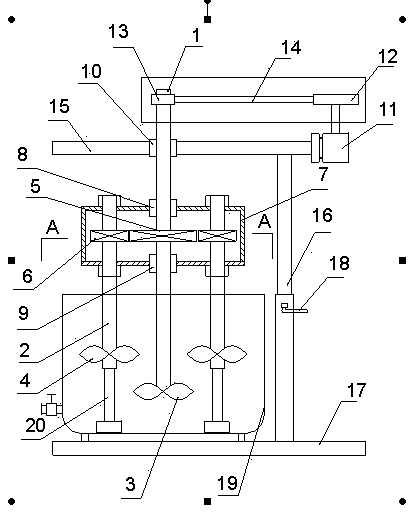

Concrete mixer for construction site

InactiveCN107186889AImprove the mixing effectSimple structureDischarging apparatusCement mixing apparatusMotor driveHelical blade

The invention discloses a concrete mixer for a construction site, which comprises a base, a buffer pad is provided at the lower end of the base, a support plate is vertically provided on the upper left side of the base, a mixing drum is provided above the base, a stirring shaft is provided inside the mixing drum, and a stirring shaft The left end passes through the left side wall of the mixing drum and the support plate, and is connected to the output end of the No. Movable stirring rod, the stirring shaft on the right side of the movable stirring rod shaft is provided with a helical blade. The structure of the present invention is simple and reasonable. While the No. The gear ring drives the mixing drum to rotate in reverse, thus eliminating the dead angle of mixing, and this reverse cross mixing mechanism can generate shear force on the material during mixing, thereby greatly improving the mixing effect of the material and has strong practicability.

Owner:童红妃

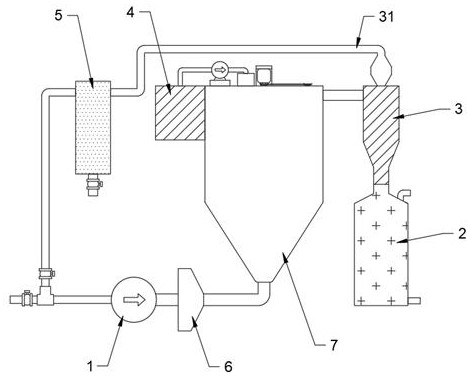

Lake asphalt melting and stirring system

ActiveCN102732281AAvoid high temperature heatingReduce the temperatureWorking-up pitch/asphalt/bitumen by meltingAsphaltPolymer chemistry

The invention relates to a melting and stirring system in the building material industry, in particular to a lake asphalt melting and stirring system for treating naturally mined lake asphalt solidified into solid state. The lake asphalt melting and stirring system comprises a heat insulating stirring pot, and also comprises a melting device communicated with the pot body of the heat insulating stirring pot; the melting device comprises a melting bin with a first heating unit and a second heating unit installed on the outer wall; the second heating unit is provided with a gap part for the lake asphalt molten into liquid to flow into the heat insulating stirring pot; and the lake asphalt enters the heat insulating stirring pot after the completion of melting. Both the heat insulating stirring pot and the melting device can be used for continuous production, and intermittent shutdown is avoided, so that the yield is improved, and as only the melting device is subject to high-temperature heating, the temperature of the heat insulating stirring pot keeps low, not all the asphalt is subject to high-temperature heating, and energy consumption is reduced.

