Patents

Literature

35results about How to "Poor flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

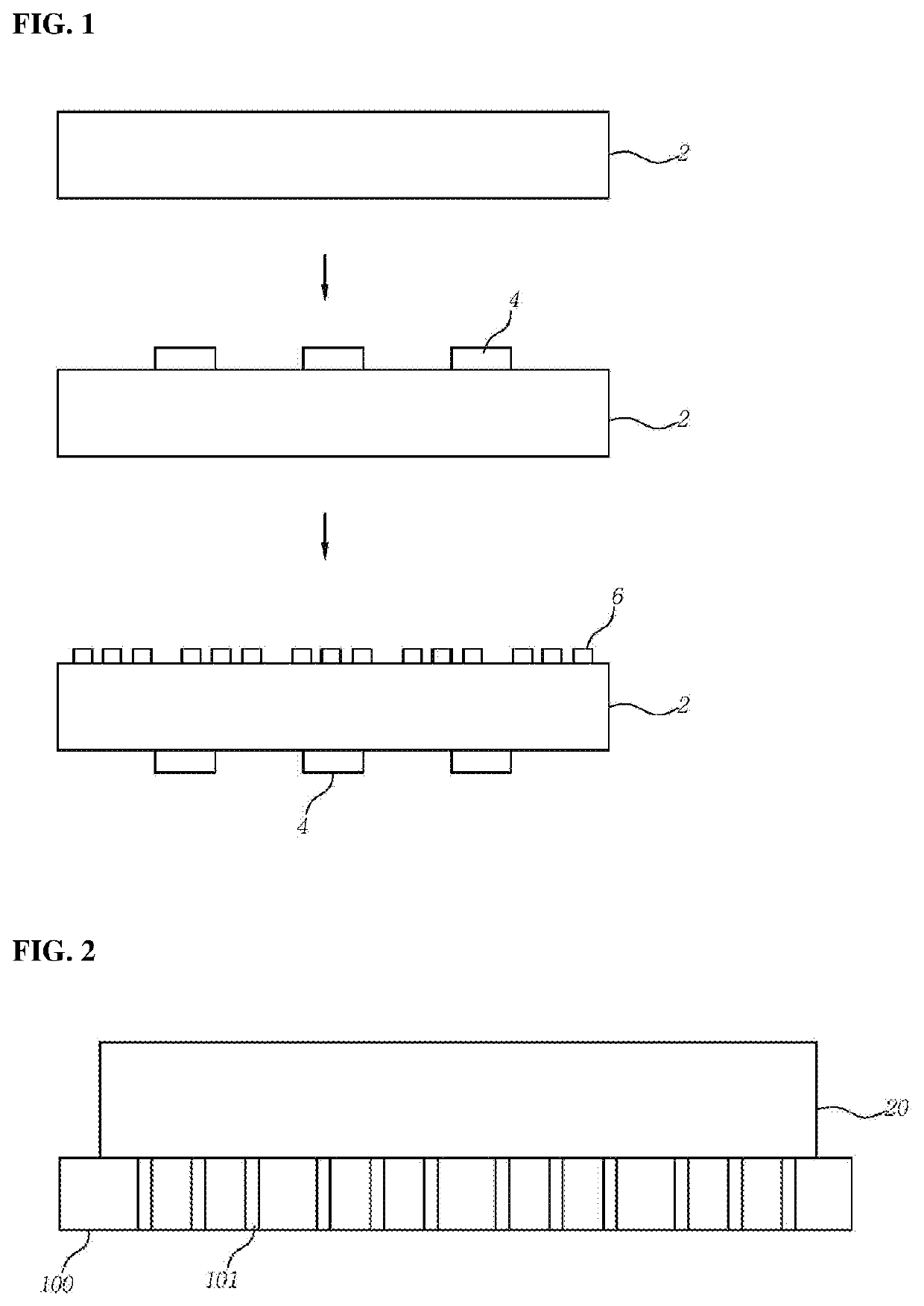

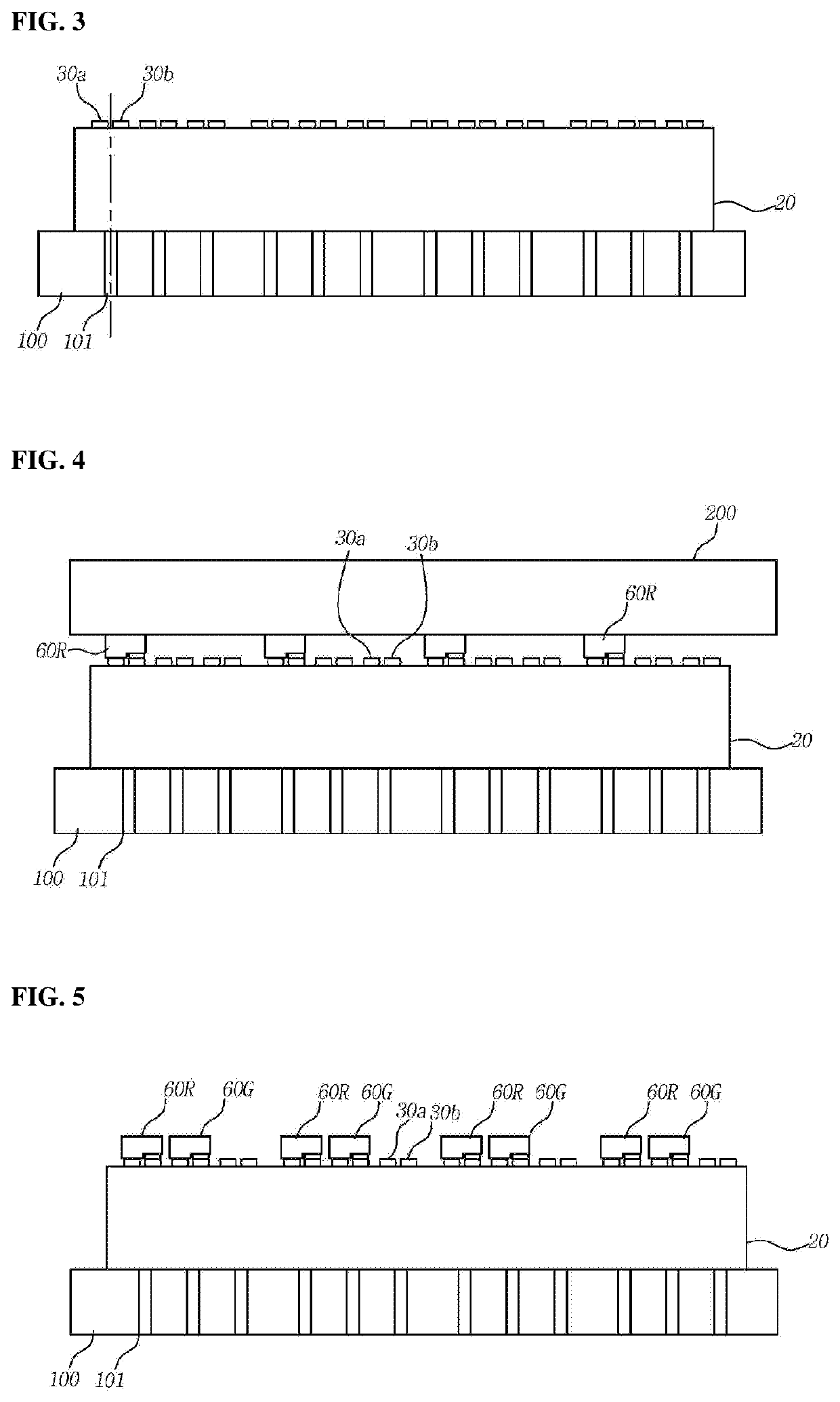

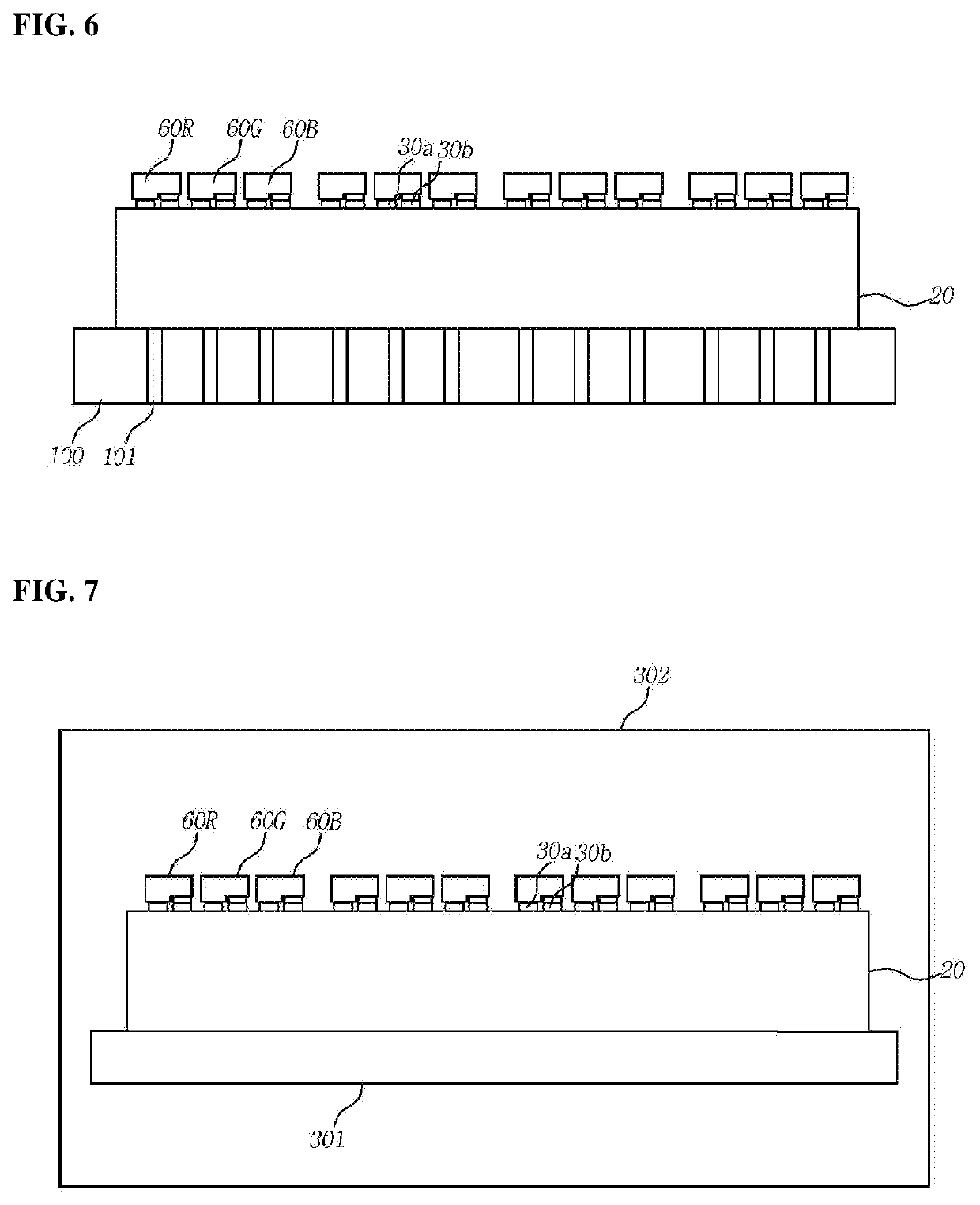

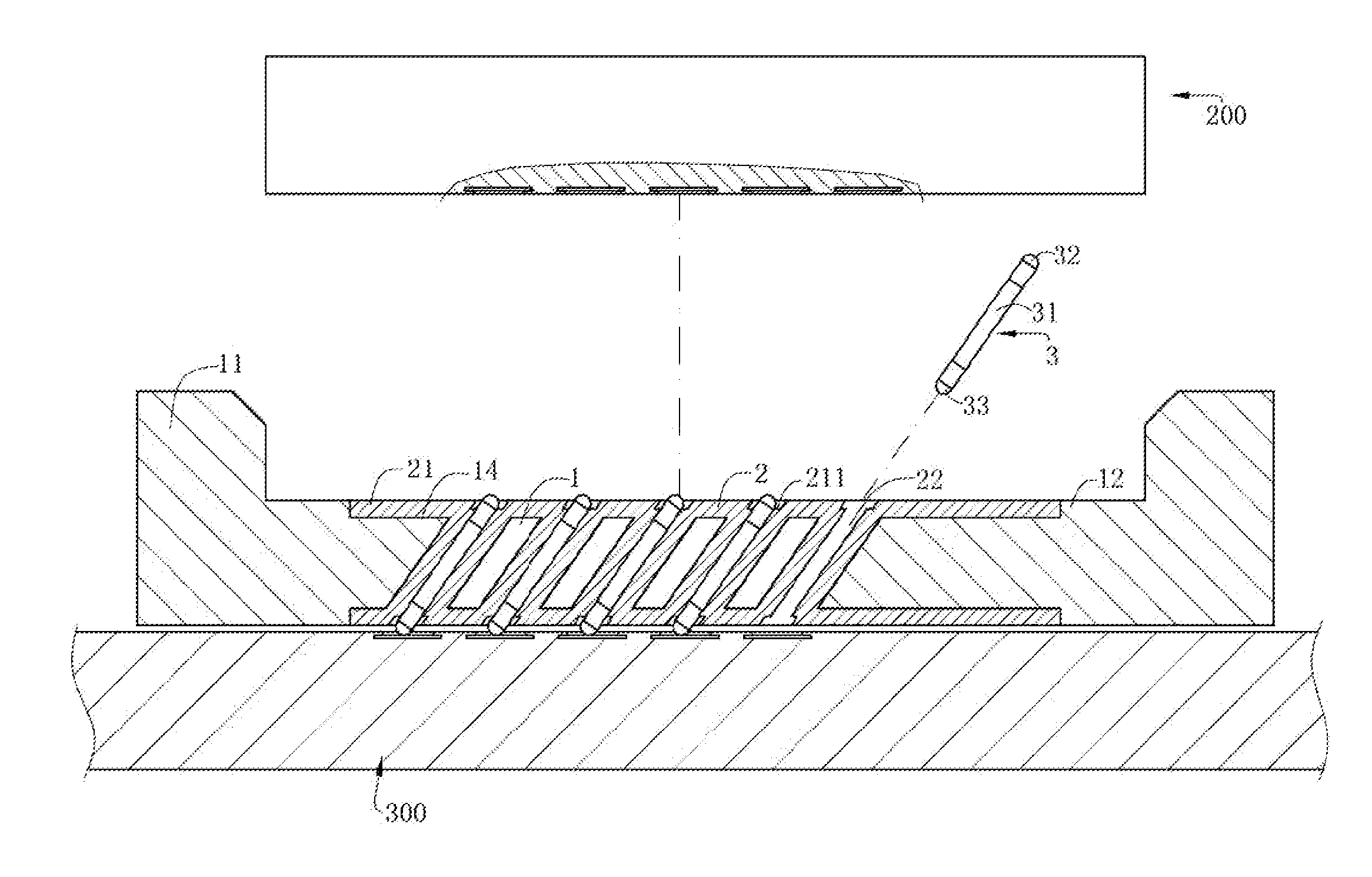

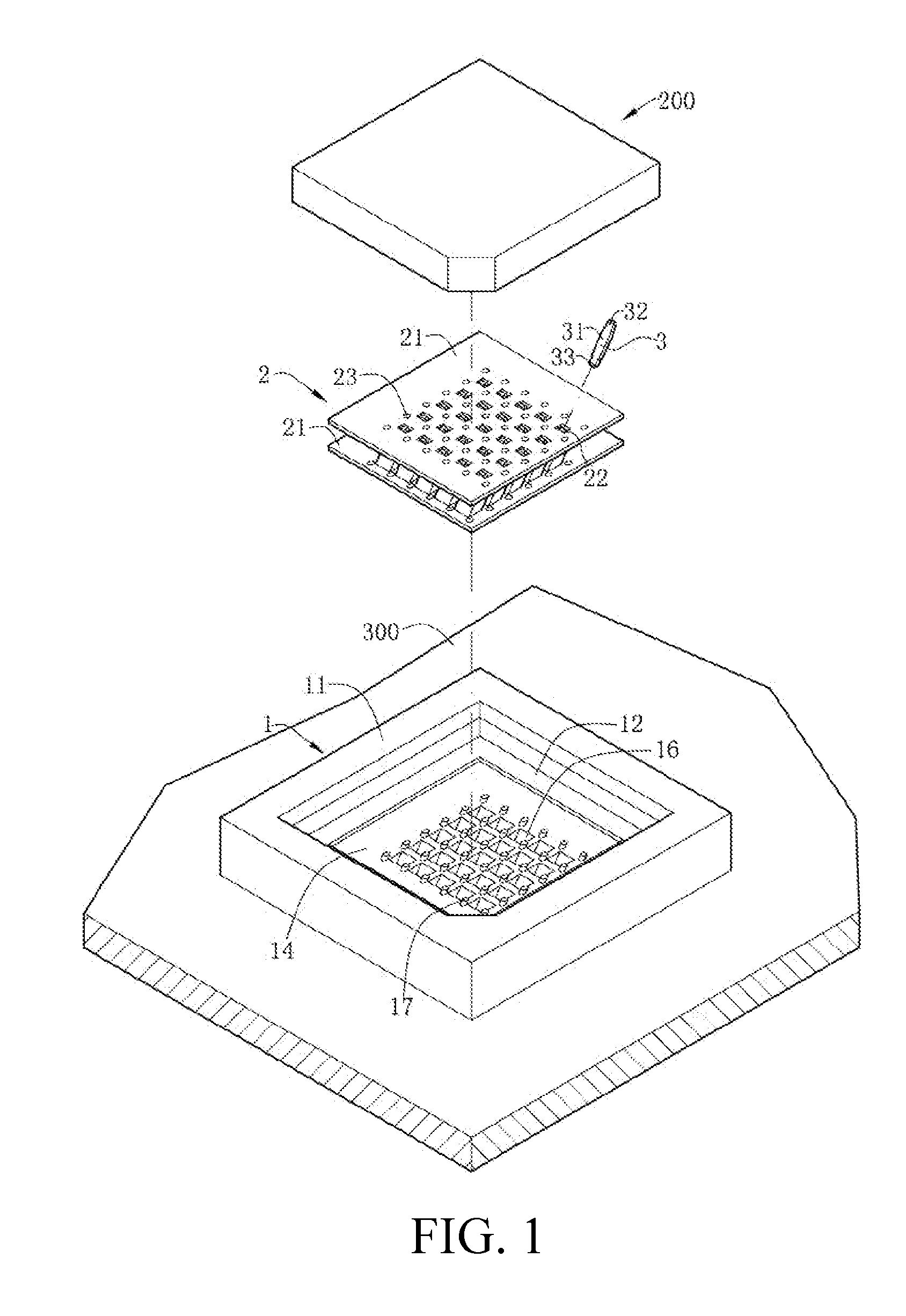

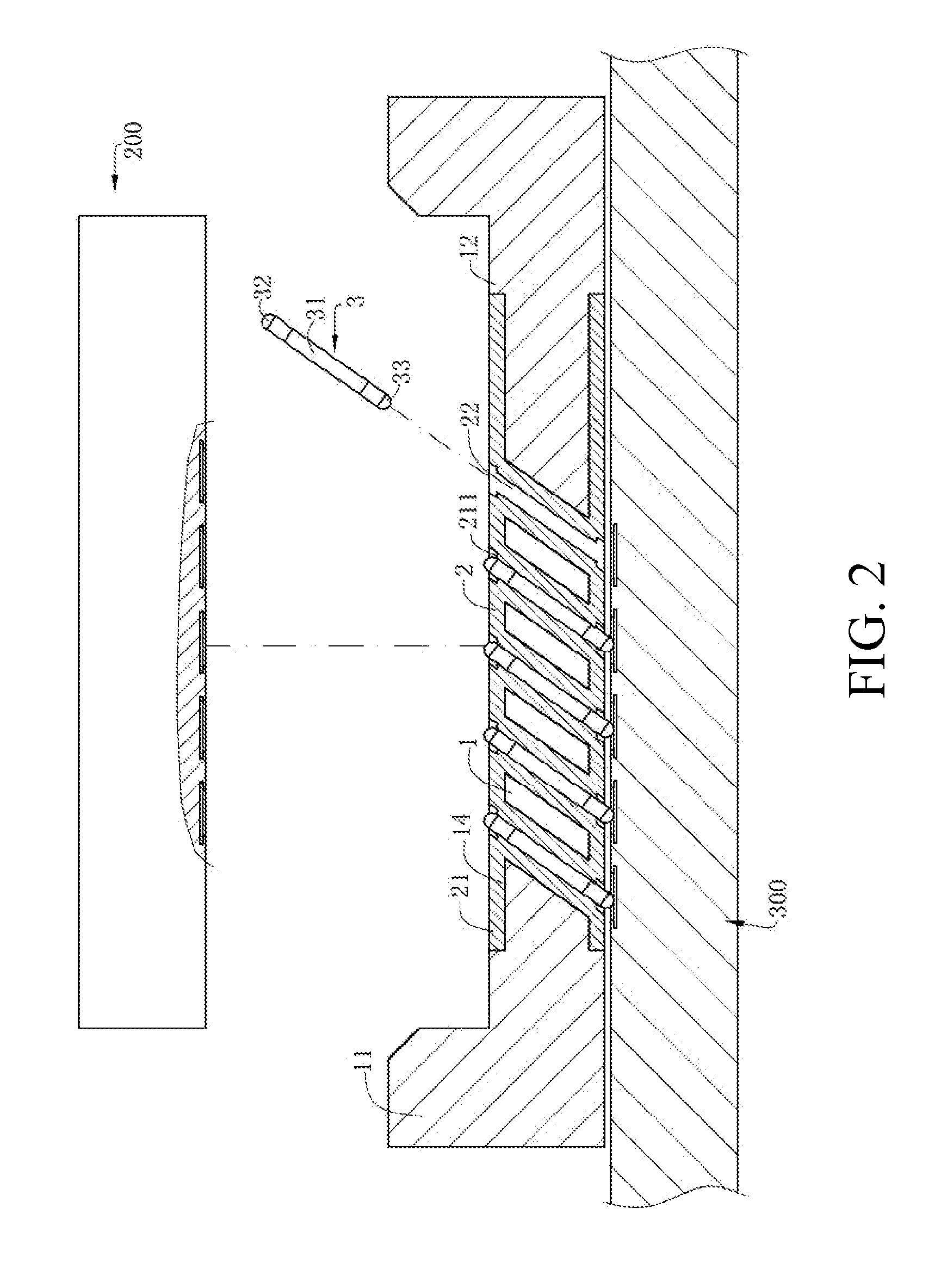

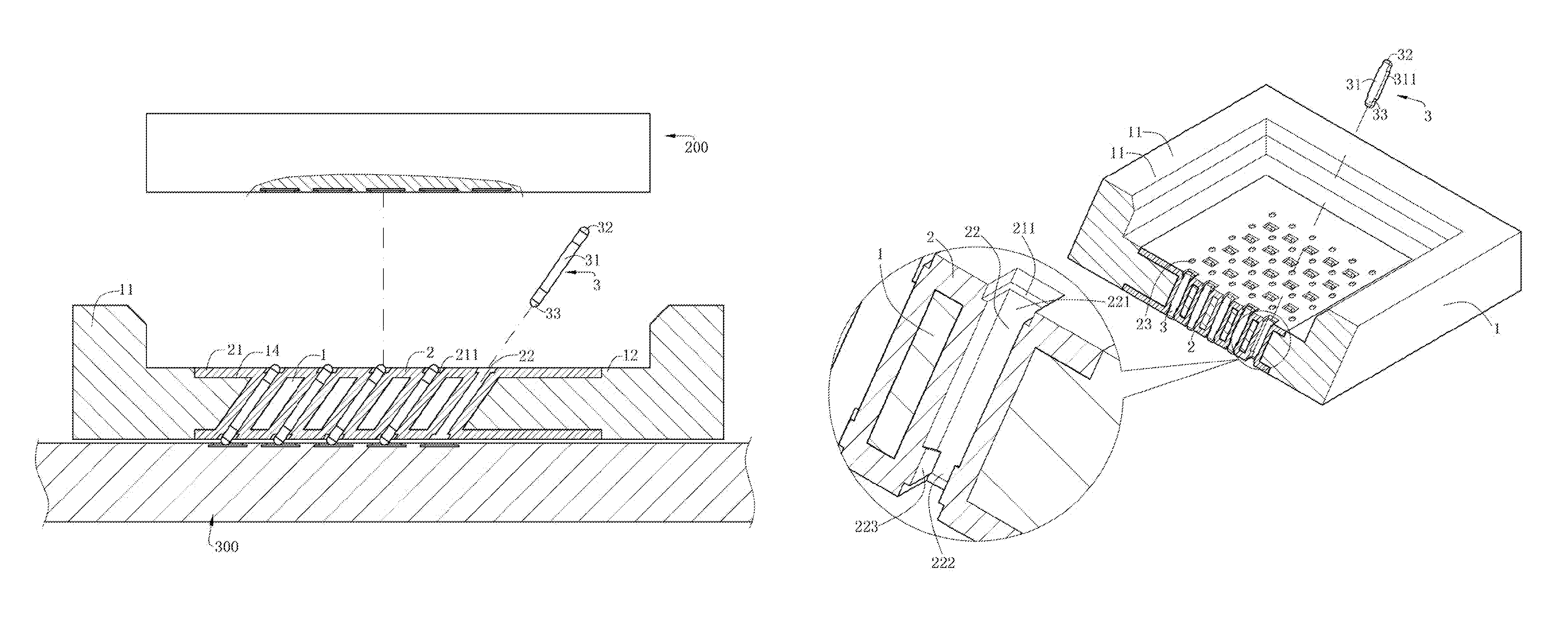

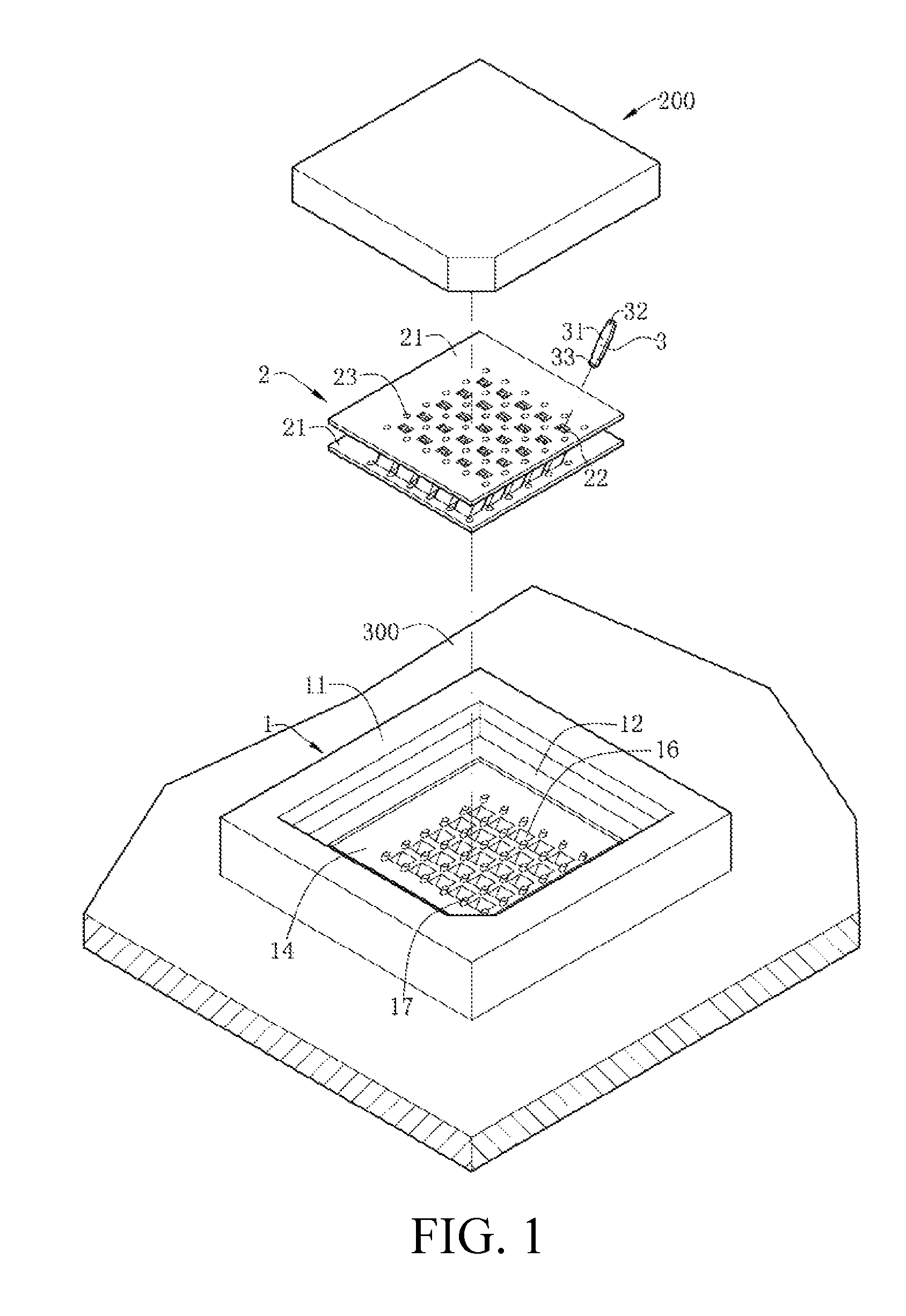

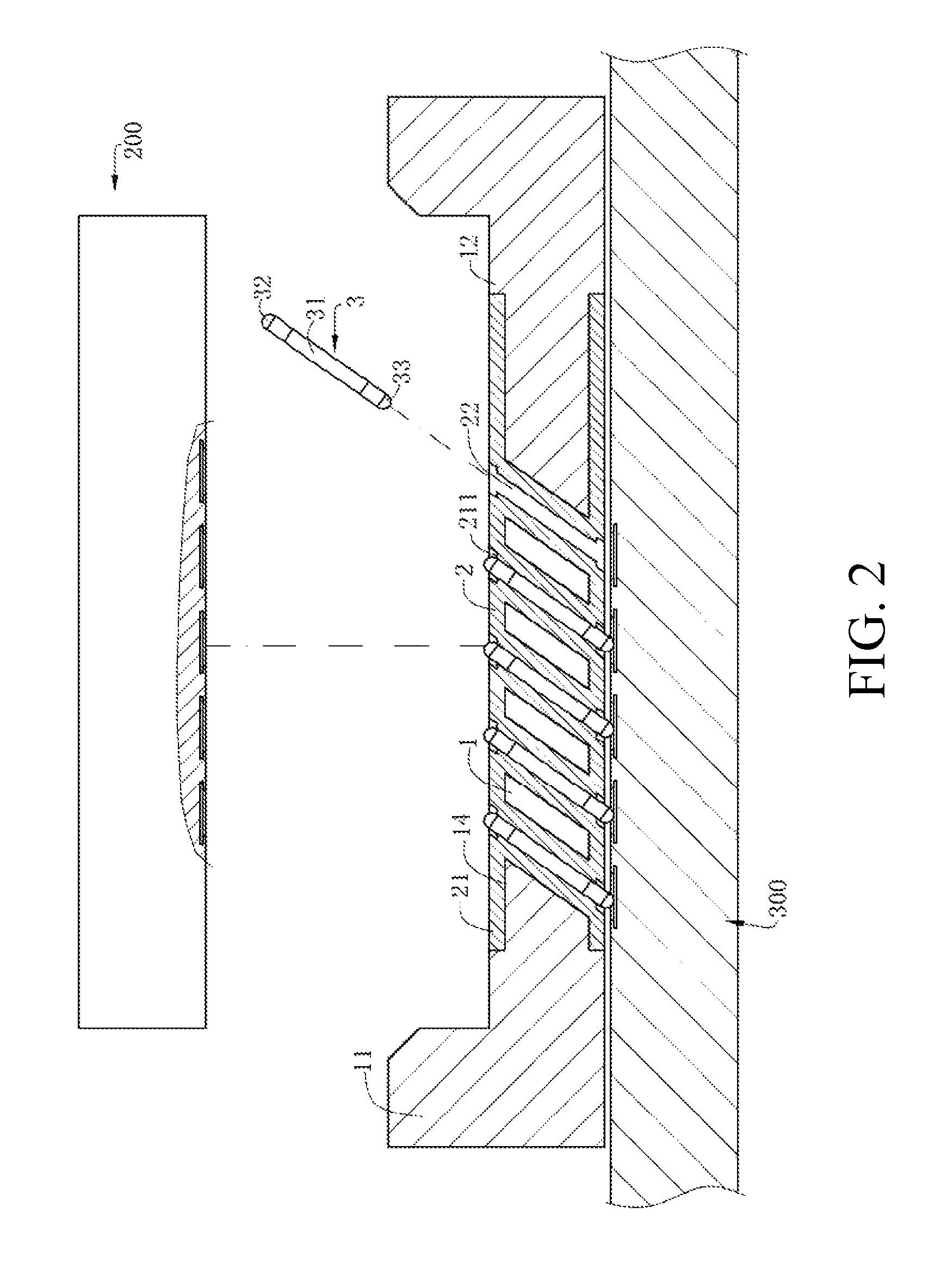

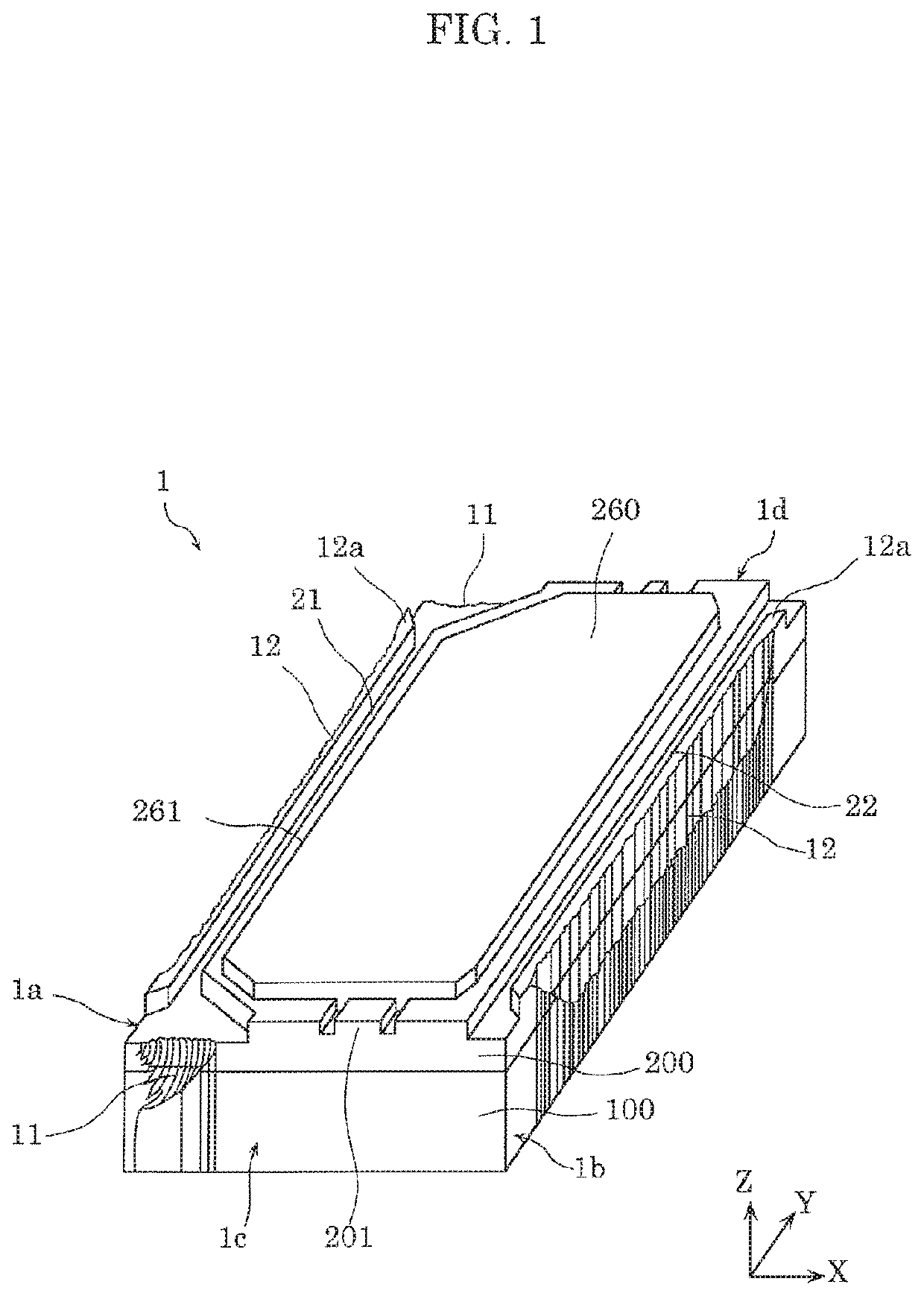

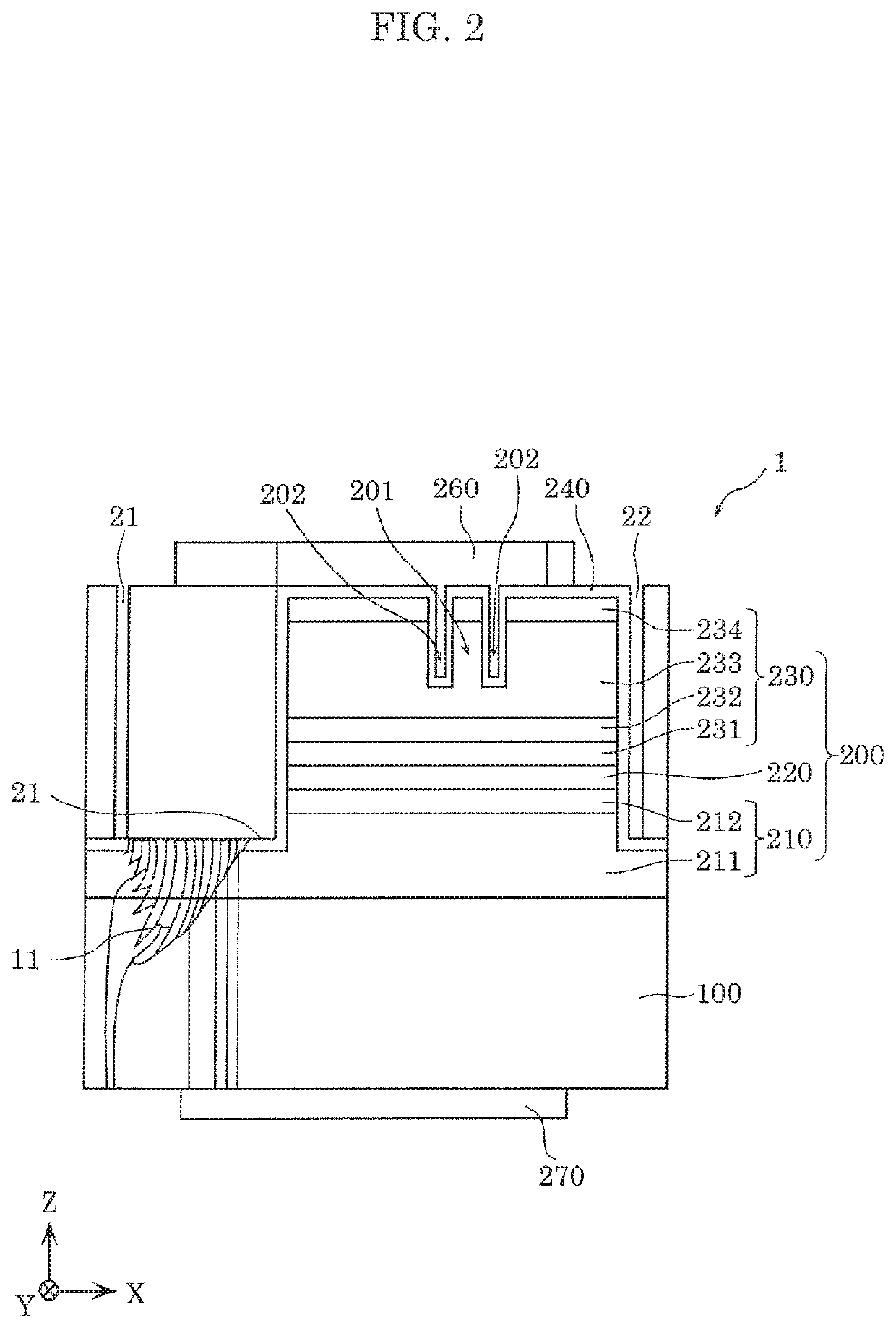

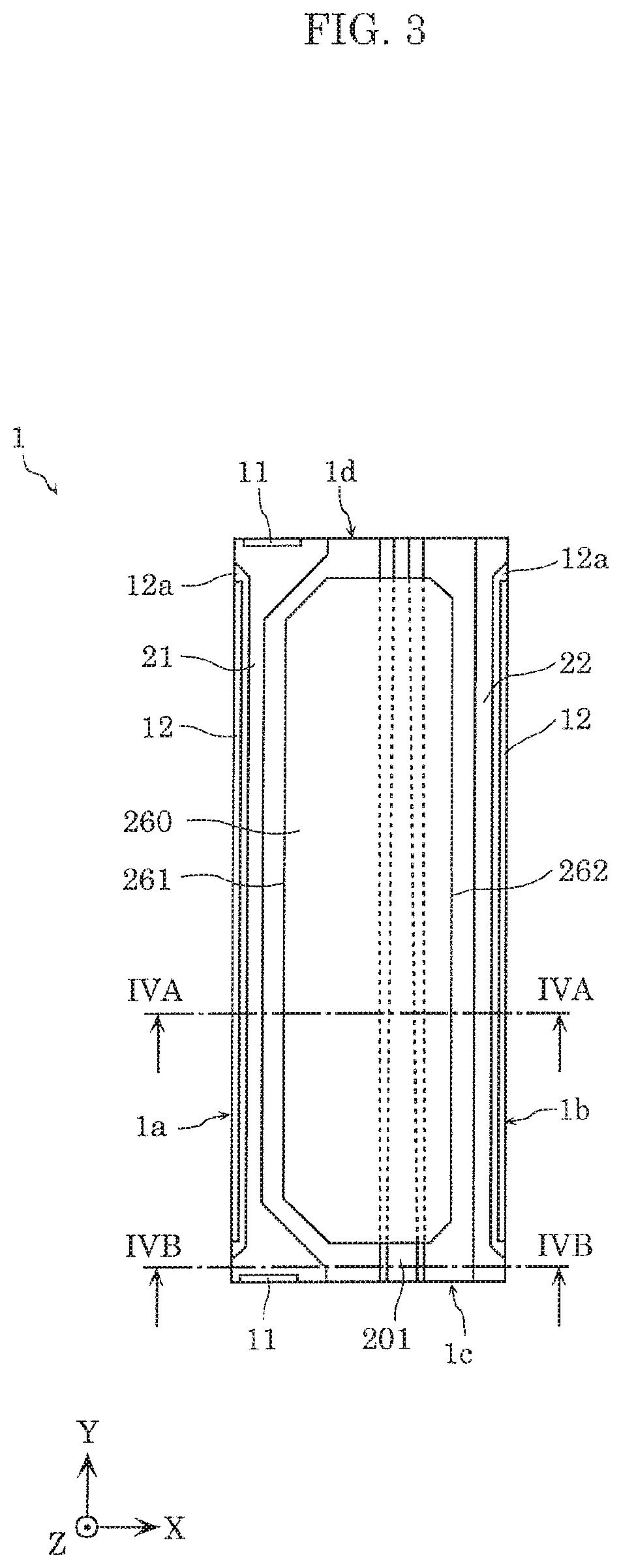

Micro-led module and method for fabricating the same

ActiveUS20190360673A1Flatness can be worsenedPrecise and accurate mounting of micro-LEDFinal product manufactureElectric circuit arrangementsComputer moduleEngineering

