Patents

Literature

226results about How to "Improve stirring and mixing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

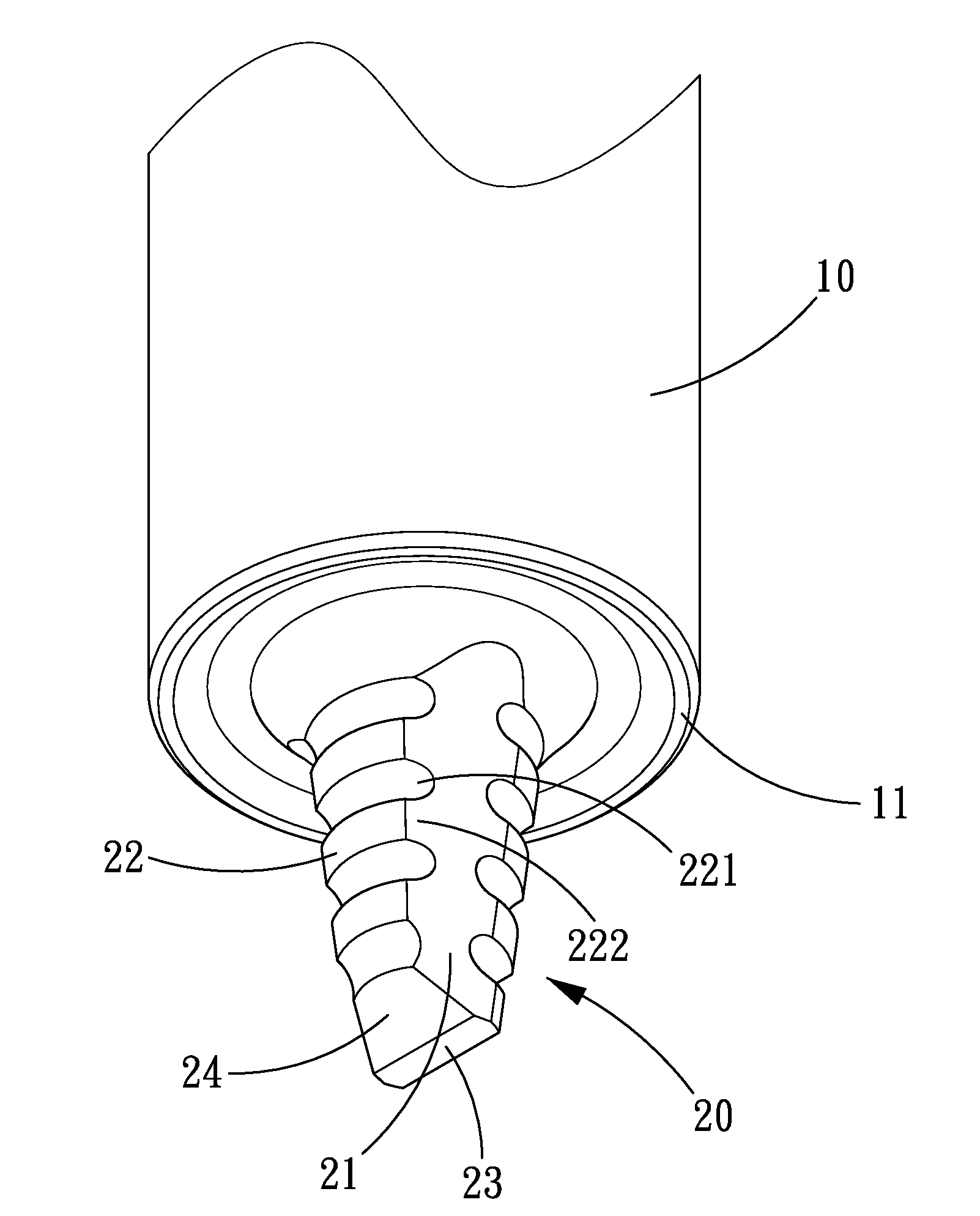

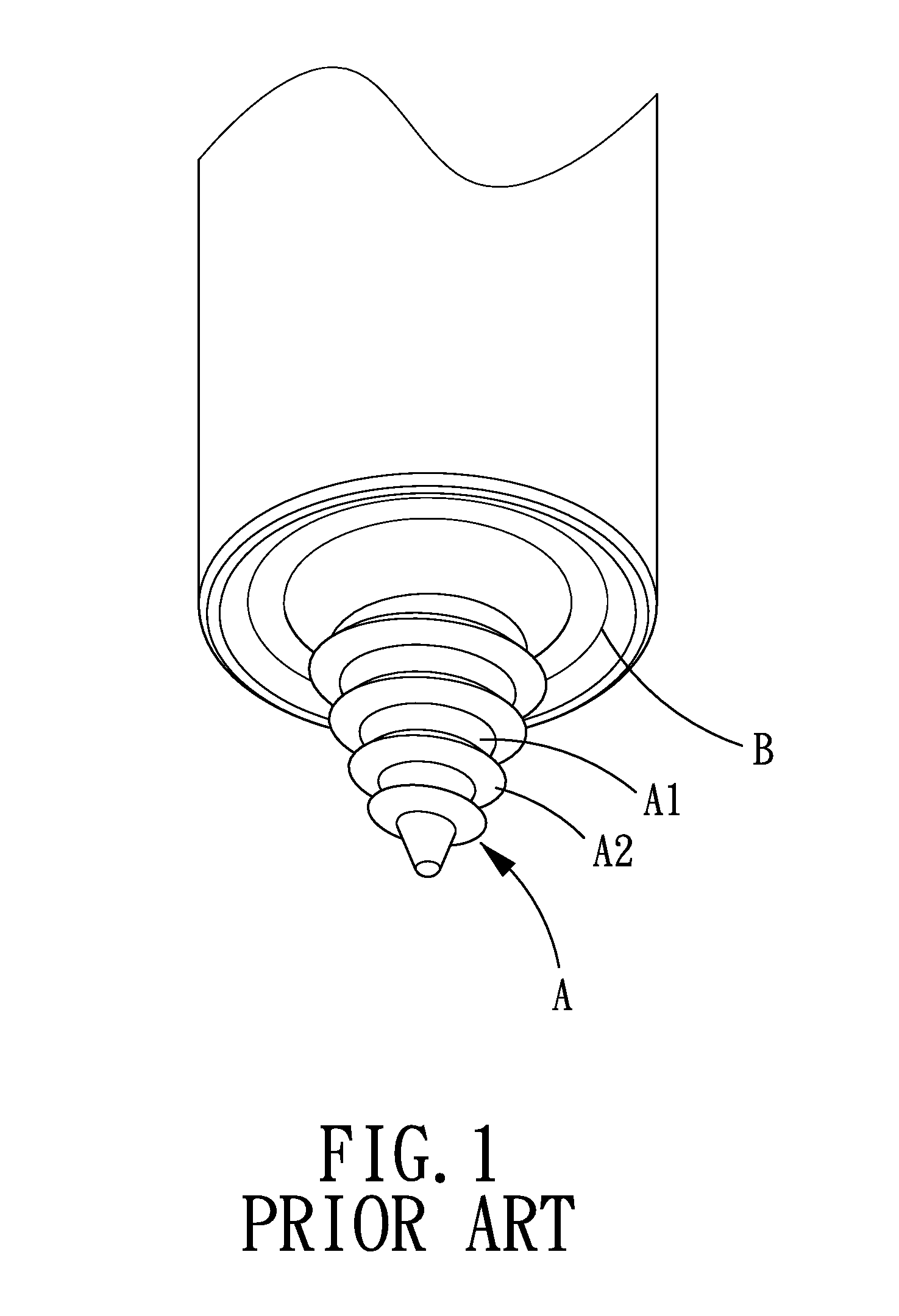

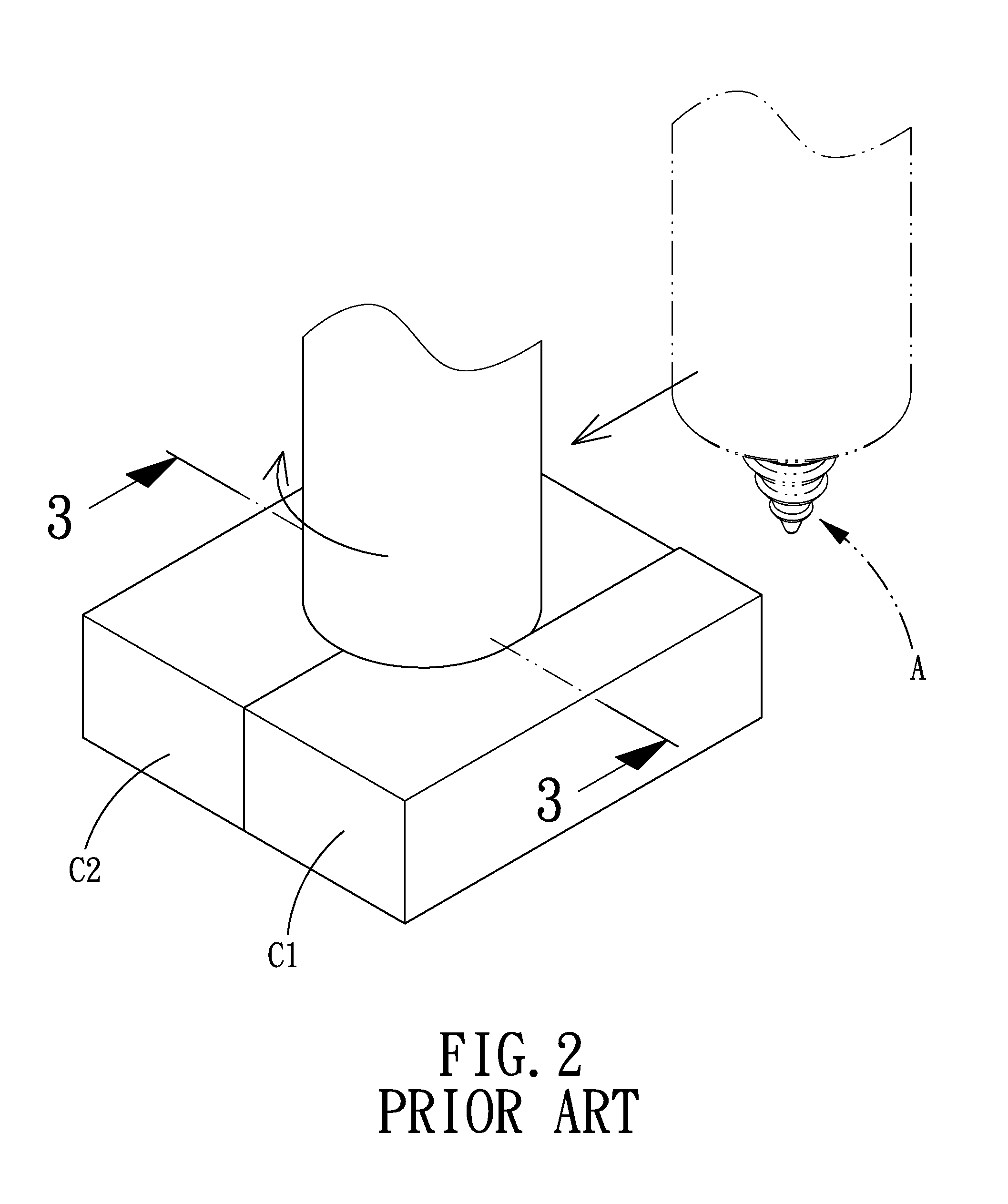

Friction Stir Welding Tool and Weld Metal Structure with Plural Onion Rings

InactiveUS20100081005A1High strengthAvoid defect formationWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

A friction stir welding tool and weld metal structure with plural onion rings, in which the tool is formed on the tool head with three surfaces, which are connected to one another through three spaced surfaces. An eccentrical axis of the tool head deviates from a central axis of the tool handle. One of the three surfaces is a deviation cutting surface which is a flat surface formed by cutting off a wall thickness from one side of an outer peripheral surface of the tool head toward the central axis of the tool handle. Each of the three spaced surfaces is alternately formed with plural notches and plural protrusions. The above welding tool is used to perform a stir friction welding operation to two metals to form the weld metal structure with the same number of onion rings as the protrusions and notches of each of the spaced surfaces.

Owner:AEROSPACE INDUSTRIAL DEVELOPMENT CORPORATION

Sewage treatment equipment

InactiveCN106477782AEasy to handleReduce the number of replacementsDispersed particle separationTreatment involving filtrationTreatment effectSprayer

The invention discloses sewage treatment equipment. The sewage treatment equipment comprises a tank, the tank is internally partitioned into a water inlet cavity, a mixing cavity and a clear water cavity sequentially from left to right through a first filter screen and a second filter screen, and the first filter screen is positioned on the left side of the second filter screen. The upper end of the water inlet cavity is communicated with a biological deodorizer through an exhaust pipe, a sewage inlet pipe communicated with the water inlet cavity is arranged at the upper end of the left side of the water inlet cavity, a sprayer is arranged in the water inlet cavity at the lower end of the sewage inlet pipe and communicated with an output end of a liquid pump outside the left side of the tank through a delivery pipe, and an input end of the liquid pump is communicated with a foam cleaning agent storage vessel at the lower end of the liquid pump. The sewage treatment equipment is reasonable in structural design and convenient to use, and mixing, stirring, deodorizing and filtering of sewage and a foam cleaning agent are completed in one time, so that sewage treatment effects are improved; the first filter screen and the second filter screen can be brushed automatically to avoid blockage, and accordingly replacement frequency and maintenance cost of the first filter screen and the second filter screen are reduced.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

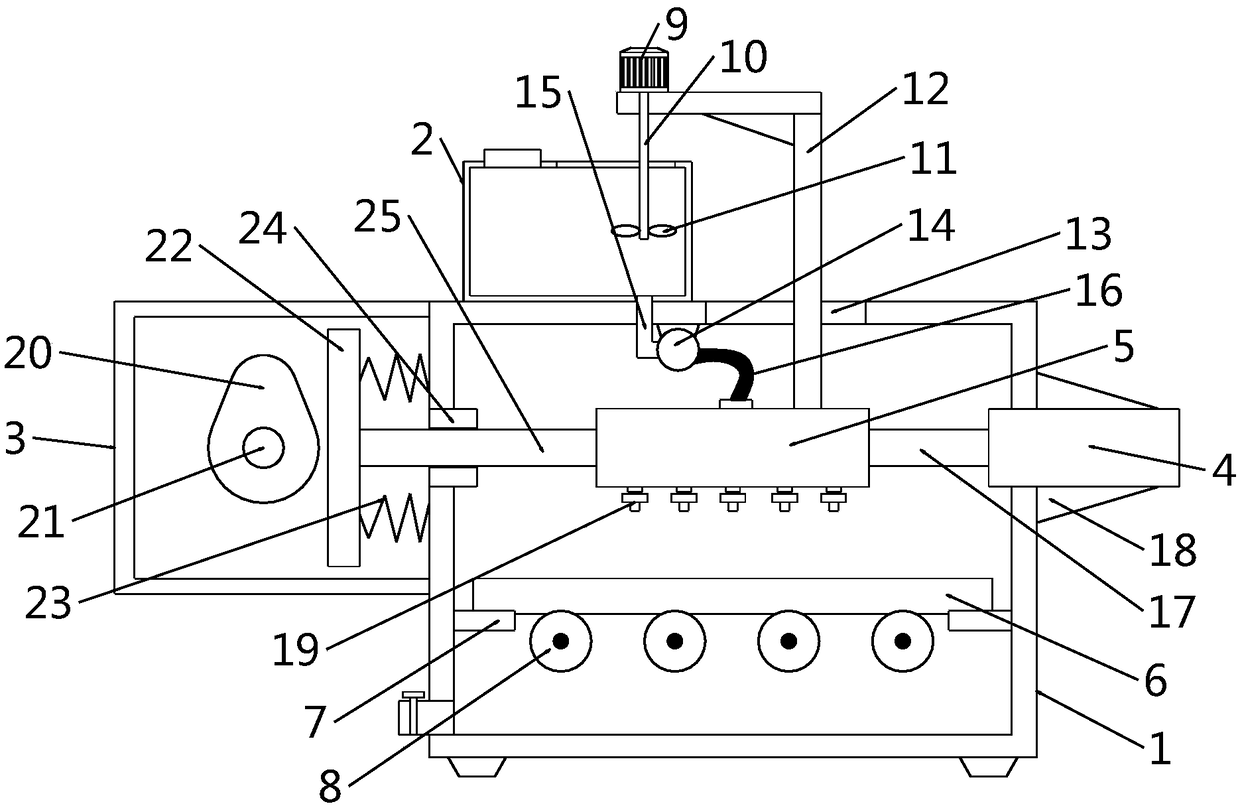

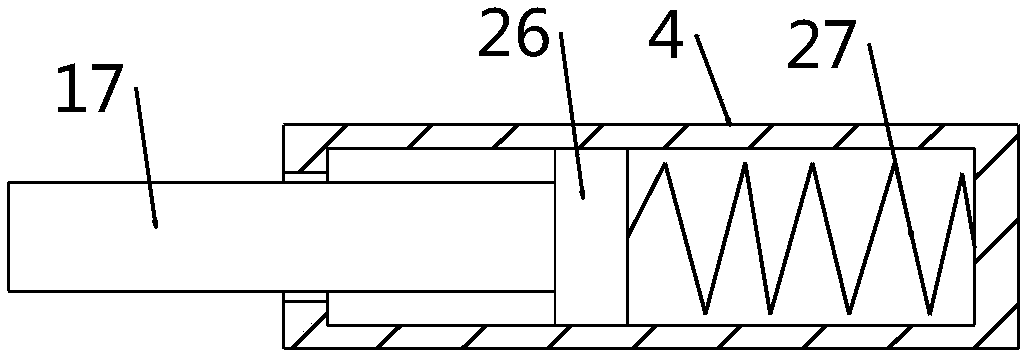

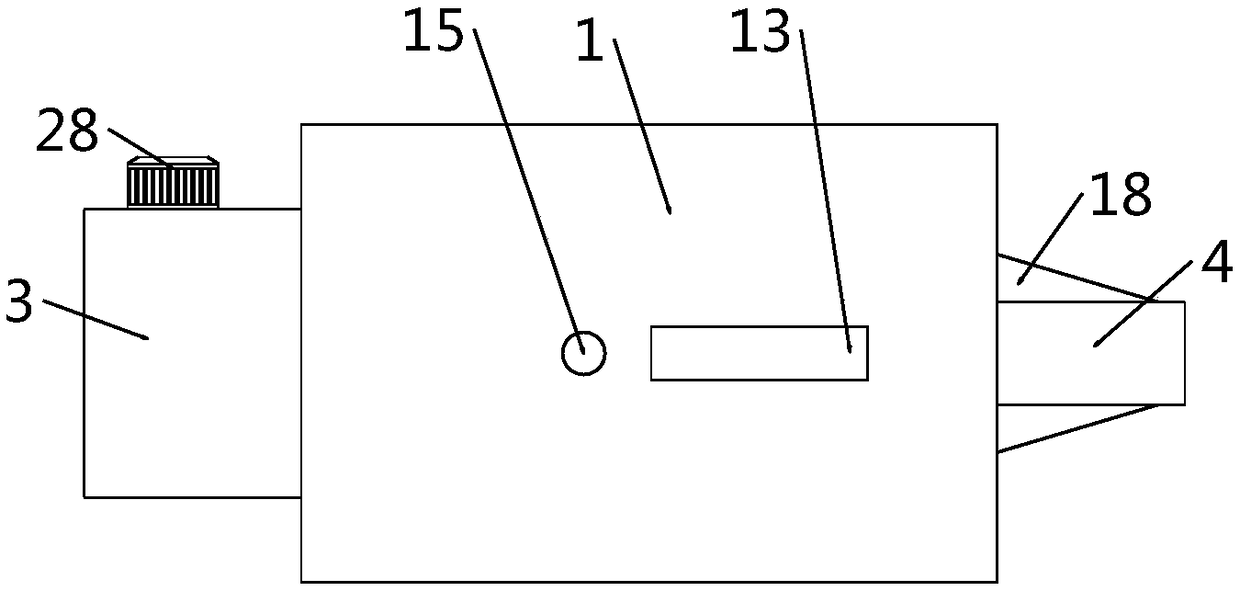

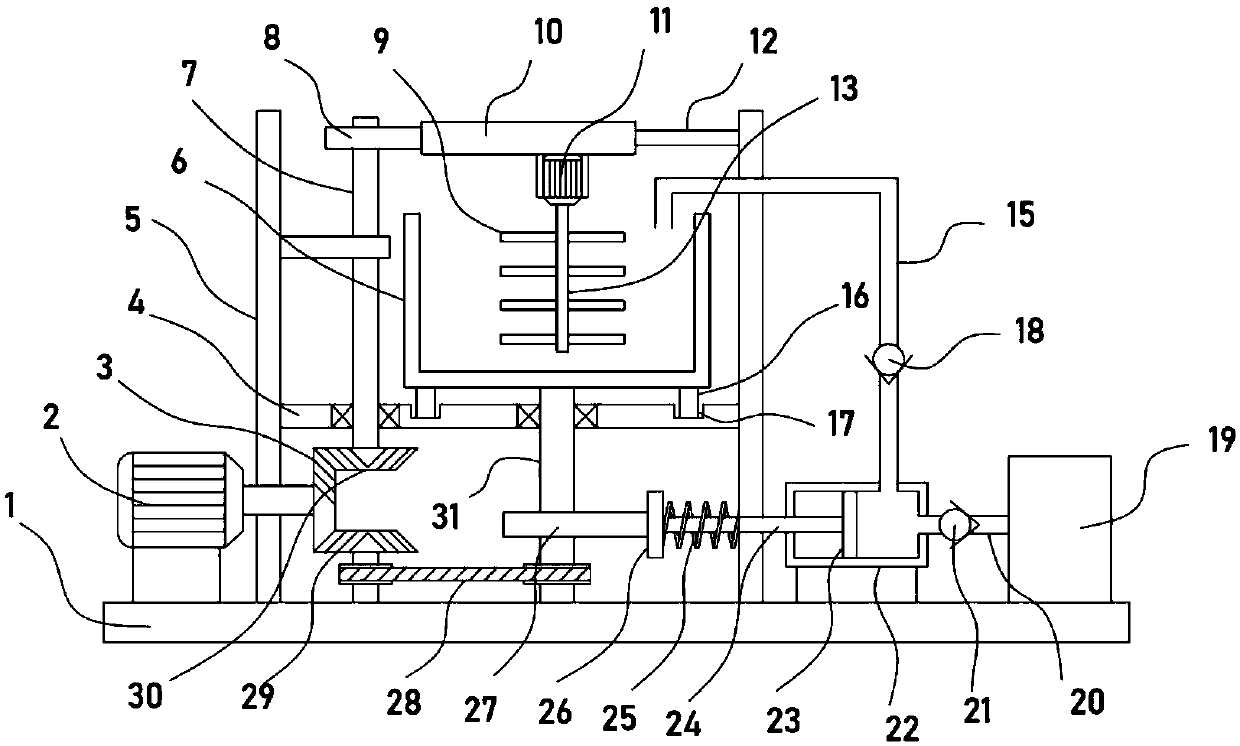

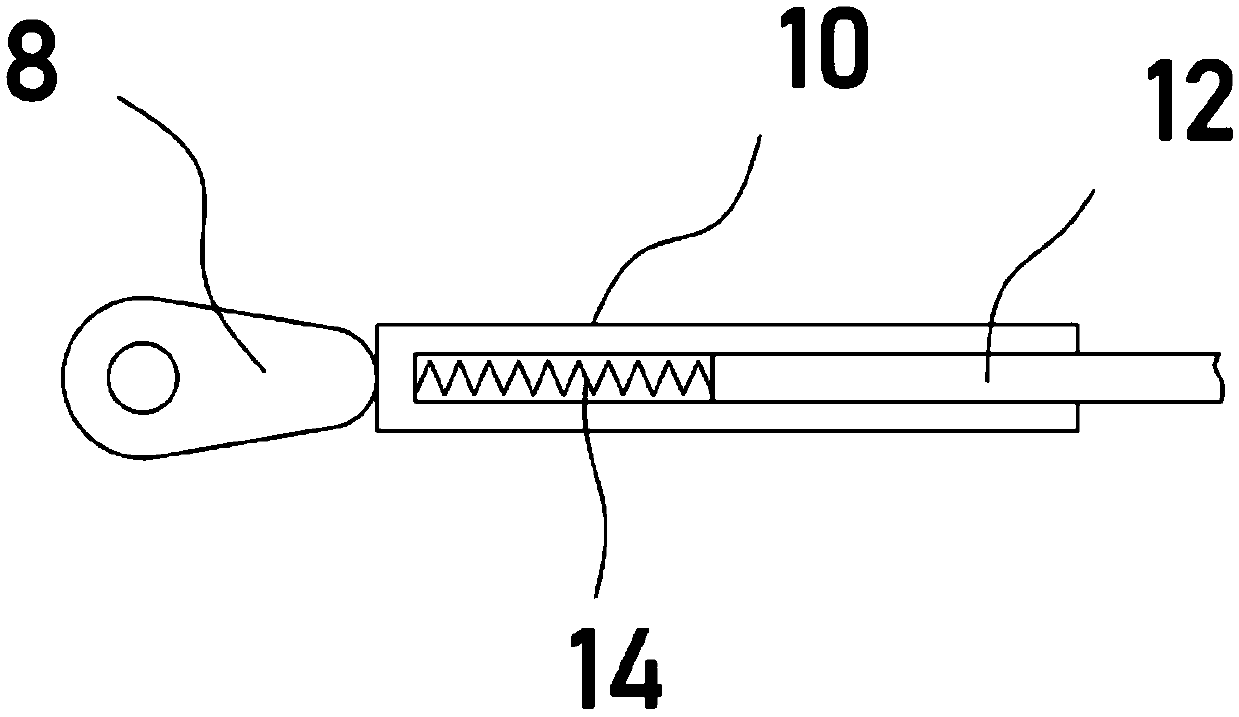

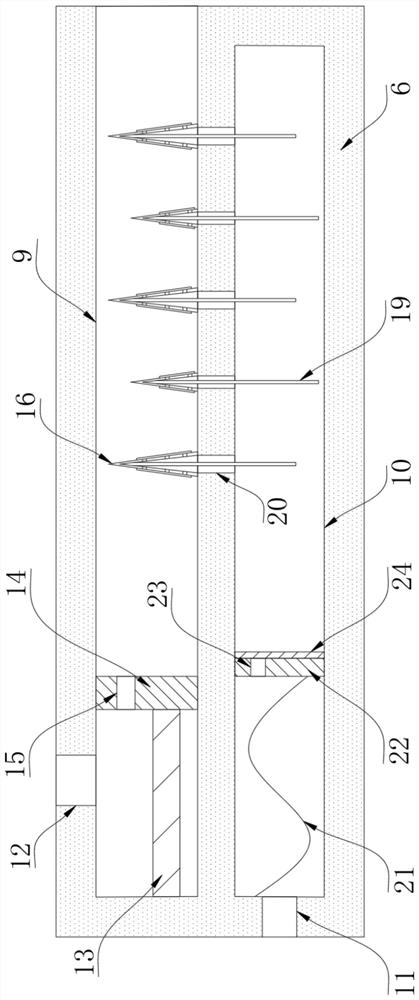

Cam driving based swinging type wooden board painting device for building engineering

ActiveCN108654890ASpray evenlyAvoid the phenomenon of spraying not in placeSpray boothsReciprocating motionElectric machinery

The invention discloses a cam driving based swinging type wooden board painting device for building engineering. The device comprises a painting box, a paint box, a driving box, a moving seat, stirring blades, a spraying head, a cam, a first spring and a left supporting cross rod. According to the device, the cam is driven to rotate through a driving motor, and the rotating cam continuously knockson a pressing plate, and the first spring supports to realize the horizontal reciprocating of the moving seat in the painting box, thus paint sprayed by the spraying head can be uniformly sprayed toa wooden board, and the problem that the paint is not sprayed in place can be avoided; when the moving seat horizontally moves, the rotating stirring blades can be driven to move in the paint box, thus the stirring and mixing effect of paint in the paint box can be effectively improved, and the paint is prevented from deposition, and as a result, the painting effect is ensured, and the device is suitable for popularization and use.

