Patents

Literature

66results about How to "Taking into account production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

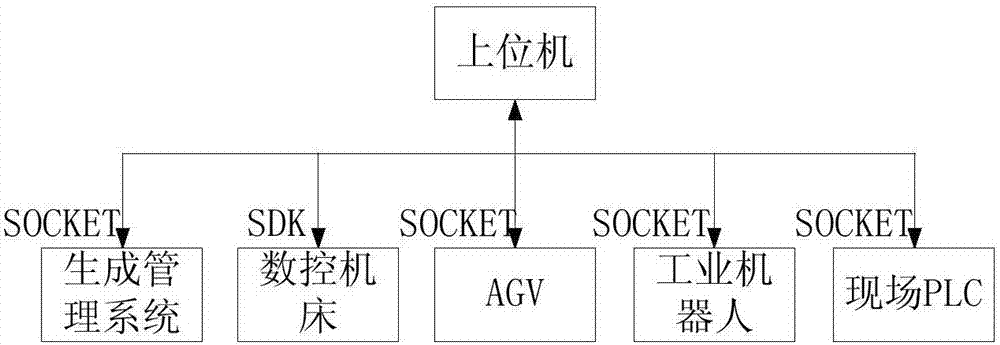

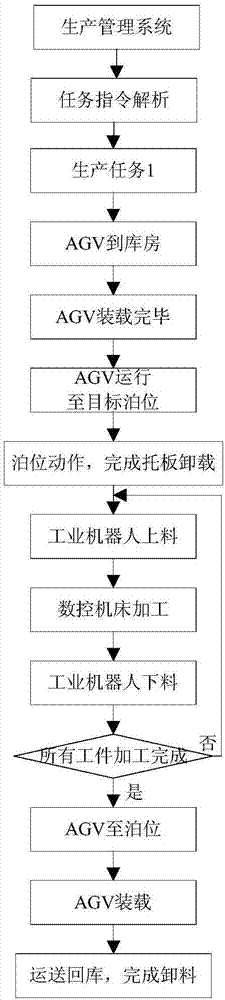

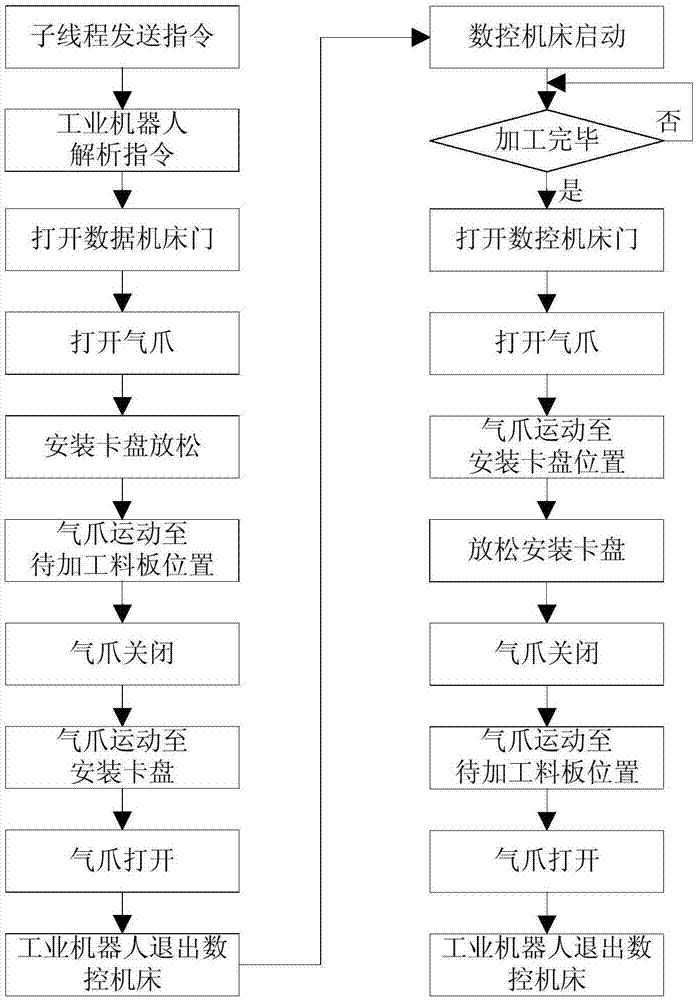

Automatic production line task scheduling method

ActiveCN107272630AEasy to set upEasy to transformElectric/hybrid propulsionTotal factory controlProduction lineNumerical control

The invention relates to an automatic production line task scheduling method. With an Ethernet communication interface, network connection is formed based on a TCP / IP protocol to realize automatic control and scheduling of a numerically-controlled machine tool, an industrial robot and an AGV. A main thread is established in an upper computer; for a production task issued by a production management system, a sub thread is started to schedule the AGV to a warehouse to transport to-be-processed material plates stacked at a unified tool to a place specially for AGV parking in front of the numerically-controlled machine tool; unloading is carried out by automatic parking and the AGV returns; the sub thread commands the industrial robot to complete feeding to the numerically-controlled machine tool; after feeding by the industrial robot, the numerically-controlled machine tool is started to carry out part processing; after completion of the parts by the numerically-controlled machine tool, the industrial robot lays off the parts to an original capturing device; and after completion of all parts, the AGV is scheduled to move the processed workpieces to the warehouse.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