Owner:LUMENS

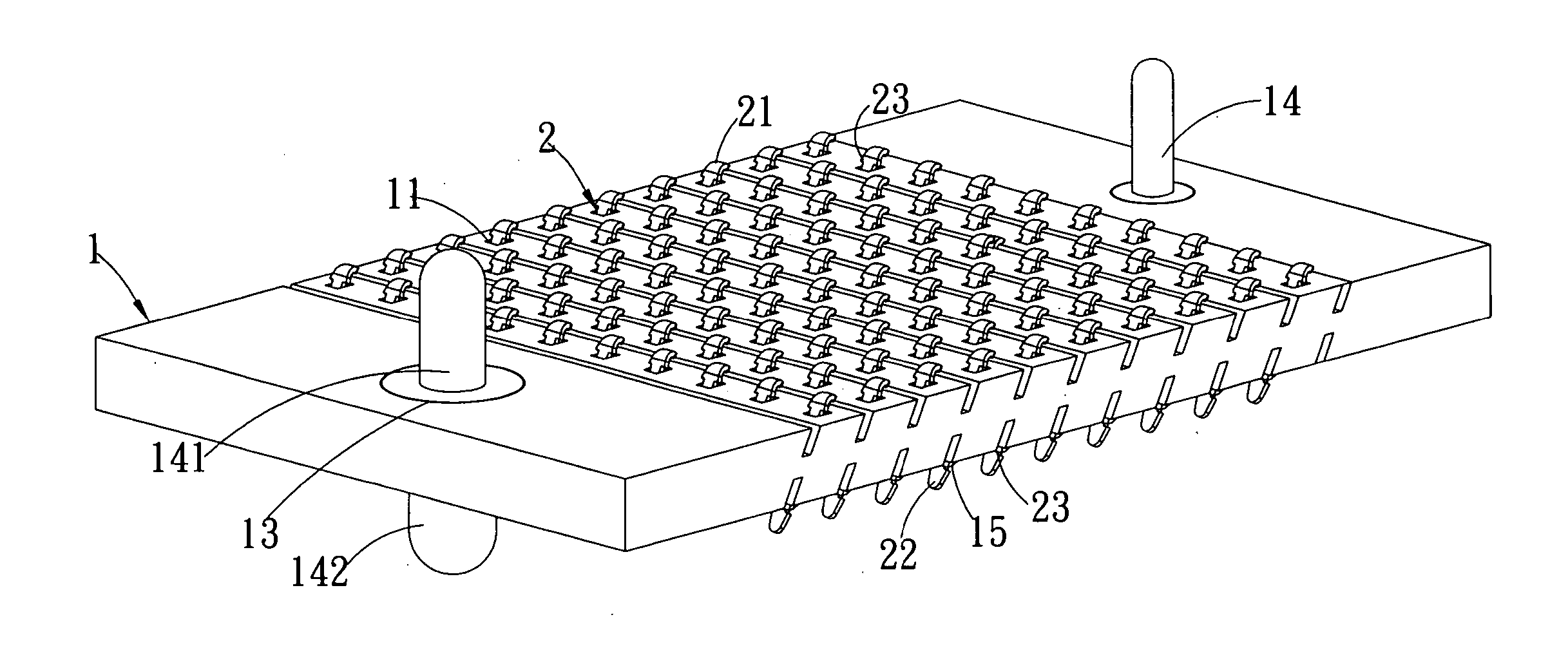

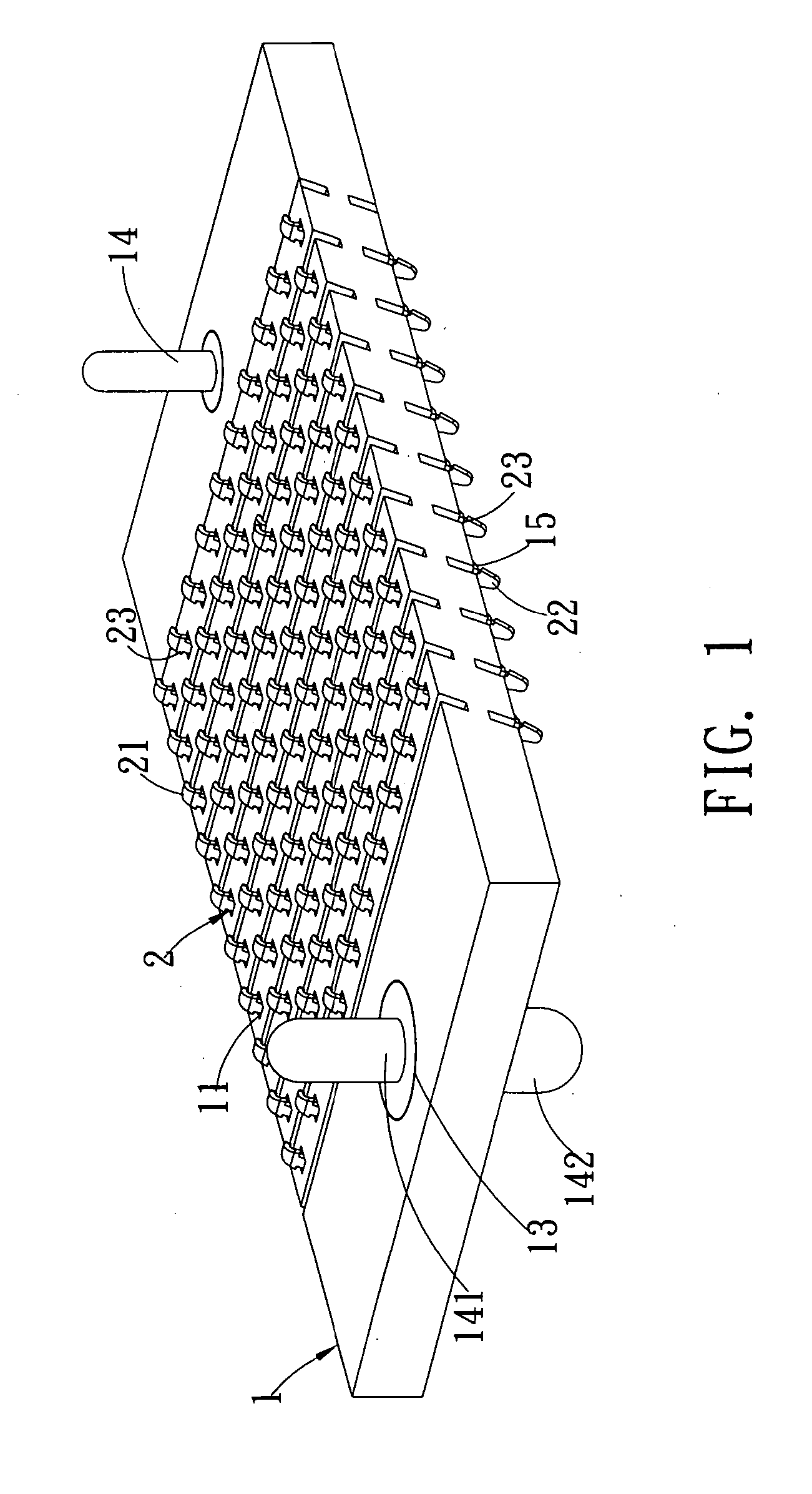

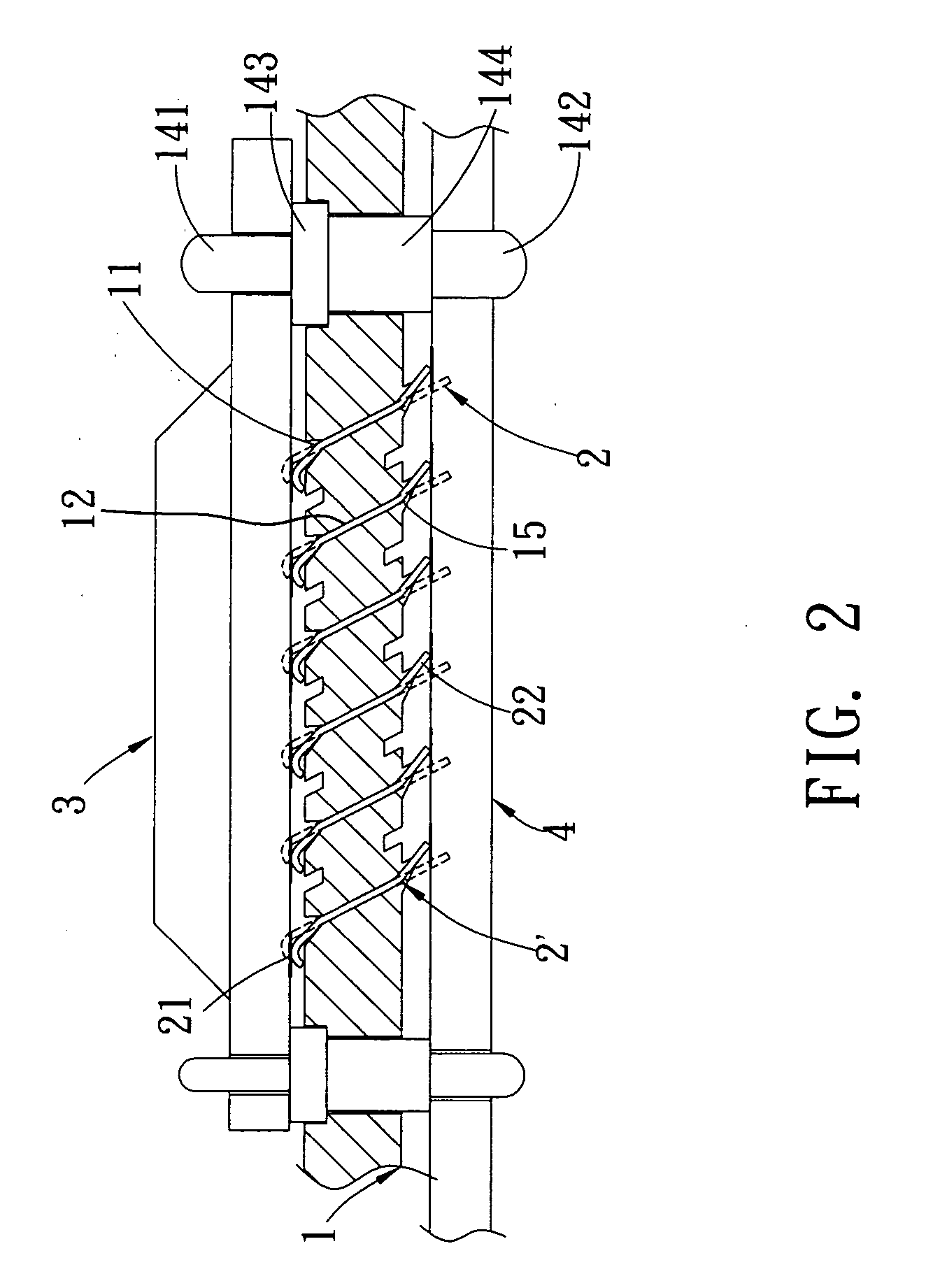

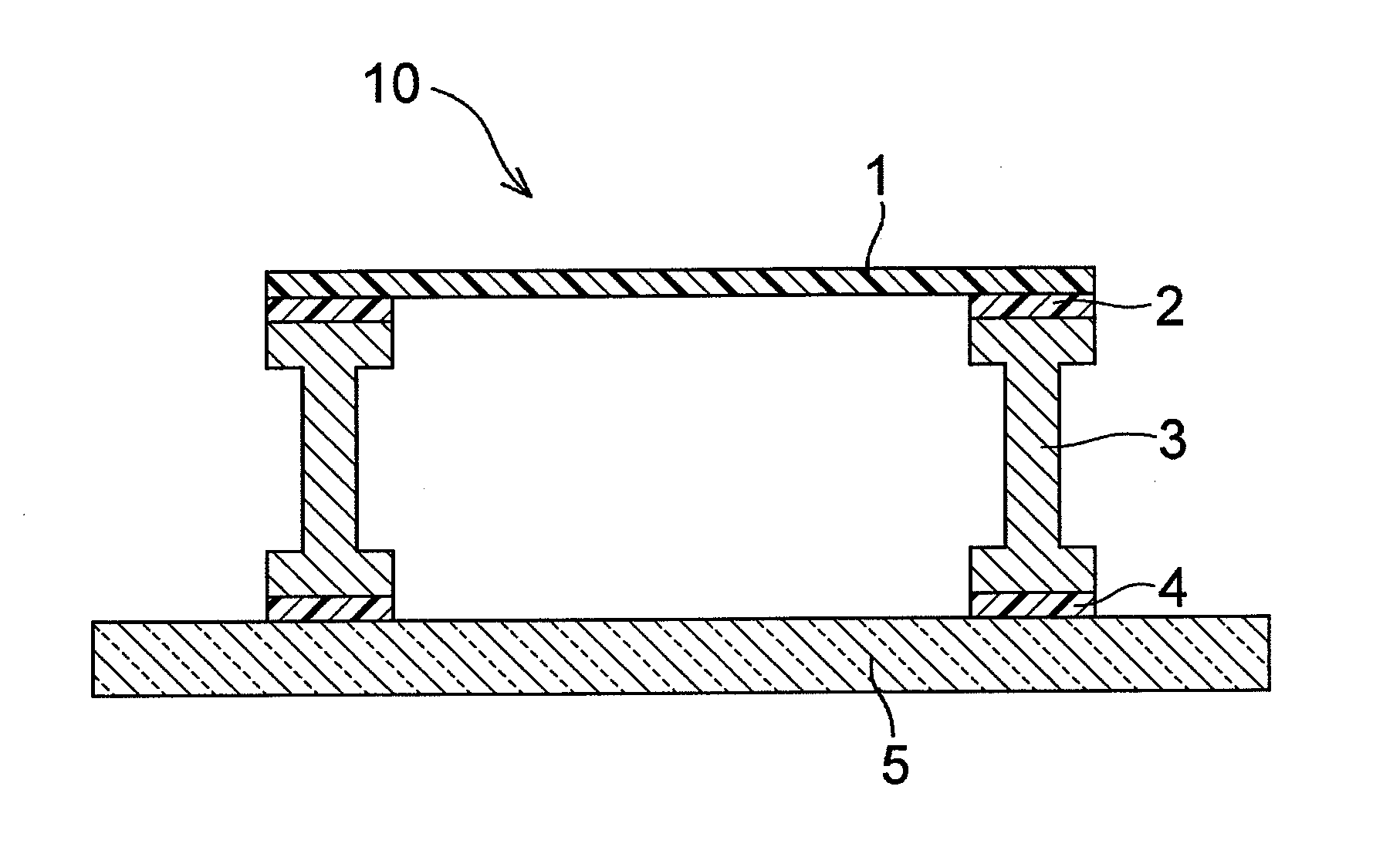

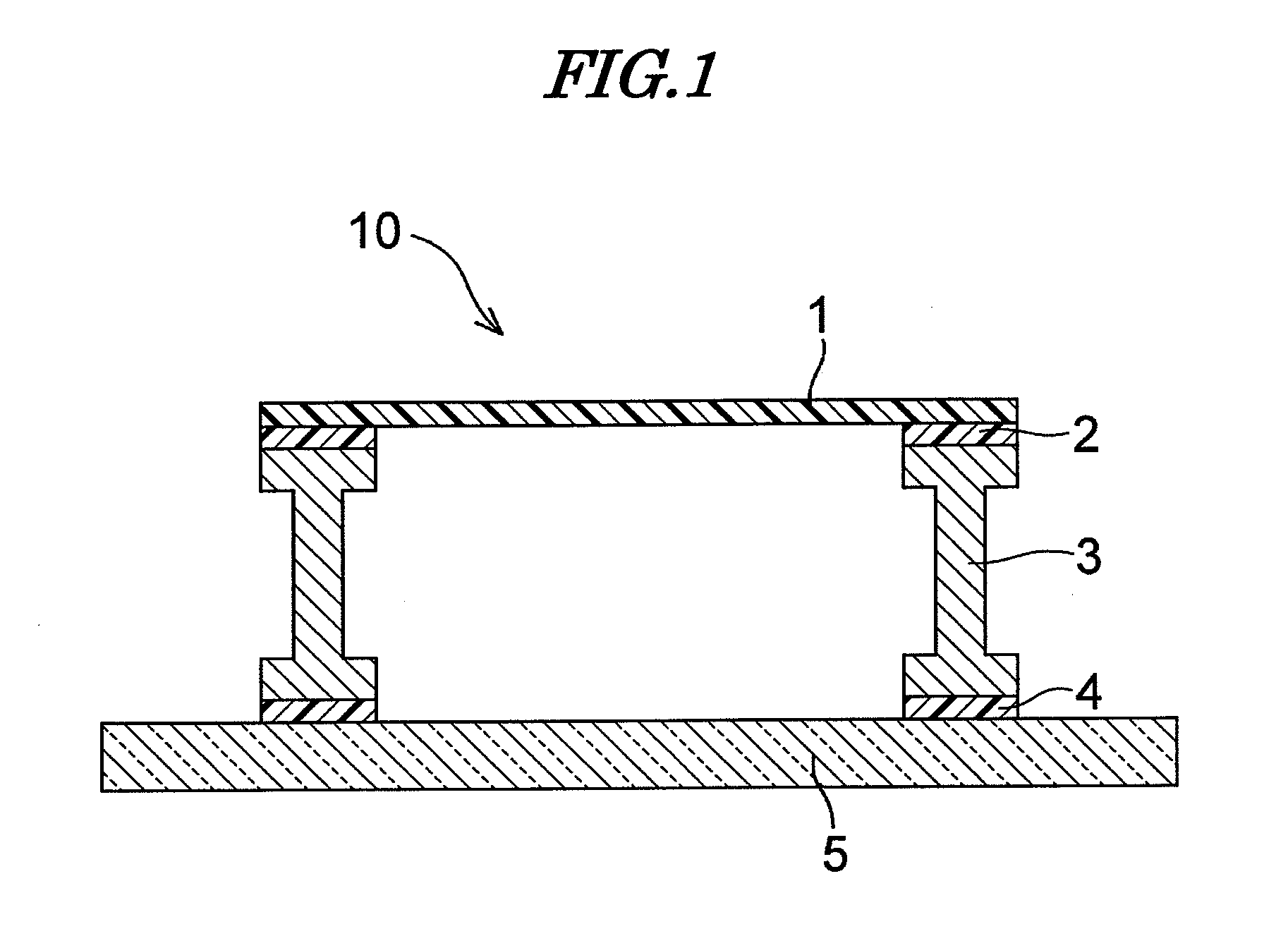

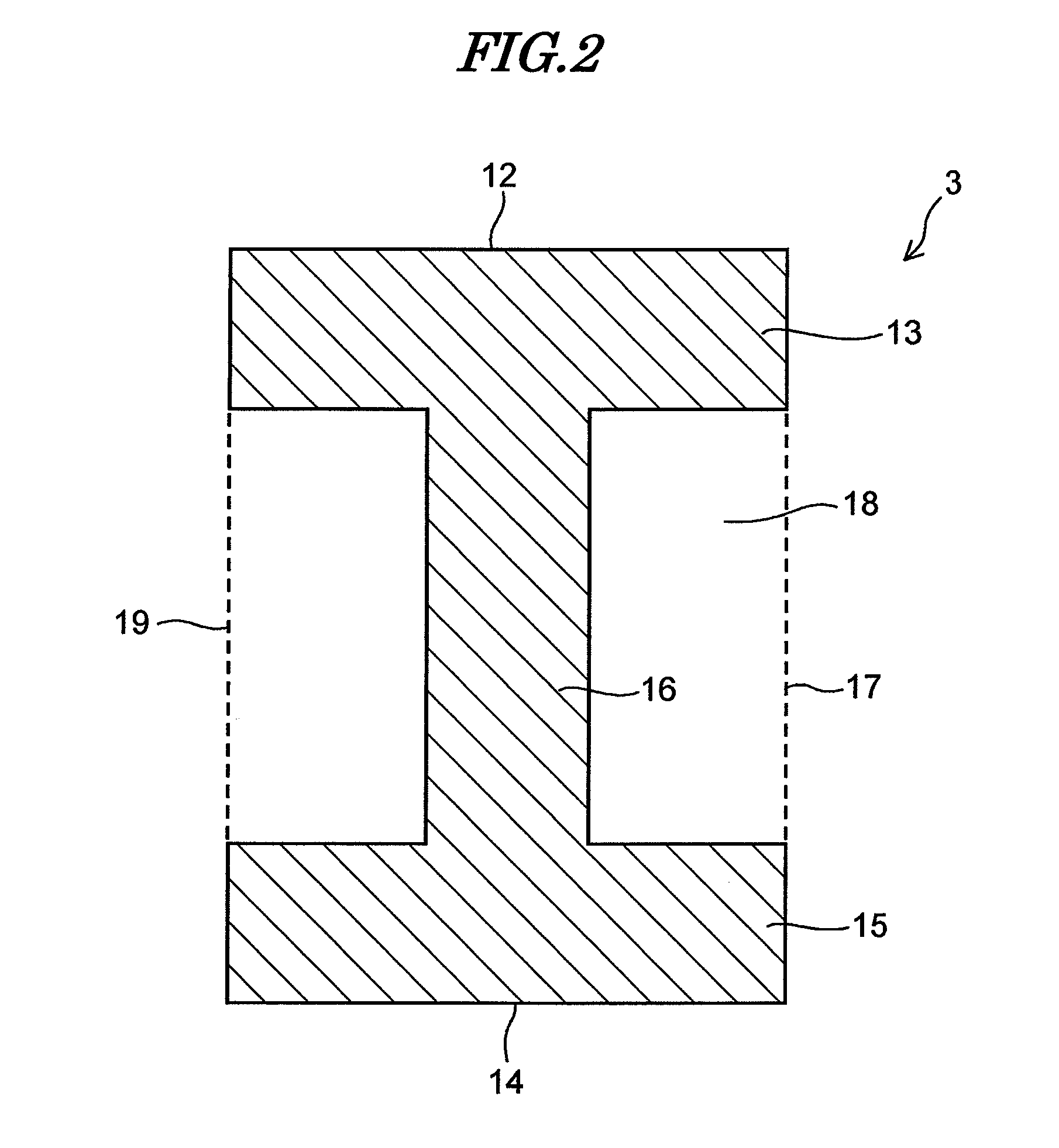

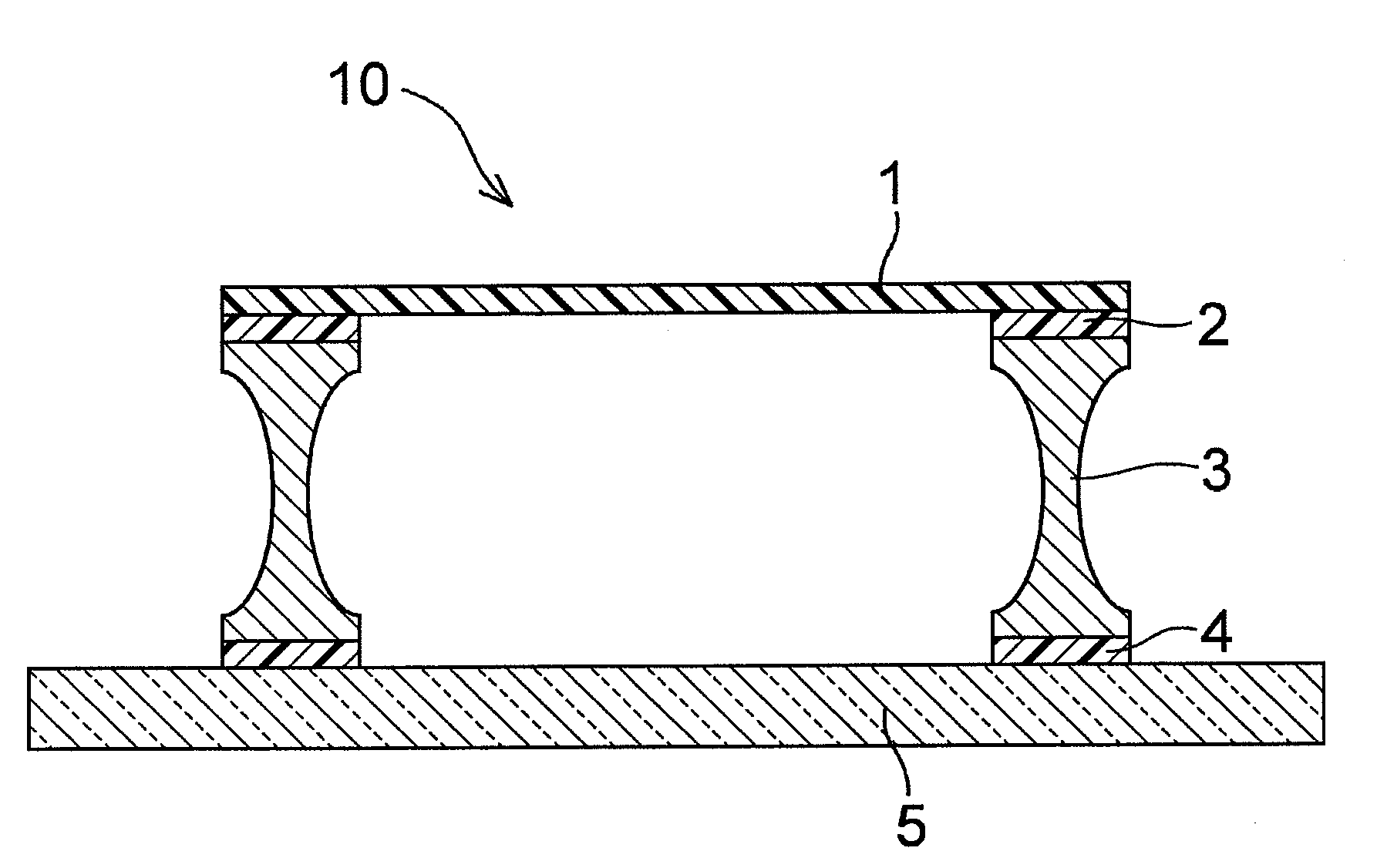

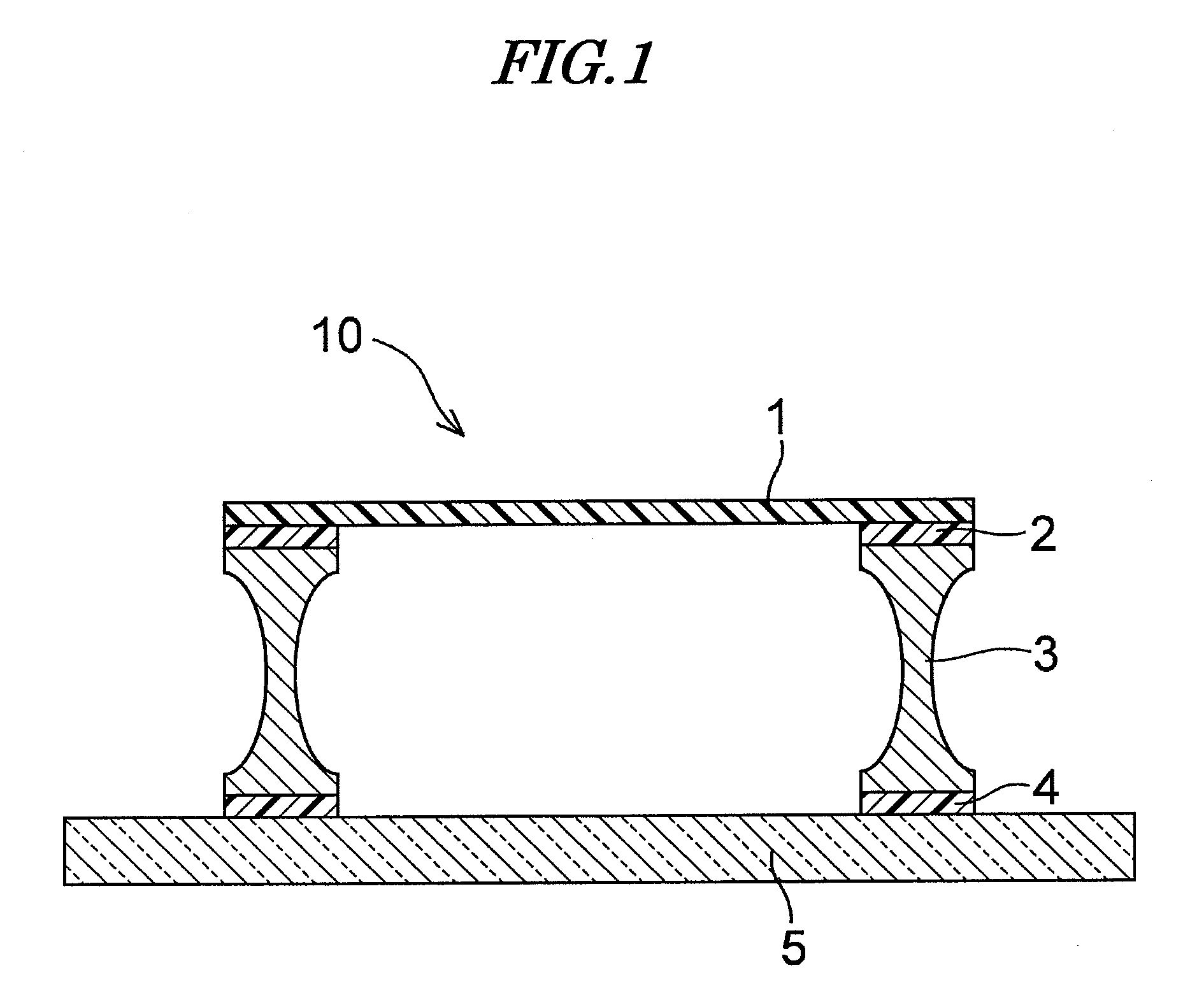

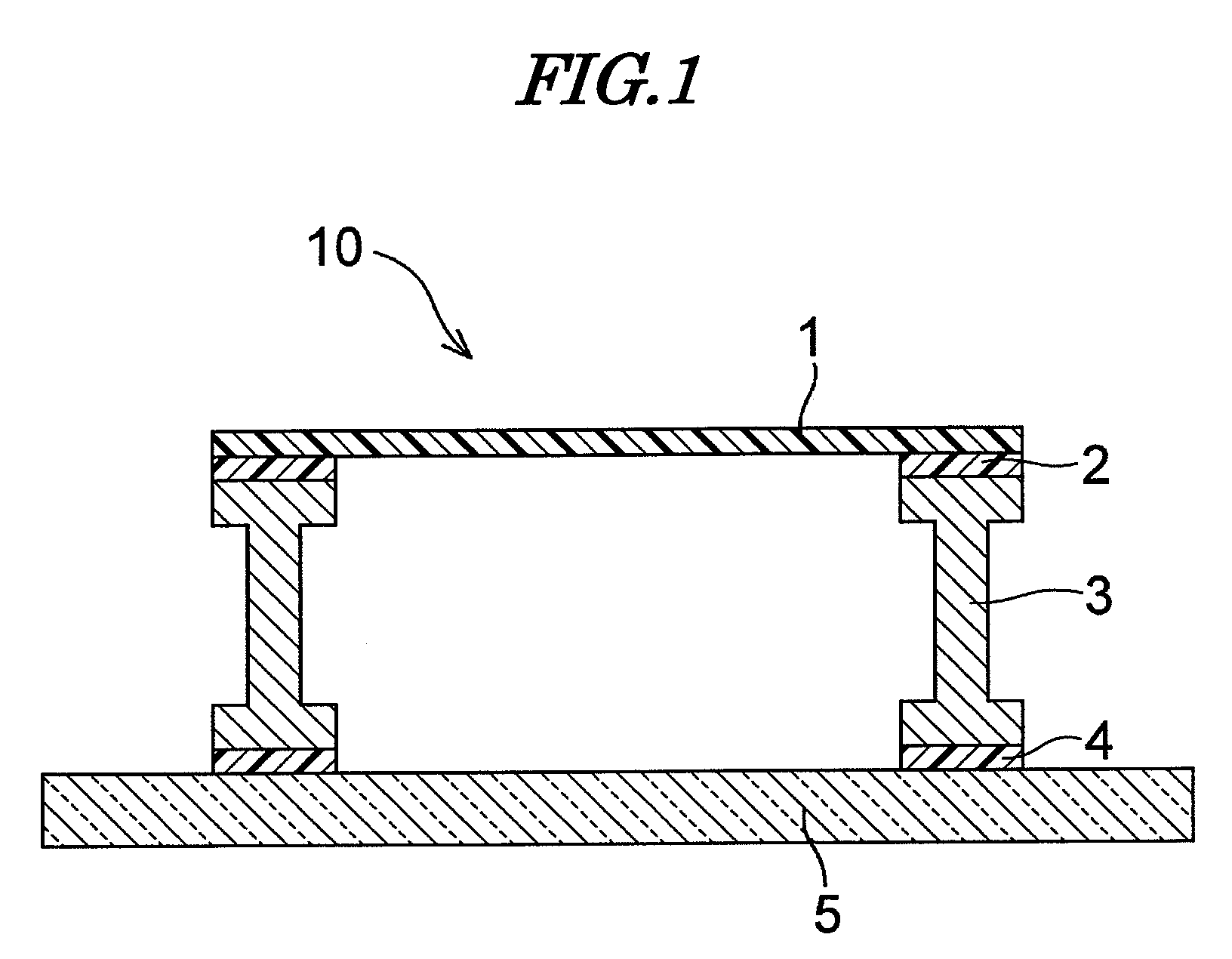

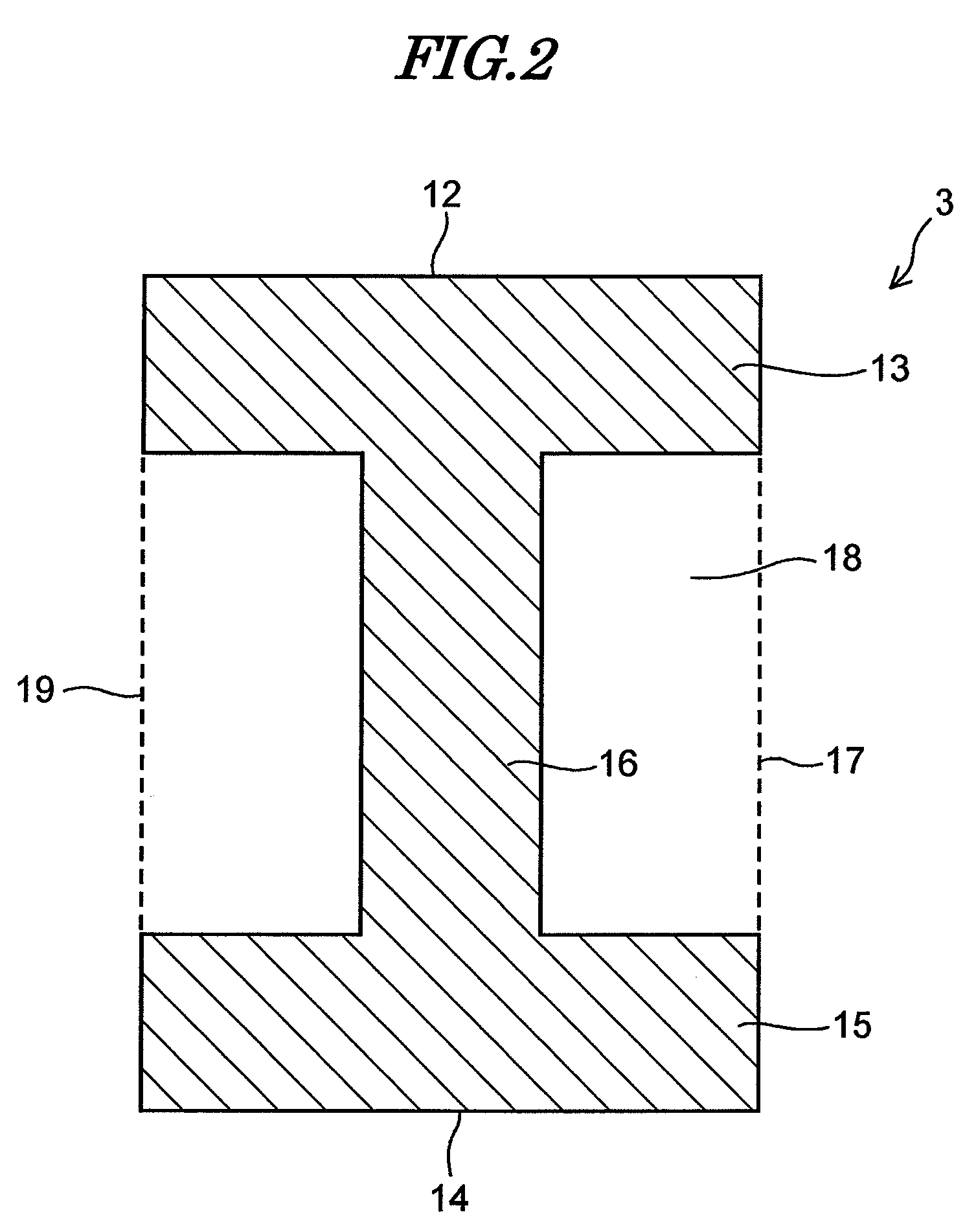

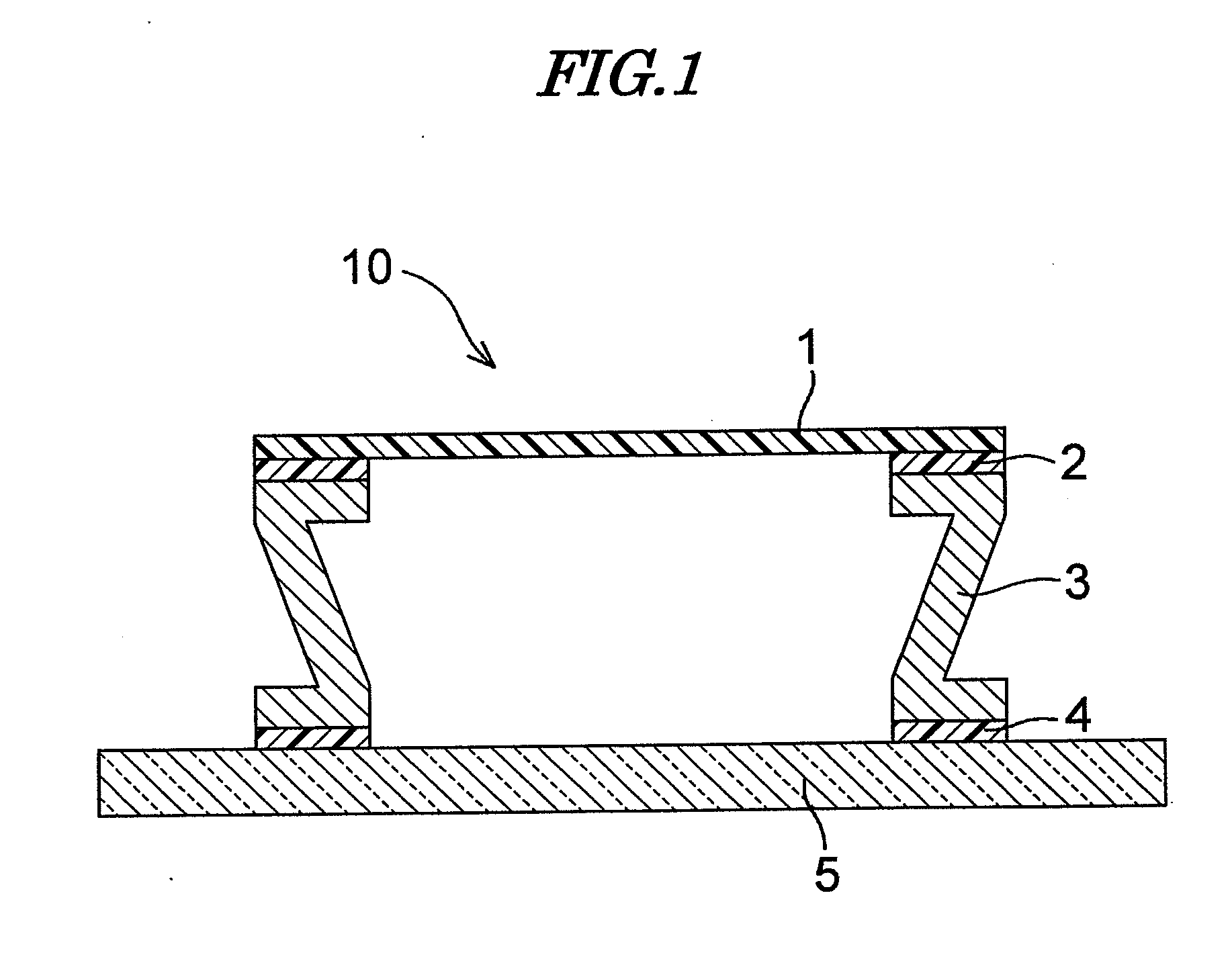

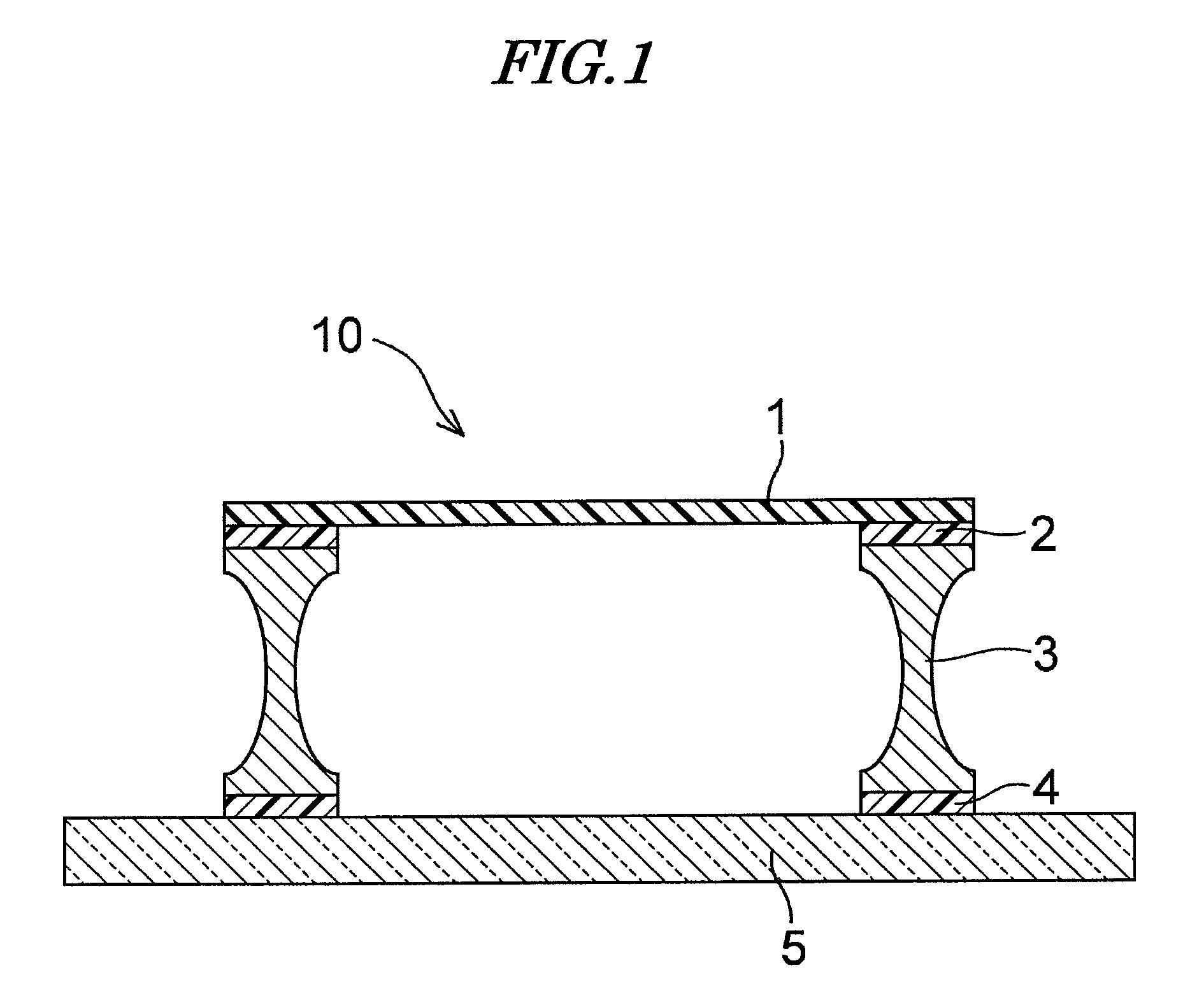

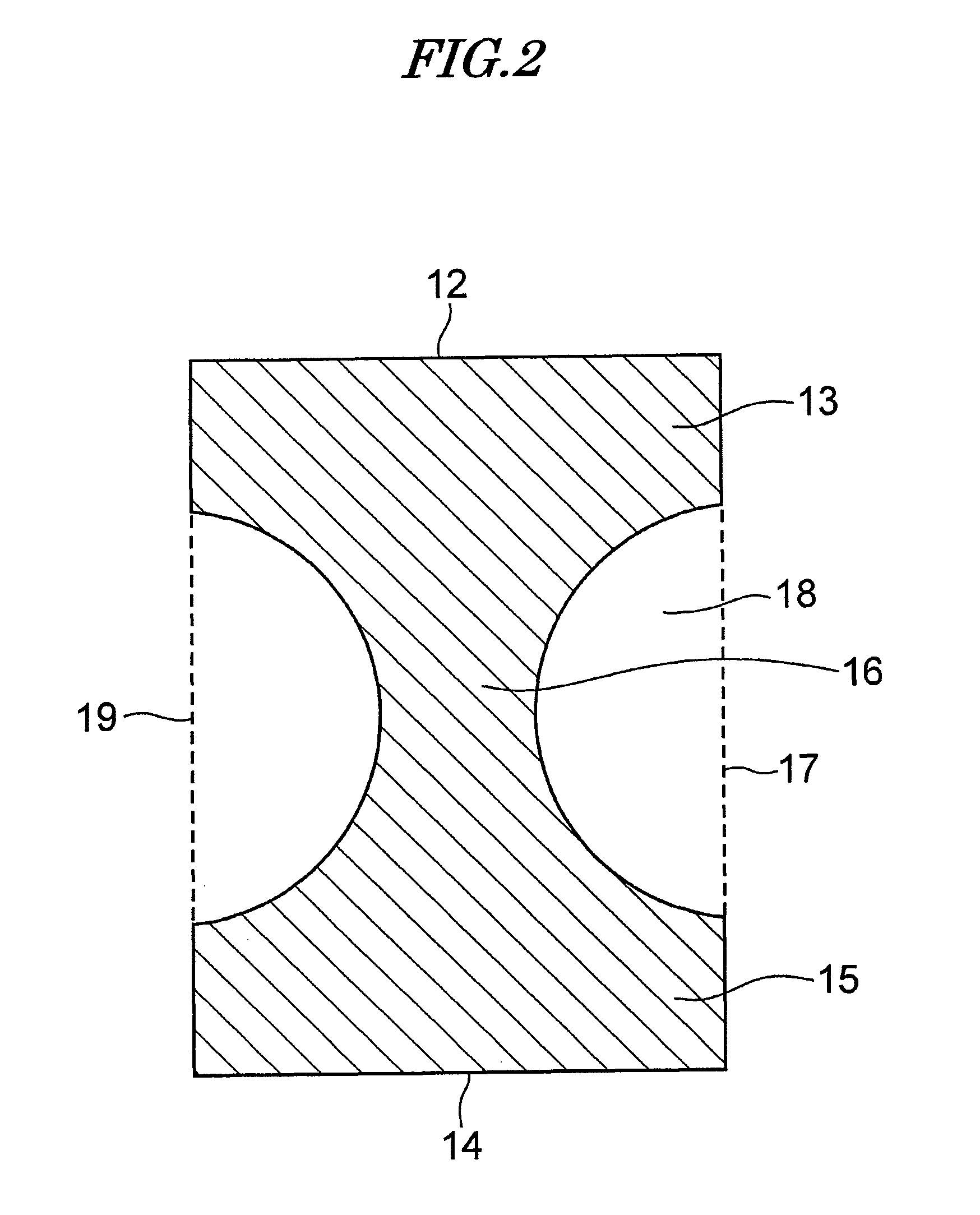

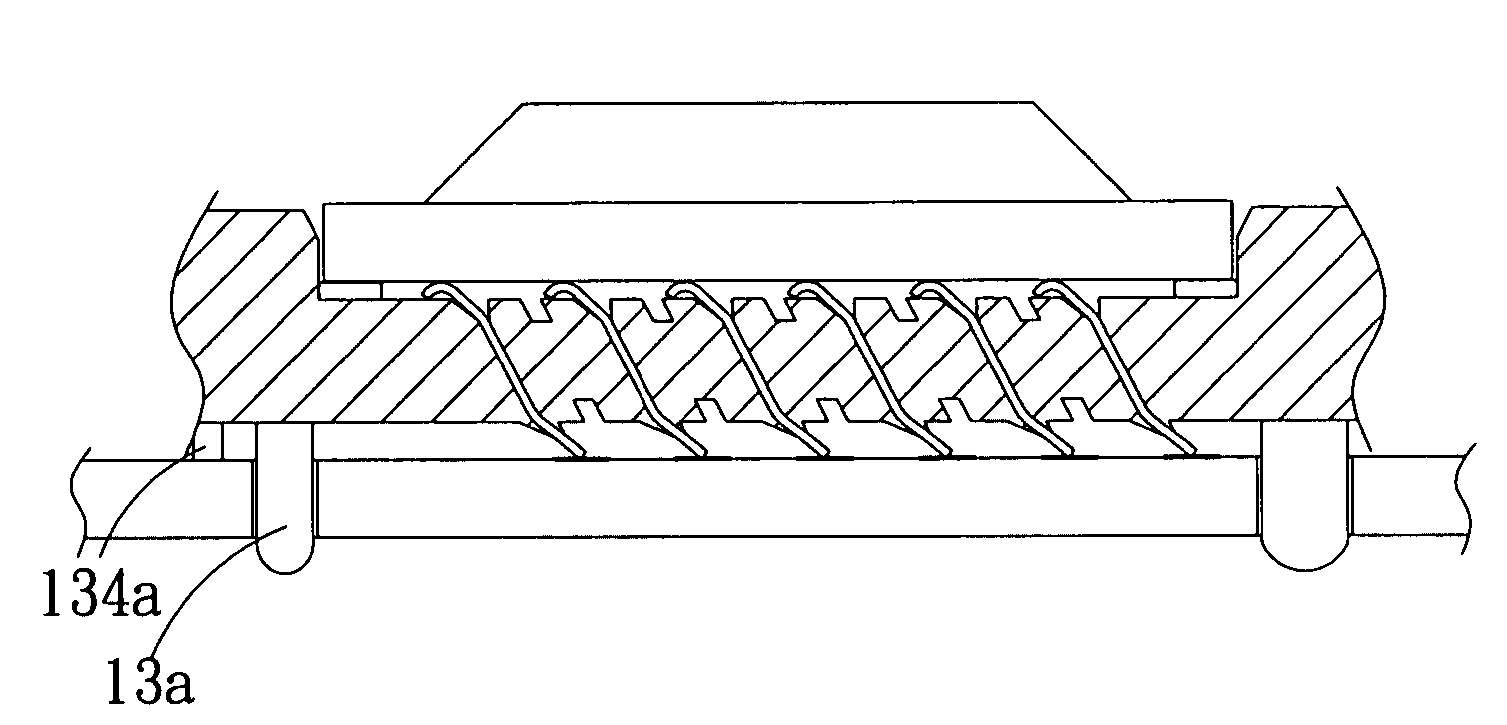

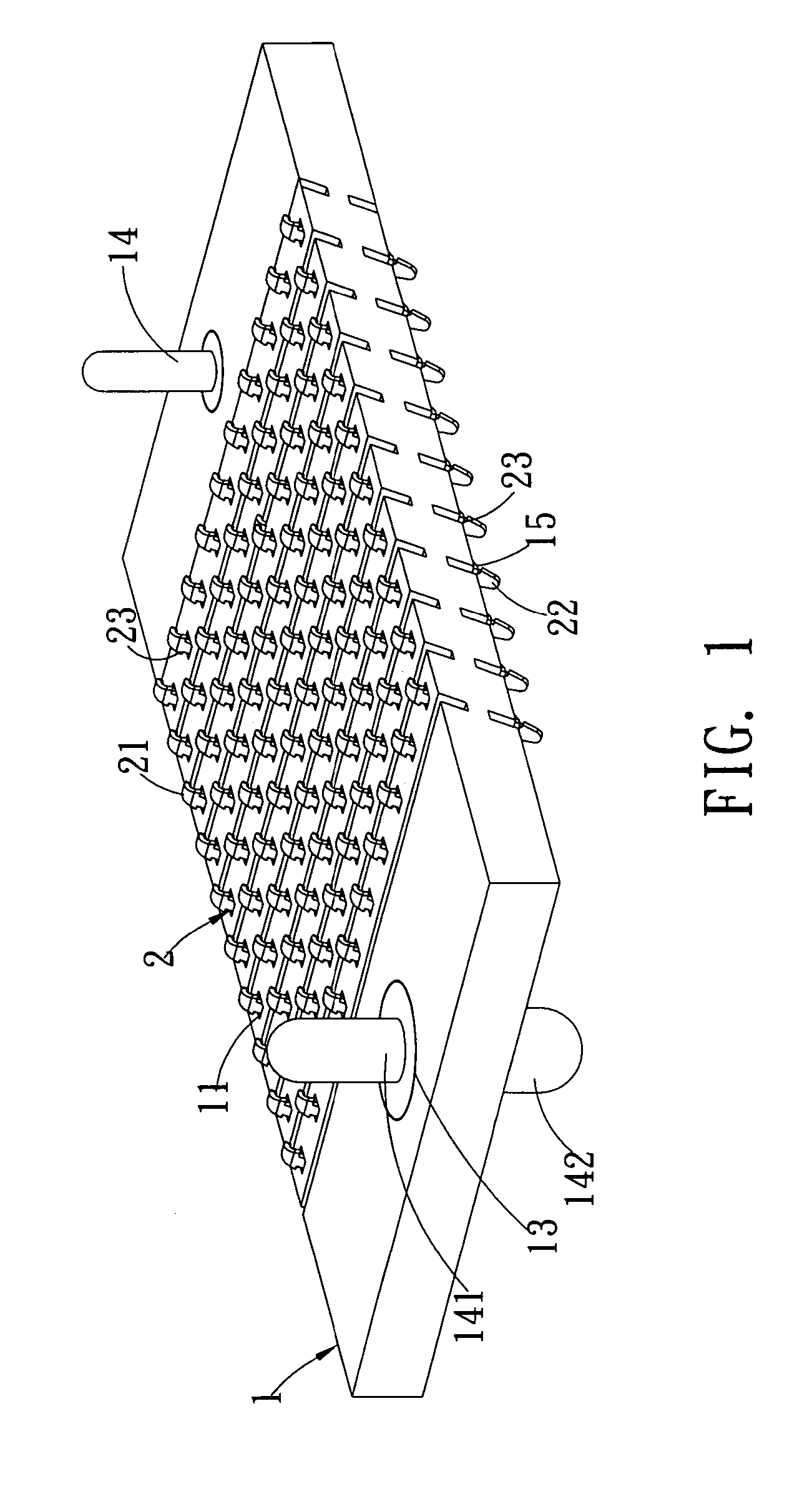

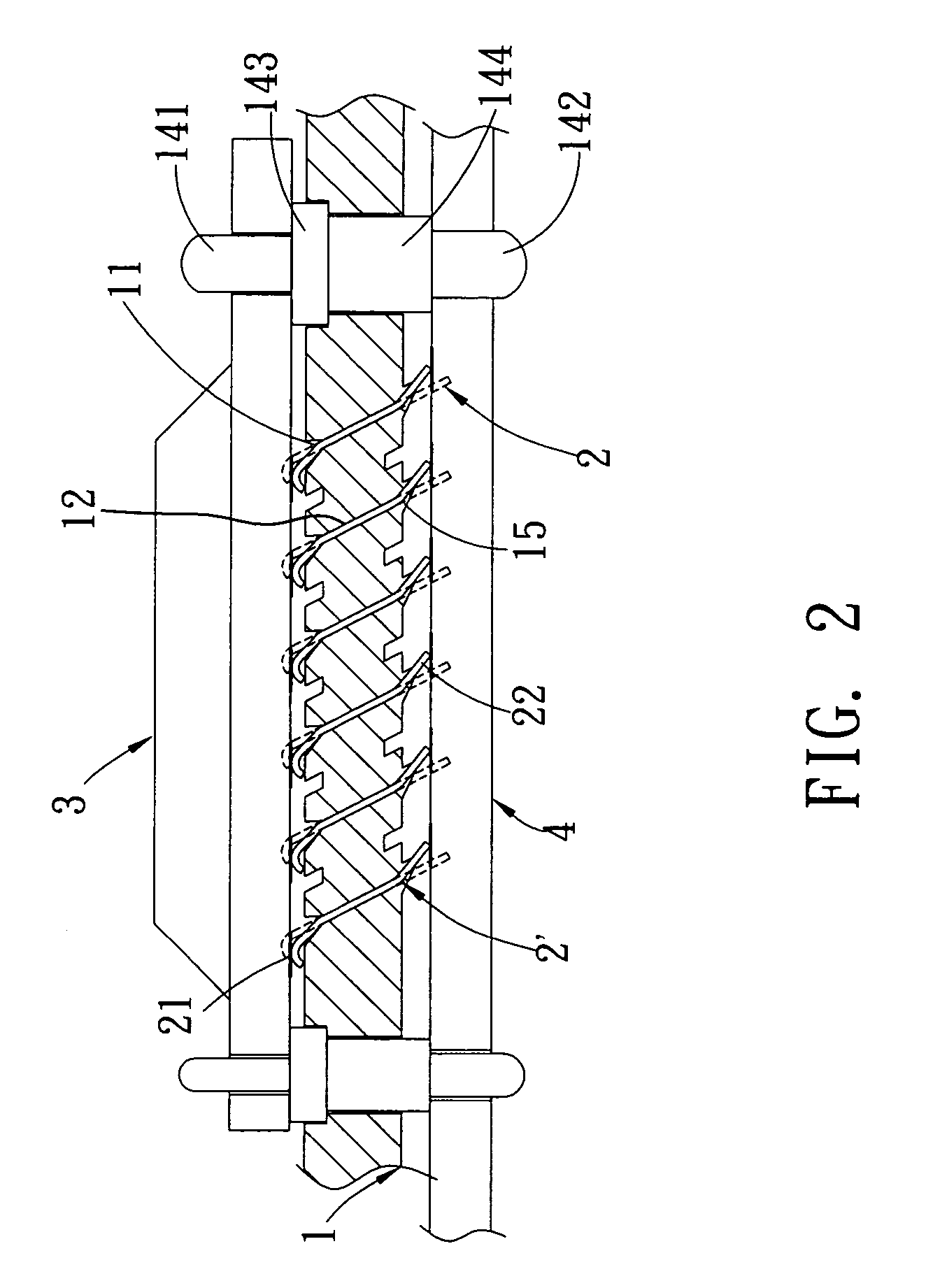

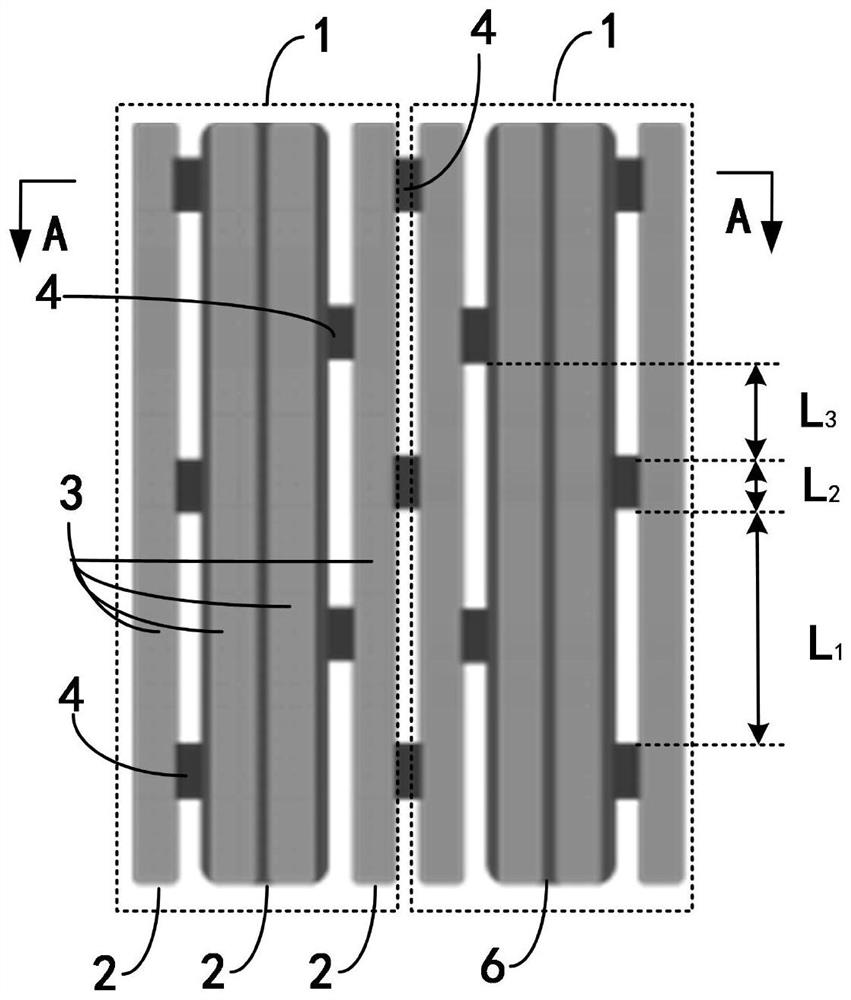

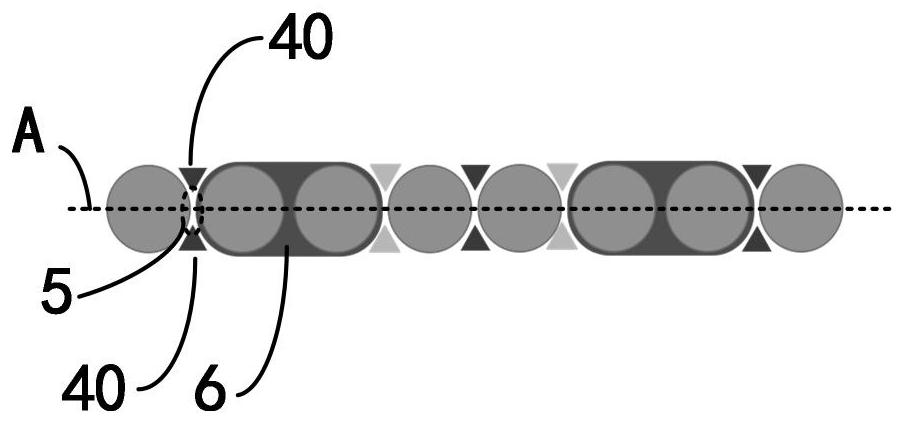

Electrical connector

ActiveUS20070281501A1Good contactLarge normal forceCoupling device detailsPrinted circuitsElectrical and Electronics engineeringNormal force

An electrical connector with an electrically insulating elastic body is disclosed, comprising an electrically insulating elastic body and a multiple of electrical pieces inclinedly disposed in the electrically insulating elastic body. When the electrical connector is compressively contacted with external electronic devices, the electrical pieces will undergo rotating displacement; when the external electronic devices retreat from the compressive contact, the electrically insulating elastic body will push the electrical pieces back to their original positions. Compared with conventional prior art, the electrical piece of the electrical connector according to present invention can undergo rotating displacement to enable the electrical pieces to have larger elastic deformation, such that good contact can be ensured when the flatness of the connected electronic devices is poor and larger normal force on the electrical pieces can be obtained.