Owner:安徽家骎建设工程有限公司

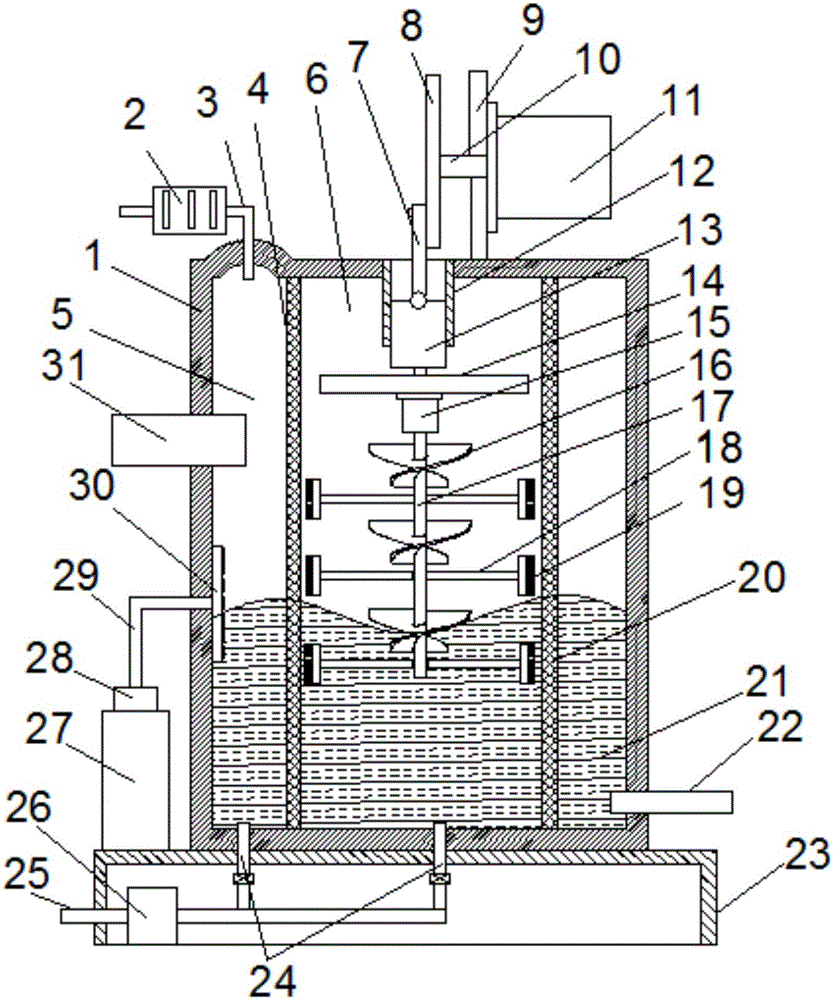

Integrated high-efficiency sewage treatment equipment

InactiveCN107010765AReasonable structural designEasy to useWater/sewage treatment with mechanical oscillationsDispersed particle separationEngineeringSewage treatment

The invention discloses integrated high-efficiency sewage treatment equipment which comprises a box body, wherein the interior of the box body is sequentially partitioned into a water inlet chamber, a mixing chamber and a water purification chamber from the left to the right by virtue of a first filtering net and a second filtering net; the first filtering net is positioned on the left side of the second filtering net; the upper end of the water inlet chamber communicates with a biological deodorization device through an exhaust pipe; a sewage inlet pipe communicating with the water inlet chamber is arranged at the upper end on the left side of the water inlet chamber; a sprayer is arranged in the water inlet chamber in the lower end of the sewage inlet pipe; the sprayer communicates with the output end of a liquid pump outside the left side of the box body through a conveying pipe; and the input end of the liquid pump communicates with a foam cleaning agent storage tank at the lower end of the liquid pump. The integrated high-efficiency sewage treatment equipment disclosed by the invention is reasonable in structural design and is capable of completing the operations of mixing sewage and foam cleaning agents, stirring, deodorizing, filtering, performing air-flotation treatment, removing residues and scraping mud at a time, the sewage treatment effect is improved, the first filtering net and the second filtering net can be automatically cleaned, blockage is avoided, and the replacement frequency and the maintenance costs of the first filtering net and the second filtering net can be reduced.

Owner:合肥图腾龙企业管理事务所(有限合伙)

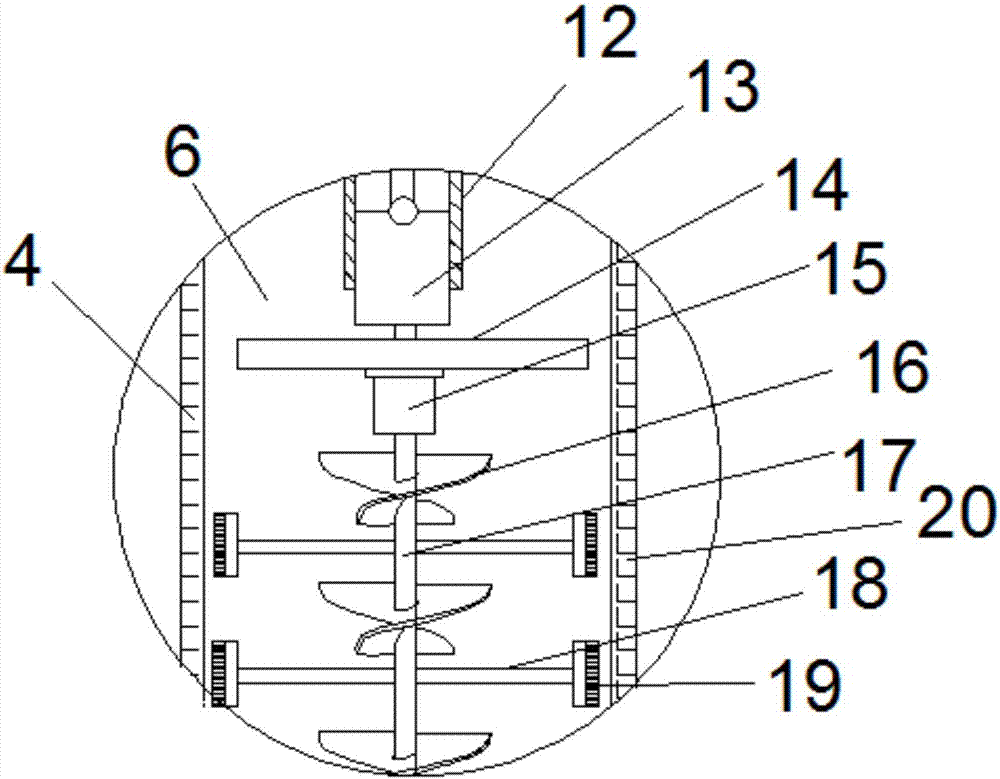

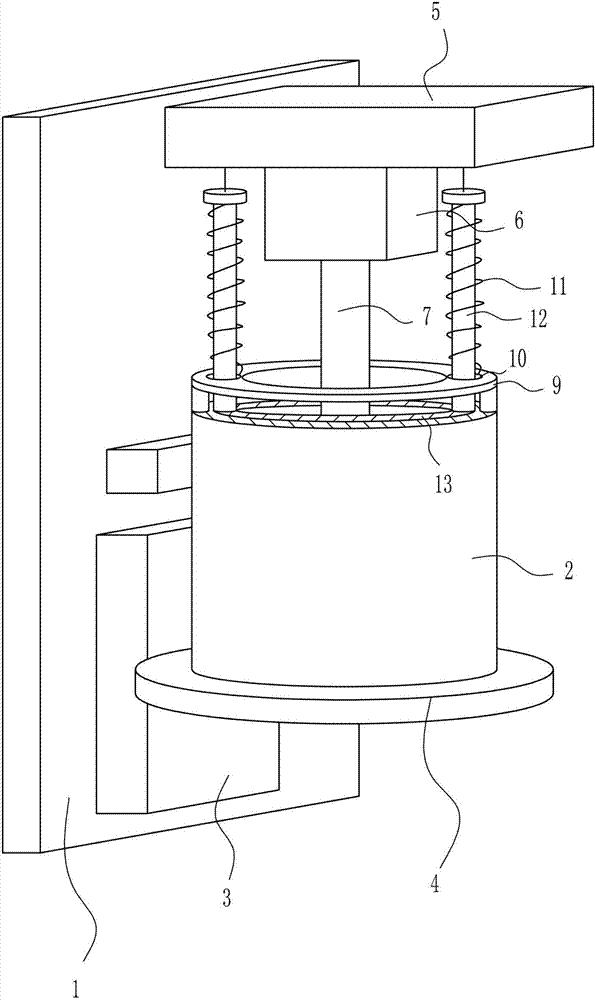

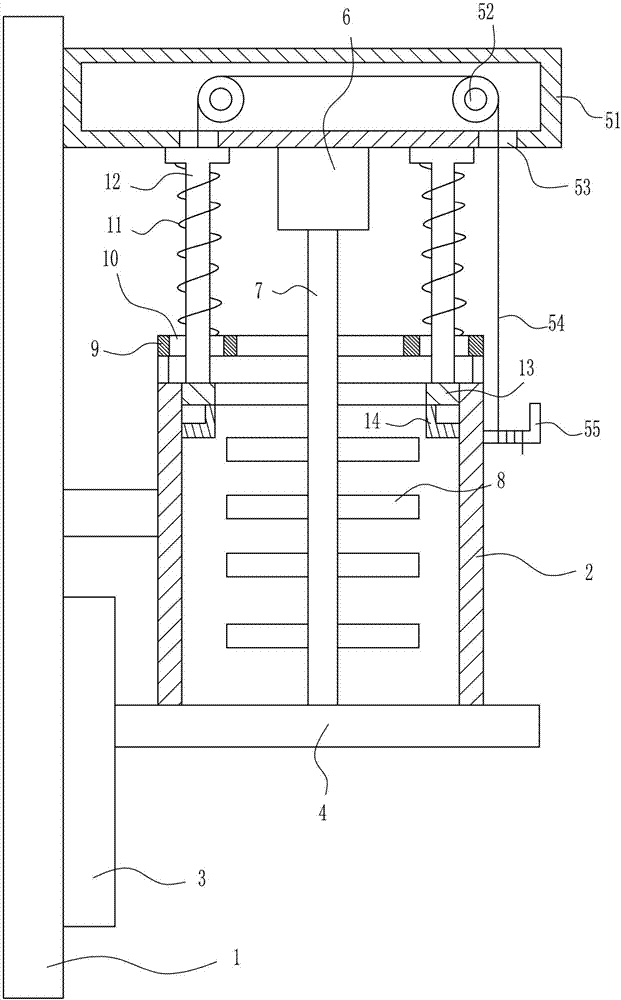

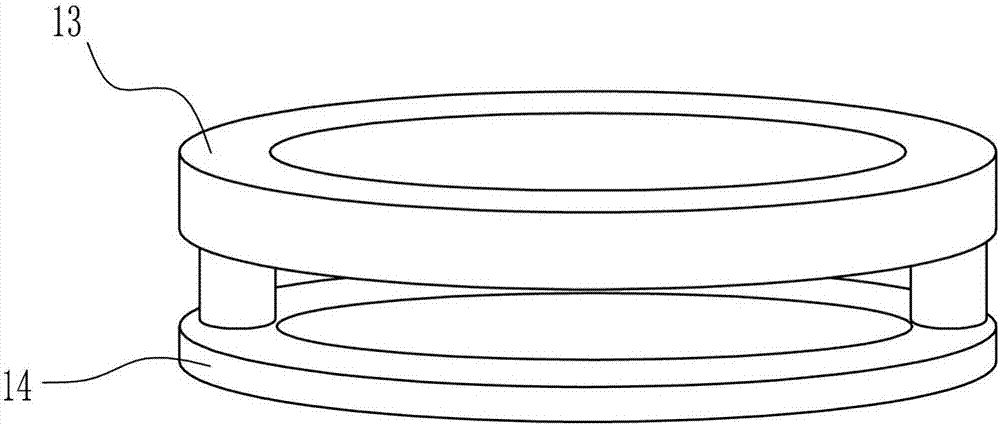

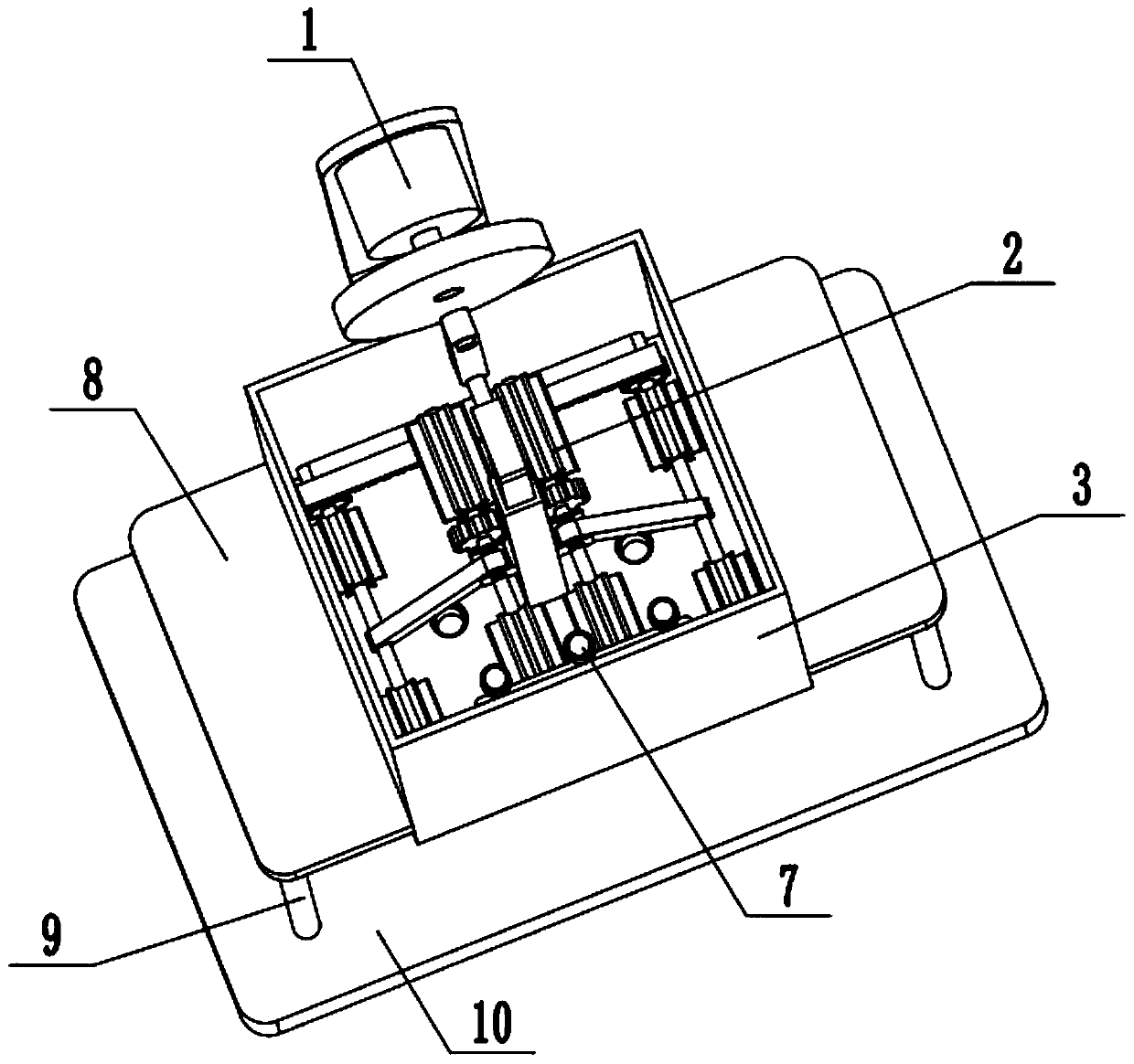

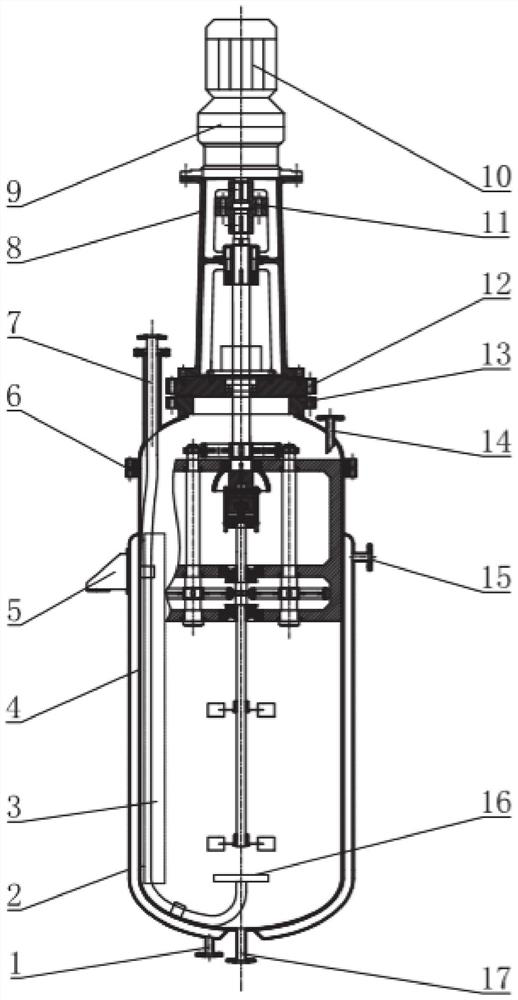

Stirring device

ActiveCN108310995AAvoid cloggingAvoid mixingShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringElectromagnet

The invention belongs to the technical field of stirring equipment and in particular discloses a stirring device. The stirring device comprises a stirring barrel and a charging basket, wherein a motoris arranged on the stirring barrel; a rotating shaft is connected onto an output shaft of the motor; the lower end of the rotating shaft is rotationally connected into the charging basket; two feeding holes are formed in top walls of the stirring barrel; two grinding roller groups are arranged in the stirring barrel; a spring is arranged on the rotating shaft in a sleeving manner; the upper end of the spring is fixed on the top wall of the stirring barrel; a screen is arranged at the lower end of the spring and connected onto the inner wall of the stirring barrel in a sliding manner; a chuteis formed in a side wall of the rotating shaft; two upper and lower layers of stirring paddles are connected onto the chute in a sliding manner; a first electromagnet, a second electromagnet and a third electromagnet are sequentially arranged at the top end, in the middle and at the lower end of the chute; permanent magnets are arranged on the screen and the two groups of stirring paddles; the left and right sides of the screen are downwards inclined; circulating orifices are formed in side walls on two sides of the stirring barrel; screw feed mechanisms are arranged outside the circulating orifices; orifices in the upper ends of the two screw feed mechanisms are respectively communicated with the two feeding holes.

Owner:青岛泰富科技有限公司

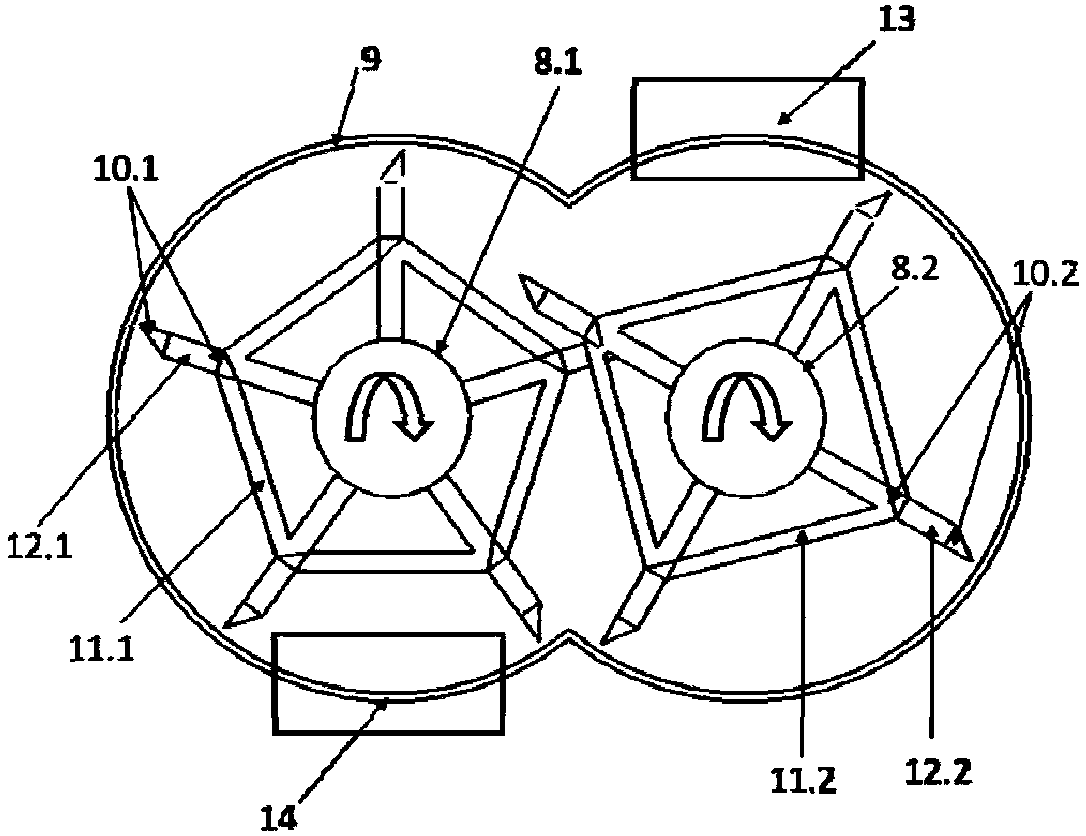

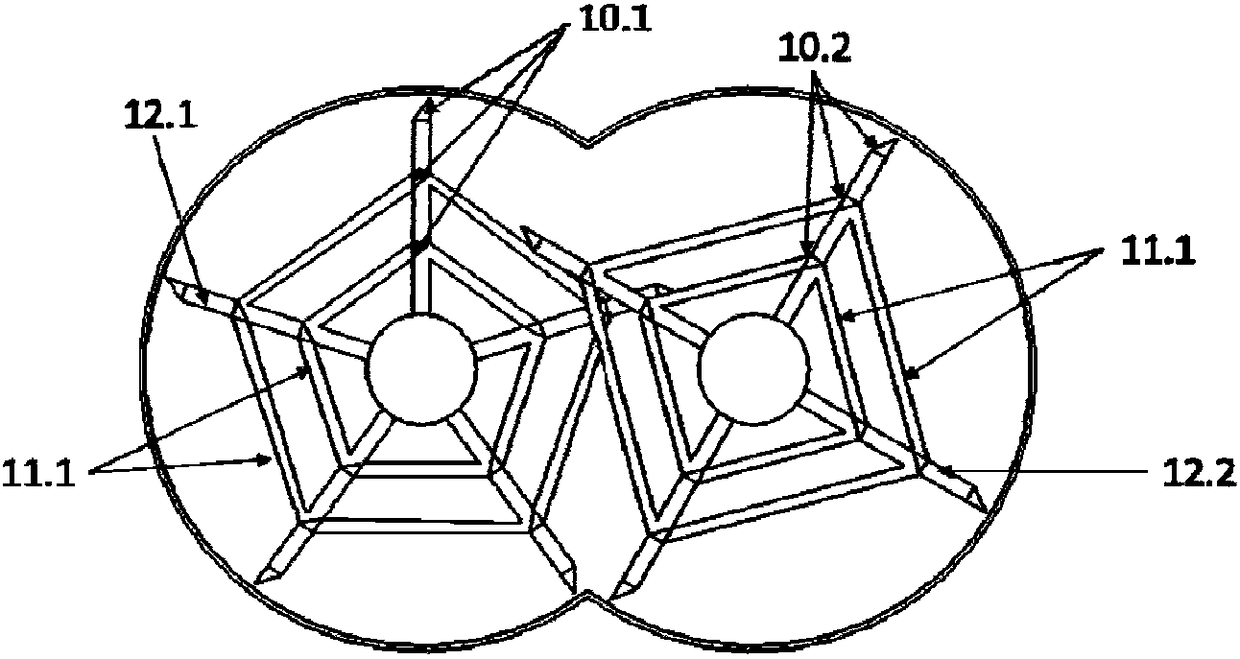

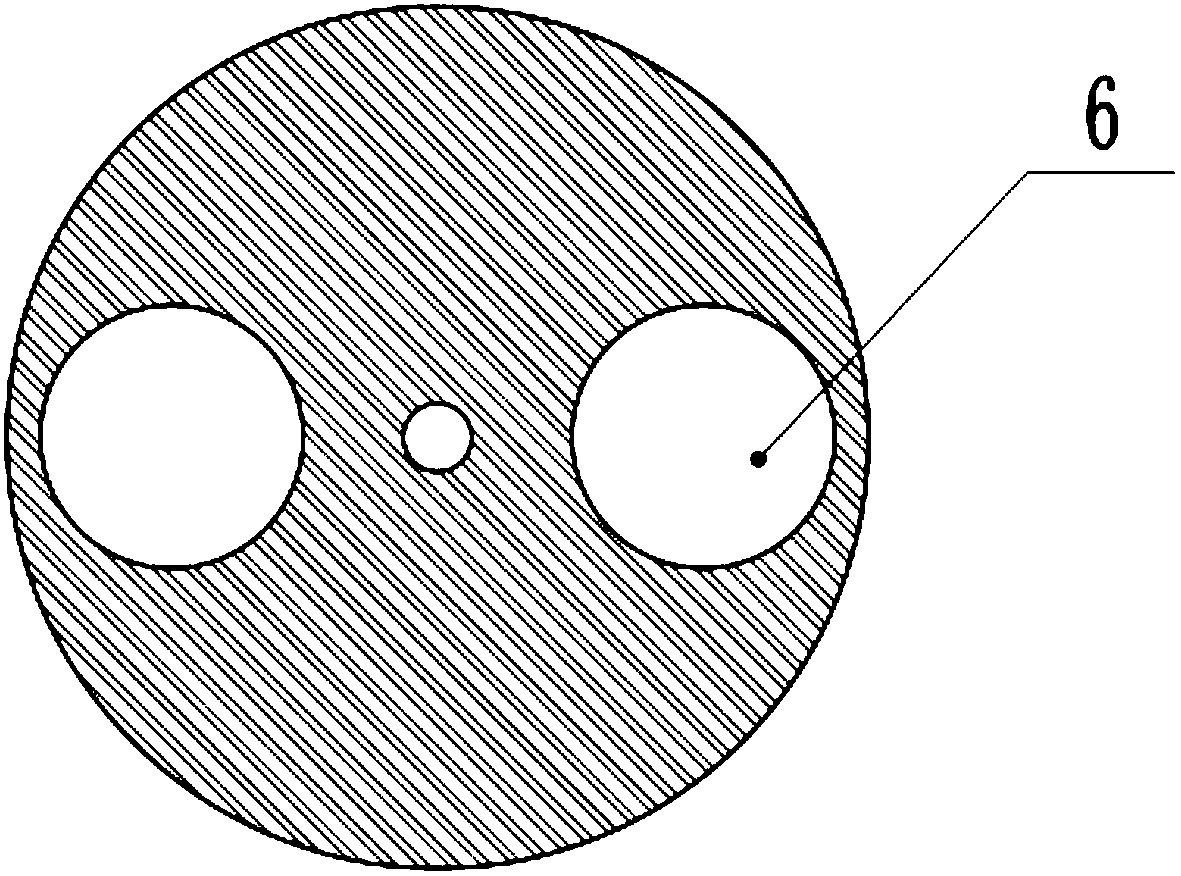

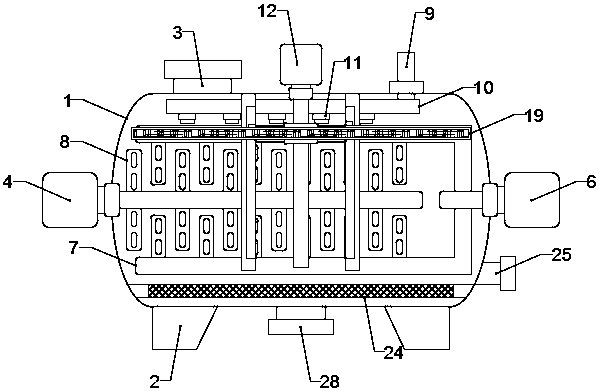

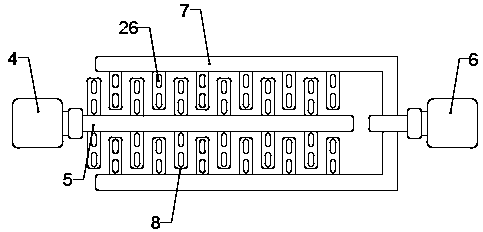

Stirring device and horizontal double-shaft self-cleaning reactor

ActiveCN108236910AImprove clippingStrong shearRotary stirring mixersTransportation and packagingEngineeringViscosity

The invention relates to a stirring device which comprises two rotating shafts, wherein a plurality of same stirring discs are axially fixed to the rotating shaft; each stirring disc is composed of aplurality of same radially arranged stirring rods and a fixed rod connected to two adjacent stirring rods; each stirring rod comprises supporting rods arranged radially and two or more stirring bladesarranged on the supporting rods vertically, wherein one of the stirring blades is located at the tail end of the supporting rod, and the stirring discs on the two rotating shafts are arranged in a staggered manner. The invention also provides a horizontal double-shaft self-cleaning reactor based on the stirring device. Compared with a conventional horizontal double-shaft reactor, the horizontal double-shaft self-cleaning reactor is simple in structure, has a bigger reaction space, materials are sheared and stretched in a kettle body, so that the reactor is suitable for fluids with different viscosities; the standing time is controllable; compared with the conventional horizontal double-shaft reactor, full reaction regions in the kettle body scratch one another, so that the self-cleaning effect is good. The reaction energy consumption is low, and the mixing efficiency is high.