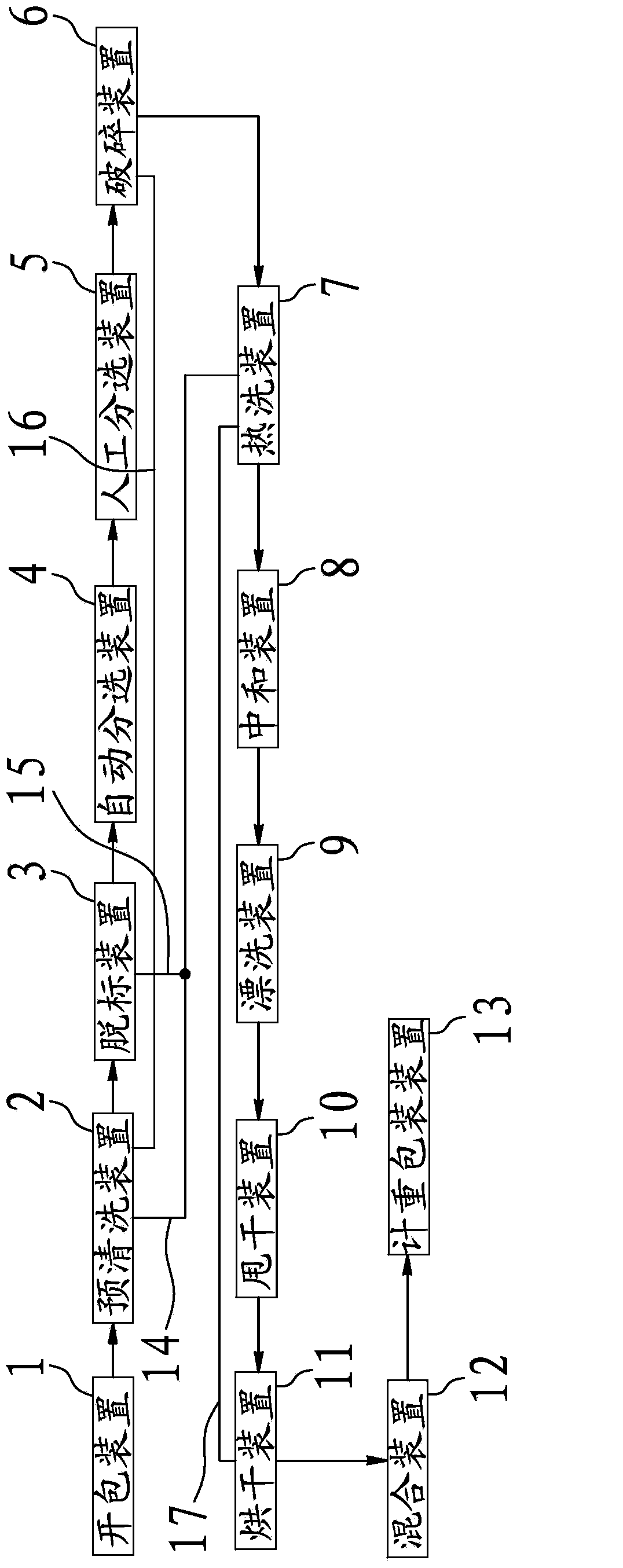

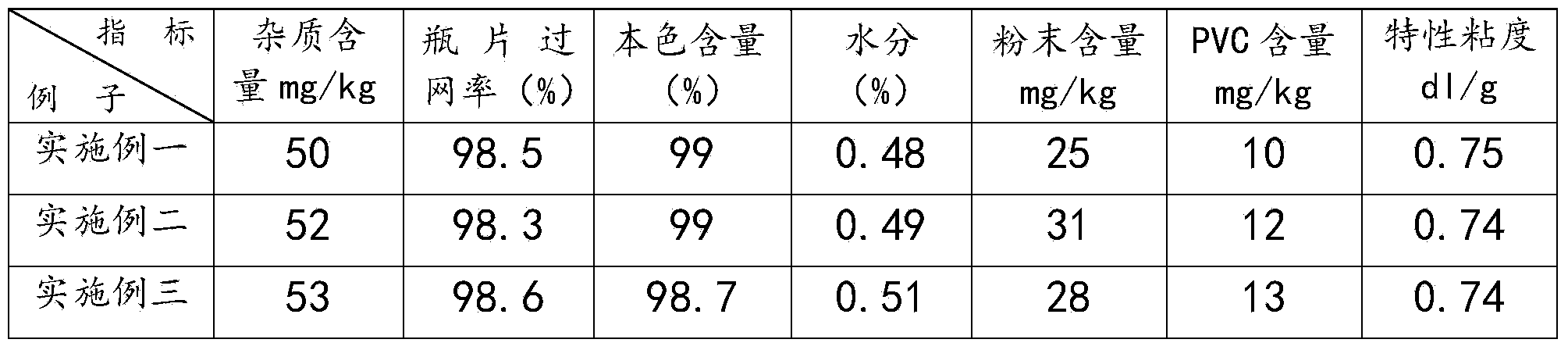

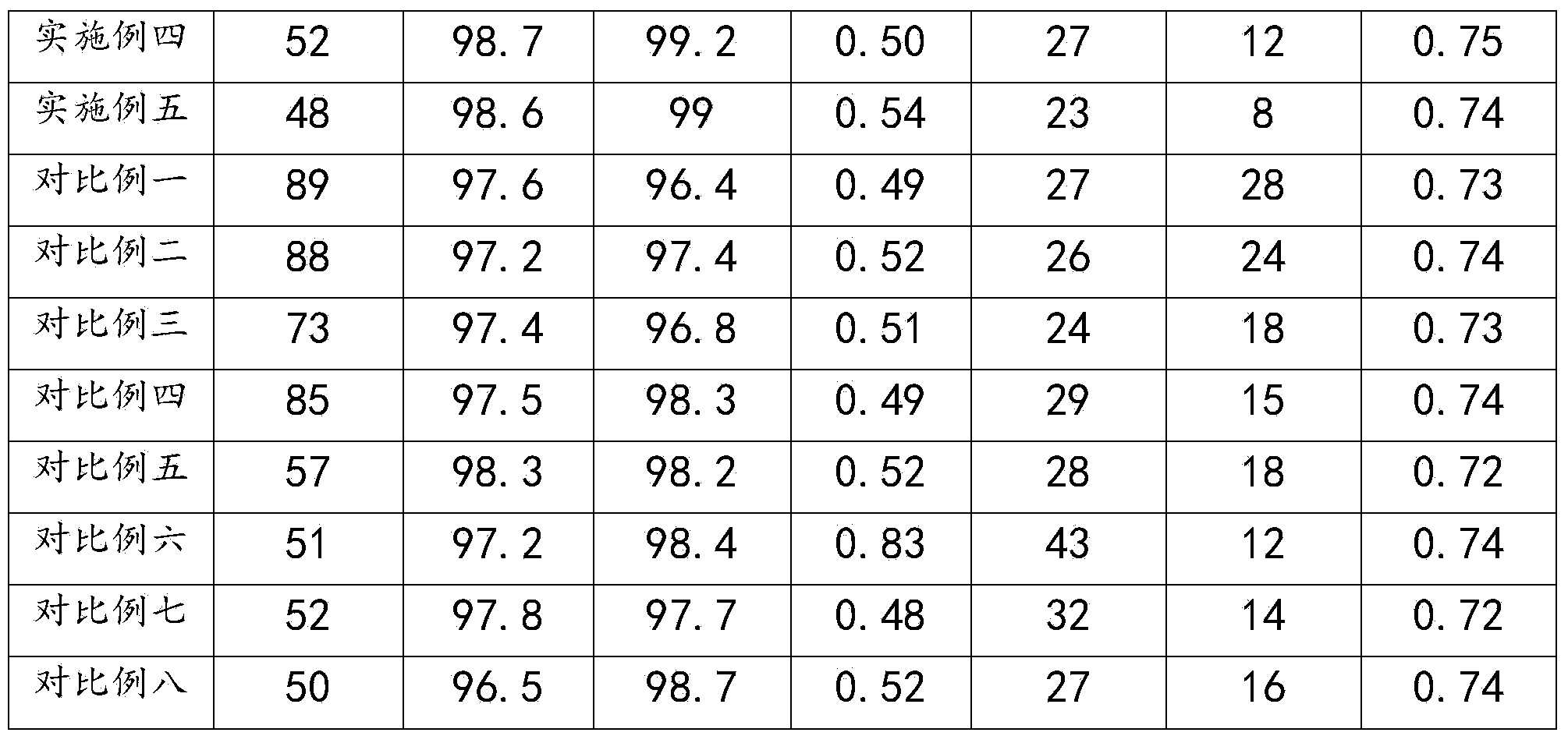

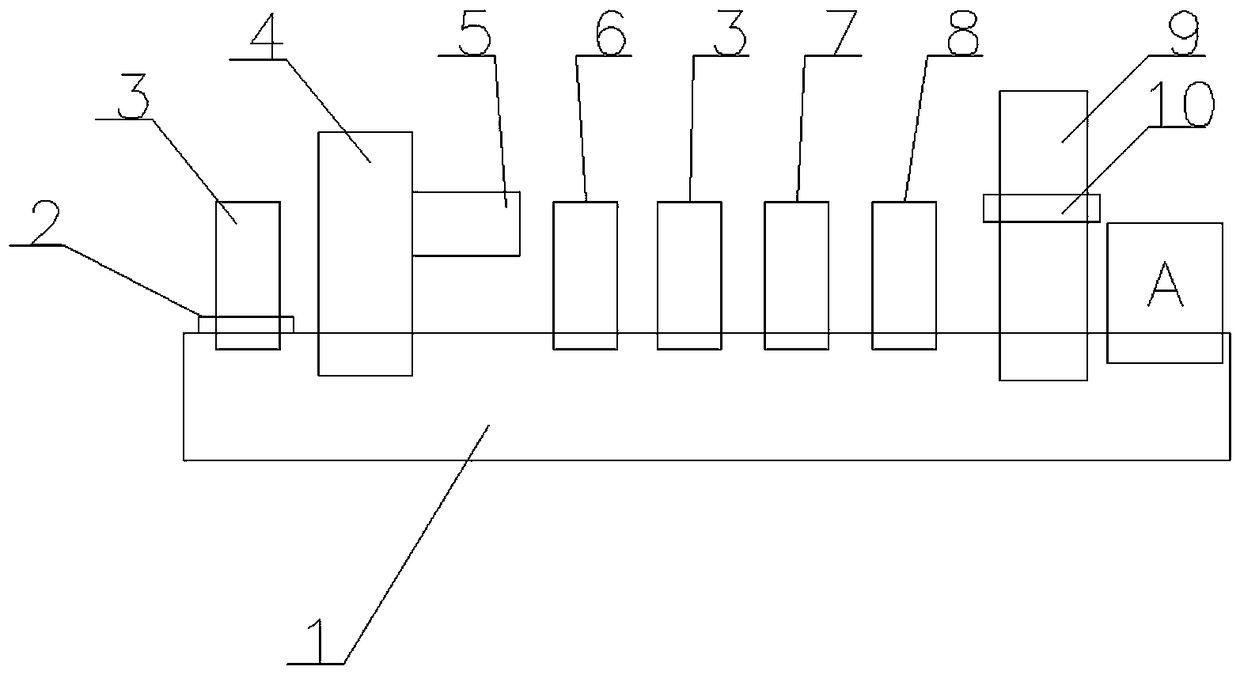

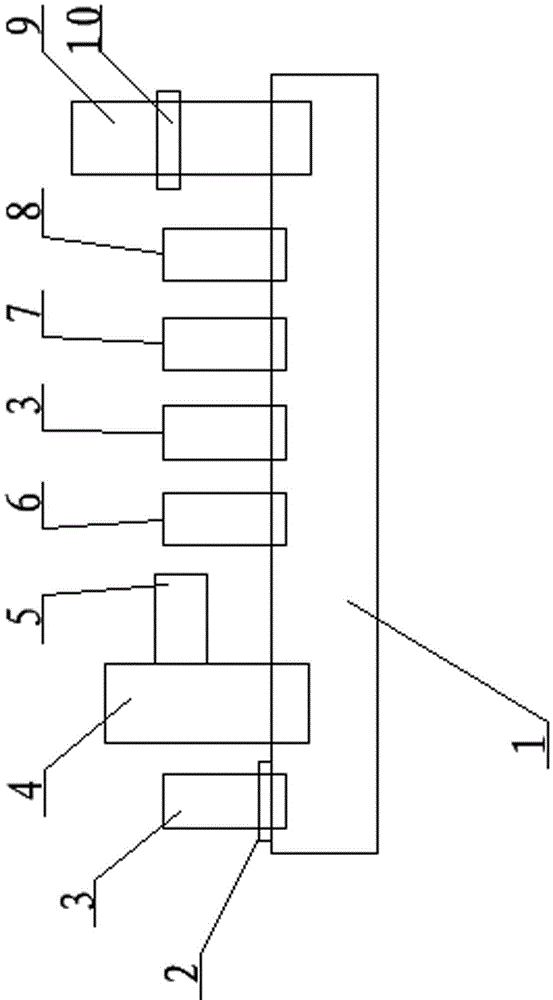

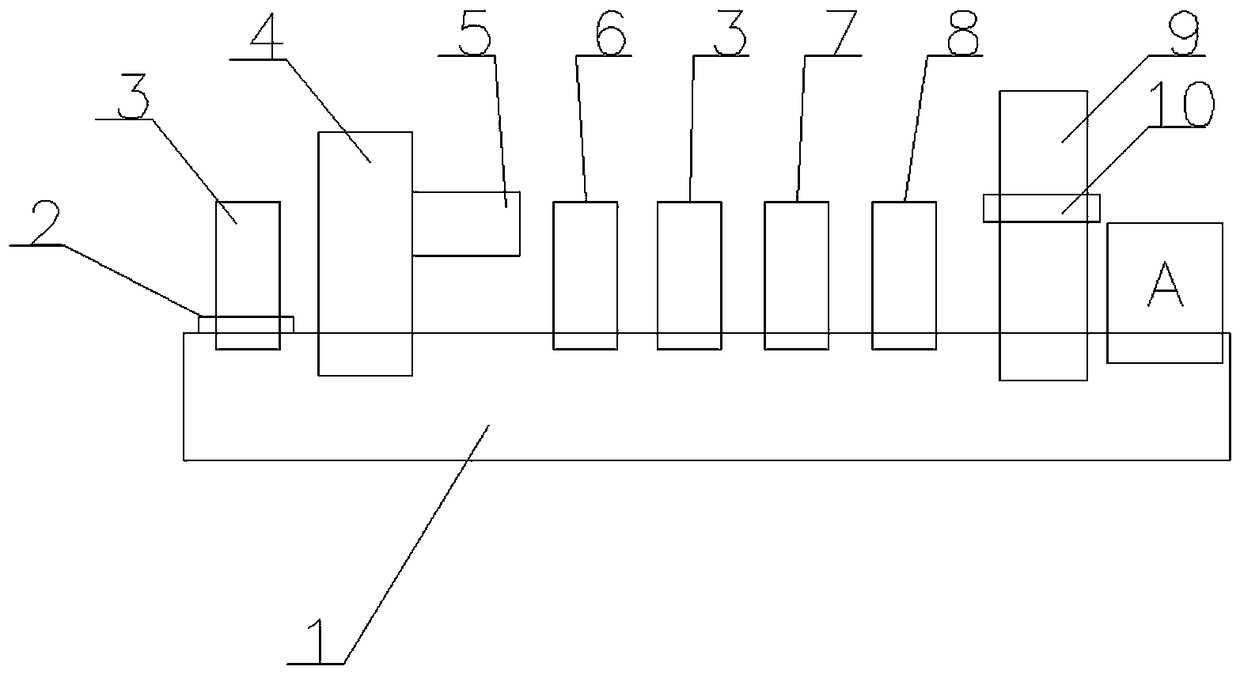

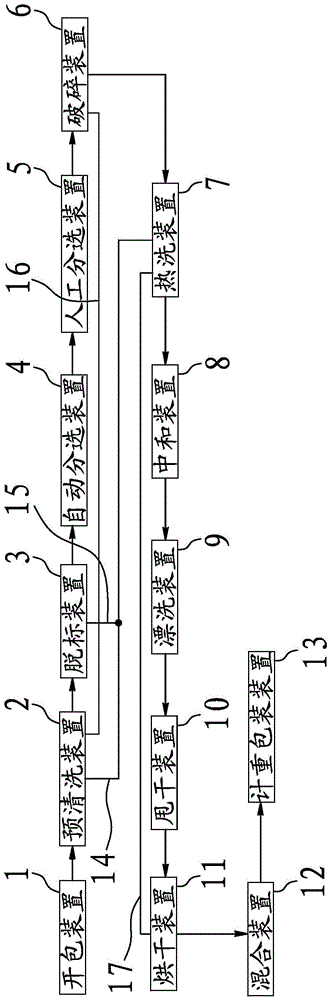

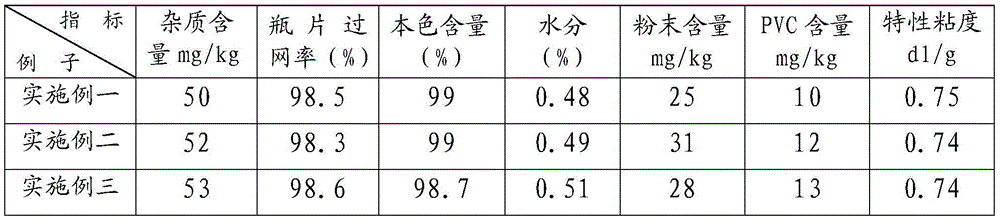

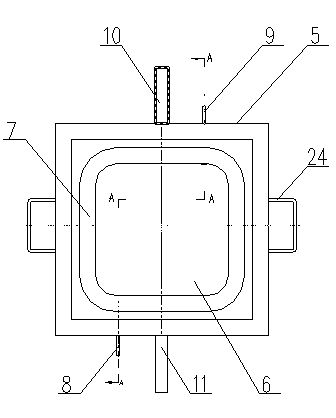

Cleaning process and production line of PET (polyethylene terephthalate) bottle sheets

InactiveCN103640111AImprove product qualityImprove energy efficiencyPlastic recyclingCleaning using liquidsPollutantProcess engineering

The invention discloses a cleaning process and a production line of PET (polyethylene terephthalate) bottle sheets. The cleaning process comprises the following steps of unpacking PET bottles, carrying out primary impurity removing by utilizing a whole bottle pre-cleaning device, removing labels from the PET bottles by utilizing a label removing device, removing heterochromous bottles and the bottles which are not made of PET materials by utilizing a sorting device, carrying out manual sorting by using a manual sorting platform, crushing by utilizing a crushing device, carrying out thermal cleaning by utilizing a thermal boiling boiler, neutralizing by utilizing a neutralizing tank, rinsing by utilizing a rinsing device, carrying out spin drying, drying by utilizing a drying cylinder, mixing, weighing and packaging, thus finishing the cleaning. According to the cleaning process, in full consideration of problem that too many impurities and pollutants exist in recycled PET bottles, various devices in a production process are adaptively transformed to be fit for the cleaning of the PET bottle sheets; the bottle sheets produced by utilizing the cleaning process and the production line can completely meet subsequent production and processing requirements, and the quality of the bottle sheets is improved; by utilizing a steam recycling system and the continuous spin-drying and drying operations, the energy utilization ratio can be greatly improved, the subsequent production and processing costs are lowered, and the cleaning process and the production line have wide social generalization significances.

Owner:福建鑫华股份有限公司

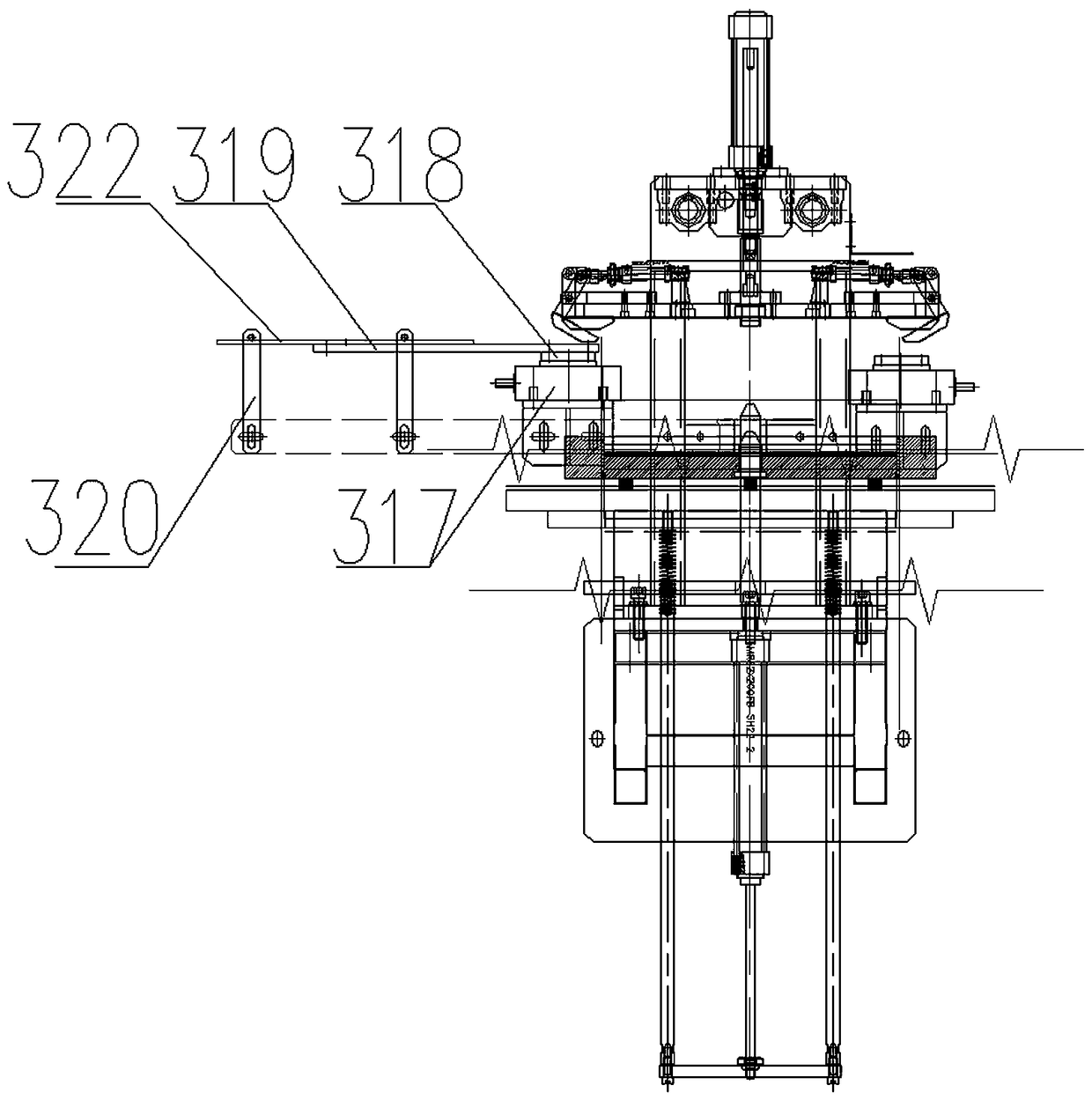

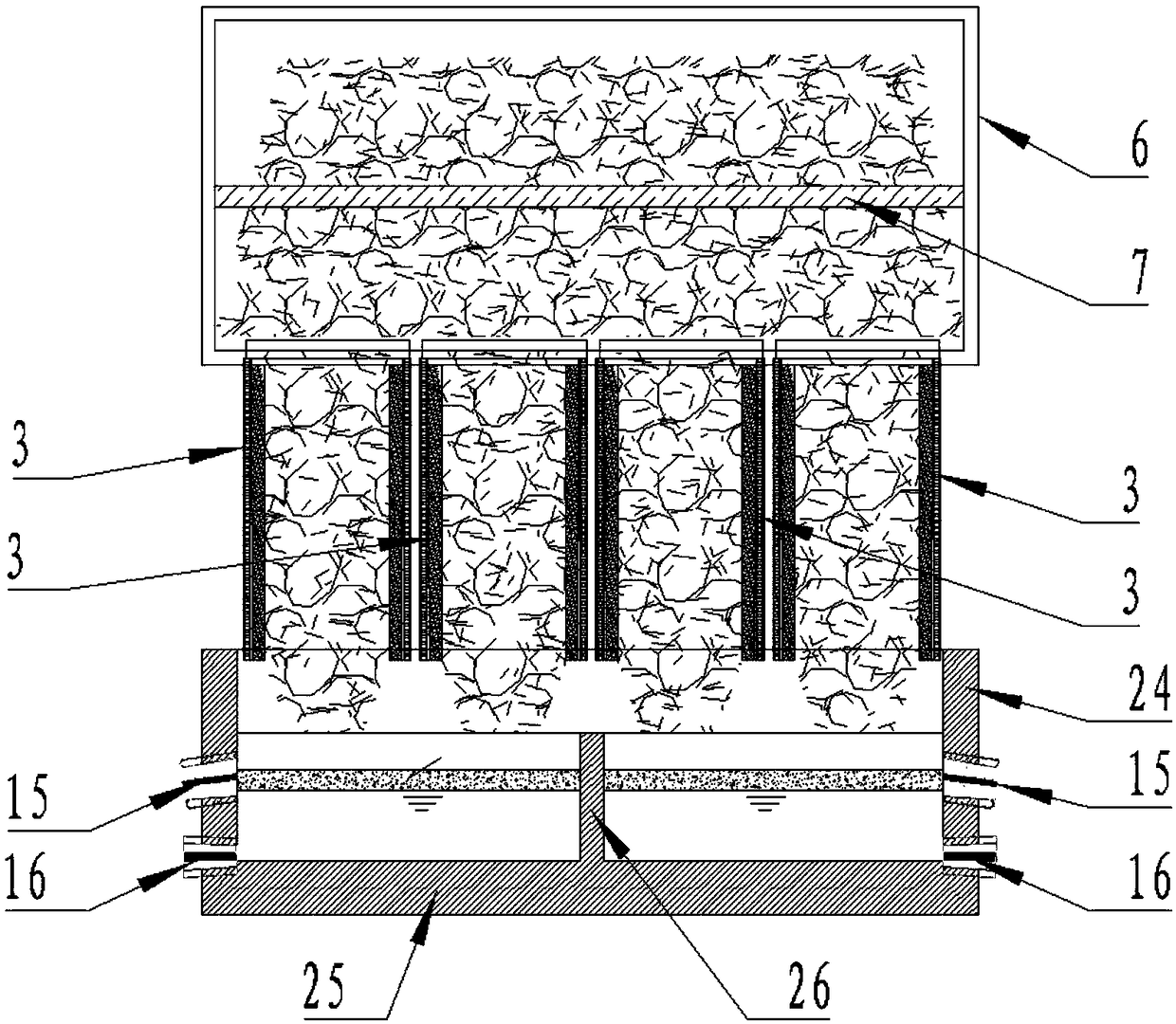

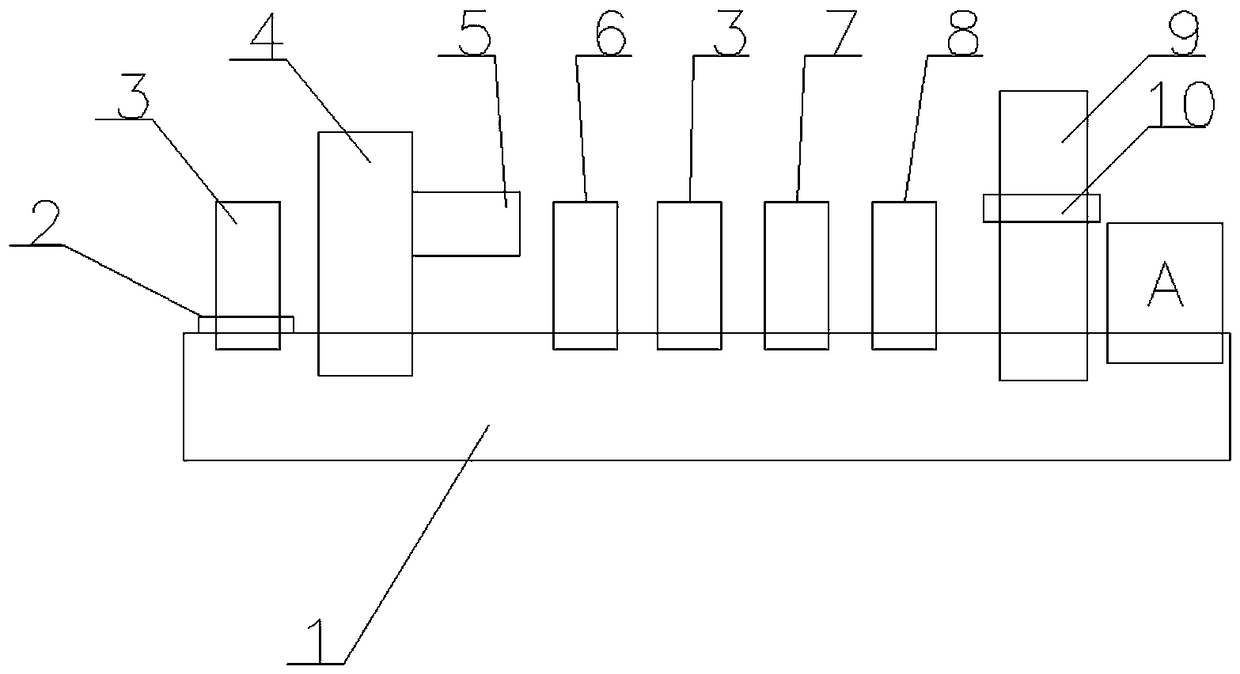

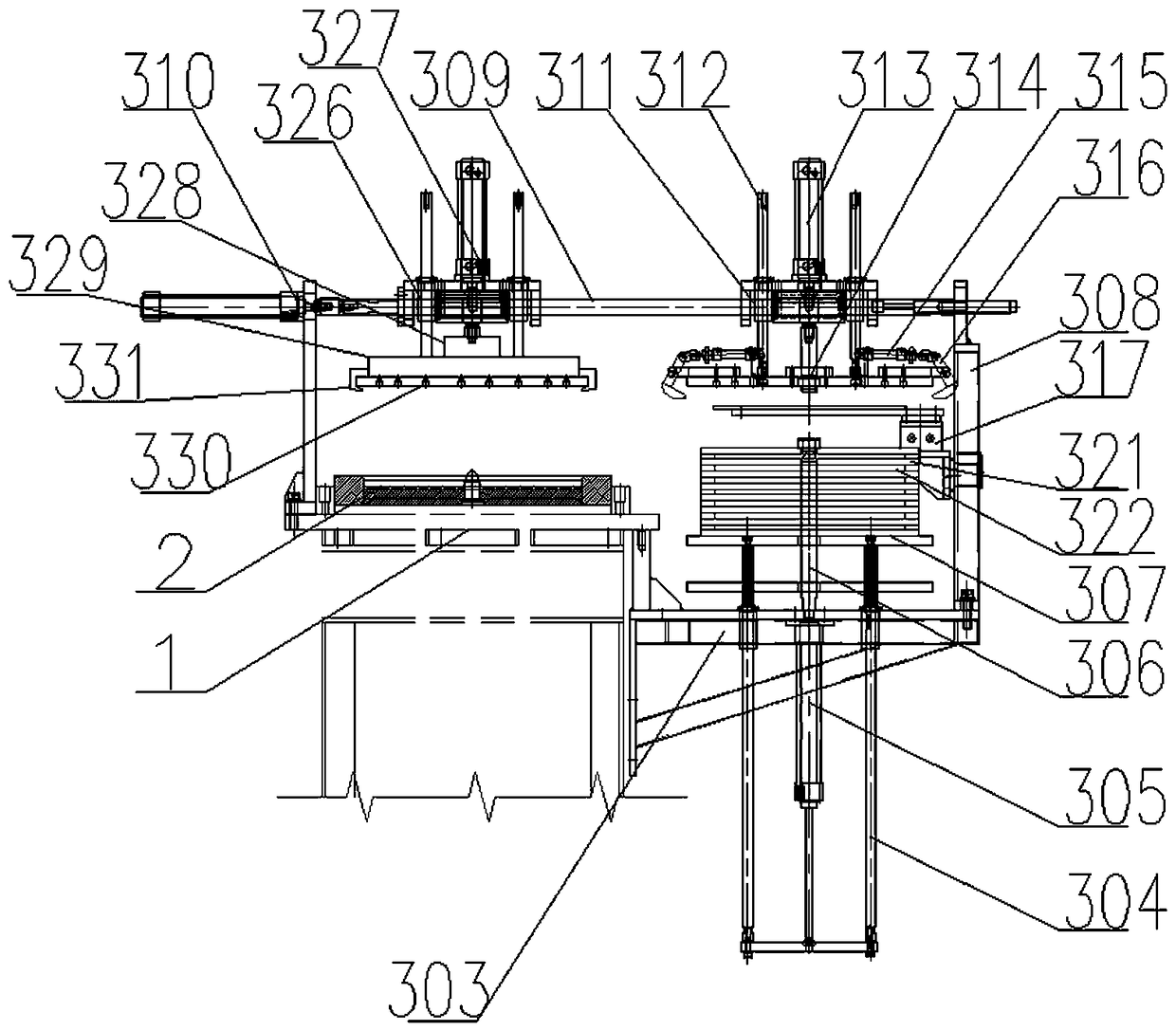

Automatic production line for high-precision grinding wheel

InactiveCN109048701AWell mixedAvoid overfeeding all the timeGrinding devicesProduction lineEngineering

The invention relates to an automatic production line for a high-precision grinding wheel. The automatic production line comprises a grinding wheel forming die and further comprises a lower mesh containing system, a feeding system, a charging system, a material scraping system, an upper mesh containing system, a mesh pressing system, a core ring containing system, a die pressing machine and a demoulding device, all of which are arranged on a production track. The grinding wheel forming die is arranged on the production track and conveyed, and lower mesh containing, feeding, charging, flat material scraping, upper mesh containing, mesh pressing flattening, core ring containing, die pressing forming and demoulding are sequentially finished. The automatic production line is high in automationdegree, feeding is convenient, charging is stable and uniform, meshes are flatly placed, raw materials in the die are uniform, and the grinding wheel die pressing forming quality can be better improved.