Owner:LOTES

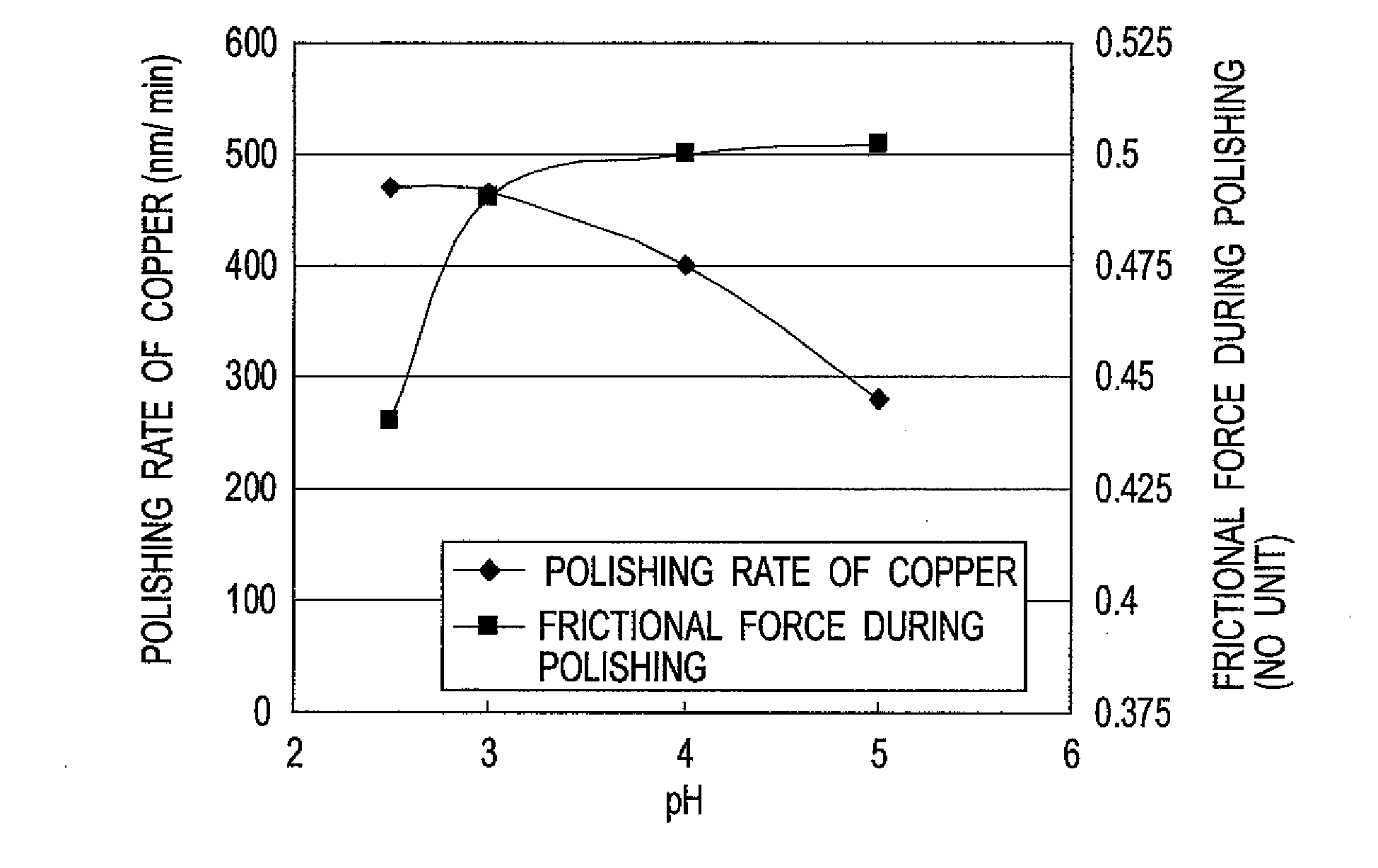

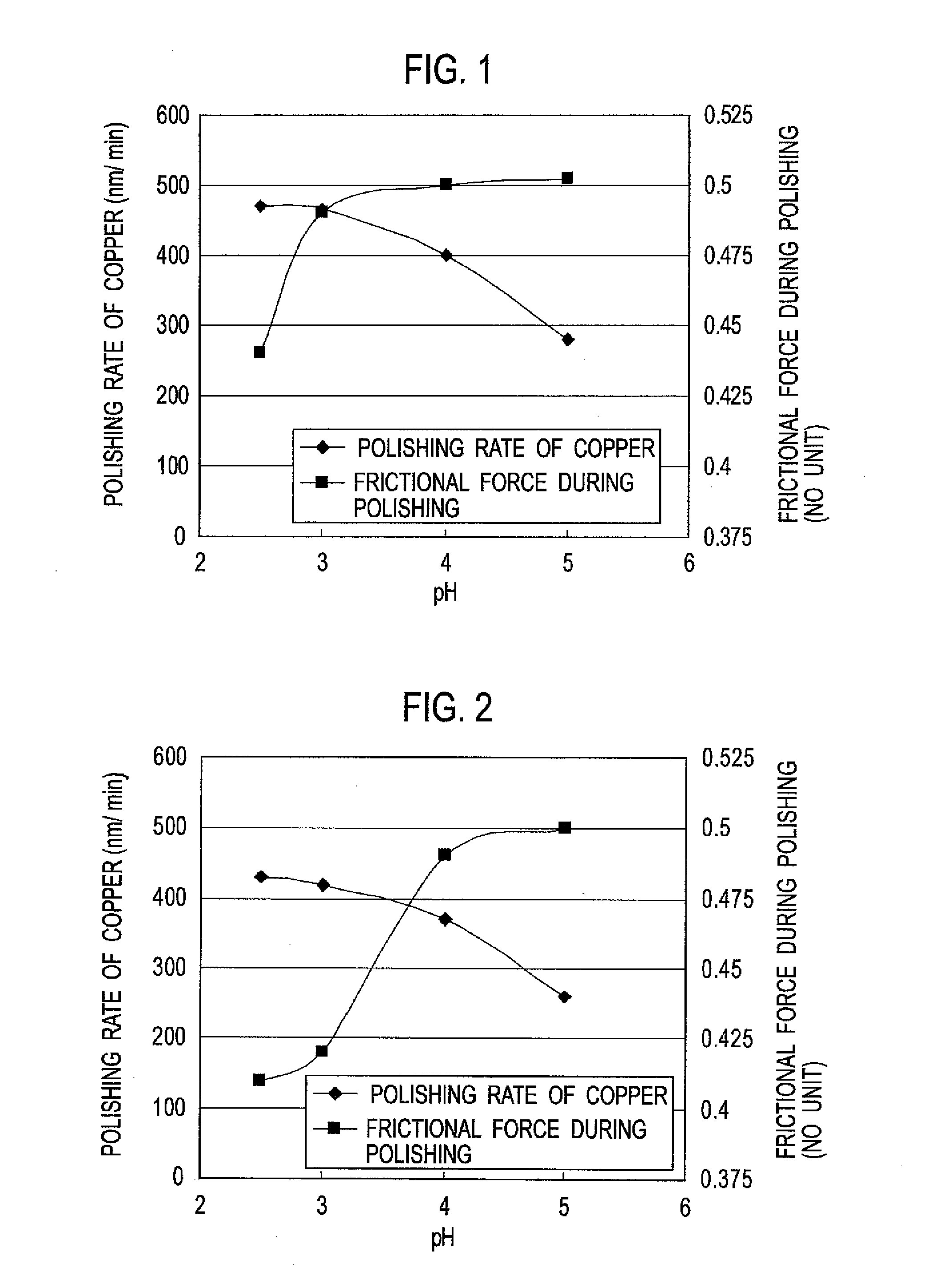

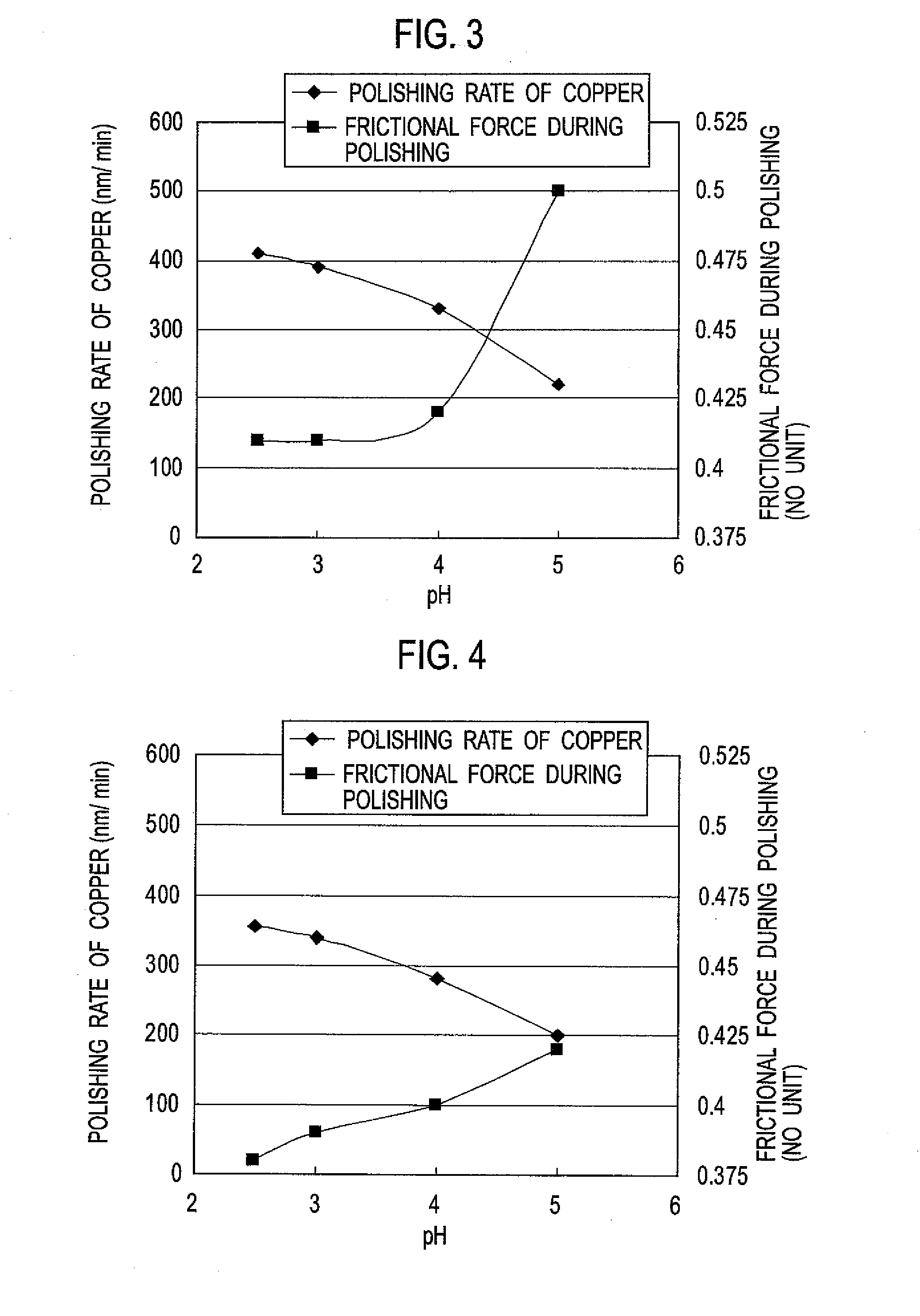

Polishing liquid for metal and method of polishing

InactiveUS20100197201A1Improve flatnessReduce frictionOther chemical processesNon-surface-active detergent compositionsOxidizing agentMetal

Disclosed is a metal-polishing liquid comprising: a metal-oxide-dissolving agent; a metal-oxidizing agent; a metal anticorrosive; a water-soluble polymer having a weight-average molecular weight of 8,000 or higher and having an anionic functional group and a nonionic functional group; and water, and having a pH within the range of 2.5 or higher but 5.0 or less. The metal-polishing liquid is effective in reducing the frictional force in polishing which generates during CMP. And is highly effective in flattening the surface of a work to be polished.

Owner:HITACHI CHEM CO LTD

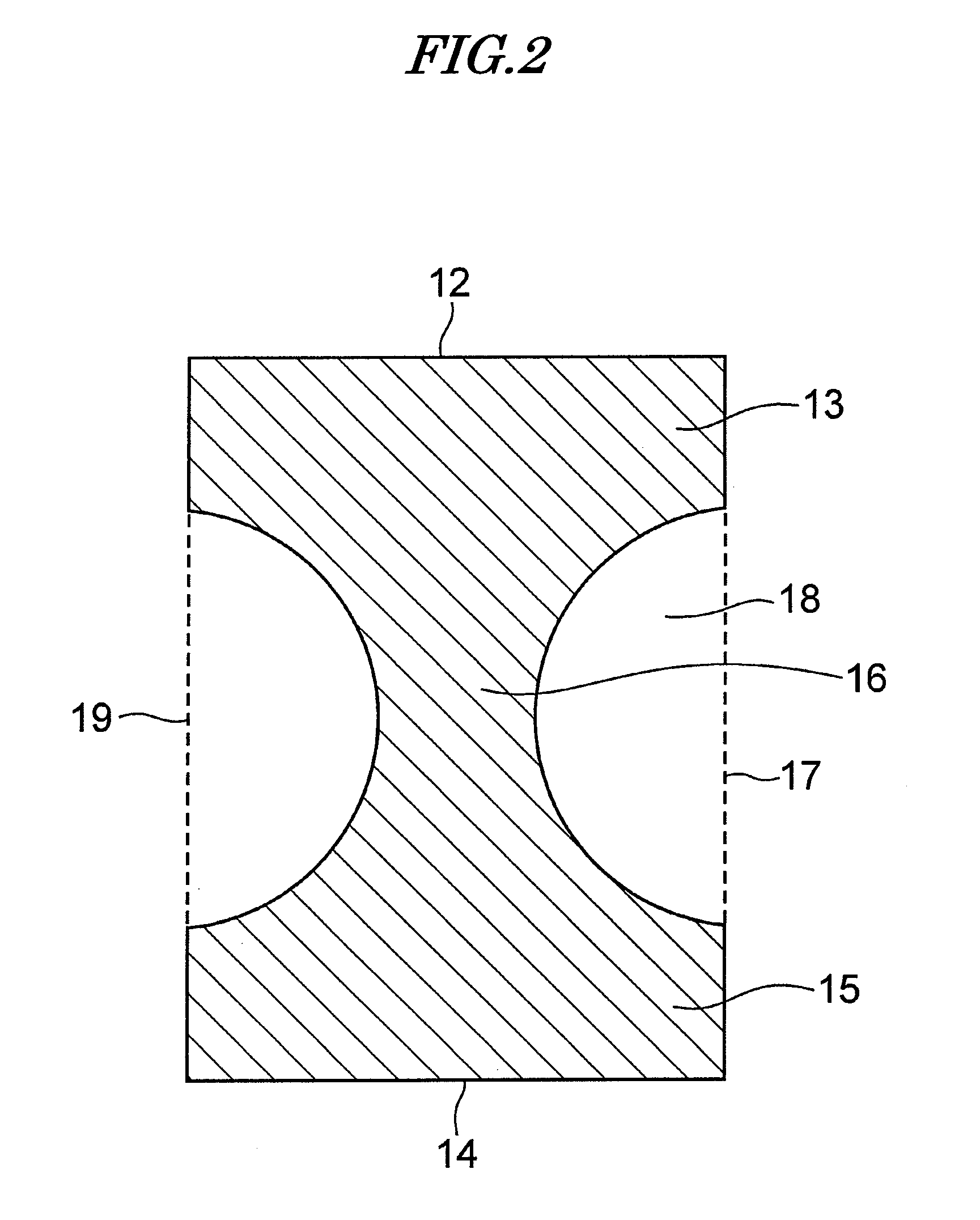

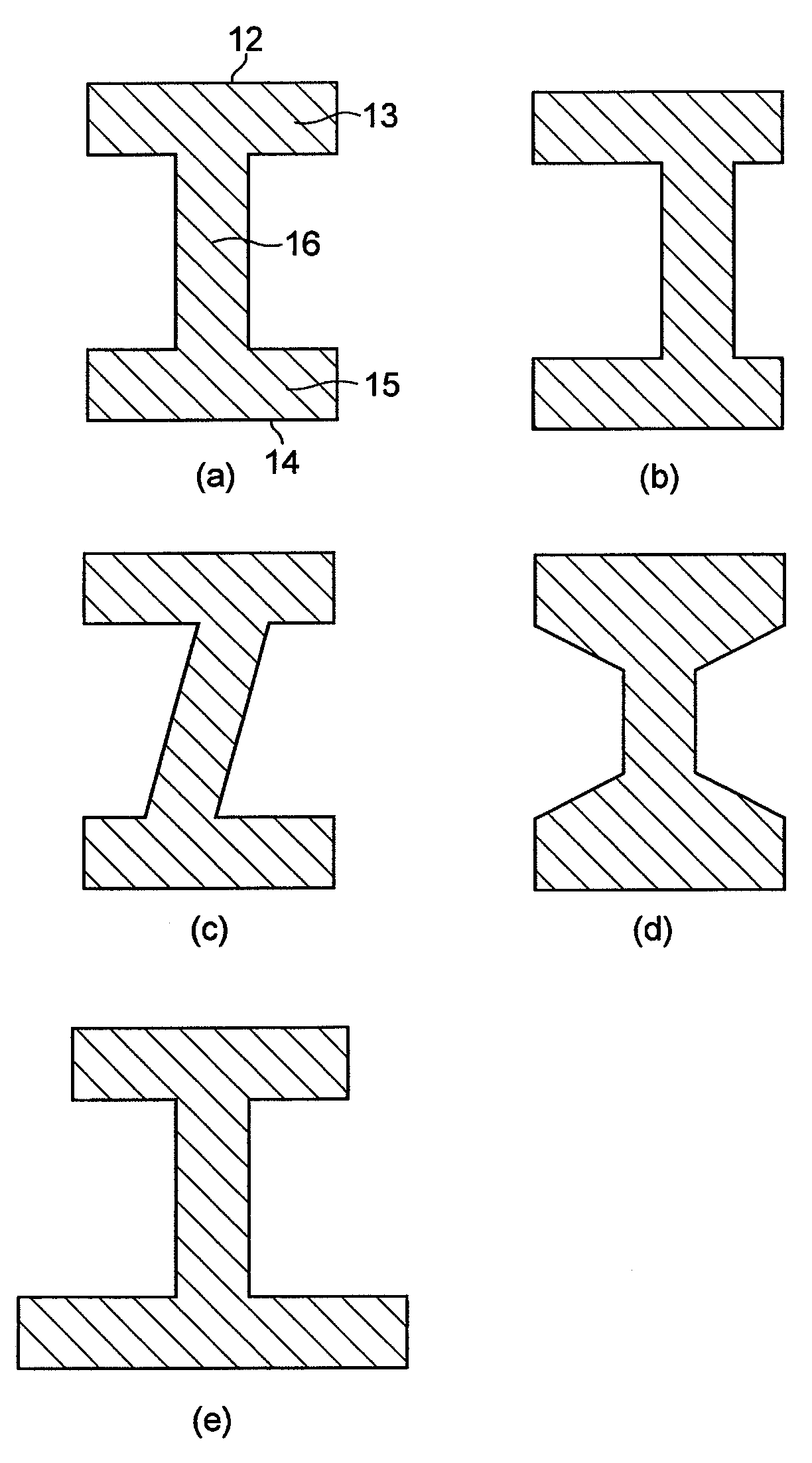

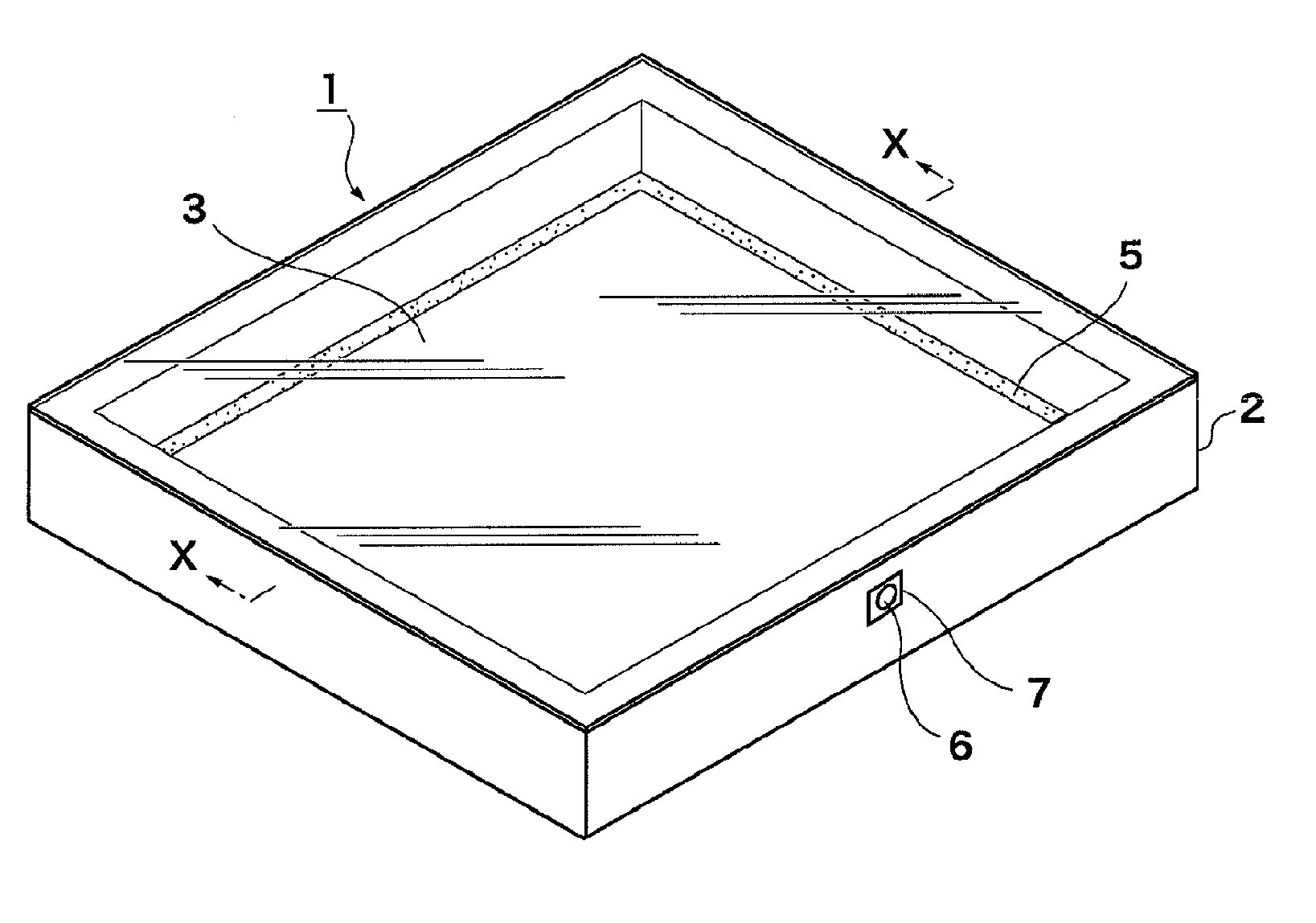

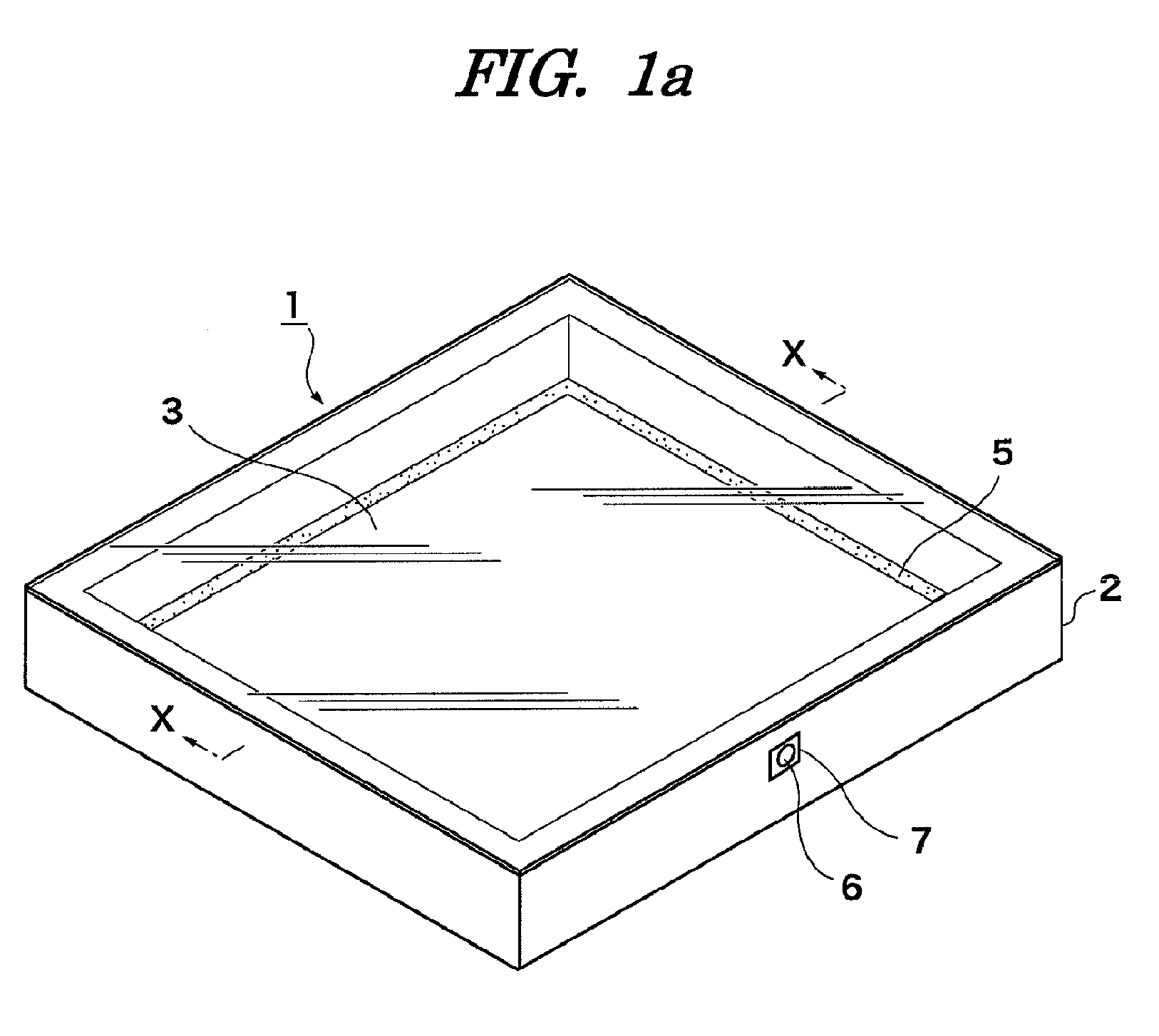

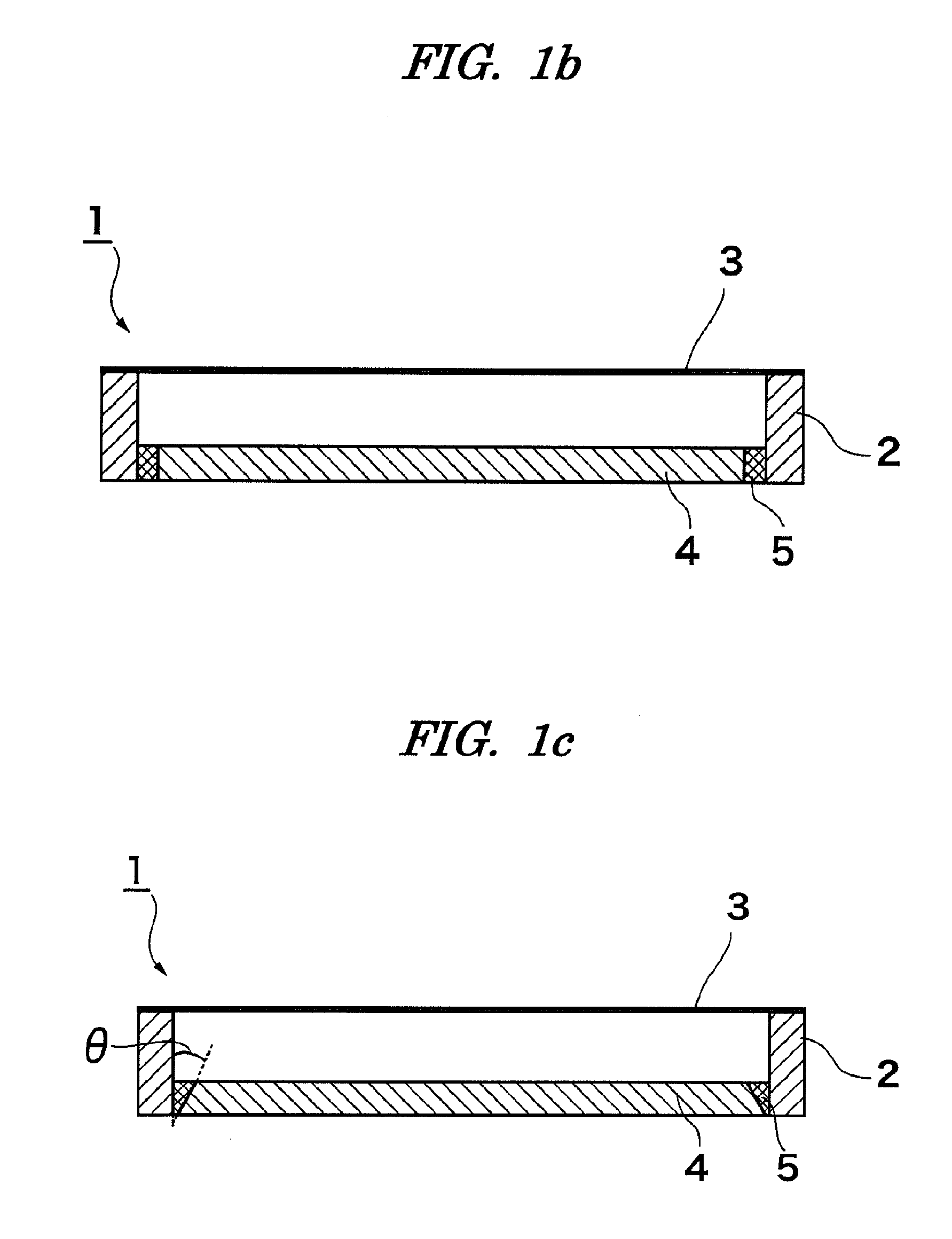

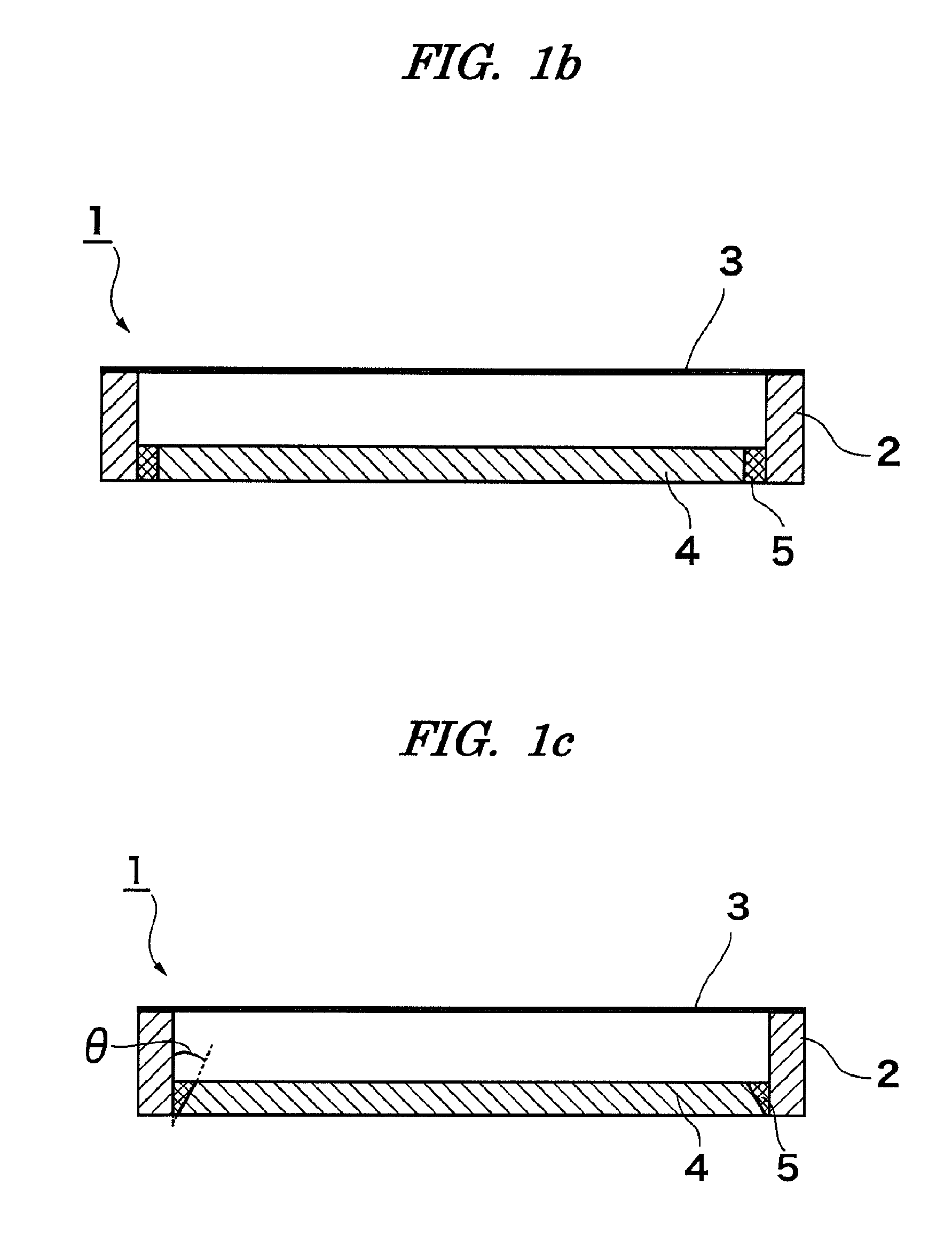

Pellicle frame and lithographic pellicle

ActiveUS20100330466A1Avoid deformationFlatnessSemiconductor/solid-state device manufacturingPackagingAdhesiveEngineering

A pellicle frame is provided that comprises a pellicle frame bar having a quadrilateral cross-section, wherein an upper edge and a lower edge of a basic quadrilateral forming said cross-section are parallel to each other and each of side edges of the basic quadrilateral has one quadrilateral recess. There is also provided a lithographic pellicle that includes a pellicle film stretched over one end face of the pellicle frame via a pellicle film adhesive, and that includes an exposure master plate adhesive on the other end face.