Owner:JIZHOU XINCHENG CHEM EQUIP TECH +1

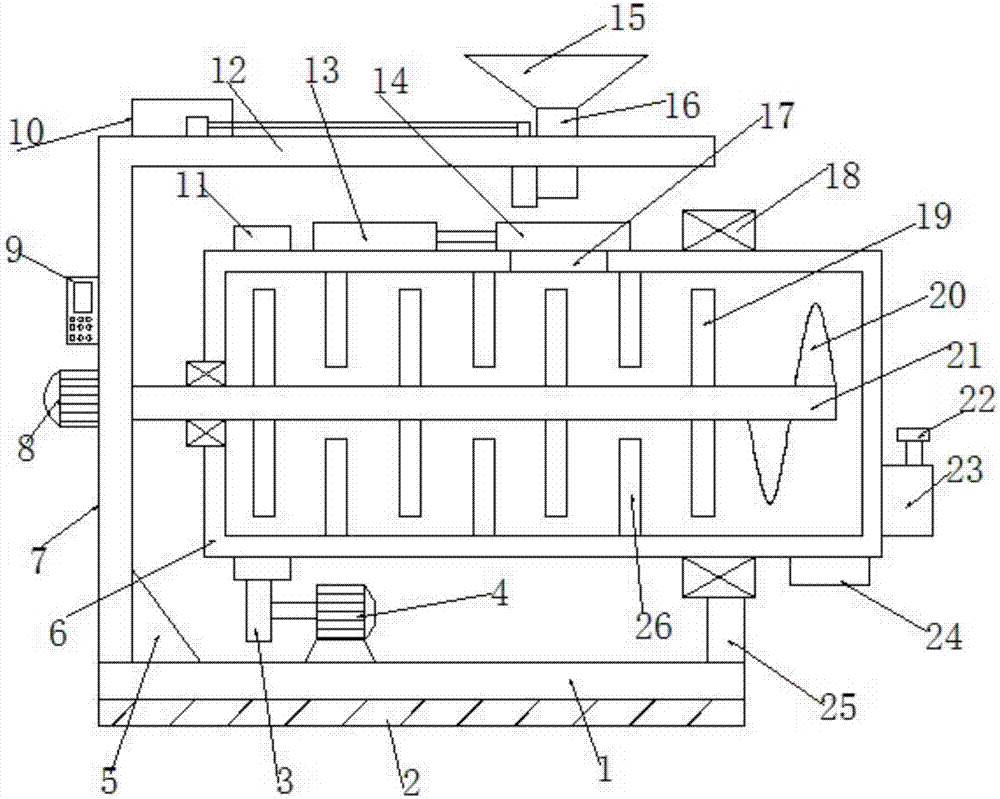

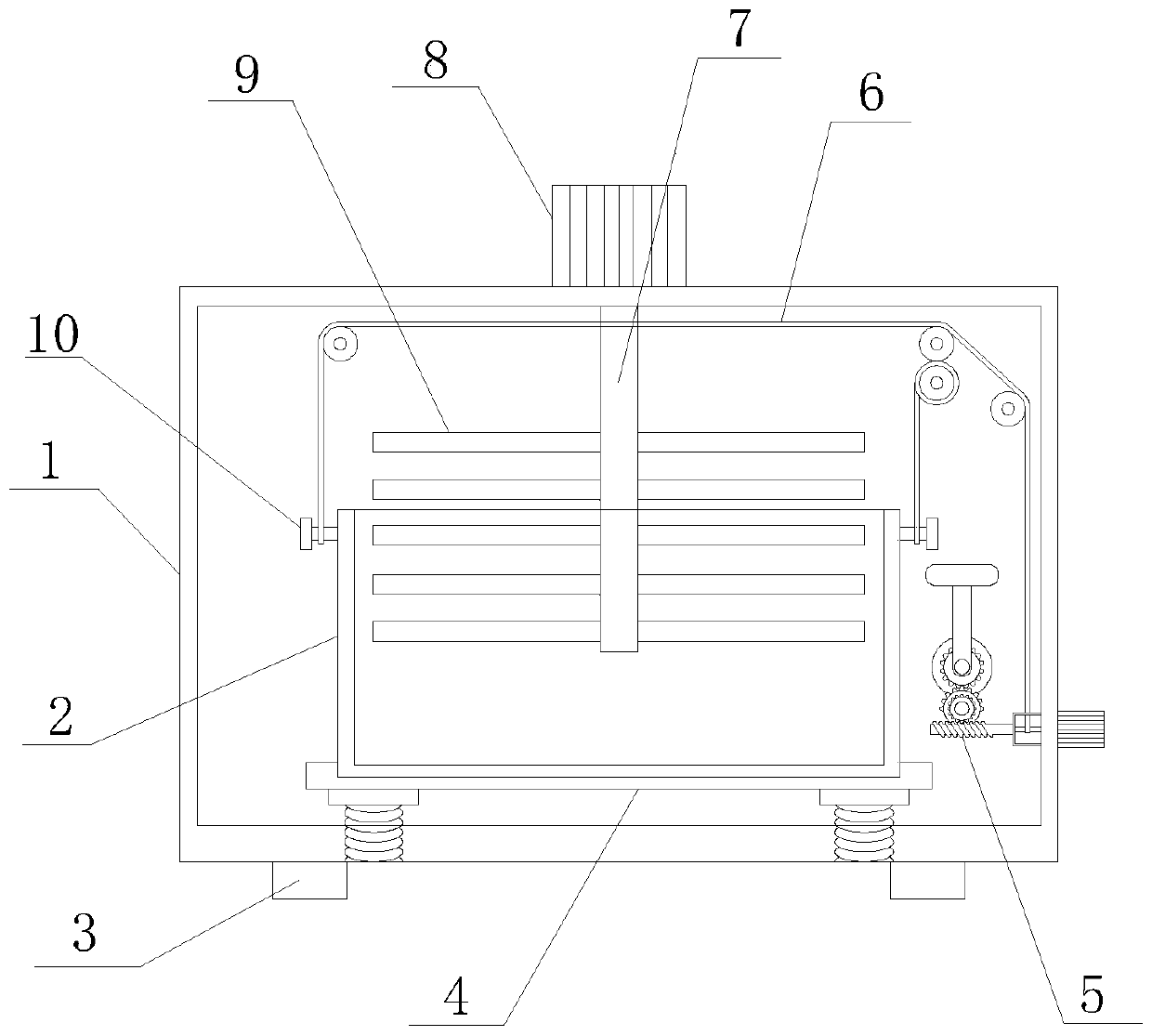

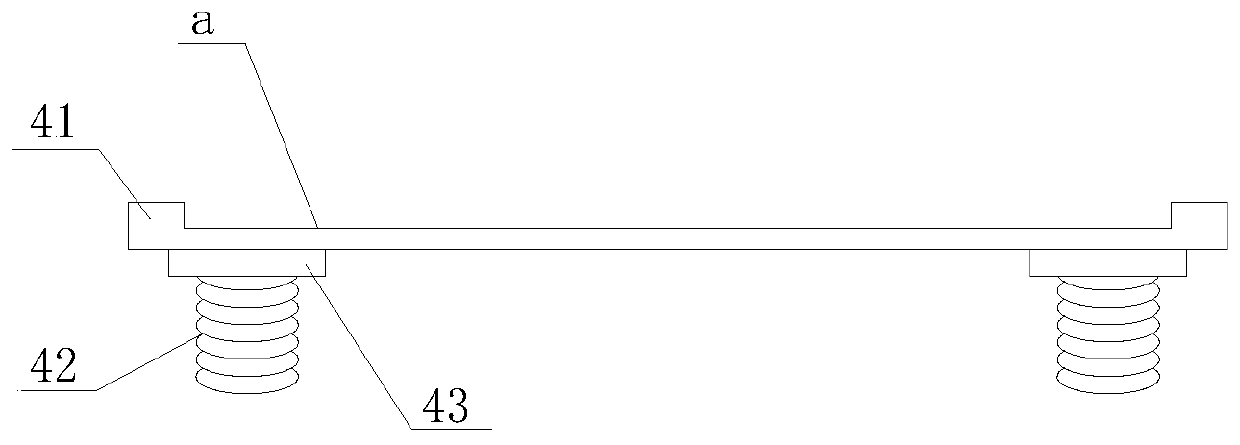

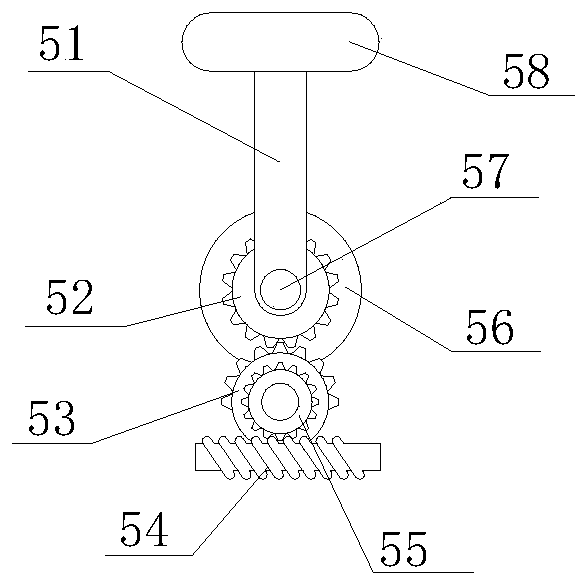

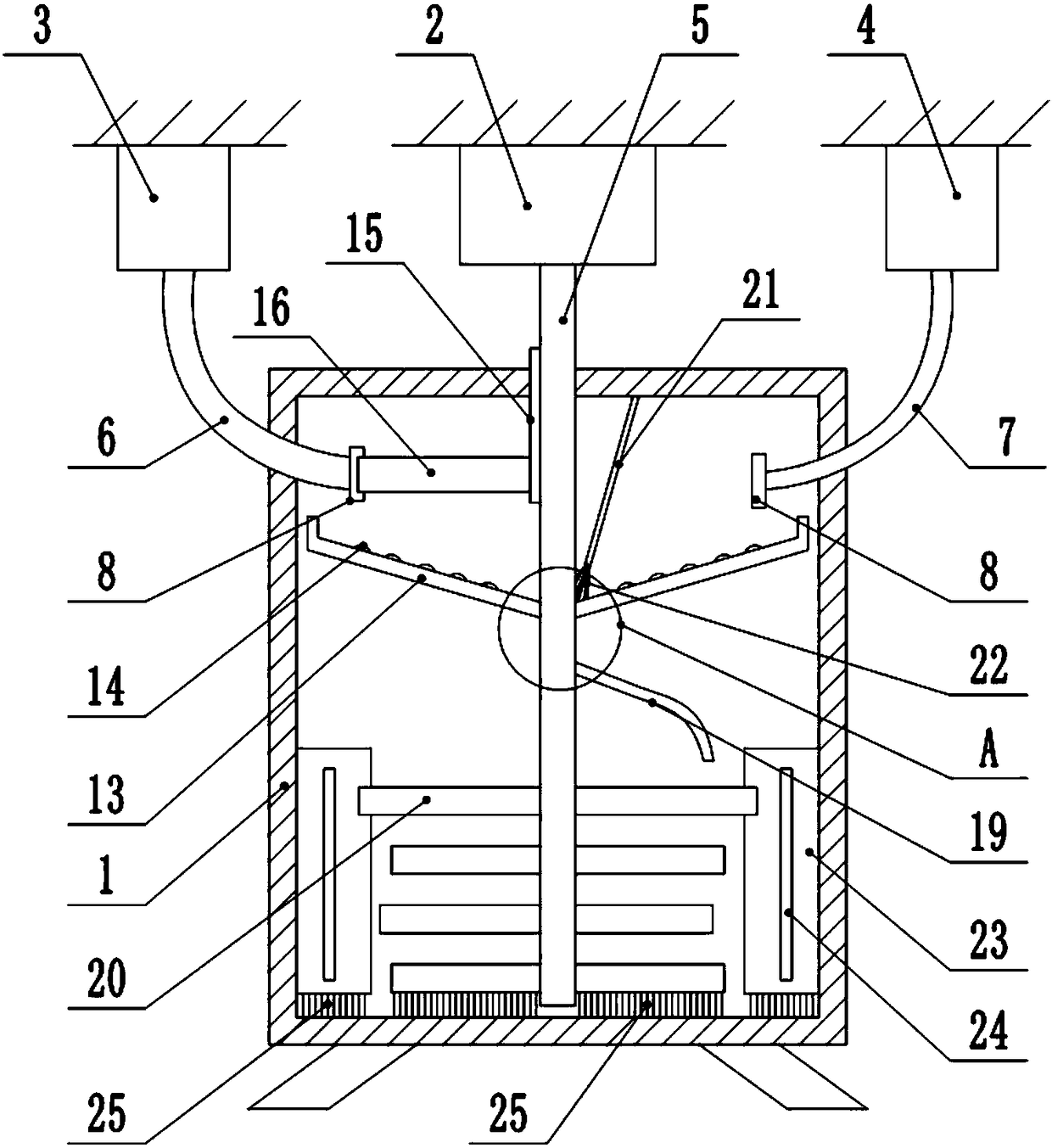

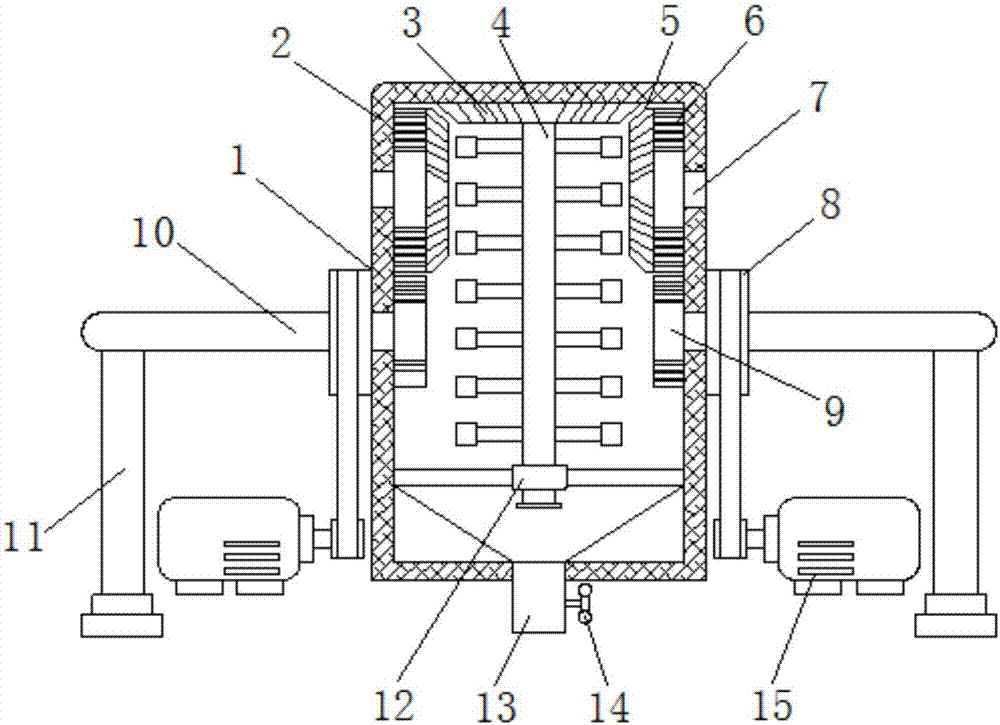

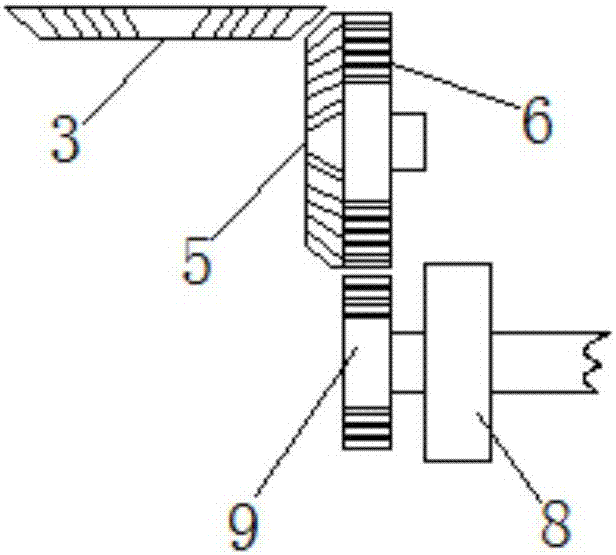

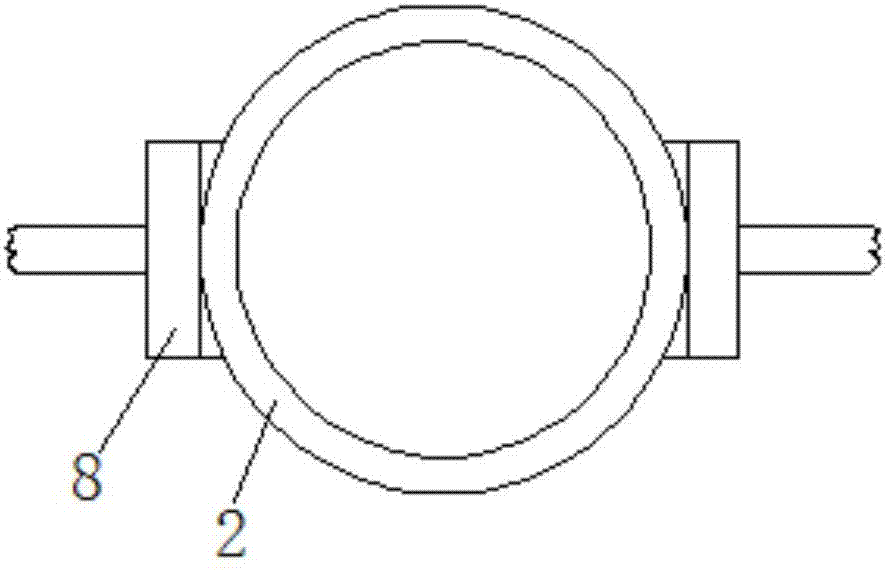

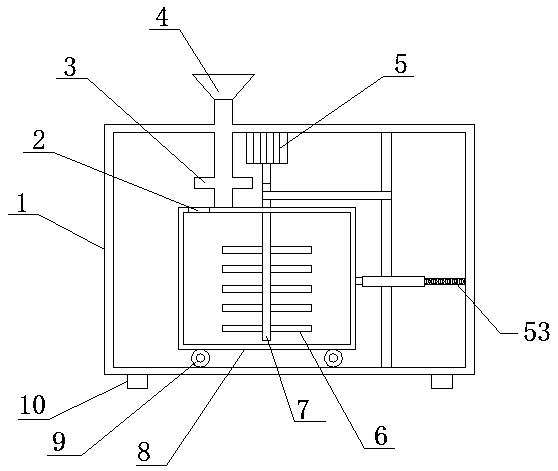

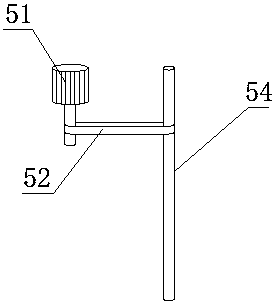

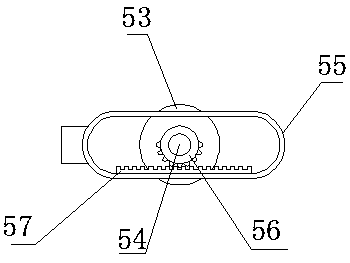

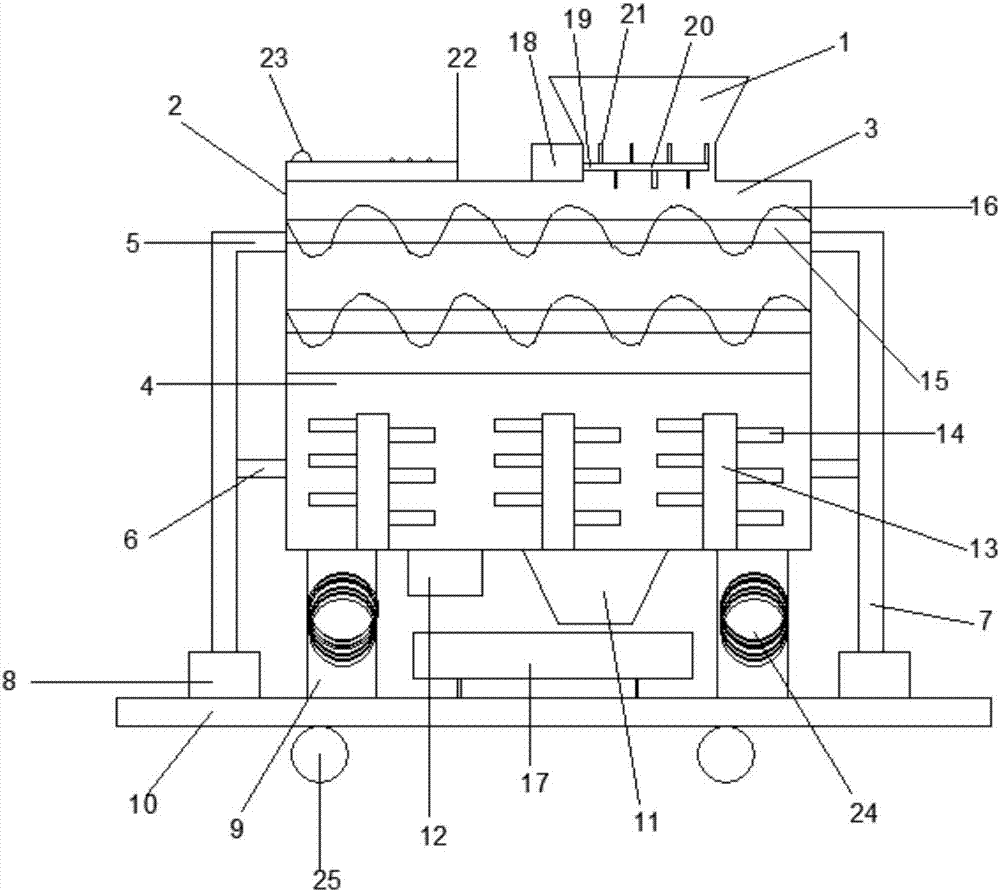

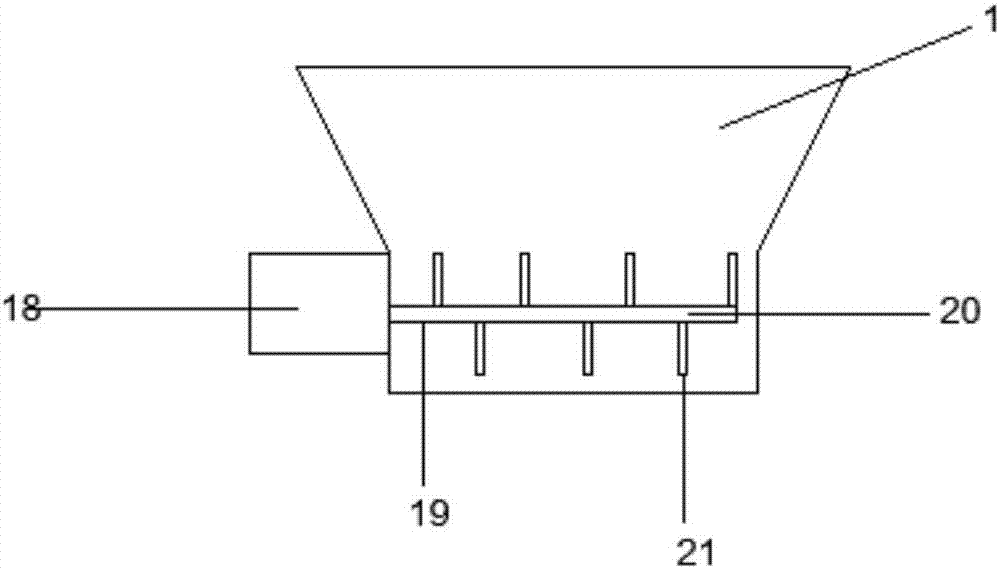

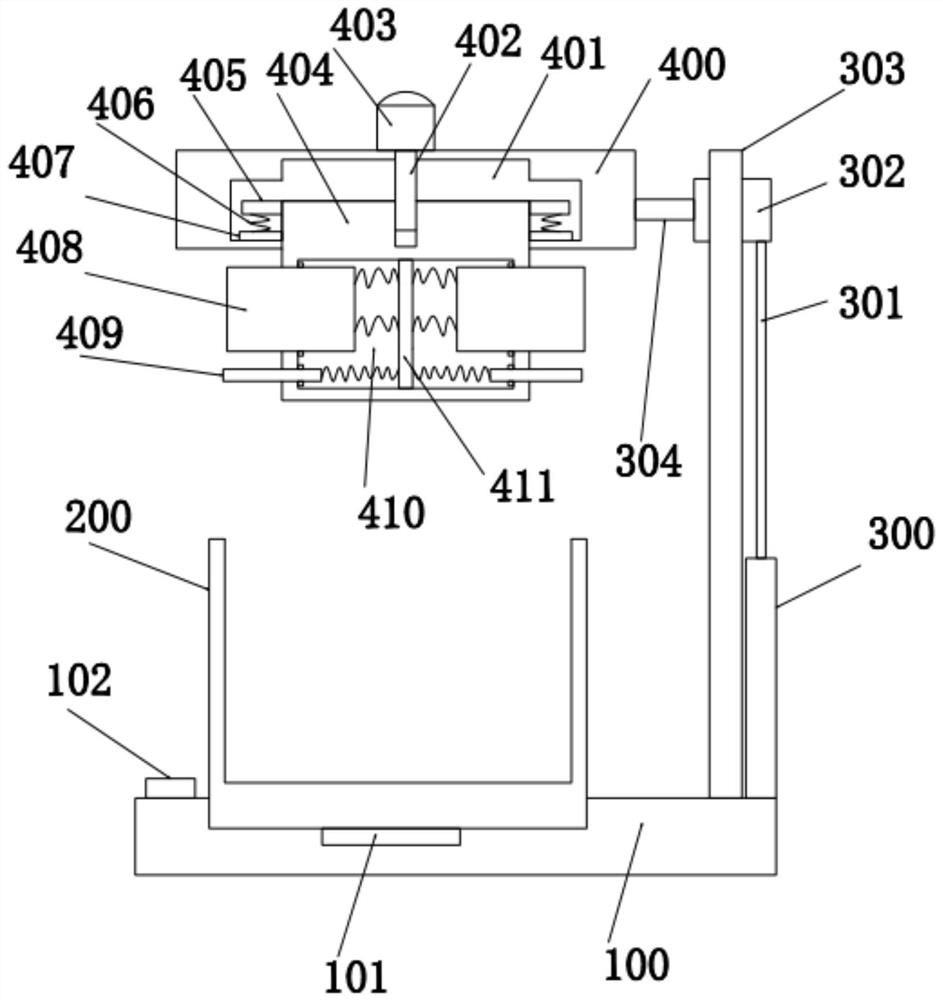

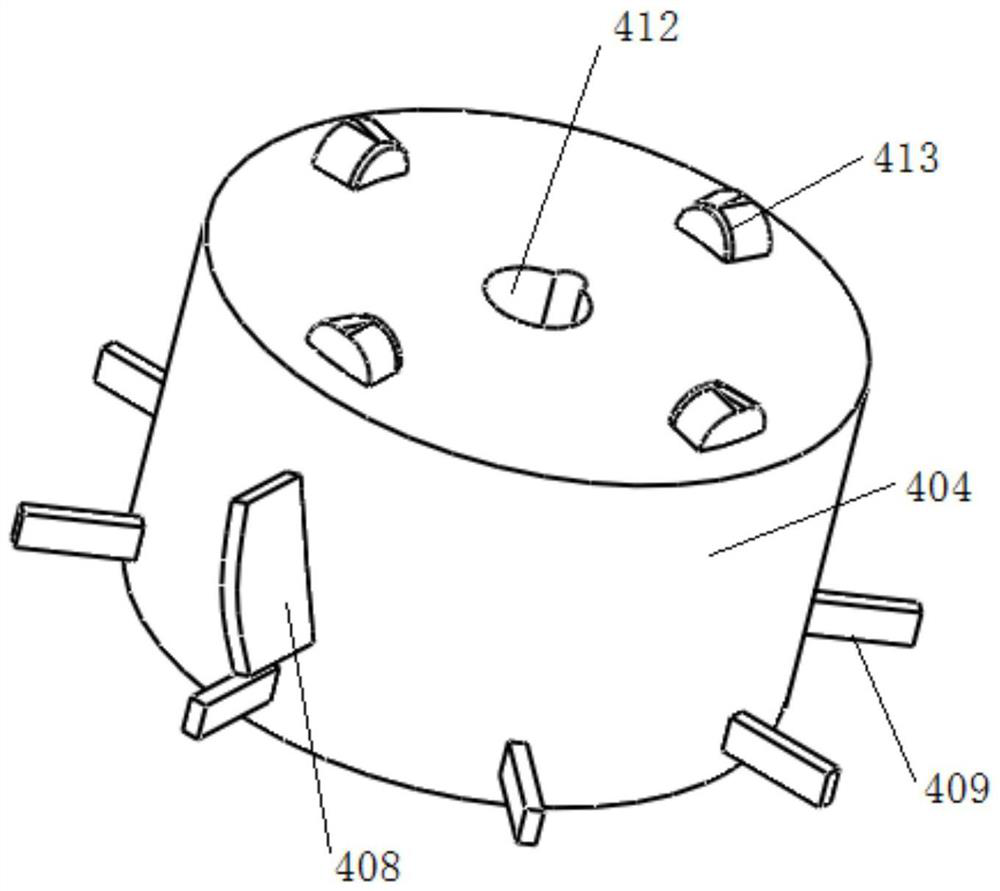

Manufacturing device for processing aluminum curtain wall material

InactiveCN109894033AAvoid pollutionSave raw materialsShaking/oscillating/vibrating mixersMixer accessoriesGear wheelEngineering

The invention relates to a manufacturing device for processing an aluminum curtain wall material. The manufacturing device comprises a box, a processing barrel, a rotation shaft, a driving machine, astirring shaft, pin shafts, a long rope, an electric shaker, a short rope, a hammer handle, a transmission gear, an incomplete gear, a worm, a turbine, a torsion spring, an installation shaft, and a vibration hammer. The vibration hammer is connected to the output end of the driving machine in a transmission mode. The stirring shaft is arranged on the rotation shaft. One end of the long rope is wound in the electric shaker, and the other end sequentially goes through an angle changing device, a pulley (B), and a pulley (A) and is wound around one pin shaft. One end of the short rope is wound around a pulley (C). The worm is connected to the output end of the electric shaker in a transmission mode. The incomplete gear is coaxially fixed with the turbine and rotates along with the turbine. The transmission gear is rotatingly arranged in the box through the installation shaft. The vibration hammer is arranged on the top end of the hammer handle. The structure of the manufacturing device is excellent, the design is reasonable, the operation is convenient, the dead angle is eliminated, the cost is reduced, the stirring effect and the processing efficiency are improved, the application prospect is wide, and the creativity is strong.

Owner:安徽唯楚新材料有限公司

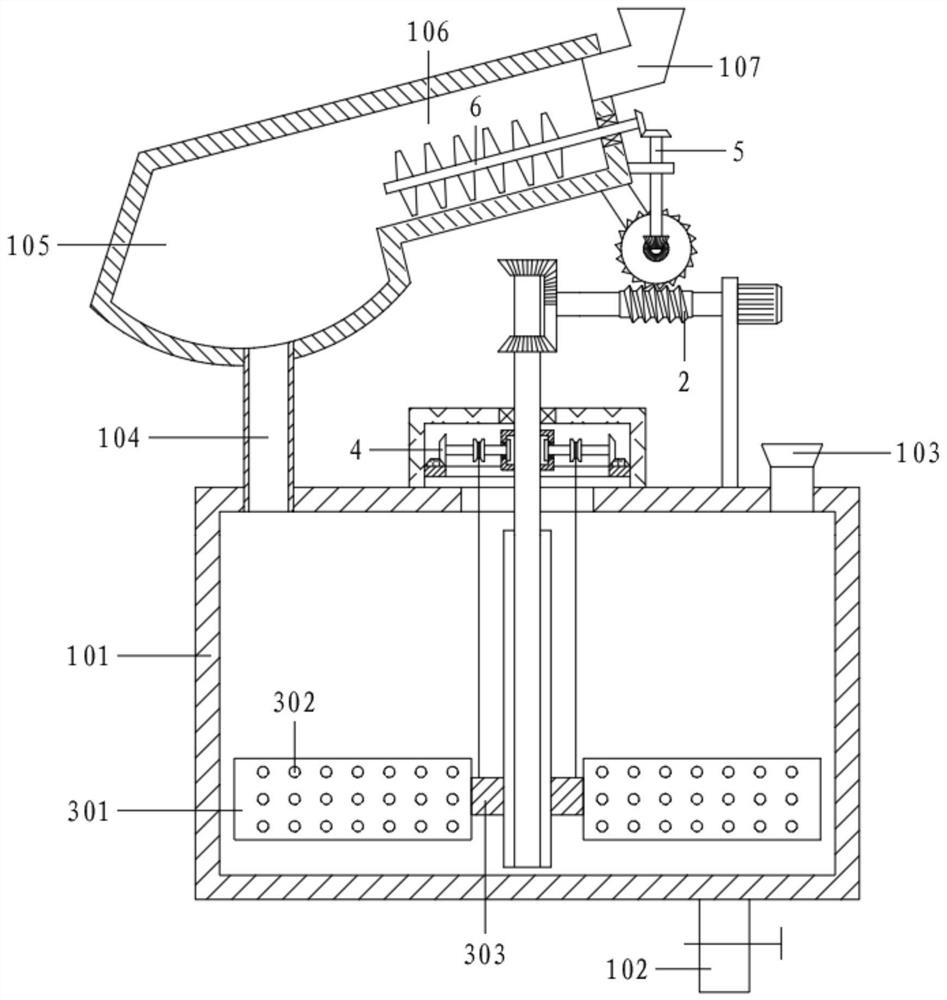

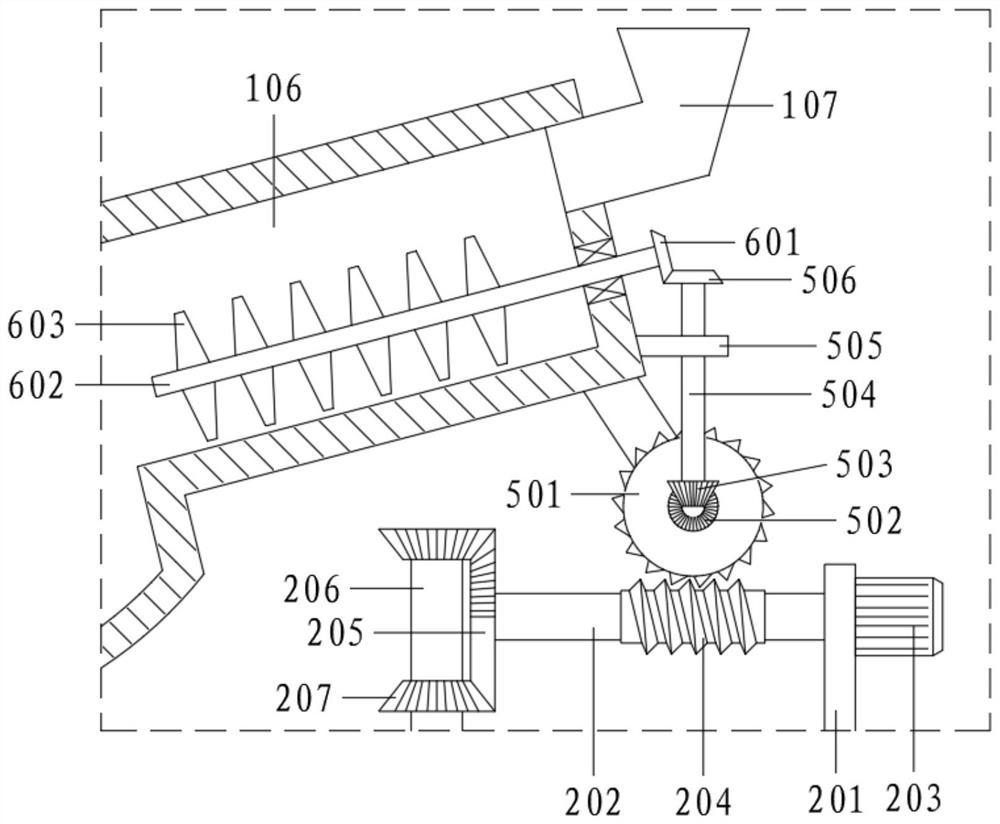

Xiang pig feed mixing equipment

ActiveCN108465426ARealize intermittent feedingImprove uniformityFeeding-stuffTransportation and packagingEngineeringFeed additive

The invention relates to the field of livestock breeding equipment and in particular discloses Xiang pig feed mixing equipment which comprises a mixing tank, a motor and two storage chambers, whereinthe motor is arranged above the mixing tank; the output end of the motor is coaxially fixedly connected with a rotating shaft; the storage chambers are connected with discharge tubes; control mechanisms are mounted at discharge holes of the discharge tubes; the rotating shaft is hinged with push plates for opening the control mechanisms; holding discs are arranged below the discharge holes; a cavity is formed inside the rotating shaft; feeding holes are formed in the side wall of the rotating shaft; the feeding holes are communicated with the cavity and the mixing tank; a third discharge tubeis communicated with the bottom of the cavity; the rotating shaft is coaxially fixedly connected with a plurality of stirring blades; a plurality of vertically arranged rotating plates are hinged withthe side wall of the mixing tank along the circumference of the mixing tank; the rotating plates are pushed to rotate in the rotation process of the stirring blades. By adopting the equipment, primary mixing of feed with feed additives can be achieved through the holding discs, secondary mixing can be achieved through the stirring blades, meanwhile, feed on the side wall of the mixing tank can bestirred and mixed through rotation of the rotating plates, and the uniformity degree of the feed and the feed additives can be increased.