Owner:ZHEJIANG UNIV

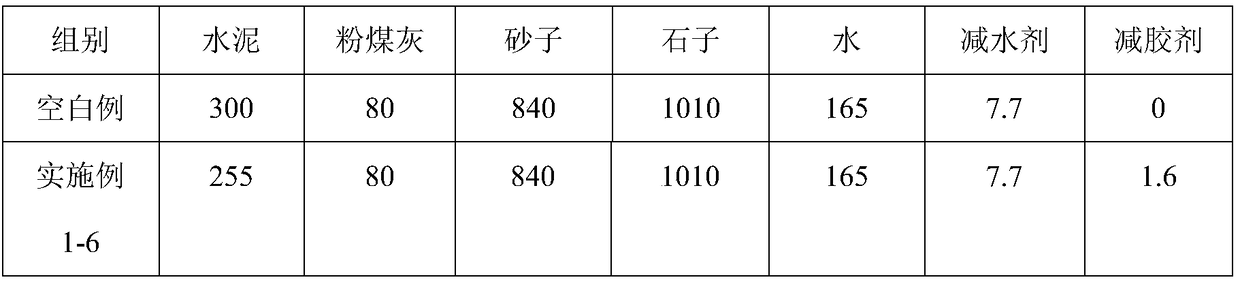

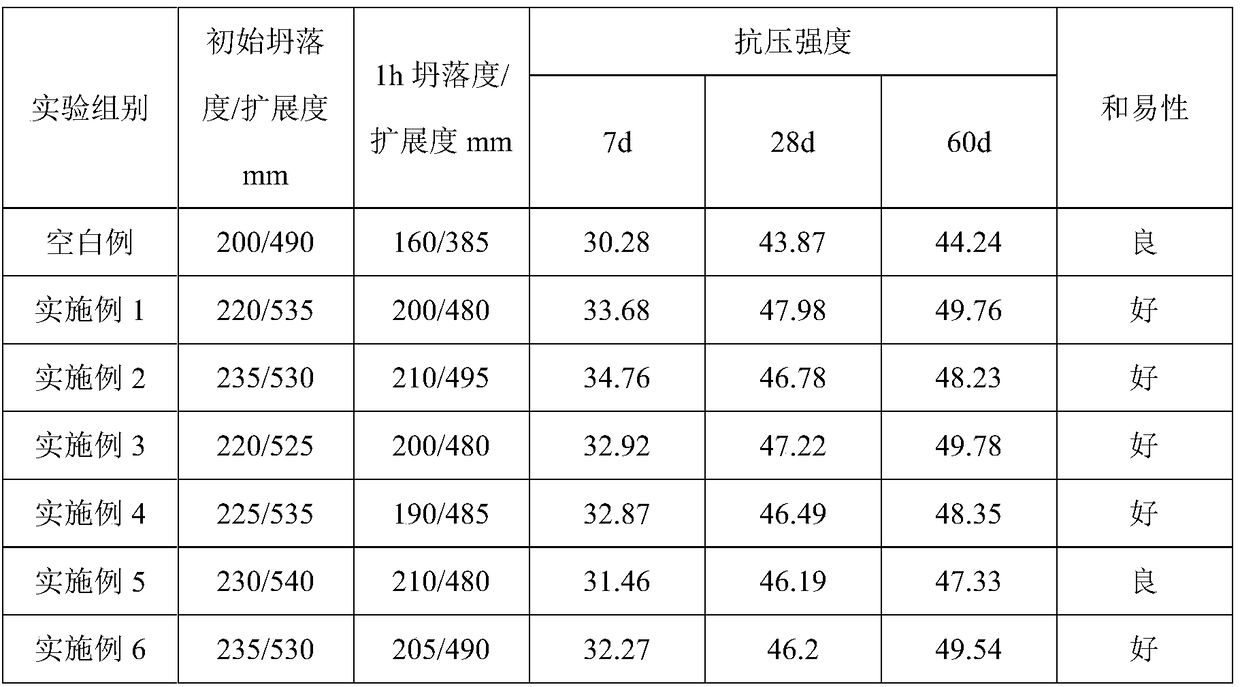

Method for preparing glue reduction agent by amphiprotic polyester polycarboxylic acid compound

The invention provides a method for preparing a glue reduction agent by an amphiprotic polyester polycarboxylic acid compound. The glue reduction agent is prepared from, by weight, 35-45 parts of amphiprotic polyester polycarboxylic acid compounds, 4-10 parts of alcohol and amine compounds, 0.5-4 parts of polyhydric alcohol, 0.1-0.5 part of organic silane lubricating agents, 0.02-0.08 part of emulsification dispersing agents, 0.01-0.1 part of isothiocyanate compounds and the rest water, and the total weight is 100 parts. The components are placed into a reaction kettle and sufficiently stirredfor 0.5 hour to obtain the glue reduction agent prepared from the amphiprotic polyester polycarboxylic acid compound. Methoxy polyethylene glycol monomethyl ether with the molecular weight of 600 isesterified, and positive ion micro-monomers serve as raw materials, reasonable dosage of a chain transfer agent is implemented, so that a molecular configuration with a short main chain and a side chain is acquired, a certain good steric hindrance effect is achieved, the high-density side chain adsorbs water by capillary effects, hydration reaction is delayed, a compact water film is formed on thesurface, and dispersibility and workability of concrete are improved.

Owner:HUBEI UNIV OF TECH

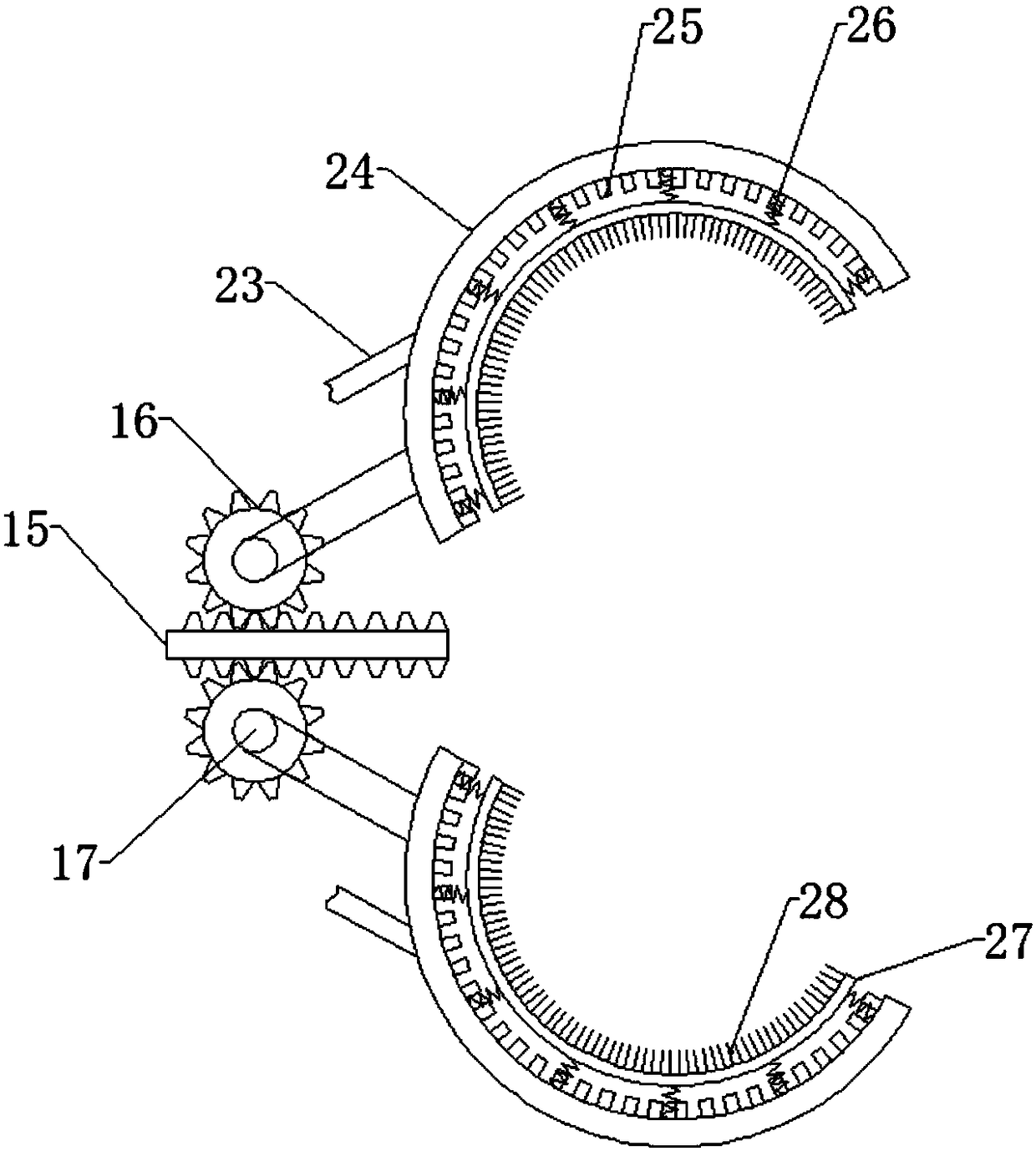

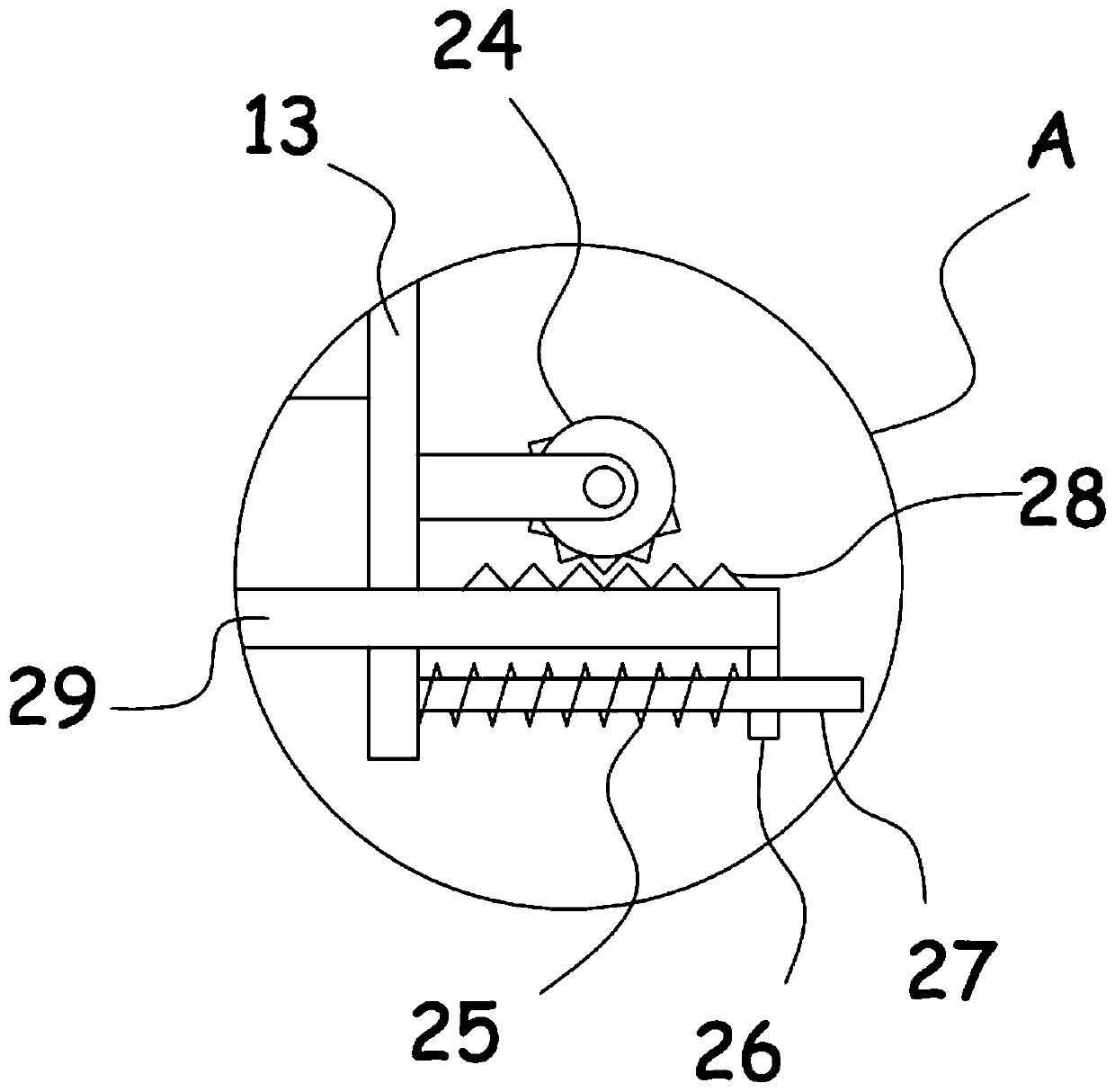

Two-face rack type trunk whitewashing device for municipal engineering

InactiveCN108160390AFast Surrounding PositioningRapid positioningLiquid surface applicatorsCoatingsArchitectural engineeringMixing effect

The invention discloses a two-face rack type trunk whitewashing device for municipal engineering. The device comprises a bottom plate, an L-shaped installation plate, a first motor, a thread rod, a sleeve, a fixing plate, an electric push rod, a two-face rack, a gear, a rotating shaft, a semi-circular whitewashing device, a lime water box, a booster pump, a second motor, a stirring shaft, a stirring rod and a through hole. The semi-circular whitewashing device comprises a semi-circular shell, a semi-circular installation plate, a brush and a nozzle. The device is provided with the electric push rod, the two-face rack, the gear and the semi-circular whitewashing device, surrounding positioning can be rapidly achieved through the cooperation of the components, operation is convenient, and time and labor are saved. The second motor, the stirring shaft, the stirring rod and the through hole are arranged, lime water is stirred, and the problem that whitewashing is insufficient and uneven due to lime water precipitation is avoided. In the stirring rod rotating process, lime water moves from a large opening to a small hole of the through hole, accordingly, the pressure intensity is increased after the lime water passes through the through hole, the lime water is sprayed out from the small hole, impact is produced, and the stirring mixing effect is further improved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

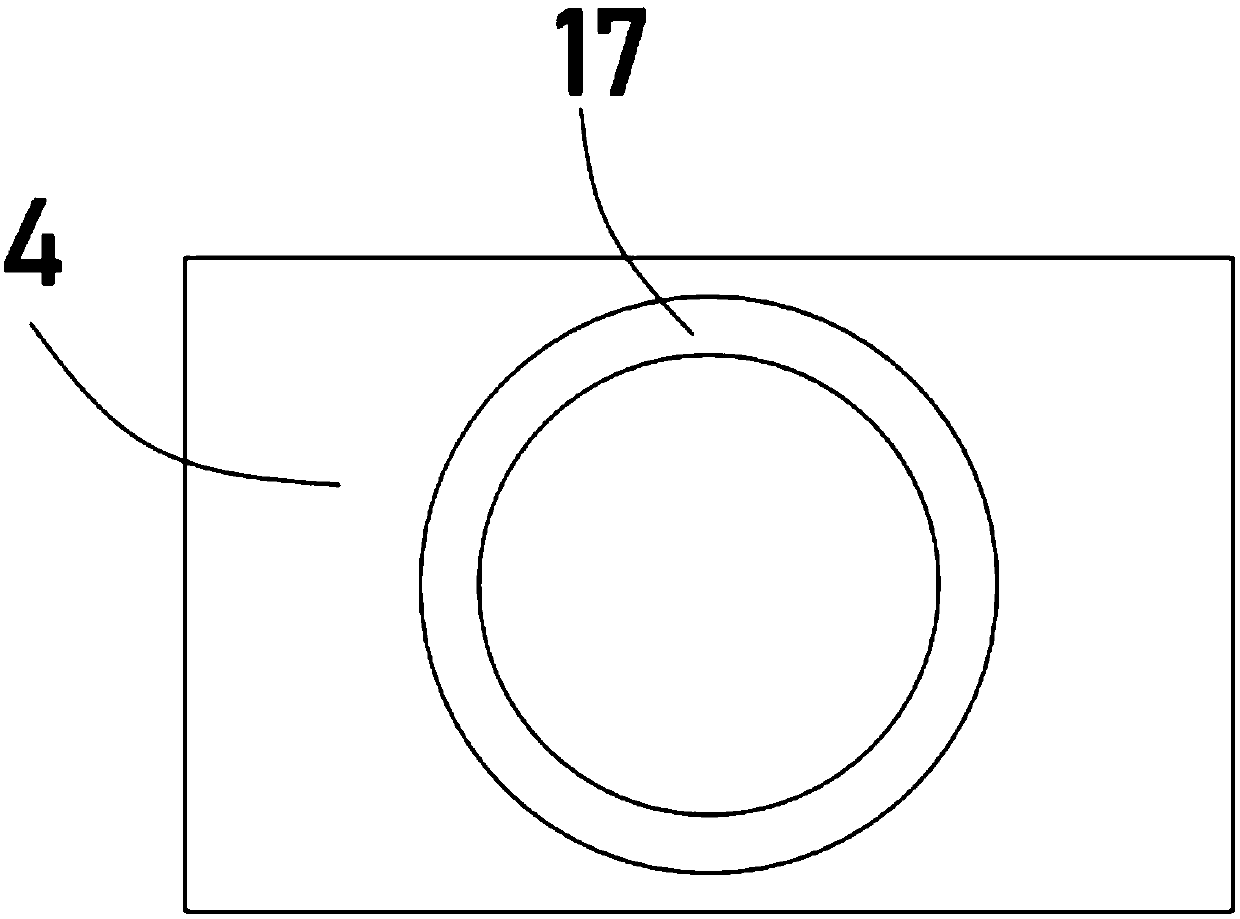

Raw material mixing device for manufacturing steel backing of disc type brake pad

InactiveCN106943920AEasy to cleanNo residueTransportation and packagingRotary stirring mixersMixing tankBrake pad

The invention relates to a raw material mixing device and particularly relates to a raw material mixing device for manufacturing a steel backing of a disc type brake pad. According to the raw material mixing device, raw material residue can be avoided, and the raw material mixing device is easy to take and use. The raw material mixing device for manufacturing the steel backing of the disc type brake pad comprises a support plate, a mixing tank, a rotating mechanism, a baffle, a lifting mechanism, a first motor, a first rotating rod, a stirring rod, an annular guide plate, a first spring, a lifting rod and the like, wherein the mixing tank is connected to the middle of the right wall of the support plate, the rotating mechanism is connected to the lower part of the right wall of the support plate, and the baffle is connected to the upper part of the right side of the rotating mechanism. According to the raw material mixing device, the first motor is firstly designed so as to drive a first rotating rod to rotate clockwise, and then the first rotating rod drives the stirring rod to rotate clockwise so as to stir and mix.