Owner:SHIN ETSU CHEM IND CO LTD +1

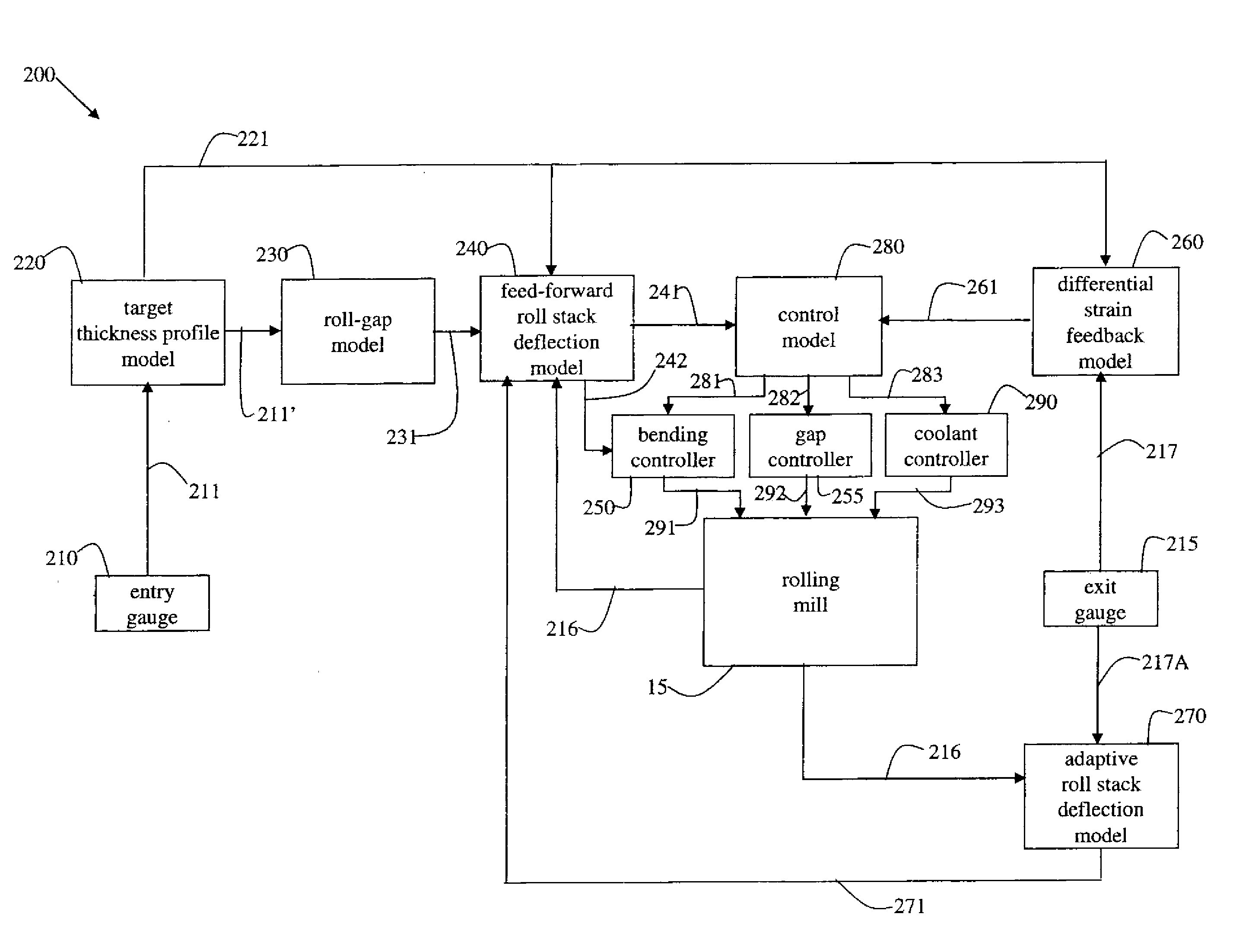

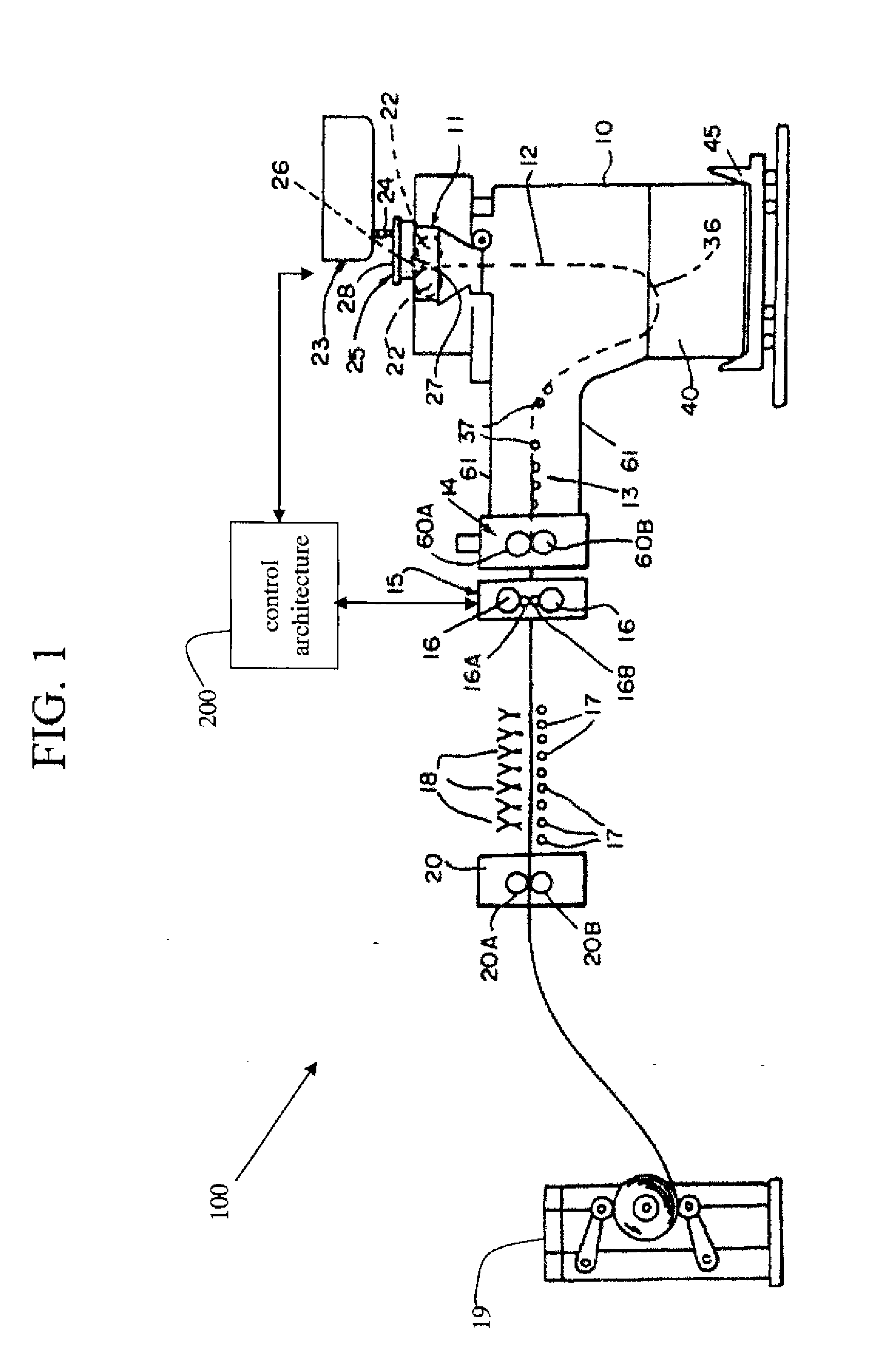

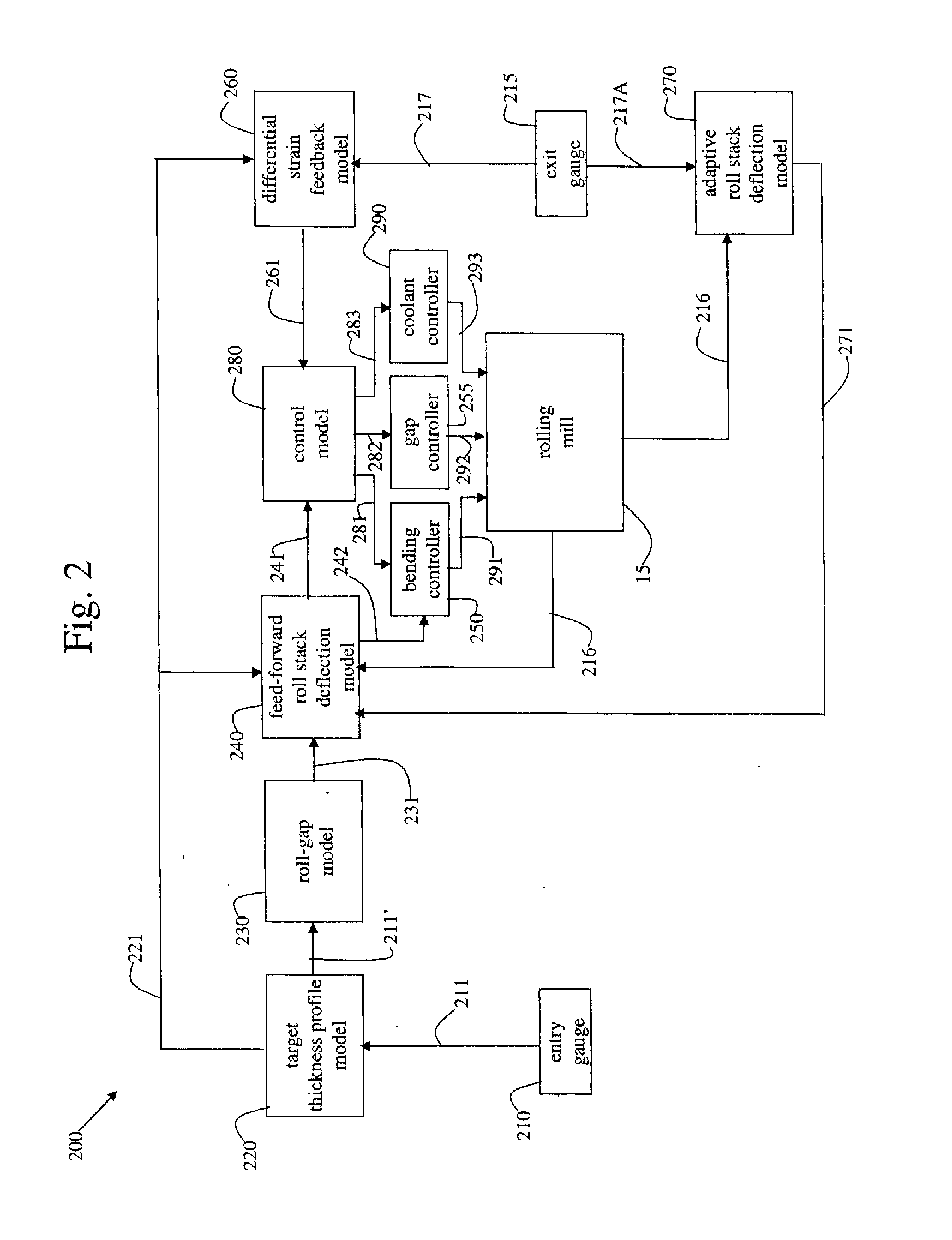

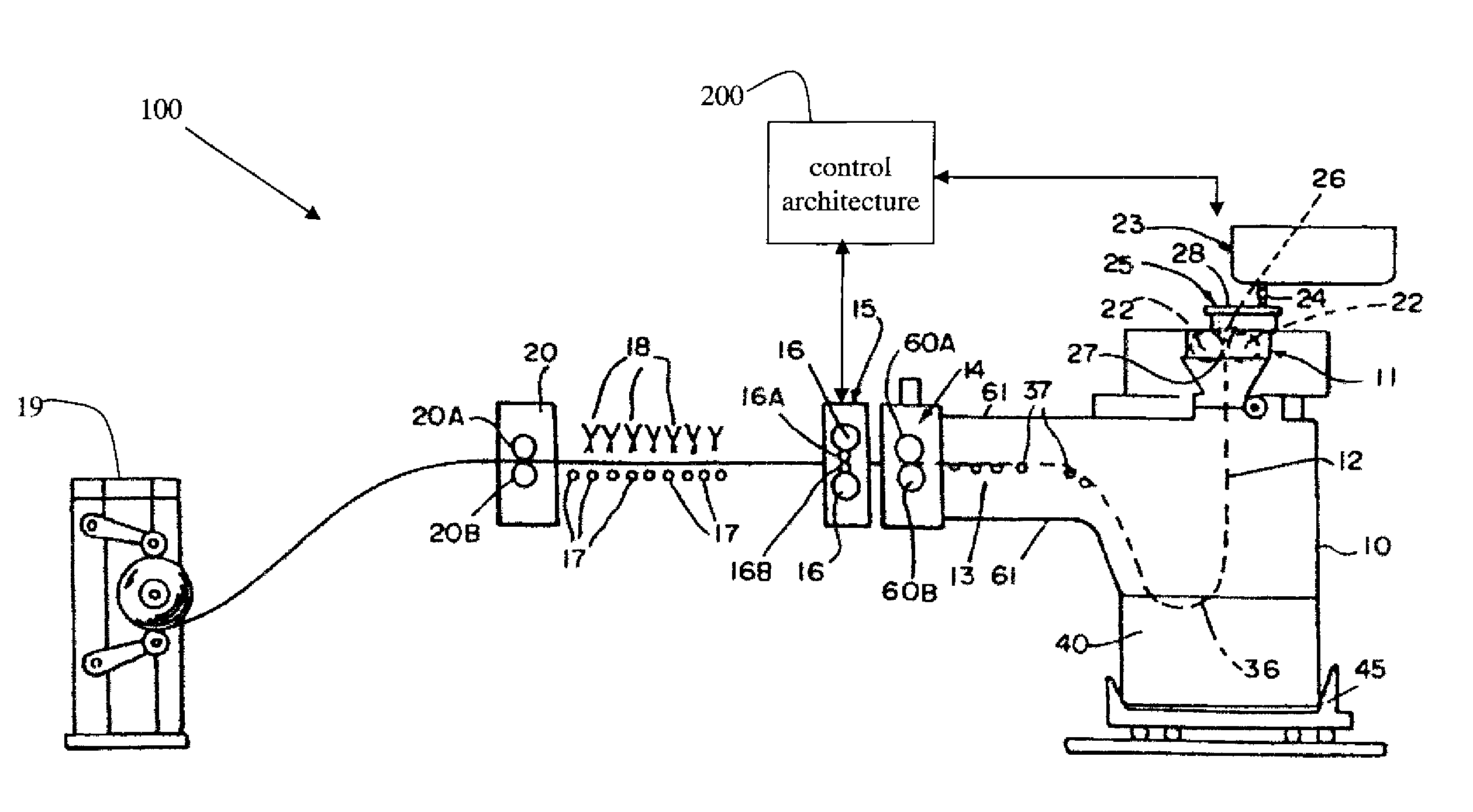

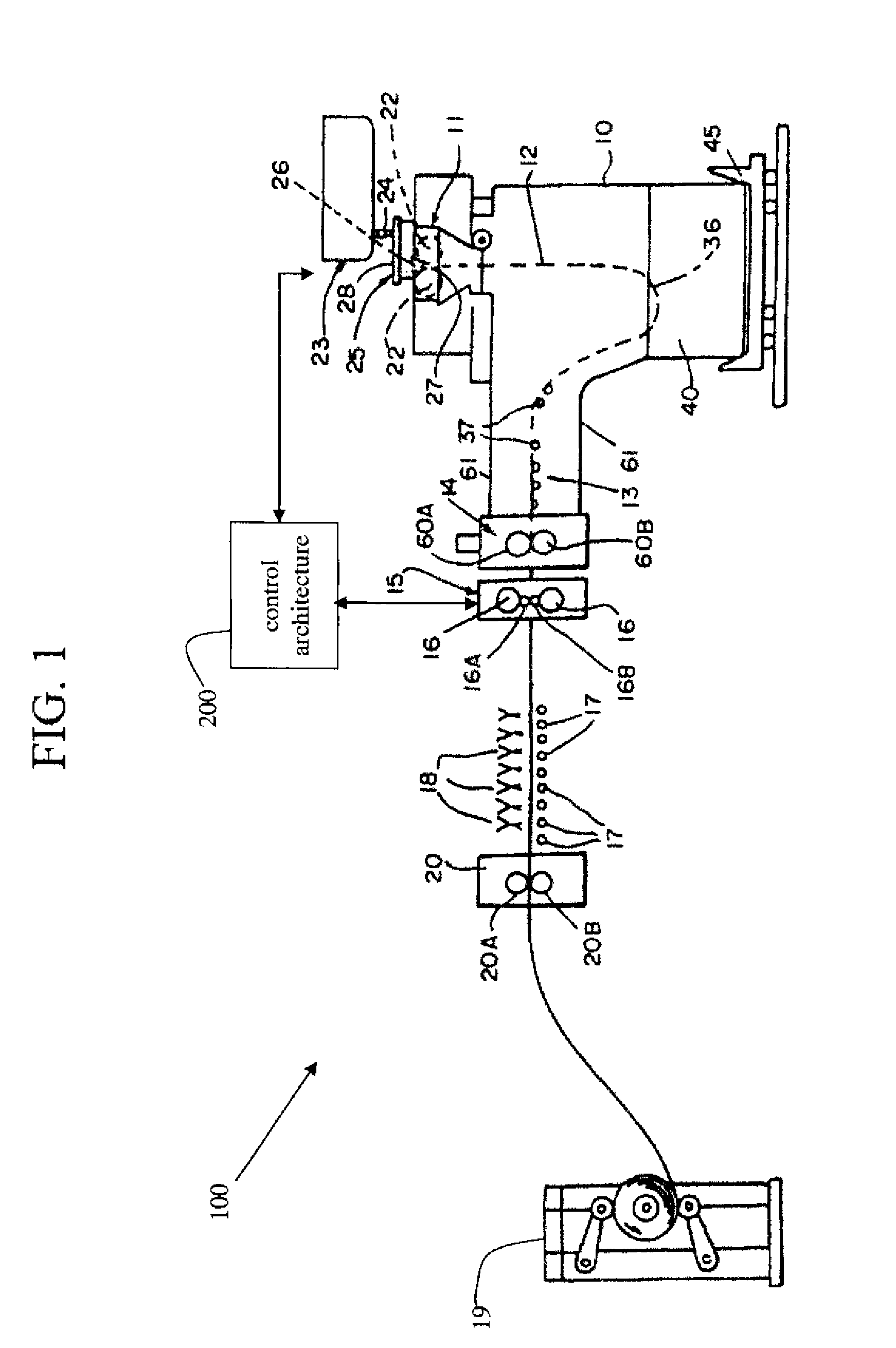

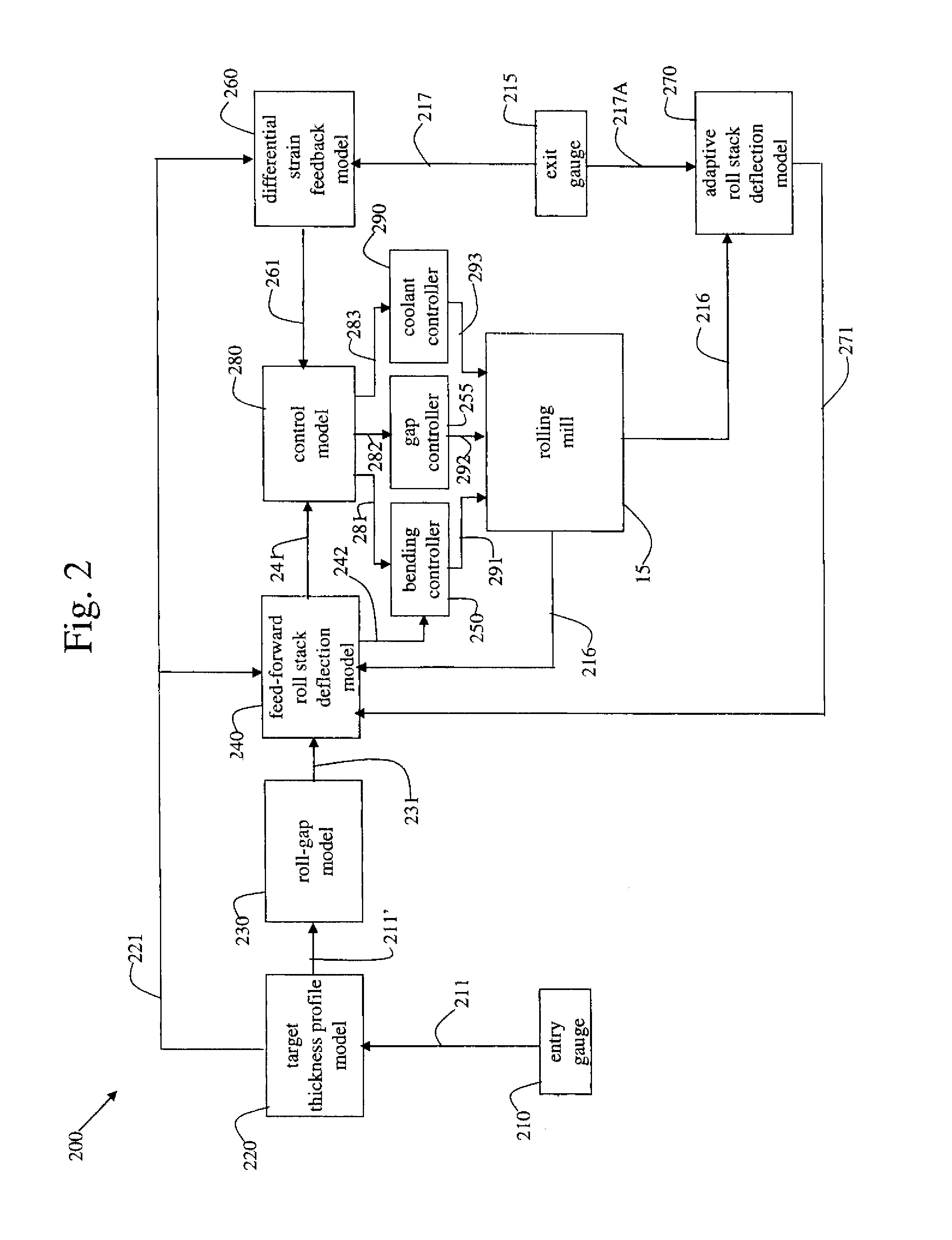

Method and plant for integrated monitoring and control of strip flatness and strip profile

ActiveUS20070220939A1Reduce tensionSusceptible to bucklingRoll force/gap control deviceMetal rolling stand detailsIntegrated monitoringControl signal

Apparatus and method of controlling strip geometry in casting strip having a rolling mill. A target thickness profile is calculated as a function of the measured entry thickness profile of the strip while satisfying profile and flatness operating requirements. A differential strain feedback from longitudinal strain in the strip is calculated by a control system by comparing the exit thickness profile with the target thickness profile, and a control signal is generated to control a device capable of affecting the geometry of the strip processed by the hot rolling mill. A feed-forward control reference and / or sensitivity vector may also be calculated as a function of the target thickness profile, and used in generating the control signal sent to the control device. The control device may be selected from one or more of the group consisting of a bending controller, gap controller and coolant controller.

Owner:NUCOR CORP

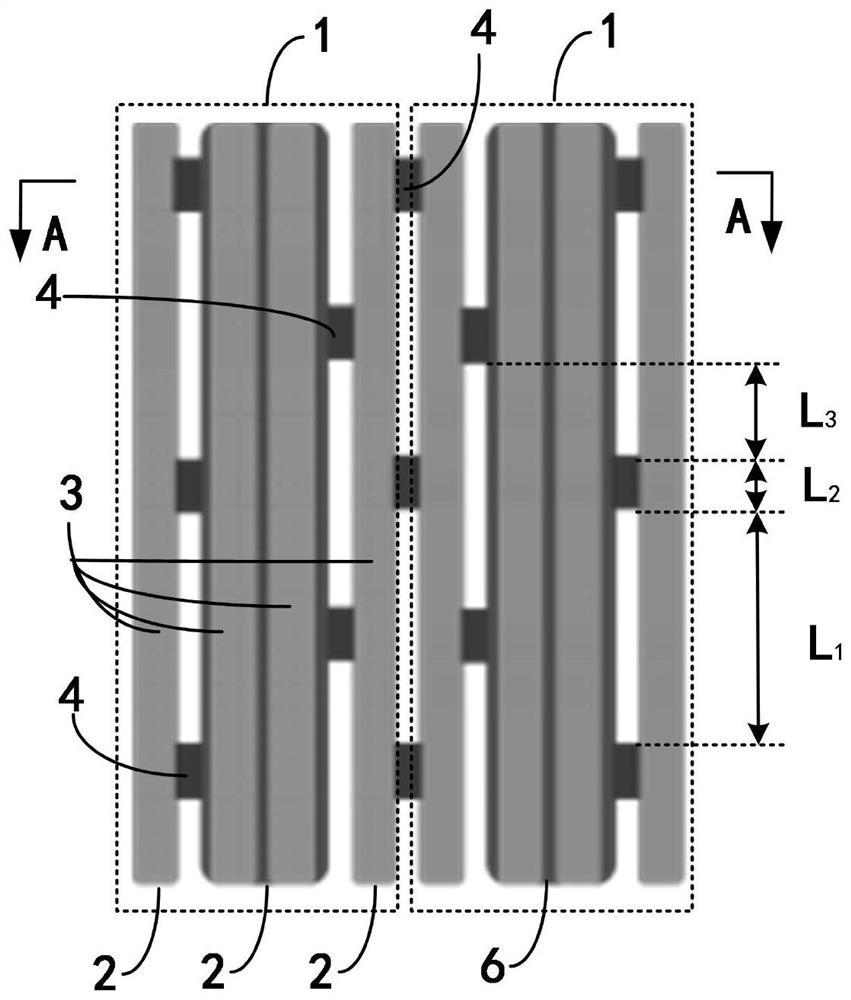

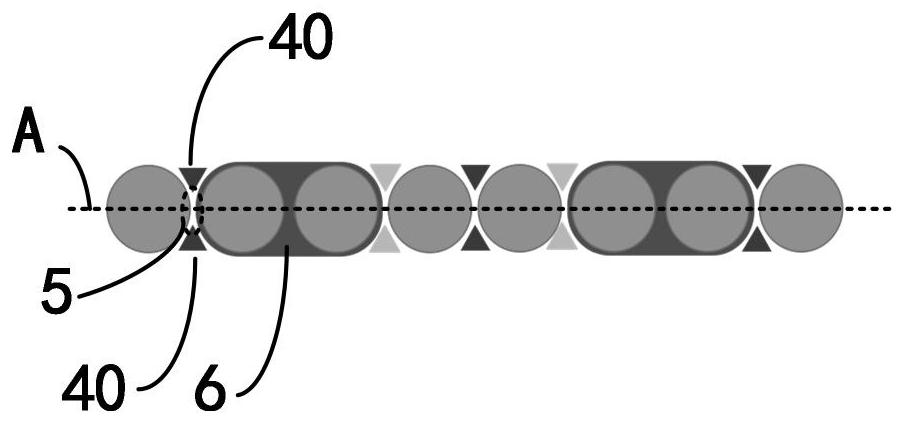

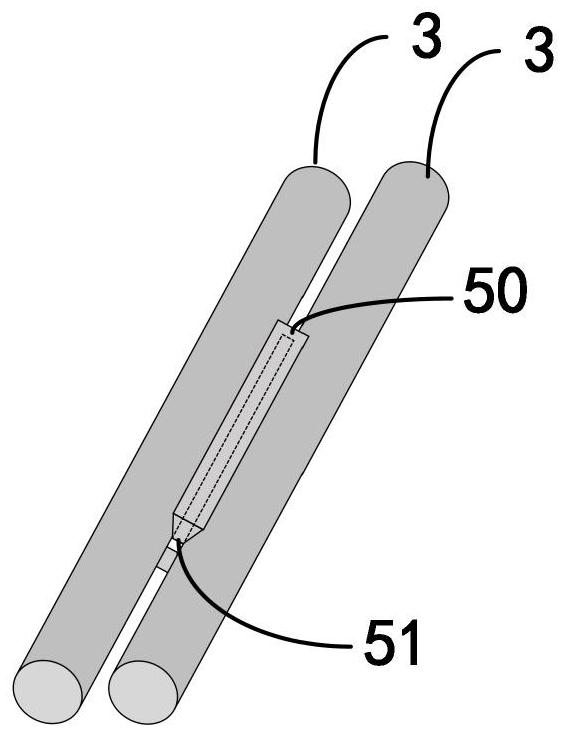

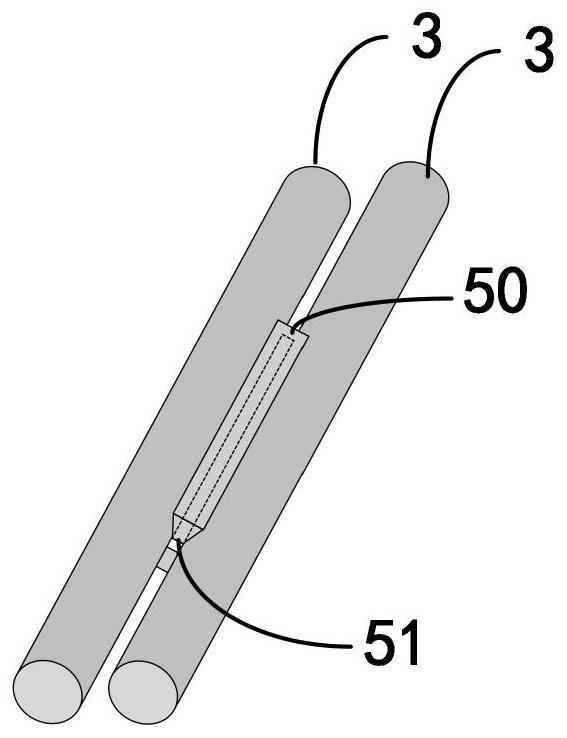

Flexible optical fiber ribbon and optical cable

ActiveCN113359230AReduce the risk of potential stress concentrationSolve the phenomenon of uneven stress distributionFibre mechanical structuresBundled fibre light guideEngineeringMaterials science

The invention relates to a flexible optical fiber ribbon and an optical cable, the flexible optical fiber ribbon comprises a plurality of core tape groups, the core tape groups are arranged in parallel, and each core tape group comprises three optical fiber units; the three optical fiber units of the core belt group are arranged in parallel, the optical fiber units on two sides comprise one optical fiber, and the optical fiber unit in the middle comprises at least one optical fiber which is arranged in parallel and connected; every two adjacent core belt groups and every two adjacent optical fiber units in the core belt groups are connected through a plurality of first connecting parts which are discontinuously arranged in the length direction of the optical fiber; and a plane passing through the axes of the two adjacent optical fibers is used as a reference plane, the first connecting part comprises two connecting units located above and below the reference plane respectively, and buffer cavities are formed between the two adjacent optical fibers and between the two connecting units above and below the reference plane. The problem that the flatness of the optical fiber ribbon is poor due to the fact that resin is easily damaged when the optical fiber ribbon is bent in the width direction in the prior art can be solved.

Owner:FENGHUO COMM SCI & TECH CO LTD

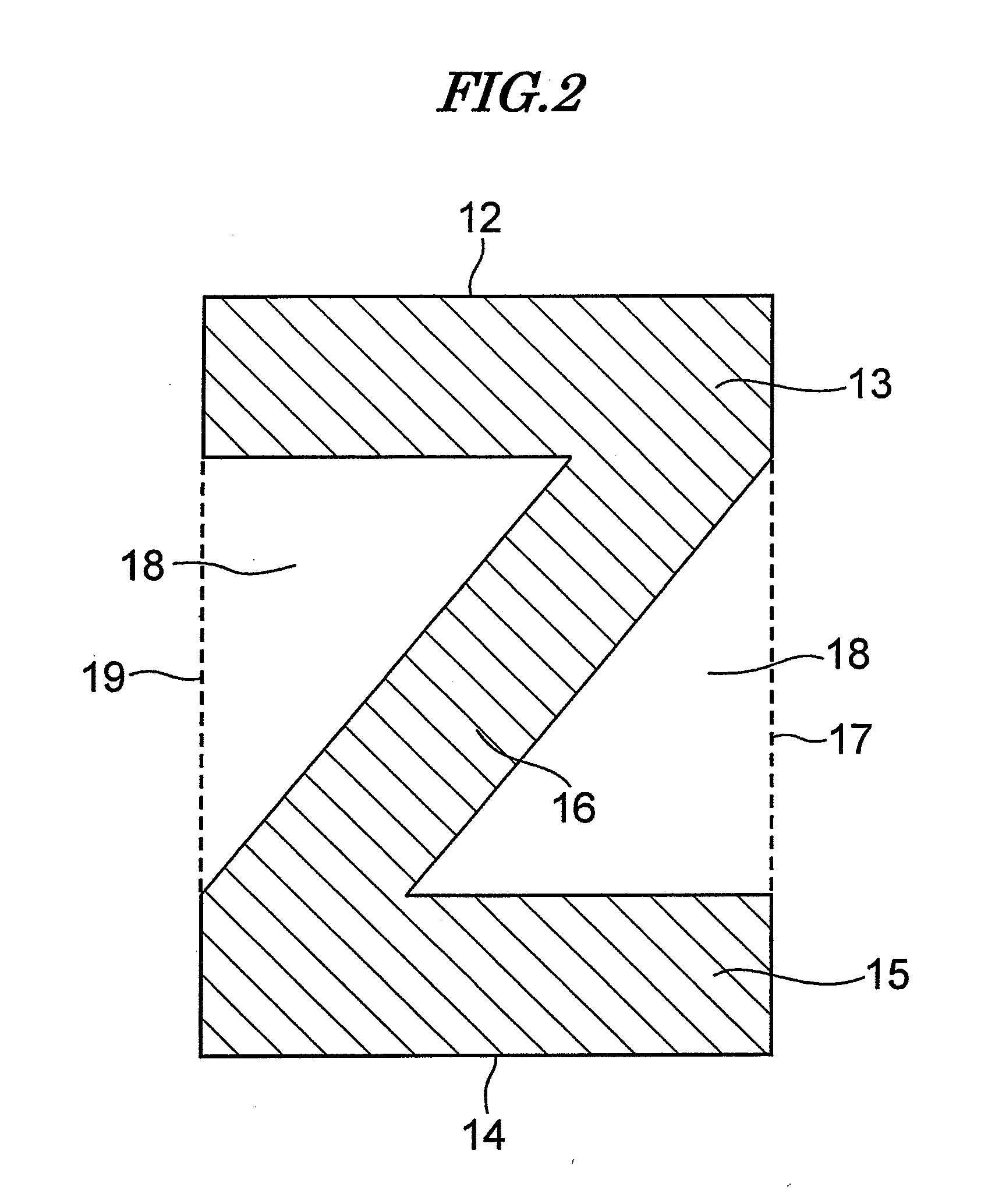

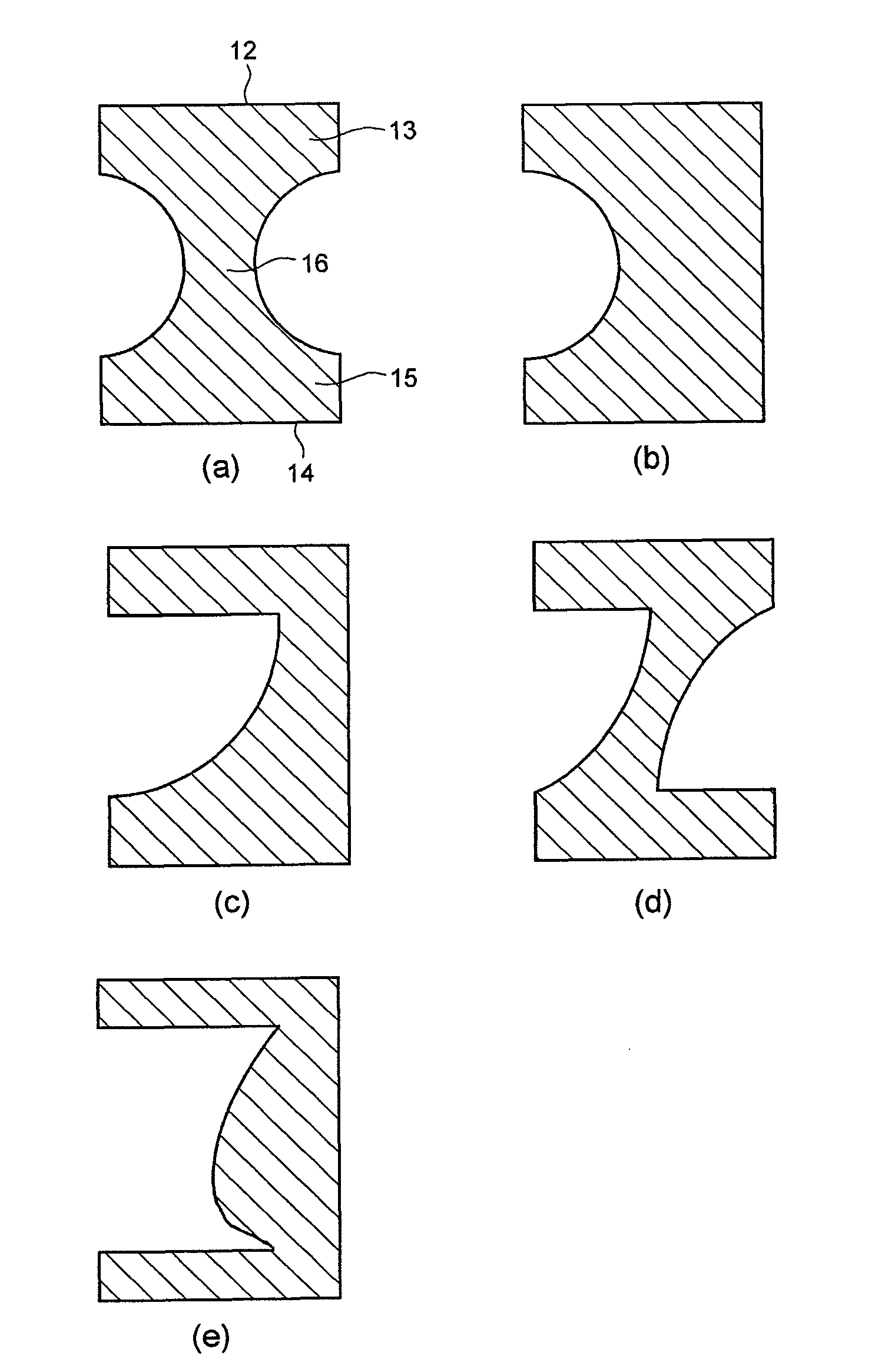

Pellicle frame and lithographic pellicle

ActiveUS20100330467A1Avoid deformationFlatnessSemiconductor/solid-state device manufacturingPackagingEngineeringPellicle membrane

A pellicle frame is provided that includes a pellicle frame bar having a cross-section with a shape that has a curved line-containing recess in at least one side edge of a quadrilateral having an upper edge and a lower edge parallel to each other and an area of no greater than 20 mm2.

Owner:SHIN ETSU CHEM IND CO LTD +1

Pellicle frame and lithographic pellicle

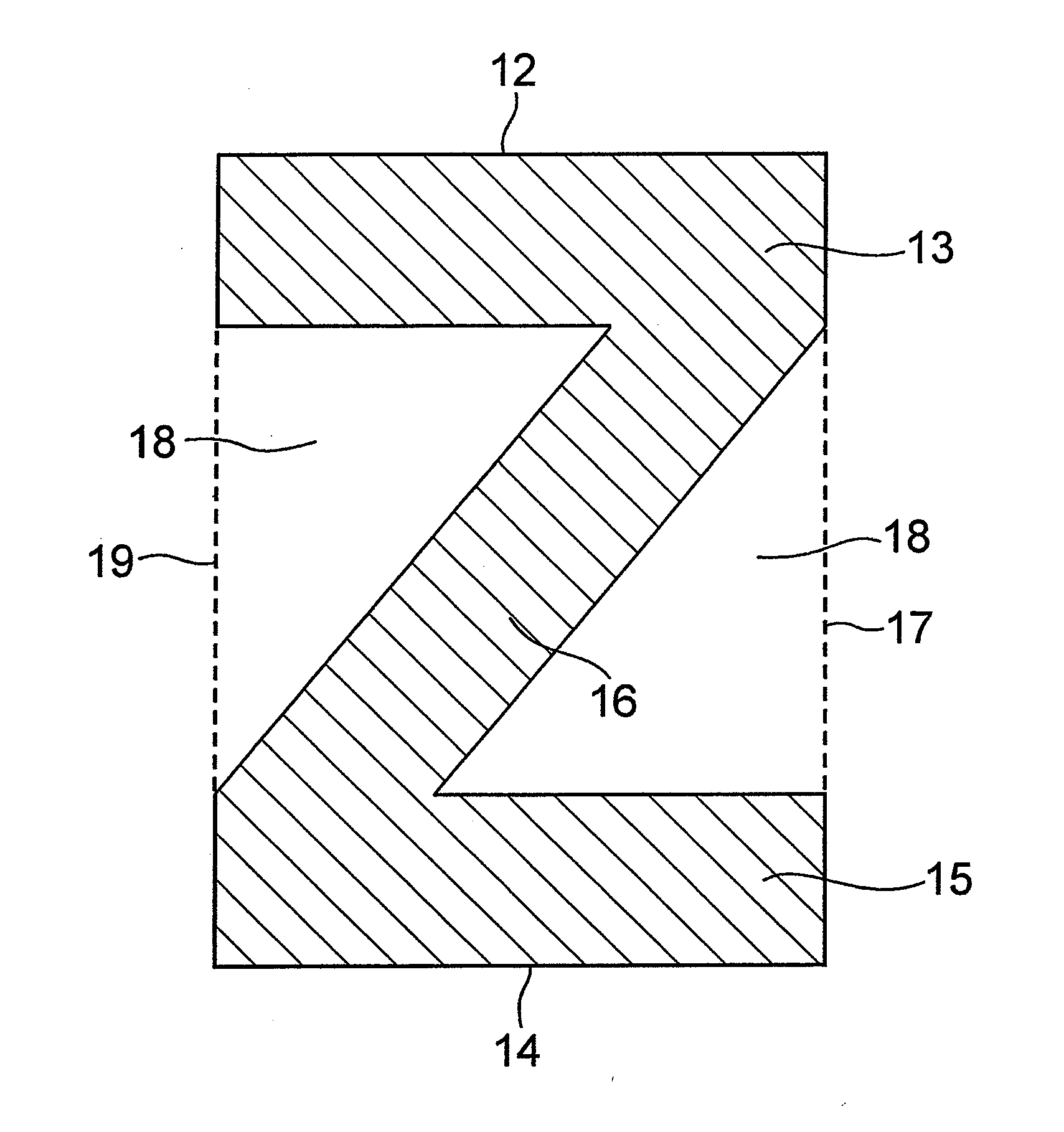

ActiveUS8221944B2FlatnessPoor flatnessSemiconductor/solid-state device manufacturingPackagingAdhesiveEngineering

A pellicle frame is provided that comprises a pellicle frame bar having a quadrilateral cross-section, wherein an upper edge and a lower edge of a basic quadrilateral forming said cross-section are parallel to each other and each of side edges of the basic quadrilateral has one quadrilateral recess. There is also provided a lithographic pellicle that includes a pellicle film stretched over one end face of the pellicle frame via a pellicle film adhesive, and that includes an exposure master plate adhesive on the other end face.