Owner:湖南俊旺科技饲料有限公司

Dead angle-free stirring sprinkling machine for pouring

InactiveCN106827240AChange flow fieldProtective envelopeMixing operation control apparatusPretreatment controlSpiral bladeEngineering

The invention discloses a stirring sprinkler with no dead angle for pouring. One end of the stirring shaft in the stirring device passes through the upper end of the stirring tank and is connected with the driving device. The upper screw and the lower screw are set; the water supply device is composed of a water nozzle, a guide pipe, a time controller, a stirring blade, a micro motor, a bevel gear transmission box, a water container and a flow control valve; The discharge port is set at the bottom of the stirring tank and connected with the screw conveyor, and the screw conveyor is connected with the spray gun through the feeding pipe. The invention changes the flow field of the vortex formed by the helical blade, protects the coating of quicklime particles, can supply water intermittently, can improve the uniformity of stirring, greatly increases the service strength and life after solidification, and reduces the eddy current contacting the bottom of the stirring tank and then upwards The energy consumption of changing the flow direction expands the influence range of the vortex and eliminates the dead angle of stirring existing on the liquid surface of the stirring tank.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

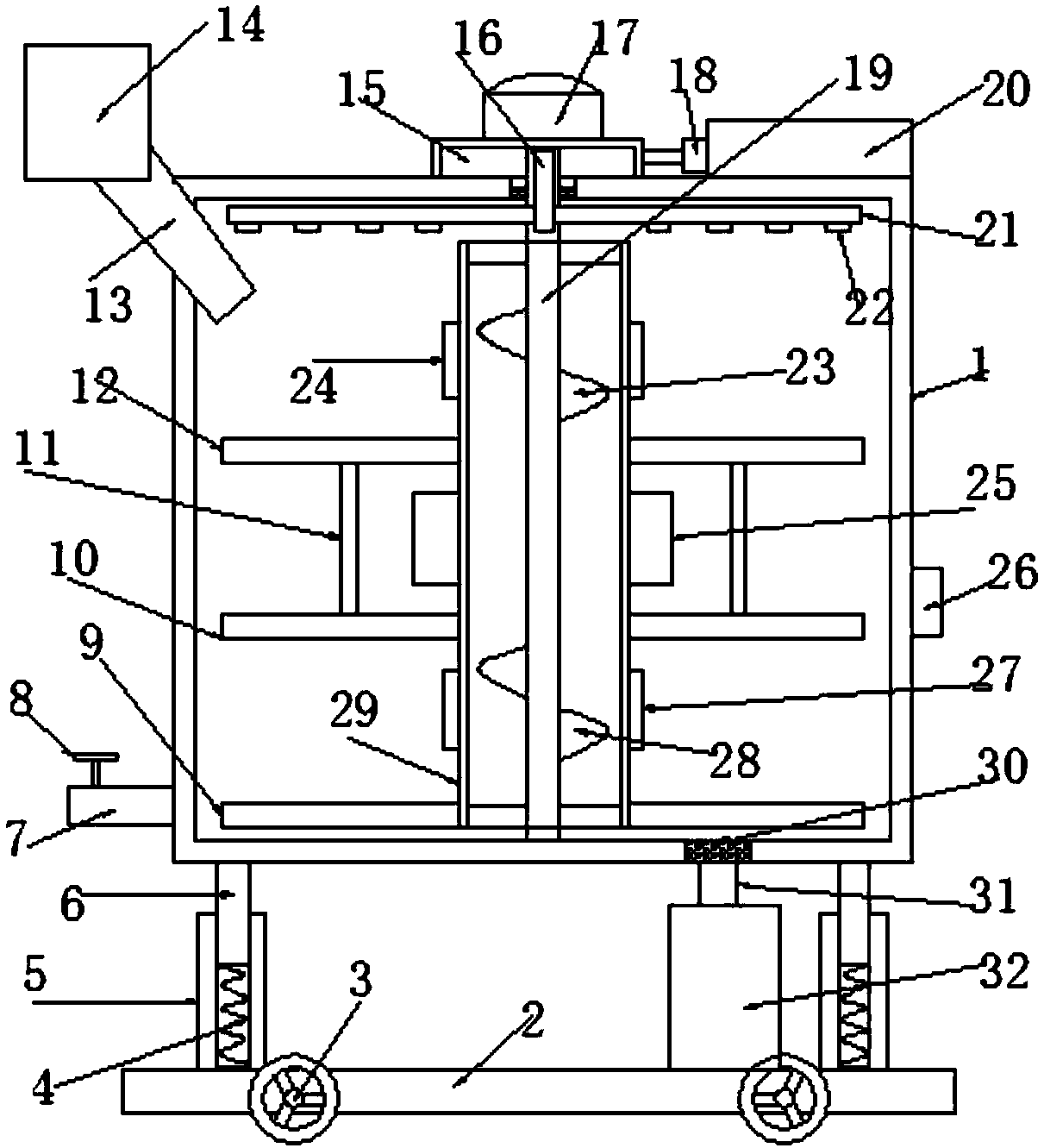

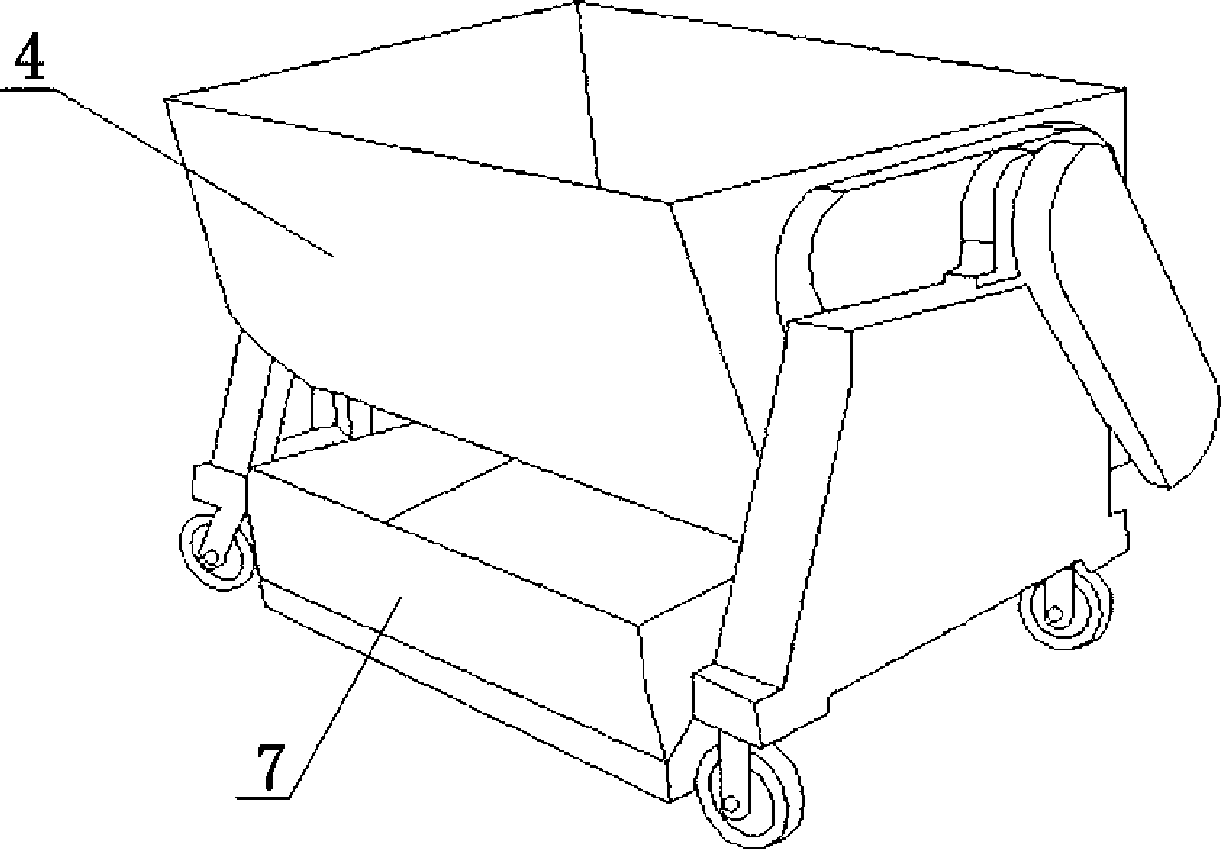

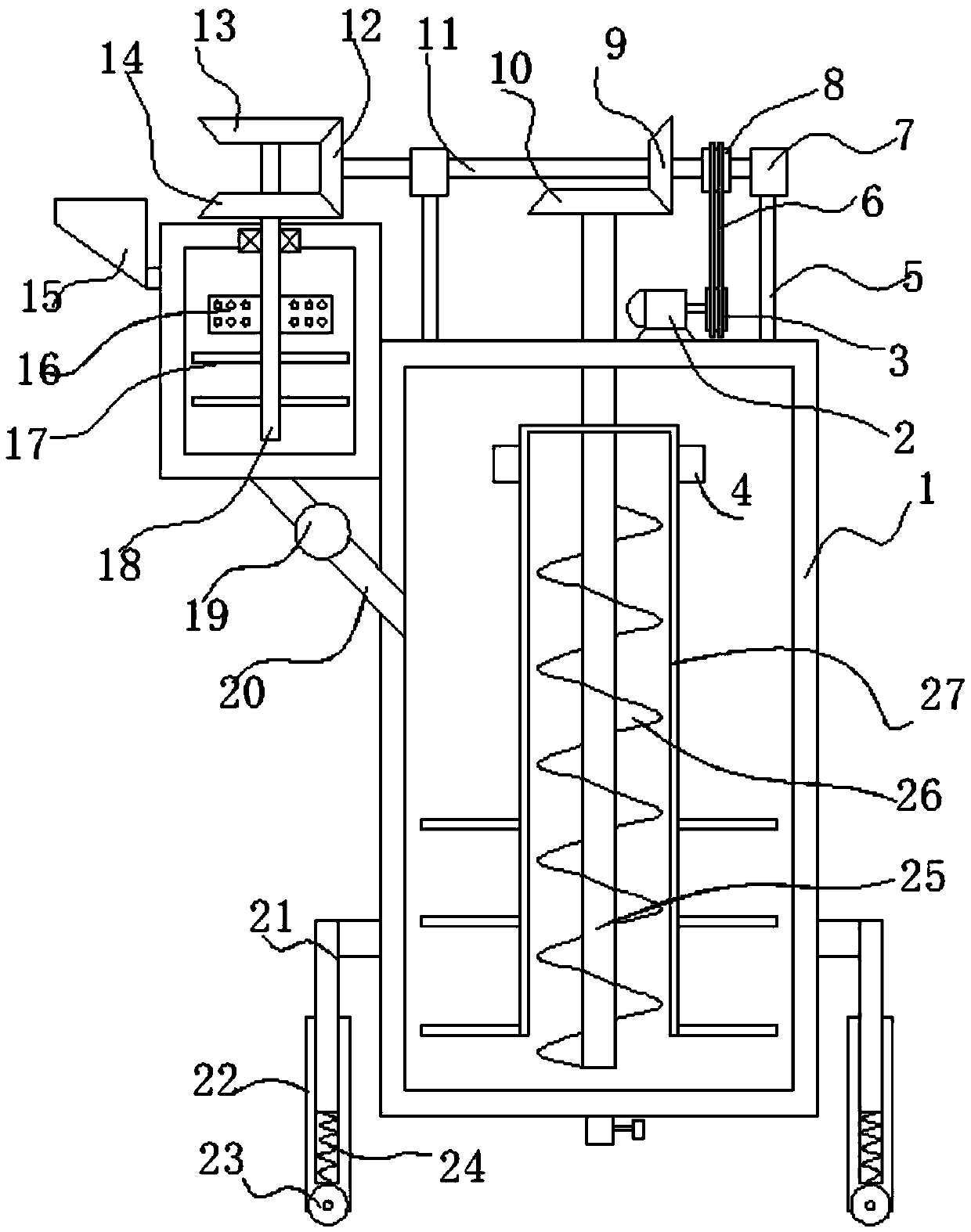

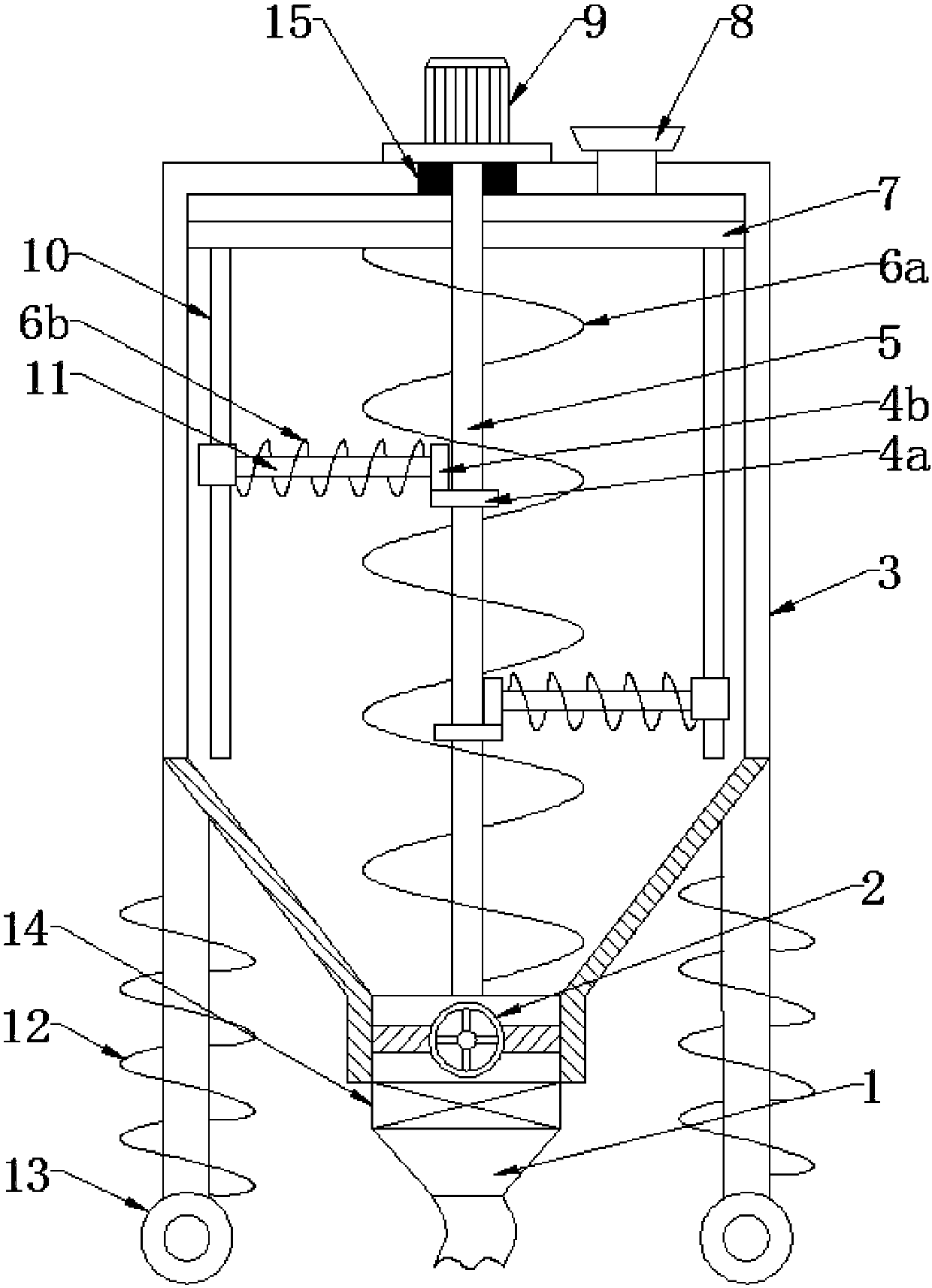

High-efficiency convective building concrete mixing device

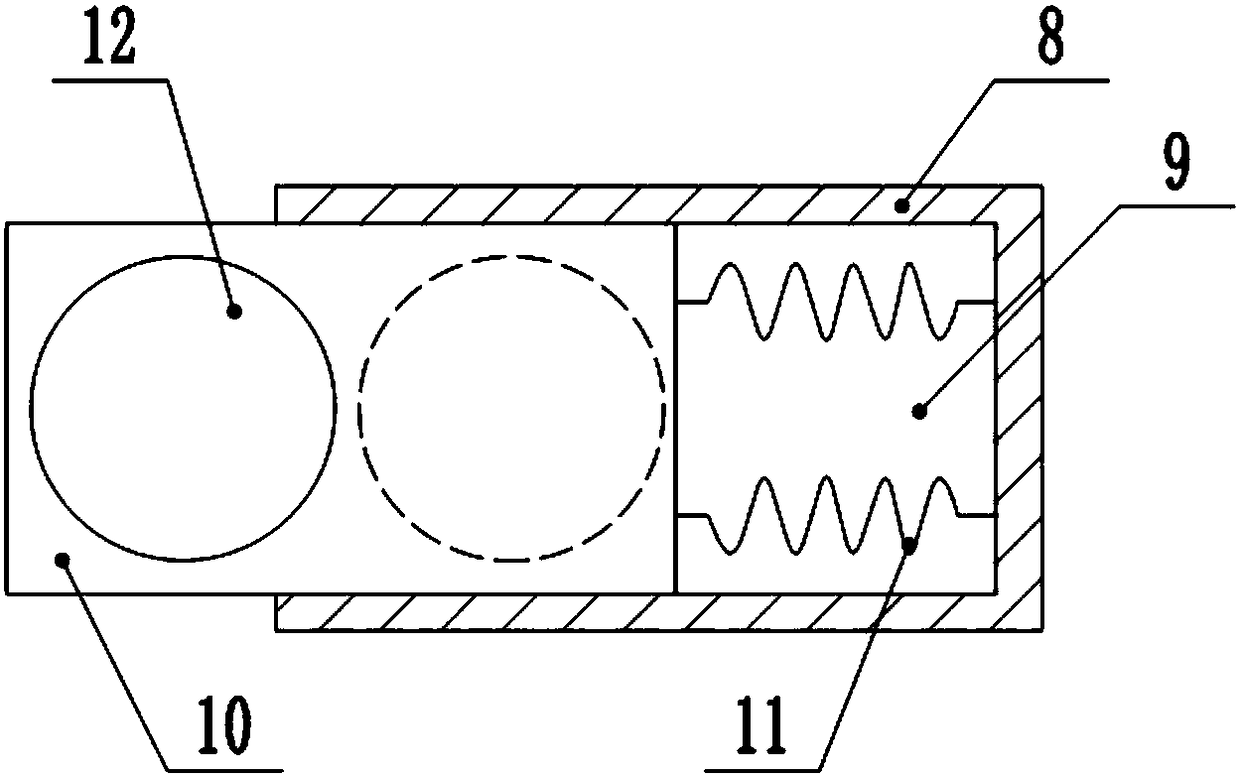

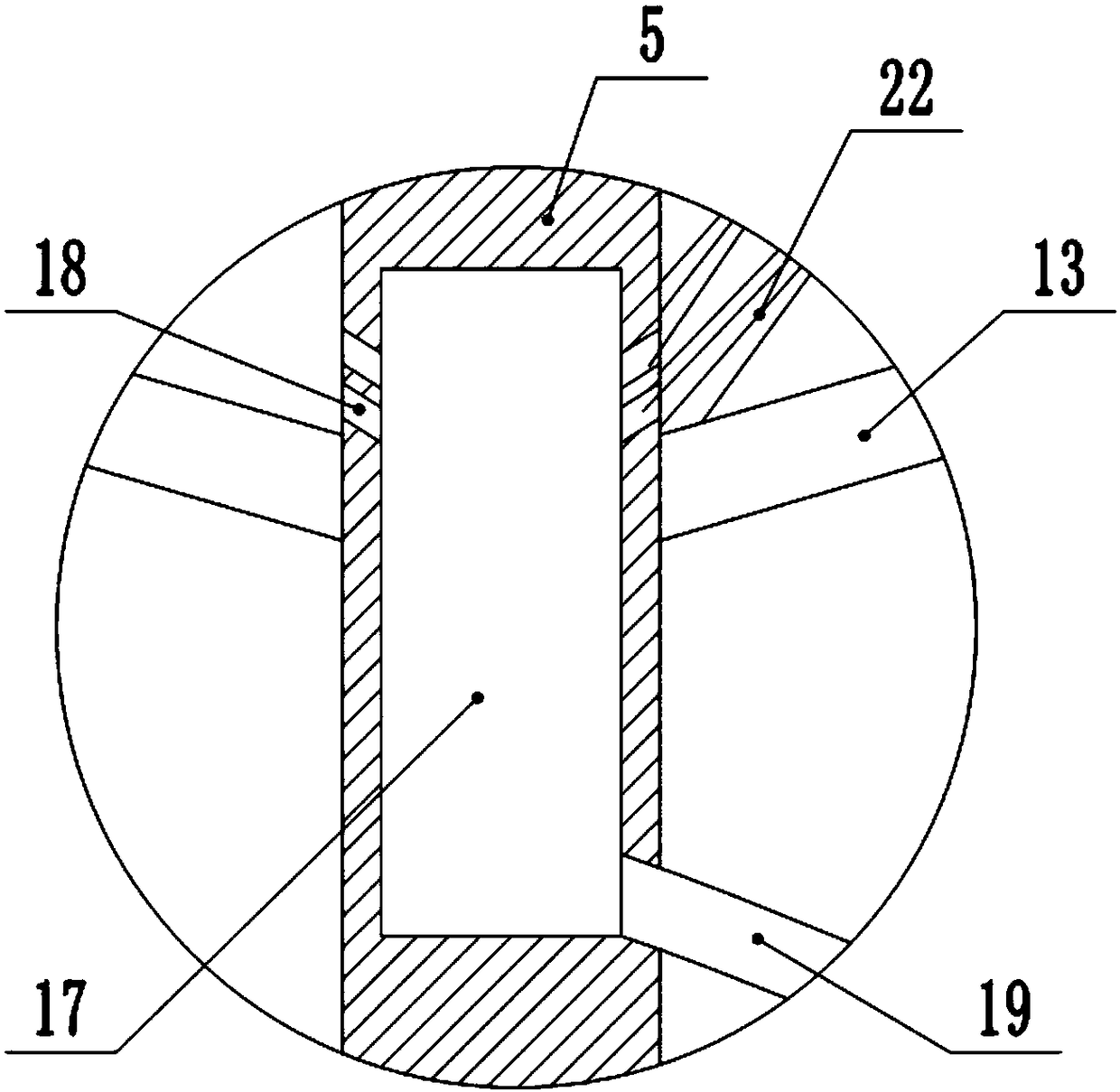

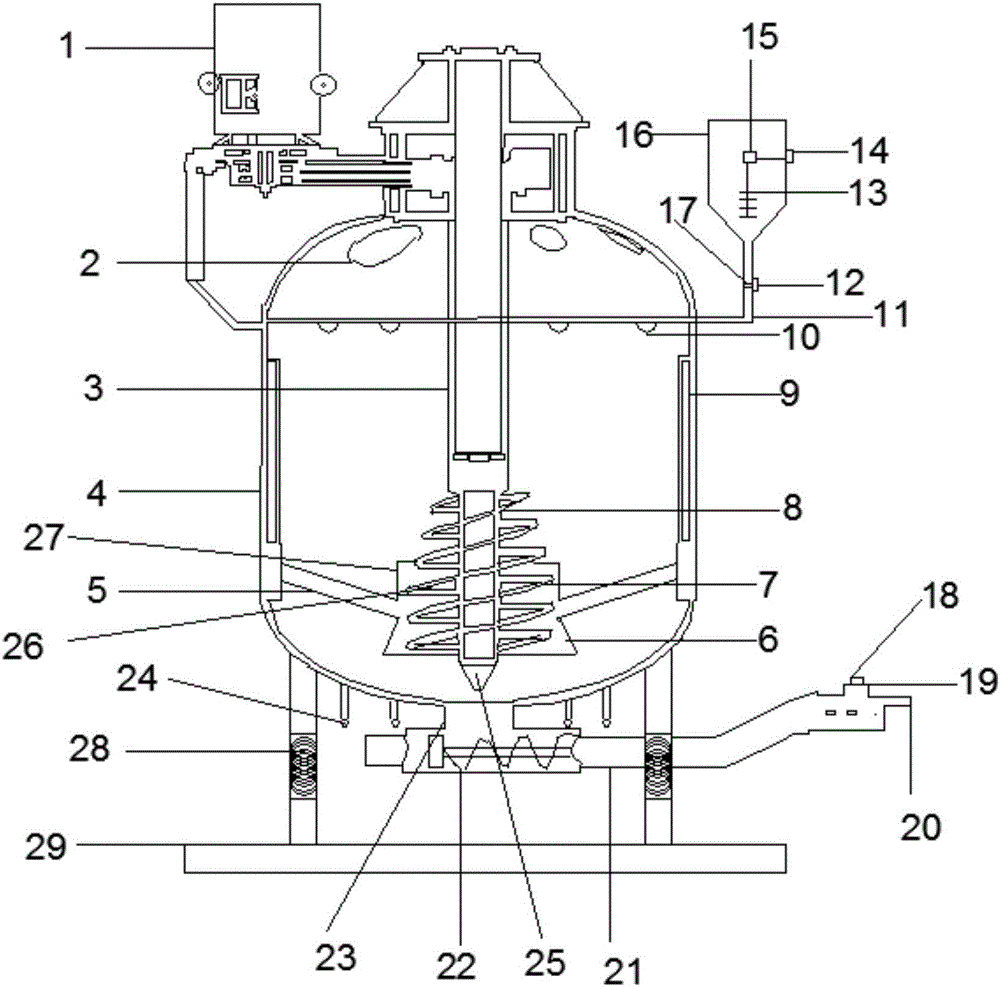

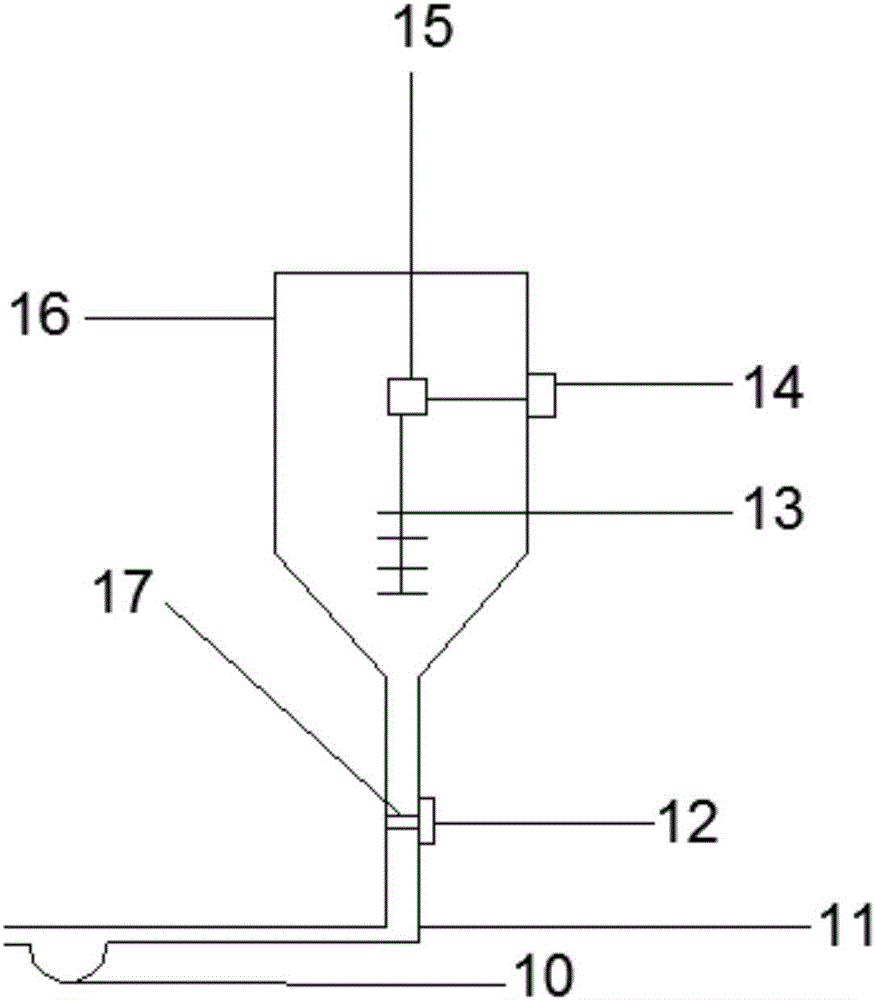

InactiveCN108214913AImprove stirring and mixing effectReduce pollutionDischarging apparatusCement mixing apparatusArchitectural engineeringMixing effect