Owner:来安县华鹏摩擦材料厂

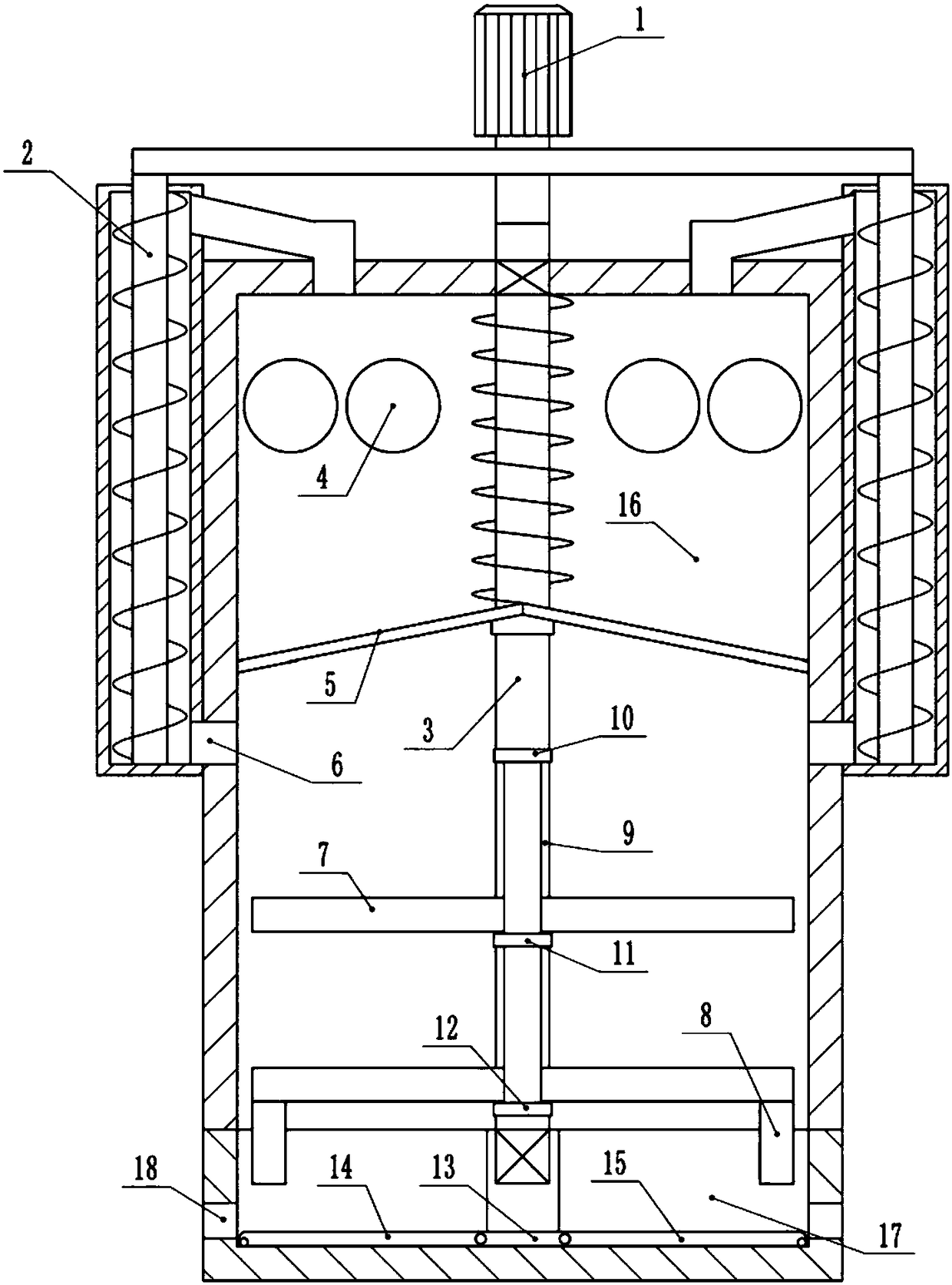

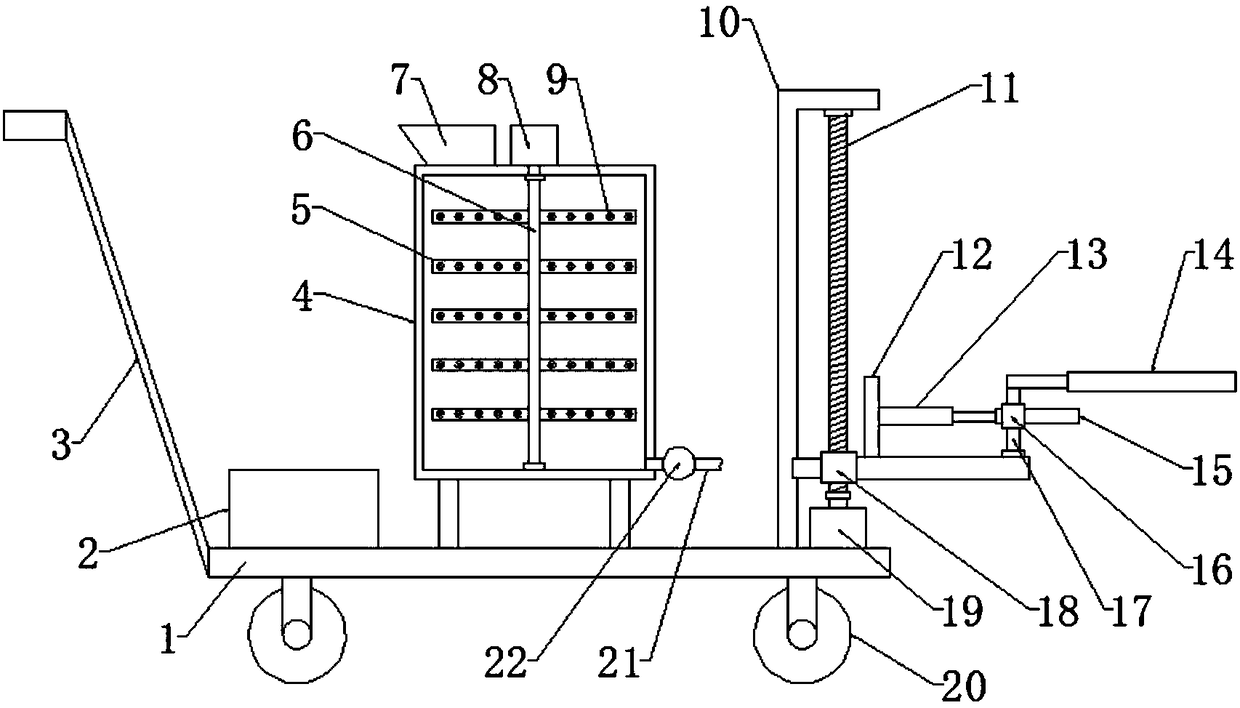

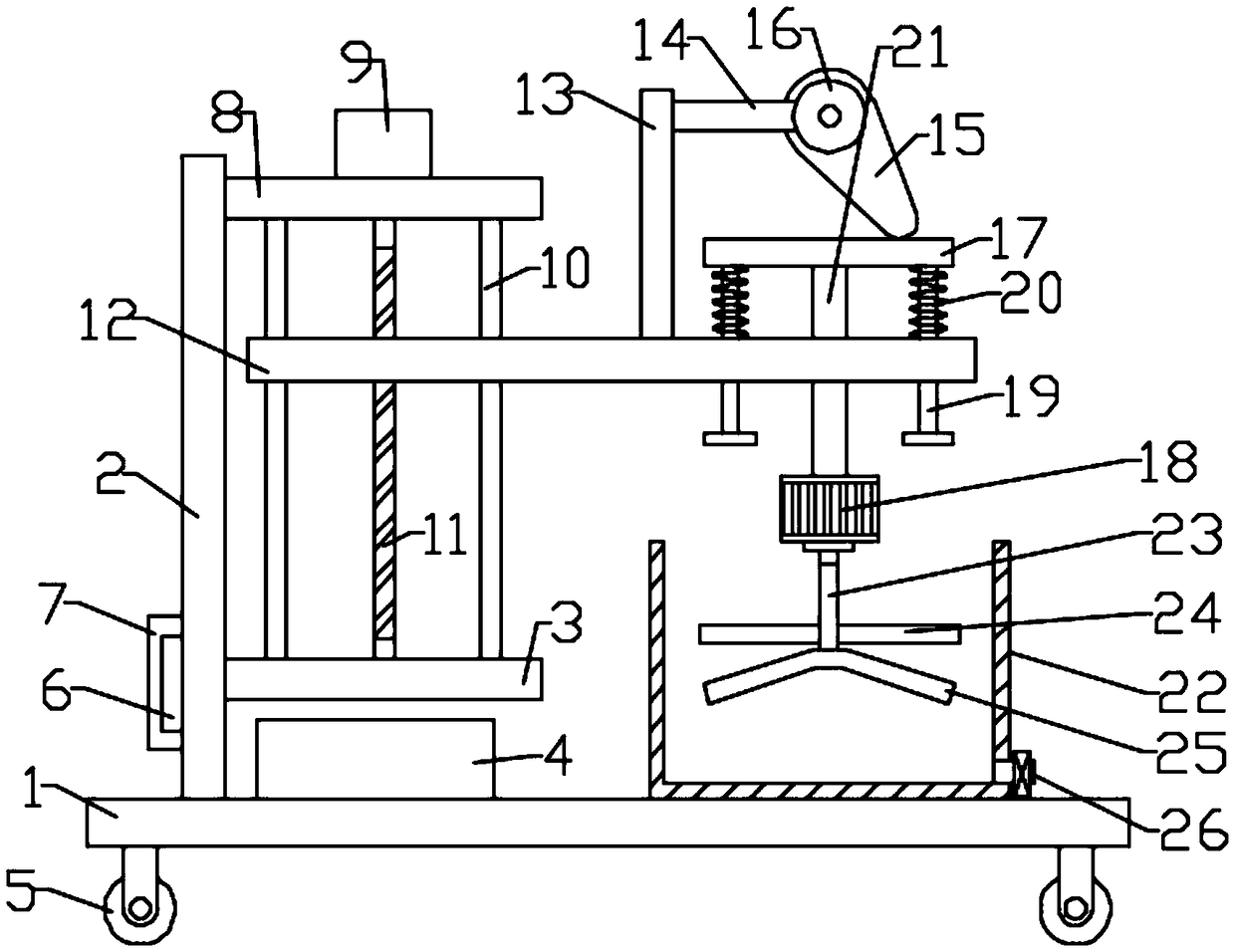

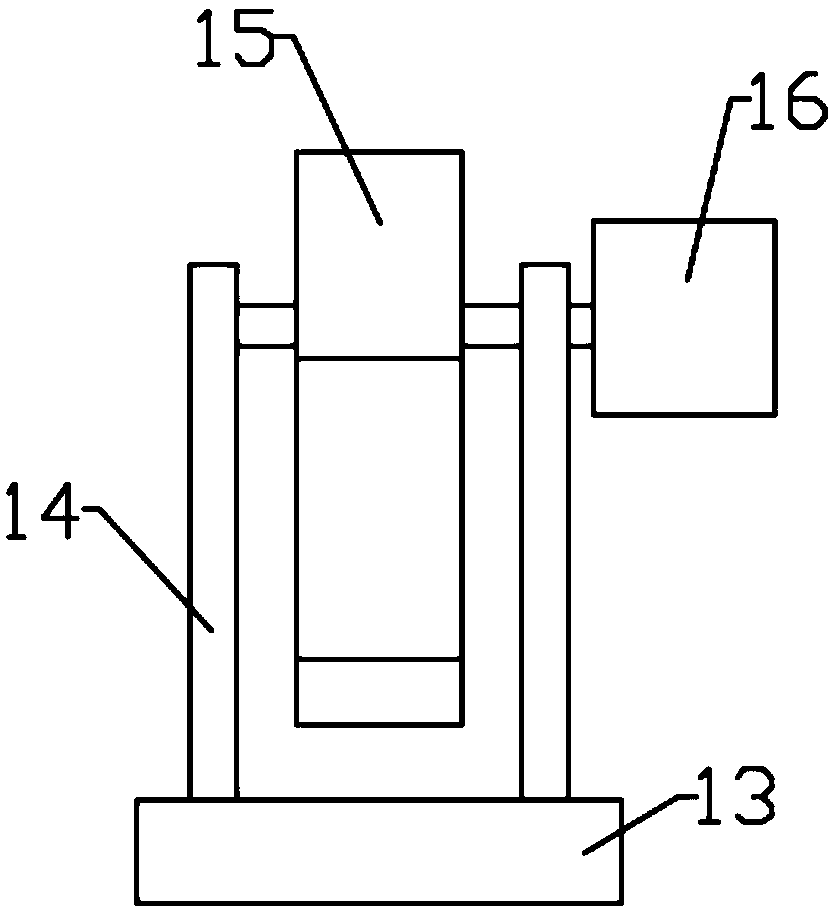

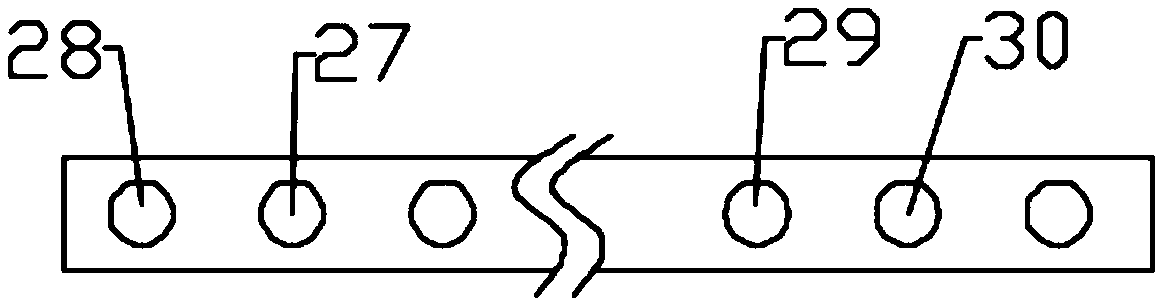

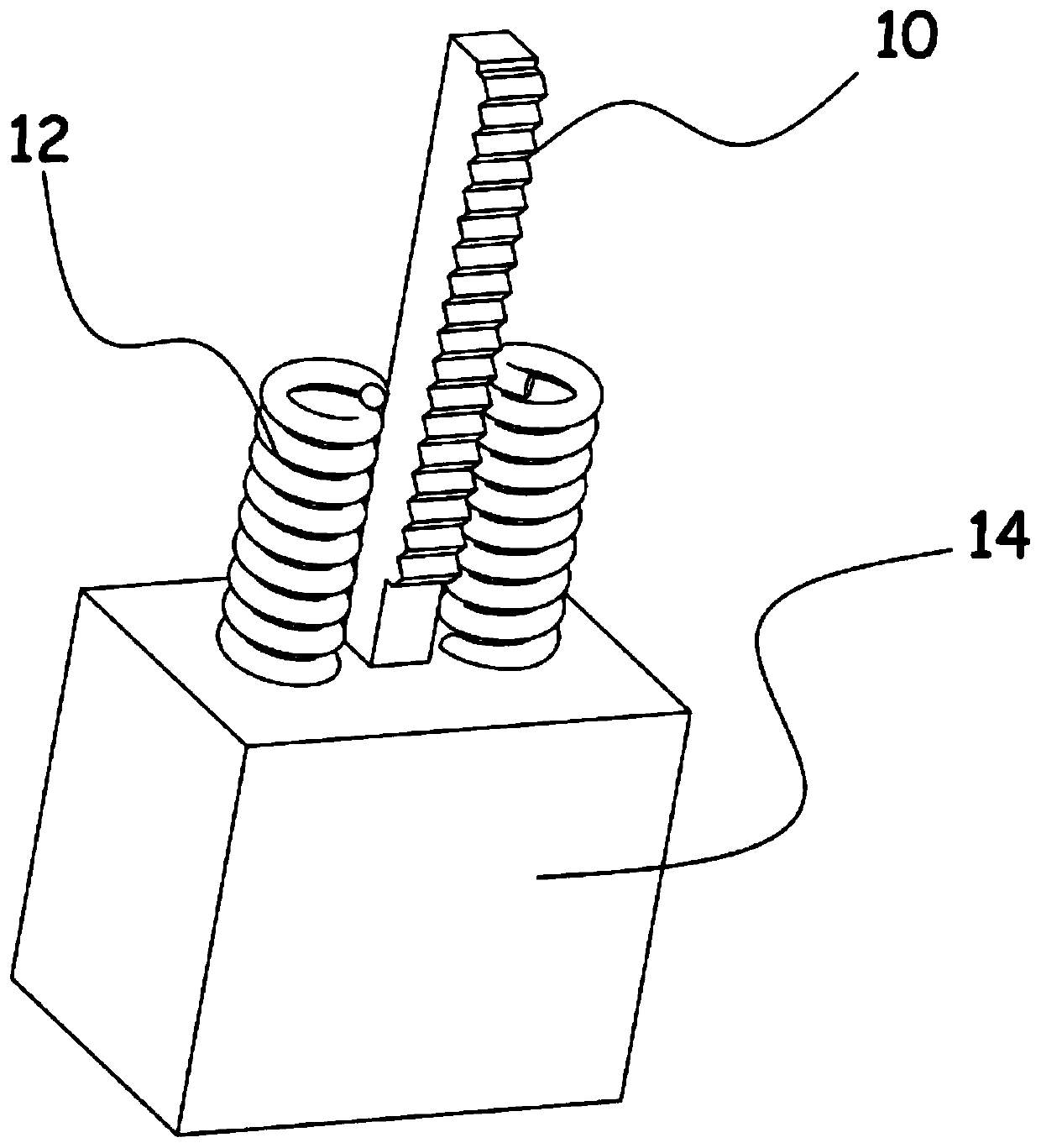

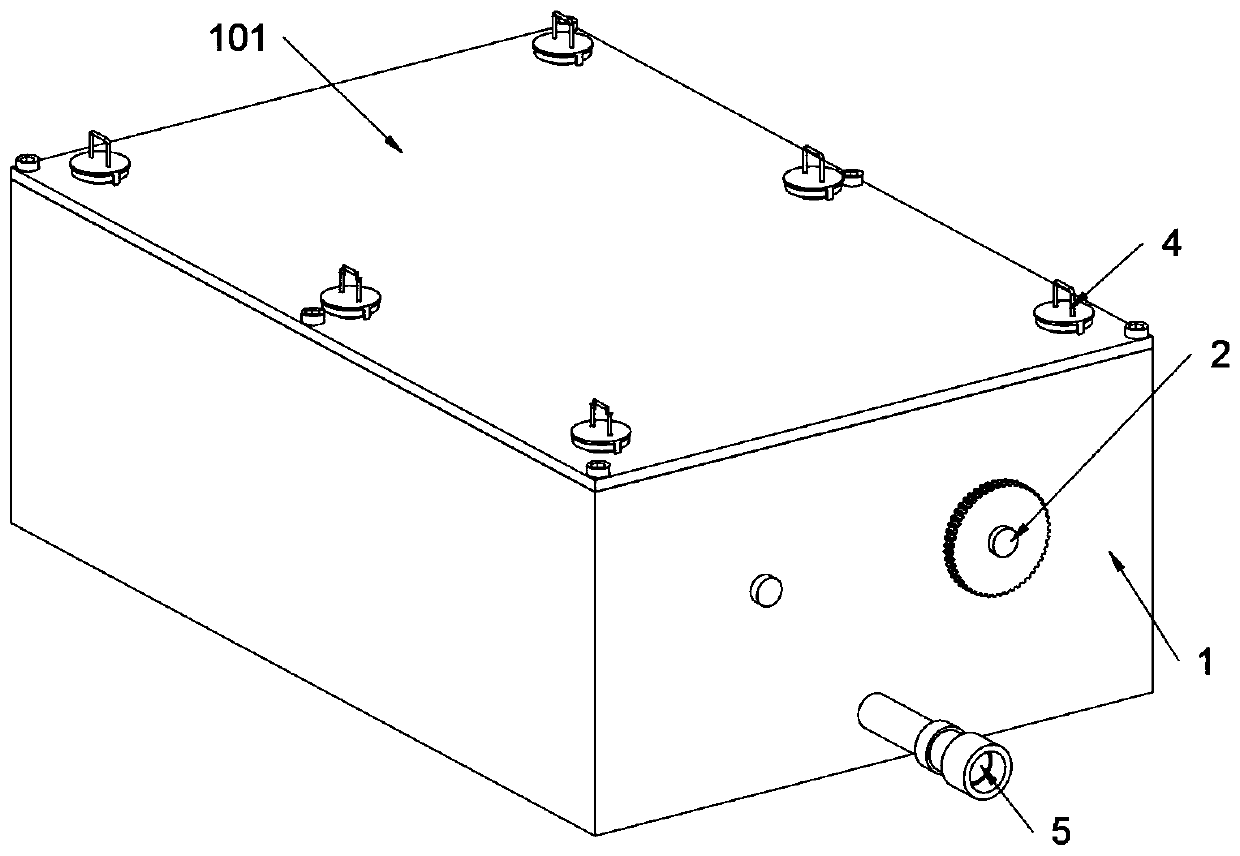

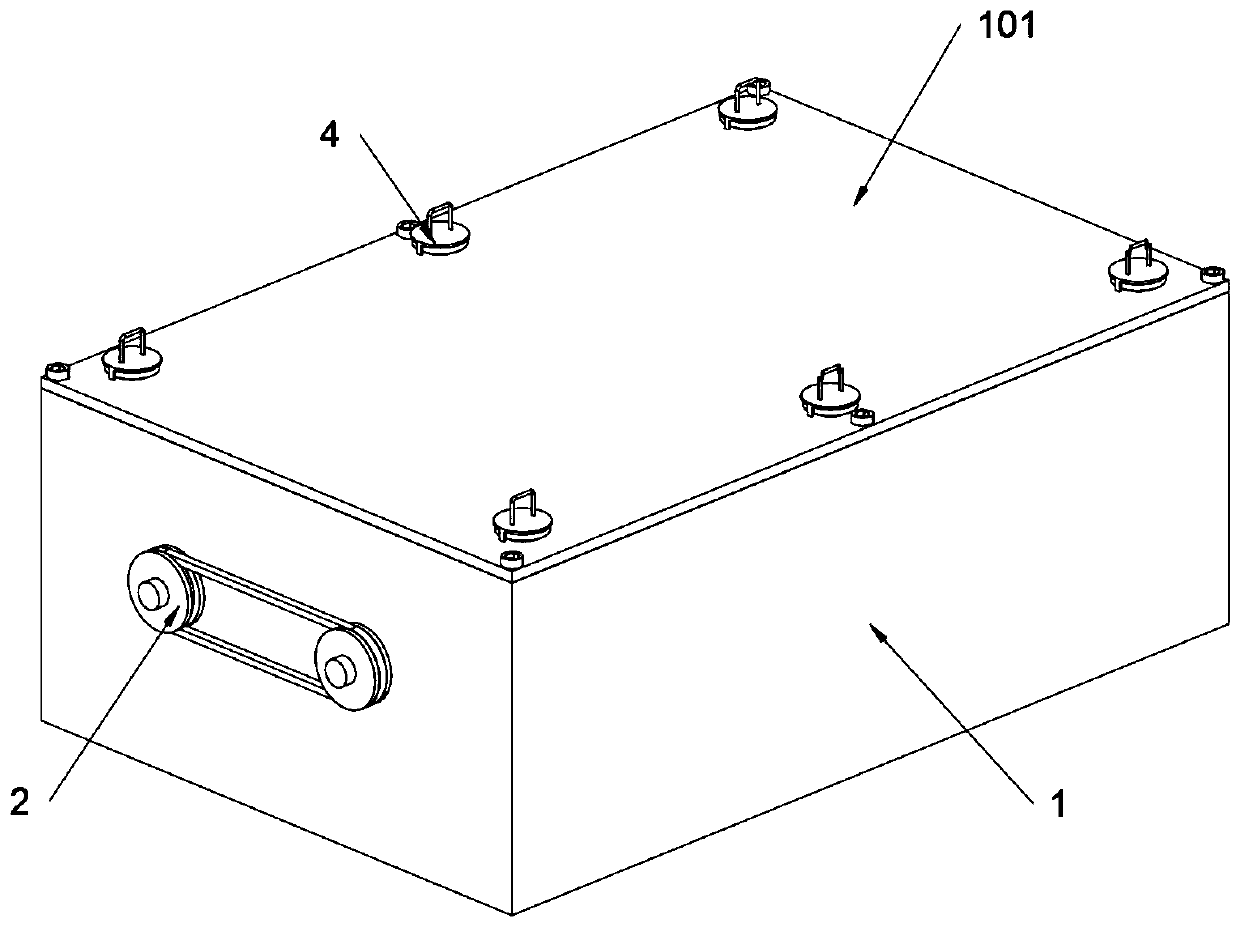

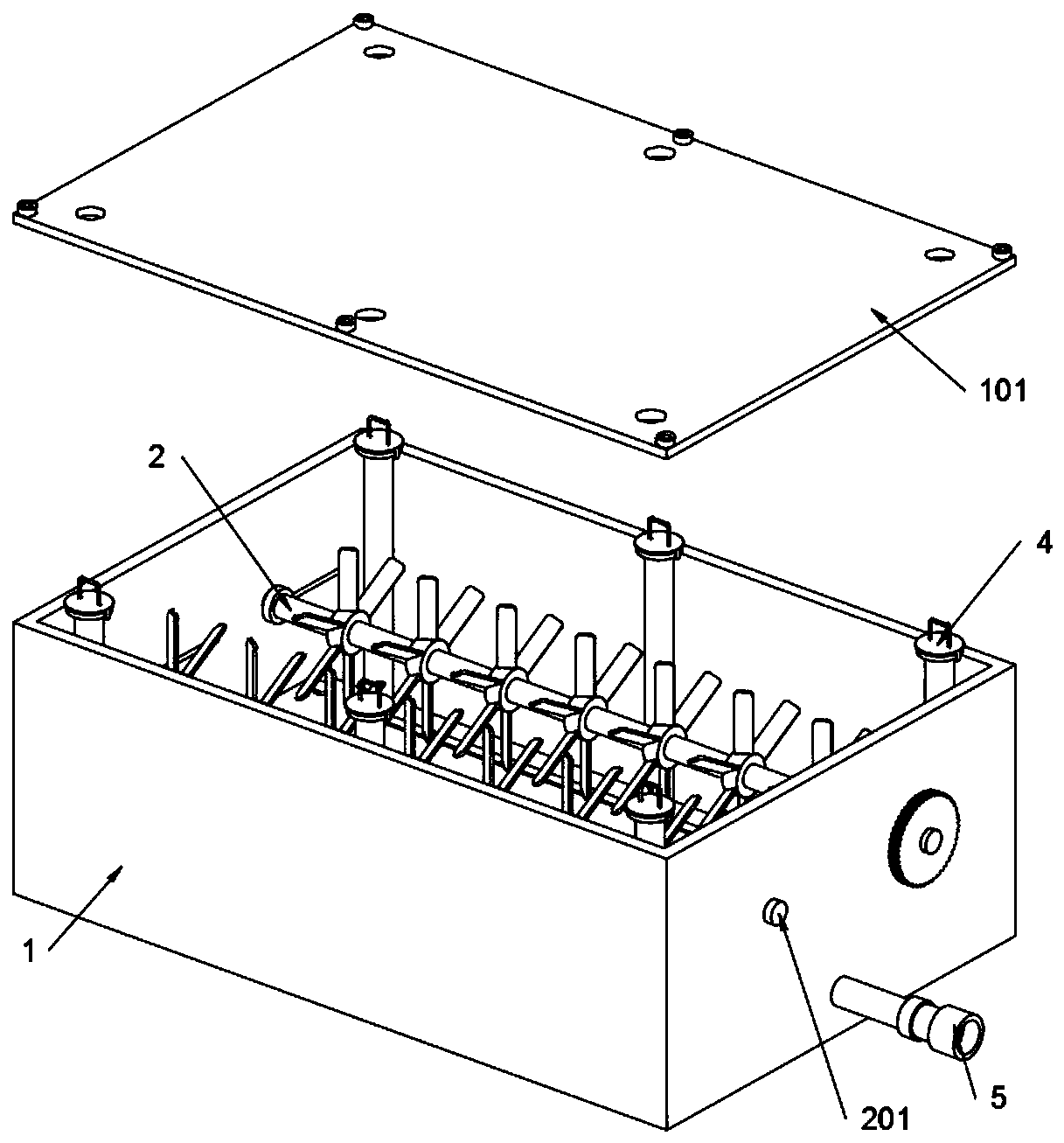

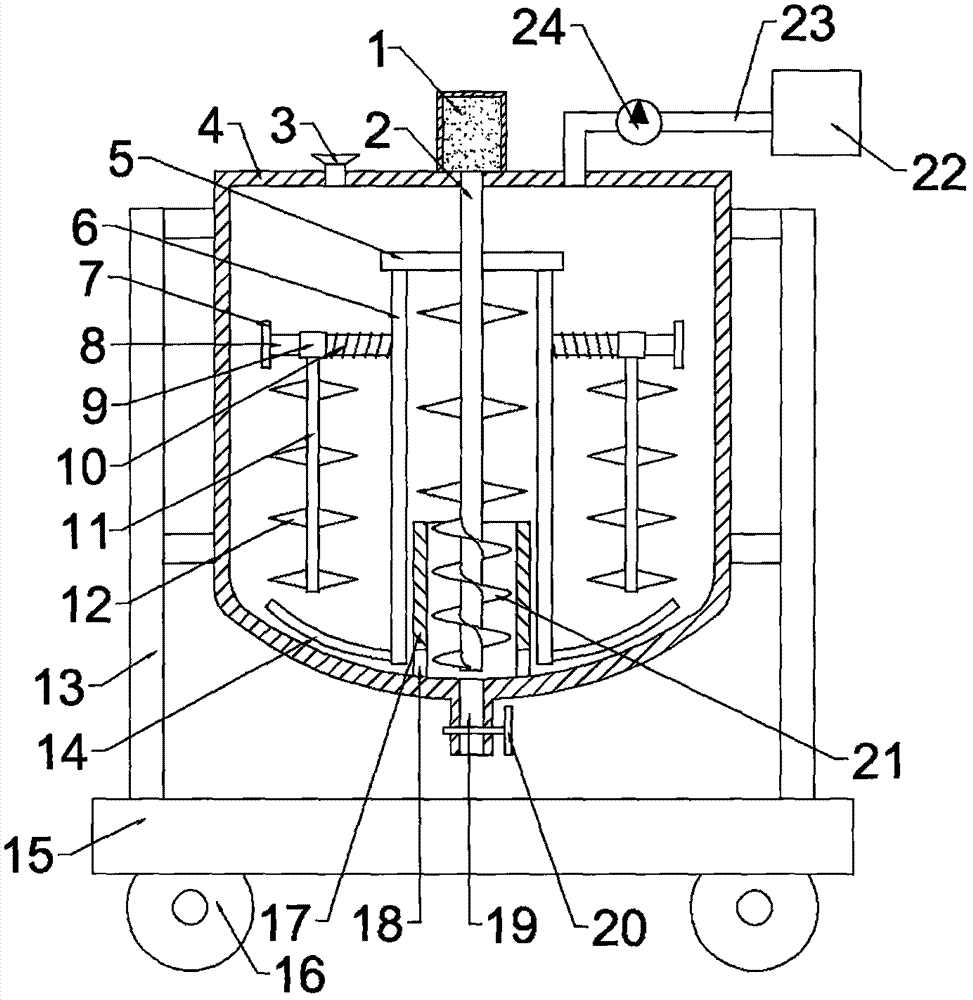

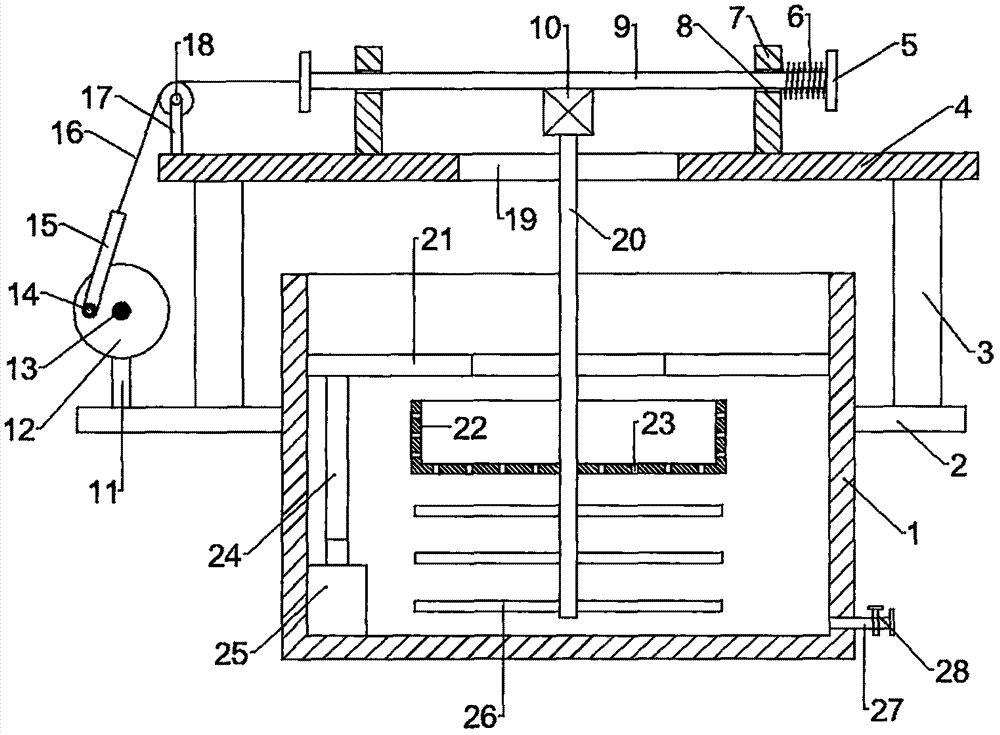

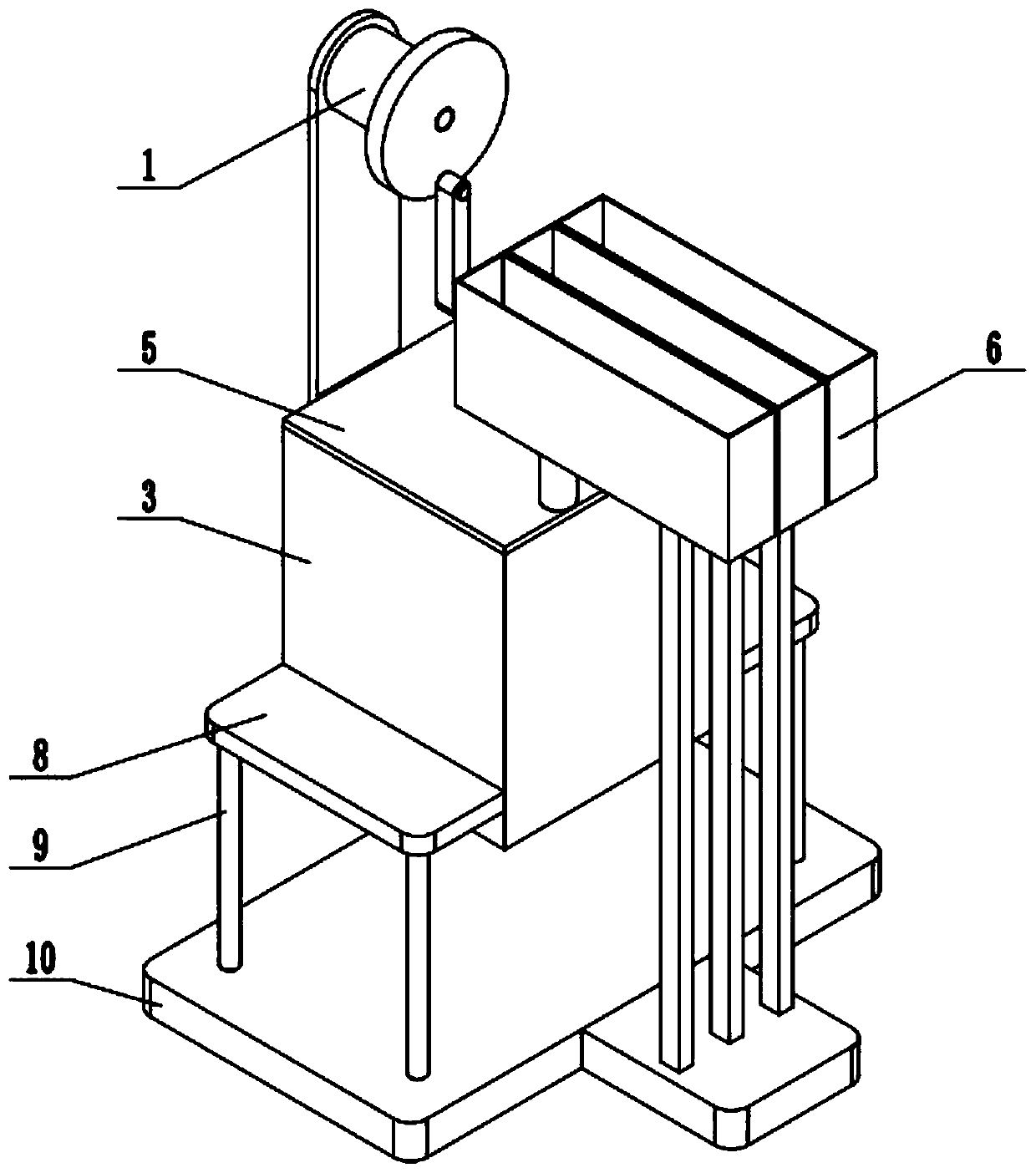

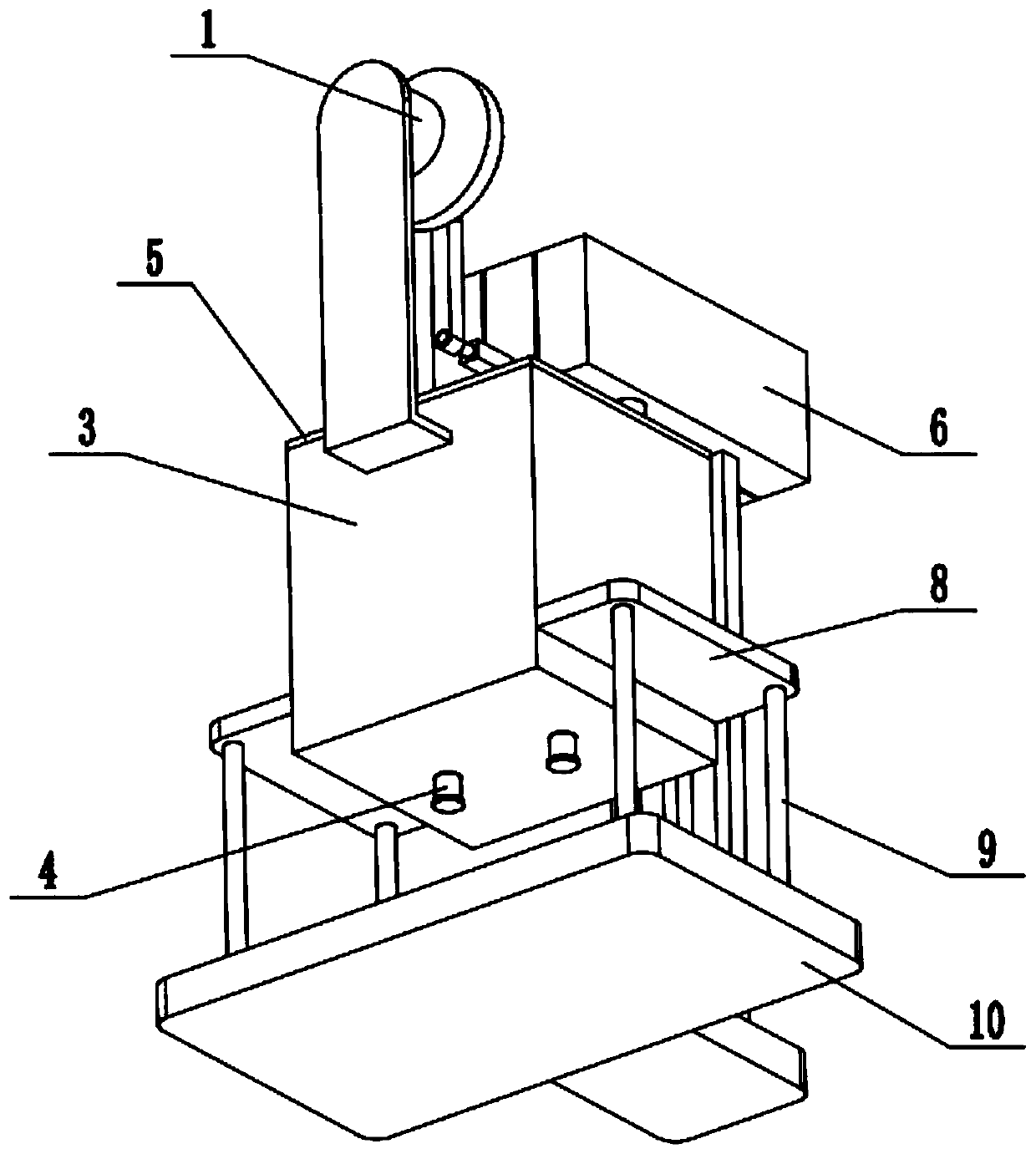

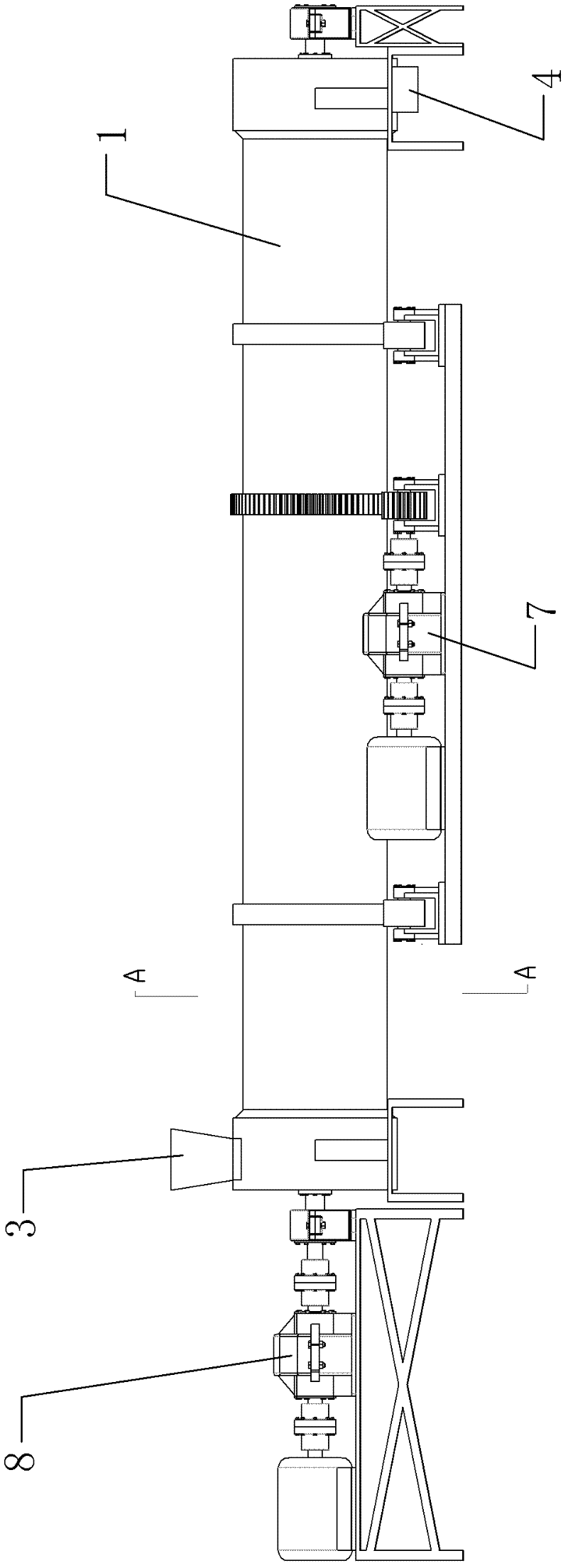

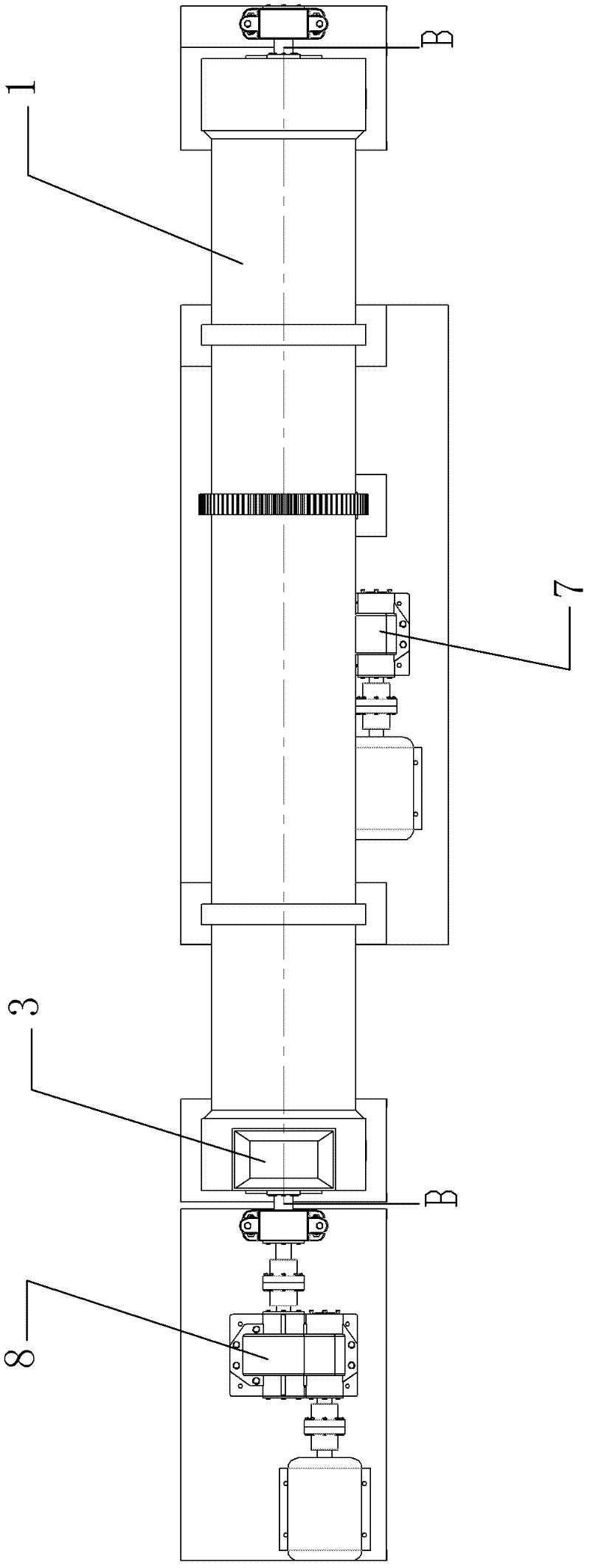

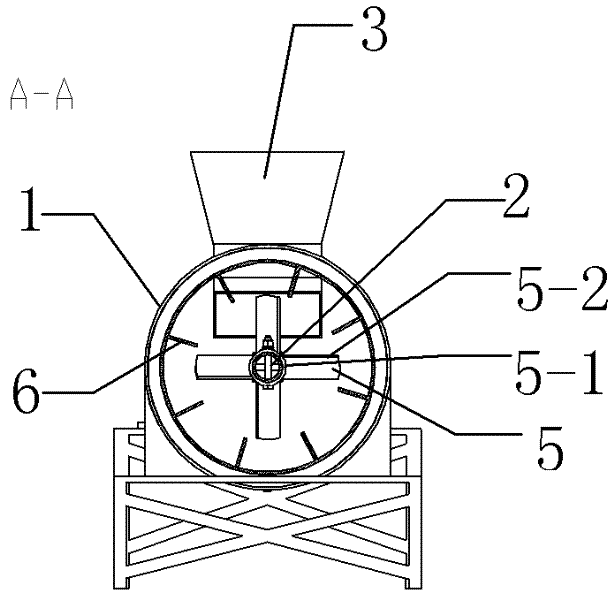

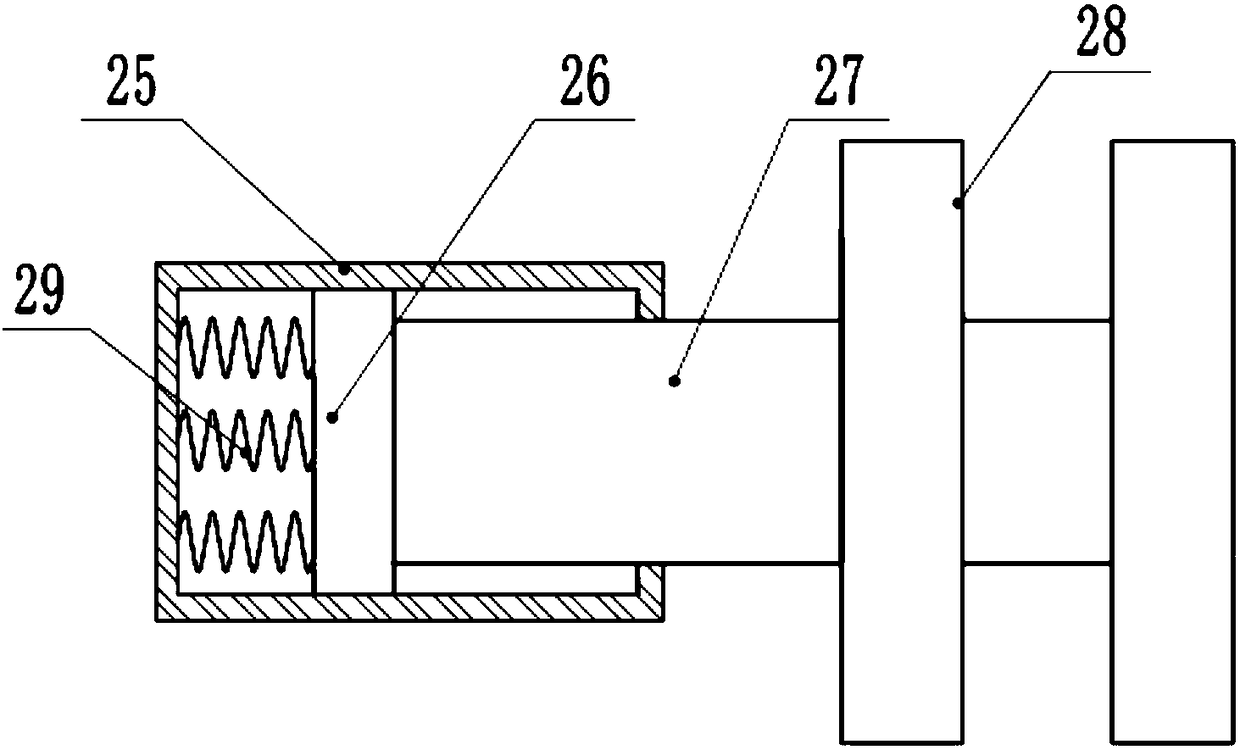

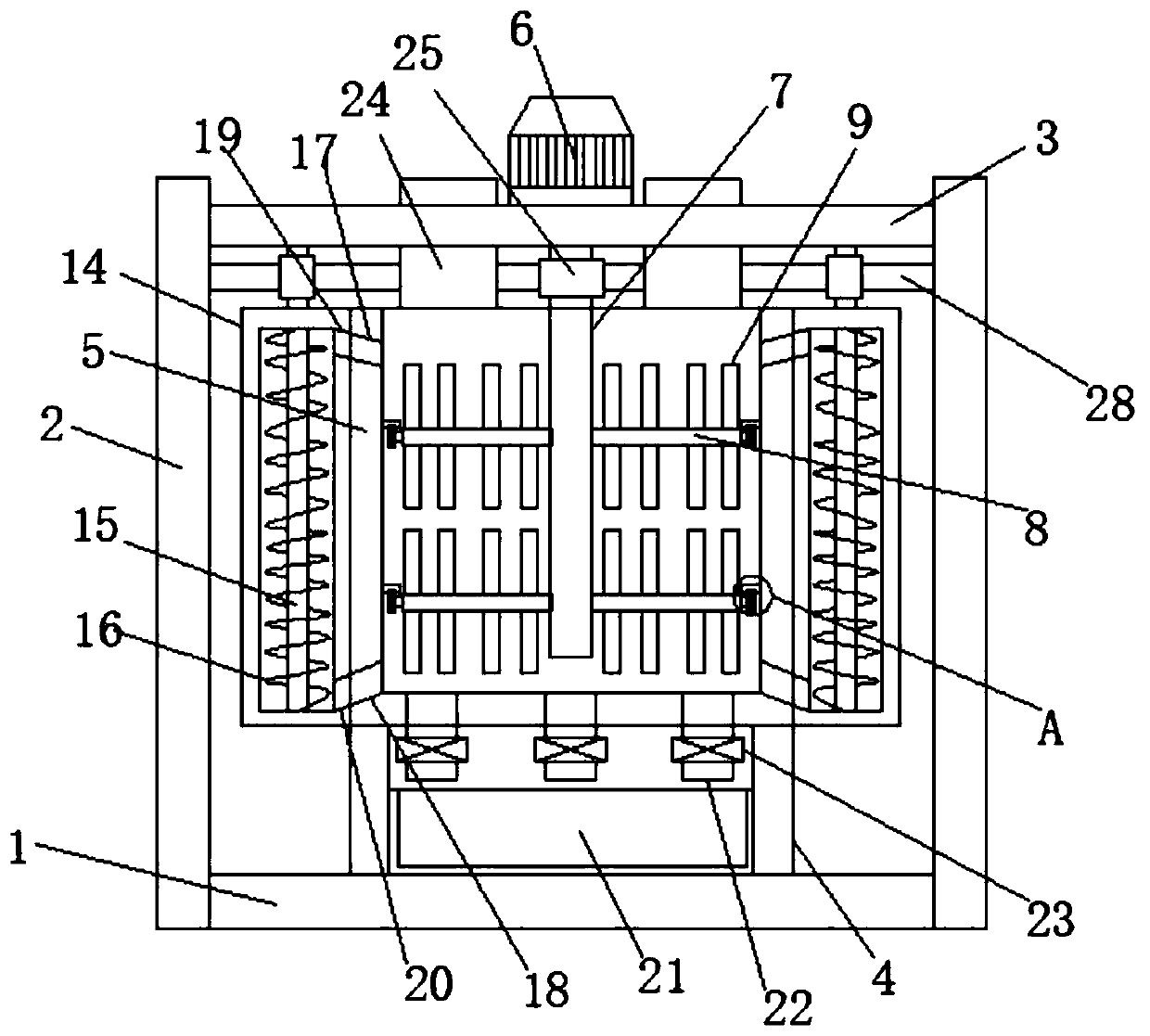

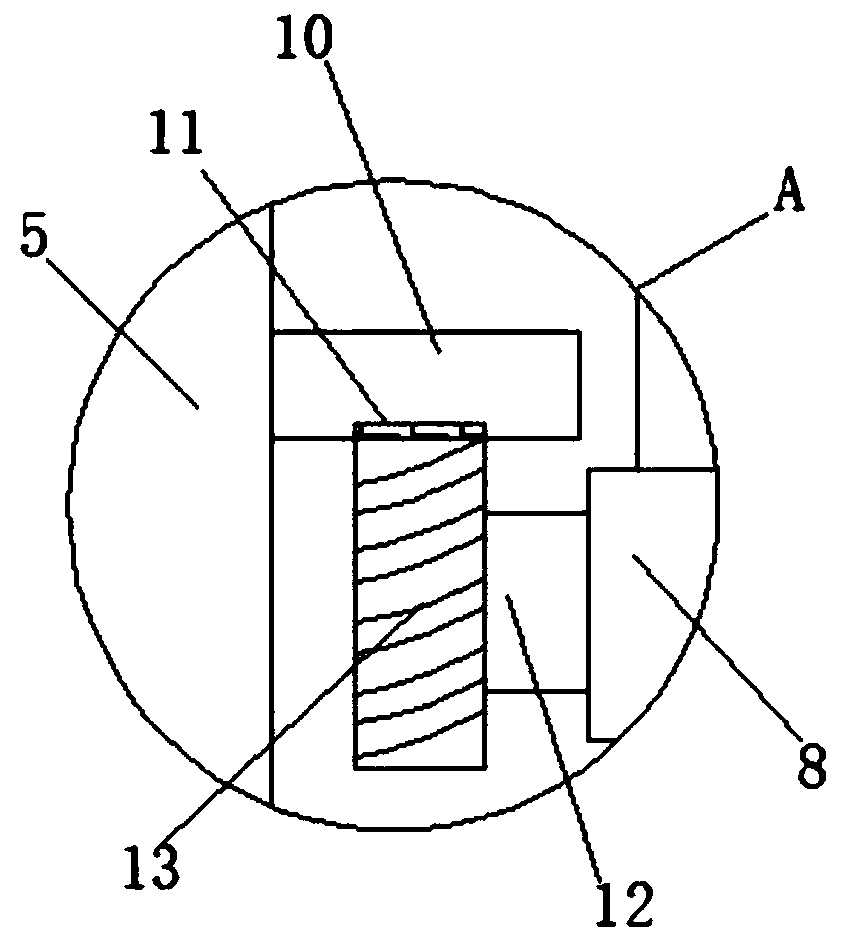

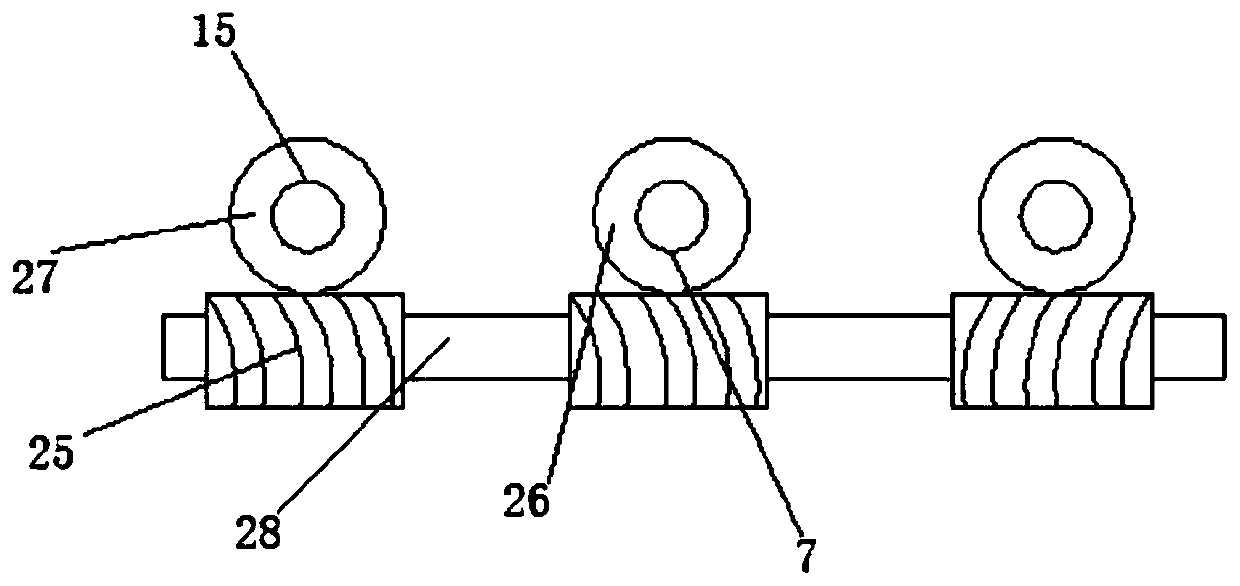

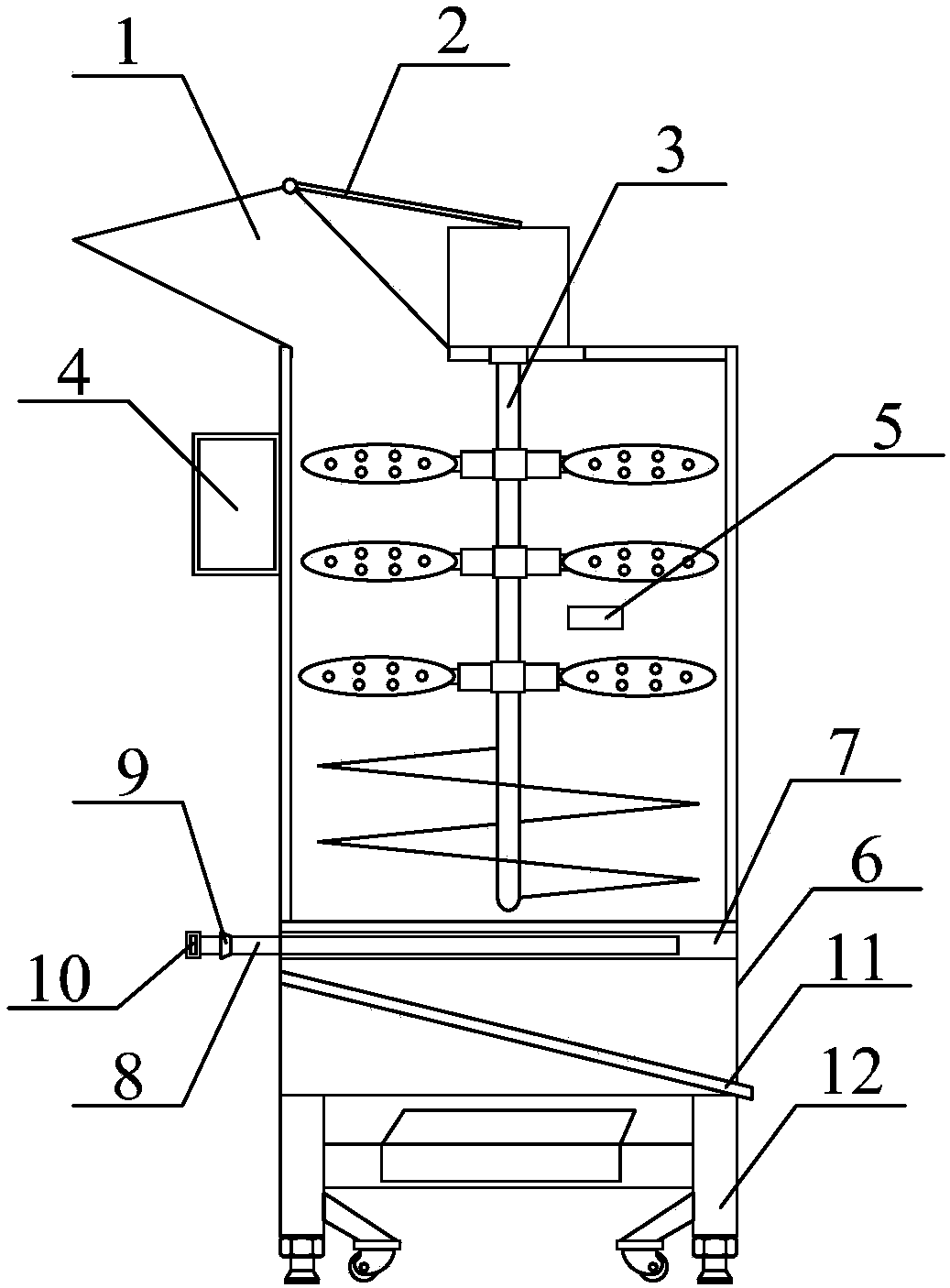

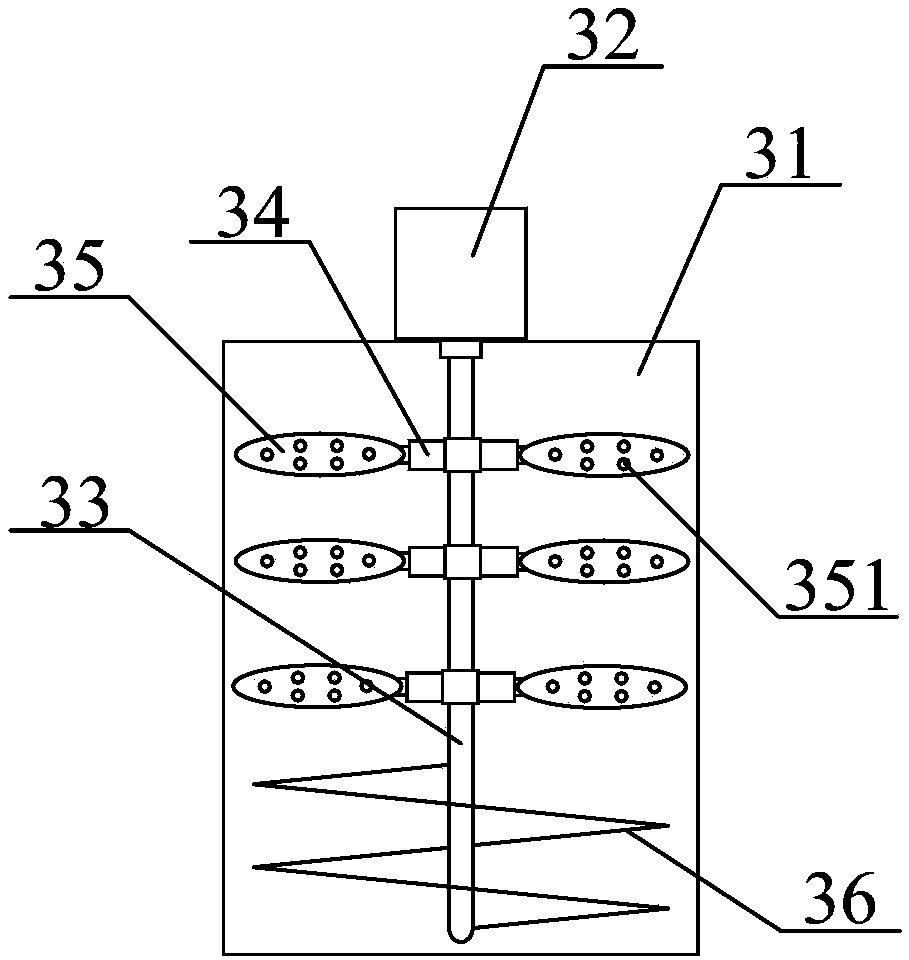

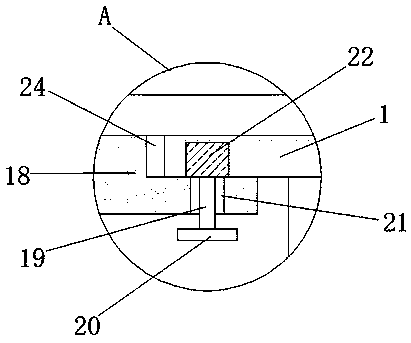

Mobile agricultural liquid fertilizer mixing device

InactiveCN108993277AImprove stirring and mixing effectImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionAgricultural engineering

The invention discloses a mobile agricultural liquid fertilizer mixing device. The mobile agricultural liquid fertilizer mixing device comprises a frame, a fixed stand column, a screw rod, a movable plate, a stirring motor, a second guiding rod assembly, a lifting rod, a mixing box, a mixing mechanism and a cam mechanism. The stirring mechanism stirs to mix the fertilizer liquid in the mixing box,can realize the lifting and dropping of a lifting plate thereby adjusting the height of the stirring mechanism in the mixing box, and improves the stirring and mixing effects of the liquid fertilizerin the mixing tank and the stirring mechanism. A cam in rotation is used to drive the movable plate to move downward and cooperate with the elastic force produced by a compressed first spring so thatthe reciprocating motion of the movable plate in the vertical direction is realized and the stirring mechanism is driven to carry out reciprocating motion in the vertical direction and thus the stirring mechanism has good stirring effects on the liquid mixture in the mixing box.