Owner:张和庆

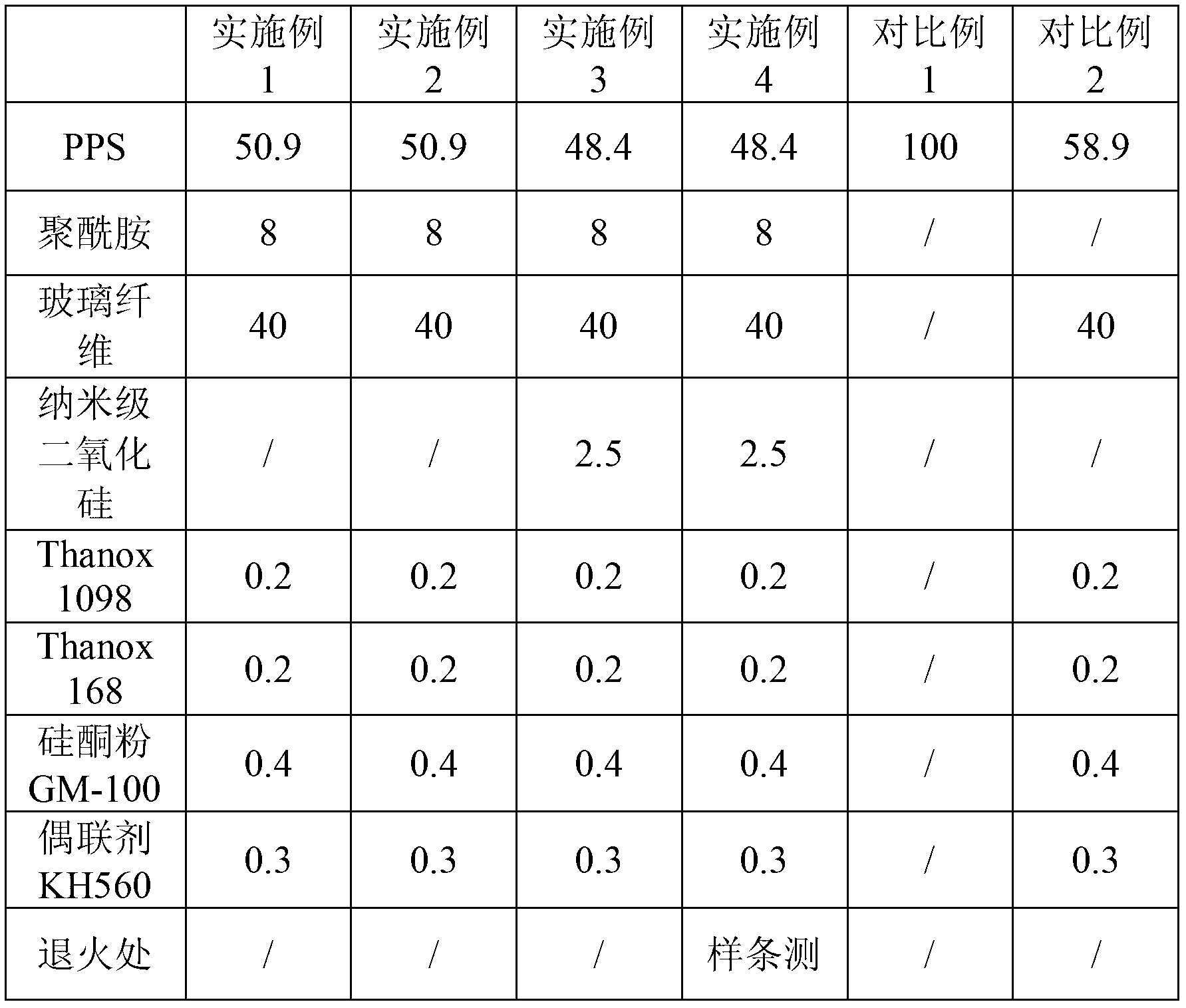

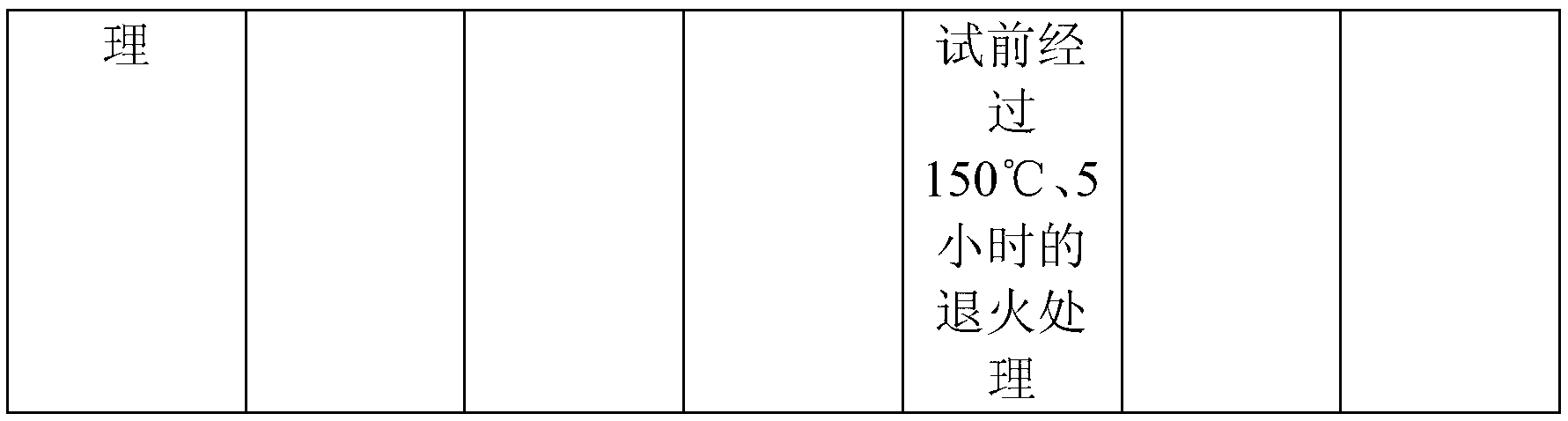

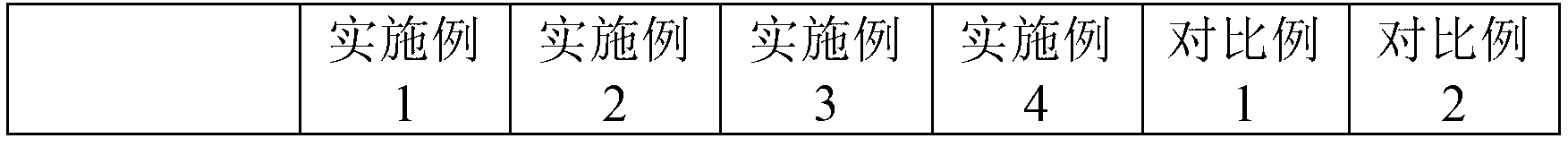

Polyphenylene sulfide composite material, preparation method and molding method thereof

The present invention discloses a polyphenylene sulfide composite material, a preparation method and a molding method thereof. The polyphenylene sulfide composite material comprises the following components, by weight, 21-62% of polyphenylene sulfide, 1-8% of polyamide, 34-65% of an inorganic reinforcement material, 0.05-2% of an antioxidant, and 0.05-4% of a processing additive. The present invention further discloses a preparation method for the polyphenylene sulfide composite material, wherein the preparation method comprises: placing polyphenylene sulfide and polyamide into a blast drying box to dry, placing the pre-dried polyphenylene sulfide, the pre-dried polyamide, an antioxidant and a processing additive into a high speed mixer to uniformly mix and stir to obtain a premix, feeding the premix from a main feeding port, feeding an inorganic reinforcement material from a side feeding port, and carrying out melt extrusion, cooling, and pelletizing with a twin-screw extruder. The present invention further discloses a molding method for the polyphenylene sulfide composite material, wherein the molding method comprises: placing the polyphenylene sulfide composite material in a blast dryer to dry, and then carrying out injection molding to obtain the finished product. The composite material has high mechanical property, and can be used for rapid injection molding. The molding method has a characteristic of annealing eliminating so as to save processes.

Owner:CGN JUNER NEW MATERIALS +1

High-energy-ratio low-internal-resistance cylindrical lithium ion battery

InactiveCN105742721ALower internal resistanceImprove performanceFinal product manufactureCylindrical casing cells/batteryElectricityInternal resistance

The invention discloses a high-energy-ratio low-internal-resistance cylindrical lithium ion battery. The lithium ion battery comprises a cell, wherein the cell comprises a positive plate, a negative plate, an inner diaphragm and an outer diaphragm; the blank foil regions, used as conductive tabs, on the positive plate and the negative plate are positioned at the two ends of the cell respectively; the inner diaphragm, a material-coating region of the negative plate, the outer diaphragm, and a material-coating region of the positive plate are laminated and coiled in sequence to form the cell; and the two ends of the cell are ultrasonically kneaded to form full tabs. According to the high-energy-ratio low-internal-resistance cylindrical lithium ion battery provided by the invention, the positive electrode and the negative electrode take the blank foil regions of the positive plate and the negative plate as the conductive tabs; due to the full tab ultrasonic kneading design, the dense and compacted full tabs which can be subjected to subsequent laser welding conveniently are formed on the electrodes at the two ends of the cell; therefore, the internal resistance of the battery is greatly reduced, and the performance of the battery is improved; due to the coiling way, the efficiency of productivity is taken into consideration as well; and in addition, the lithium ion battery is simple in overall coiled cell design, excellent in electrical performance, high in productivity, and high in practicability.

Owner:GUOXUAN NEW ENERGY SUZHOU CO LTD

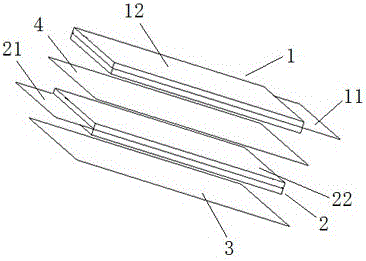

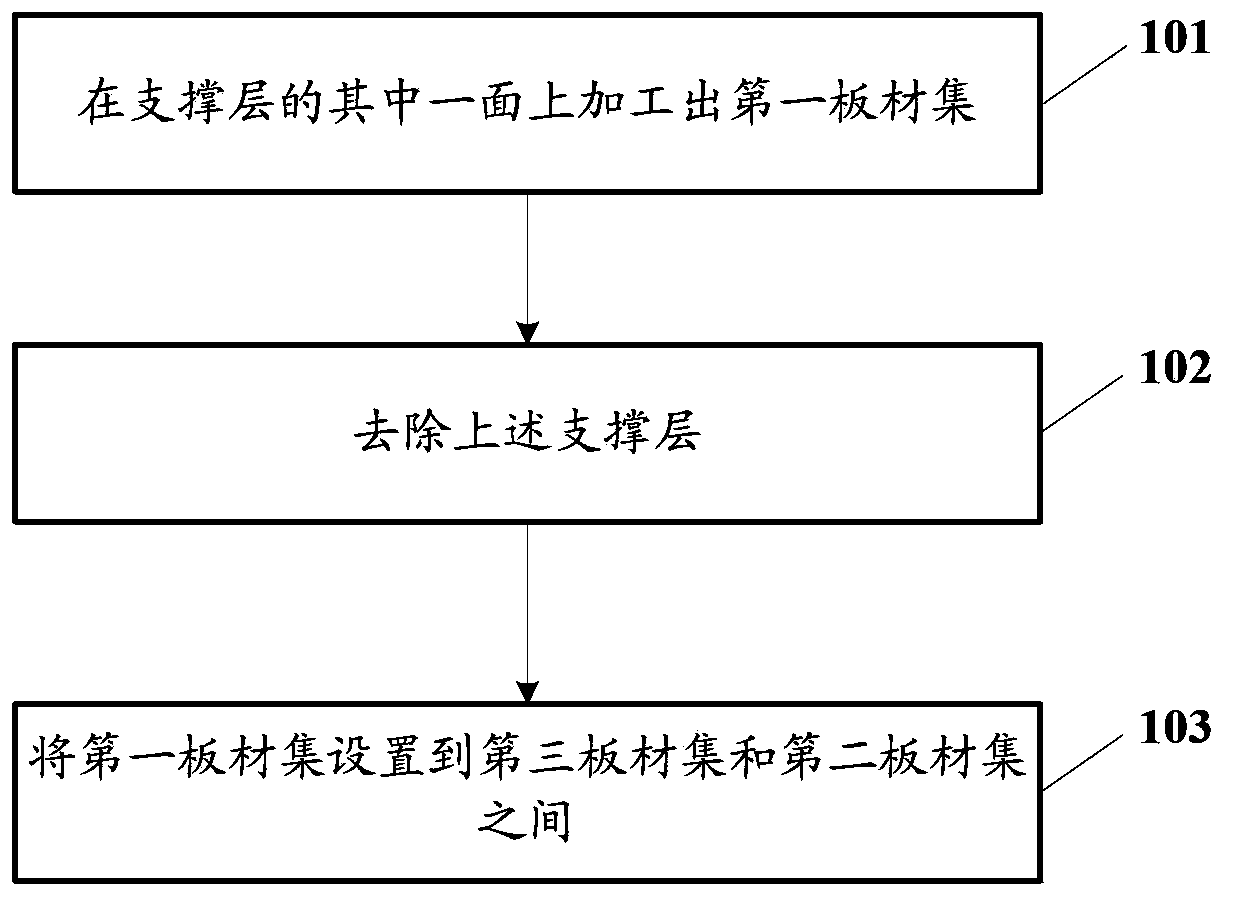

Coreless substrate processing method

ActiveCN104168726AOvercome warpage-prone problemsOvercome warpingMultilayer circuit manufacturePrinted element electric connection formationComputer science

An embodiment of the invention discloses a coreless substrate processing method which comprises the following steps: carrying out processing to form a first board set on one surface of a support layer; removing the support layer; and arranging the first board set between a third board set and a second board set. The technical scheme provided in the embodiment of the invention helps to improve production efficiency and qualified rate of the products.

Owner:SHENNAN CIRCUITS

Sand wheel automatic production line

The invention relates to a sand wheel automatic production line, comprising a sand wheel molding die, and a lower mesh placing system, a charging system, a feeding system, a scraping system, an upper mesh placing system, a mesh pressing system, a core ring placing system and a block press which are arranged on a production rail in sequence; and the sand wheel molding die is arranged and conveyed at the production rail and sequentially finishes lower mesh placing, charging and feeding, flat scraping, upper mesh placing, mesh pressing and flattening, core ring placing and die press molding. The automatic degree is high, charging is convenient, feeding is stable and uniform, meshes are flatly placed, raw materials in the die are uniform and the die press molding quality of a sand wheel is favorably improved.