The invention discloses a high-efficiency convective building concrete mixing device. The high-efficiency convective building concrete mixing device comprises a processing box and a pedestal; the pedestal is arranged below the processing box; the left and right sides of the pedestal are symmetrically provided with idler wheels which provide conveniences for transferring the device; the two sides of the upper end of the pedestal are symmetrically provided with supporting sleeves; the upper end of each supporting sleeve is slidably provided with a supporting rod; the upper end of each supportingrod is fixedly connected with the bottom of the processing box; each supporting sleeve is internally provided with a buffer spring; each buffer spring is used for fixedly connecting the correspondingsupporting sleeve with the corresponding supporting rod; the left upper side of the processing box is provided with a feeding pipe; the upper end of the feeding pipe is provided with a feeding hopper; the upper end of the processing box is provided with a buffer storage box; and a driving motor is arranged at the upper end of the buffer storage box. The high-efficiency convective building concrete mixing device disclosed by the invention is simple and reasonable in structure and convenient to transfer, greatly improves the stirring and mixing effect of materials, can also reduce dust pollution and is high in practicability.

Owner:祝小攀

Double-horizontal axle concrete-mixer

InactiveCN101474825AAchieve fixationSpacing is easy to adjustCement mixing apparatusReducerScrew thread

A double-horizontal axle concrete-mixer comprises a material barrel, mixing shafts in the material barrel and mixing blades which are connected with the mixing shaft. The mixing shaft is connected with the revolving mechanism of speed reducer of main motor. Two mixing shafts are installed in parallel in the material barrel. The mixing blades on two mixing shafts have same installation form and opposite installation directions. The mixing blades are distributed with a spiral form along the axial directions of mixing shafts. The middle part of mixing shaft is connected with middle mixing blades. Two ends of mixing shafts are connected with end mixing blades. The blade surface of middle mixing blade has a sickle shape. The blade surface of end mixing blade has a kitchen knife shape. The end of knife handle is provided with screw thread. The knife handle traverses the radial preserved hole passage of mixing shaft. The screw thread at end of knife handle is connected with the nut. The double-horizontal axle concrete-mixer of the invention has advantages of stronger mixing capability, simpler structure of mixing shaft, and easy changing and regulation of mixing blade.

Owner:建研建材有限公司 +1

Novel stirring equipment special for producing dry powder mortar

InactiveCN107443584AEasy to produceImprove stirring efficiencyCement mixing apparatusGear wheelBiochemical engineering

The invention discloses a new type of special mixing equipment for producing dry powder mortar, which includes a mixing equipment body, a mixing chamber and a stirring shaft. Both sides of the mixing equipment body are symmetrically provided with support legs, and both sides of the mixing chamber are symmetrically welded with belt pulleys. , the belt pulleys are all rotatably connected to the cross bar, the end of the cross bar is located inside the mixing chamber and is welded with a fixed gear, and the second bevel gear is connected to the stirring shaft through the first bevel gear. In the present invention, through the transmission effect of the motor, the stirring chamber can be turned over, and the turning of the stirring chamber will make the fixed gear and the movable gear welded on the end of the cross bar continuously mesh and rotate. This transmission structure can make the stirring chamber rotate At the same time, the internal stirring shaft also rotates at the same time and performs stirring work, so that the materials in the stirring chamber are continuously mixed under the action of gravity, which effectively improves the stirring efficiency.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

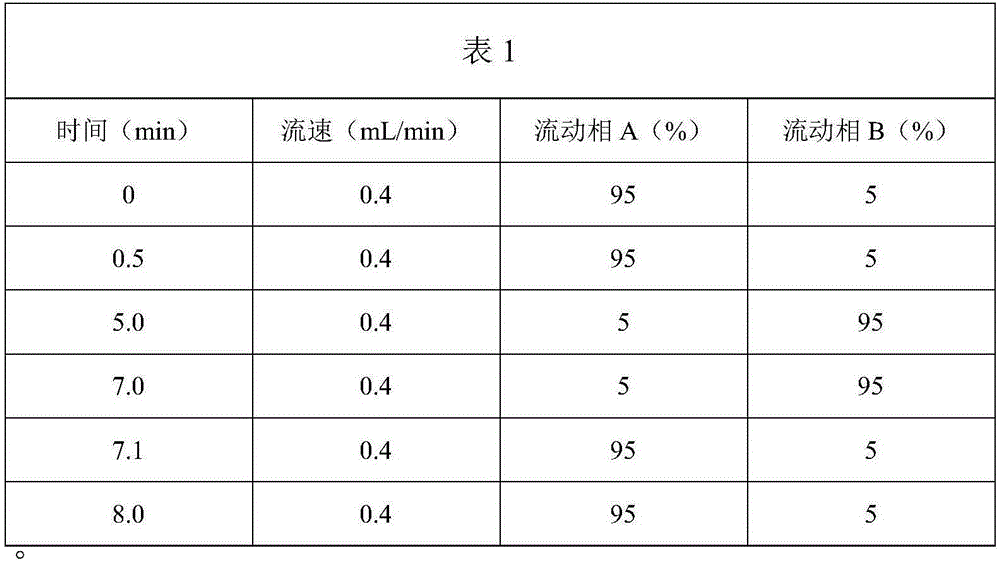

Detection and analysis method of short-chain chlorinated paraffin

InactiveCN105588889AEase of detectionEasy to implement analysisComponent separationFiltrationChlorinated paraffins

The invention relates to the technical field of chemical detection. A detection and analysis method of short-chain chlorinated paraffin includes the following steps of firstly, processing a sample, wherein the sample is put in acetonitrile to be shaken after being subjected to ultrasonic extraction through tetrahydrofuran, and a processed extraction solution is obtained after sedimentation and filtration; secondly, conducting quanlitative analysis on the processed extraction solution through a high performance liquid chromatography-tandem triple quadrupole mass spectrometer; thirdly, conducting quantitative analysis on the processed extraction solution through the high performance liquid chromatography-tandem triple quadrupole mass spectrometer. According to the method, by optimizing a traditional detection and analysis method of short-chain chlorinated paraffin, pretreatment extraction is improved under the condition of ensuring consistency of extraction effects, and therefore the extraction solution can be suitable for liquid-phase analysis. In addition, by means of the high performance liquid chromatography-tandem triple quadrupole mass spectrometer and through the combination with the advantages of the phase liquid and mass spectrums, detection and analysis on short-chain chlorinated paraffin are conveniently achieved, and a lower method detection limit is obtained.

Owner:上海英格尔认证有限公司 +1

New energy automobile single-layer lithium ion battery diaphragm manufacturing equipment and manufacturing process thereof

InactiveCN111129401ARealize the purpose of intermittent feedingWell mixedTransportation and packagingRotary stirring mixersNew energyGear wheel

The invention relates to new energy automobile single-layer lithium ion battery diaphragm manufacturing equipment and a manufacturing process thereof. The equipment comprises a preparation box body, afeeding hole, a feeding bin, a heating stirring rod, a rotating shaft, a mixing box, a motor, a transmission belt, a torsional spring, a transmission shaft, an annular frame, a half gear and a rack;the feeding bin is arranged on the left side of the top end surface of the preparation box; the feeding hole is formed in the left side of the top end surface of the mixing box; the rotating shaft isrotationally connected into the preparation box body; the heating stirring rod is arranged on the rotating shaft; the output end of the motor is fixedly connected with the rotating shaft; the annularframe is connected to the right end surface in the preparation box body through a spring; the output end of the motor is connected with the transmission shaft through the transmission belt; the rack is located in the annular frame; the half gear is installed on the transmission shaft; and the mixing box is fixedly connected with the annular frame. The purpose of intermittent discharging is achieved, mixing is made to be uniform as much as possible, and in the stirring process, the mixing box is made to move, the stirring effect is improved, stirring dead corners are eliminated, and the stirring efficiency is improved.

Owner:柳州四通材料科技有限公司

Plastic mixing equipment

The invention discloses plastic mixing equipment which comprises a case, a control panel, a feed port, upper air pipes, lower air pipes, fans, a motor, a discharge port and a belt conveyer; the control panel and the feed port that are arranged at and formed in the top of the case; a mixer is arranged in the feed port; the upper air pipes are arranged on the sides of the case; the lower air pipes are arranged below the upper air pipes; the fans are arranged below the lower air pipes and are fixed to a bottom plate; the motor, the discharge port and the belt conveyer are arranged below the case and are located in the middle of a rack; the interior of the case is divided into an upper case part and a lower case part; first main shafts are arranged in the upper case part; screw blades are arranged on the first main shafts; second main shafts are arranged in the lower case part; and blades are uniformly arranged on the second main shafts. In a double mixing mode, a mixing dead angle is eliminated, the mixing effect is improved comprehensively, plastic raw materials are kept in a suspension state in a mixing process and can not be accumulated at a place, the mixing effect is further guaranteed, an unfavorable condition that the mixing is stopped due to raw material accumulation is avoided, and the working safety performance is improved.

Owner:合肥智慧殿机械设计有限公司

Novel concrete stirring device for building and use method thereof

InactiveCN108274635AWell mixedQuality improvementIngredients weighing apparatusCement mixing apparatusDrive shaftArchitectural engineering

The invention provides a novel concrete stirring device for building and a use method of the novel concrete stirring device for building. The novel concrete stirring device for building comprises a second support, a feeding machine and a material inlet. A controller is arranged on the lower portion of the second support. The side, far away from the controller, of the lower portion of the second support is provided with a second motor. A driving belt pulley is arranged on one side of the second motor. The surface of the driving belt pulley is provided with a triangular belt. The inner side of the triangular belt is provided with a driven belt pulley. One side of the driven belt pulley is provided with a transmission shaft. The end, far away from the driven belt pulley, of the transmission shaft is provided with a first roller. The side, far away from the first roller, of the transmission shaft is provided with a second roller. A mixing tank is arranged on the upper surfaces of the firstroller and the second roller. One end of the mixing tank is provided with a discharging opening. The novel concrete stirring device for building adopts the design of integrating feeding and mixing, after sand and gravel, cement and water pass through a hopper and weighed by a weighing device, the sand and gravel, the cement and the water enter the mixing tank through the material inlet for mixingoperation, and the sand and gravel, the cement and the water are fully mixed.

Owner:海宁鼎合工程技术开发有限公司

Mixing device for whitening cream processing

InactiveCN109603667ARealize intermittent forward and reverseSmall footprintTransportation and packagingMixer accessoriesEngineeringCentrifugal force

The invention discloses a mixing device for whitening cream processing. The device comprises a box body, the lower end of the box body is provided with a discharging pipe and a discharging valve whichis located on the discharging pipe, a pre-processing box which stirs a material is arranged on the upper left side of the box body, a feeding hopper is arranged at a feeding end of the pre-processingbox, a discharging end at the lower end of the pre-processing box is connected with a feeding end of the left side of the box body through a connecting pipe, and the connecting pipe is provided witha throttle valve. The mixing device has the advantages that improvement is made on the defects of an existing device, an upright cylindrical box body is arranged, the floor occupation area of the device is reduced, a stirring mechanism which is used for performing convection stirring on materials is arranged in the box body, existing stirring dead angles of an existing device are eliminated, the processing quality is improved, the intermittent reverse and positive rotation of a pre-processing mechanism is achieve, the influence on pre-processing caused by centrifugal force is reduced, the pre-processing quality is improved, and the practicability is high.

Owner:广州嘉芳美妆格化妆品研究院

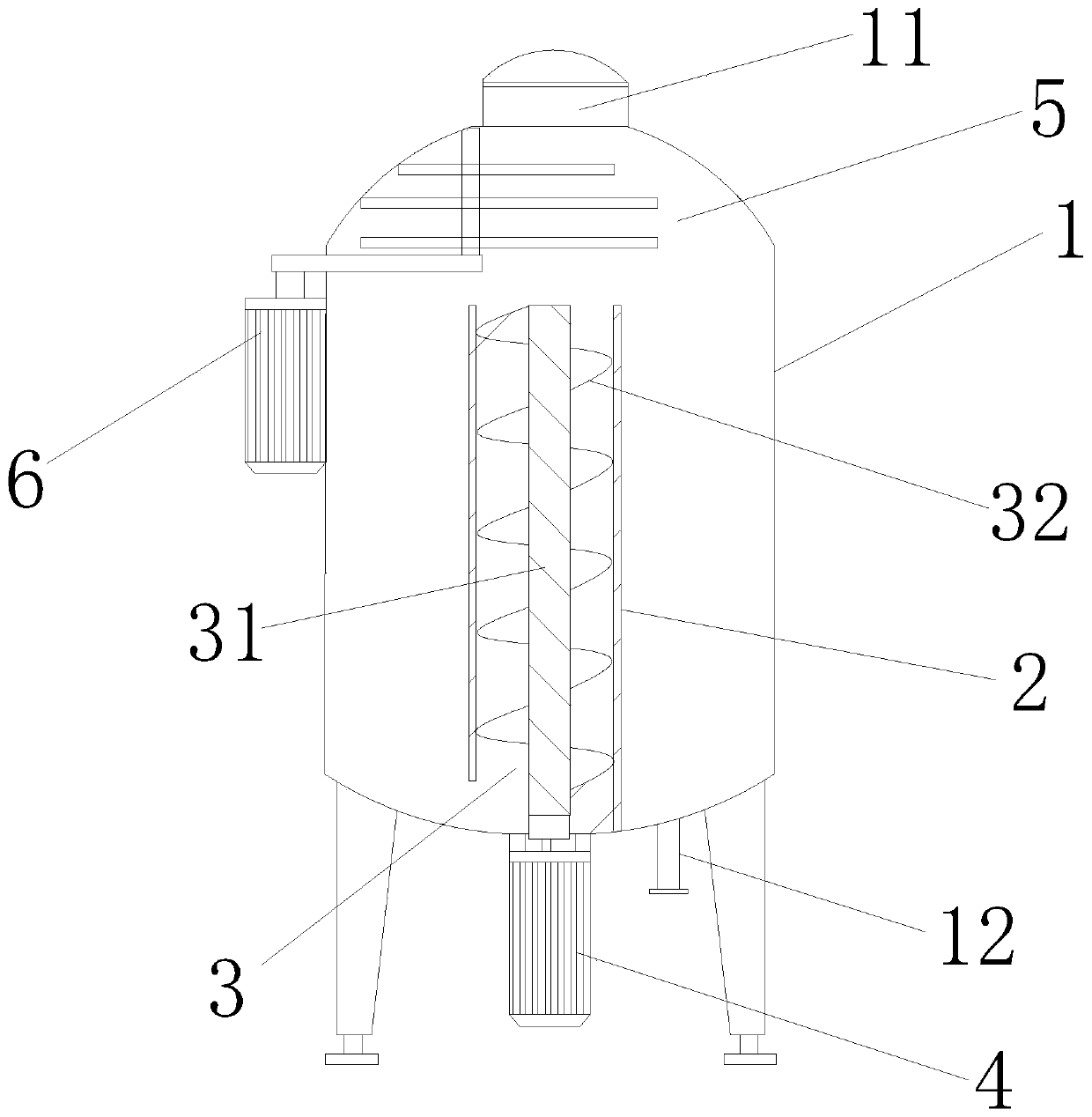

Stirring device

InactiveCN109806794AImprove stirring efficiencyEffective stirringRotary stirring mixersPulp and paper industryDrive motor

The invention discloses a stirring device. The stirring device comprises an outer tank body, an inner tank body arranged in the outer tank body and a mixing space arranged between the outer tank bodyand the inner tank body, a feeding opening assembly is arranged at the top of the outer tank body, a discharging opening assembly is arranged at the bottom of the outer tank body, and the bottom of the inner tank body is connected with the inner side bottom wall of the outer tank body. A feeding opening is formed in the side wall of the bottom of the inner tank body, a discharging opening is formed in the top of the inner tank body, and a stirring and conveying assembly is mounted in the inner tank body and comprises a stirring shaft and spiral stirring blades arranged on the stirring shaft. Afirst drive motor is mounted on the bottom wall of the outer side of the outer tank body, and a connecting shaft extending the outer tank body and connected with the output end of the first drive motor is connected to the lower end of the stirring shaft. Therefore, compared with the prior art, the stirring device has the advantages of high stirring efficiency, and stirring dead angles do not exist.

Owner:黄山市益天士生物科技有限公司

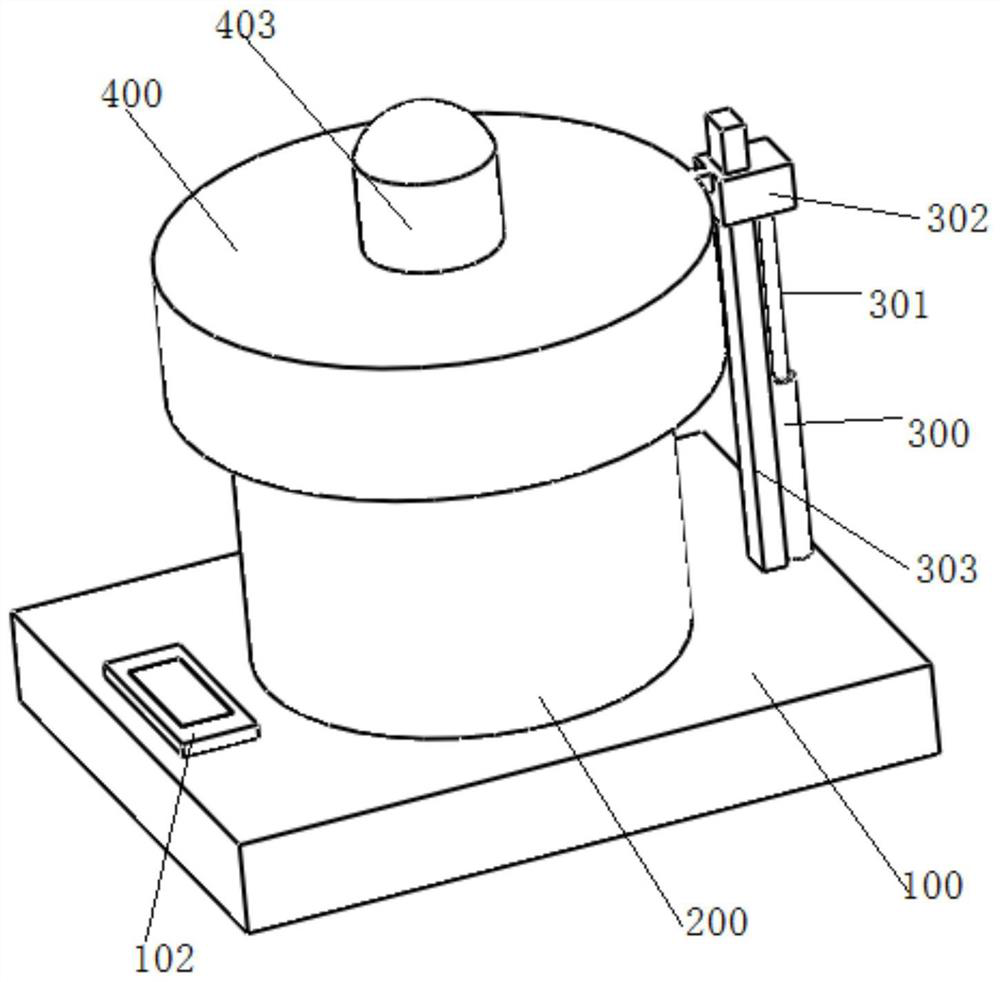

Rapid stirring device for preparing monoclinic lead tungstate nanobelt crystal material

InactiveCN111330490AEliminate stirring dead angleStir quicklyRotating receptacle mixersTransportation and packagingPhysical chemistryPhysics

The invention discloses a rapid stirring device for preparing a monoclinic lead tungstate nanobelt crystal material, and mainly relates to the field of production of monoclinic lead tungstate nanobeltcrystal materials. The rapid stirring device comprises a stirring barrel body and a supporting seat, wherein a sliding block is arranged at the bottom of the stirring barrel body, an annular slidinggroove is formed in the top of the supporting seat, a supporting frame is arranged on one side of the stirring barrel body, the bottom end of the supporting frame is fixed on the supporting seat, a cover body matched with the stirring barrel body is arranged on the supporting frame, a lifting device used for adjusting the height of the cover body is arranged on the supporting frame, a supporting pipe is vertically arranged on the cover body, and a rotating shaft is vertically arranged in the supporting pipe. The rapid stirring device has the beneficial effects that the lifting type rotating shaft is matched with the stirring barrel body capable of moving annularly, so that the fluidity of raw materials in the stirring barrel body is improved, stirring dead corners in the stirring barrel body are eliminated, stirring of the raw materials can be completed rapidly, and the stirring efficiency and the stirring quality are improved.