Owner:苏州艾捷尔斯生物科技有限公司

Environmentally-friendly building material manufacturing extrusion forming device

InactiveCN111037714ARealize automatic suppression effectStir wellDischarging apparatusAuxillary shaping apparatusElectric machineryMixing effect

The invention discloses an environmentally-friendly building material manufacturing extrusion forming device, and relates to the technical field of environmentally-friendly building materials. The environmentally-friendly building material manufacturing extrusion forming device comprises a stirring box. A sleeve is vertically arranged on the stirring box in a rotating mode, and a stirring shaft which is connected through a connecting mechanism is installed in the sleeve in a rotating mode. A lifting mechanism is connected with a compression cylinder through a conveying pipe, a press mechanismwhich is used for extruding raw materials is arranged on the compression cylinder, and a limiting mechanism is arranged on the compression cylinder. According to the environmentally-friendly buildingmaterial manufacturing extrusion forming device, the connecting mechanism is driven by an arranged double-shaft motor, a stirring frame and stirring blades rotate in the opposite directions, and therefore the raw materials inside the stirring box are fully stirred and mixed; an arranged circulating mechanism can upwards lift the raw materials at the bottom of the interior of the stirring box, andtherefore the raw materials can be repeatedly subjected to the stirring effects of the stirring frame and the stirring blades, the stirring and mixing effect is better, and stirring operation is comprehensive and full; and the arranged press mechanism can achieve the effect that the raw materials in the compression cylinder are automatically pressed, and the effect that the raw blank materials ofan environmentally-friendly building material are efficiently pressed is achieved.