Owner:张书楷

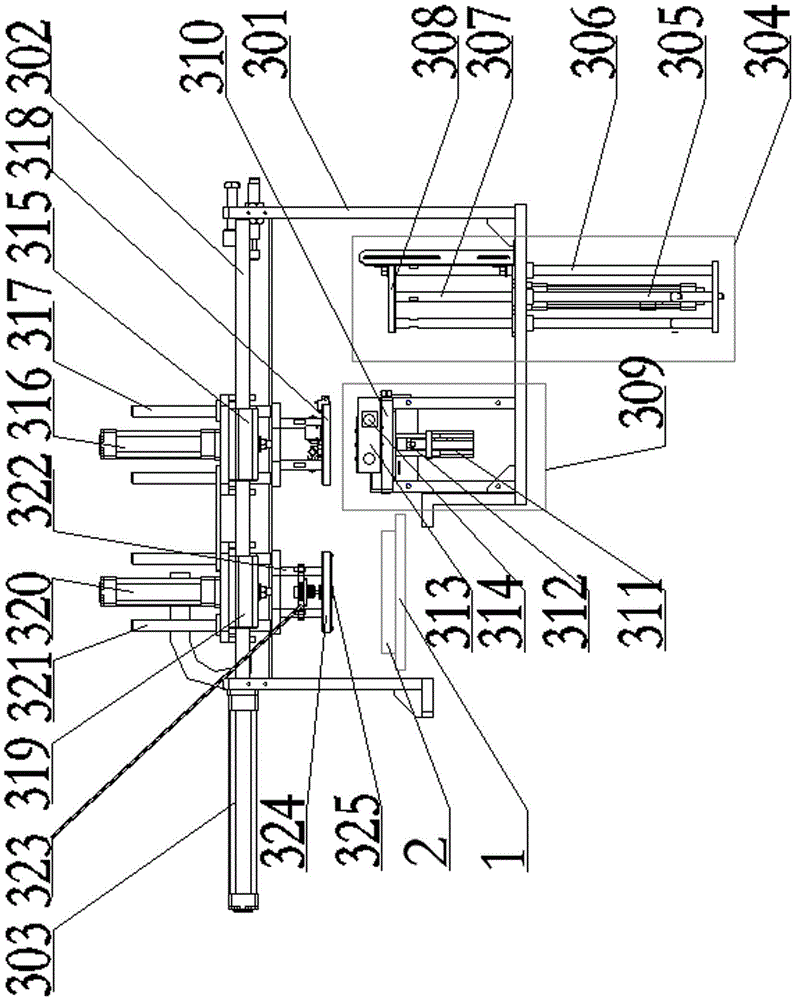

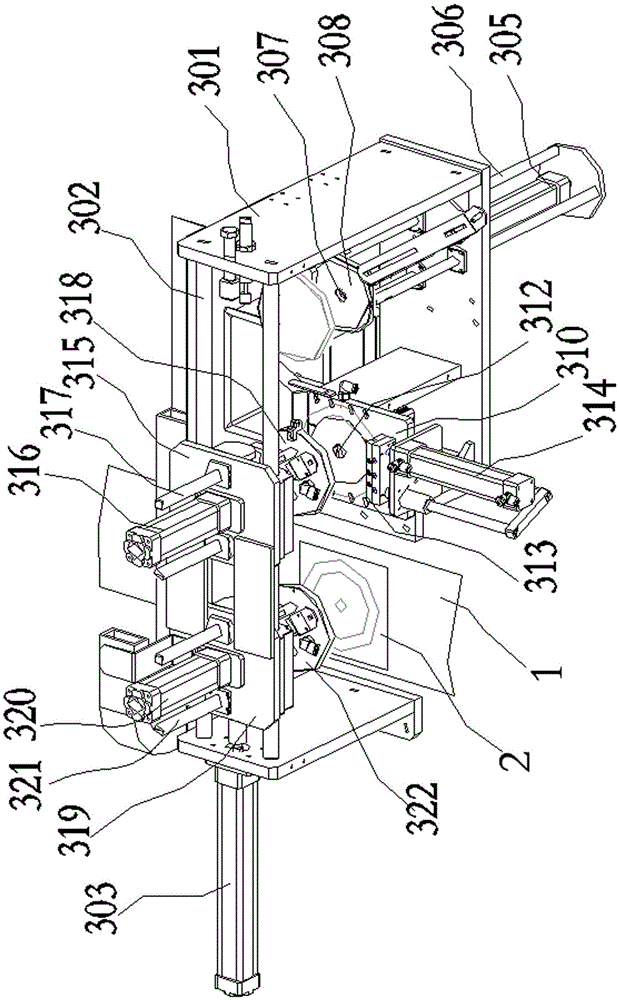

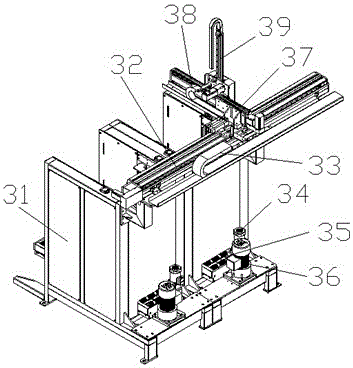

Cleaning, loading and unloading automation device

InactiveCN106269679AImprove working environmentEliminate poor quality outflowCleaning using liquidsConveyor partsQuenchingSolvent

The invention provides a cleaning, loading and unloading automation device. The device comprises a collecting conveyor, a cleaning mechanism, a lifting mechanism, a robot mechanism, an upper-layer cooling system, a water tank, a control panel, a controller, a high-frequency quenching mechanism and a high-frequency quenching power supply; the collecting conveyor is connected with the cleaning mechanism; the lifting mechanism and the robot mechanism are near the cleaning mechanism; the upper-layer cooling system is connected with the water tank, the control panel and the robot mechanism; the high-frequency quenching mechanism is connected with the high-frequency quenching power supply; and the control panel is connected with the controller. The device has an error preventing function to improve the produced product quality. The device changes the cleaning mode as an aisle form and the cleaning solvent as degreasing powder and water, so that the cost of the cleaning solvent is largely reduced when the production efficiency is improved.

Owner:无锡仓佑汽车配件有限公司

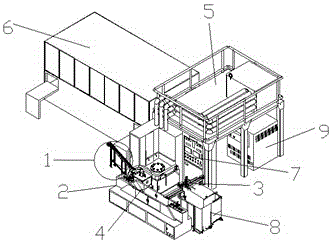

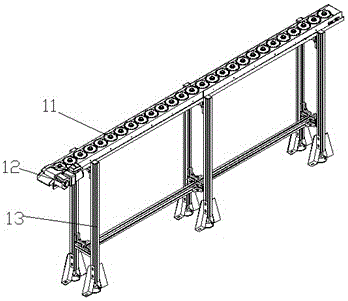

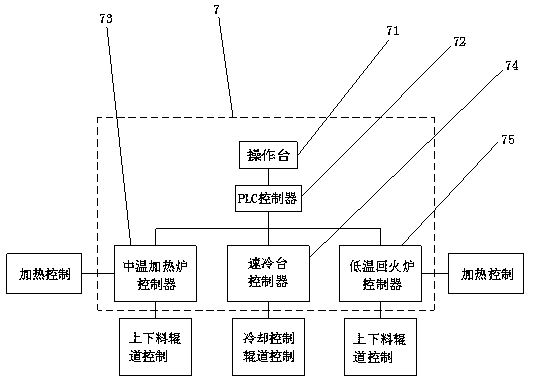

Continuous heat treatment production line and heat treatment method thereof

PendingCN111500845ACompact and reasonable layoutTaking into account the quality of quick coolingFurnace typesHeat treatment process controlTemperingProcess engineering

The invention relates to a continuous heat treatment production line and a heat treatment method thereof. The continuous heat treatment production line comprises a feeding table, a medium temperaturenormalizing furnace, a quick cooling table, a low temperature tempering furnace and a discharging table; a medium temperature feeding furnace door is arranged at the feeding end of the medium temperature normalizing furnace, a medium temperature discharging furnace door is arranged at the discharging end of the medium temperature normalizing furnace, the quick cooling table is arranged on one sideof the discharging end of the medium temperature normalizing furnace in a matched mode, the low temperature tempering furnace is arranged on one side of the discharging end of the quick cooling tablein a matched mode, a low temperature feeding furnace door is arranged at the feeding end of the low temperature tempering furnace, and a low temperature discharging furnace door is arranged at the discharging end of the low temperature tempering furnace; and the discharging table is arranged on one side of the low temperature tempering furnace in a matched mode, and the feeding table, the mediumtemperature normalizing furnace, the quick cooling table, the low temperature tempering furnace and the discharging table are connected to one other through material transfer roller ways to transportworkpieces. Normalizing heating and rapid and uniform cooling of bainite alloy steel point rails are achieved, normalizing residual heat is used for entering the furnace for tempering, the layout of the production line is compact and reasonable, automatic furnace installing and discharging are achieved, and production efficiency and product quality are improved.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

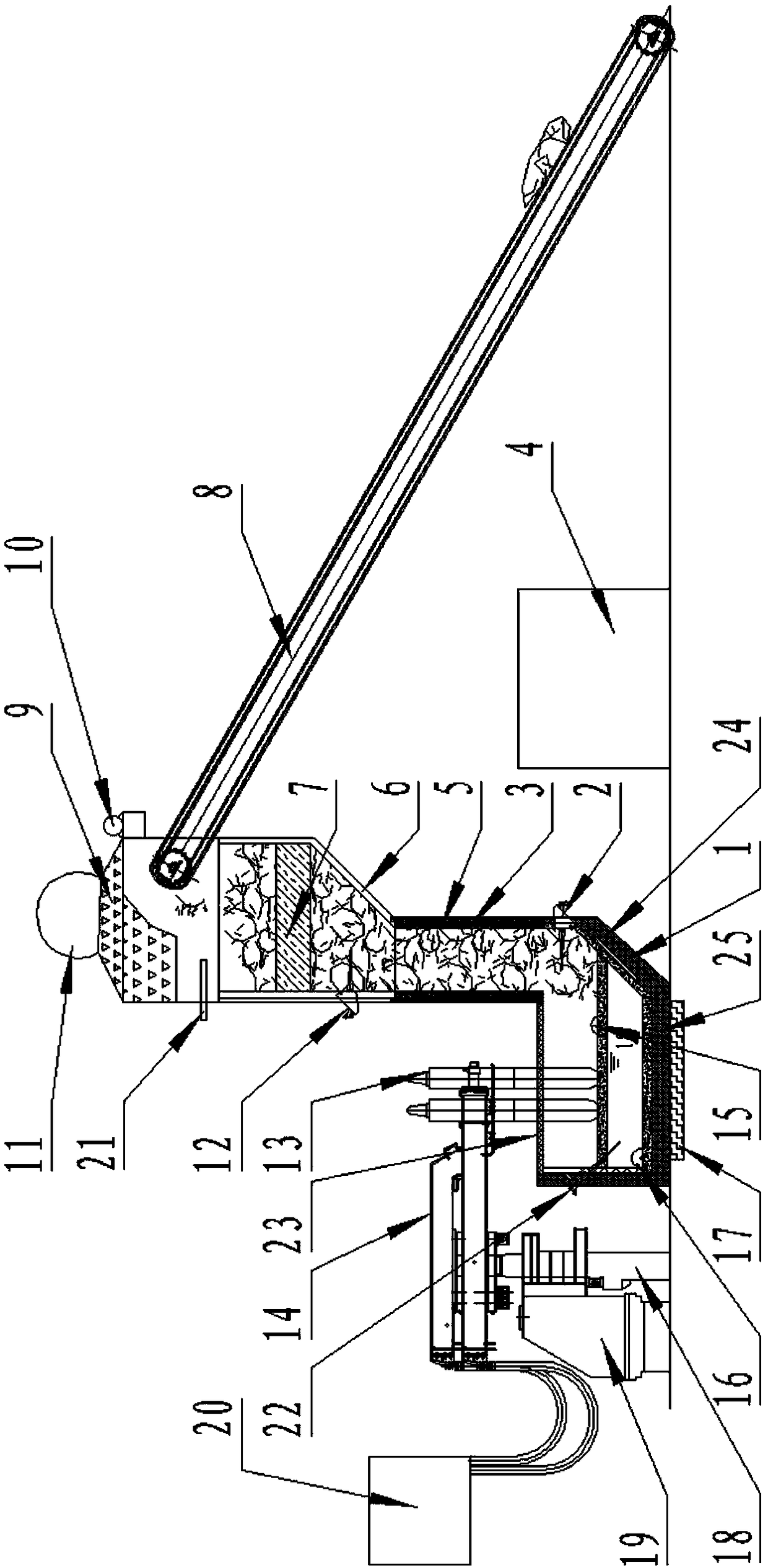

Steel-making equipment for steel scrap steelmaking and smelting method

ActiveCN108624739AMelt stableReduce shockProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

The invention discloses steel-making equipment for steel scrap steelmaking and a smelting method. The steel-making equipment for the steel scrap steelmaking comprises a non-contact melting device (3),an electric arc furnace (1) and a steel scrap preheating chamber (6), wherein the non-contact melting device (3) can carry out non-contact heating on a furnace burden in the non-contact melting device (3); the lower end of the non-contact melting device (3) is correspondingly connected with the feeding port of the electric arc furnace (1); and an electromagnet (7) capable of attracting the furnace burden is arranged in the steel scrap preheating chamber (6). The steel-making equipment for the steel scrap steelmaking and the smelting method are in a fully-closed state, steel remaining and slagremaining operation are adopted, through energy supplying mode of combining the non-contact melting, electric arc heating, oxygen blowing and carbon spraying, oxygen and fuel gas combustion co-melting, the problems that a traditional steel scrap steelmaking technology and device are low in heat efficiency, a steel material consumption is high, the smoke amount is large, and the impact on a powergrid is large are solved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

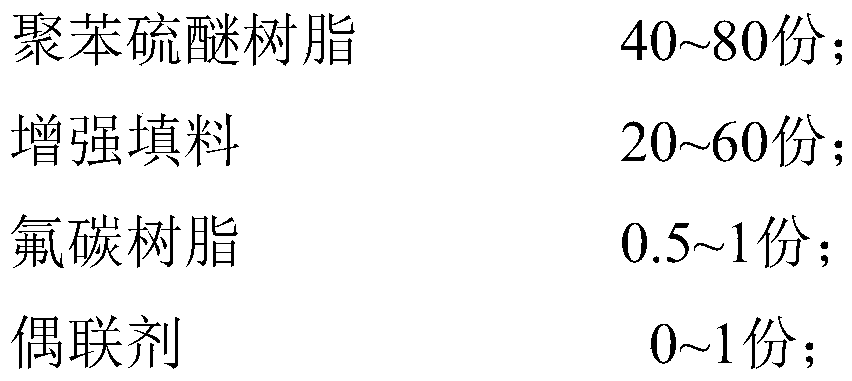

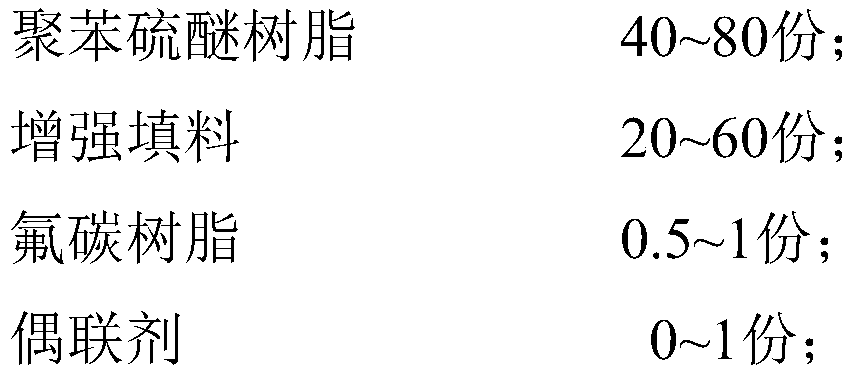

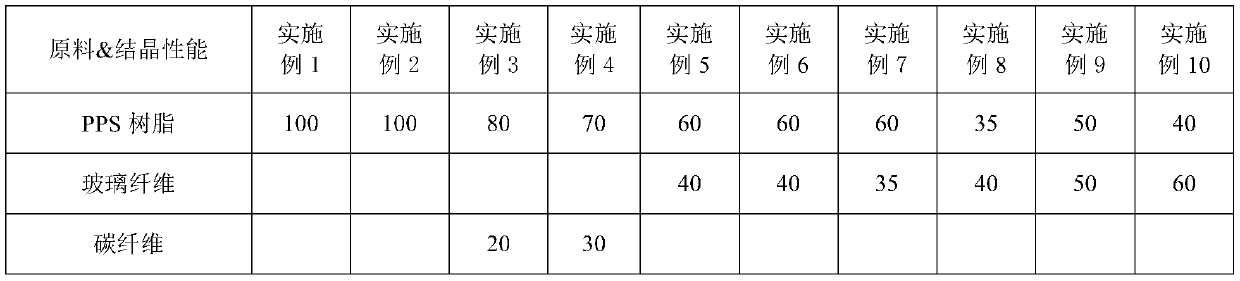

High-crystallinity polyphenylene sulfide composite material easy for machining shaping, preparation method and application thereof

ActiveCN110903650ARaise the crystallization temperatureIncrease the rate of crystallizationCrystallinityFluorocarbon Resins

The invention relates to the technical field of high polymer materials, in particular to a high-crystallinity polyphenylene sulfide composite material easy for machining shaping. The high-crystallinity polyphenylene sulfide composite material easy for machining shaping provided by the invention comprises the following raw materials by weight: 40-100 parts of polyphenylene sulfide resin, 0-60 partsof a reinforcing filler and 0.3-2 parts of fluorocarbon resin, wherein the fluorocarbon resin is a copolymer formed by copolymerization of vinylidene fluoride and other fluorine-containing monomers,preferably, the fluorocarbon resin is one of or a combination of several of a vinylidene fluoride homopolymer, a vinylidene fluoride-trifluoroethylene copolymer and a vinylidene fluoride-tetrafluoroethylene copolymer. The high-crystallinity polyphenylene sulfide composite material easy for machining shaping provided by the invention can obviously improve the crystallization temperature and crystallization rate of polyphenylene sulfide, and then the production efficiency of a product injection molding processing plant is improved.

