Method for preparing polyimide thin film with low friction coefficient and high cohesive force

A polyimide film, low friction coefficient technology, applied in the formulation of low friction coefficient high adhesion polyamic acid preparation, low friction coefficient high adhesion polyimide film manufacturing field, can solve the problem of polyamide The problems of low surface energy, poor bonding performance and poor hydrophilicity of imine film can improve the performance and reliability of the use process, strong bonding force and high insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

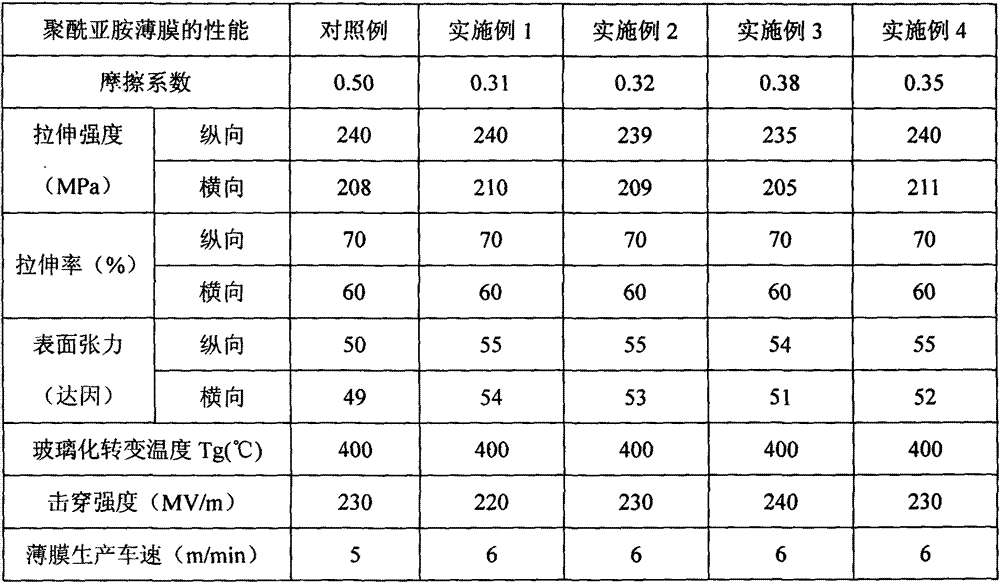

Examples

Embodiment 1

[0036]Add 750kg of N,N-dimethylacetamide to the storage tank at a temperature of 10±2°C, add 7kg of filler calcium phosphate, 10kg of nano-scale organic silicon, and 3kg of dispersant during the resin synthesis process. It is mixed evenly with a polyamic acid solution with a solid content of 20% and a viscosity of 250,000 at a mass ratio of 1:7.5. After filtering and natural defoaming, it is sprayed by an extrusion touch head device and placed in a width of 50~ On a 70cm mirror steel belt (the inside is a closed clean system), it is dried at a speed of 6m / min at 75°C, 130°C, and 175°C to form a film, and then part of the thermally imidized film is passed through a peeling roller The steel strip is peeled off, and then sent into a high-temperature furnace with five temperature sections of 300°C, 350°C, 400°C, 450°C and 250°C through biaxial stretching (stretch ratio is 1.10) for complete imidization treatment. The amount of residual solvent is 0.1% to 1.0%. Finally, the polyimi...

Embodiment 2

[0038] Add 750kg of N,N-dimethylacetamide to the storage tank at a temperature of 10±2°C, add 7kg of filler calcium phosphate, 15kg of nano-scale organic silicon, and 3kg of dispersant during the resin synthesis process. After mixing evenly, press It is mixed with a polyamic acid solution with a solid content of 20% and a viscosity of 250,000 at a mass ratio of 1:6. After filtering and natural defoaming, it is sprayed by an extrusion touch head device and placed in a width of 50~ On a 70cm mirror steel belt (the inside is a closed clean system), it is dried at a speed of 6m / min at 75°C, 130°C, and 175°C to form a film, and then part of the thermally imidized film is passed through a peeling roller The steel strip is peeled off, and then sent into a high-temperature furnace with five temperature sections of 300°C, 350°C, 400°C, 450°C and 250°C through biaxial stretching (stretch ratio is 1.10) for complete imidization treatment. The amount of residual solvent is 0.1% to 1.0%. F...

Embodiment 3

[0040] Add 750kg of N,N-dimethylacetamide to the storage tank with a temperature of 10±2°C, add 17kg of filler calcium phosphate and 3kg of dispersant during the resin synthesis process, stir and mix evenly, according to its solid content of 20 The polyamic acid solution with a viscosity of 250,000% is 1:7.5 mass ratio. After mixing evenly, after filtering and defoaming naturally, it is casted by an extrusion touch head device and placed on a mirror steel belt with a width of 50-70cm. (The inside is a closed clean system), drying at a speed of 6m / min in three stages of 75°C, 130°C, and 175°C to form a film, and then part of the thermally imidized film is peeled off the steel strip by a peeling roller, and then After biaxial stretching (stretch ratio 1.10), it is sent into a high-temperature furnace with five temperature sections at 300°C, 350°C, 400°C, 450°C and 250°C for complete imidization treatment, and the residual solvent in the film is 0.1%. ~1.0%, and finally treated w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com