Owner:SHIN ETSU CHEM CO LTD +1

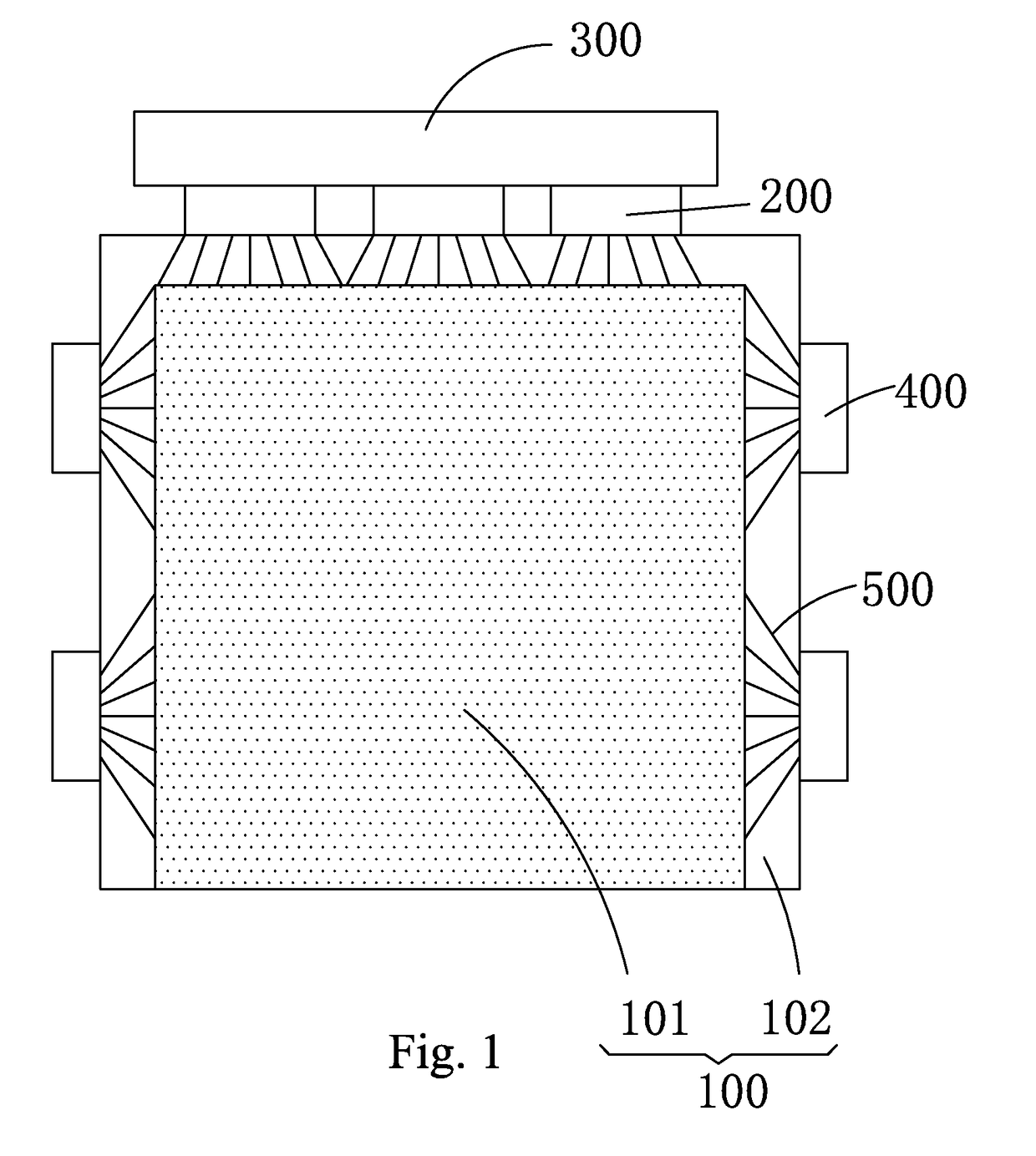

Pellicle, mounting method therefor, pellicle-equipped mask, and mask

ActiveUS20110235016A1Poor flatnessImprove flatnessSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEngineeringFace shield

A pellicle is provided that includes a pellicle film, a pellicle frame having the pellicle film stretched over one end face thereof and having the other end face open, and a pressure-sensitive adhesion layer for adhering the pellicle frame to a mask, the pressure-sensitive adhesion layer being provided on an inner peripheral face of the pellicle frame, and the pressure-sensitive adhesion layer being capable of adhering to a side face of a mask having a mask image on a front face. There are also provided a method of mounting a pellicle that includes fixing to a side face of a mask an inner peripheral face of a pellicle frame of a pellicle that includes a pellicle film and a pellicle frame having the pellicle film stretched over one end face thereof and having the other end face open, a method of mounting a pellicle that includes adhering the pellicle to a side face of the mask that is inclined in going from the reverse face of the mask toward the front face where the mask image is provided, thus adhering the side face of the mask to the pellicle frame inner peripheral face, a pellicle-equipped mask that includes the pellicle adhered to a mask, and a mask that includes a side face that is inclined in going toward the front face where a mask image is provided.

Owner:SHIN ETSU CHEM IND CO LTD

Method for manufacturing flexible array substrate

ActiveUS20180343750A1Poor flatnessFabrication yield be improvePrinted circuit aspectsElectrical connection printed elementsEngineeringElectrical and Electronics engineering

The present invention provides a method for manufacturing a flexible array substrate. The method includes, first, successively forming an adhesive layer, a passivation layer, a back-side drive circuit, a planarization layer, a flexible backing plate, and a front-side drive circuit and a display circuit, in a stacked arrangement, on a rigid support plate and then peeling off the rigid support plate and the adhesive layer to form a flexible array substrate having a double-sided circuit structure. The entirey process requires no steps of peeling, reversing, and then re-attaching of the flexible backing plate so that it is possible to avoid the issues of poor flatness and low yield resulting from improper or wrongful re-attachment of the flexible backing plate and thus, fabrication difficulty of a flexible array substrate having a double-sided circuit structure may be lowered down to thereby improve fabrication yield of the flexible array substrate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

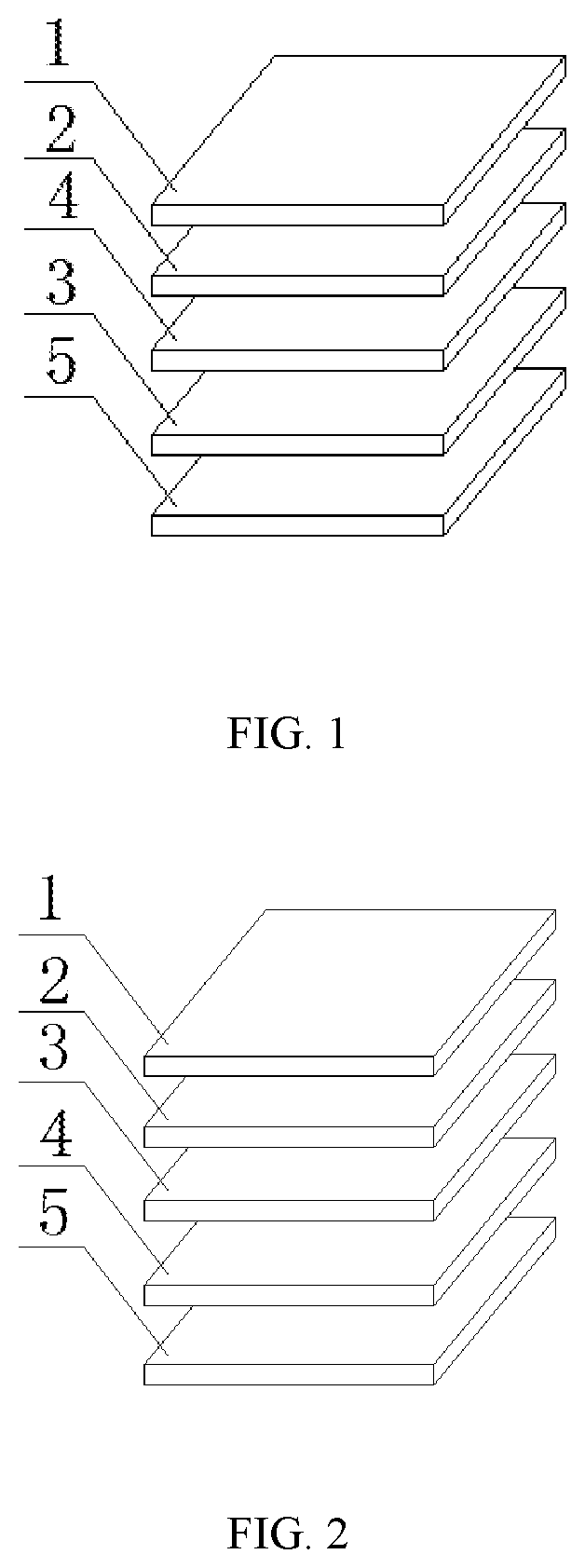

Plastic building template and manufacturing process

The present invention relates to a plastic building form and its production method. Said invention adopts the waste plastics as raw material, and adopts the production processes of pug milling, mixing by using mill mixer, cooling, pressing and secondary cooling to obtain a plastic sheet. Said plastic sheet and wood chip can be alternately superimposed, heated and pressurized, and integrally-formed into the invented plastic wood composite form, and the above-mentioned plastic sheet and bamboo net also can be alternately superimposed, heated, pressurized and integrally-formed into the invented plastic bamboo composite form.

Owner:李道春

Method and plant for integrated monitoring and control of strip flatness and strip profile

ActiveUS7849722B2Reduce tensionSusceptible to bucklingRoll force/gap control deviceMetal rolling stand detailsIntegrated monitoringControl system

Apparatus and method of controlling strip geometry in casting strip having a rolling mill. A target thickness profile is calculated as a function of the measured entry thickness profile of the strip while satisfying profile and flatness operating requirements. A differential strain feedback from longitudinal strain in the strip is calculated by a control system by comparing the exit thickness profile with the target thickness profile, and a control signal is generated to control a device capable of affecting the geometry of the strip processed by the hot rolling mill. A feed-forward control reference and / or sensitivity vector may also be calculated as a function of the target thickness profile, and used in generating the control signal sent to the control device. The control device may be selected from one or more of the group consisting of a bending controller, gap controller and coolant controller.

Owner:NUCOR CORP

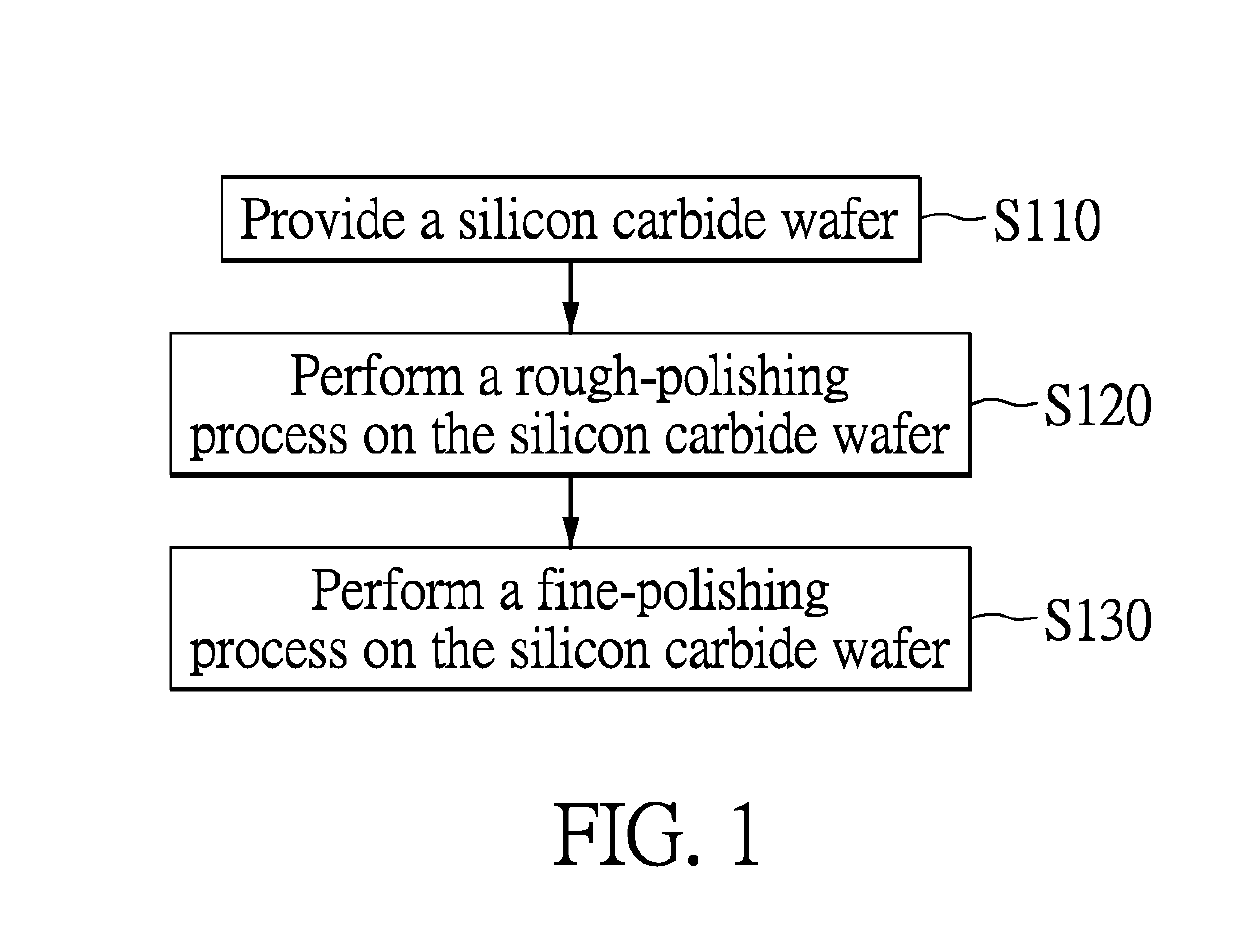

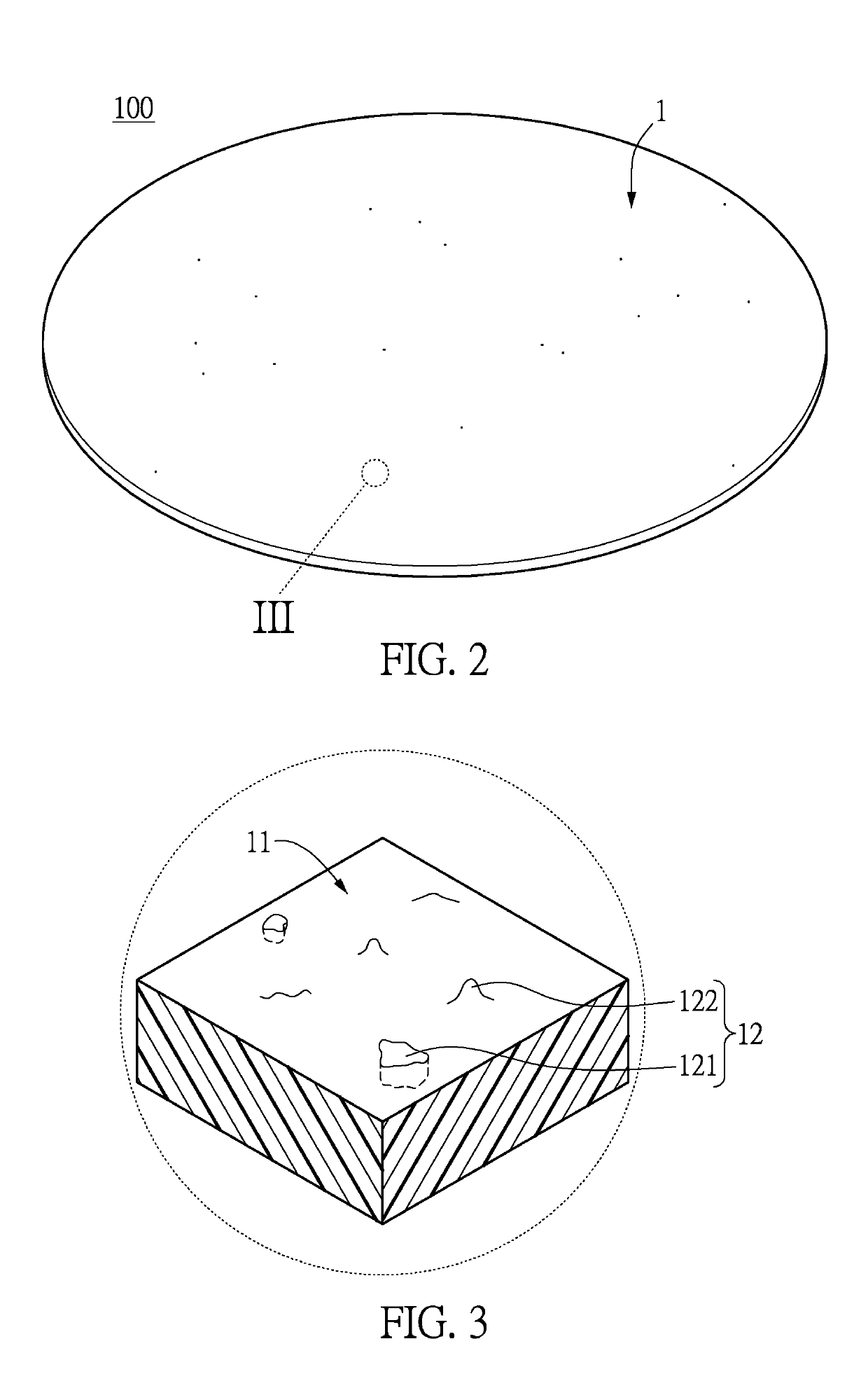

Silicon carbide wafer and method for production thereof

ActiveUS20190115205A1Additional drawbackPoor flatnessSemiconductor/solid-state device manufacturingLapping machinesSilicon carbideCrystal

A method for producing a silicon carbide wafer includes: providing a silicon carbide wafer having an unpolished surface; in which the unpolished surface has a first crystal face and a second crystal face; polishing one face of the first crystal face and the second crystal face of the unpolished surface in a first polishing solution by using a polisher; in which the polisher includes a polishing pad and a plurality of abrasive particles fixed on the polishing pad; and polishing the other face of the first crystal face and the second crystal face of the unpolished surface in a second polishing solution by using the polisher; in which a pH value of the first polishing solution is less than or equal to 7, and a pH value of the second polishing solution is greater than or equal to 7. The present disclosure also provides a silicon carbide wafer.

Owner:GLOBALWAFERS CO LTD

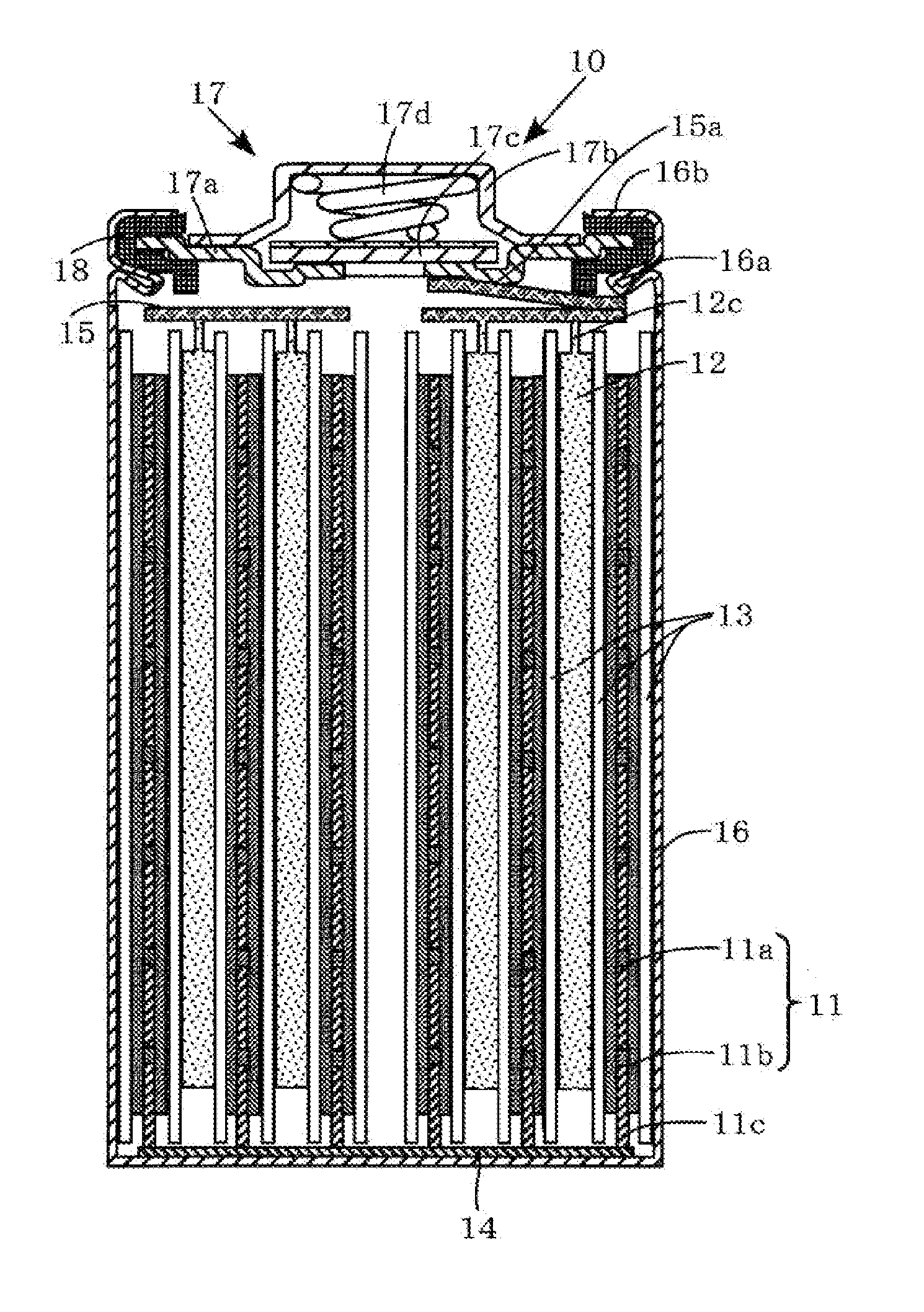

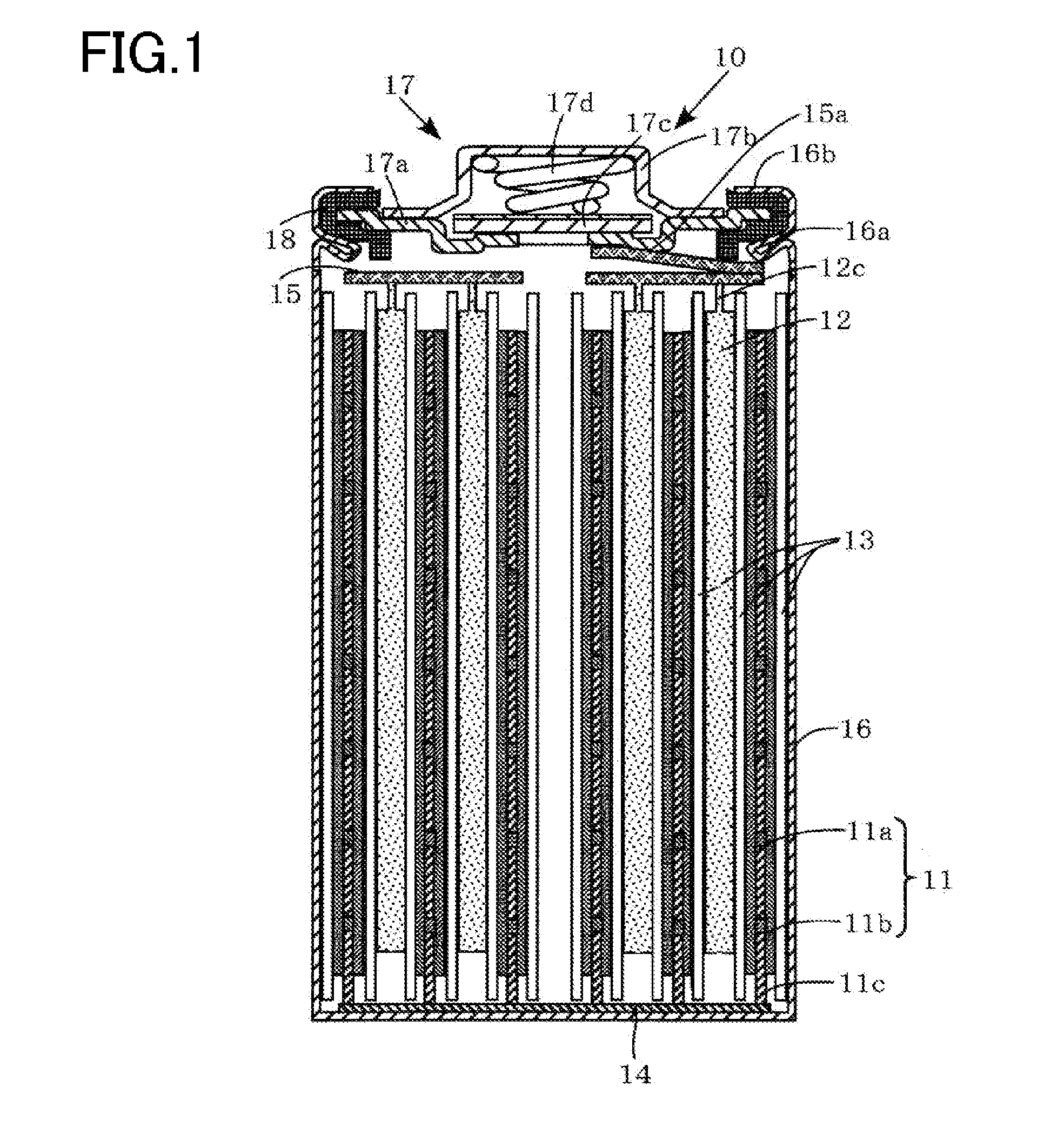

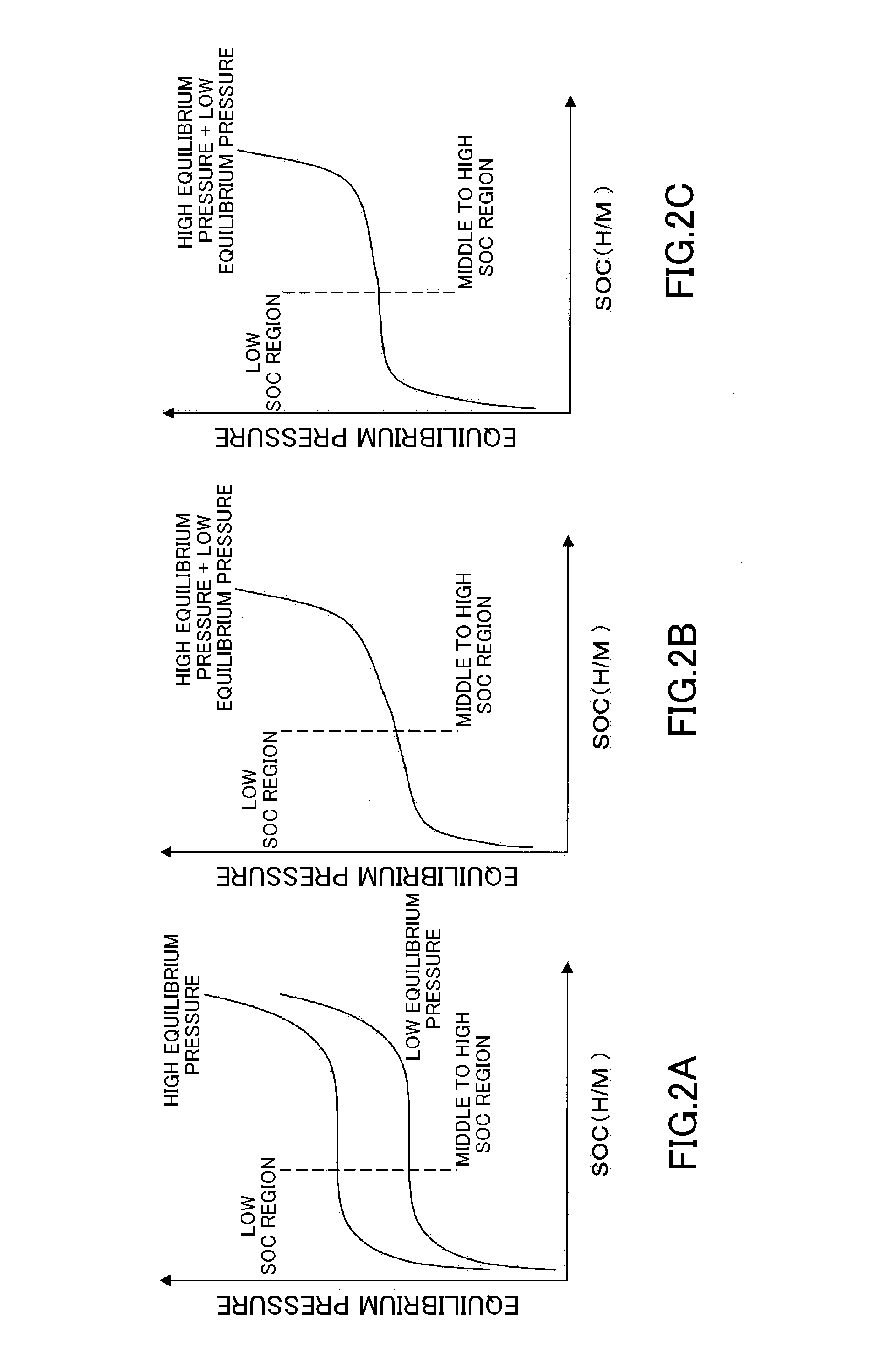

Hydrogen-absorbing alloy for alkaline storage battery and method for manufacturing the same

ActiveUS20100323243A1Improve power characteristicsImprove output power stabilityFinal product manufactureSecondary cellsRare-earth elementChemical measurement

A hydrogen-absorbing alloy for an alkaline storage battery with high power characteristics and excellent output power stability and a method for manufacturing the same are provided. The hydrogen-absorbing alloy for an alkaline storage battery of the invention is represented by ABn (A: LaxReyMg1-x-y, B: Nin-zTz, Re: at least one element selected from rare earth elements including Y (other than La), T: at least one element selected from Co, Mn, Zn, and Al, and z>0) and has a stoichiometric ratio n of 3.5 to 3.8, a ratio of La to Re (x / y) of 3.5 or less, at least an A5B19 type structure, and an average C axis length α of crystal lattice of 30 to 41 Å.