Owner:BENSONG ENG PLASTICS HANGZHOU

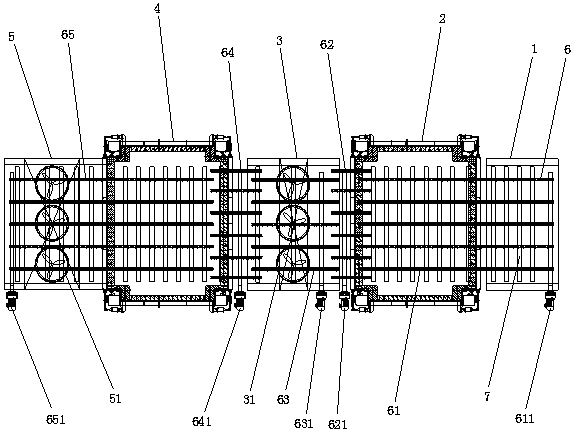

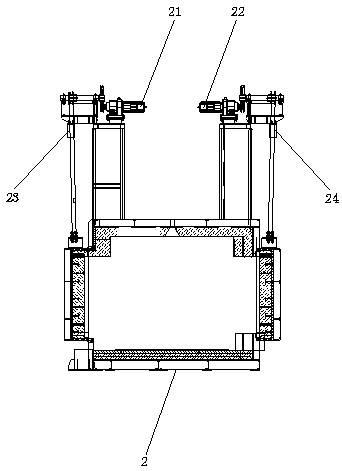

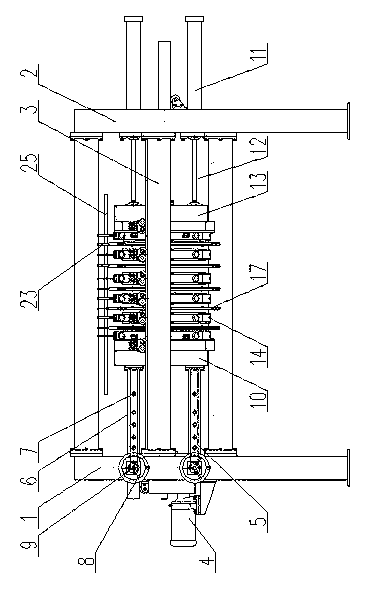

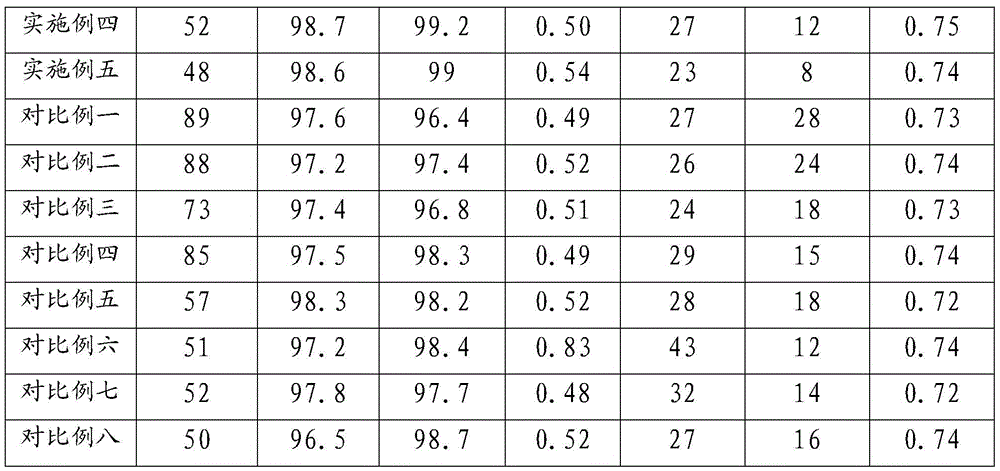

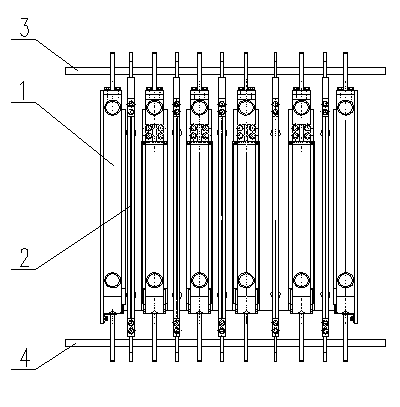

Device and method for vertically pouring organic glass

The invention relates to a device and a method for vertically pouring organic glass. The device is characterized in that two racks are connected in parallel by two horizontal beams; a fixed plate is vertically supported on the two horizontal beams at any rack side; a fixed plate adjustment device is arranged on one of the racks and the fixed plate is connected to the fixed plate adjustment device and is arranged on the two horizontal beams in a slide adjustment localizable state; a movable plate is vertically and slidingly supported on the two horizontal beams at the other rack side; a movable plate adjustment device is arranged at the other one of the racks and the movable plate is connected to the movable plate adjustment device and is arranged on the two horizontal beams in a slide adjustment localizable state; multiple water tanks are vertically supported on the two horizontal beams between the fixed plate and the movable plate at intervals; and an injection mold is vertically arranged in a gap of each adjacent two of the multiple water tanks and is sealedly clamped between vertical sides of the water tanks by being pushed by the movable plate. The device has a simple and compact structure, can be used conveniently and can guarantee molding quality and production efficiency.

Owner:JIANGSU TOMSON NEW MATERIAL TECH CO LTD

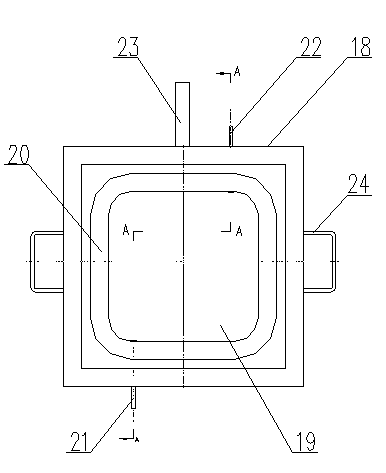

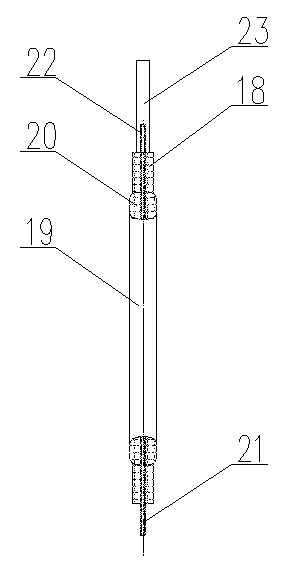

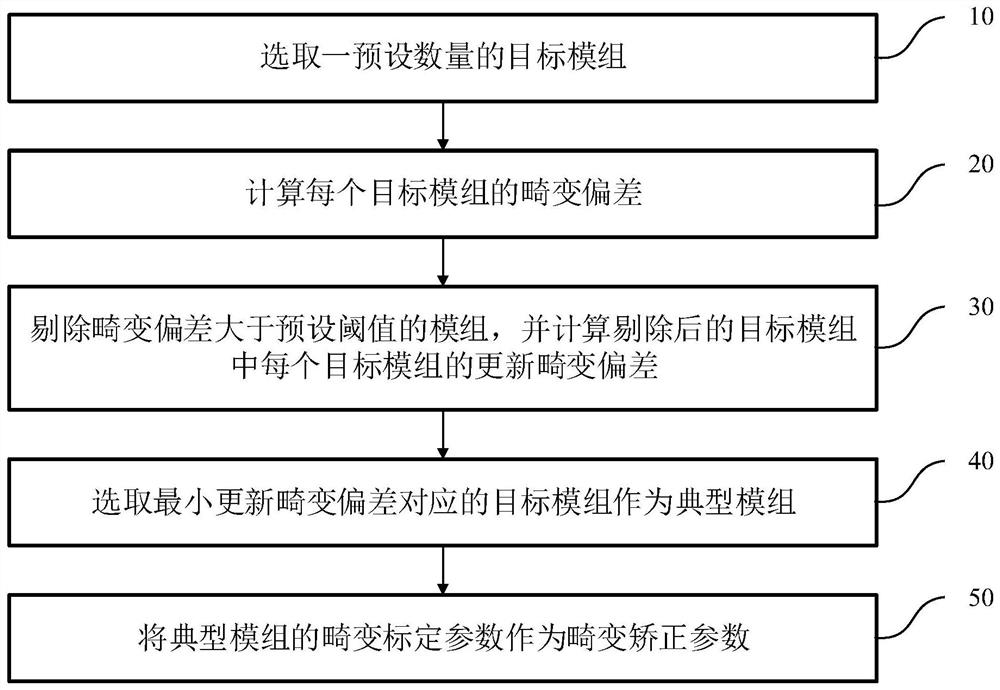

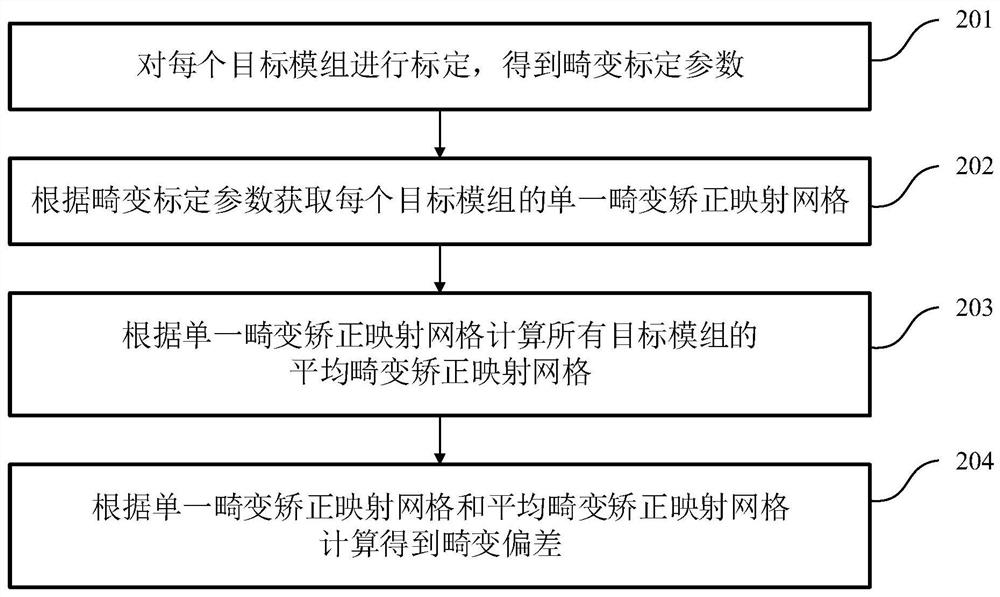

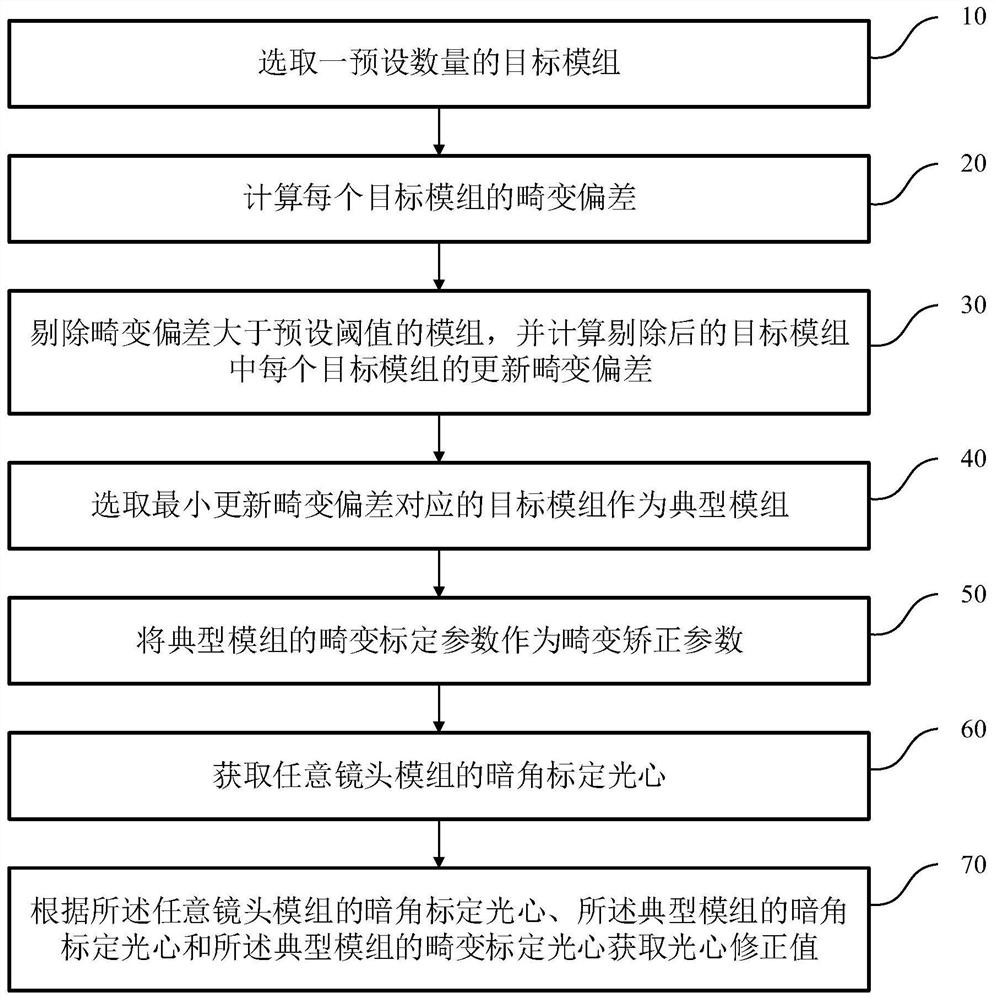

Distortion calibration method, system and device for lens module and storage medium

ActiveCN112465917ATaking into account production efficiencyTaking into account the effect of distortion correctionImage analysisDistortion correctionEngineering

The invention discloses a distortion calibration method, system and device for a lens module, and a storage medium. The distortion calibration method comprises the steps: selecting a preset number oftarget modules; calculating the distortion deviation of each target module, wherein the distortion deviation is used for representing the deviation between the distortion correction mapping grid of each target module and the average distortion correction mapping grid of all the target modules; removing modules with distortion deviations greater than a preset threshold, returning to the step of calculating the distortion deviation of each target module, and calculating the updated distortion deviation of each target module in the removed target modules; selecting a target module corresponding to the minimum update distortion deviation as a typical module; taking the distortion calibration parameter of the typical module as a distortion correction parameter; wherein the distortion correctionparameters are used for carrying out distortion correction on any lens module. Typical modules are screened out based on small-batch calibration, calibration parameters of the typical modules are applied to other modules, a production line one-by-one calibration task is omitted, and meanwhile the production efficiency and the distortion correction effect are both considered.

Owner:BEIJING SPREADTRUM HI TECH COMM TECH CO LTD

A process of producing a cellulose carbamate fiber filament

InactiveCN106637460AImprove spinnabilitySolve the problem of not being able to adapt to industrial mass productionArtificial filaments from cellulose derivativesCelluloseFiber

The invention relates to a process of producing a cellulose carbamate fiber filament, and belongs to the technical field of cellulose carbamate fiber production. Through specific cellulose activation, cellulose carbamate preparation, cellulose carbamate solution preparation, and spinning steps, a complete cellulose carbamate fiber filament producing process having a high degree of completion is formed. A prepared spinning stock solution has good spinnability, a final product has good performance, the process is particularly suitable for industrial large-scale production, and the production cost, the production efficiency and product quality are all taken into account.

Owner:YIBIN GRACE GROUP CO LTD

Electrostatic spraying production technology of vehicular steel plate spring paint

InactiveCN103302014ATaking into account cost efficiencyTaking into account production efficiencyLiquid surface applicatorsCoatingsInjection portMetallurgy

The invention discloses an electrostatic spraying production technology of vehicular steel plate spring paint. The technology comprises the steps that the paint and a diluent are mixed at a specific weight ratio of 3:1; the prepared paint is sprayed to the surface of a steel plate spring by an electrostatic spraying method, wherein a spraying distance, namely a distance from an injection port of a spray gun to the surface of a steel plate spring piece, is 30-32mm, the spraying speed is 2-2.2m / minute, and an spraying angle between the spray gun and a sprayed spring surface is 45 degrees; and then the sprayed steel plate spring piece is dried, wherein the drying temperature is 25-30 DEG C, and the surface drying time is 4.5-5h. With the adoption of the technology, the film thickness of the automobile steel plate spring after electrostatic spraying and an effect of a salt spray test can meet requirements of an automobile manufacturer, and the salt spray test time reaches above 150h.

Owner:昆明方大春鹰板簧有限公司

Production method of cellulose carbamate filament yarn

InactiveCN106544745AImprove spinnabilitySolve the problem of not being able to adapt to industrial mass productionArtificial filaments from cellulose derivativesArtifical filament manufactureCelluloseCarbamate

The invention relates to a production method of a cellulose carbamate filament yarn, and belongs to the technical field of production of cellulose carbamate fiber. Through activation of specific cellulose, preparation of cellulose carbamate, and preparation of cellulose carbamate solution, and a spinning step, a complete production process of the cellulose carbamate filament yarn with high completion degree is formed; the prepared raw spinning liquid has good spinning property and final product performance, and is very suitable for the large-scale industrial production, and further gives consideration to production cost, production efficiency and product quality.