Owner:王毅

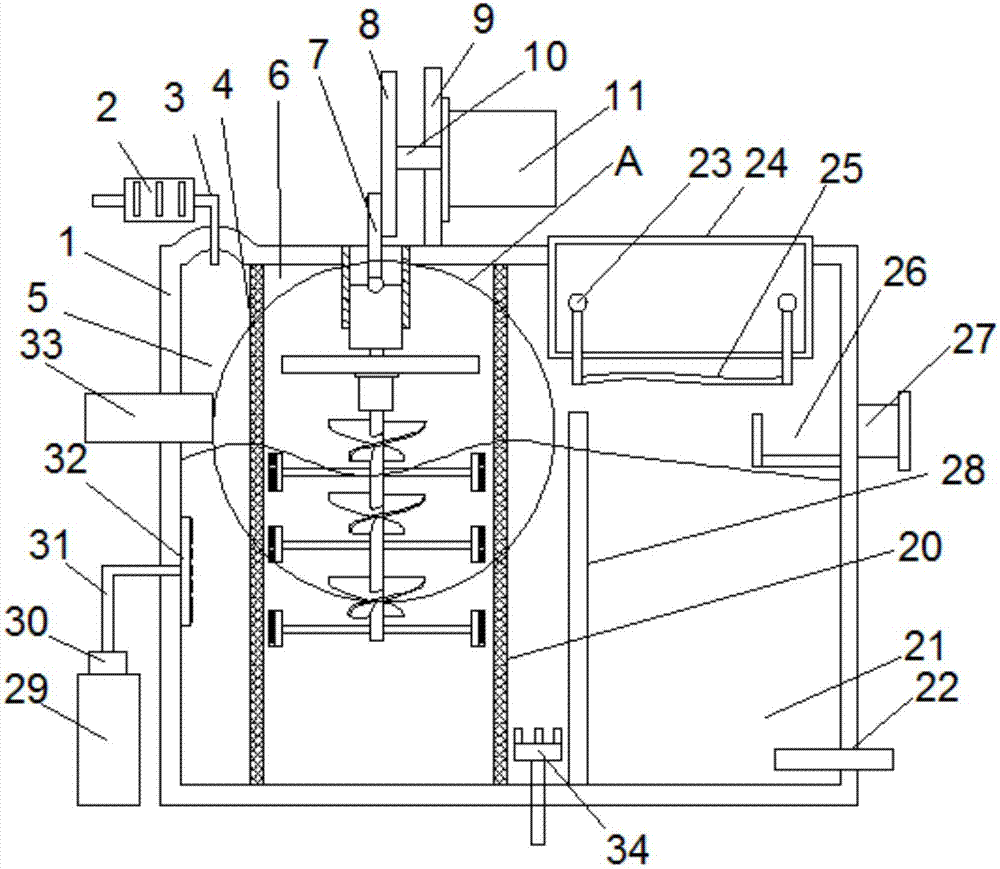

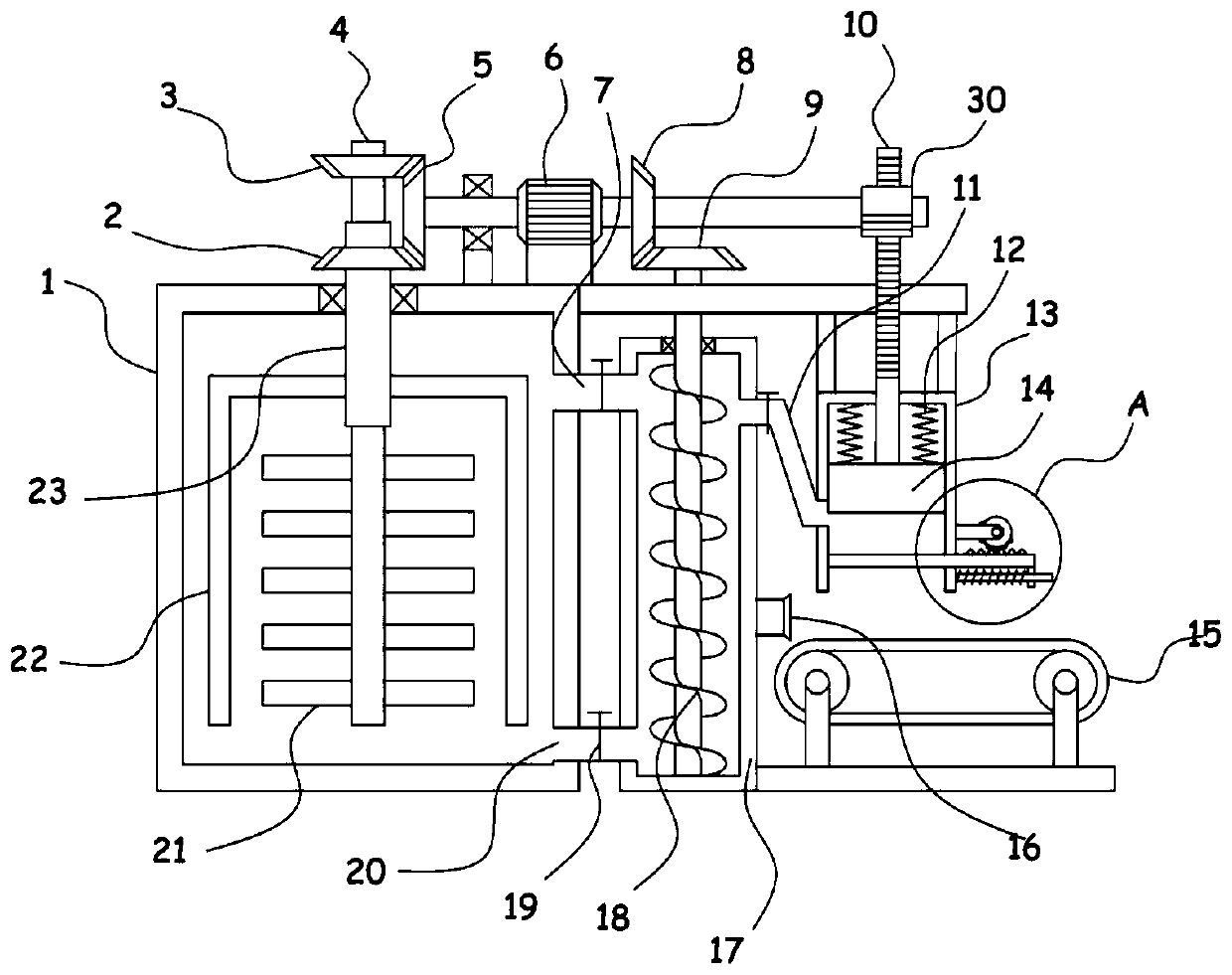

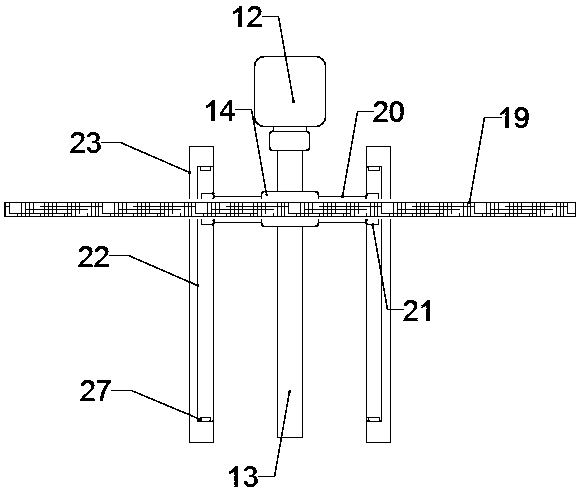

Preparation equipment for producing chemical divinylbenzene catalyst

InactiveCN111530323AQuick switchEasy to carry and transferShaking/oscillating/vibrating mixersRotary stirring mixersPtru catalystReciprocating motion

The invention provides preparation equipment for producing a chemical divinylbenzene catalyst, relates to the field of preparation of chemical catalysts, and solves the problems that sampling work under different liquid level states cannot be achieved at the same time, samples are inconvenient to carry and move after being sampled, a filter screen of a liquid discharge pipe needs to be detached and cleaned during cleaning, quick cleaning on the basis of no detachment cannot be realized, synchronous reverse stirring and mixing of a plurality of stirring shafts and linkage work of two stirring structures cannot be realized. The preparation equipment for producing the chemical divinyl benzene catalyst comprises a cylinder body, and the cylinder body is filled with liquid. A sliding rod and anelastic piece jointly form an elastic reset structure of a mixing plate; the length of a poke rod is greater than the distance between a rotating shaft and the mixing plate, and when the rotating shaft drives the poke rod to rotate, the mixing plate is in an up-and-down reciprocating motion state under the poke action of the poke rod, so that auxiliary mixing can be realized.

Owner:梁远起

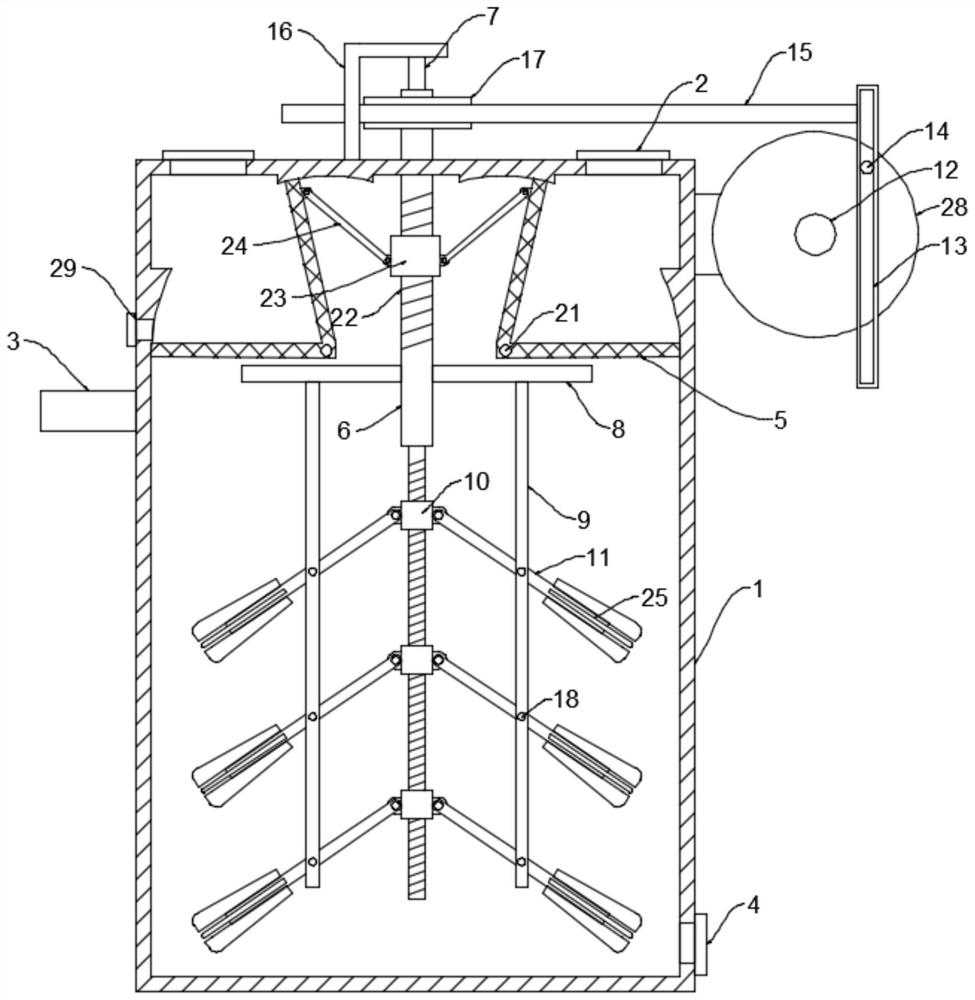

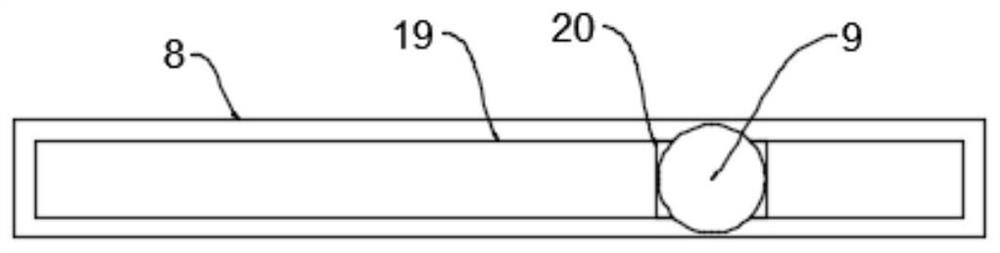

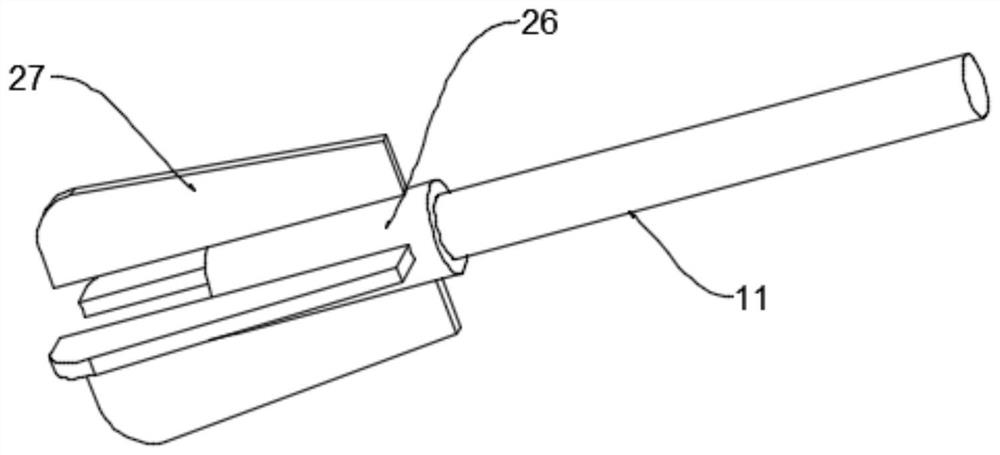

Dye stirring, stirring and mixing device for textile processing

InactiveCN111701500AImprove the mixing effectSimple structureShaking/oscillating/vibrating mixersTransportation and packagingBLENDER/MIXERMixing effect

The invention discloses a dye stirring, stirring and mixing device for textile processing. The device comprises a mixing box body and a stirring mechanism arranged in the mixing box body, the stirringmechanism comprises a rotating sleeve, a fixed screw rod, a plurality of stirring assemblies and a driving assembly; the top of the fixed screw rod is rotationally mounted in the center of the top wall of the mixing box body and is driven by a driving assembly to rotate forwards and backwards; the stirring assembly comprises a cross rod, a vertical rod and a swing rod; the end of the vertical rodis slidably connected to the transverse rod, the middle of the swing rod is hinged to the rod wall of the vertical rod through a connecting pin shaft, a first driving threaded sleeve matched with thefixed lead screw is arranged at the lower end of the fixed lead screw, the end of the swing rod is rotatably connected with the side wall of the first driving threaded sleeve, and a stirring piece isarranged at the end, away from the first driving threaded sleeve, of the swing rod. Thedevice is simple in structure, capable of driving the stirring piece to swing up and down while rotating forwards and backwards, capable of effectively improving the stirring and mixing effect, uniform in mixing and avoiding solid block forming, convenient to operate and high in practicability.

Owner:任春宏

Concrete mixing equipment capable of controlling water addition

InactiveCN106945177AImprove stirring and mixing effectExpand the mixing rangeCement mixing apparatusLiquid ingredients supply apparatusEngineeringMixing effect

Owner:刘云海

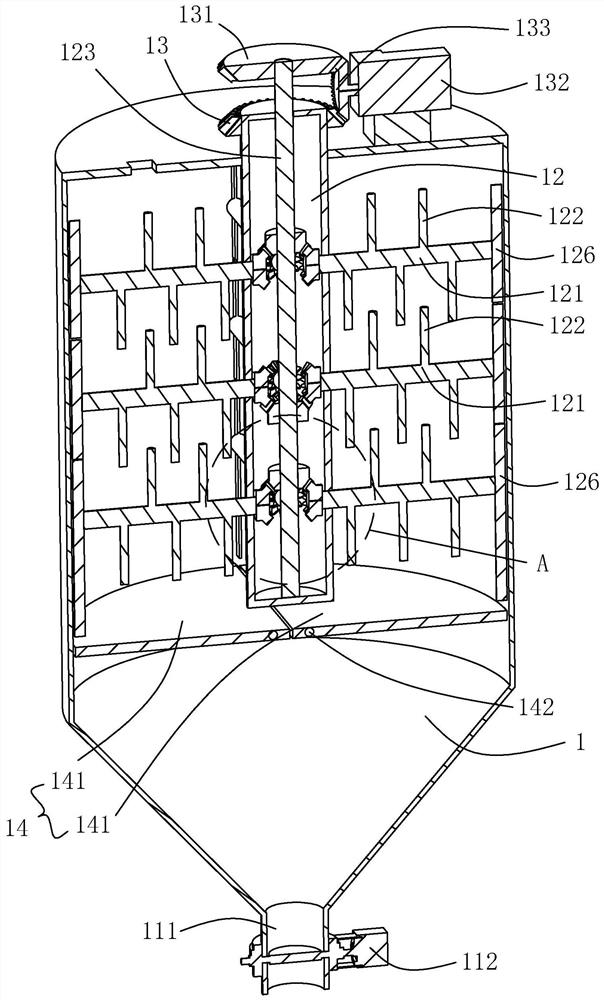

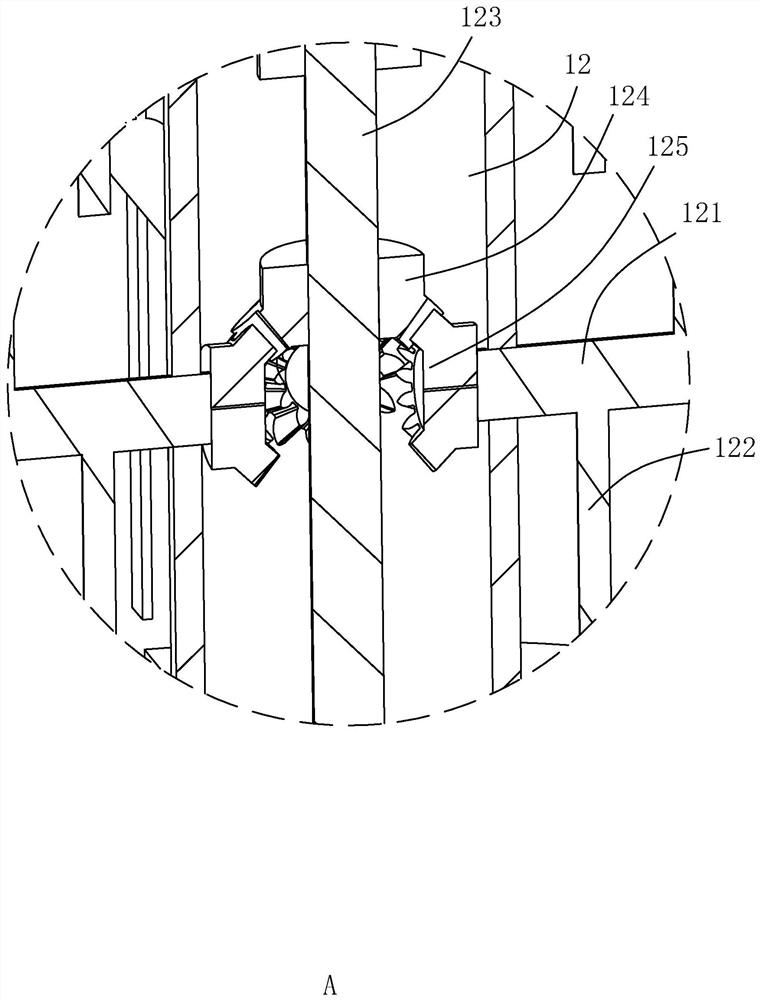

Stirring device for producing aerated concrete

ActiveCN111993581AExtrude and stirImprove stirring and mixing effectMixing operation control apparatusPretreatment controlDrive shaftClassical mechanics

The invention relates to a stirring device for producing aerated concrete. The stirring device for producing aerated concrete comprises a tank, wherein a feeding pipe and a discharging pipe are arranged on the tank; a stirring mechanism is arranged in the tank, and comprises a rotating shaft; a plurality of groups of first stirring elements are arranged on the rotating shaft, and each group of first stirring element comprises a plurality of first stirring rods; each first stirring rod is provided with a plurality of groups of second stirring pieces, and each group of second stirring piece comprises a plurality of second stirring rods; the first stirring rods penetrate and are rotatably connected to the hollow rotating shaft, a driving shaft is rotatably connected in the rotating shaft, andis sleeved and fixedly connected with a plurality of first bevel gears, a second bevel gear for meshing with the corresponding first bevel gear is arranged at the end, located in the hollow driving shaft, of each first stirring rod, and the adjacent first bevel gears face oppositely; and a driving element for driving the rotating shaft and the driving shaft to rotate reversely simultaneously is arranged on the top wall of the tank. The stirring device has the advantage of better stirring and mixing effect.

Owner:四川宏量基筑建材有限公司

Flocculation equipment for sewage treatment plant

InactiveCN107311280AHybrid effect achievedChange the mixing rangeWater/sewage treatment by flocculation/precipitationFlocculationSewage

A flocculation equipment used in a sewage treatment plant, including a flocculation tank, two installation seats are symmetrically fixedly connected to the left and right side walls of the flocculation tank, and installation posts are fixedly connected to the installation seats, and the tops of the two installation posts are fixedly connected together There is a mounting plate, two vertical plates are symmetrically fixedly connected on the upper side of the mounting plate, a moving slot is opened on the vertical plate, a moving plate passes through the two moving slots, and baffle plates are fixedly connected at both ends of the moving plate; The mounting seat on the side is fixedly connected with a first support frame, the top of the first support frame is rotatably connected with a first rotating shaft, the rear end of the first rotating shaft is connected with a driving device, the front end of the first rotating shaft is fixedly connected with a turntable, and the edge of the turntable Fixed connection with mounting rod. Compared with the prior art, the beneficial effect of the present invention is that the pump body is used to pump the flocculant and sewage into the liquid spraying device, and then the mixture is sprayed out from the liquid spraying device. During the spraying process, the sewage and the flocculant are obtained A certain mix of effects.

Owner:刘奇美

Liquid medicine stirring apparatus for gene engineering

InactiveCN109569381AAchieve rotationAchieving rotary stirringRotating receptacle mixersShaking/oscillating/vibrating mixersReciprocating motionDrive motor

The invention discloses a liquid medicine stirring apparatus for gene engineering, which relates to the technical field of gene engineering. The liquid medicine stirring apparatus comprises a carrierplate, wherein a supporting frame is fixedly installed on the carrier plate, a horizontal plate is horizontally fixed on the supporting frame, the horizontal plate is provided with a stirring trough for holding liquid medicine, the surface of a stirring shaft is uniformly fixedly provided with a plurality of pairs of stirring blades, the bottom of the stirring trough is vertically provided with arotating shaft pivoted onto the horizontal plate, the rotating shaft is driven by a driving mechanism to rotate, and the carrier plate is fixedly provided with a chemical box which is unidirectionallycommunicated with the stirring trough. An incomplete bevel gear can be alternately engaged with a bevel gear I and a bevel gear II by virtue of the driving of the driving motor, the rotating shaft drives the stirring trough to rotate, the rotation of the liquid medicine inside the stirring trough is realized, and a casing pipe also drives a stirring motor to make transverse reciprocating movementto drive the stirring blades to stir the liquid medicine on different positions inside the stirring trough, so that the stirring and mixing effect of the liquid medicine components can be greatly improved.