Owner:CHONGQING VOCATIONAL INST OF ENG

Efficient feed stirring device

InactiveCN107754664APlay the role of stirringImprove stirring efficiencyFeeding-stuffRotary stirring mixersSpiral bladeEngineering

The invention discloses an efficient feed stirring device, belongs to the technical field of feed stirring devices, and solves the problems that an existing feed mixing and stirring device is low in mixing efficiency, the stirring dead points exist in the stirring process as the stirring device is fixed in position on a rotary shaft when the device stirs a feed by rotation of a primary shaft and in the feed mixing process, the feed is inconvenient to store as the temperature is raised. A feed inlet is formed in the upper end of the stirring box, a discharge port is formed in the lower end of the stirring box, a rotary primary shaft is arranged on the stirring box, the rotary primary shaft is connected to a driving motor, a first spiral blade is arranged on the outer side of the rotary primary shaft in a sleeving manner, a rotary bracket is also arranged on the upper section of the rotary primary shaft in a sleeving manner too, a fixed rod is arranged at the lower end of the rotary bracket, a roll shaft is arranged on the fixed rod, the other end of the roll shaft is connected to the rotary primary shaft, and a second spiral blade is arranged on the outer side of the roll shaft in asleeving manner; and a seal ring is arranged at the upper end of the stirring box, the seal ring is matched with the rotary primary shaft, a cooling device is arranged at the discharge port, and thedischarge port is provided with a control valve.

Owner:CHENGDU KECHUANGGU TECH CO LTD

Flour fermentation stirring machine capable of uniformly mixing dough and method

InactiveCN111937924AEliminate stirring dead angleImprove the mixing effectMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringMixing effect

The invention discloses a flour fermentation stirring machine capable of uniformly mixing dough and a method. The stirring machine comprises a base and a stirring assembly arranged at the upper end ofthe base. The stirring assembly comprises a material carrying barrel; a mounting groove facilitating placement of the material carrying barrel is formed in the upper end of the base; a weighing device used for detecting the weight of the base is arranged in the mounting groove; the weighing device and the stirring assembly are electrically connected with a control panel; an upper cover is arranged above the material carrying barrel in a matched mode; the upper cover is connected with a lifting mechanism used for driving the upper cover to move up and down; a transmission cavity is formed in the lower end face of the upper cover; and a rotating block is arranged in the transmission cavity in a matched mode. The stirring machine is designed for the defects of an existing device, the stirring height can be longitudinally adjusted, stirring dead corners can be eliminated, and materials on the inner wall can be scraped off; and in addition, the rotating block can be driven to move up and down, so that flour is intermittently pressed and kneaded, and the mixing effect is effectively improved.

Owner:河南慧广科技服务有限公司

Solar slurry stirring device

InactiveCN112755900AEasy Lifting CycleAvoid accumulationFlow mixersRotary stirring mixersElectric machineEngineering

The invention provides a solar slurry stirring device. The solar slurry stirring device comprises a stirring barrel, a barrel cover, a spiral lifting pipe, a spiral lifting blade, a central shaft, a rotating disc, a stirring rod, a stirring motor and a driving block, a conical sliding surface is arranged at the bottom of the stirring barrel, a platform surface is arranged at the bottom end of the conical sliding surface, a discharging opening is formed in the middle of the platform surface, a spiral lifting pipe is arranged above the discharging opening, the central shaft is arranged in the spiral lifting pipe, the spiral lifting blade is fixed outside the central shaft, and the top end of the central shaft penetrates out of the barrel cover and is in driving connection with the stirring motor; at least one group of driving blocks are further fixed outside the central shaft, the top end of the rotating disc is rotationally connected to the barrel cover, driving notches used for being matched with the driving blocks in an inserted mode are further formed in the bottom side of the rotating disc, and at least one group of stirring rods located between the spiral lifting pipe and the stirring barrel are further fixed to the bottom side of the rotating disc. The stirring cost is low, the stirring uniformity is better, and precipitated dry powder at dead angles can be better eliminated so that the stirring effect is better.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

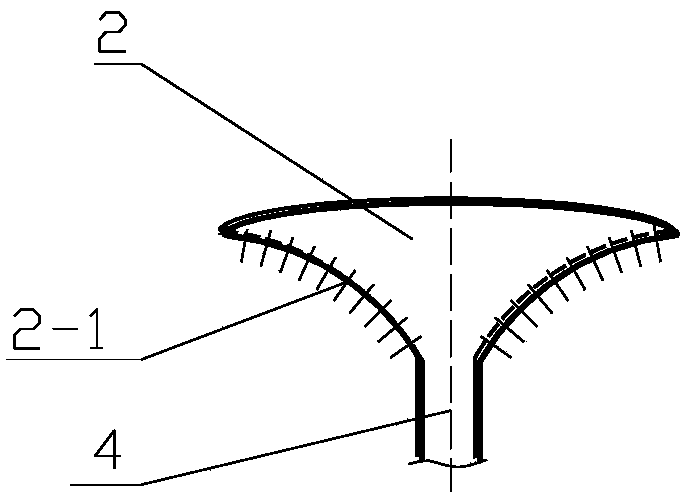

Stirrer

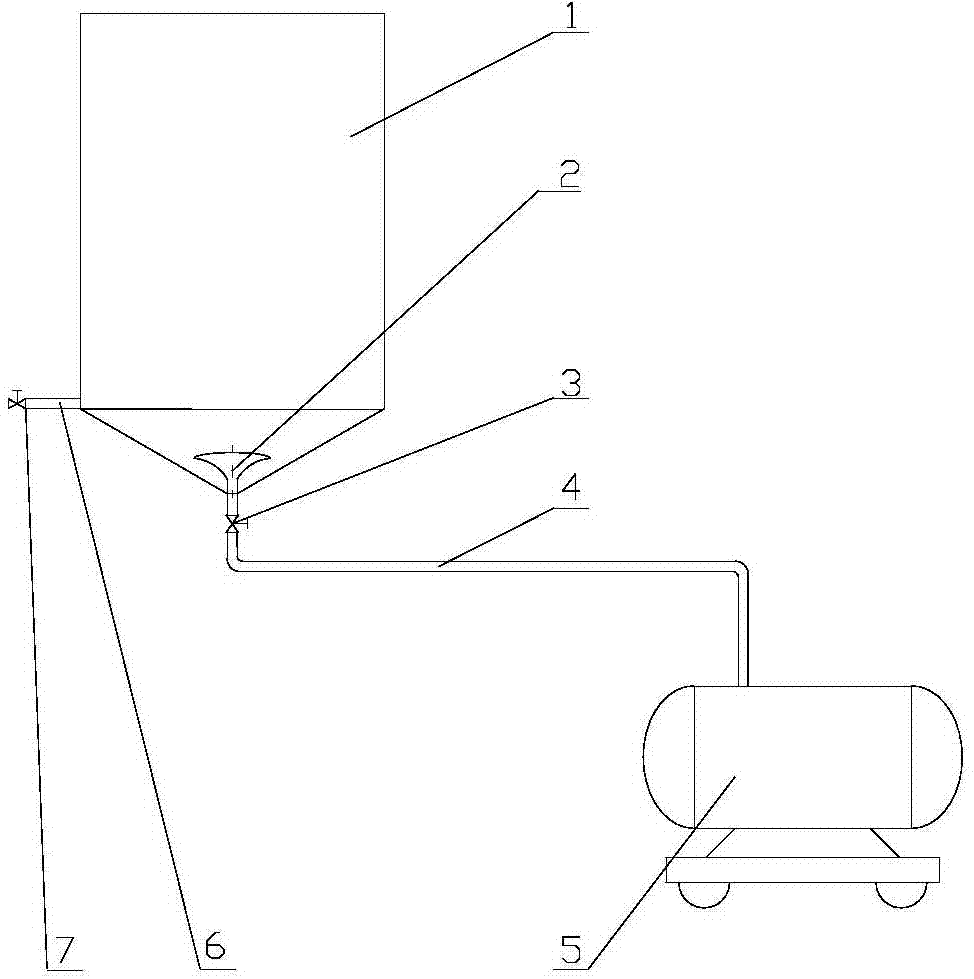

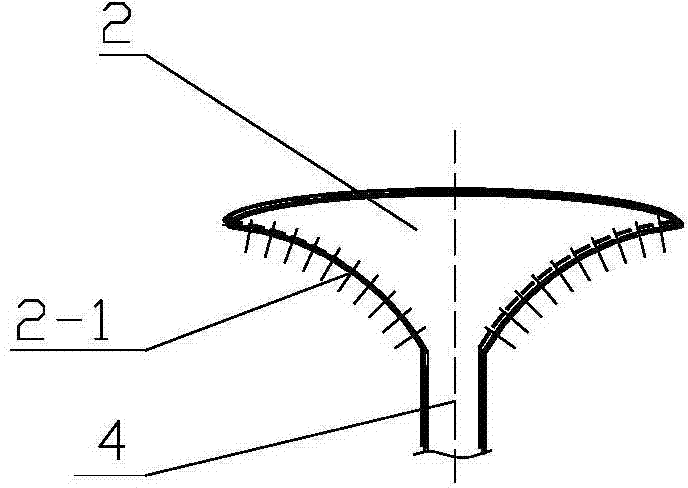

InactiveCN104722233ASimple structureEasy to installTransportation and packagingMixersGas compressorInlet valve

The invention provides a dead-angle-free stirring reactor and relates to the technical field of a reaction kettle. The stirrer comprises an air bubble stirrer, foam overflowing holes, an air inlet valve, an air inlet pipe and an air compressor, and is characterized in that the air bubble stirrer is in the shape of a reversed cone; the foam overflowing holes are formed in the side face of the cone of the air bubble stirrer; the top of the cone of the air bubble stirrer is connected with the air inlet pipe; the air inlet pipe is provided with the air inlet valve; and the air inlet valve is connected with the air compressor. The side face of the cone of the air bubble stirrer is an arc surface which is concave inwards. The foam overflowing holes with the equal pore diameter of 2mm-5mm are formed in the side face of the cone of the air bubble stirrer. The dead-angle-free stirring reactor has the characteristics of simple structure, convenience for installation, convenience for maintenance and low power consumption.

Owner:薛应东

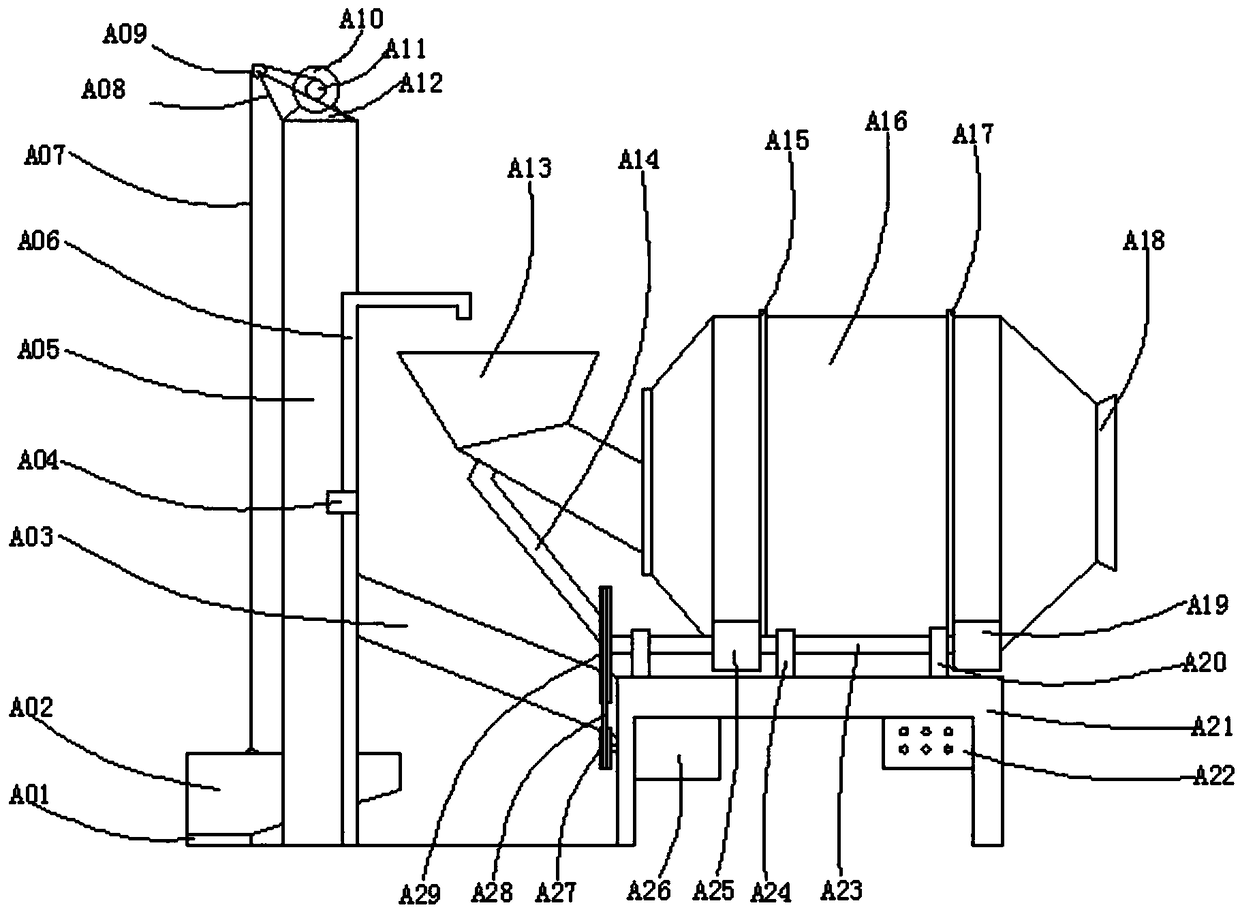

Rapid blending equipment for mortar production

InactiveCN112692999AParticle refinementFor subsequent pulpingMixing operation control apparatusPretreatment controlControl engineeringProcess engineering

The invention relates to the technical field of mortar preparation treatment, in particular to rapid blending equipment for mortar production. According to the equipment, a servo motor is adopted to drive a first rotating shaft to rotate, a transmission assembly drives a crushing assembly to work, and a crushing knife generates a crushing effect in a crushing cavity so as to carry out particle refinement on mortar raw materials, and subsequent pulping is facilitated; the first rotating shaft drives a second rotating shaft to rotate forwards and backwards in a reciprocating mode through a driving assembly, and a spline shaft below the second rotating shaft rotates along with the second rotating shaft and drives a sliding sleeve to drive stirring blades to circumferentially rotate to achieve a stirring effect; the second rotating shaft also circumferentially rotates along with the first rotating shaft, and a second driven bevel gear at an outer end is matched with a gear ring at a fixed position, and the second driven bevel gear drives the second rotating shaft to rotate, so that a reel performs automatic and periodic take-up and pay-off operations; and by matching with the dead weight of the stirring assembly, the stirring assembly moves up and down along the spline shaft, so that the stirring action area of the stirring blades is changed and the stirring dead angle is eliminated.

Owner:安徽瞬达信息科技有限公司

Agitated reactor without dead angle

InactiveCN103418322ASimple structureEasy to installTransportation and packagingMixersInlet valveCircular cone

The invention discloses an agitated reactor without a dead angle, and belongs to the technical field of reaction kettles. The agitated reactor without the dead angle comprises a reactor body, a bubble agitator, an air inlet valve, an air inlet pipe, an air compressor, a discharging pipe, a discharging valve and bubble overflowing holes. The agitated reactor without the dead angle is characterized in that the reactor body is a cone-base reactor, the bubble agitator is of an inverted-cone shape, the bubble overflowing holes are formed in the side face of a conical body of the bubble agitator, the bubble agitator is arranged at the bottom of the reactor body, the conical top of the bubble agitator is connected with the air inlet pipe, the air inlet valve is installed on the air inlet pipe, the air inlet valve is connected with the air compressor, the conical side face of the bubble agitator is an inwards-concave cambered surface, the equal-hole-diameter bubble overflowing holes are formed in the conical side face of the bubble agitator, the diameter of each bubble overflowing hole is 2-5mm, and the bubble overflowing holes are evenly distributed along the inwards-concave side face of the conical body. The agitated reactor without the dead angle has the advantages of being simple in structure, convenient to install and maintain and low in power consumption.

Owner:薛应东

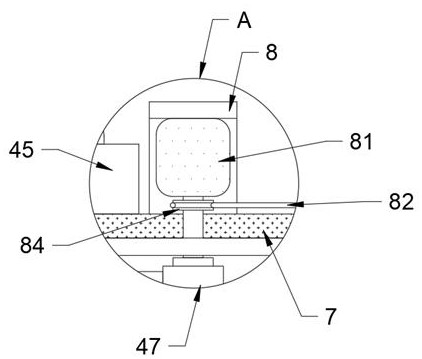

Spray dryer for pea protein powder production

PendingCN114642891APrevent overflowIncrease drynessEvaporator accessoriesEvaporation by sprayingBiotechnologyDesiccant

The invention discloses a spray dryer for pea protein powder production, and relates to the technical field of spray dryers, the spray dryer comprises a dryer main body, a feeding mechanism is fixedly mounted on the outer wall of one side of the dryer main body, a dispersing assembly and a scraping assembly are arranged on the inner wall of the dryer main body, and a heating assembly is arranged on the inner wall of a heating box; one end of the first recycling pipe is connected with a recycling mechanism, and a powder drying mechanism is arranged on the inner wall of the collecting barrel. The first motor is started to drive the drying filter cylinder to rotate and the stirring rod to rotate, the drying filter cylinder is of a hollow structure, a space for hot air to rise is provided, hot air with residual moisture in protein powder can penetrate through a filter cloth bag to enter the drying filter cylinder and then is exhausted upwards through a steam exhaust pipe, and the arranged filter cone can prevent the protein powder from overflowing; and a drying agent can be arranged in the drying filter cylinder and is used for adsorbing residual moisture in the protein powder, so that the drying degree of the protein powder is further improved.