Owner:YIBIN GRACE GROUP CO LTD

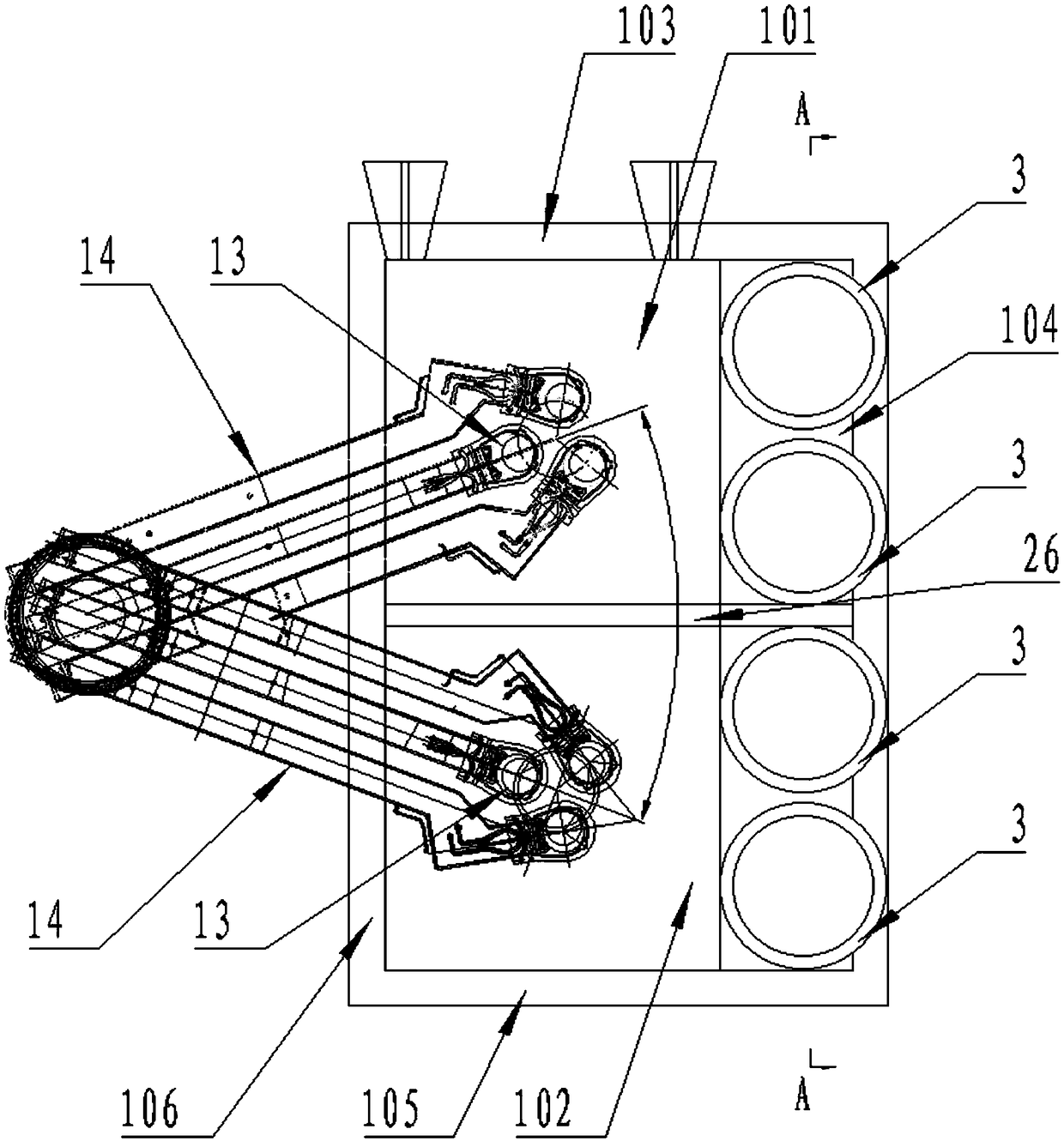

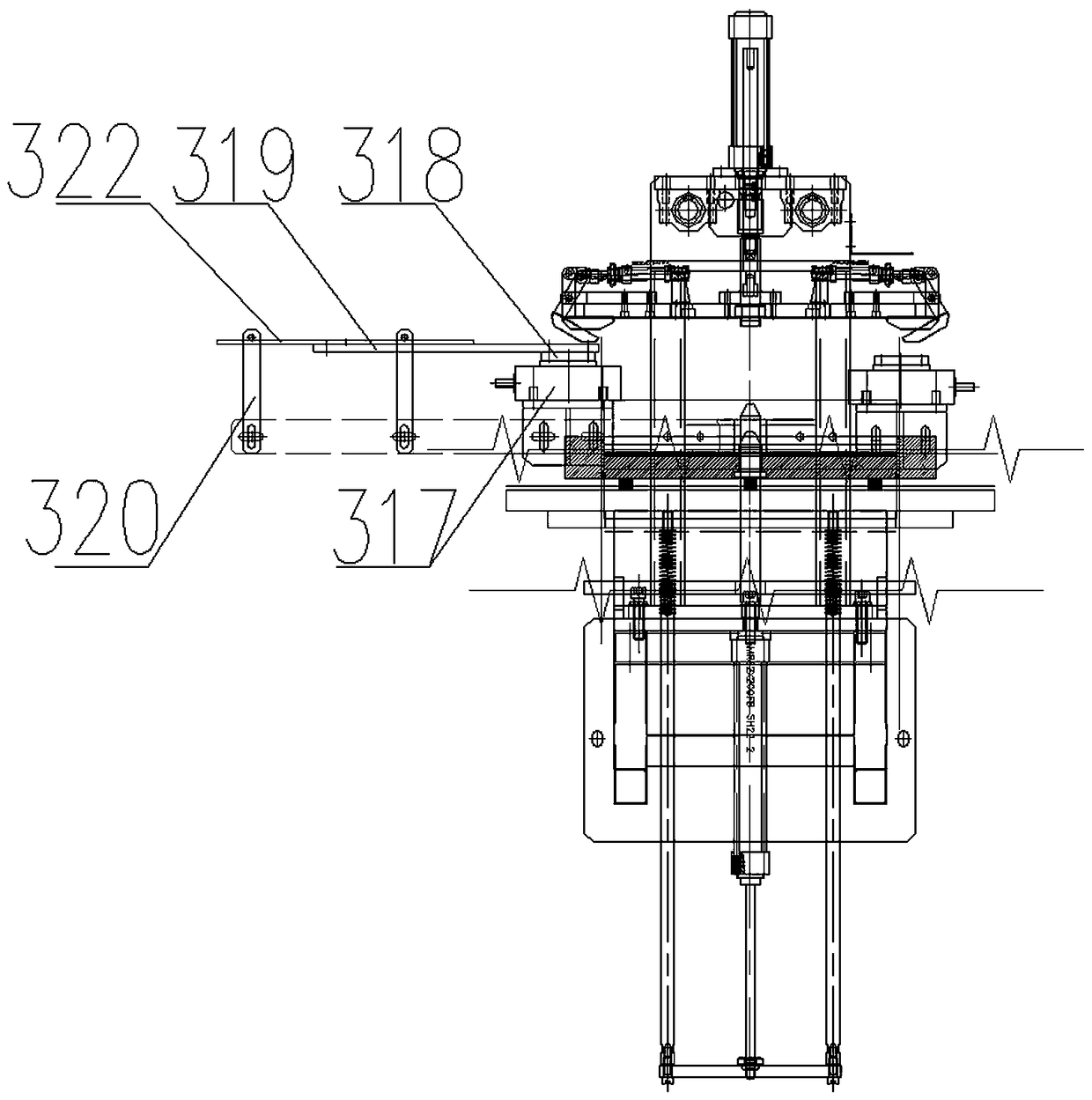

Grinding wheel partition and mesh integrated picking and releasing claw

The invention relates to a grinding wheel partition and mesh integrated picking and releasing claw. The grinding wheel partition and mesh integrated picking and releasing claw includes a vacuum chuck,wherein an upper end surface of the vacuum chuck is uniformly provided with three or more supporting claw cylinders, an inner end of each of the supporting claw cylinders is fixedly hinged with an upper end surface of the vacuum chuck, an outer end of each of the supporting claw cylinders is movably hinged with an upper end of a supporting claw, the middle portion of the supporting claw is movably hinged with the vacuum chuck, a lower end of the supporting claw rotatably rotating around a middle hinge point extends into a lower portion of the vacuum chuck, the diameter of the circumference ofthe supporting claw extending into the deepest portion below the vacuum chuck is larger than the diameter of a partition and is smaller than the diameter of a fiber mesh, the vacuum chuck is externally connected with a vacuum pump and an air compressor through a switching valve, and the air compressor is the hot air structure with a heater. The integrated picking and releasing claw has a high degree of automation, is convenient for feeding, is stable and uniform for feeding, achieves flat laying of the mesh, has uniform raw materials in the mold and facilitates to improve the quality of molding of a grinding wheel.

Owner:张和庆

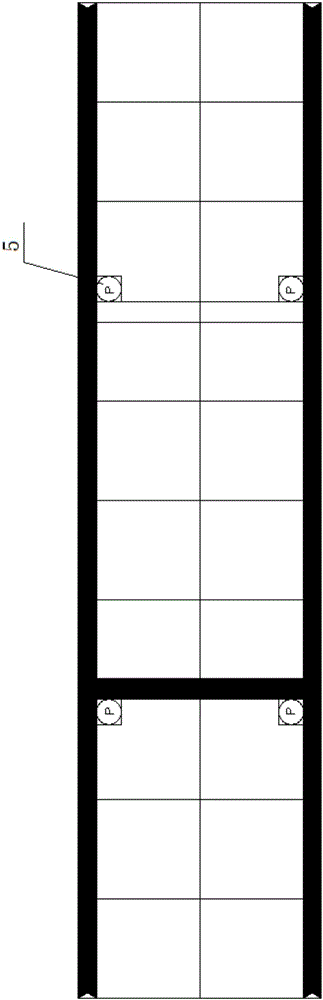

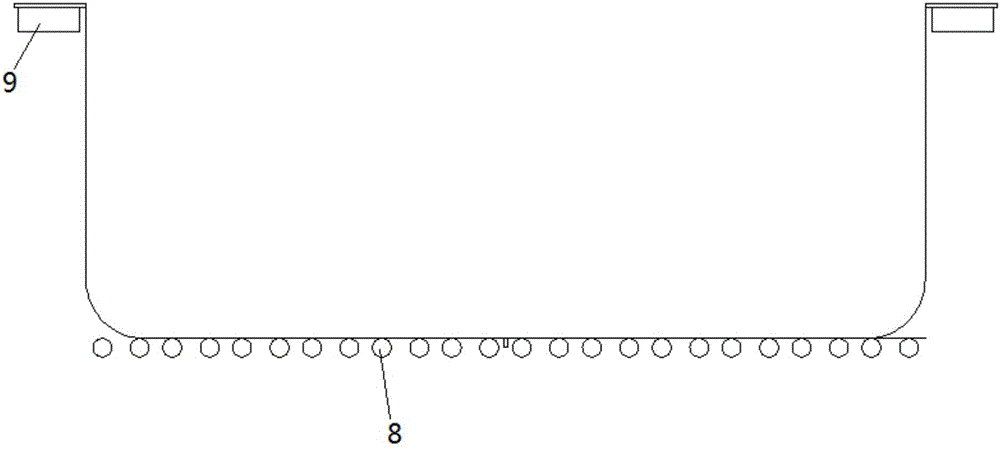

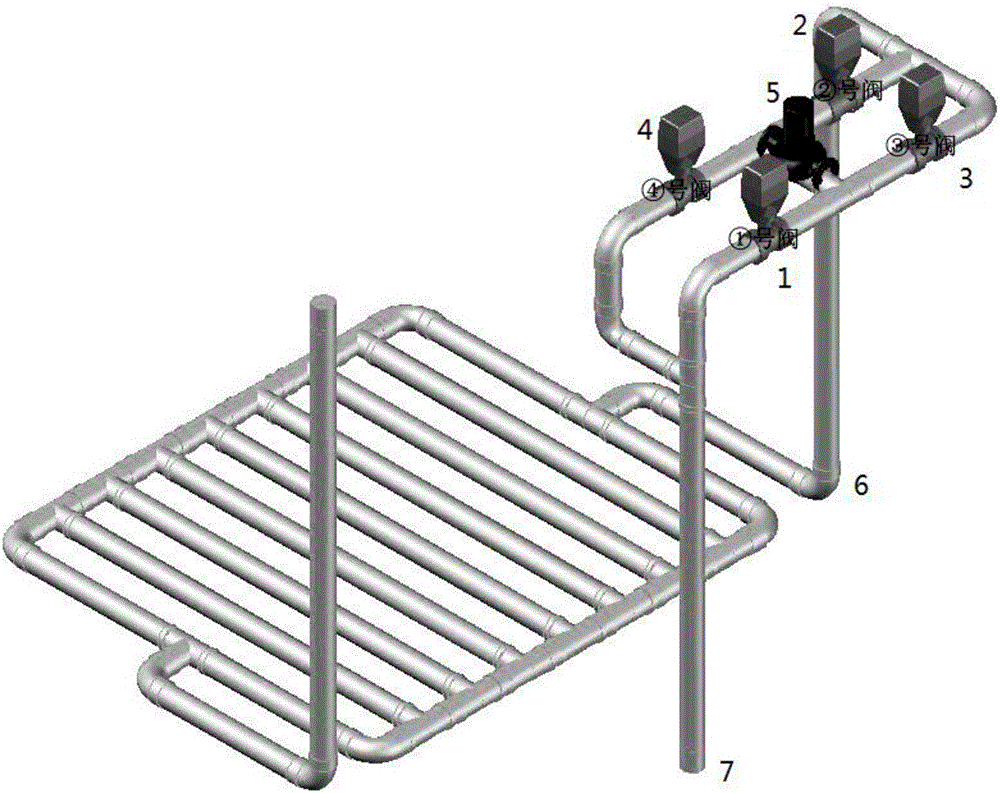

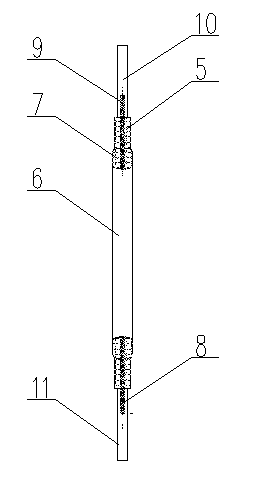

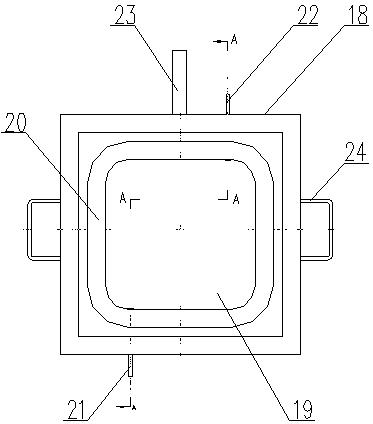

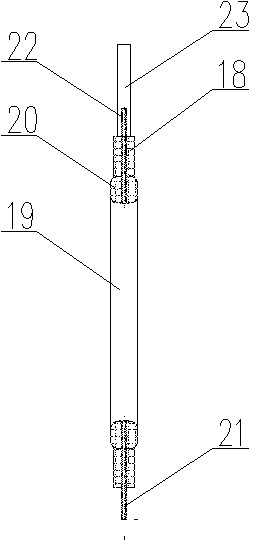

Flowing water breeding tank lifting system

ActiveCN106359224ATaking into account the efficiency of farming productionIngenious designClimate change adaptationPisciculture and aquariaPipingLift system

The invention relates to a flowing water breeding tank lifting system. A first floating pad is arranged at the bottom of a flowing water breeding tank; the gravity of the flowing water breeding tank is greater than the buoyancy force provided by the first floating pad; a plurality of ballast pipe devices are uniformly arranged at the bottom of the flowing water breeding tank in a gravity symmetry manner; the ballast pipe devices comprise water pumps and four-way reversing pipelines; four valves, comprising a first valve, a second valve, a third valve and a fourth valve, a ballast coil connection end connected with a ballast coil at the bottom of the tank, and a pool water communication end communicated with external pool water are arranged on each of the ballast pipe devices; tail ends of the ballast coils stretches upward out of water and are communicated with air. The flowing water breeding tank lifting system provided by the invention is adaptive to different breeding production links of breeding and fishing by controlling lifting of the flowing water breeding tank, so as to facilitate the fishing operation of the flowing water breeding tank, effectively reduce labor intensity, and also improve breeding production efficiency.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