Owner:李敏

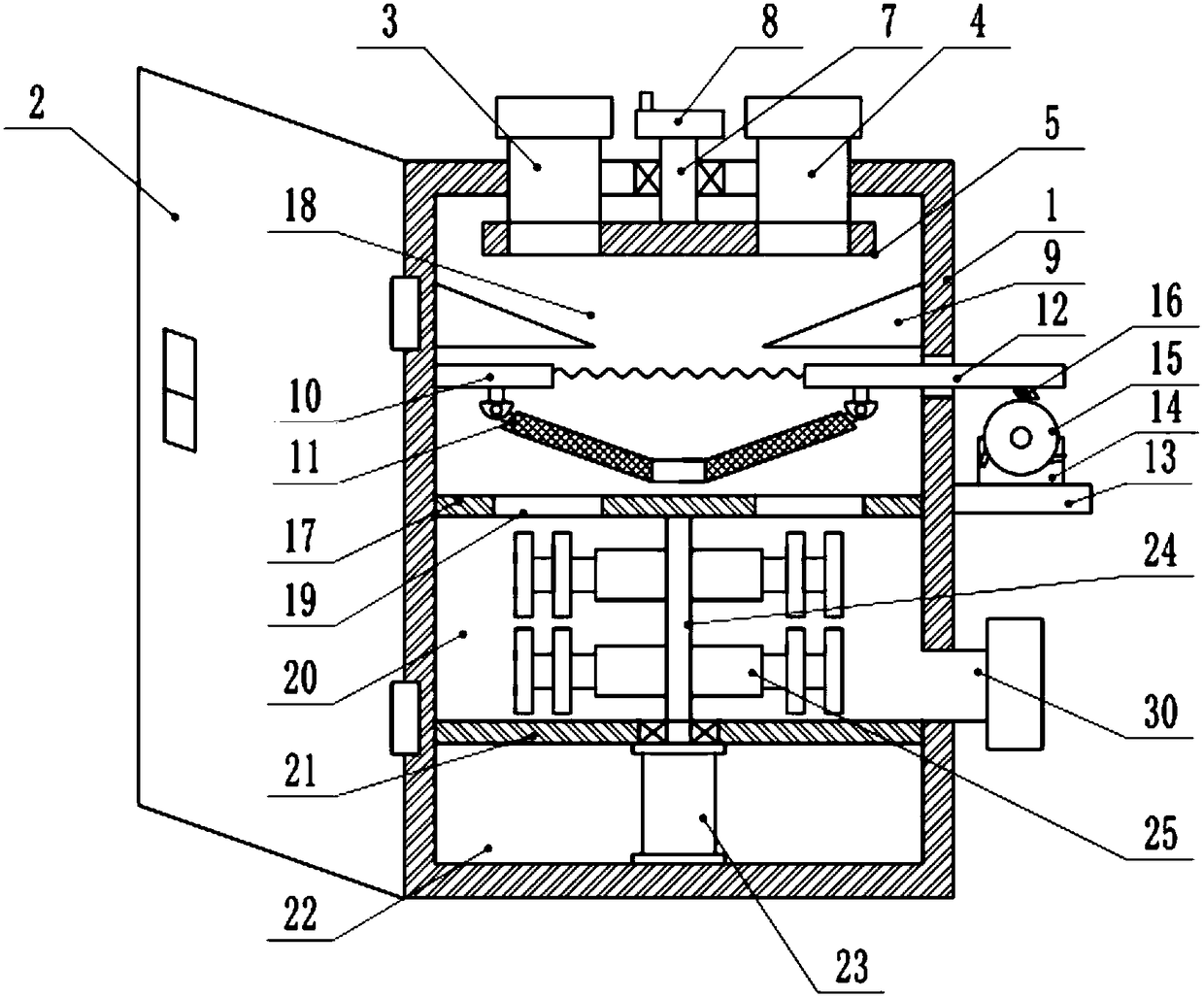

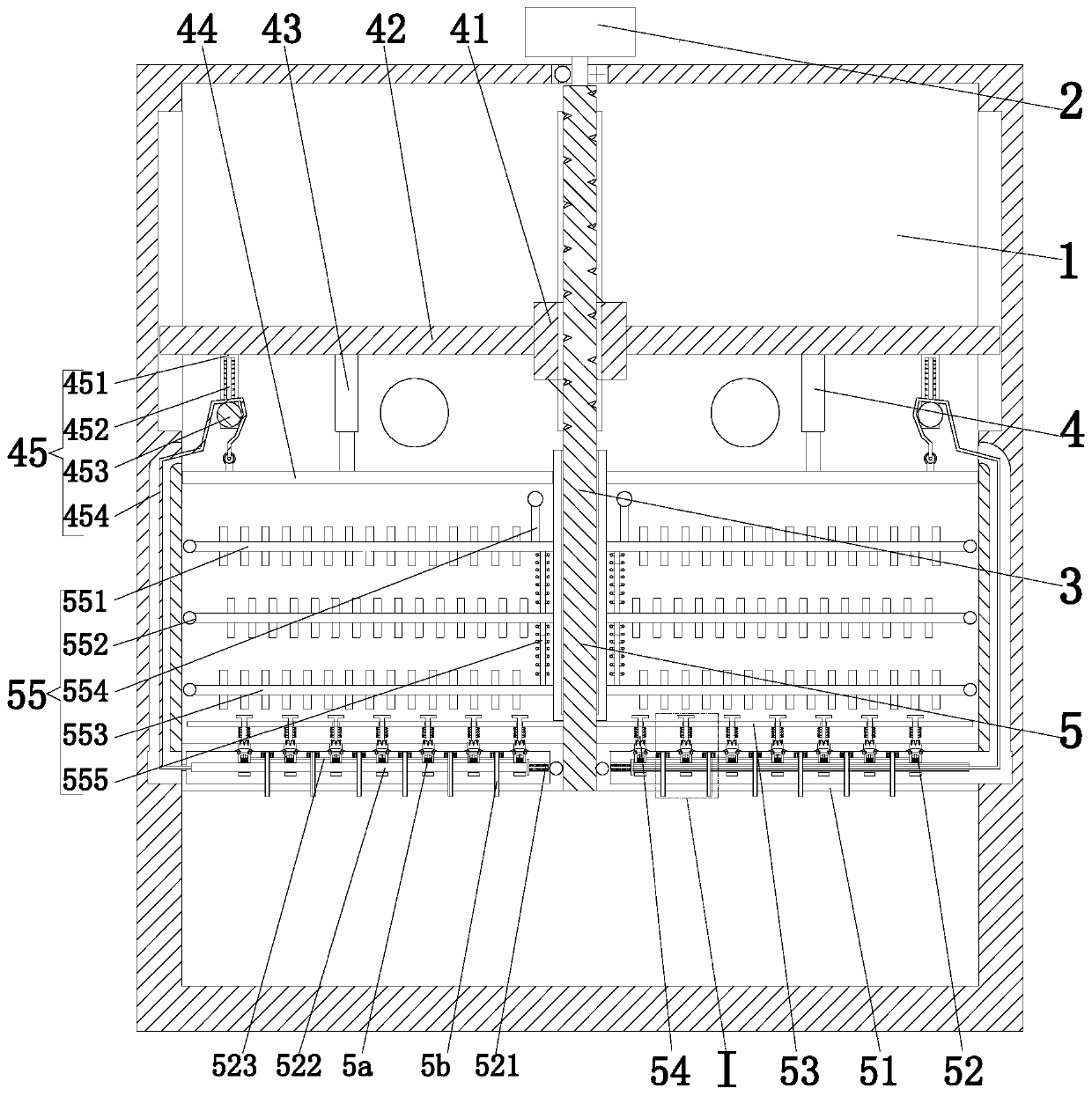

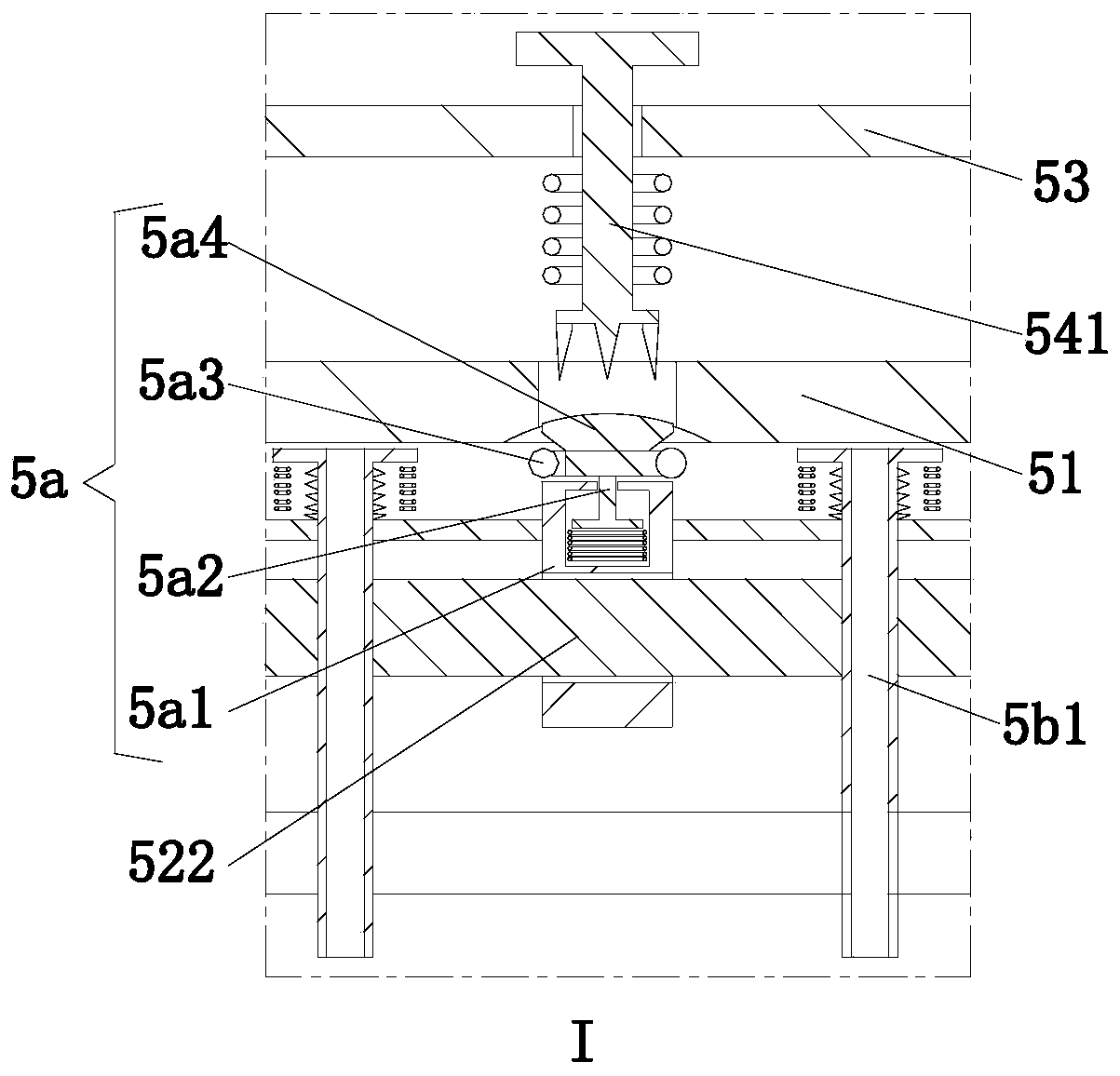

Body wash production stirring system

ActiveCN109731511AImprove the mixing effectImprove stirring and mixing effectShaking/oscillating/vibrating mixersMixer accessoriesEngineeringMixing effect

The invention relates to the field of body wash processing, in particular to a body wash production stirring system. The body wash production stirring system comprises a stirring drive mechanism, a stirring mechanism, a stirring box, a liquid outlet pipe with a valve, a detachable box cover, a storage mechanism, a feeding control mechanism, upper seat plates, support rods and a lower seat plate and is characterized in that the top surface of the stirring box is hollowed out, and the top end of the stirring box is fixedly connected with the detachable box cover in a sealed manner; the bottom end of the stirring box is fixedly connected and communicated with the liquid outlet pipe; one upper seat plate is fixedly connected to each of the left end and the right end of the stirring box; the bottom ends of the upper seat plates are fixedly connected to the lower seat plate through two support rods. The body wash production stirring system has the advantages that vertical stirring and horizontal stirring of raw materials inside the stirring box can be achieved, and the stirring and mixing effect and efficiency are increased by the vertical stirring and horizontal stirring; during the stirring of various raw materials, intermittent raw material adding can be achieved, and the stirring effect increasing can be facilitated.

Owner:舒芙雅生物科技有限公司

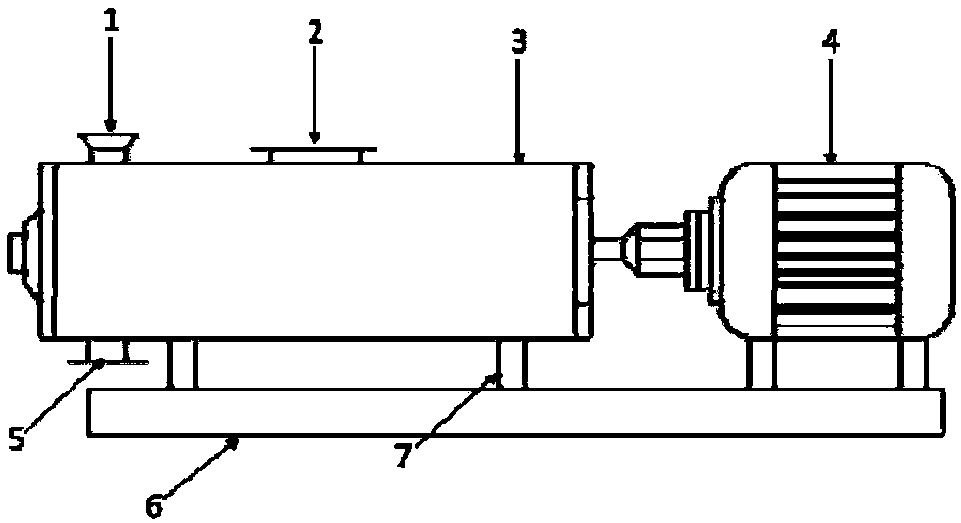

Powdery and granular garbage stirrer

InactiveCN102489206AIncrease chance of contactImprove uniformityRotating receptacle mixersMixing methodsImpellerDry powder

The invention discloses a powdery and granular garbage stirrer. The powdery and granular garbage stirrer comprises a stirring cylinder and a stirring shaft, wherein the stirring cylinder and the stirring shaft are arranged horizontally; the stirring cylinder is sleeved outside the stirring shaft; the stirring cylinder and the stirring shaft rotate coaxially and reversely; a feed port is formed at one end of the stirring cylinder and a discharge port is formed at the other end of the stirring cylinder; a plurality of impellers are fixedly installed in the axial direction of the stirring shaft; and the stirring cylinder and the stirring shaft are driven by a stirring cylinder transmission device and a stirring shaft transmission device respectively. The powdery and granular garbage stirrer is deigned for stirring and mixing garbage powder and granules after urban garbage is crushed; and the design comprehensively takes a property that additives and the garbage powder and granules are dry powder and granules into consideration and makes stirring and mixing process more sufficient on the premise of considering the production cost and the production efficiency.

Owner:GUILIN UNIV OF ELECTRONIC TECH +1

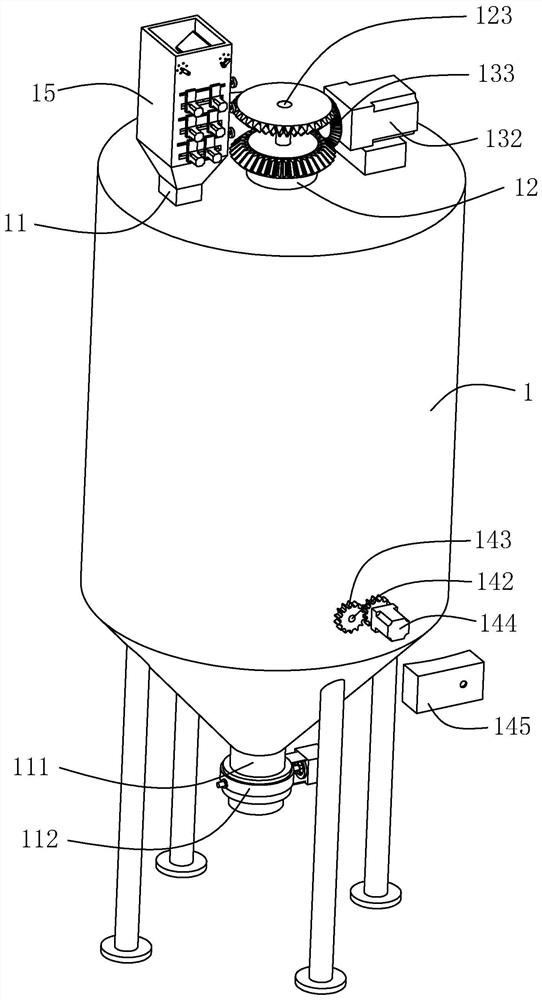

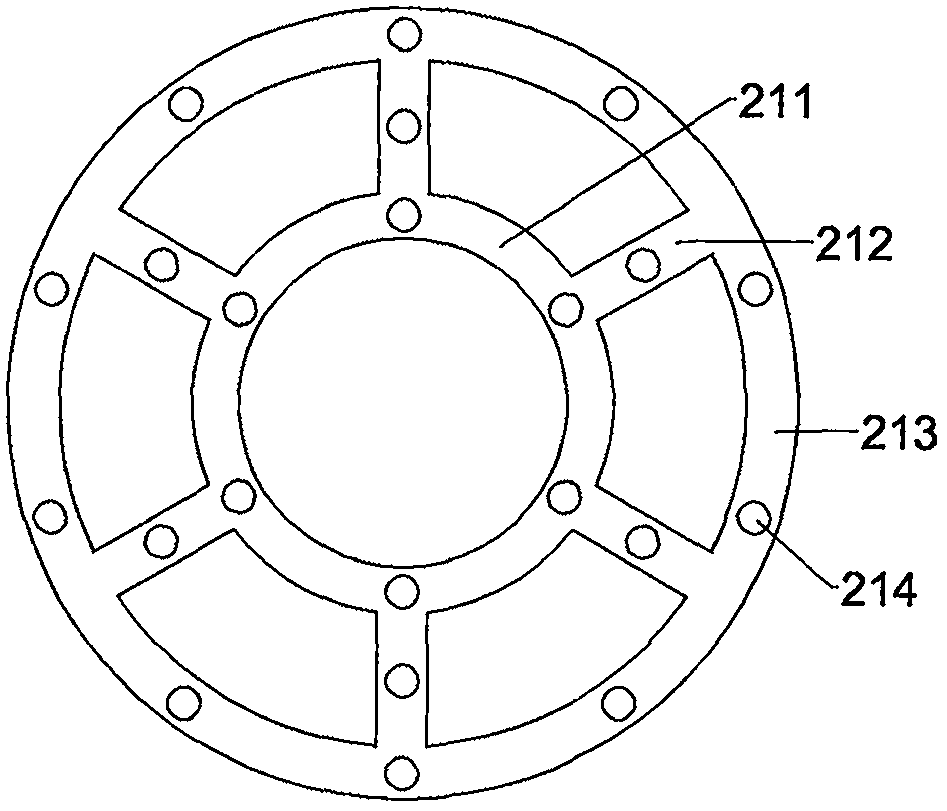

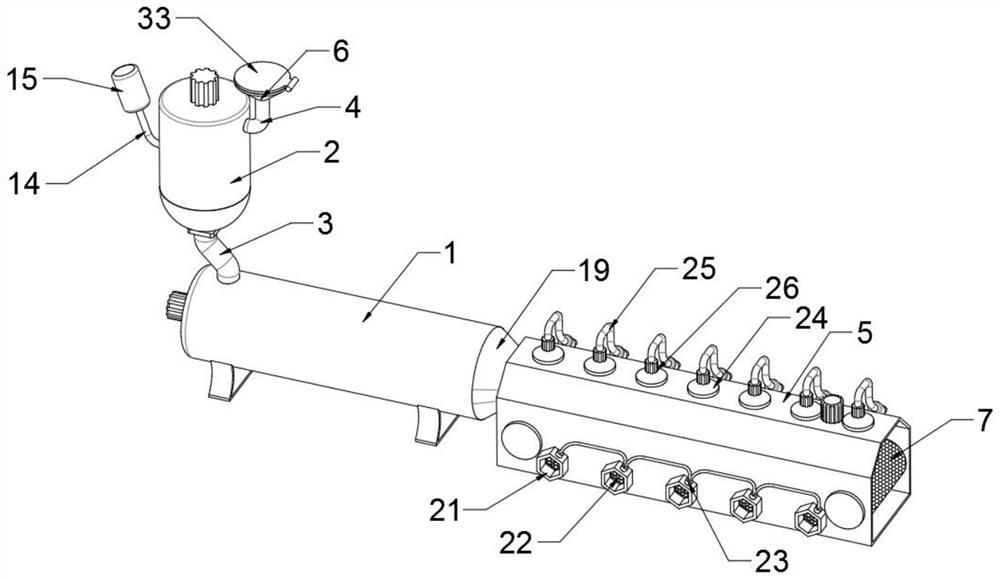

Equivalent filtering and mixing device for biomass liquid fuel

ActiveCN108079831AEqual feed realizationSpeed up filteringRotary stirring mixersTransportation and packagingLiquid fuelDrive motor

The invention discloses an equivalent filtering and mixing device for biomass liquid fuel. The equivalent filtering and mixing device comprises a tank, an equivalent feeding plate, a tank filter screen, a first drive motor, a second drive motor and stirring blades and is characterized in that the equivalent feeding plate is arranged at the lower ends of a fuel feeding pipe A and a fuel feeding pipe B, the filter screen is arranged below a fixed plate and a movable plate, each outer loop bar is of a hollow structure, a slider is slidably mounted inside each outer loop bar, a telescopic rod is welded to one side of each slider, and the stirring blades are welded to each telescopic rod. The equivalent filtering and mixing device has the advantages that by the equivalent feeding plate, fuel entering the tank in unit time can be identical in quantity, that is to say, equivalent feeding can be achieved, fuel measuring before mixing is not needed, and time and labor are saved; the telescopinglength of the telescopic rods can be changed according to centrifugal force during mixing so as to change the stirring range of the stirring blades, and accordingly the situation that fuel on two sides or in the middle of a stirring cavity cannot be stirred can be prevented, and the stirring and mixing effect can be increased greatly.

Owner:江西云顺新能源有限公司

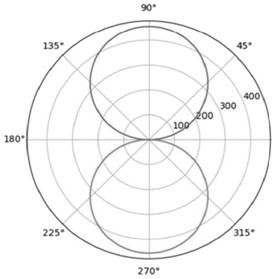

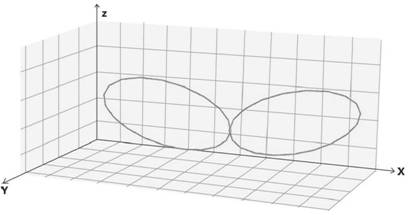

Variable-angle planet inclined stirring device with stirring paddle capable of planning path

ActiveCN111701474AEnhanced ChaosImprove the mixing effectTransportation and packagingRotary stirring mixersEngineeringCam

The invention discloses a variable-angle planet inclined stirring device with a stirring paddle capable of planning a path. The variable-angle planet inclined stirring device comprises a stirring shaft, a transmission main shaft, a transmission mechanism, a support frame, a stirring joint and a stirring shaft, a semi-spherical shell-shaped cam is fixed on the support frame, and a groove formed according to a set track is formed in the cam; the lower part of the transmission main shaft penetrates through the support frame and the cam to be matched with the stirring shaft joint; a pin rod horizontally penetrates through the lower portion of the transmission main shaft, the two ends of the pin rod are connected with the side portions of the stirring shaft connector in a sliding mode through connecting rods, the center of the pin rod is connected with a driven piece, the driven piece penetrates through the transmission main shaft to be matched with a groove in the cam, and the transmissionmain shaft drives the stirring shaft to rotate through a transmission mechanism.

Owner:SHANDONG UNIV

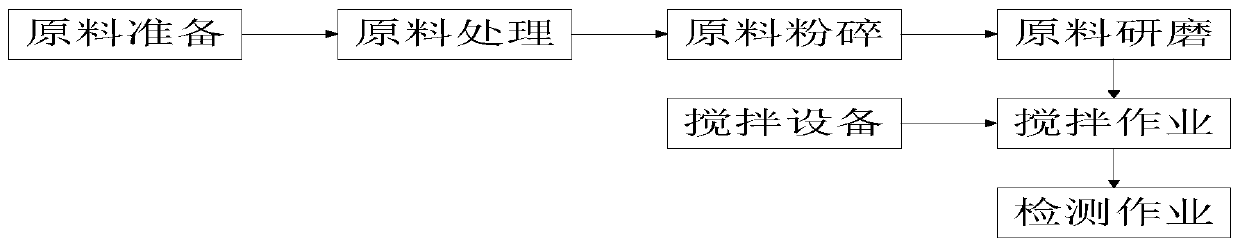

Ink production and manufacturing process

ActiveCN110404444ARealize the function of efficient stirring preparationIncrease pressureTransportation and packagingRotary stirring mixersDirect effectsDrive motor

The invention relates to an ink production and manufacturing process. The ink production and manufacturing process mainly comprises the following steps of raw material preparation, raw material treatment, raw material pulverization, raw material grinding, stirring operation, testing operation and the like, wherein roller stirring equipment comprises a stirring operation frame, the stirring operation frame is provided with a driving motor through a motor base, an output shaft of the driving motor is connected with a rotating column, the upper end of the rotating column is provided with a compression mechanism, and the lower end of the rotating column is provided with a filtering stirring mechanism. The ink production and manufacturing process can solve the following problems in an existingink production and manufacturing process that a, existing stirring equipment adjusts the stirring effect simply by changing the rotating speed, which cannot make ink raw materials mixed uniformly in the stirring operation, and directly affects the use effect of the ink; b, the existing equipment cannot treat particle objects in the ink raw materials during ink stirring operation, and the stirred raw materials are mixed together, which affects the quality of the ink.

Owner:迪爱生太原油墨有限公司

Food stirrer

InactiveCN110756075ASolve the problem that the fluidity is not strong and the overall stirring effect is not obviousImprove the mixing effectFlow mixersRotary stirring mixersProcess engineeringFood material

The invention belongs to the field of stirring, and particularly relates to a food stirrer. Aiming at solving the problems that in the using process of existing food stirrers, rotary stirring is conducted usually through stirring blades, some stirrers have the effect of being capable of conducting up-down lifting on rotating blades, thus the effect of stirring can be improved, but for stirring ofsome food raw materials, in the stirring way, raw material liquidity is low, and the overall stirring effect is not obvious, the following scheme is proposed currently, specifically, the food stirrerdisclosed by the invention includes a first support plate, symmetrically-arranged second support plates are fixed to the side walls of the top end of the first support plate, and a third support plateis fixed between the side walls of the sides, close to each other, of the second support plates. According to the food stirrer, raw materials can be mixed and stirred, stirring columns can be rotatedand autorotate, thus the stirring and mixing effects are improved, meanwhile, the raw materials can be automatically stirred in a spirally ascending mode, finally, the raw materials return into a stirring box to be stirred and mixed again, and the overall stirring effect is improved.

Owner:西安德贝盈农业科技有限公司

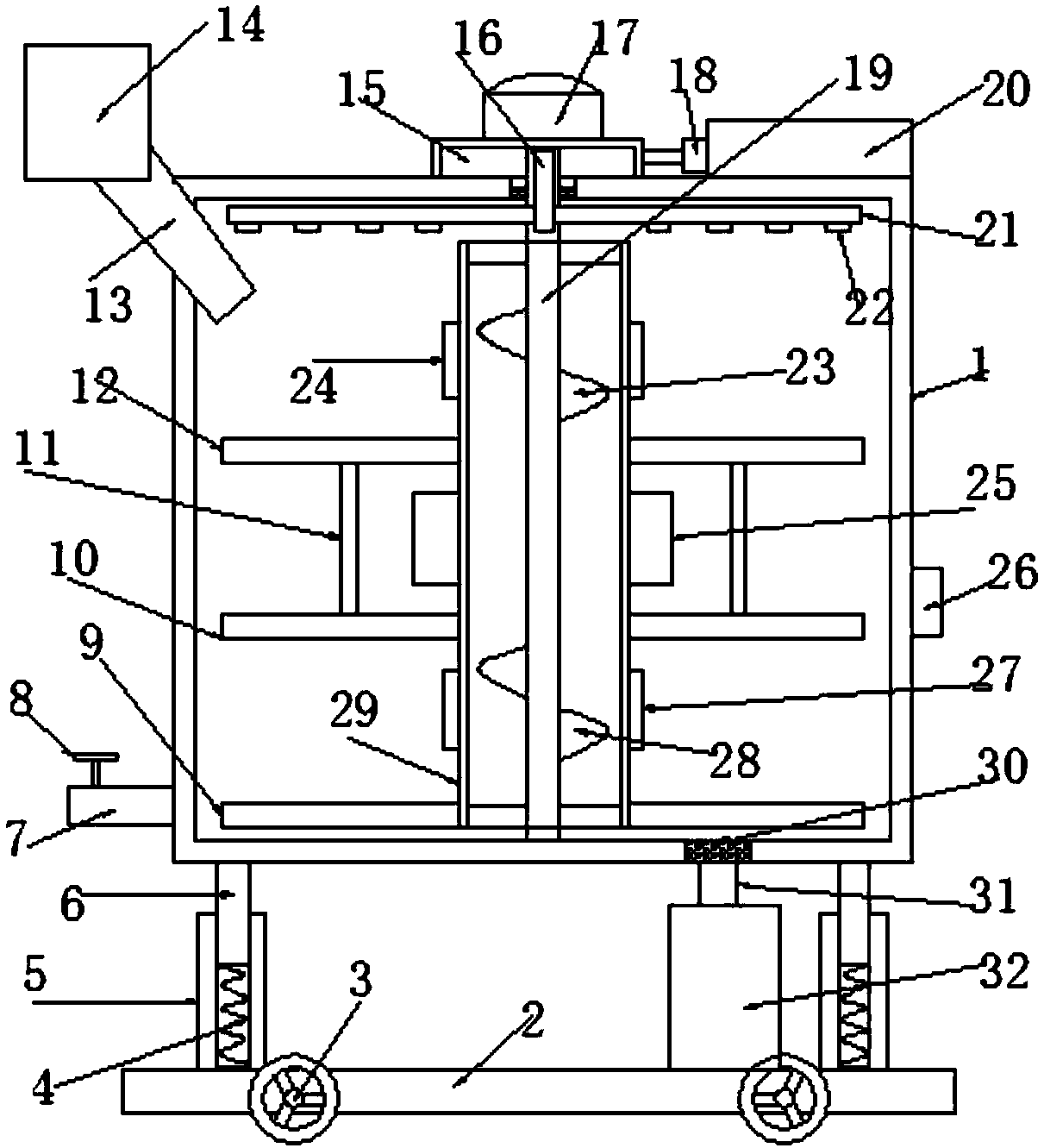

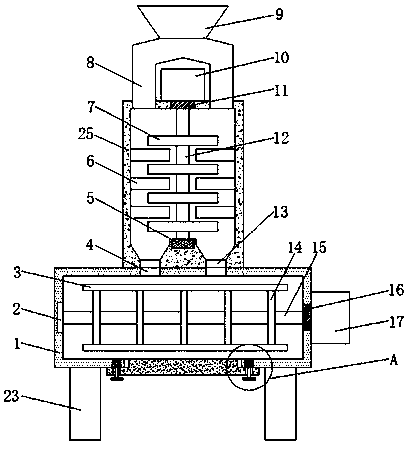

High-efficiency convective building concrete mixing device

InactiveCN108214913AImprove stirring and mixing effectReduce pollutionDischarging apparatusCement mixing apparatusArchitectural engineeringMixing effect

The invention discloses a high-efficiency convective building concrete mixing device. The high-efficiency convective building concrete mixing device comprises a processing box and a pedestal; the pedestal is arranged below the processing box; the left and right sides of the pedestal are symmetrically provided with idler wheels which provide conveniences for transferring the device; the two sides of the upper end of the pedestal are symmetrically provided with supporting sleeves; the upper end of each supporting sleeve is slidably provided with a supporting rod; the upper end of each supportingrod is fixedly connected with the bottom of the processing box; each supporting sleeve is internally provided with a buffer spring; each buffer spring is used for fixedly connecting the correspondingsupporting sleeve with the corresponding supporting rod; the left upper side of the processing box is provided with a feeding pipe; the upper end of the feeding pipe is provided with a feeding hopper; the upper end of the processing box is provided with a buffer storage box; and a driving motor is arranged at the upper end of the buffer storage box. The high-efficiency convective building concrete mixing device disclosed by the invention is simple and reasonable in structure and convenient to transfer, greatly improves the stirring and mixing effect of materials, can also reduce dust pollution and is high in practicability.

Owner:祝小攀

Method for making avocado salad sauce and water-phase premixing device

InactiveCN110447882AWon't change colorImprove stirring and mixing effectRotary stirring mixersTransportation and packagingCooking & bakingBeta-Carotene

The invention discloses a method for making an avocado salad sauce. After the iced egg liquid of the heat-stable egg yolk liquid is taken out of a warehouse, the outer packaging is removed and the material is placed in a special box for egg thawing, and drinking water is added to a water-phase premixing tank, stirring is started, white granulated sugar, heat-stable egg yolk liquid, brilliant blue,lemon yellow, beta-carotene, citric acid, avocado puree, disodium ethylenediaminetetraacetate, edible salt, steviol glycoside and sucralose are added, stirred and dissolved; soybean oil is added to an oil-phase premixing tank, the stirring is performed, and then the xanthan gum is added for uniform dispersion; an emulsifier is turned on for vacuum 500bar, the emulsification cycle is carried out,wherein an emulsification speed is 3000rpm / min; a bottom valve of the oil-phase premixing tank is opened, vacuum oil feeding is carried out, and an oil feeding speed is 60-80L / min, after the oil isfed, emulsification is continuously carried out for 85 seconds and the emulsification is turned off, stirring is carried out, the vacuum is adjusted to 100 bar, and vacuum degassing id carried out for4 minutes. The method has the beneficial effect that the product is resistant to baking.

