Preparation method of waterborne polyurethane synthetic leather Bayse and applications thereof

A water-based polyurethane and synthetic leather technology, applied in polyurea/polyurethane adhesives, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of product performance degradation, low production efficiency, cumbersome operation, etc., and achieve speed Uniformity, low cost, good hand feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

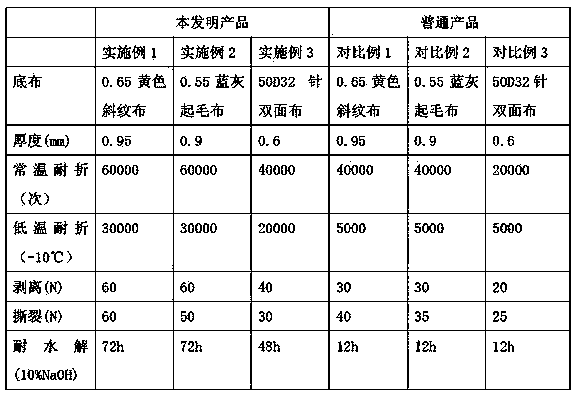

Examples

Embodiment 1

[0030] A kind of preparation method of aqueous polyurethane synthetic leather bass, required material and reagent are as follows:

[0031]Base fabric: Greer 0.65mm yellow twill fabric, impregnating liquid: magnesium nitrate aqueous solution, water-based polyurethane resin: Ketian 731, foaming agent: Buset STA, foam stabilizer: Buset SR, foam stabilizer: Zhongbao ZBH-207, thickener: Ketian ZZ18, water-based color paste: Shenlan Technology 519, crosslinking agent Ketian ZQ10, filler: Gree T03.

[0032] Its preparation method comprises the following steps,

[0033] (1) Prepare the base cloth;

[0034] (2) Impregnation of the base cloth: in parts by weight, the impregnation formula is 100 parts of water and 5 parts of salt, and the liquid carrying rate of the base cloth after impregnation is about 20%;

[0035] (3) After the base fabric is impregnated, it is heated and ironed by six rollers, calendered and dried successively; among them, the temperature of heated and ironed by s...

Embodiment 2

[0044] A kind of preparation method of aqueous polyurethane synthetic leather bass, required material and reagent are as follows:

[0045] Base fabric: Greer 0.55mm blue gray fleece cloth, impregnating liquid: sodium nitrate aqueous solution, water-based polyurethane resin: Ketian 735, foaming agent: Buset STA, foam stabilizer: Buset SR, foam stabilizer: Zhongbao ZBH-207, thickener: Ketian ZZ18, water-based color paste: Deep Blue Technology 519, crosslinking agent Ketian ZQ10, filler: Shengdeli F11.

[0046] Its preparation method comprises the following steps,

[0047] (1) Prepare the base cloth;

[0048] (2) Impregnation of the base cloth: in parts by weight, the impregnation formula is 100 parts of water and 2 parts of salt, and the liquid carrying rate of the base cloth after impregnation is 12%;

[0049] (3) After the base fabric is impregnated, it is heated and ironed by six rollers, calendered and dried successively; among them, the temperature of heated and ironed by...

Embodiment 3

[0057] A kind of preparation method of aqueous polyurethane synthetic leather bass, required material and reagent are as follows:

[0058] Base fabric: Greer 50D32 needle double-sided fabric, impregnating liquid: calcium nitrate aqueous solution, water-based polyurethane resin: Ketian 736, foaming agent: Buset STA, foam stabilizer: Buset SR, foam stabilizer: medium Bao ZBH-207, thickener: Ketian ZZ18, water-based color paste: Deep Blue Technology 519, crosslinking agent Ketian ZQ10, filler: Shengdeli F11.

[0059] Its preparation method comprises the following steps,

[0060] (1) Prepare the base cloth;

[0061] (2) Impregnation of the base cloth: in parts by weight, the impregnation formula is 100 parts of water and 8 parts of salt, and the liquid carrying rate of the base cloth after impregnation is 26%;

[0062] (3) After the base fabric is impregnated, it is heated and ironed by six rollers, calendered and dried successively; among them, the temperature of heated and iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com