Powdery and granular garbage stirrer

A technology of powder and granule and mixer, which is applied in the directions of mixer, mixer with rotating container, mixing method, etc., can solve the problem of inability to take into account the production efficiency and the uniformity of mixing, the flying of additives and garbage powder and granule, and the unsatisfactory effect. and other problems, to achieve the effect of high production efficiency, large processing capacity and high contact probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

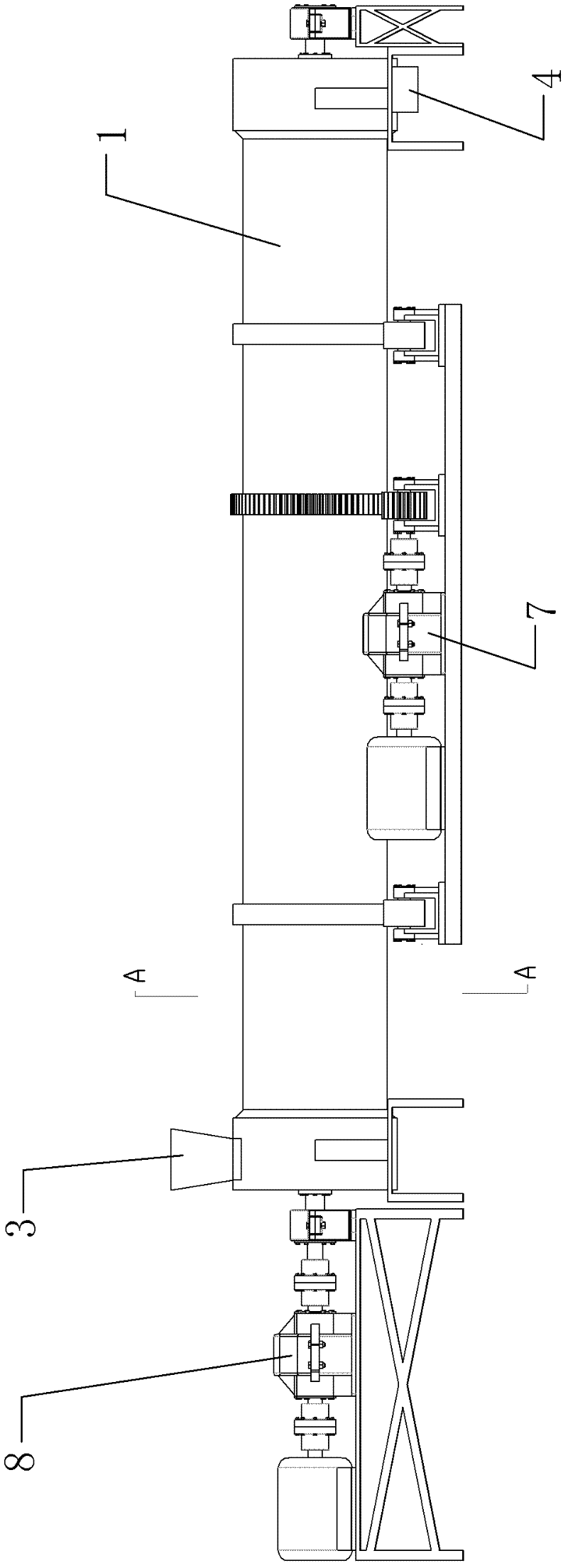

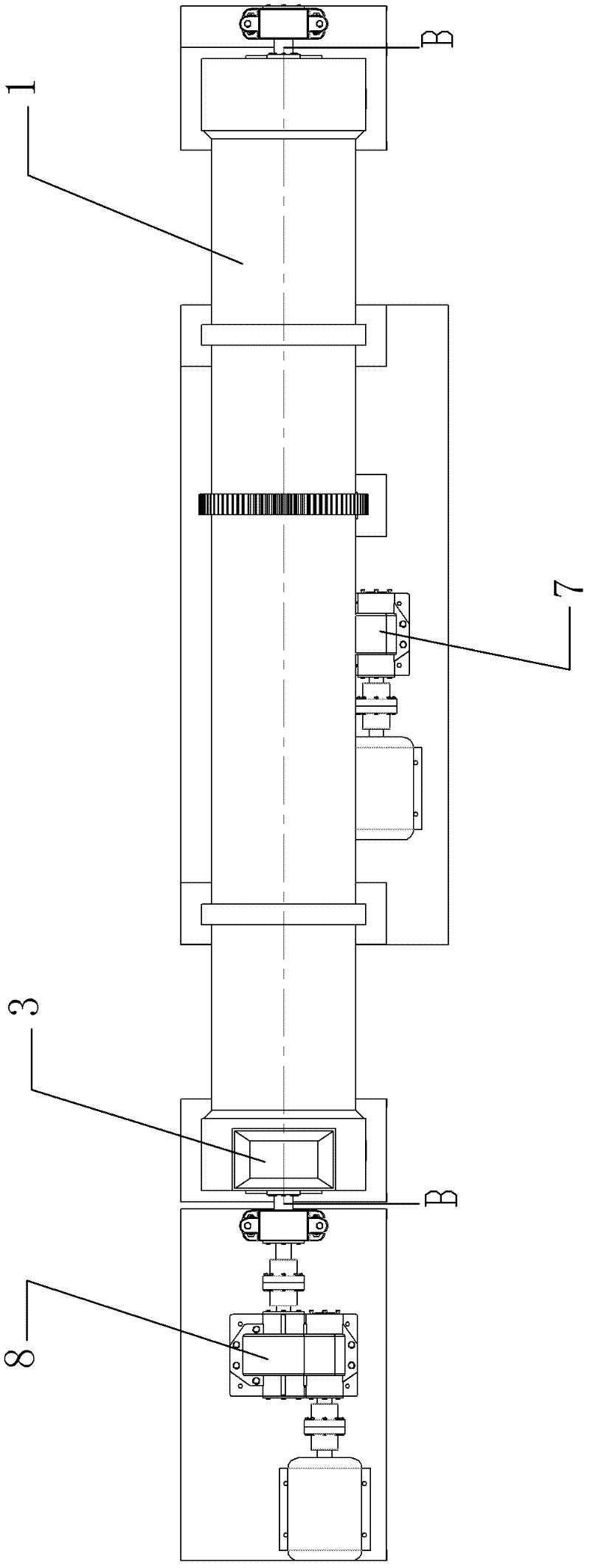

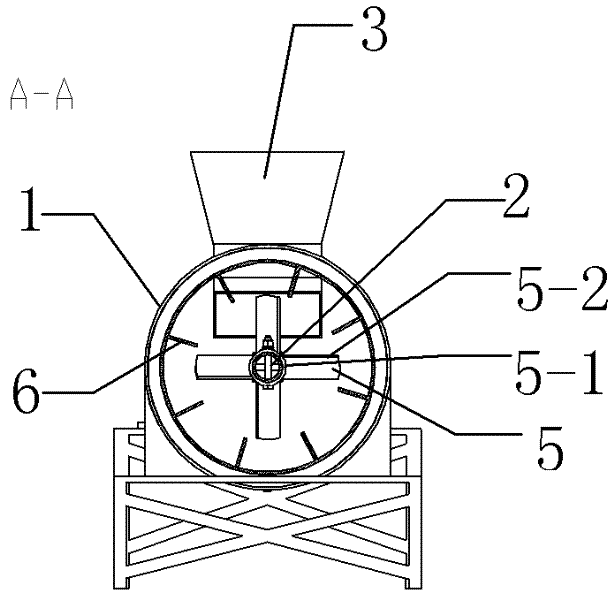

[0019] Such as figure 1 , figure 2 Shown, a kind of mixer of powdery and granular garbage of the present invention comprises a mixing drum (1), a mixing drum transmission device (7) connected with the mixing drum (1), a stirring shaft (2) and a mixing shaft (2) connected Stirring shaft transmission (8), stirring drum (1) and stirring shaft (2) are driven by stirring drum transmission (7) and stirring shaft transmission (8) respectively; Described mixing drum (1) and stirring shaft (2) ) is arranged horizontally, the mixing drum (1) is set outside the stirring shaft (2), and the mixing drum (1) is concentric with the stirring shaft (2), but rotates in the opposite direction; the upper part of one end of the mixing drum (1) is equipped with The feed port (3) is provided with a discharge port (4) at the lower part of the other end; the stirring shaft (2) is fixedly equipped with a plurality of impellers (5) equidistantly along its axial direction.

[0020] Such as Figure 4 S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com