Device and method for vertically pouring organic glass

A plexiglass and casting mold technology, which is applied to other household appliances, flat products, household appliances, etc., can solve the problems of unfavorable mass production, cumbersome clamping operation, and high clamping requirements, and achieves convenient casting, convenient operation, and product quality. Accurate and high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

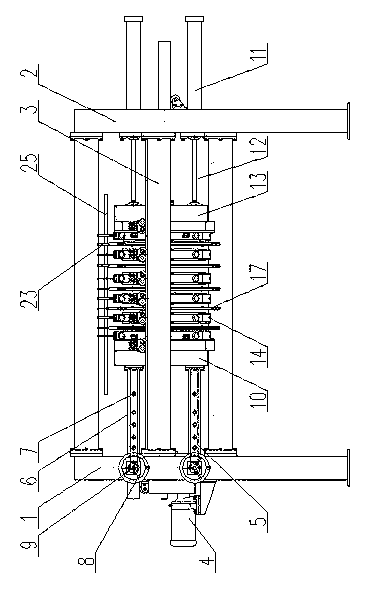

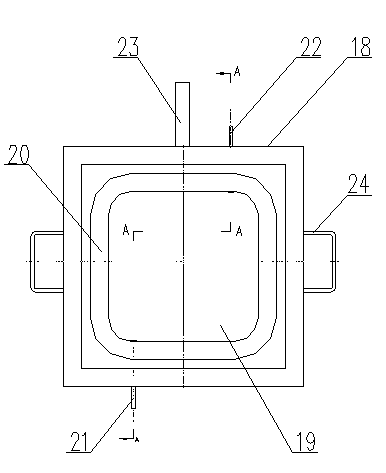

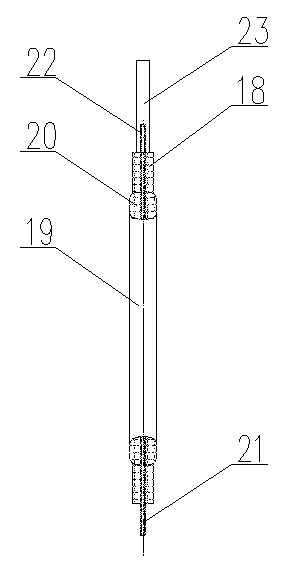

[0028] figure 1 As shown, a plexiglass vertical pouring device includes a left frame 1, a right frame 2, a horizontal beam 3, a fixed plate adjustment motor 4, a fixed plate adjustment screw 5, a screw cover 6, a positioning handwheel 8, a hand wheel Rocking screw pin shaft 9, fixed plate 10, moving plate regulating cylinder 11, moving plate 13, water tank 14, casting mold 17 and suspension rod 24. The left and right frames 1 and 2 are connected by two horizontal beams 3, the left frame 1 is provided with a positioning adjustment motor 4, and the positioning adjustment screw rod 5 is covered with a screw rod sleeve 6 and slides through the left frame 1, and the positioning adjustment motor 4. The driving connection positioning screw rod 5 is in the state of driving the positioning adjusting screw rod 5 to feed along the direction of the horizontal beam 3, and the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com