Owner:SANYO ELECTRIC CO LTD

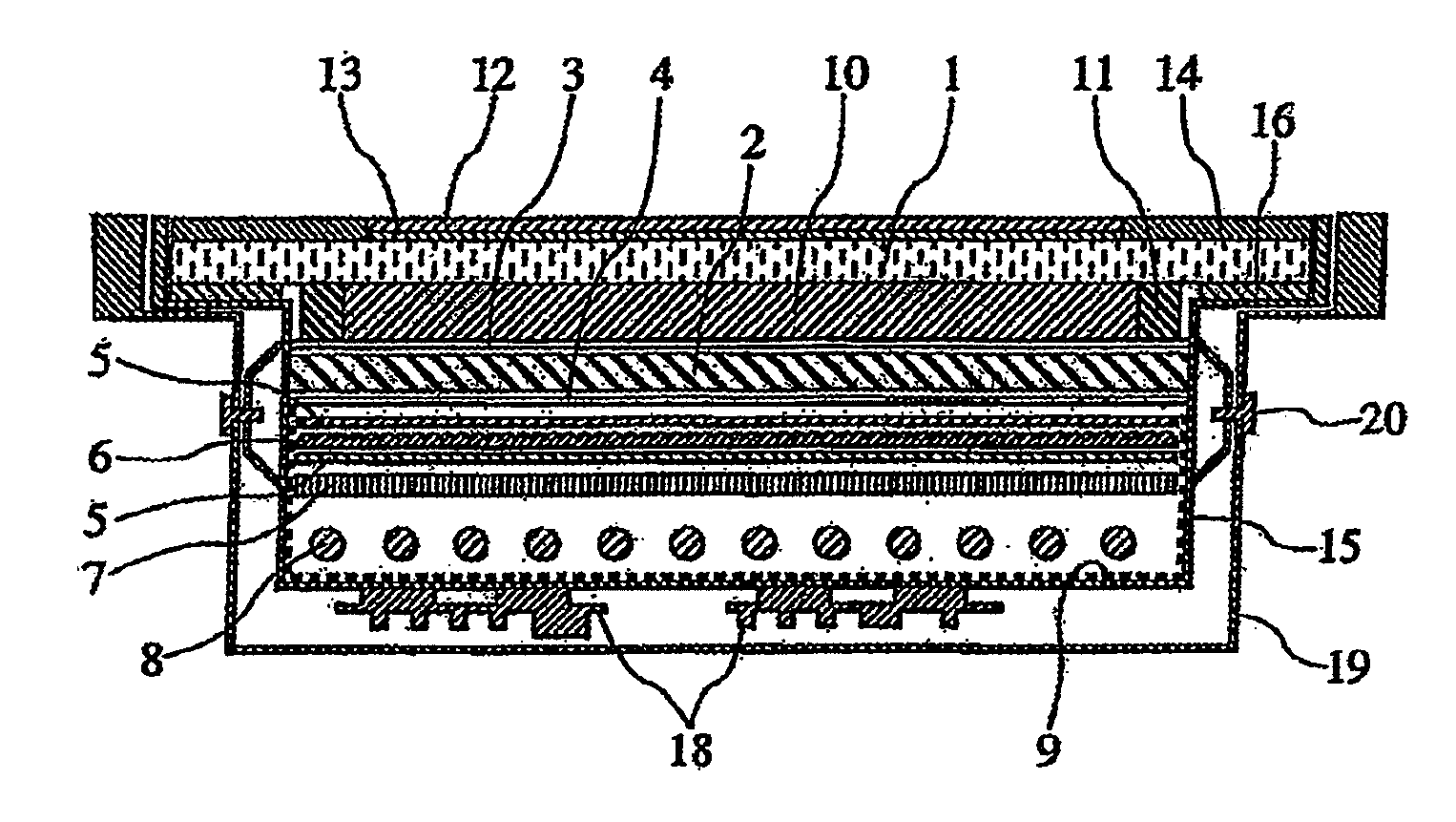

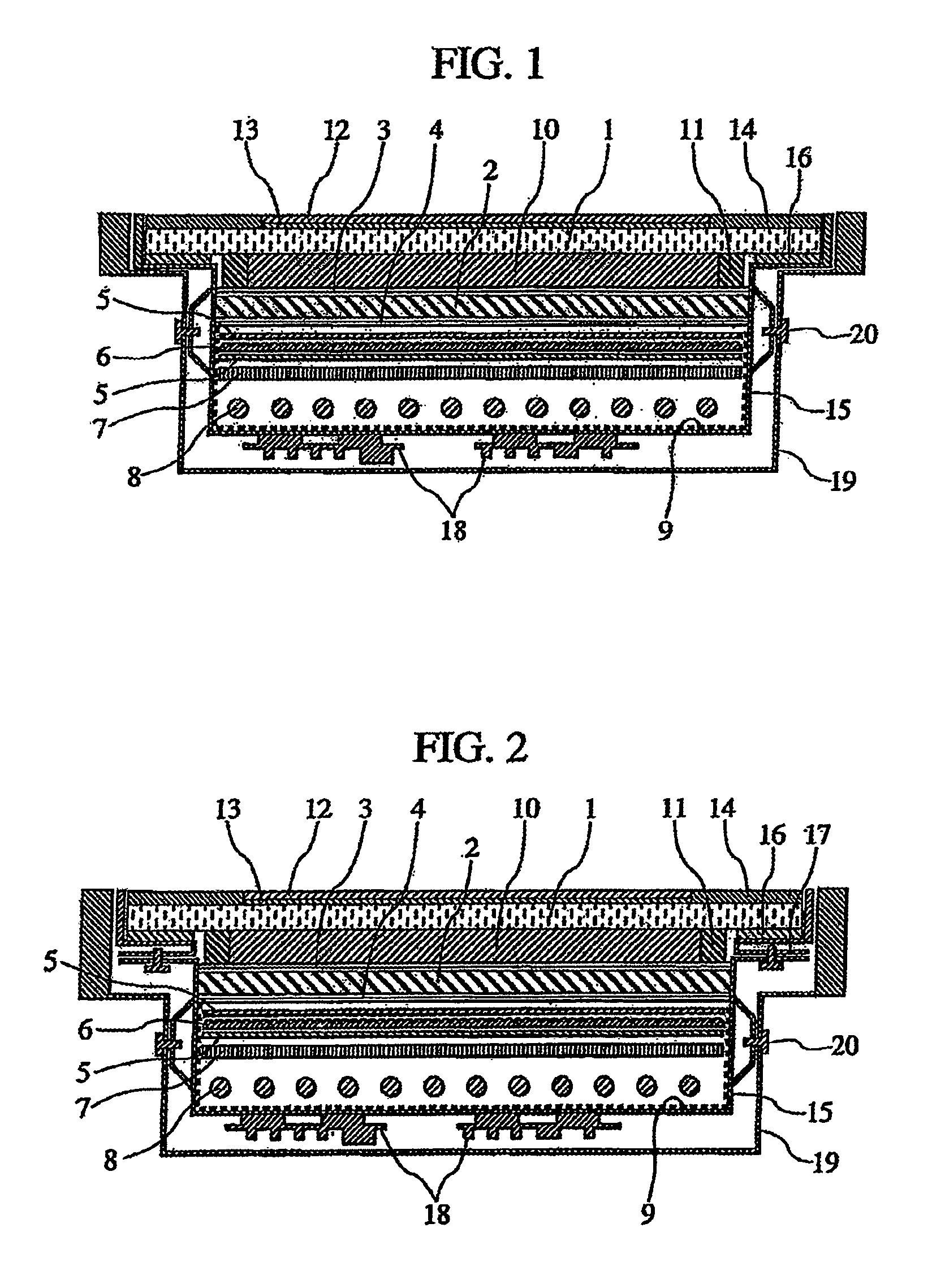

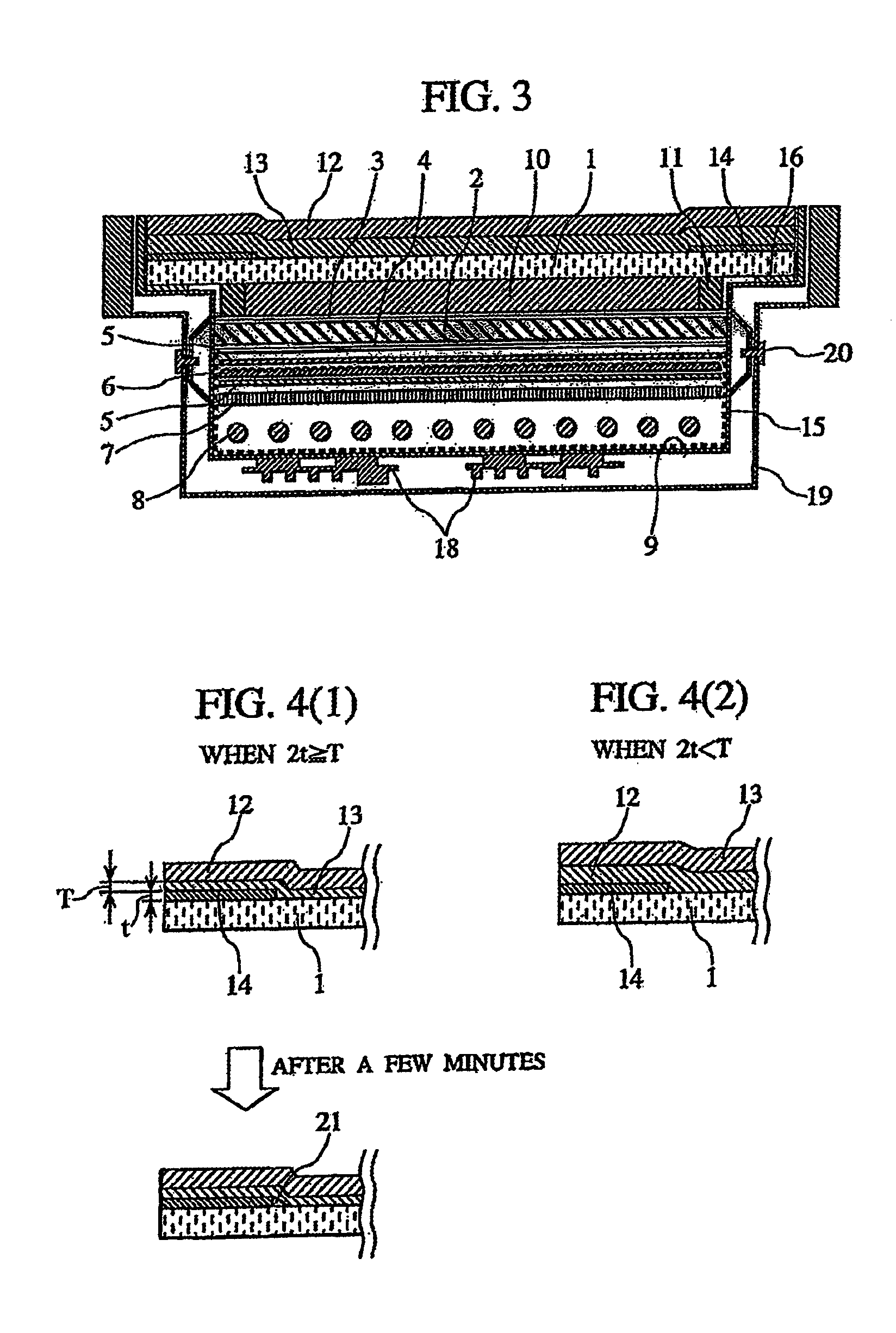

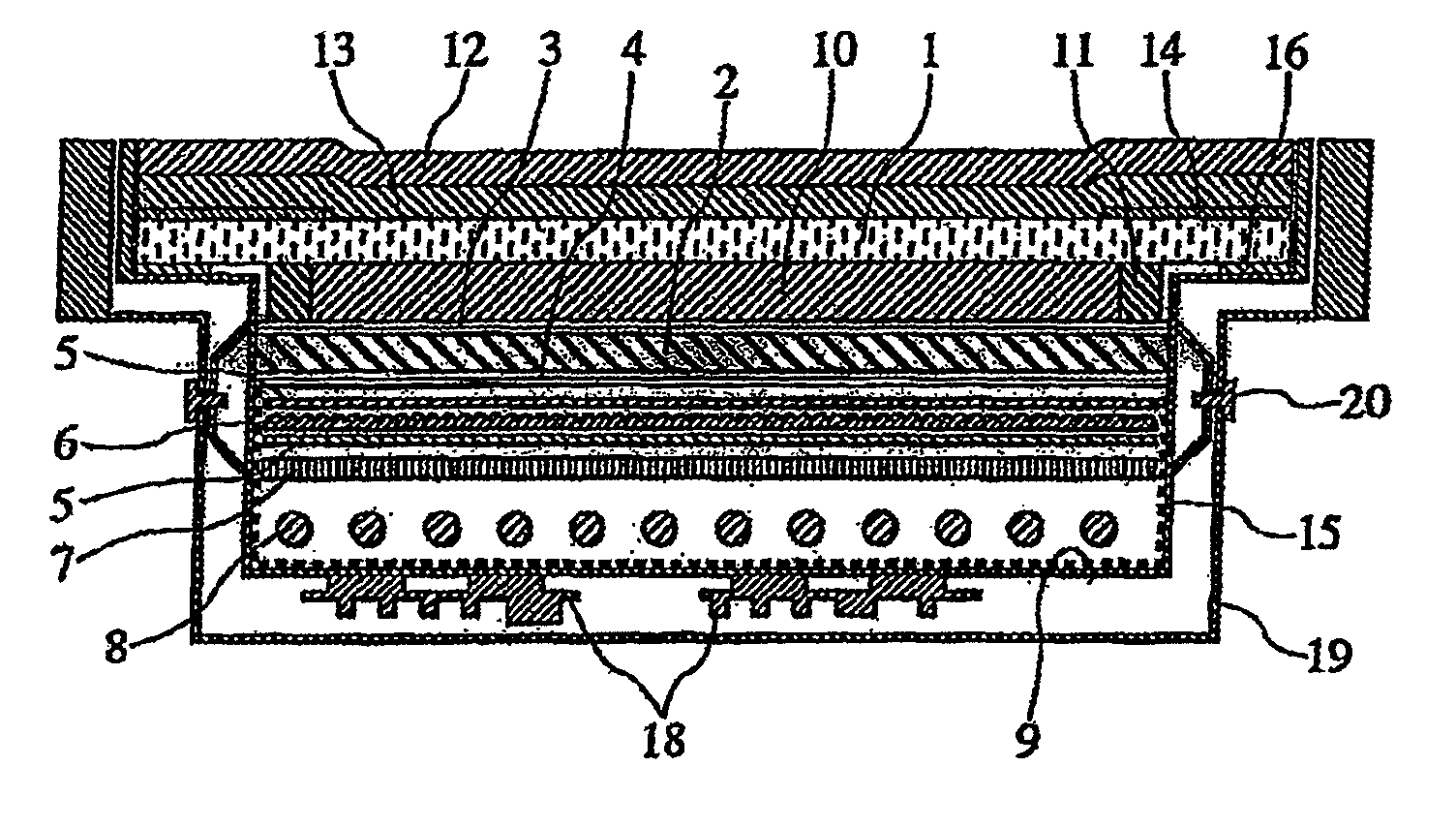

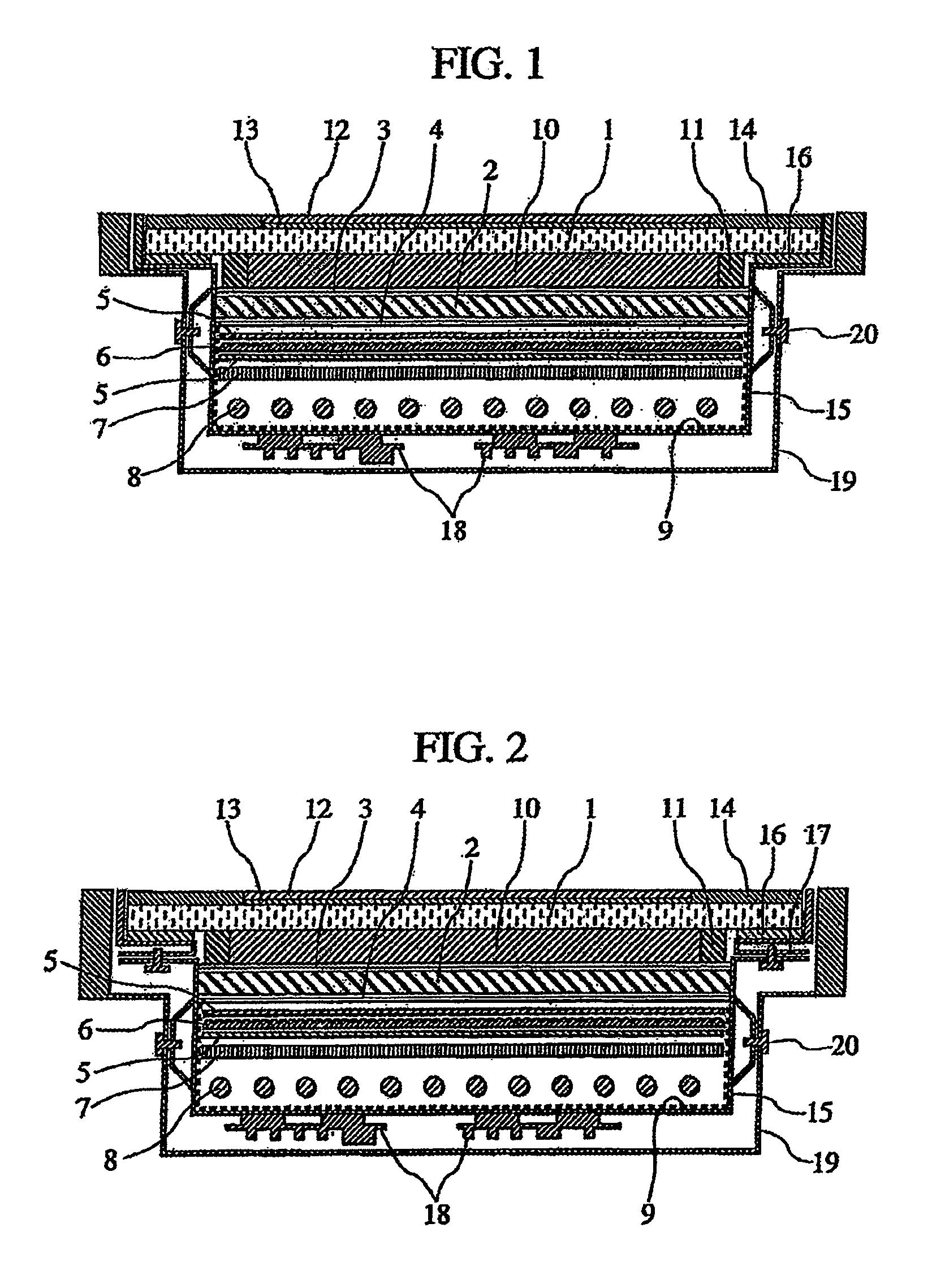

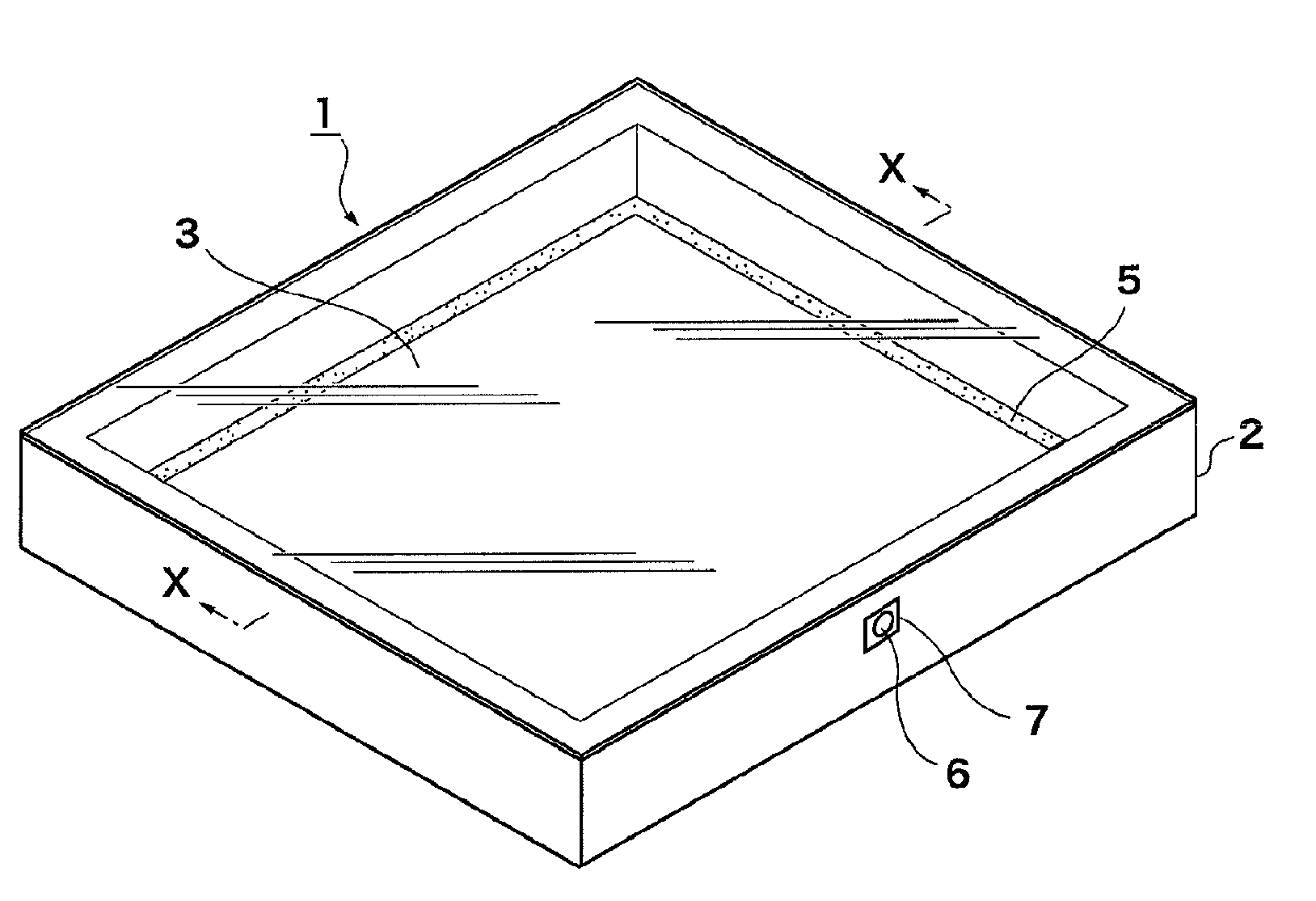

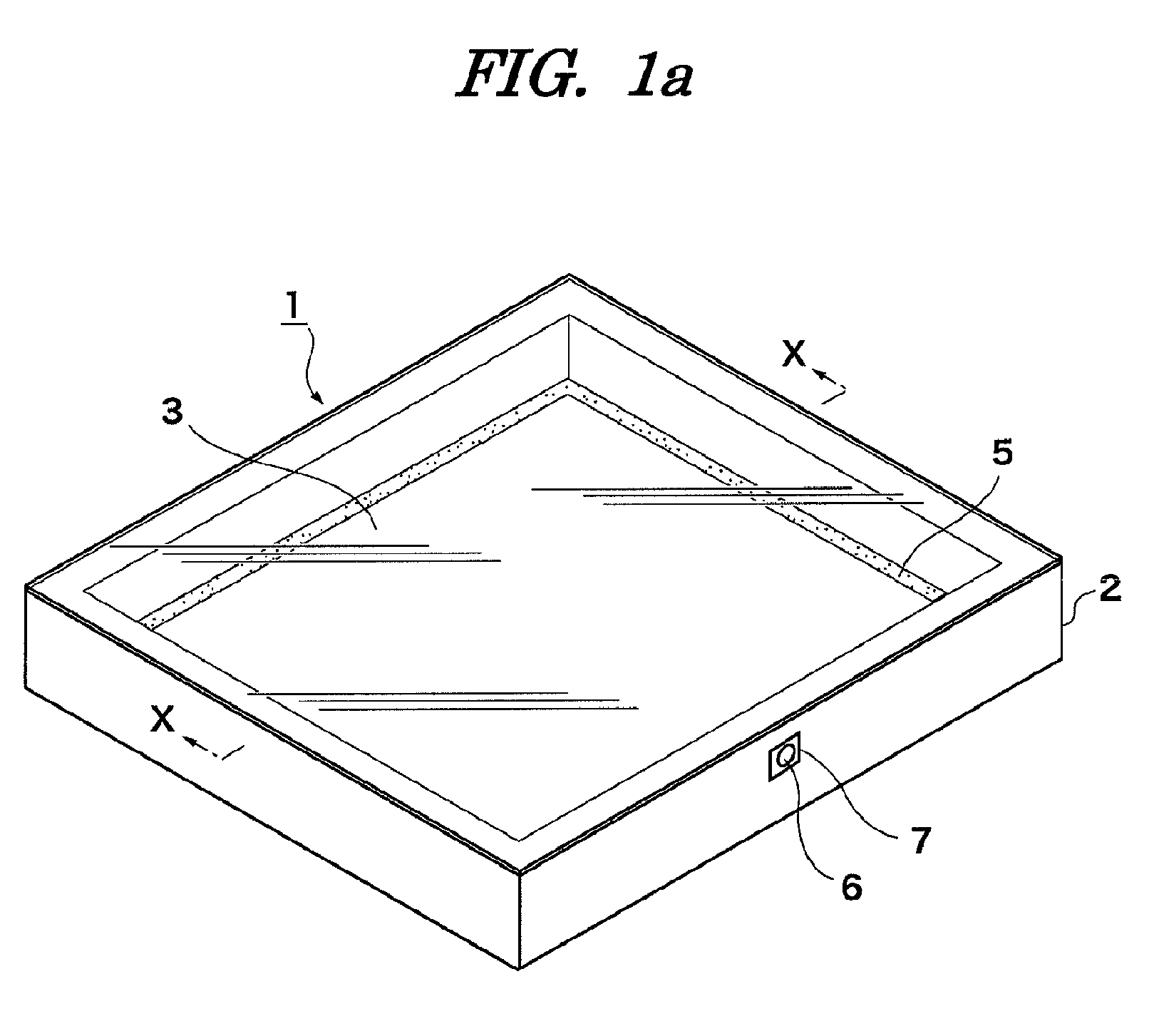

Liquid Crystal Display Device

ActiveUS20090086120A1Prevent peelingWithout degrading design featureNon-linear opticsLiquid-crystal displayEngineering

An object of the present invention is to propose the structure and constitution of a liquid crystal display device having a protection plate, which prevents exfoliation of black painting at ends of the protection plate when dust on the protection plate of the liquid crystal display device is wiped off, thus preventing degradation of design features.The liquid crystal display device comprises: a transparent protection plate formed above a liquid crystal panel; a pair of polarizing plates disposed to sandwich and hold the liquid crystal panel; a transparent organic medium layer formed between the protection plate and the liquid crystal panel; a black coloring layer formed at ends of four sides on a side of the protection plate, the side being opposite to a side at which the transparent organic medium layer is disposed; and an anti-glare film composed of an anti-glare layer and an adhesion layer formed on a side of the protection plate, the side being opposite to a side at which the transparent organic medium layer is disposed.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Pellicle frame and lithographic pellicle

ActiveUS20100328641A1Avoid deformationFlatnessSemiconductor/solid-state device manufacturingPackagingAdhesiveEngineering

A pellicle frame is provided that includes a pellicle frame bar having a cross-section with a shape that has at least one triangular recess in at least one side edge of a quadrilateral having an upper edge and a lower edge parallel to each other and a cross-sectional area of no greater than 20 mm2. There is also provided a lithographic pellicle that includes a pellicle film stretched over one end face of the pellicle frame via a pellicle film adhesive, and that includes an exposure master plate adhesive on the other end face.

Owner:SHIN ETSU CHEM IND CO LTD +1

Pellicle frame and lithographic pellicle

ActiveUS8221945B2FlatnessPoor flatnessSemiconductor/solid-state device manufacturingPackagingEngineeringPellicle membrane

Owner:SHIN ETSU CHEM IND CO LTD +1

Pellicle

InactiveUS20110081603A1FlatnessPoor flatnessSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentLithographic artistBiomedical engineering

A pellicle for lithography is provided that includes a pellicle frame, a pellicle film stretched over one end face of the pellicle frame, and a pressure-sensitive adhesion layer provided on the other end face, the pressure-sensitive adhesion layer being formed from a gel composition.

Owner:SHIN ETSU CHEM IND CO LTD

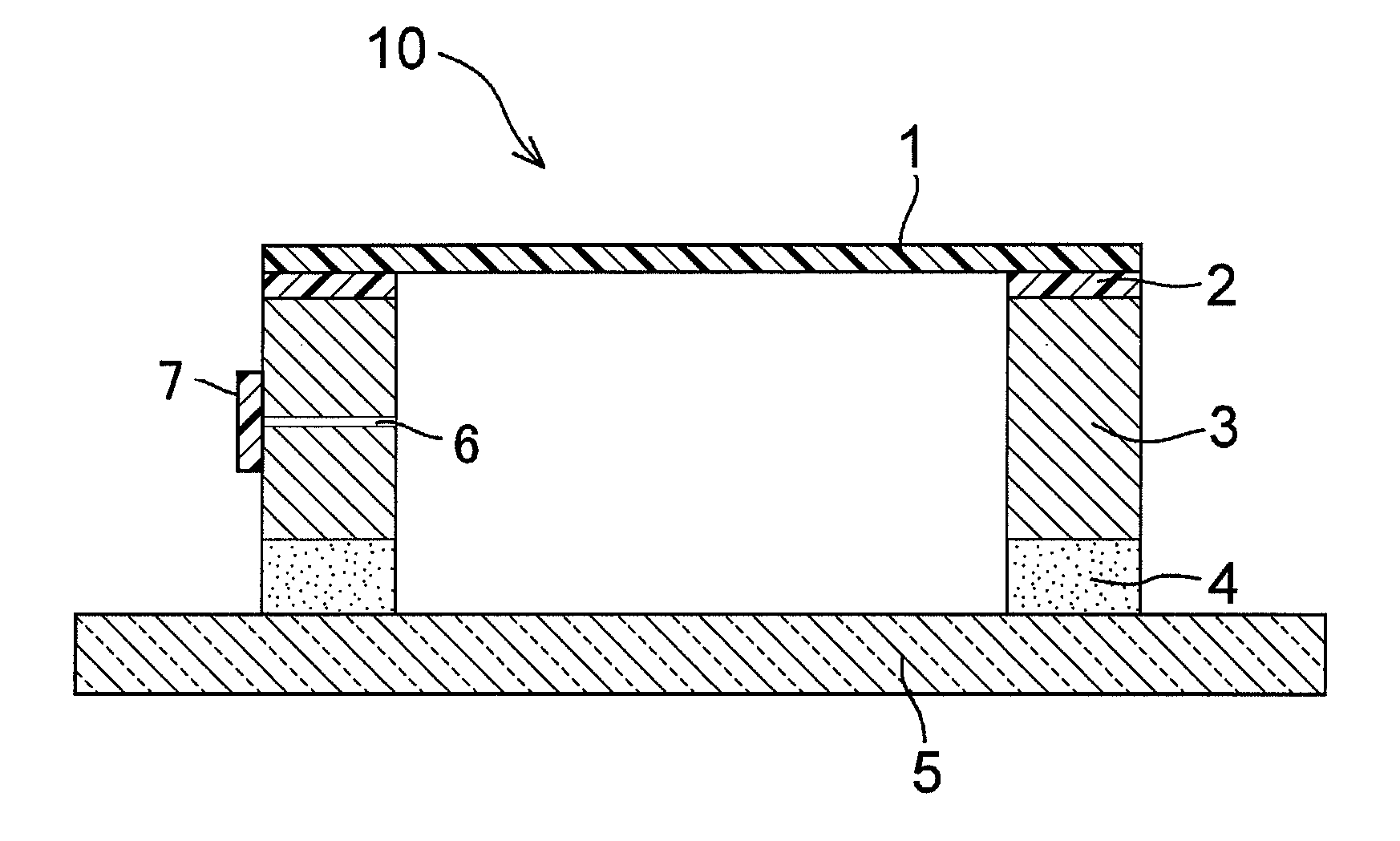

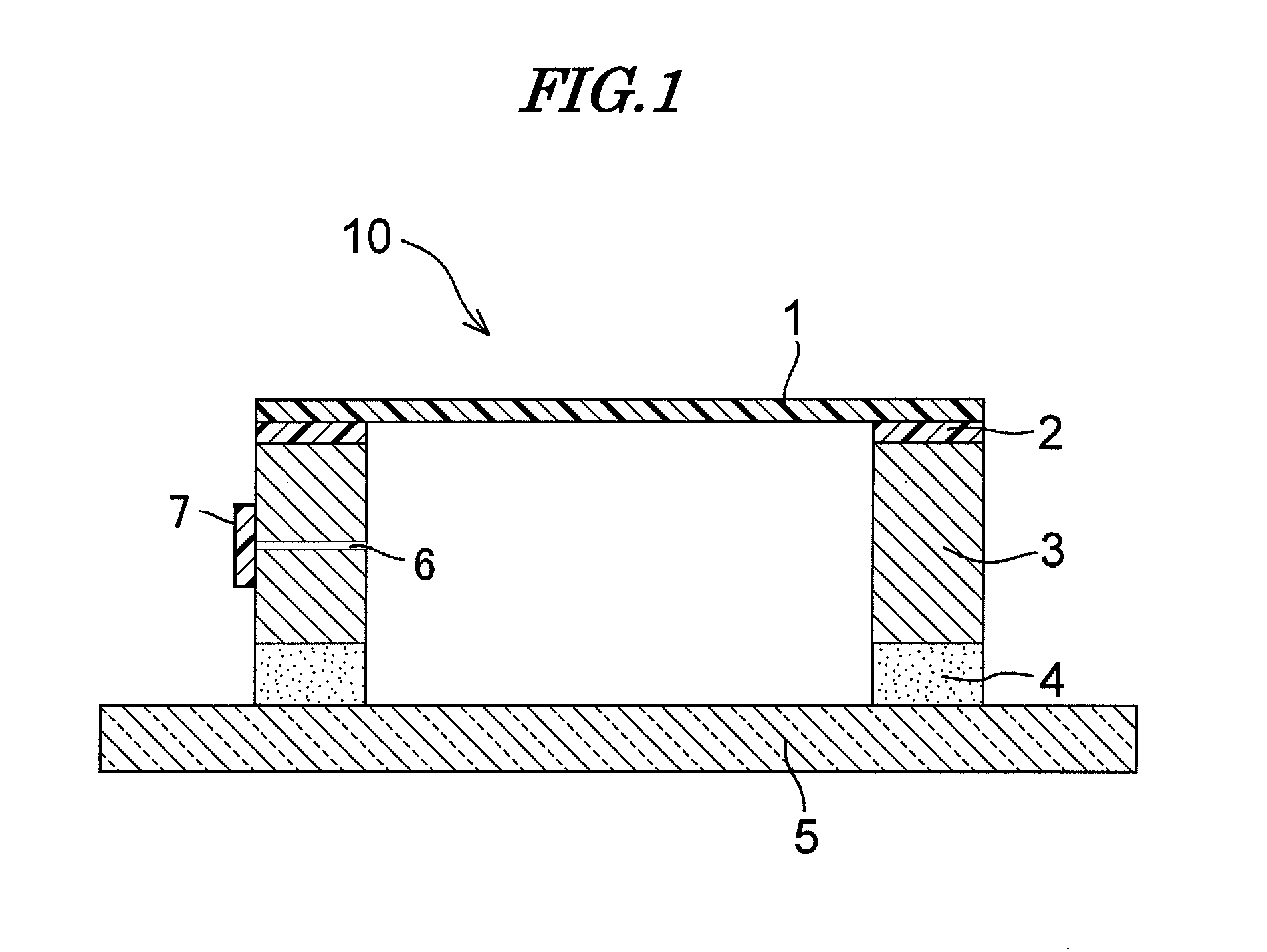

Electrical connector

InactiveUS20150214648A1Good electrical contactLarge forceElectric discharge tubesIncorrect coupling preventionElastomerElectricity

An electrical connector for connecting a first electronic element and a second electronic element, includes an insulating body, multiple elastic bodies integrally formed with the insulating body, and multiple conductors. Each of the elastic bodies has a receiving slot, and each conductor is received in a corresponding receiving slot in an inclined manner. The receiving slot has a first urging portion and a second urging portion respectively providing an inclined upward elastic counterforce and an inclined downward elastic counterforce against the conductor, so that the conductor has a large normal force. Multiple stopping portions of the receiving slot and multiple shoulder portions of the conductor are in clearance fit, so that the conductor can be displaced vertically in the receiving slot when receiving a force.

Owner:LOTES

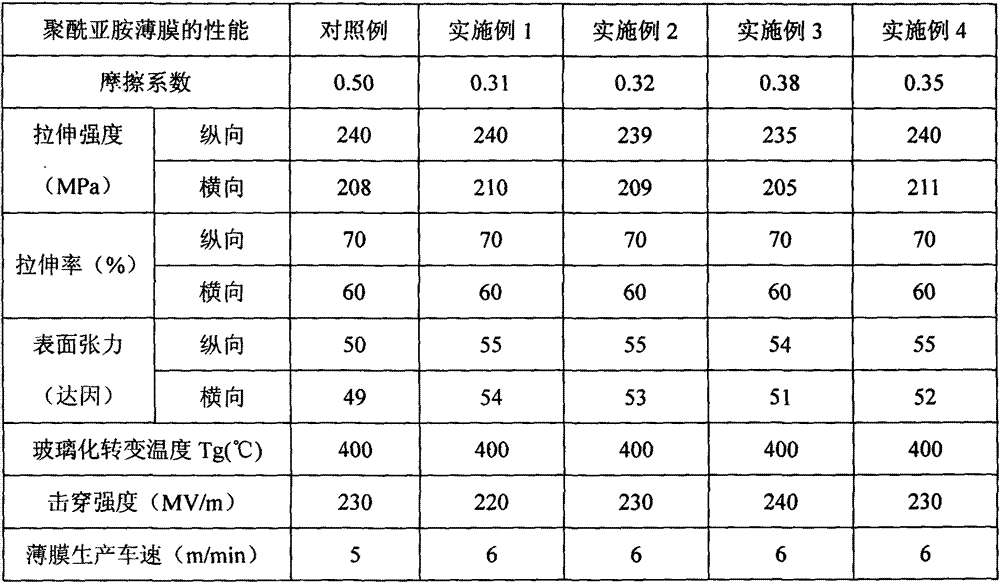

Method for preparing polyimide thin film with low friction coefficient and high cohesive force

InactiveCN103772704AGood mechanical propertiesImprove insulationMetal layered productsOxygen compoundCalcium biphosphate

The invention discloses a method for preparing a polyimide thin film with low friction coefficient and high cohesive force, and belongs to the technical field of electronic thin film insulating material preparation. During the preparation process, a composition of a filtering material and a dispersing agent of which the mass ratio is (10:1)-(1:1) is used, the filtering material is microscale or nanoscale spherical organosilicone, silicate, aluminum-oxygen compound or calcium phosphate filtering material and the like; the dispersing agent is polyphosphate or polyacrylic acid compound or composition; every 100 parts of a polyamide acid resin liquid (solid content) by weight uses 10-20 parts of the composition of the filtering material and the dispersing agent by weight. Through the addition of the microscale filtering material, the internal performance of the thin film is improved, the surface roughness of the thin film is increased, the mechanical occlusion action of the thin film and the coating surface and the adhesive force of the thin film and the coating are enhanced, the wettability and the adhesion are greatly improved, so that the working efficiency is effectively improved, the product quality is optimized, and the suitability and the reliability of the thin film in various fields can be improved.