Owner:恒源生物科技有限公司

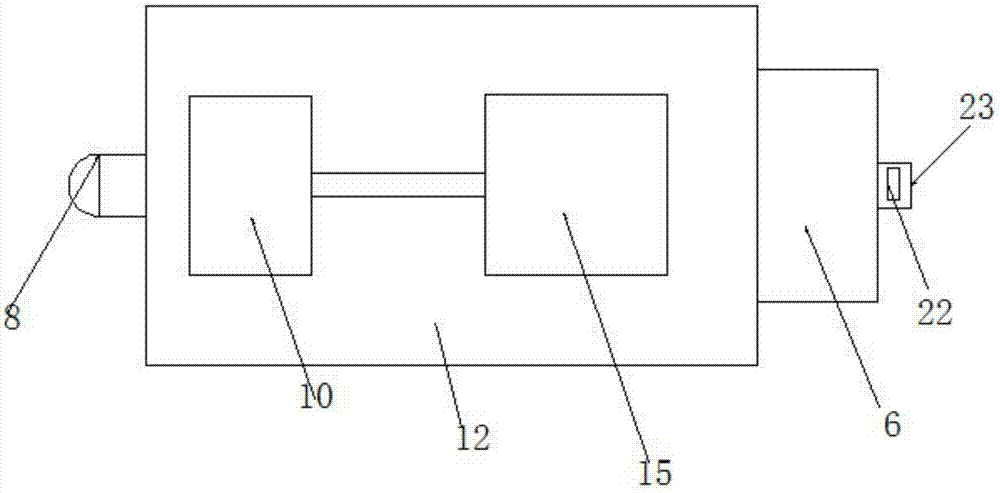

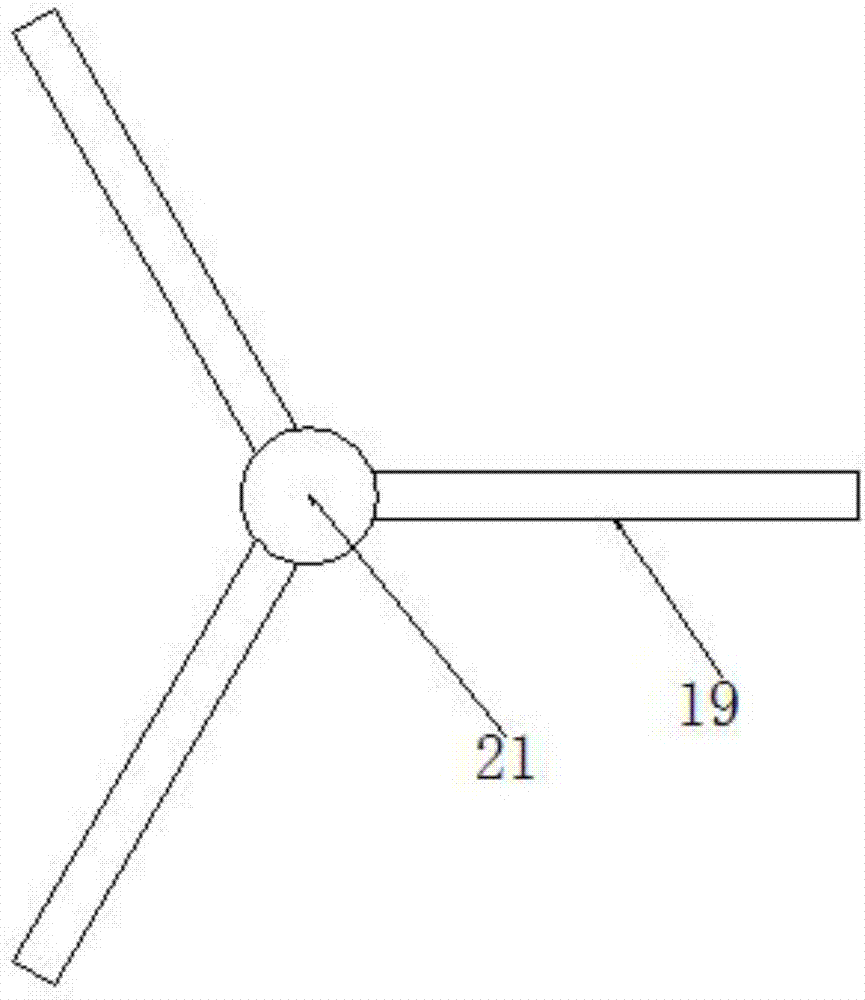

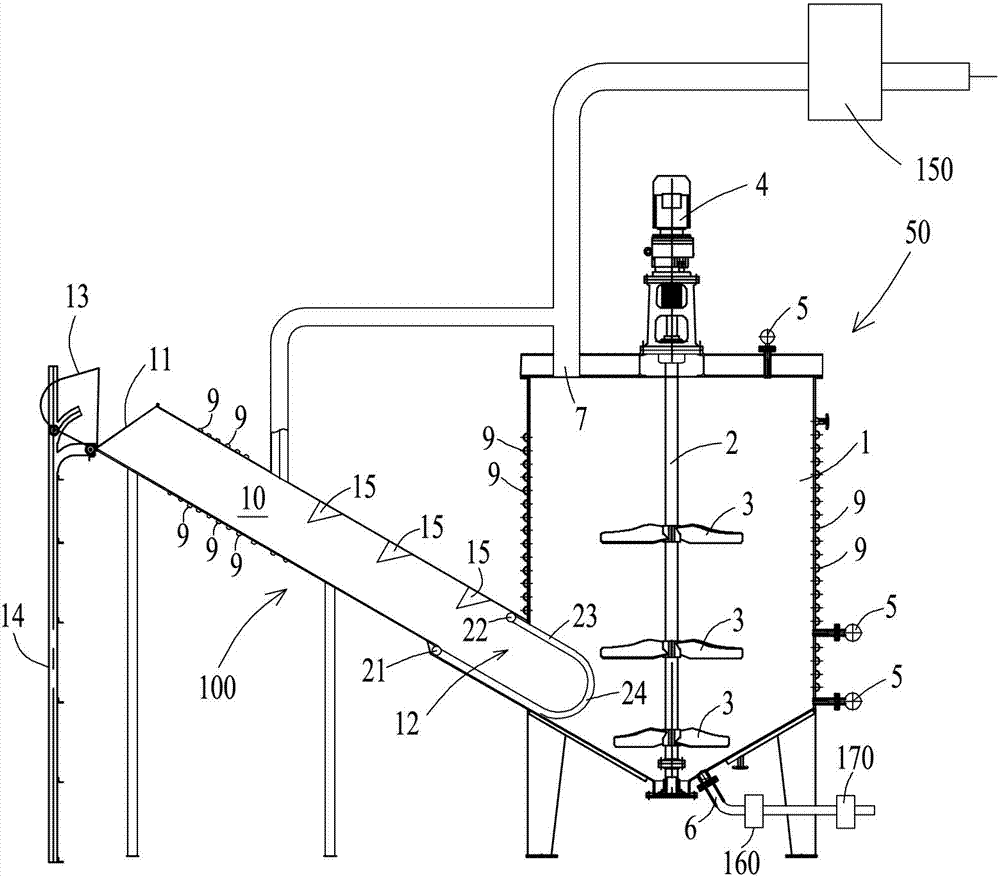

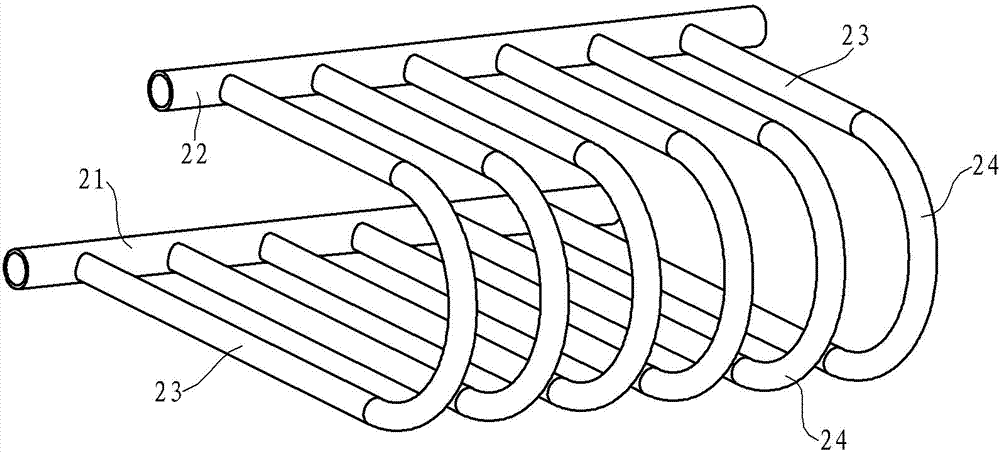

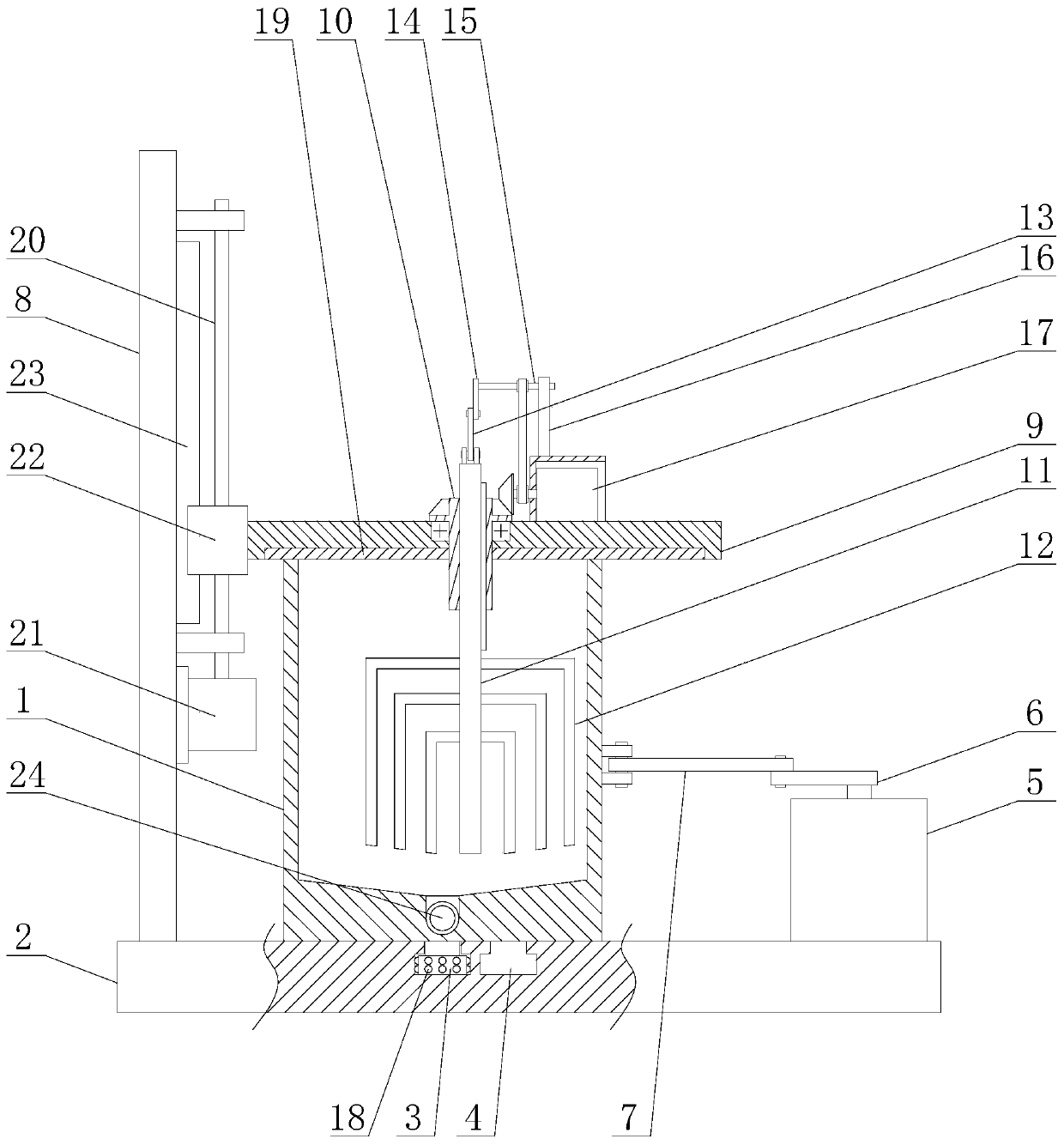

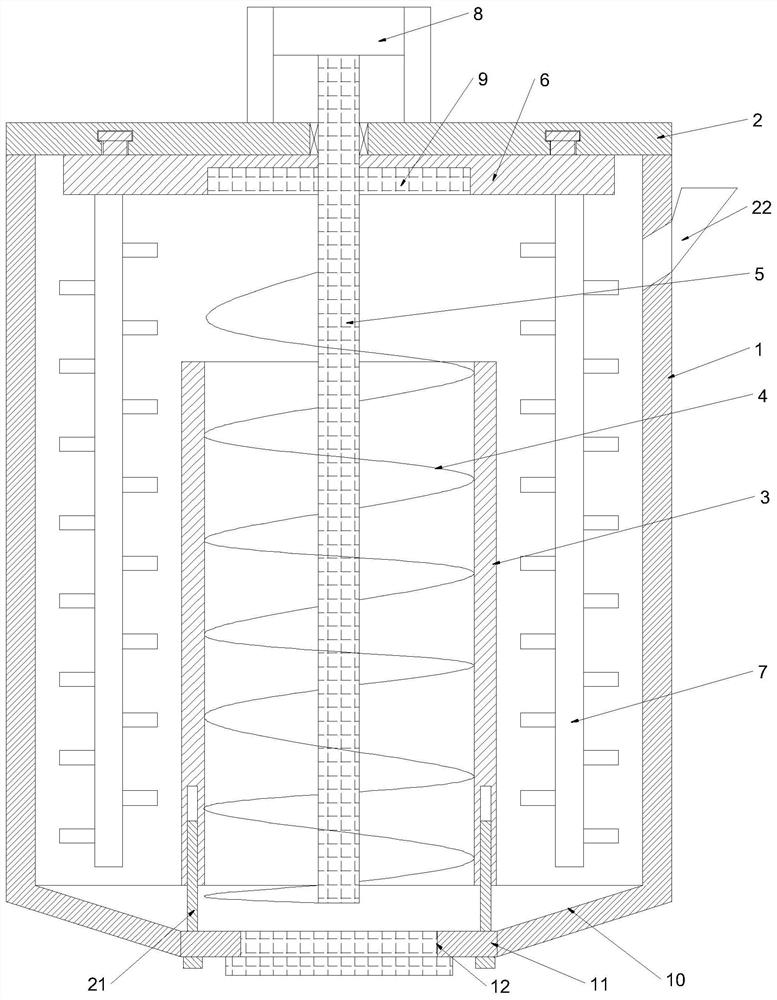

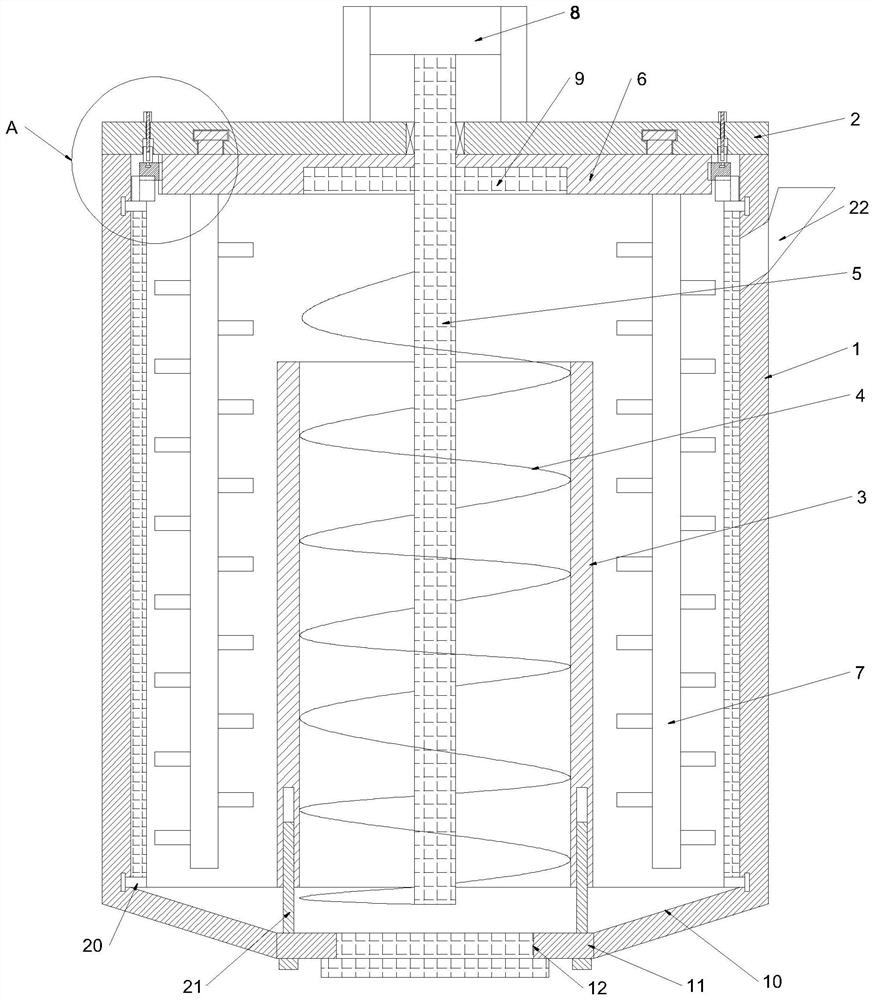

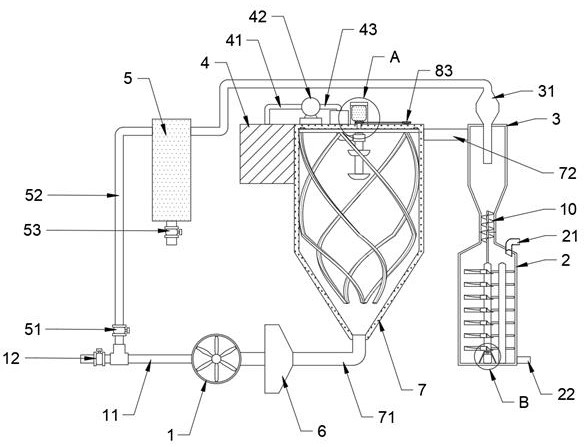

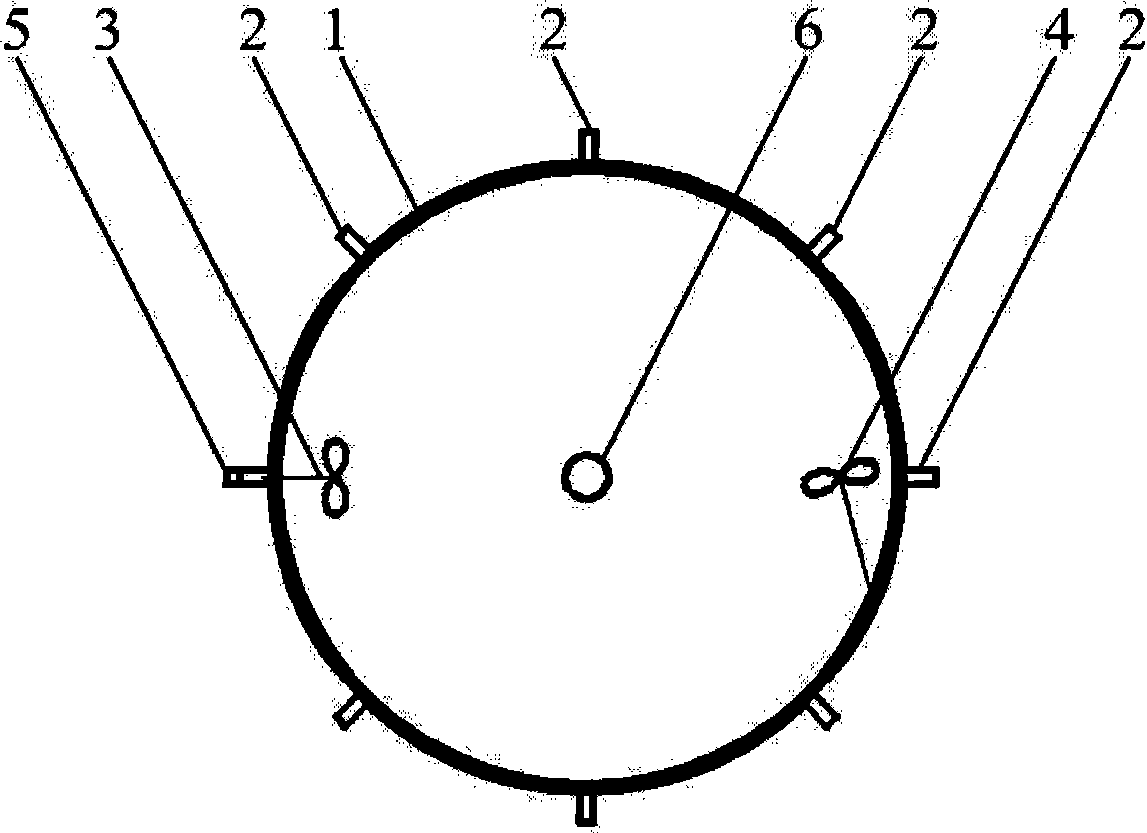

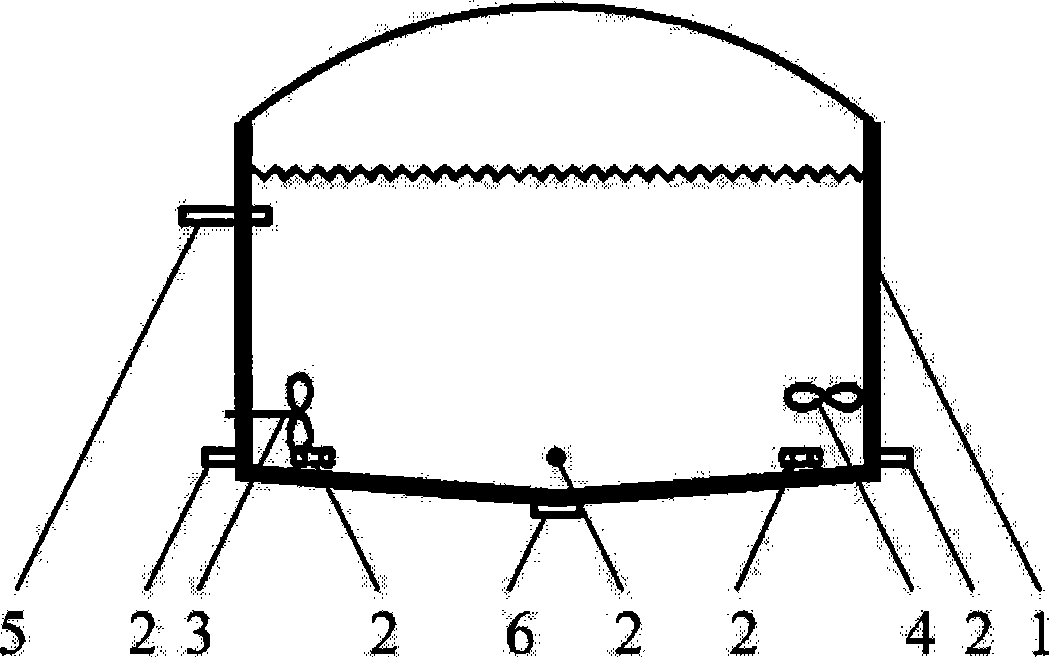

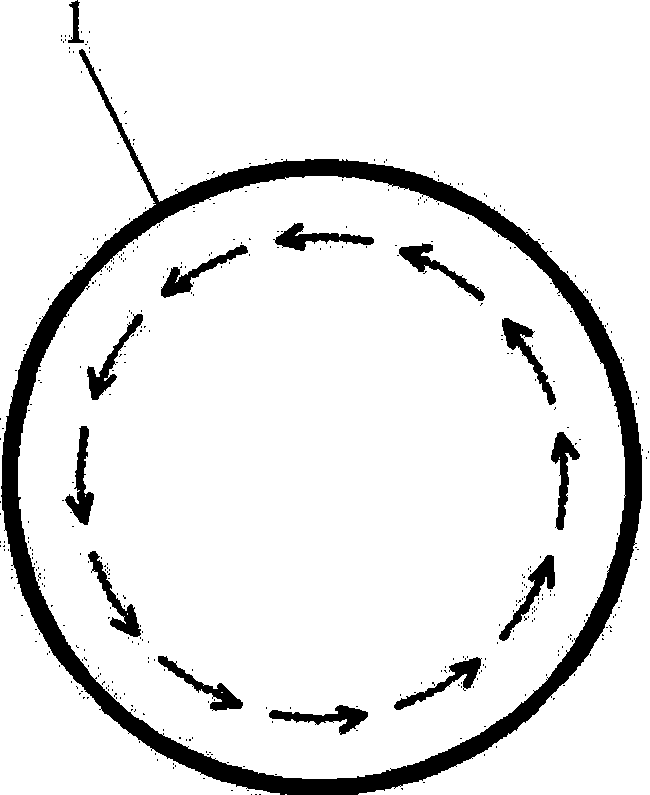

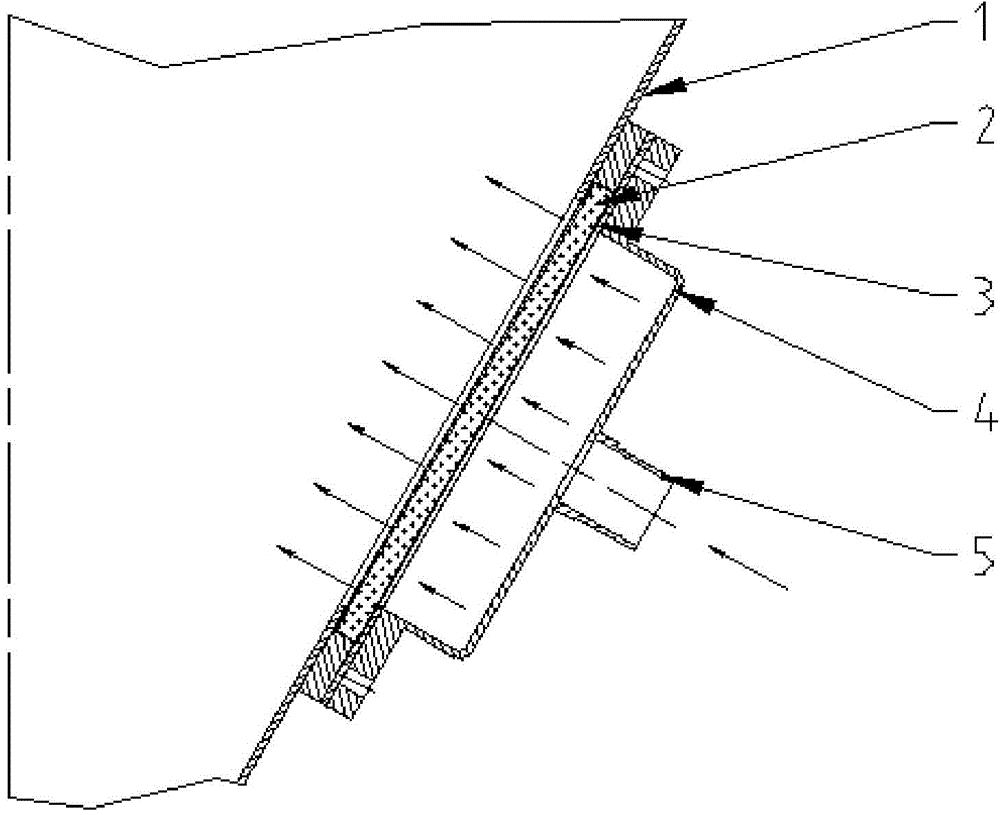

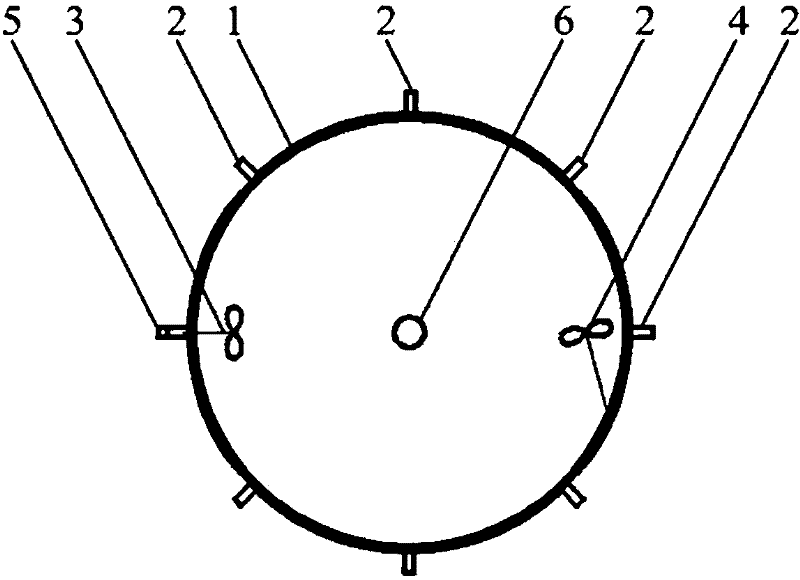

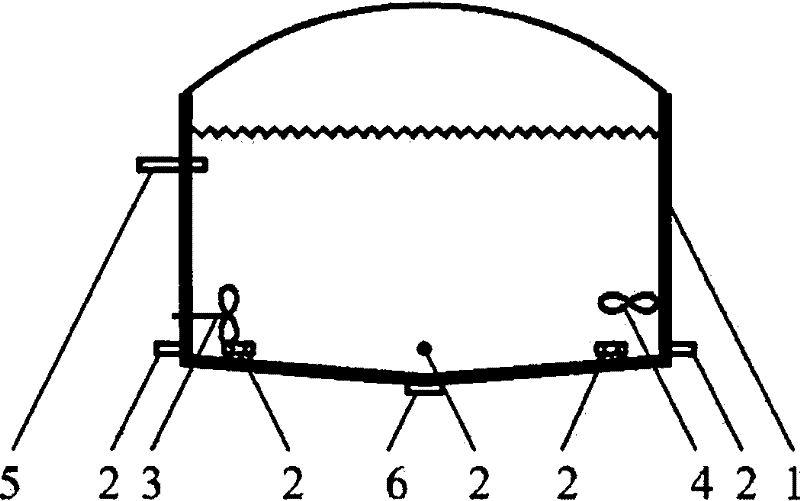

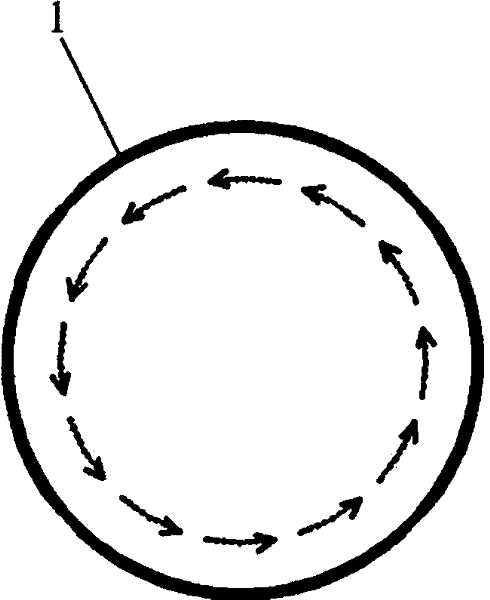

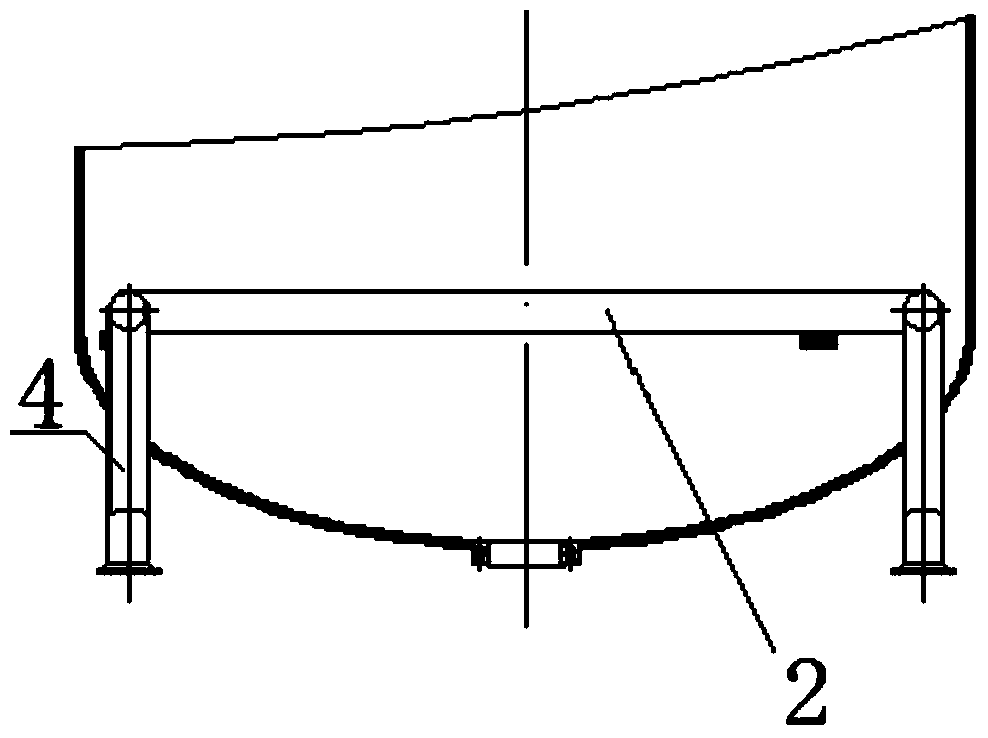

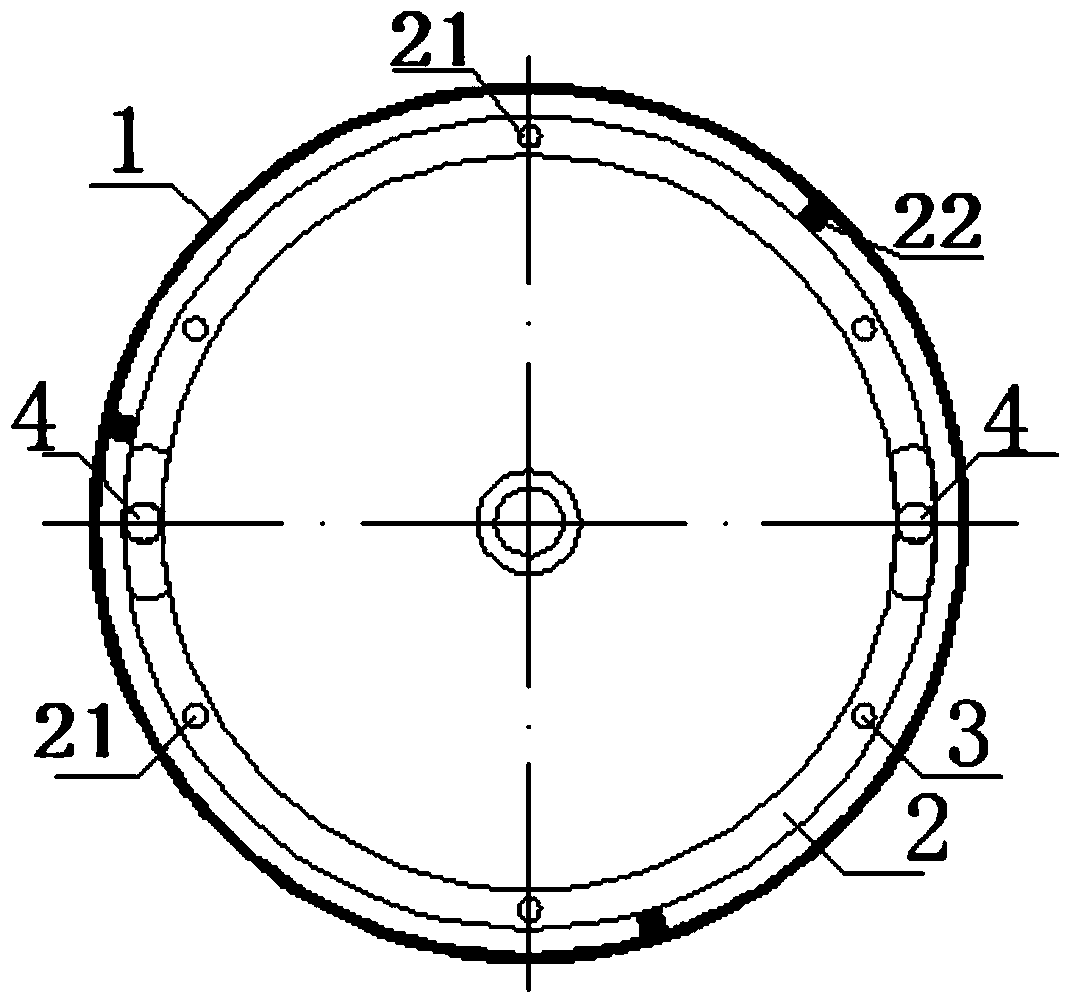

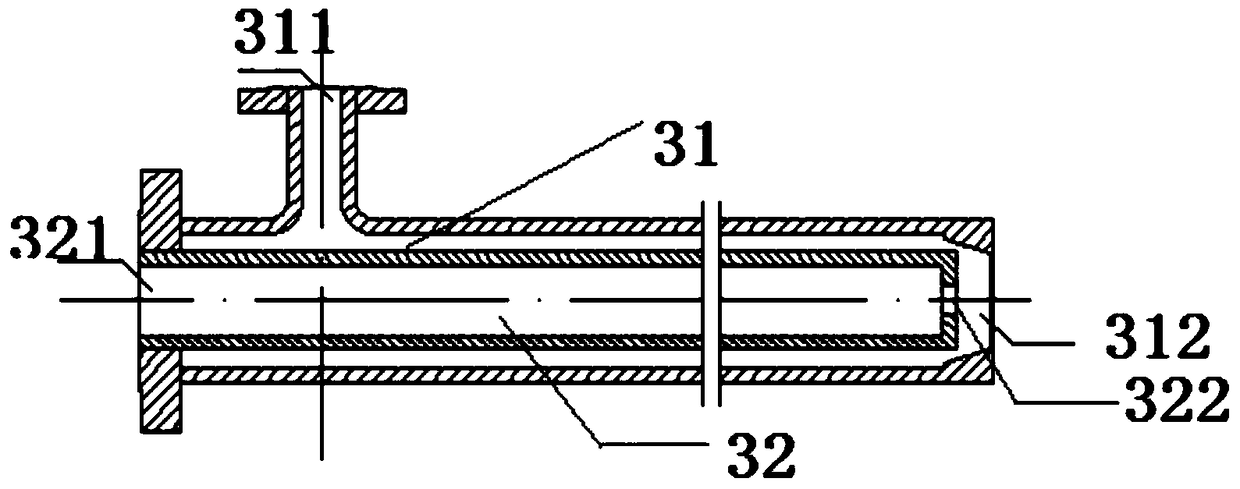

Combined stirring means and apparatus in high solid anaerobic digestion biogas production

InactiveCN101376895AEliminate stirring dead angleAvoid material encrustationBioreactor/fermenter combinationsBiological substance pretreatmentsJet flowProcess engineering

The invention discloses a combined stirring method and a device in the production of high-solid anaerobic digestion marsh gas. The lower part of the wall of a cylindrical closed reactor is provided with a radial stirrer and a tangential stirrer; four to twenty sand pipes are connected with the wall of the reactor and tightly adhered to the bottom side of the reactor equantly; the upper part of the wall of the reactor is connected with a feeding pipe; the bottom of the reactor is connected with a large discharge pipe. A material in-and-out cycle is divided into two stages, in which the material is stirred tangentially and radially; after being fed in, the material is stirred in the radial direction, and then in stirred in the tangential direction, so that the sand is collected around the bottom of the reactor under the centrifugal effect; next, the sand pipes are opened, the sand is discharged as the jet flow formed by the centrifugal effect, and the material discharge and sand removal are completed at the same time; the