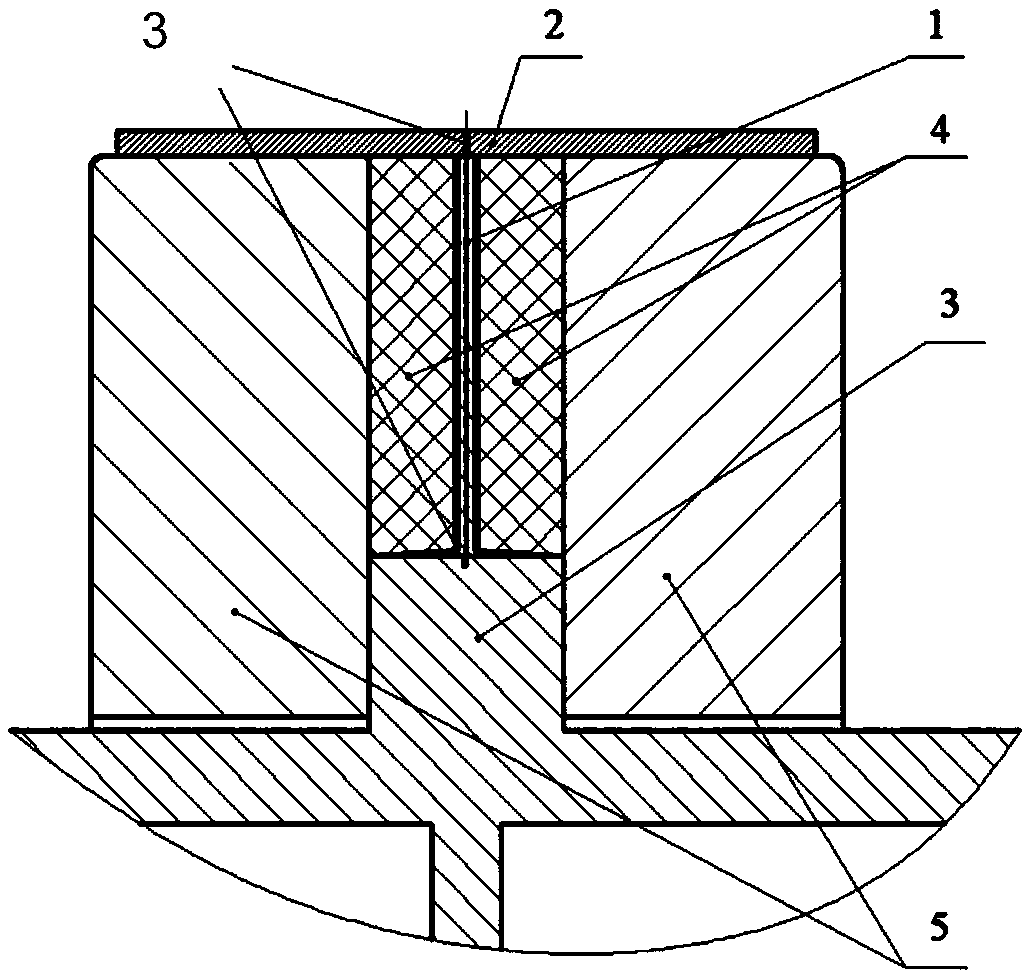

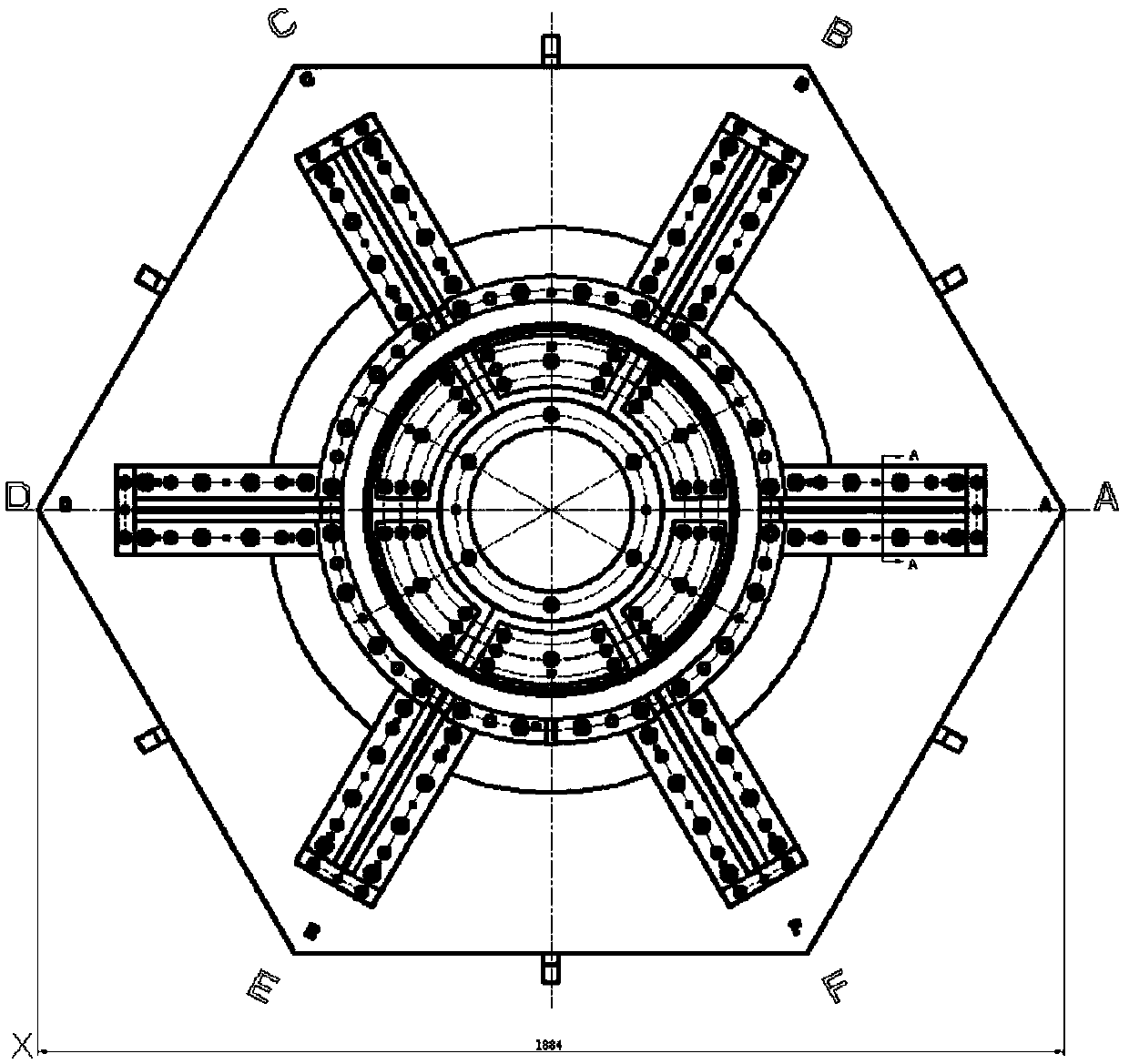

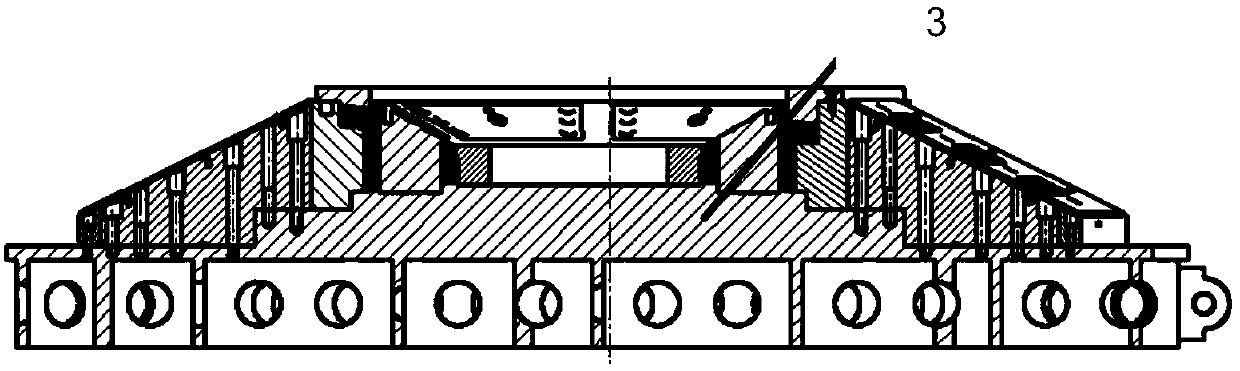

Forming mould for composite radial curved surface back bar of satellite antenna reflector

The invention provides a forming mould for a composite radial curved surface back bar of a satellite antenna reflector. The overall mould design idea comprises the steps that composite preform plateswith a plurality of positioning convex table structures are adopted, and are positioned on the bottom plate moulding surface and a plurality of clamping grooves formed in preform plate positioning plates; and both sides of the preform plates are overlaid, pressure soft mould assembles on both sides are positioned by designing circular steps with increasing height on a bottom plate, the pressure soft mould assemblies on both sides are composed of steel mould cores and silicone rubber or silicone rubber strips and limiting steel plates of the silicone rubber strips, wherein the pressure soft mould assemblies are coated with the silicone rubber. According to the forming mould for the composite radial curved surface back bar of the satellite antenna reflector, a design method that the composite preform plates are positioned through the clamping grooves formed in the bottom plate and the preform positioning plates, the two sides of the composite preform plates are overlaid and are soft mould pressure is developed.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

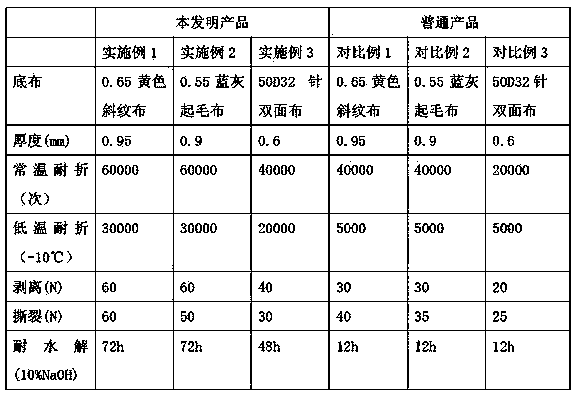

Preparation method of waterborne polyurethane synthetic leather Bayse and applications thereof

ActiveCN102787510BNo pollutionObvious cloth seamLamination ancillary operationsPolyureas/polyurethane adhesivesPolymer sciencePolymer chemistry

Owner:浙江昶丰新材料有限公司

Method of synthesizing phosphatide emulsifier for food

ActiveCN102018156AImprove stabilityGuaranteed stabilityFood preparationSynthesis methodsEsterification reaction

The invention relates to a method of synthesizing phosphatide emulsifier for food by using refined palm oil as raw material. The emulsifier is produced through semi-esterification, multiple phosphorus esterification reaction and hydroxylation reaction successively. The invention is characterized in that: the source of the raw material for the invention is abundant and cheap, the quality of the product is stable for each batch, the product not only has a similar structure with natural phosphatide but also has good emulsifying property, the operation is simple, the synthetic route is short, theproductivity is high and industrial production is easy to realize.

Owner:GUANGZHOU FOOD IND RES INST

Grinding wheel forming die demoulding device

InactiveCN109048700AImprove molding qualityImprove qualityGrinding devicesVertical vibrationEngineering

The invention relates to a grinding wheel forming die demoulding device. The demoulding device is arranged on a production track. The production track is provided with a demoulding positioning sensor.The production track is provided with a circle of demoulding ring corresponding to the demoulding positioning sensor and the position above a demoulding vertical vibration hammer, and a plurality ofdemoulding positioning holes which are located in the outer side of the demoulding ring and correspond to demoulding lifting suction heads. A demoulding rotation base is driven through a demoulding motor and connected with one or more demoulding vertical vibration hammers. The two sides of the production track correspond to two demoulding horizontal vibration hammers on the outer circumference ofa grinding wheel forming die. The demoulding lifting suction heads are arranged below the production track and fixed to be in a state that the demoulding lifting suction heads can ascend and descend to penetrate through the demoulding positioning holes to actuate the bottom end face of the grinding wheel forming die. The grinding wheel forming die demoulding device is high in automation degree, feeding is convenient, charging is stable and uniform, meshes are flatly placed, raw materials in the die are uniform, and the grinding wheel die pressing forming quality can be better improved.

Owner:张和庆

Production method of turtle peptide

PendingCN112941137AUniform contentRegulatory immunityPeptide preparation methodsFermentationBiotechnologyMeat paste

The invention belongs to the technical field of biological preparation, and relates to a production method of turtle peptide, which comprises the following steps: slaughtering adult live turtles, cleaning, removing bones, and crushing into turtle meat paste slurry; mixing the tortoise shell extract and the tortoise meat paste slurry, performing ultrasonic homogenization, blending with ultrapure water to obtain a substrate solution, and adding protease for enzymolysis; and carrying out enzyme deactivation, sterilization, ultrafiltration separation and vacuum freeze drying on the reaction product obtained by enzymolysis to obtain the soluble powdery turtle peptide. According to the turtle peptide produced by taking multiple turtle compound components as raw materials and applying an enzymolysis method, active peptide molecules in adult turtles are extracted to the maximum extent, meanwhile, other bioactive components in the raw materials are preserved, and multiple bioactive components supplement one another. The turtle peptide can effectively regulate immunity, resist oxidation, resist tumors, resist fatigue, regulate blood fat, improve sleep and delay senescence, so that the effects of nourishing yin, tonifying yang, building bodies, maintaining beauty, keeping young and prolonging life are achieved.

Owner:海南金龟岛生物科技有限公司

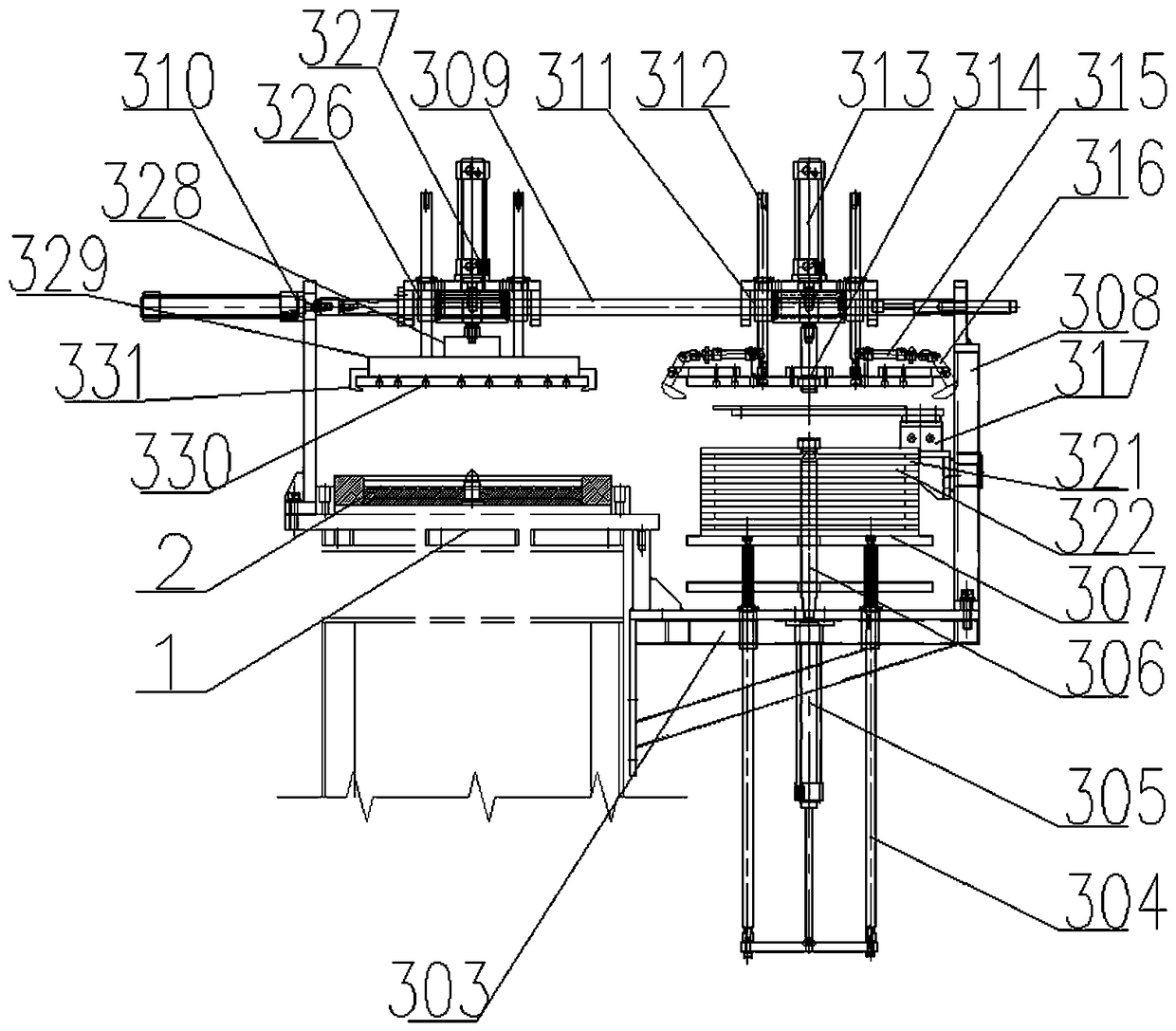

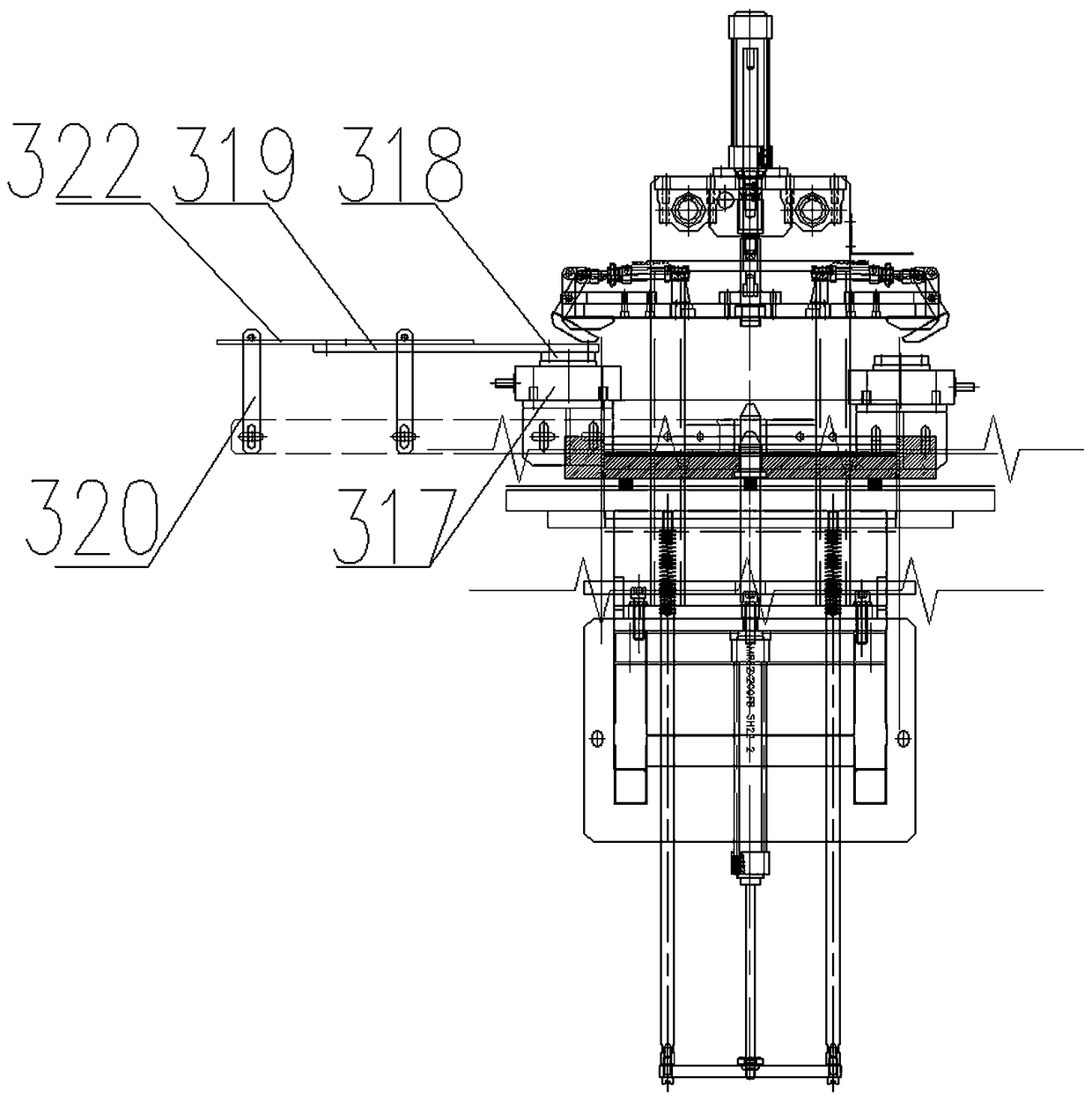

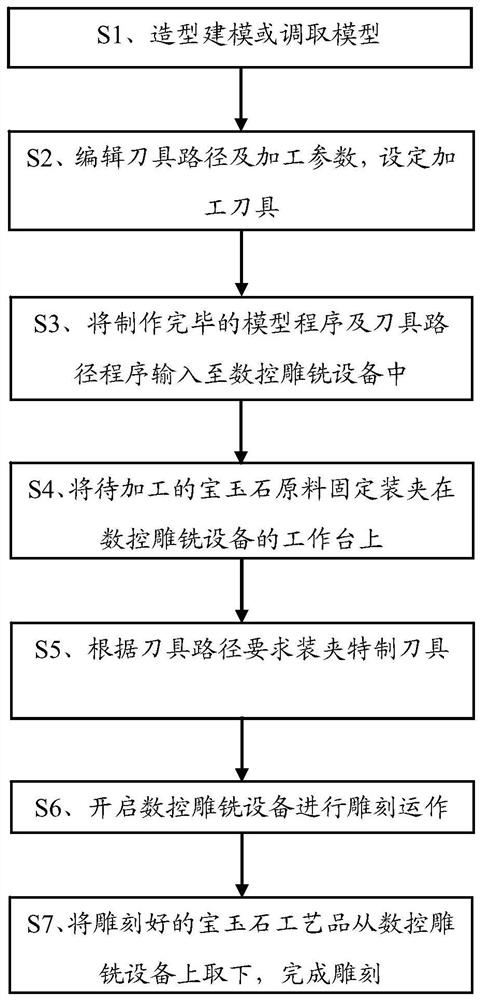

Method for numerical control engraving and milling processing of gem and jade handicrafts

ActiveCN113075908AAutomatic engraving processing adaptationHigh precisionProgramme controlComputer controlNumerical controlIndustrial engineering

The invention discloses a method for numerical control engraving and milling processing of gem and jade handicrafts. The method comprises the steps that a 3D model of a to-be-engraved handicraft is prepared and programmed; one, two or more cutter paths are edited in CNC programming software according to the handicraft structure in a large-cutting-amount and small-path machining mode; a model program and a cutter path program are input into numerical control engraving and milling equipment; gem and jade raw materials to be machined are clamped on the numerical control engraving and milling equipment through a tool; a cutter is clamped on the numerical control engraving and milling equipment, the numerical control engraving and milling equipment is started to run the cutter paths, and engraving operation is carried out; the numerical control engraving and milling equipment sequentially operates the one, two or more cutter paths according to a preset sequence for engraving; when the cutter paths are switched, the numerical control engraving and milling equipment clamps the cutter again according to different cutter path characteristics; and the handicraft is taken down from the equipment, and carving is completed. The method provided by the invention has the advantages of standardized production, standardized processing, controllable handicraft quality, high processing efficiency and high precision, and both production efficiency and product quality are considered.