Owner:JILIN JINYI FOOD CO LTD

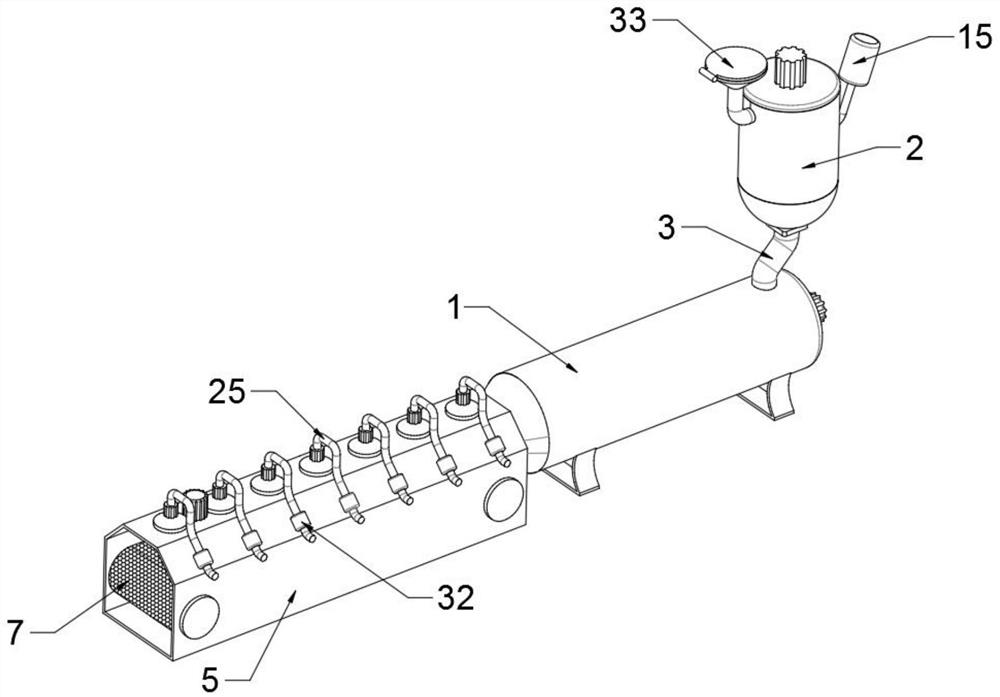

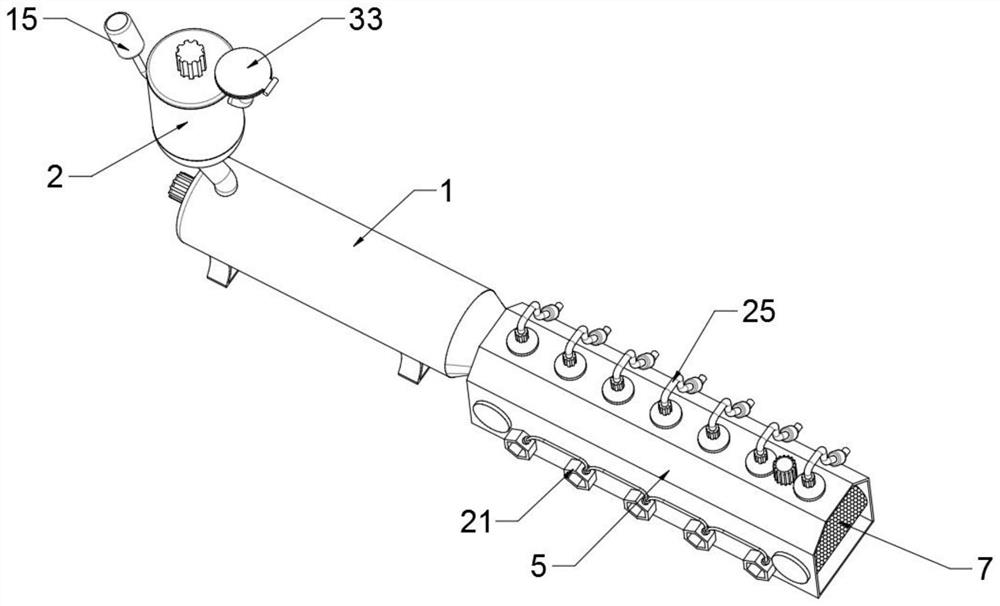

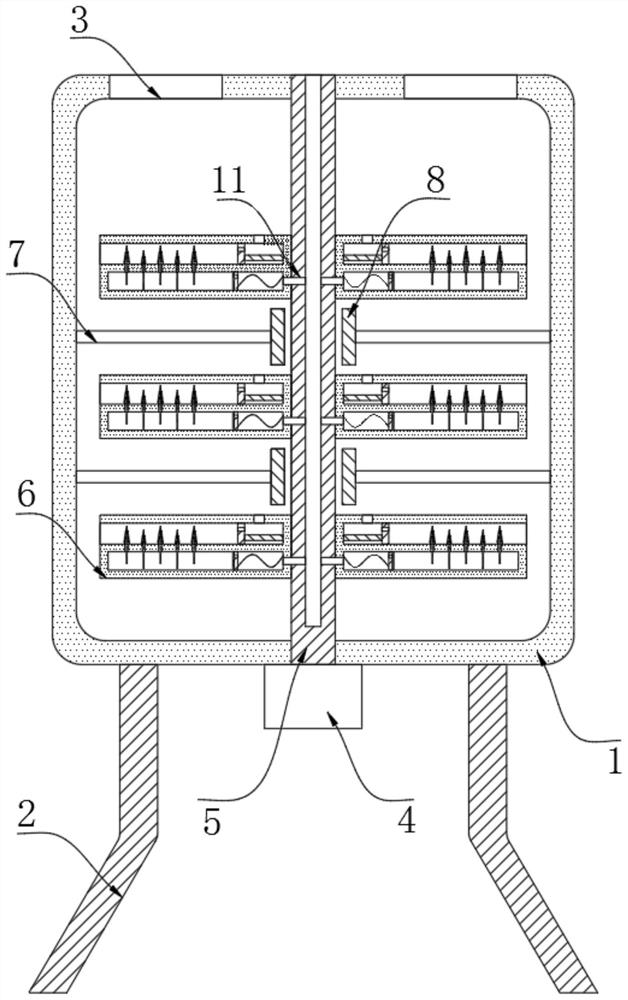

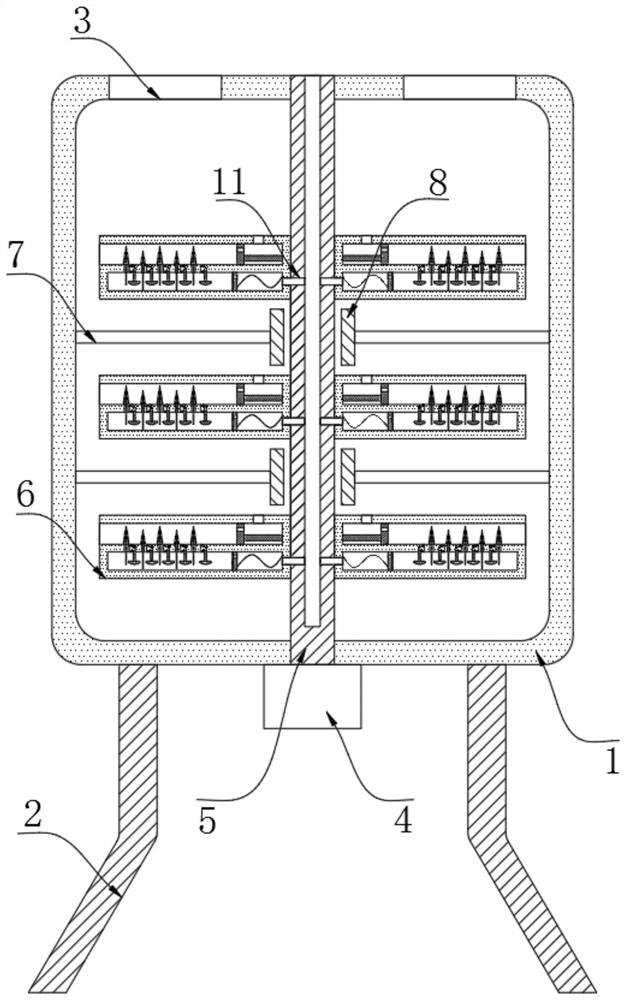

Livestock manure fertilizer recovery equipment

ActiveCN111848241AImprove the mixing effectPromote fermentationBio-organic fraction processingExcrement fertilisersAgricultural scienceLivestock manure

The invention relates to the technical field of treatment of livestock manure and specifically to equipment for recycling a fertilizer from livestock manure. The equipment comprises a transverse fermentation cylinder, wherein a stirring cylinder is arranged above one end of the transverse fermentation cylinder; a crushing and stirring assembly is arranged in the stirring cylinder; a liquid inlet pipe is fixedly connected to the side wall of the middle section of the stirring barrel; the upper end surface of the liquid inlet pipe is fixedly connected with a liquid storage tank; a valve is fixedly arranged on the liquid inlet pipe; a pushing assembly is arranged in the transverse fermentation cylinder; an extrusion assembly is fixedly connected to the end, away from the stirring cylinder, ofthe transverse fermentation cylinder; a conveying belt corresponding to the extrusion assembly in position is fixedly arranged on one side of the transverse fermentation cylinder; the conveying beltis covered with a closed channel; a drying assembly is arranged on the closed channel; and a cutting assembly is arranged at the end, away from the transverse fermentation cylinder, of the closed channel. With the equipment of the invention, manure can be smashed; after smashing is completed, fermentation treatment is conducted to form a fertilizer; the fertilizer is extruded, dried and cut into particles; and thus, recycling of livestock manure is effectively achieved, overall efficiency is high, and the quality of generated fertilizer particles is high.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Mixing and defoaming equipment for water paint processing

InactiveCN112742240AImprove stirring and mixing effectReduce the difficulty of subsequent processingRotary stirring mixersTransportation and packagingReciprocating motionElectric machinery

The invention discloses a mixing and defoaming equipment for water paint processing. The mixing and defoaming equipment comprises a stirring box, a support is fixed to the bottom of the stirring box, a discharging opening is formed in the upper end of the stirring box, a motor is fixed to the bottom of the stirring box, a rotating shaft is fixed to an output shaft of the motor, and a plurality of stirring blades are fixed to the circumferential side wall of the rotating shaft; a plurality of fixing rods are fixed to the inner wall of the stirring box, a magnetic block is fixed to the end of each fixing rod, and a bubble removing groove is formed in the side wall of each stirring blade. The equipment has the advantages that by arranging a telescopic rod and the magnetic blocks, in the rotating and stirring process of the stirring blades, the telescopic rod does reciprocating telescopic motion under the action of the magnetic blocks, so that a push plate does reciprocating motion, and raw materials in the center of the stirring box enter the bubble removing groove from the inner inlet and are conveyed to the edge position of the stirring box; the raw materials at the center and the edge positions are exchanged, so that the stirring and mixing effects are improved.

Owner:武汉积墨包装印刷有限公司

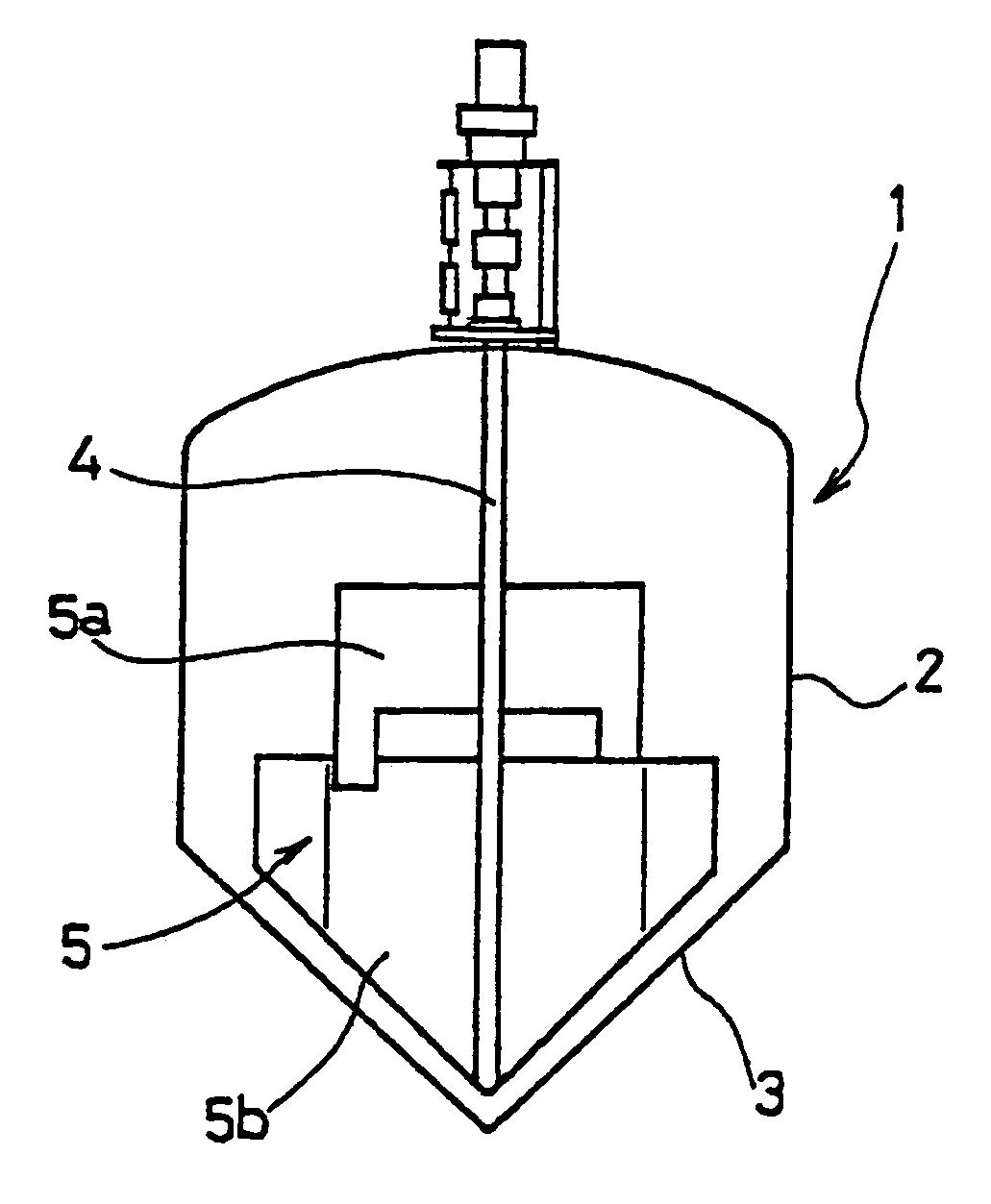

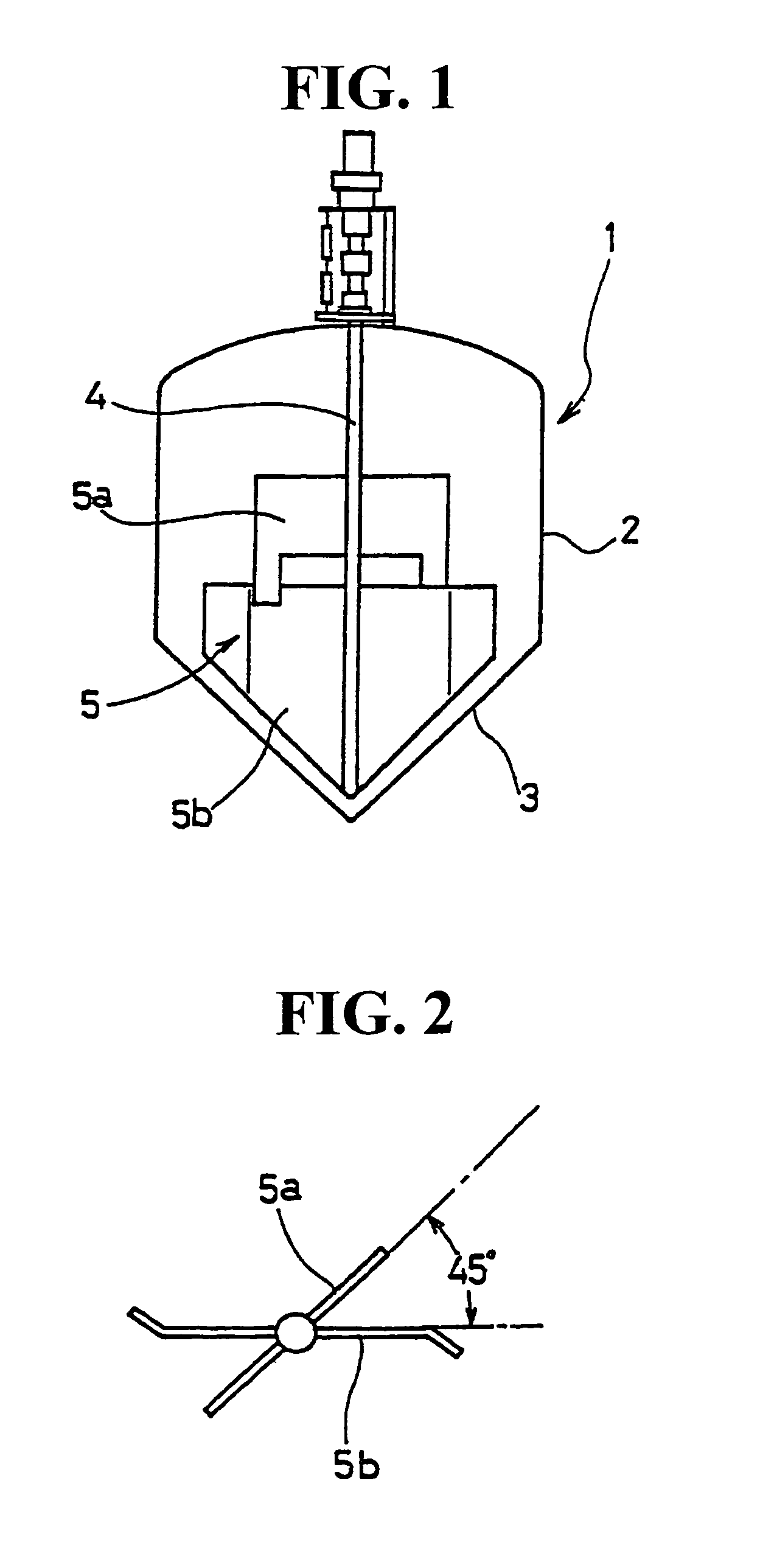

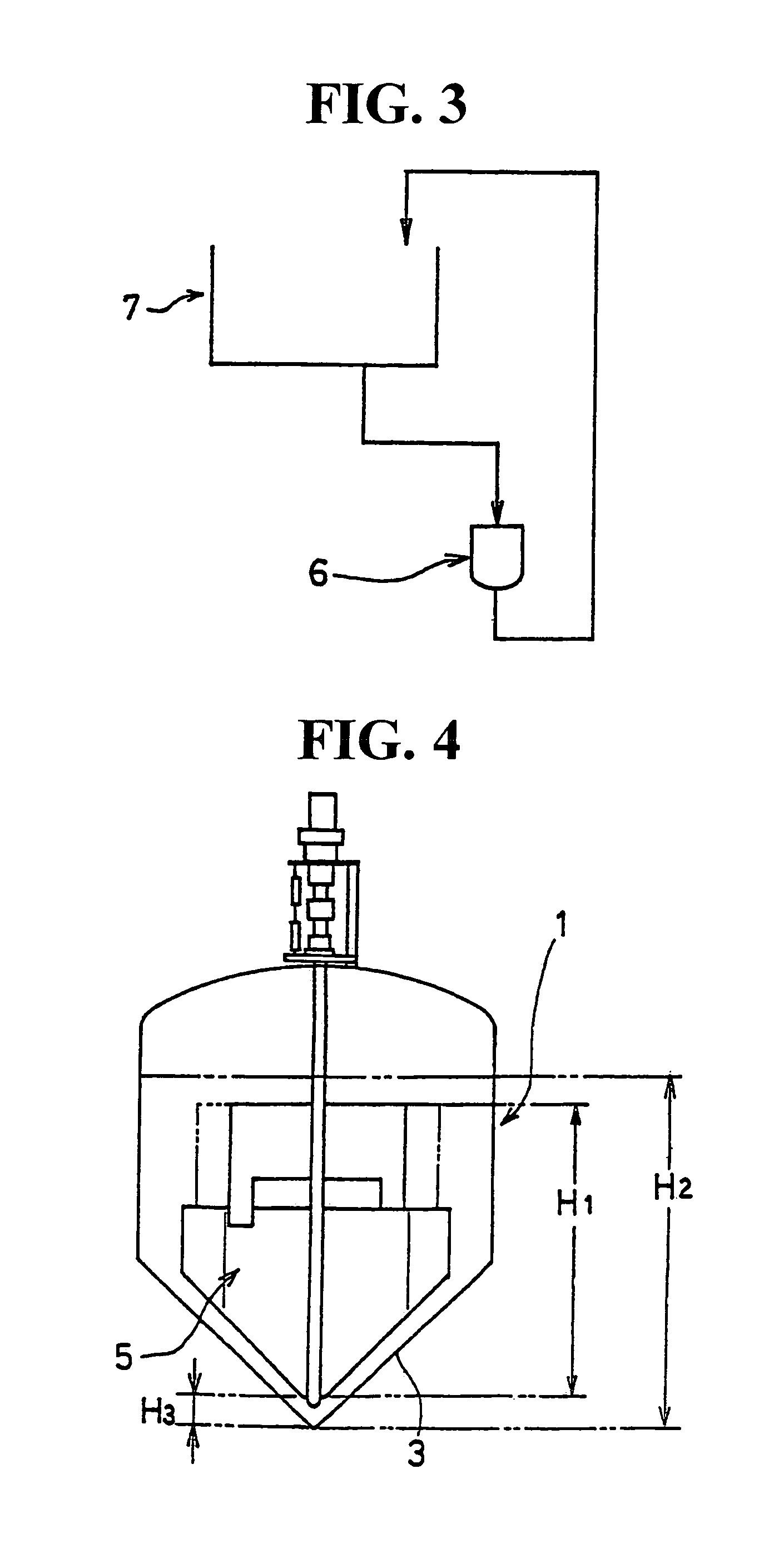

Agitation tank for storing beer yeast slurry

InactiveUS7368283B1Inhibit deteriorationProtection from damageBioreactor/fermenter combinationsBiological substance pretreatmentsYeastImpeller

Owner:ASAHI BREWERIES LTD

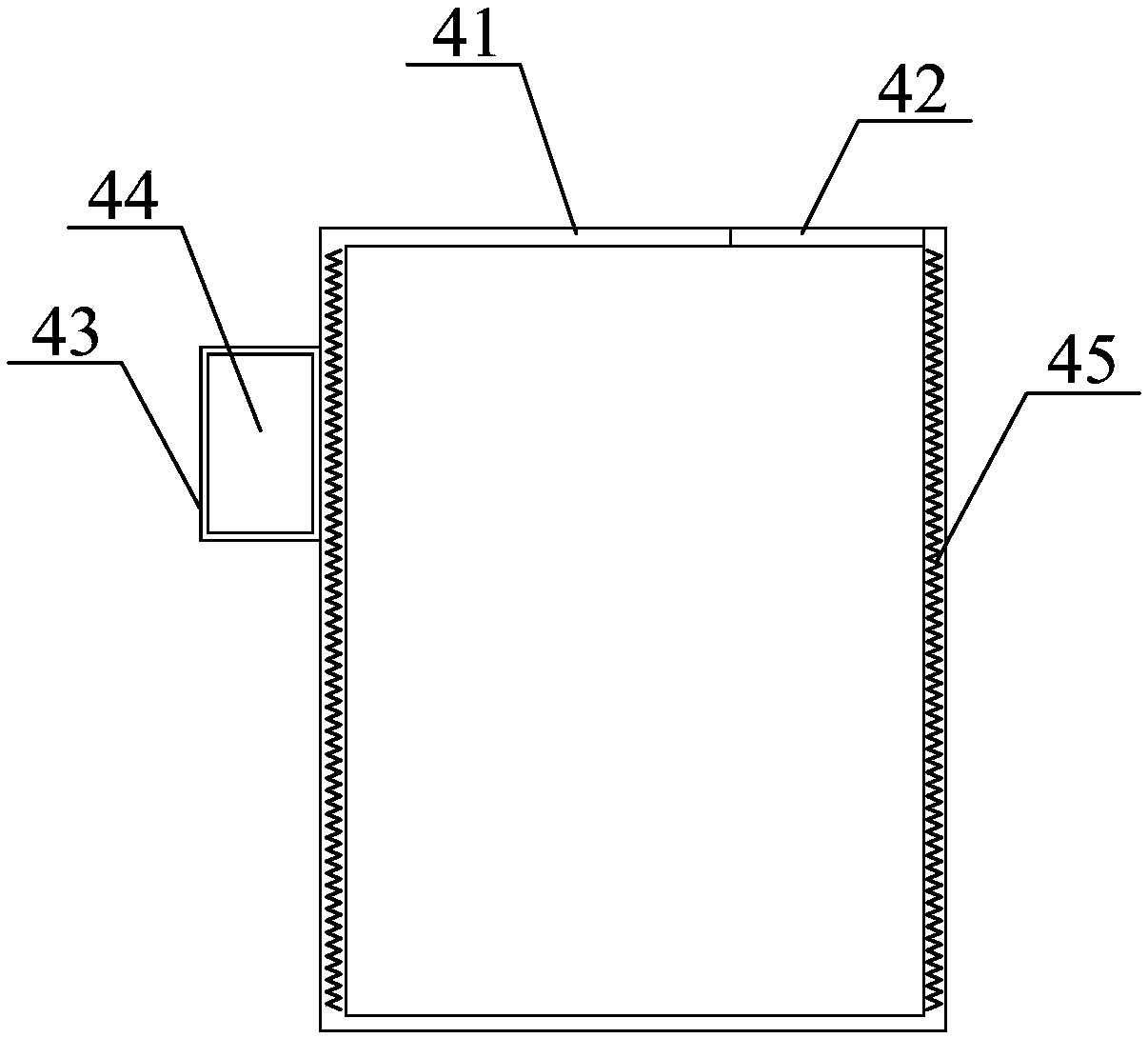

Novel aquaculture feed mixing device convenient to move

InactiveCN108579507AEasy to sendImprove mixing efficiencyFeeding-stuffTransportation and packagingElectricityEngineering

The invention provides a novel aquaculture feed mixing device convenient to move. The feed mixing device comprises a feed inlet hopper, a protective cover, a stirring mixing device, a drying heat-insulating shell structure, a temperature-humidity sensor, a feed guide frame, a slot, a partition plate, a trapezoidal rubber block, a handle, a feed guide plate and an adjustable bottom wheel structure,wherein a bolt of the feed inlet hopper is installed at the upper left part of the stirring mixing device. Through arrangement of spiral auger blades, upward conveying of the aquaculture feed is conducted conveniently, and by further combining arrangement of stirring blades, the efficiency of stirring and mixing is improved; through arrangement of a temperature controller and an electric heatingwire, improvement of a heating drying effect on the aquaculture feed in a stirring outer frame is facilitated, so that the aquaculture feed in the stirring outer frame is prevented from being exposedto moisture and damaged; through arrangement of threads of a thread rod and an adjusting nut, adjustment of the connected length of the thread rod to the outer side of the adjusting nut in an insertedmode can be facilitated according to use requirements, and by combining arrangement of universal bottom wheels, movement of the feed mixing device can be facilitated when movement is needed.

Owner:LIUZHOU WENHUA BREEDING FARM

Mixing device for production of bubble bricks

InactiveCN109895254ASmooth rotationAvoid CatonMixing operation control apparatusCement mixing apparatusBrickMixed materials

The invention discloses a mixing device for production of bubble bricks. The mixing device comprises a mixing box, a first motor is fixedly connected to the middle of the right side face of the mixingbox, a first sealed bearing is fixedly inlaid in the middle of the right side face of the mixing box, a stirring shaft is fixedly connected to the output end of the first motor, and the end, away from the first motor, of the stirring shaft penetrates through the first sealed bearing and extends into the mixing box. According to the mixing device for production of the bubble bricks, materials needing to be mixed can be guided into a crushing box, the guided-in materials can be crushed, the situation that large blocks of materials exist in the mixed materials, and consequently the production quality is affected is avoided, rotation jamming of a transmission rod in the using process can be avoided, the crushed materials are guided into the mixing box to be mixed and stirred, the problem thatthe materials on a bottom layer cannot be stirred is avoided, the stirring and mixing effects of the mixing device are improved, and the mixing box can be sealed and discharges the materials better.

Owner:扬州慕星新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com