sand pipes are then closed, the tangential stirring is stopped, the material is fed in, the two stirring methods are used alternately in a circulating way to form two different stirring flow fields which mutually remove stirring dead corners, prevent the material from incrusting and the sand from accumulating, so as to ensure the stably operation of the system. The invention is mainly used in producing marsh gas.

Owner:ZHEJIANG UNIV

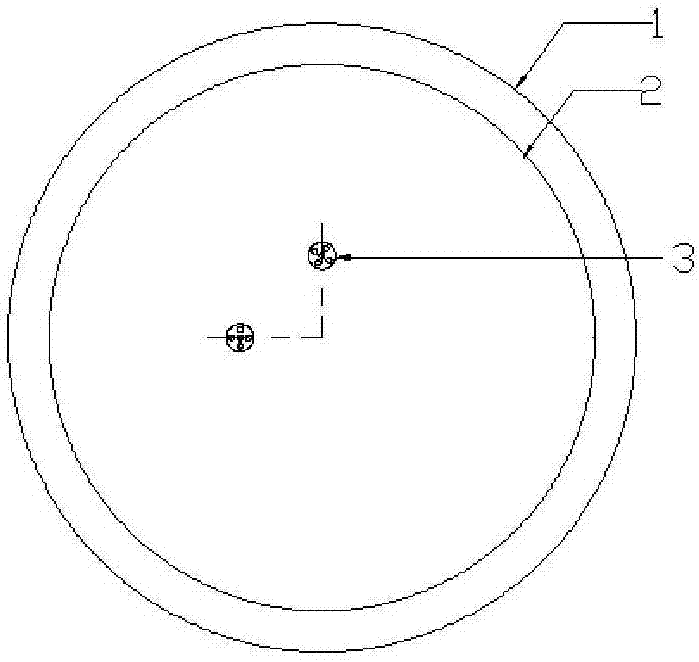

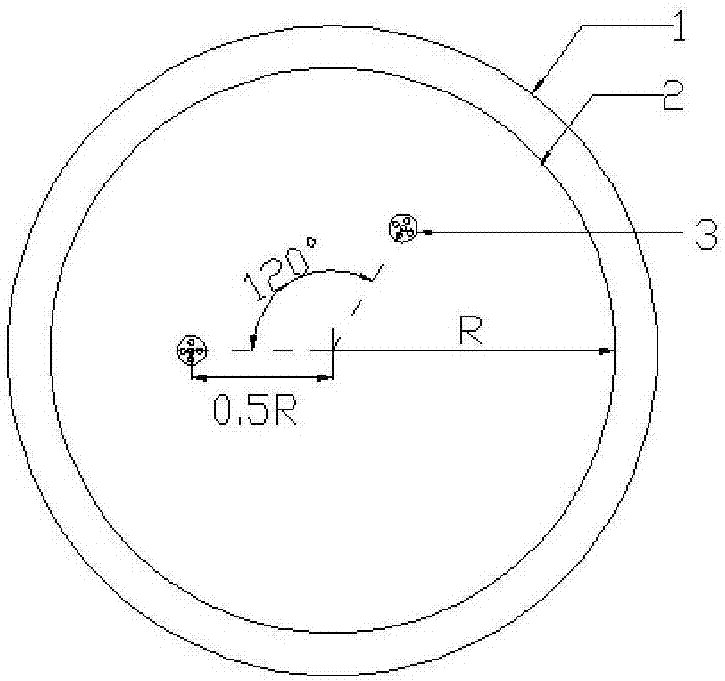

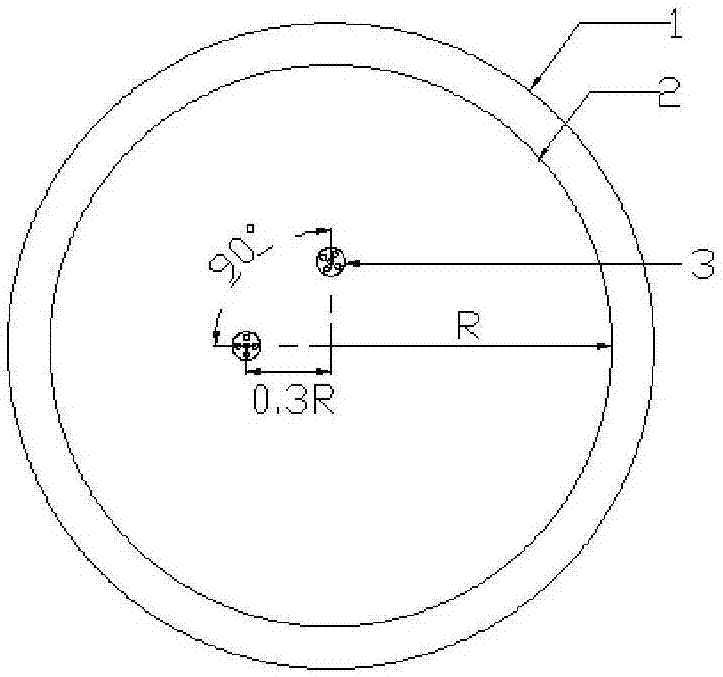

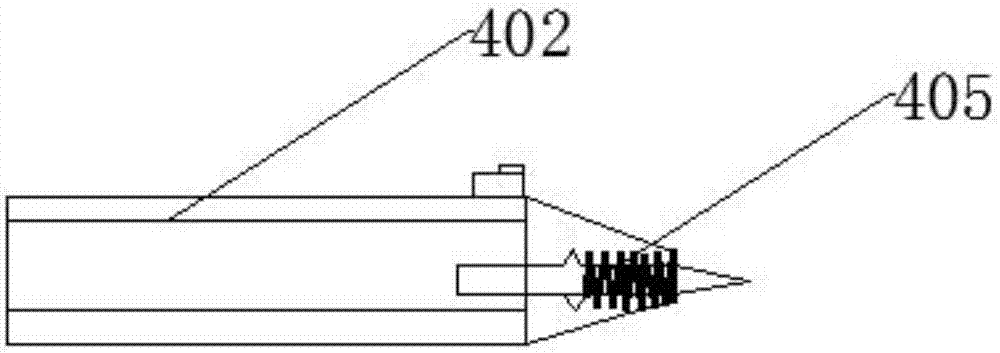

Silicon melt external refining device and method

PendingCN107352546ANo pollution in the processLess investment in infrastructureSilicon compoundsSpray nozzleSilicon

The invention relates to a silicon melt external refining device and method and belongs to the technical field of industrial silicon purification. A ladle bottom of the device is equipped with two gas nozzles, and an included angle theta between each nozzle circle center and a ladle bottom circle center meets a relationship of 90 degrees<=theta<=180 degrees; and the distance between each nozzle circle center and the ladle bottom circle center, nozzle radius r and ladle bottom radius R meet a relationship shown in the description. Compressed air or refining gas is continuously introduced into the two gas nozzles arranged on the ladle bottom; silicon melt which is smelted from a submerged arc furnace is placed into a ladle; with the increase of silicon melt discharged from the ladle, refining agents are added and the refining gas component and flow are adjusted; external blowing and slagging refining are performed; dross on the surface of the silicon melt is skimmed; and pouring is performed on the silicon melt to obtain a high-purification industrial silicon product. The device and method provided by the invention ensure the dynamic conditions of the silicon melt in the specially-made ladle, eliminate stirring dead angles, and effectively increase qualities of the silicon product.