Owner:王豪 +1

A pet bottle flake cleaning process

InactiveCN103640111BEfficient use ofEfficient removalPlastic recyclingCleaning using liquidsProduction linePolyethylene terephthalate

The invention discloses a cleaning process and a production line of PET (polyethylene terephthalate) bottle sheets. The cleaning process comprises the following steps of unpacking PET bottles, carrying out primary impurity removing by utilizing a whole bottle pre-cleaning device, removing labels from the PET bottles by utilizing a label removing device, removing heterochromous bottles and the bottles which are not made of PET materials by utilizing a sorting device, carrying out manual sorting by using a manual sorting platform, crushing by utilizing a crushing device, carrying out thermal cleaning by utilizing a thermal boiling boiler, neutralizing by utilizing a neutralizing tank, rinsing by utilizing a rinsing device, carrying out spin drying, drying by utilizing a drying cylinder, mixing, weighing and packaging, thus finishing the cleaning. According to the cleaning process, in full consideration of problem that too many impurities and pollutants exist in recycled PET bottles, various devices in a production process are adaptively transformed to be fit for the cleaning of the PET bottle sheets; the bottle sheets produced by utilizing the cleaning process and the production line can completely meet subsequent production and processing requirements, and the quality of the bottle sheets is improved; by utilizing a steam recycling system and the continuous spin-drying and drying operations, the energy utilization ratio can be greatly improved, the subsequent production and processing costs are lowered, and the cleaning process and the production line have wide social generalization significances.

Owner:福建鑫华股份有限公司

Mold for vertical pouring of organic glass and method for vertically pouring organic glass by the mold

The invention relates to a mold for vertical pouring of organic glass and a method for vertically pouring organic glass by the mold. The mold comprises multiple adhesive tape frames and multiple water tanks. Each one of the adhesive tape frames is vertically arranged between corresponding two of the multiple water tanks at an interval in a seal clamping state. Each one of the adhesive tape frames is vertically arranged between corresponding two of the multiple water tanks at an interval in a seal clamping state and different reaction heat sources are provided to the water tanks so that polymerization molding temperature requirements of raw materials in the adhesive tape frames are satisfied and thus vertical pouring and integrated curing molding of organic glass are realized. The mold has a simple and compact structure, is convenient for use, saves time and labor, can effectively guarantee molding quality, production efficiency and a production cost, and can be widely used for pouring polymerization molding of acrylic acid and acrylates.

Owner:TAIXING TOMSON ACRYLIC CO LTD

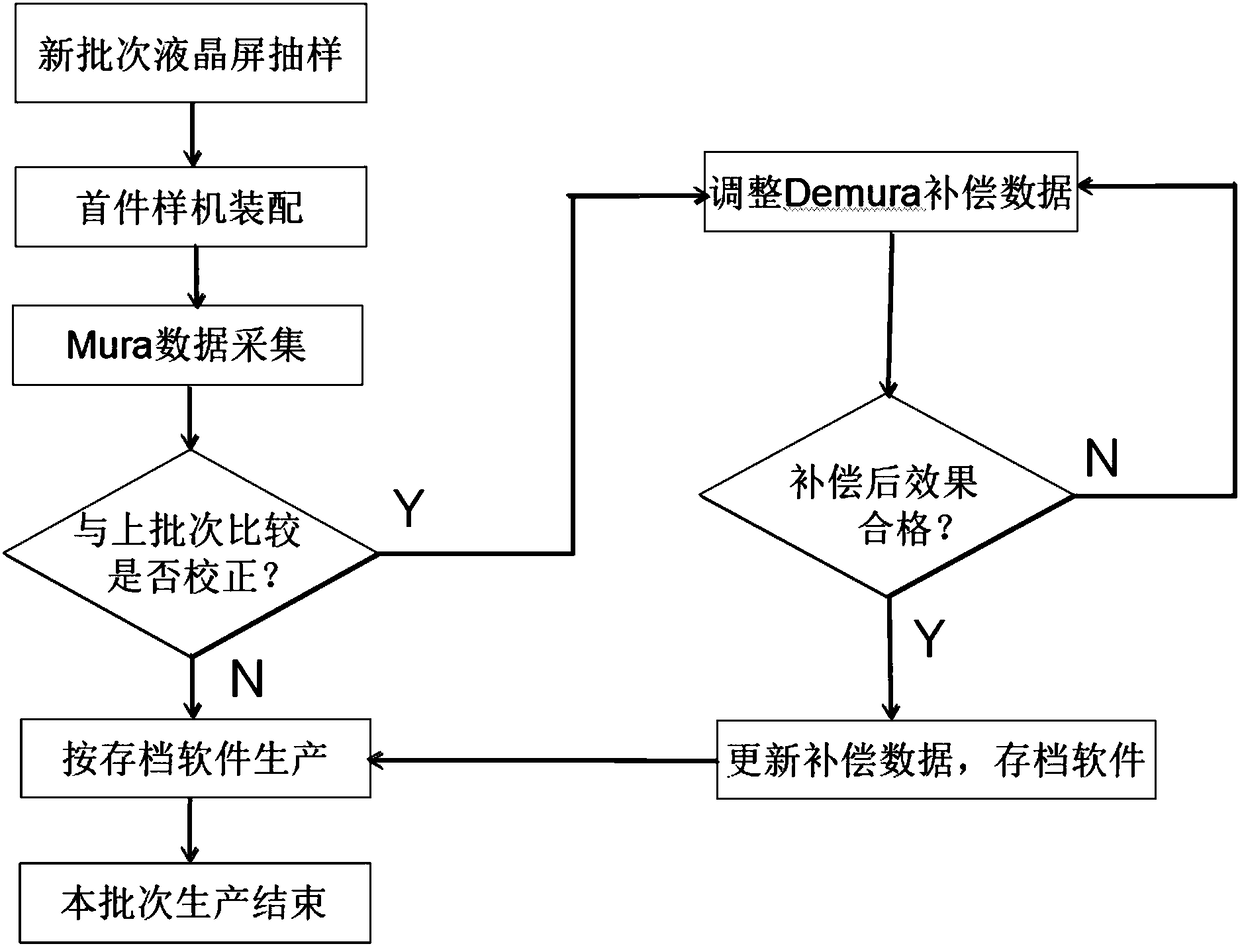

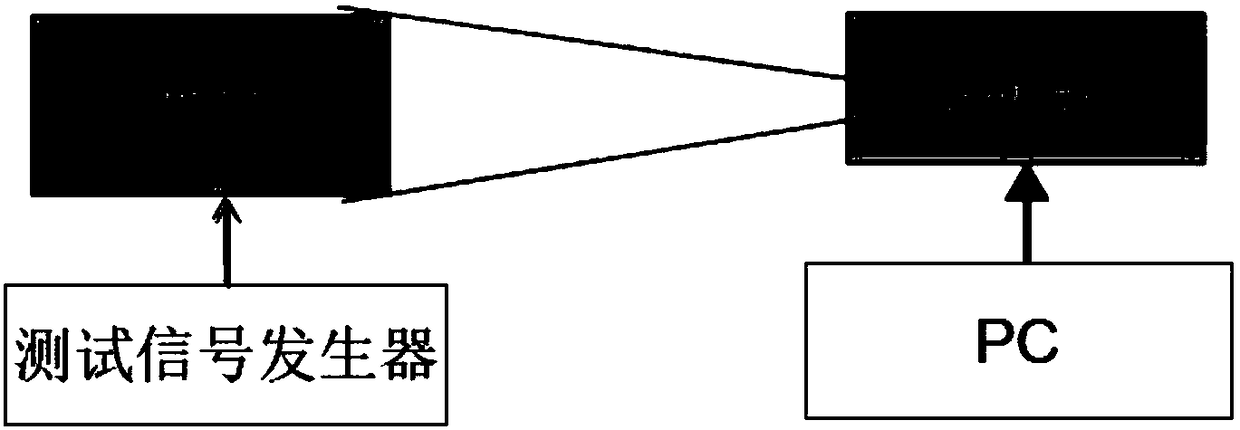

LCD TV (Liquid Crystal Display TV) whole De-Mura method

ActiveCN108377386ATaking into account the display effectTaking into account production efficiencyTelevision systemsData fileLiquid-crystal display

The invention discloses an LCD TV (Liquid Crystal Display TV) whole De-Mura method. The method comprises the steps of A, performing random sampling on a new batch of LCDs and assembling the extractedLCD samples into an LCD TV prototype; B, performing mura data collection, data statistics and analysis on the to-be-checked LCD TV prototype to obtain mura data of the to-be-checked LCD TV prototype;C, performing comparative analysis on typical mura data collected in the current batch and typical mura data collected in the last batch; D, performing data collection, data analysis, comparison and objective effect checking on the prototype after being subjected to De-Mura data supplementation and correction so as to obtain compensatory data which meet requirements; and E, integrating the compensatory data which meet the requirements to a configuration data file of the to-be-checked LCD TV prototype for storage. As the LCDs in the same batch and the whole machine are subjected to the De-Muraprocessing in batches after the typical data is obtained through sampling, independent processing for each LCD is unnecessary, and both the display effect and the protection efficiency are realized.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

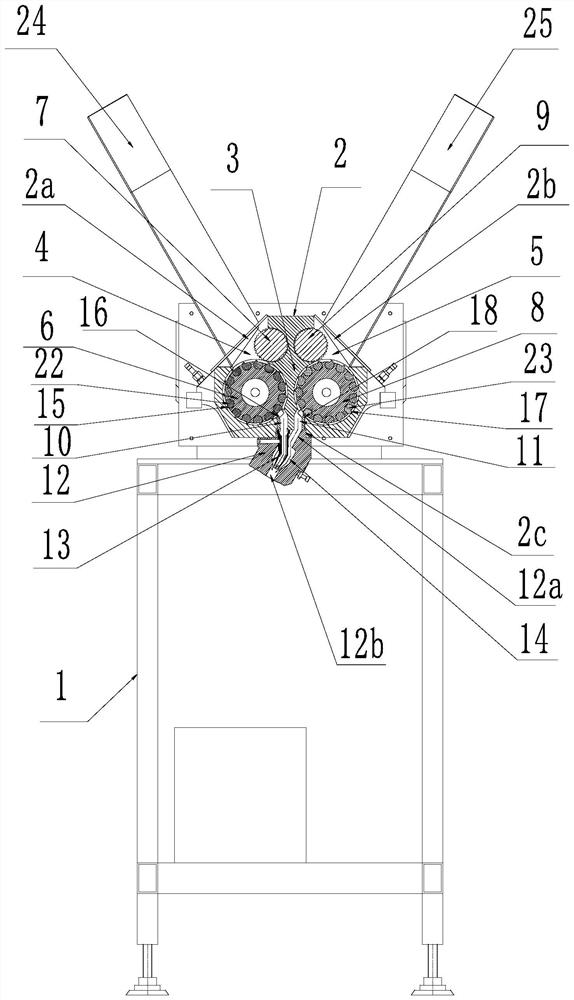

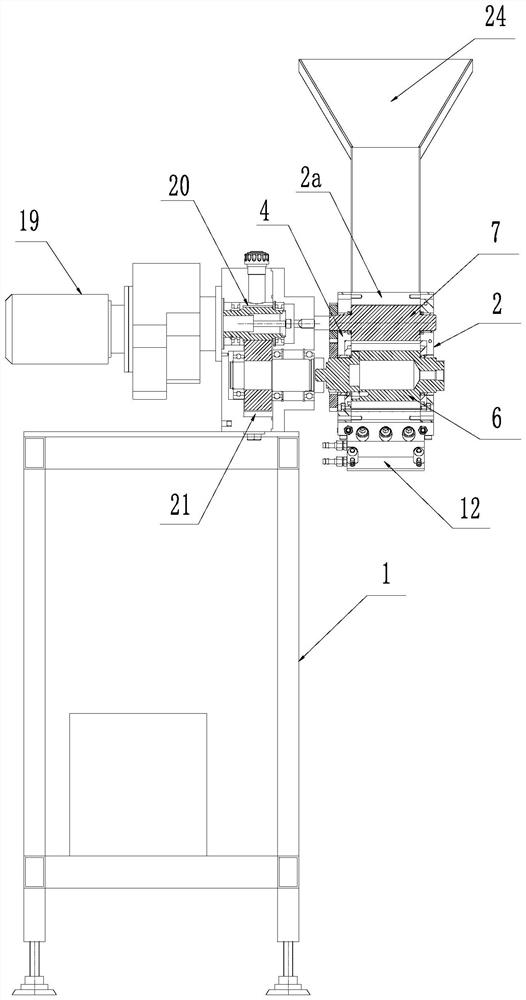

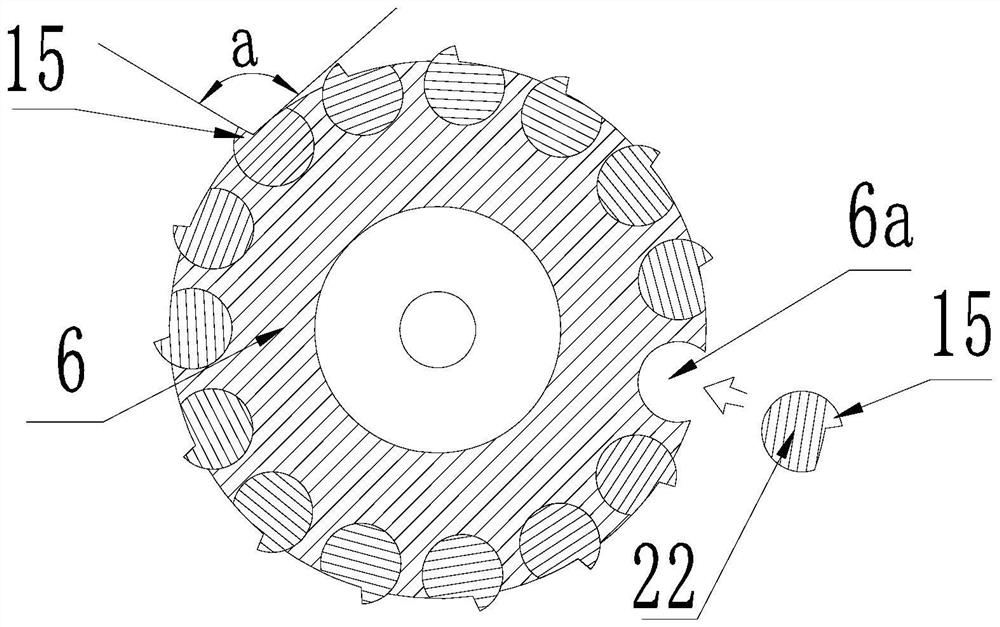

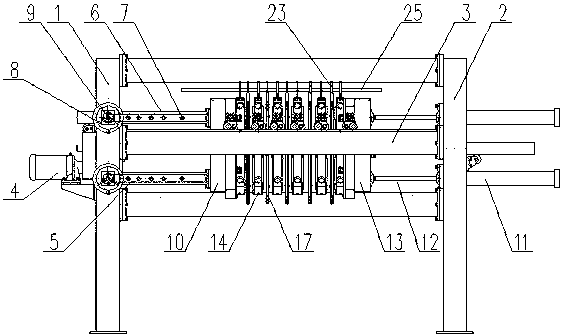

Sandwich energy bar extrusion production device

ActiveCN114847504AIncrease productivityImprove product qualityFood shapingMechanical engineeringExtrusion

The invention discloses a sandwich energy bar extrusion production device which comprises a supporting table and is characterized in that a double-material synchronous co-extrusion mechanism and a nested extrusion mold core are arranged on the supporting table, and the double-material synchronous co-extrusion mechanism comprises a co-extrusion shell, a core material co-extrusion cavity and a shell material co-extrusion cavity, a core material main tooth roller and a core material auxiliary tooth roller which are parallel and synchronously reverse are arranged in the core material co-extrusion cavity, and a shell material main tooth roller and a shell material auxiliary tooth roller which are parallel and synchronously reverse are arranged in the shell material co-extrusion cavity. A core material inlet and a shell material inlet are formed in the co-extrusion shell; the bottom of the co-extrusion shell is provided with a mold core interface which is connected with a core material co-extrusion cavity and a shell material co-extrusion cavity through a core material falling channel and a shell material falling channel respectively; the nested extrusion die core adopts a shell material extrusion sleeve to surround a core material extrusion pipe to form a shell material extrusion ring channel, the upper end of the ring channel is connected with a die core connector through a die core inlet, and the lower end of the ring channel and the core material extrusion pipe are connected with a die core outlet together. The upper end of the core material extrusion pipe is in butt joint with the core material falling channel to separate the shell material falling channel. The method is specially used for producing the sandwich energy bar with the structure that the core material is wrapped by the shell material, and the product quality and the production efficiency can be both considered.

Owner:苏州姑苏食品机械有限公司

Device for vertically pouring organic glass

The invention relates to a device for vertically pouring organic glass. The device is characterized in that two racks are connected in parallel by two horizontal beams; a fixed plate is vertically supported on the two horizontal beams at any rack side; a fixed plate adjustment device is arranged on the any rack and the fixed plate is connected to the fixed plate adjustment device and is arranged on the two horizontal beams in a slide adjustment localizable state; a movable plate is vertically and slidingly supported on the two horizontal beams at the other rack side; a movable plate adjustment device is arranged at the other rack and the movable plate is connected to the movable plate adjustment device and is arranged on the two horizontal beams in a slide adjustment localizable state; multiple water tanks are vertically supported on the two horizontal beams between the fixed plate and the movable plate at intervals; and an injection mold is vertically arranged in a gap of each adjacent two of the multiple water tanks and is sealedly clamped between vertical sides of the water tanks by movable plate pushing. The device has a simple and compact structure, can be used conveniently and can effectively guarantee molding quality and production efficiency.

Owner:TAIXING TOMSON ACRYLIC CO LTD

Apricot fruit wine and fermentation process therefor

PendingCN113621463AAvoid lostAvoid it happening againAlcoholic beverage preparationBiotechnologyFruit wine

The invention is applicable to the technical field of apricot fruit processing, and provides apricot fruit wine and a fermentation process therefor. Apricot fruits are adopted as raw materials, and screening and cleaning, pulping and denucleating, enzymolysis and fermentation, and degerming and filtering are carried out to obtain the apricot fruit wine; the apricot fruit wine is rich in nutrients and high in total flavonoid content, and has antibacterial, antiviral and antioxidant effects; pure fruit juice is adopted for low-temperature fermentation, so that bad smell is prevented; and a membrane sterilization and filtration technology is adopted, so that loss of nutrient components and fragrance substances caused by high-temperature sterilization is prevented. The process is used for fermentation of green fruit juice, a method is simple, auxiliary materials and auxiliary agents are less, the cost is low, the prepared fruit wine is wide in applicable population, process parameters are optimized, and the nutrition performance and the production efficiency are taken into account.

Owner:山西菲尼克司酒业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com