Owner:TIANJIN TIANYUAN ELECTRONICS MATERIAL +1

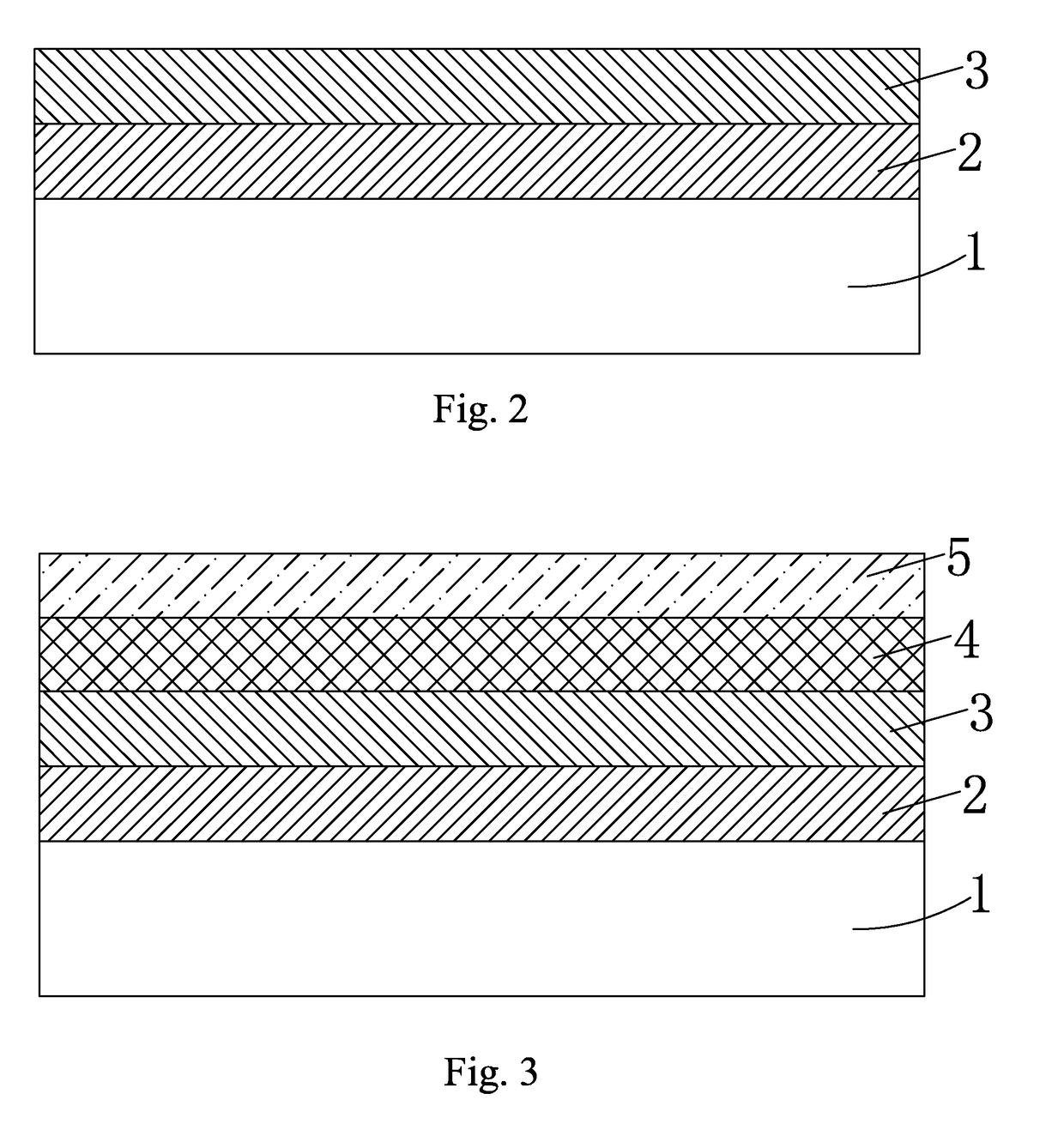

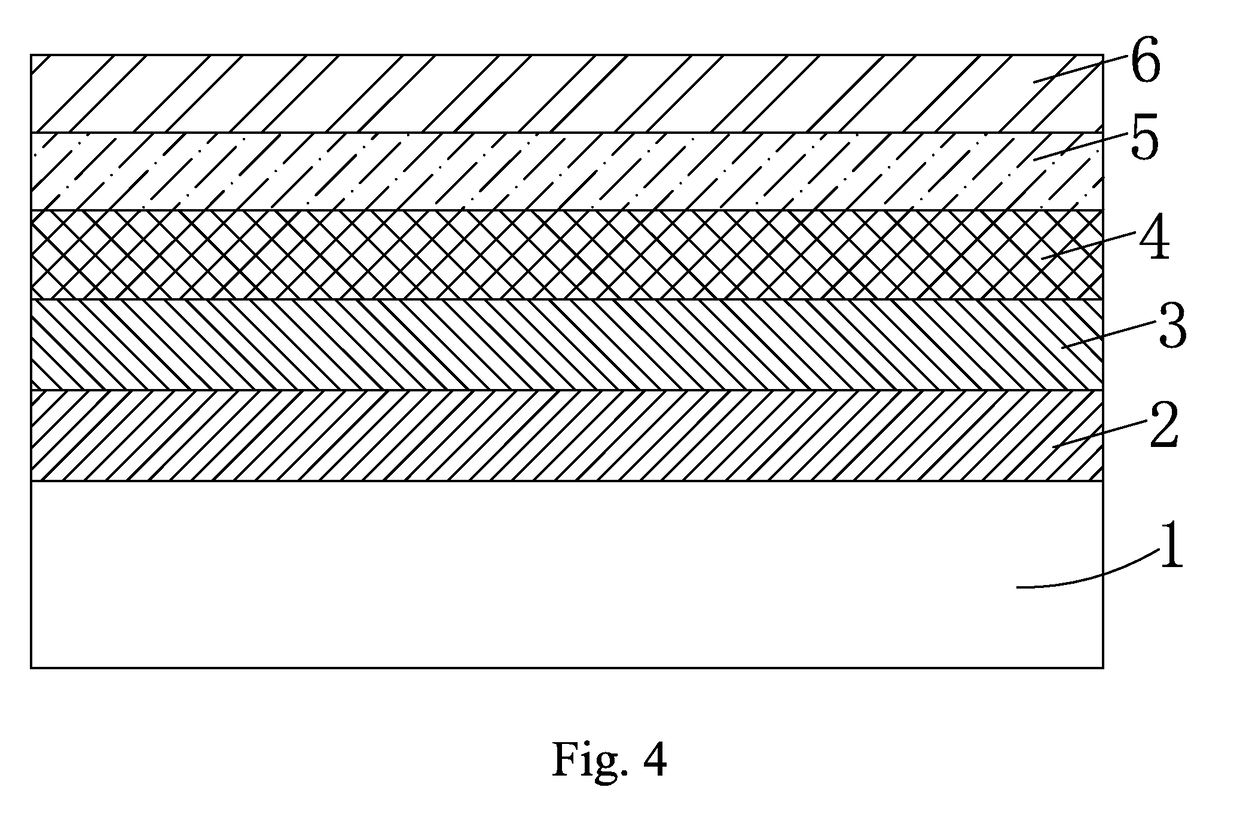

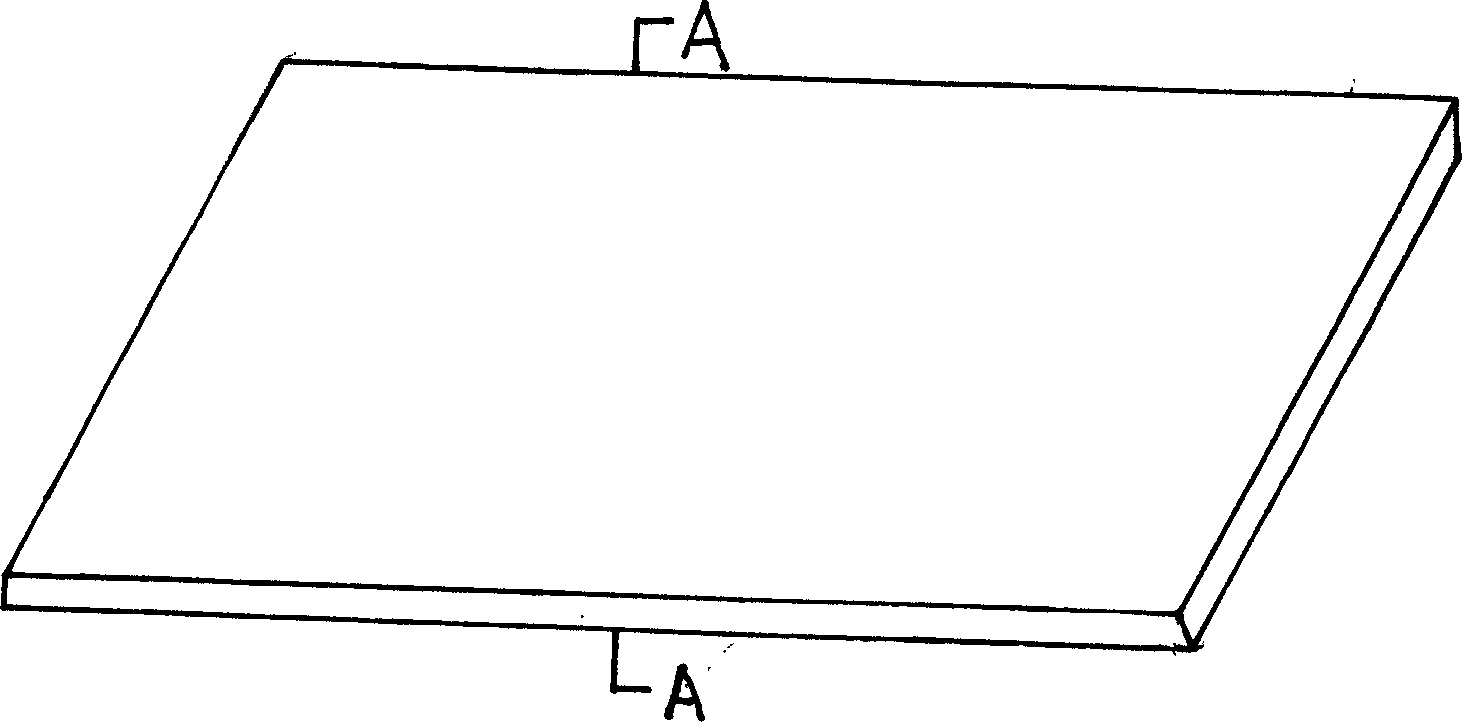

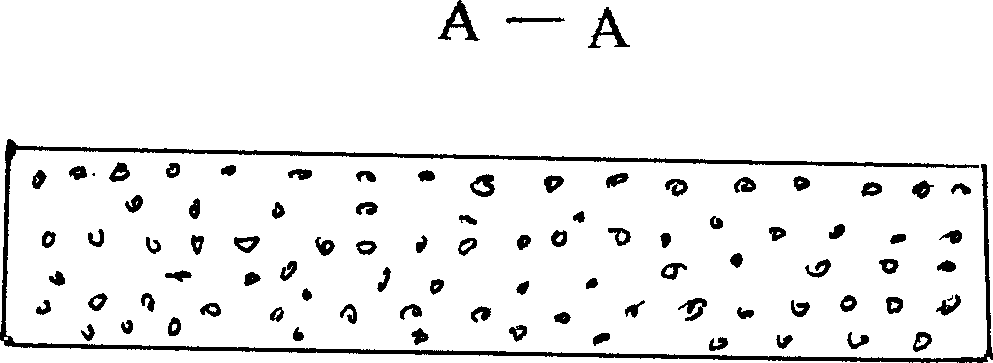

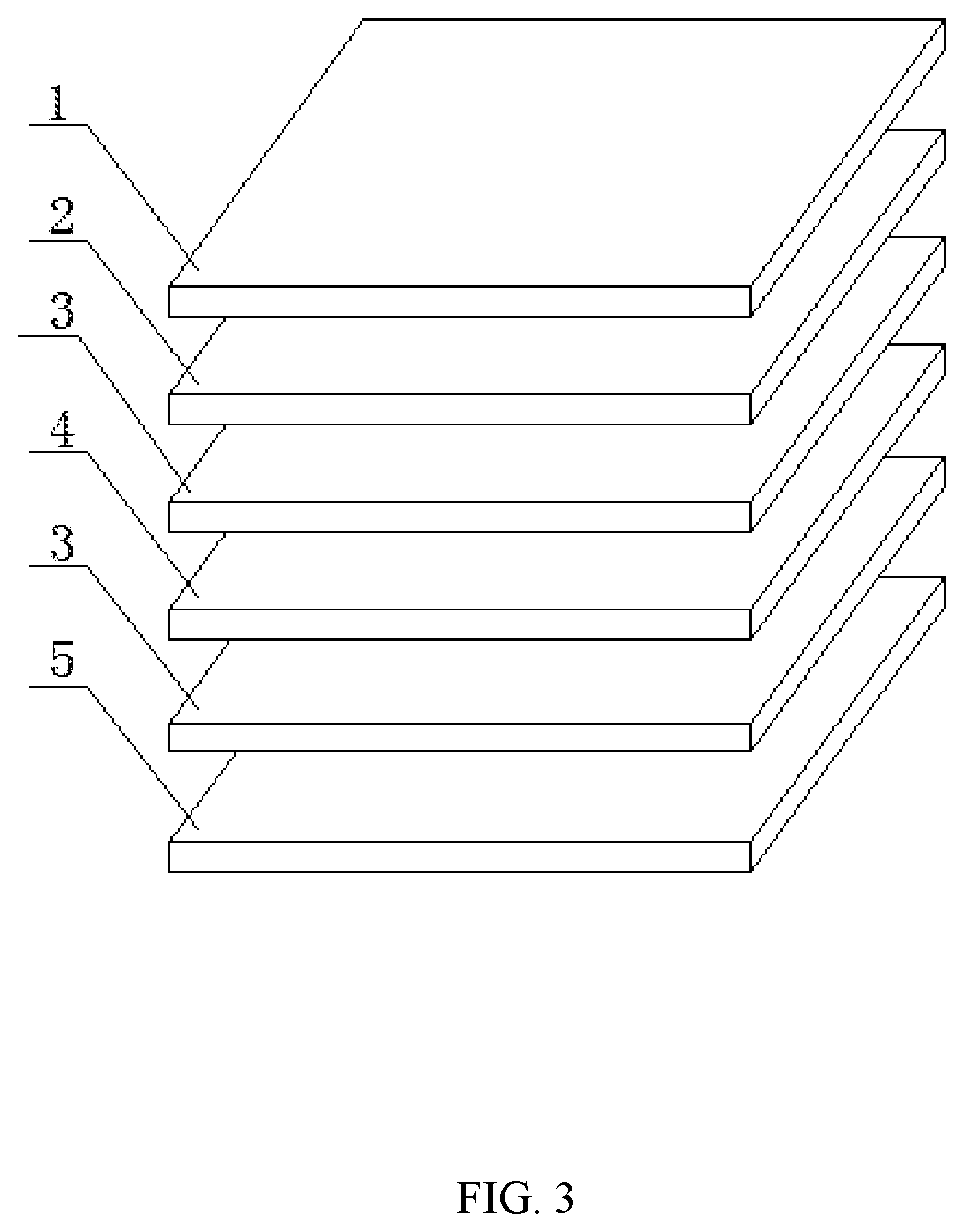

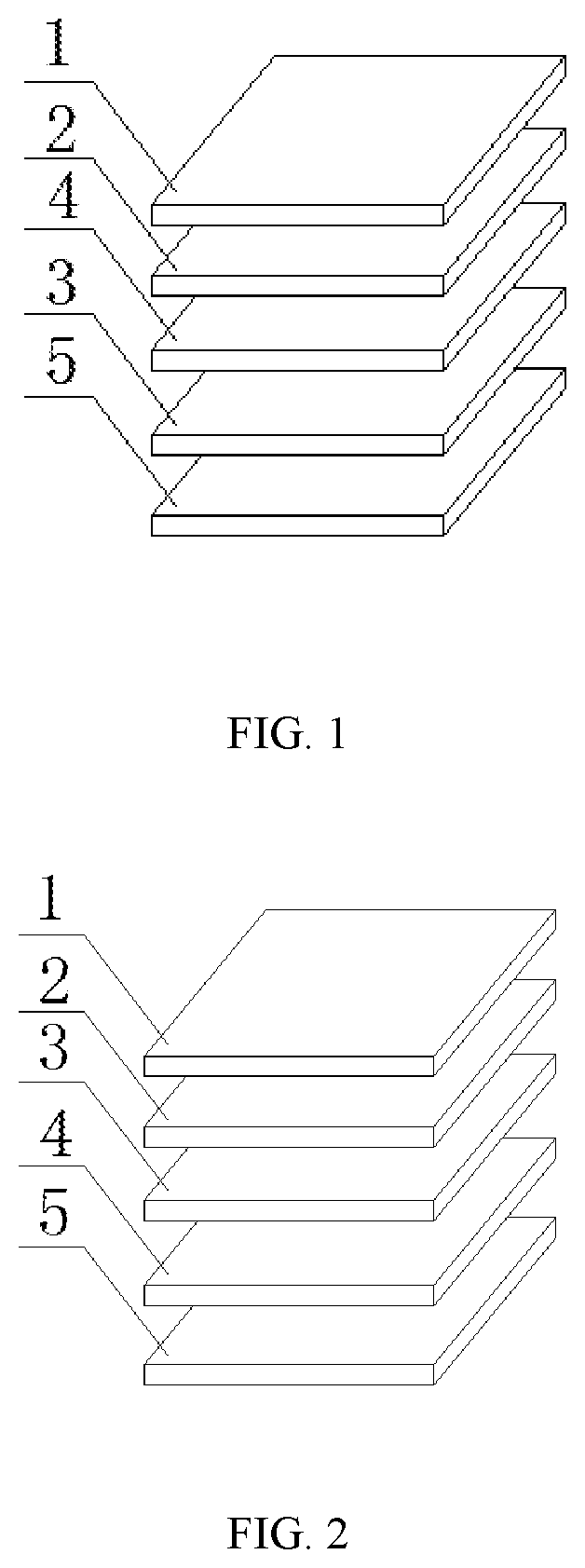

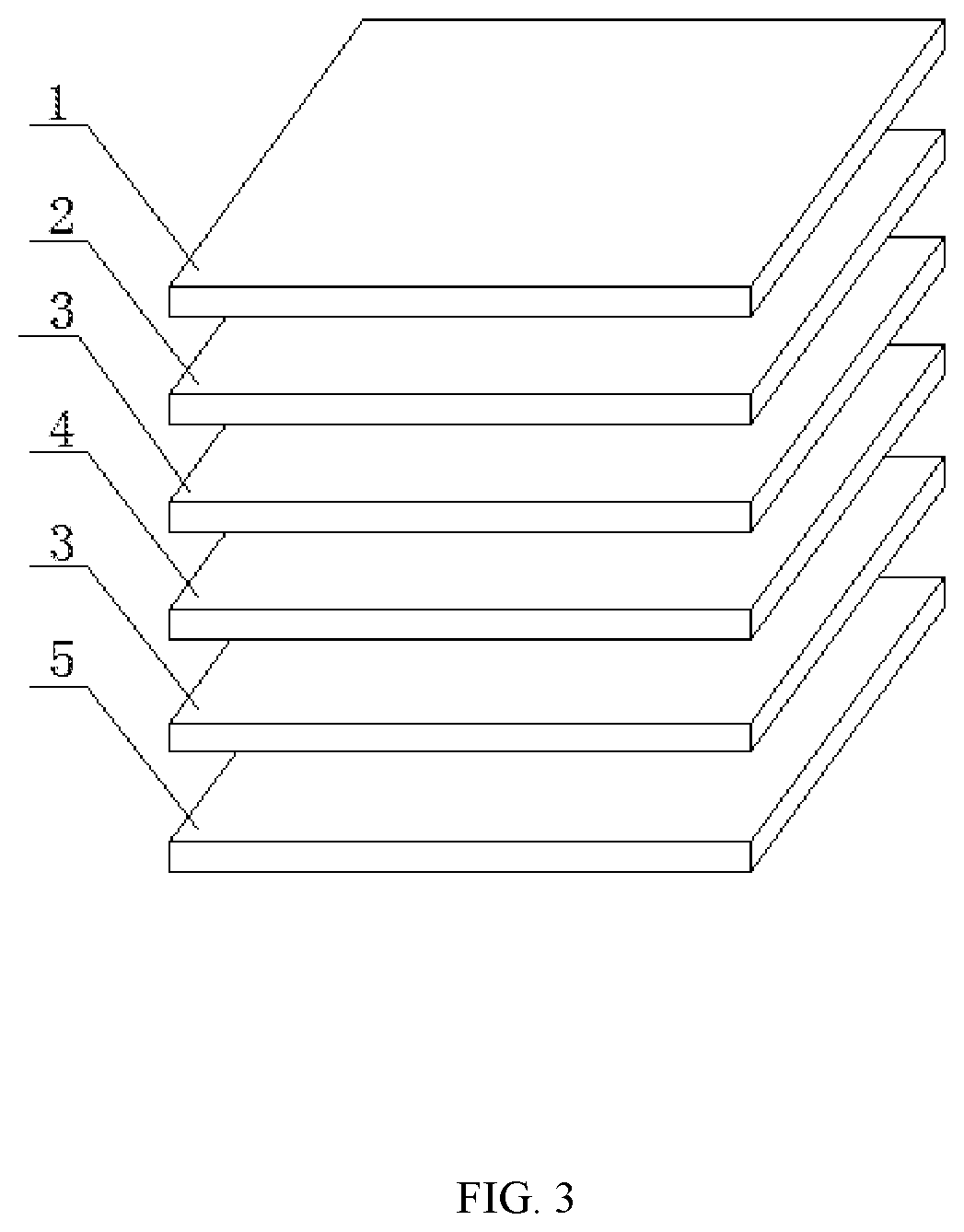

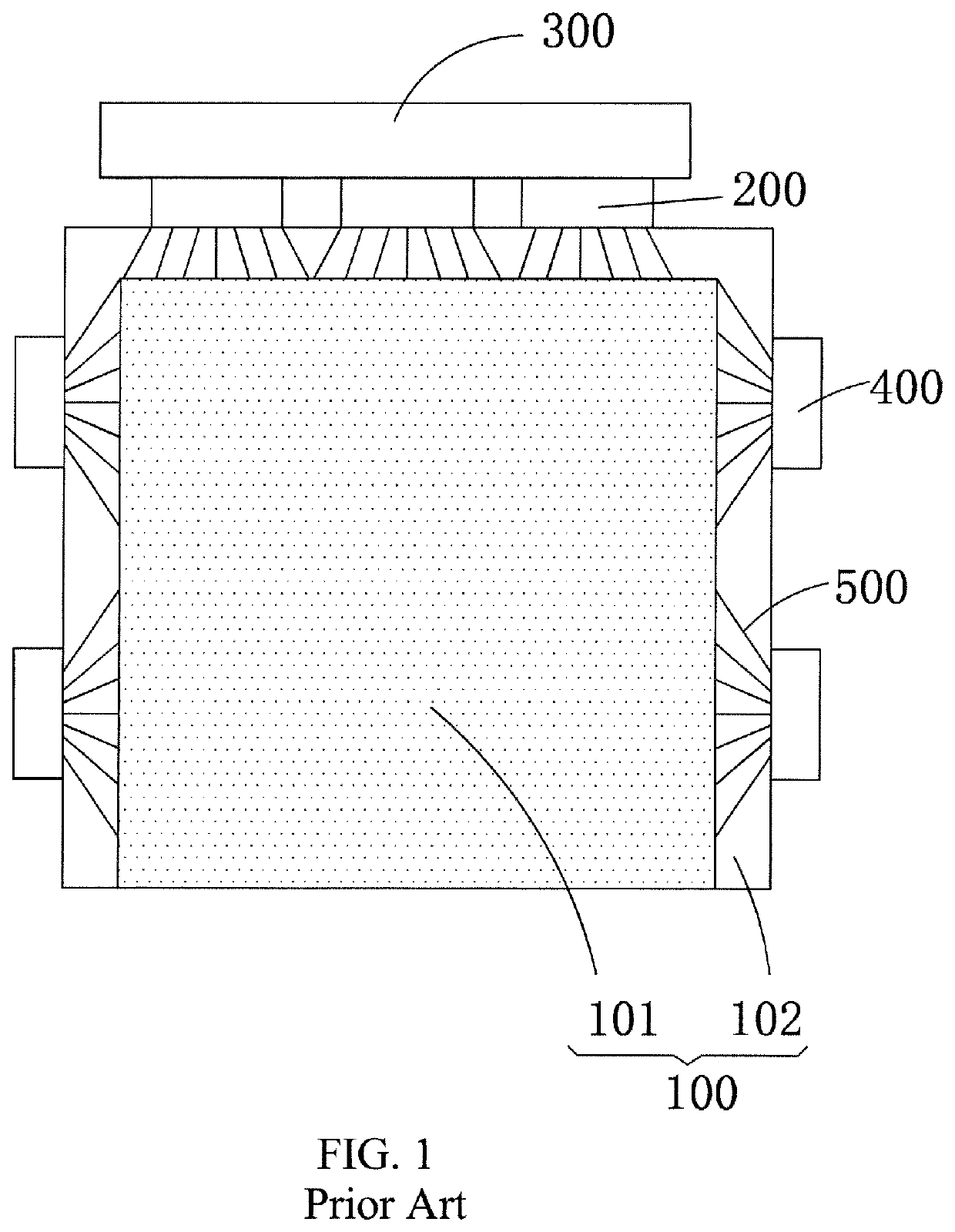

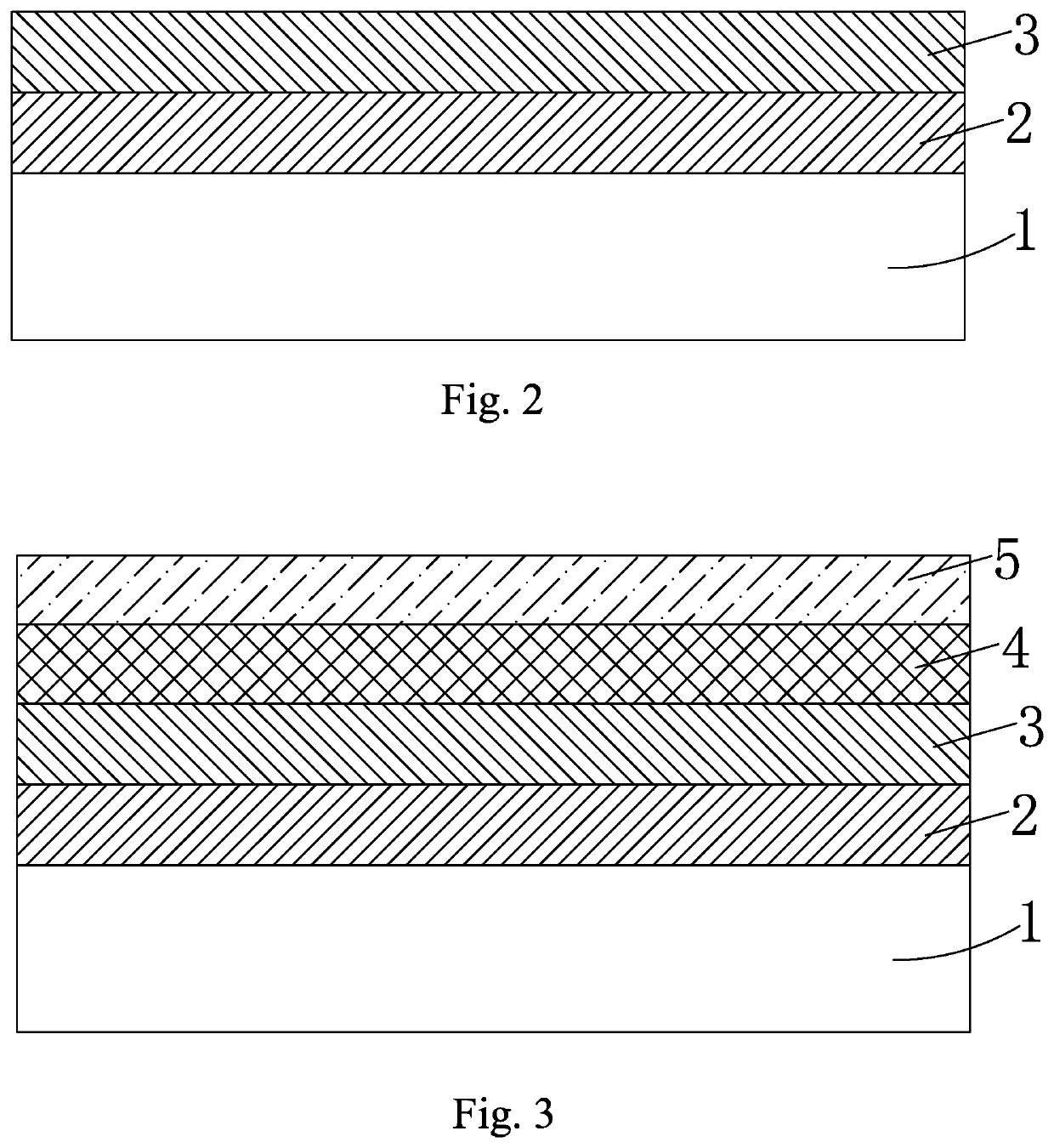

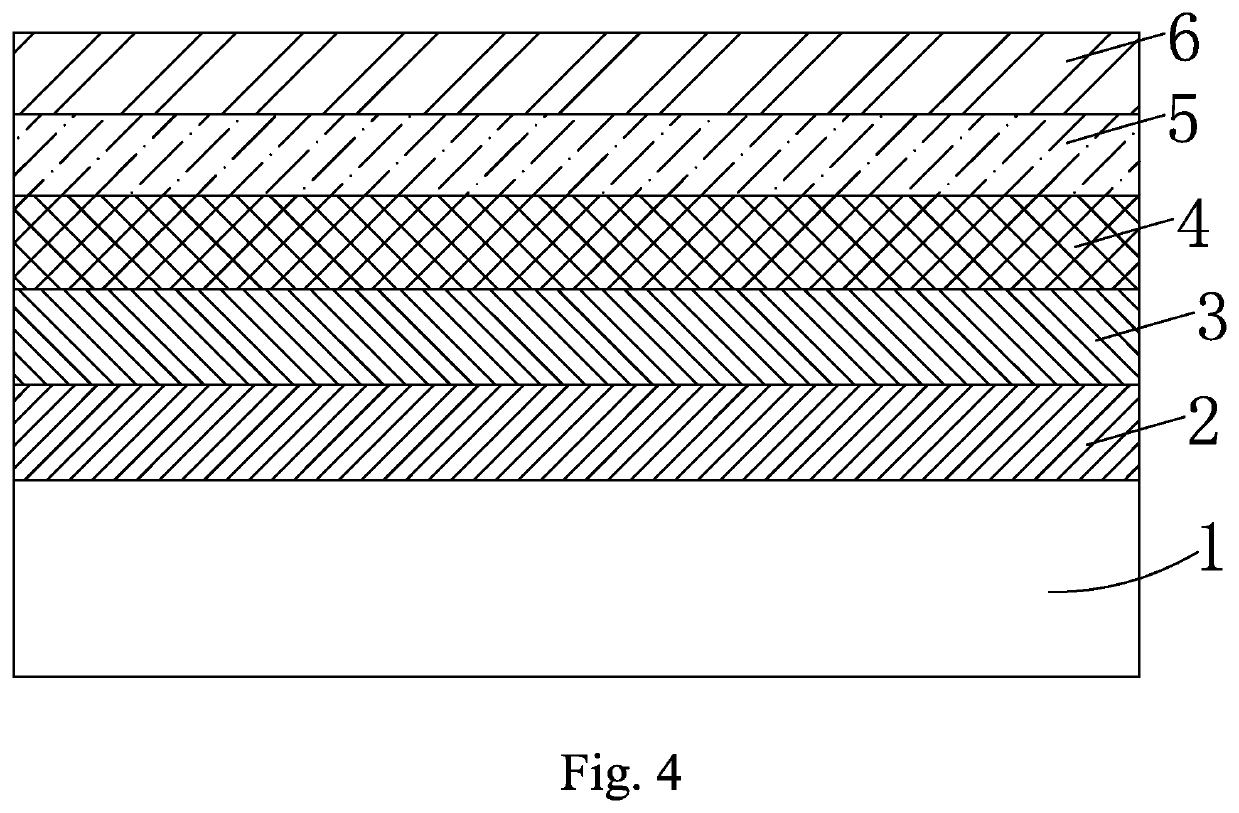

Loose lay plastic floor and preparation method thereof

ActiveUS11041317B2Poor flatnessSynthetic resin layered productsLaminationPolymer scienceHigh density

A preparation method of a loose lay plastic floor includes the following steps: (a) subjecting a wear layer, a printing layer, a semi-rigid PVC layer, a core layer and an adsorption layer to hot-melt compounding and shaping to obtain a composite board; (b) coating one or more layers of UV coating on a surface of the wear layer of the composite board; and (c) subjecting the composite board coated with the UV coating to tempering, conditioning and punching to obtain a loose lay plastic floor. The core layer is a stone plastic core (SPC), a wood plastic core (WPC), a high density fiberboard (HDF), or a medium density fiberboard (MDF).

Owner:JIANGSU ZHONGSHENG NEW BUILDING MATERIALS CO LTD

Loose lay plastic floor and preparation method thereof

ActiveUS20200318362A1Poor flatnessSynthetic resin layered productsLaminationTextile printerPolymer science

A preparation method of a loose lay plastic floor includes the following steps: (a) subjecting a wear layer, a printing layer, a semi-rigid PVC layer, a core layer and an adsorption layer to hot-melt compounding and shaping to obtain a composite board; (b) coating one or more layers of UV coating on a surface of the wear layer of the composite board; and (c) subjecting the composite board coated with the UV coating to tempering, conditioning and punching to obtain a loose lay plastic floor. The core layer is a stone plastic core (SPC), a wood plastic core (WPC), a high density fiberboard (HDF), or a medium density fiberboard (MDF).

Owner:JIANGSU ZHONGSHENG NEW BUILDING MATERIALS CO LTD

LCD panel having a black coloring layer and an anti-glare layer attached to a protection plate through an adhesion layer in which the black coloring layer and the adhesion layer have a predetermined related thickness

ActiveUS7903195B2Poor flatnessReduced feature requirementsNon-linear opticsLiquid-crystal displayEngineering

An object of the present invention is to propose the structure and constitution of a liquid crystal display device having a protection plate, which prevents exfoliation of black painting at ends of the protection plate when dust on the protection plate of the liquid crystal display device is wiped off, thus preventing degradation of design features.The liquid crystal display device comprises: a transparent protection plate formed above a liquid crystal panel; a pair of polarizing plates disposed to sandwich and hold the liquid crystal panel; a transparent organic medium layer formed between the protection plate and the liquid crystal panel; a black coloring layer formed at ends of four sides on a side of the protection plate, the side being opposite to a side at which the transparent organic medium layer is disposed; and an anti-glare film composed of an anti-glare layer and an adhesion layer formed on a side of the protection plate, the side being opposite to a side at which the transparent organic medium layer is disposed.

Owner:JAPAN DISPLAY INC +1

Pellicle, mounting method therefor, pellicle-equipped mask, and mask

ActiveUS8582077B2Poor flatnessImprove flatnessSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEngineeringFace shield

A pellicle is provided that includes a pellicle film, a pellicle frame having the pellicle film stretched over one end face thereof and having the other end face open, and a pressure-sensitive adhesion layer for adhering the pellicle frame to a mask, the pressure-sensitive adhesion layer being provided on an inner peripheral face of the pellicle frame, and the pressure-sensitive adhesion layer being capable of adhering to a side face of a mask having a mask image on a front face. There are also provided a method of mounting a pellicle that includes fixing to a side face of a mask an inner peripheral face of a pellicle frame of a pellicle that includes a pellicle film and a pellicle frame having the pellicle film stretched over one end face thereof and having the other end face open, a method of mounting a pellicle that includes adhering the pellicle to a side face of the mask that is inclined in going from the reverse face of the mask toward the front face where the mask image is provided, thus adhering the side face of the mask to the pellicle frame inner peripheral face, a pellicle-equipped mask that includes the pellicle adhered to a mask, and a mask that includes a side face that is inclined in going toward the front face where a mask image is provided.

Owner:SHIN ETSU CHEM IND CO LTD

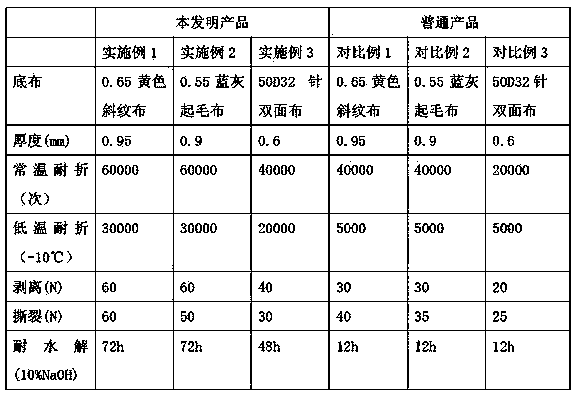

Preparation method of waterborne polyurethane synthetic leather Bayse and applications thereof

ActiveCN102787510BNo pollutionObvious cloth seamLamination ancillary operationsPolyureas/polyurethane adhesivesPolymer sciencePolymer chemistry

Owner:浙江昶丰新材料有限公司

Electrical connector

ActiveUS7462037B2Large elastic deformationIncrease contactCoupling device detailsPrinted circuitsElastomerState of art

An electrical connector with an electrically insulating elastic body is disclosed, comprising an electrically insulating elastic body and a multiple of electrical pieces inclinedly disposed in the electrically insulating elastic body. When the electrical connector is compressively contacted with external electronic devices, the electrical pieces will undergo rotating displacement; when the external electronic devices retreat from the compressive contact, the electrically insulating elastic body will push the electrical pieces back to their original positions. Compared with conventional prior art, the electrical piece of the electrical connector according to present invention can undergo rotating displacement to enable the electrical pieces to have larger elastic deformation, such that good contact can be ensured when the flatness of the connected electronic devices is poor and larger normal force on the electrical pieces can be obtained.

Owner:LOTES

Method for manufacturing flexible array substrate

ActiveUS10743424B2Reduce manufacturing difficultyHigh yieldPrinted circuit aspectsElectrical connection printed elementsHemt circuitsMechanical engineering

The present invention provides a method for manufacturing a flexible array substrate. The method includes, first, successively forming an adhesive layer, a passivation layer, a back-side drive circuit, a planarization layer, a flexible backing plate, and a front-side drive circuit and a display circuit, in a stacked arrangement, on a rigid support plate and then peeling off the rigid support plate and the adhesive layer to form a flexible array substrate having a double-sided circuit structure. The entire process requires no steps of peeling, reversing, and then re-attaching of the flexible backing plate so that it is possible to avoid the issues of poor flatness and low yield resulting from improper or wrongful re-attachment of the flexible backing plate and thus, fabrication difficulty of a flexible array substrate having a double-sided circuit structure may be lowered down to thereby improve fabrication yield of the flexible array substrate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Electrical connector with a plurality of contacts recived in a plurality of slots in a plurality of elastic bodies integrally formed with an insulating body

InactiveUS9257770B2Good electrical contactLarge forceElectrically conductive connectionsCoupling contact membersElastomerElectrical conductor

An electrical connector for connecting a first electronic element and a second electronic element, includes an insulating body, multiple elastic bodies integrally formed with the insulating body, and multiple conductors. Each of the elastic bodies has a receiving slot, and each conductor is received in a corresponding receiving slot in an inclined manner. The receiving slot has a first urging portion and a second urging portion respectively providing an inclined upward elastic counterforce and an inclined downward elastic counterforce against the conductor, so that the conductor has a large normal force. Multiple stopping portions of the receiving slot and multiple shoulder portions of the conductor are in clearance fit, so that the conductor can be displaced vertically in the receiving slot when receiving a force.

Owner:LOTES

A flexible optical fiber ribbon and optical fiber cable

ActiveCN113359230BReduce the risk of potential stress concentrationSolve the phenomenon of uneven stress distributionFibre mechanical structuresBundled fibre light guideEngineeringOptical fiber cable

The application relates to a flexible optical fiber ribbon and optical cable, which includes several core ribbon groups, each core ribbon group is arranged side by side, and the core ribbon group includes three optical fiber units; the three optical fiber units of the core ribbon group are arranged side by side, and the The optical fiber unit includes an optical fiber, and the optical fiber unit in the middle includes at least one optical fiber arranged in parallel and connected; between two adjacent core band groups, and between two adjacent optical fiber units in the core band group, through A plurality of first connecting parts intermittently arranged along the length direction of the optical fiber are connected; the plane passing through the axes of two adjacent optical fibers is used as a reference plane, and the first connecting part includes two connecting units respectively located above and below the reference plane, A buffer cavity is formed between two adjacent optical fibers and two connection units above and below the reference plane. The present application can solve the problem in the related art that when the optical fiber ribbon is bent along the width direction, the resin is easily damaged, so that the flatness of the optical fiber ribbon is not good.

Owner:FENGHUO COMM SCI & TECH CO LTD

Puncture forming method, sample separating method, semiconductor element manufacturing method, semiconductor laser element manufacturing method, and semiconductor laser element

PendingUS20210016395A1Poor flatnessQuality improvementOptical wave guidanceSemiconductor laser structural detailsLight beamEngineering

A puncture forming method is a method of forming punctures in a sample by irradiating a surface of the sample with a light beam. The puncture forming method includes: forming a first puncture by irradiating a first position on the surface of the sample with a first pulse of the light beam; and after the forming of the first puncture, forming a second puncture which at least partially overlaps the first puncture by irradiating, with a second pulse of the light beam, a second position on the surface of the sample positioned away from the first position in a first direction. The second puncture has a tip which is positioned inside the sample and which is bent in a direction opposite to the first direction.

Owner:NUVOTON TECH CORP JAPAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com