Owner:KUNMING UNIV OF SCI & TECH

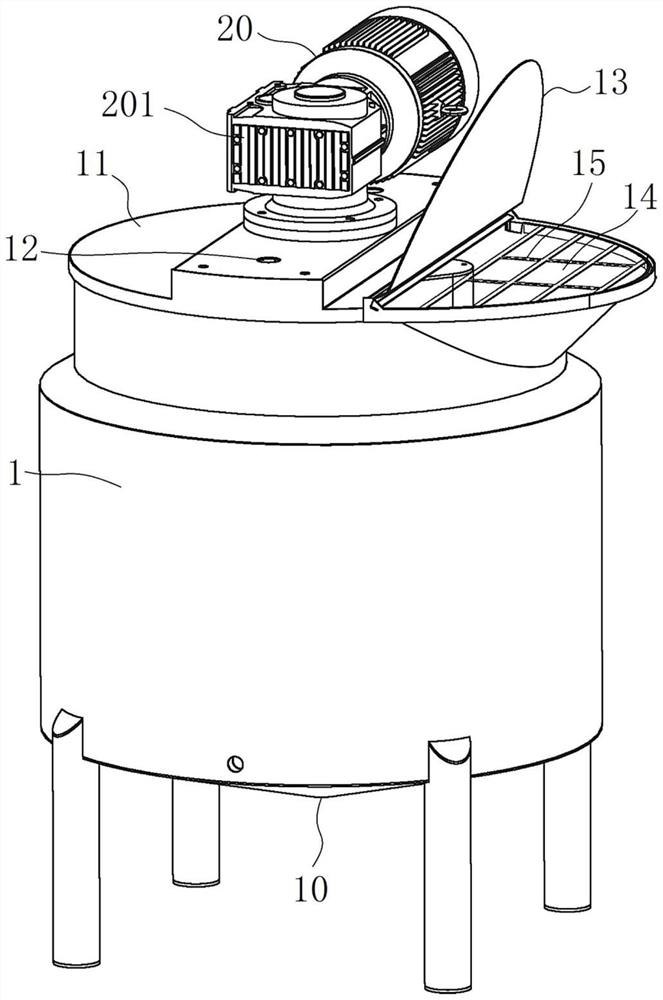

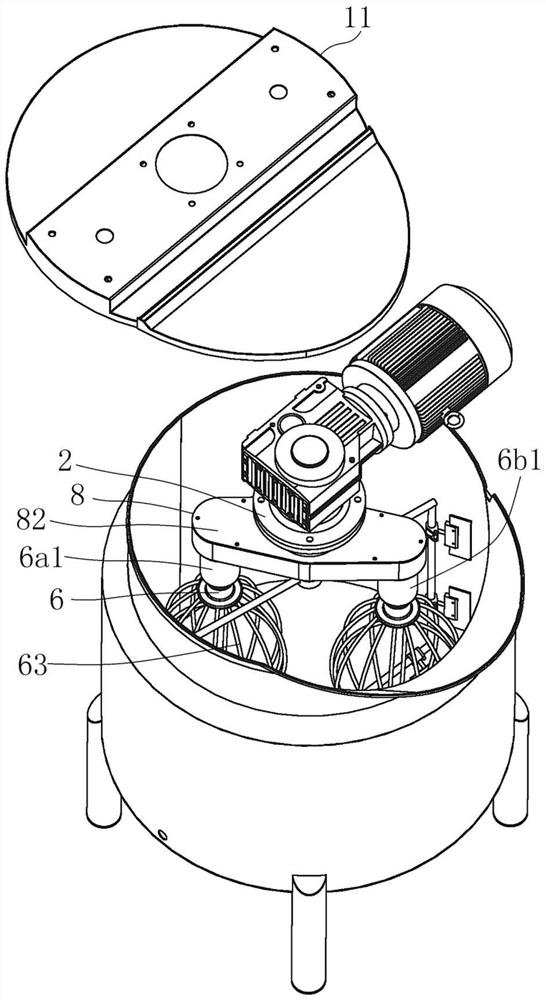

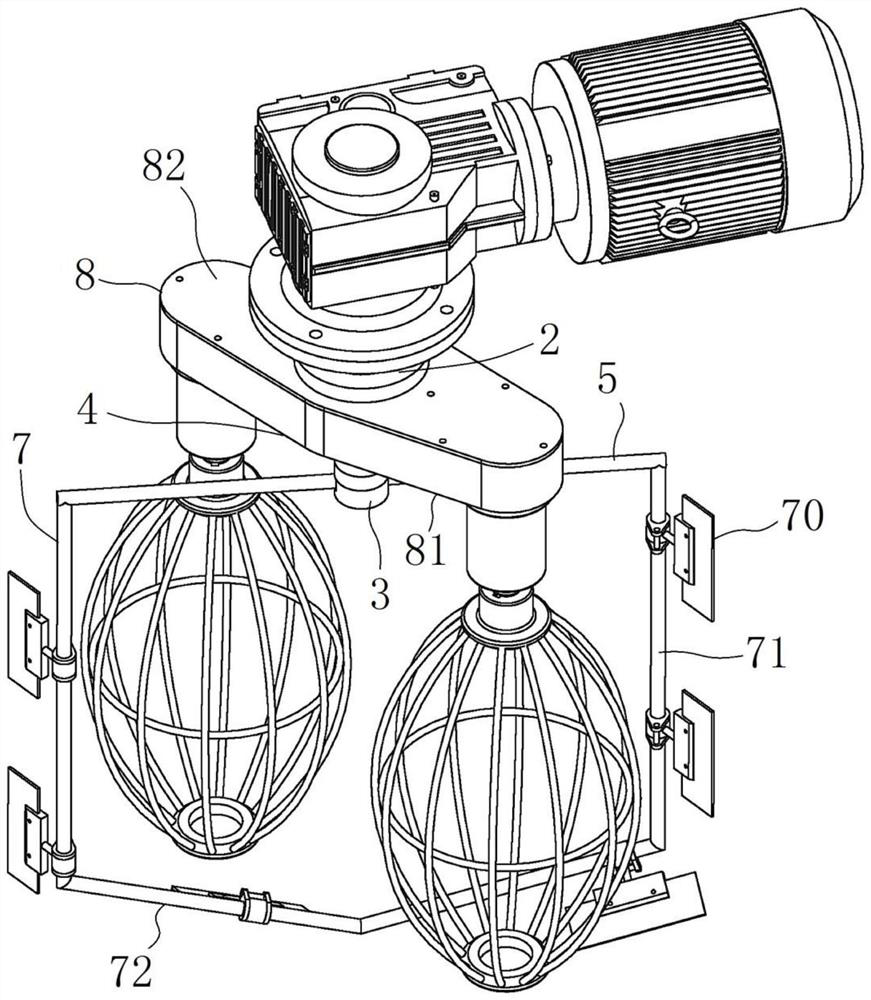

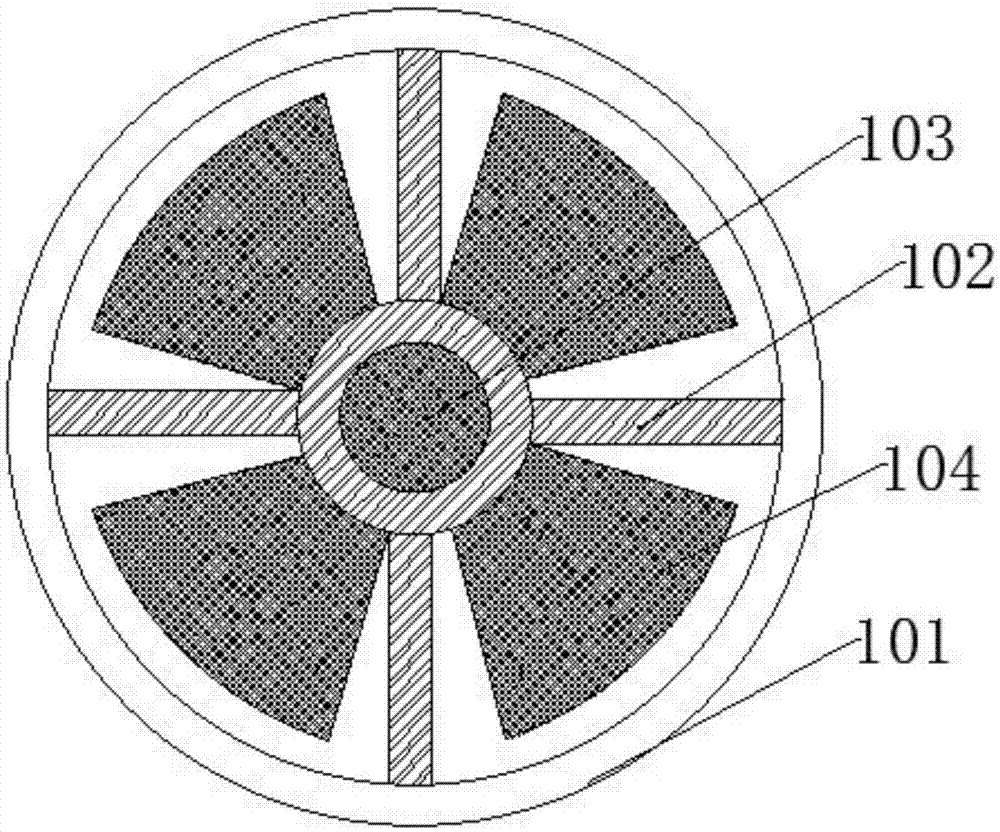

Stirring machine

PendingCN113578152AGood mixing effectEliminate stirring dead angleTransportation and packagingRotary stirring mixersPhysicsEngineering

The invention aims to provide a stirring machine with an excellent stirring effect. The structure of the stirring machine comprises a charging barrel with an opening in the upper portion, a driving mechanism arranged at the opening of the charging barrel and a stirring assembly arranged in the charging barrel, the driving mechanism comprises a mounting base, a mandrel which penetrates through the mounting base and extends downwards is arranged in the mounting base, and the lower end of the mounting base is fixedly connected with a rotation driving fluted disc; a self-rotation driving swing arm and a peripheral stirring driving swing arm are fixed to the lower end of the mandrel, the stirring assembly comprises a self-rotation stirring shaft rotationally connected with the end of the self-rotation driving swing arm and a peripheral stirring blade mounting frame connected with the end of the peripheral stirring driving swing arm, and a driving gear is arranged at the end of the self-rotation stirring shaft; the driving gear is connected with the autorotation driving fluted disc through an autorotation transmission chain, the peripheral stirring blade mounting frame comprises a vertical stirring blade mounting rod and a bottom stirring blade mounting rod, and the upper end and the lower end of the vertical stirring blade mounting rod are connected with the peripheral stirring driving swing arm and the bottom stirring blade mounting rod respectively.

Owner:吴伟江

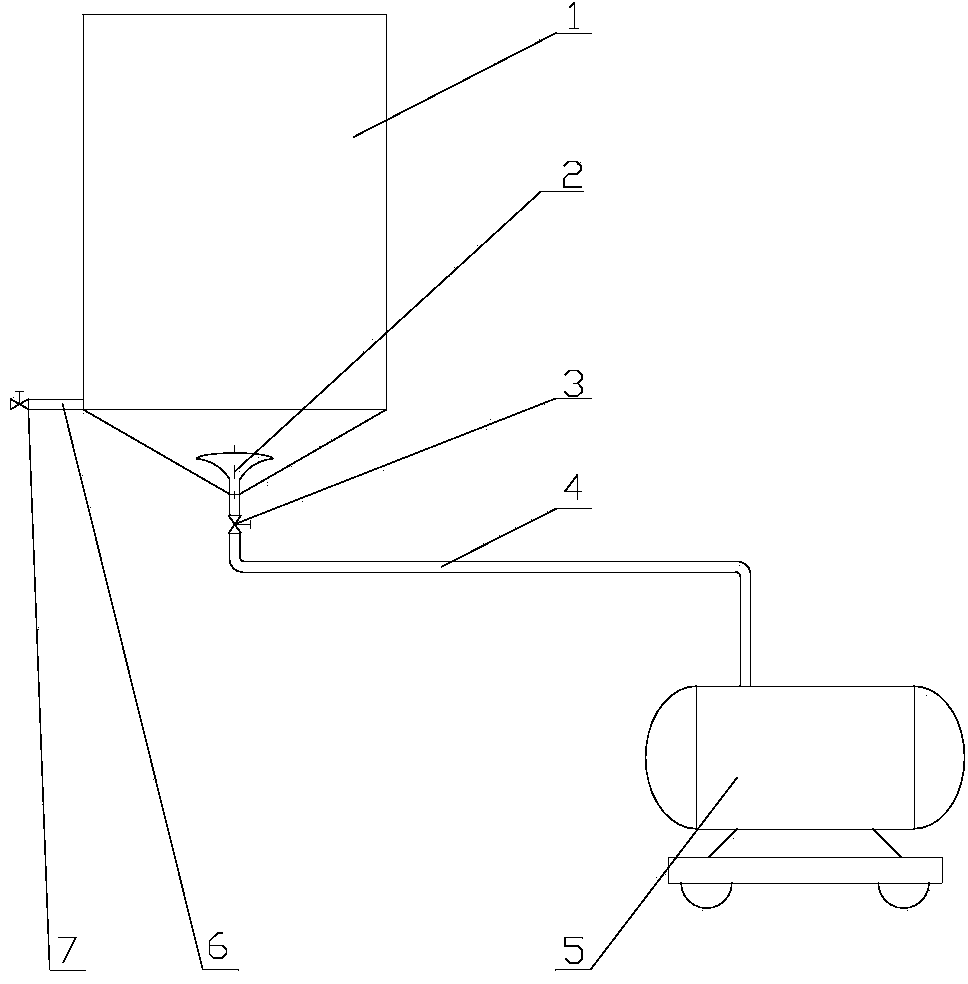

Aided flowing device of storage silo

InactiveCN104803123AUniform fluidizationAvoid accumulationLarge containersMicrowell PlateEngineering

The invention relates to an aided flowing device of a storage silo. The aided flowing device is arranged at a certain side part of the storage silo and is communicated with the storage silo, and comprises a porous plate, a packing washer, an air inflation frame and an air pipe joint, wherein the porous plate is adhered to a certain side of the storage silo and is fixed by the packing washer, the air inflation frame is arranged on the outer surface of the porous plate and is fixed by the packing washer, and the outside of the air inflation frame is connected with the air pipe joint. Compared with the prior art, compressed air is fed into the storage silo, and materials in the storage silo can be more uniformly fluidified; in addition, the accumulation of materials on the inner wall of the storage silo can be prevented, and the stirring dead angle can be eliminated.

Owner:SHANGHAI JUZONG IND

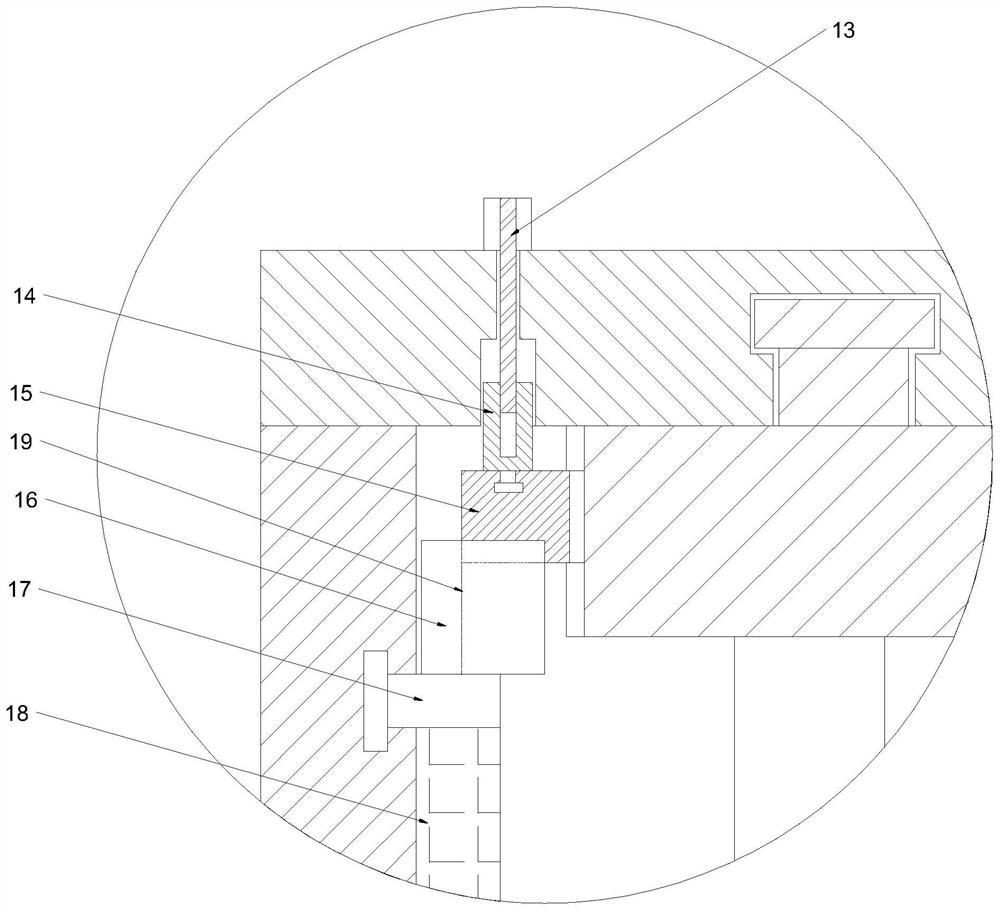

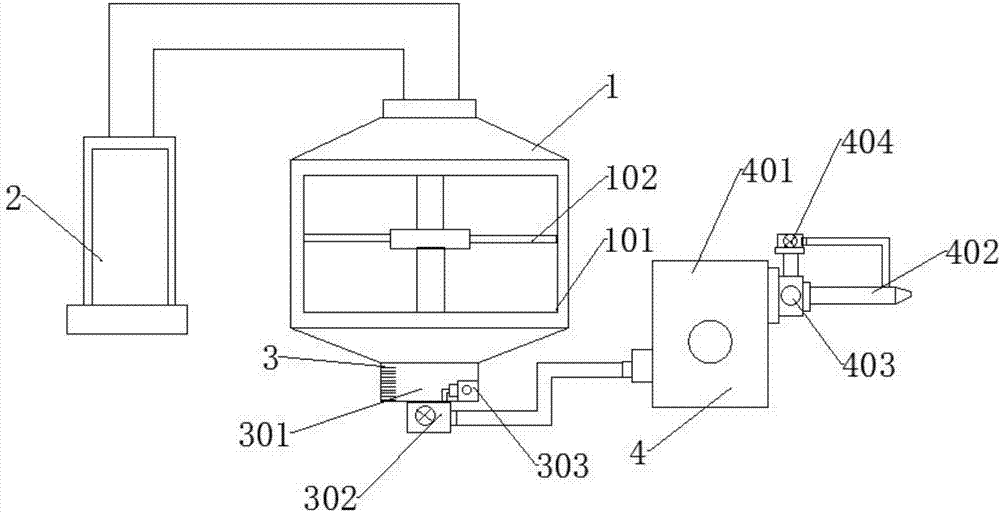

Glue-pouring device for manufacturing power module

ActiveCN107516727AAvoid shakingReduce lossFinal product manufactureCell component detailsSpray nozzlePulp and paper industry

The invention discloses a glue-pouring device for manufacturing a power module. The device comprises a stirring mechanism, a feeding hole of the stirring mechanism is connected with a material storage tank through a conduit, a discharge hole of the stirring mechanism is connected with a quantitative system through the conduit, the quantitative system is used for quantitatively controlling raw materials, and a discharge hole of the quantitative system is connected with a glue injecting device; the stirring mechanism comprises a stirring barrel, a stirring fixation support is inlaid in an inner wall of a middle segment of the stirring barrel, and a stirring shaft is penetrated in the stirring fixation support; the quantitative system comprises a quantitative barrel and an electric valve, the electric valve is clamped at an outlet of the quantitative barrel, an barrel wall of the quantitative barrel is further provided with a flowmeter, and an output end of the flowmeter is connected to a control end of the electric valve through a wire; the glue injecting device comprises a glue injecting pump, an input end of the glue injecting pump is connected to an output through hole of the electric valve through the conduit, and an output end of the glue injecting pump is connected with a glue injecting spray nozzle. The glue-pouring device can be used for stably and accurately realizing glue-pouring operation, can realize raw material backflow cycle use, saves energy and is efficient.

Owner:江苏能动电子科技有限公司

Combined stirring means and apparatus in high solid anaerobic digestion biogas production

InactiveCN101376895BPrevent crustingEven contactBioreactor/fermenter combinationsBiological substance pretreatmentsJet flowBiogas production

The invention discloses a combined stirring method and a device in the production of high-solid anaerobic digestion marsh gas. The lower part of the wall of a cylindrical closed reactor is provided with a radial stirrer and a tangential stirrer; four to twenty sand pipes are connected with the wall of the reactor and tightly adhered to the bottom side of the reactor equantly; the upper part of the wall of the reactor is connected with a feeding pipe; the bottom of the reactor is connected with a large discharge pipe. A material in-and-out cycle is divided into two stages, in which the material is stirred tangentially and radially; after being fed in, the material is stirred in the radial direction, and then in stirred in the tangential direction, so that the sand is collected around the bottom of the reactor under the centrifugal effect; next, the sand pipes are opened, the sand is discharged as the jet flow formed by the centrifugal effect, and the material discharge and sand removalare completed at the same time; the sand pipes are then closed, the tangential stirring is stopped, the material is fed in, the two stirring methods are used alternately in a circulating way to form two different stirring flow fields which mutually remove stirring dead corners, prevent the material from incrusting and the sand from accumulating, so as to ensure the stably operation of the system.The invention is mainly used in producing marsh gas.

Owner:ZHEJIANG UNIV

A device and method for improving coagulation effect of isoprene rubber

The present invention provides an apparatus and a method for improving the agglomeration effect of a polyisoprene rubber. The apparatus comprises: a pipeline provided with a plurality opening holes and annularly arranged around the circumferential direction of the inner wall of an agglomeration kettle, wherein the gas inlet of the pipeline is connected to a compressed air supply device; and a double-fluid injection system, wherein the double-fluid injection system comprises a double-fluid nozzle, the compressed air supply device connected to the double-fluid nozzle, and a glue liquid supply device connected to the double-fluid nozzle, and the compressed air from the compressed air supply device and the glue liquid from the glue liquid supply device are injected into the agglomeration kettle through the double-fluid nozzle.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com