Patents

Literature

71 results about "Longitudinal strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

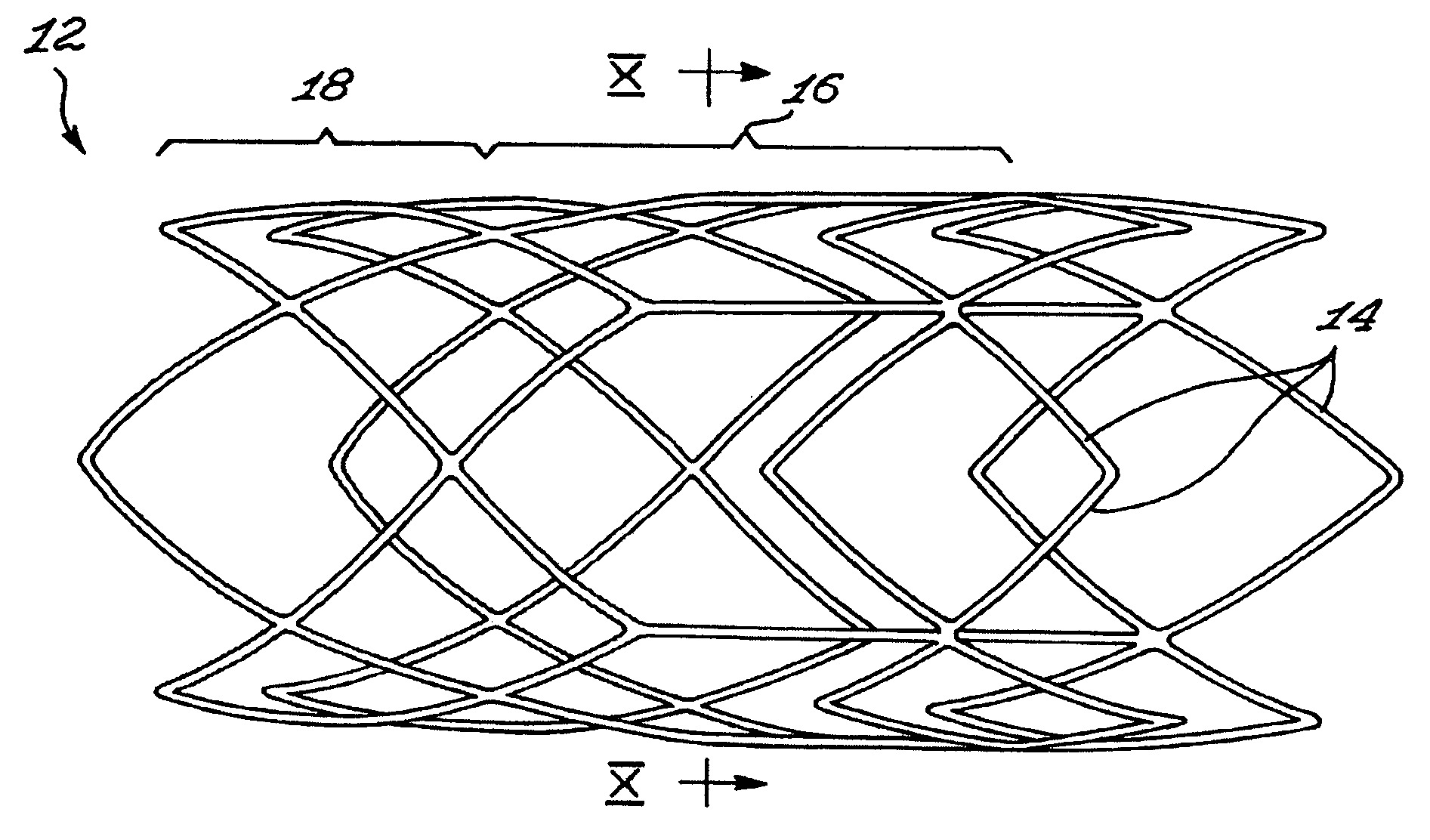

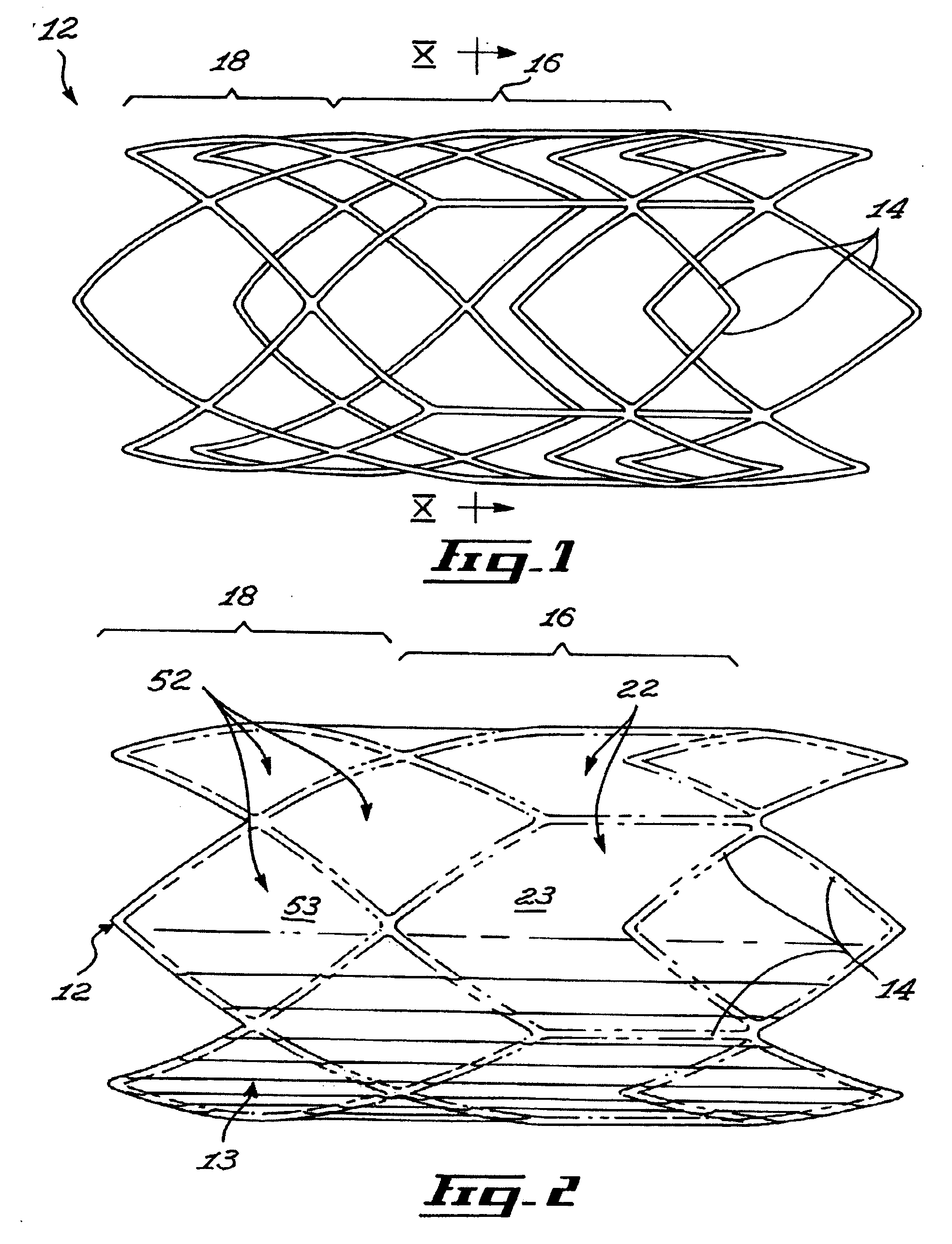

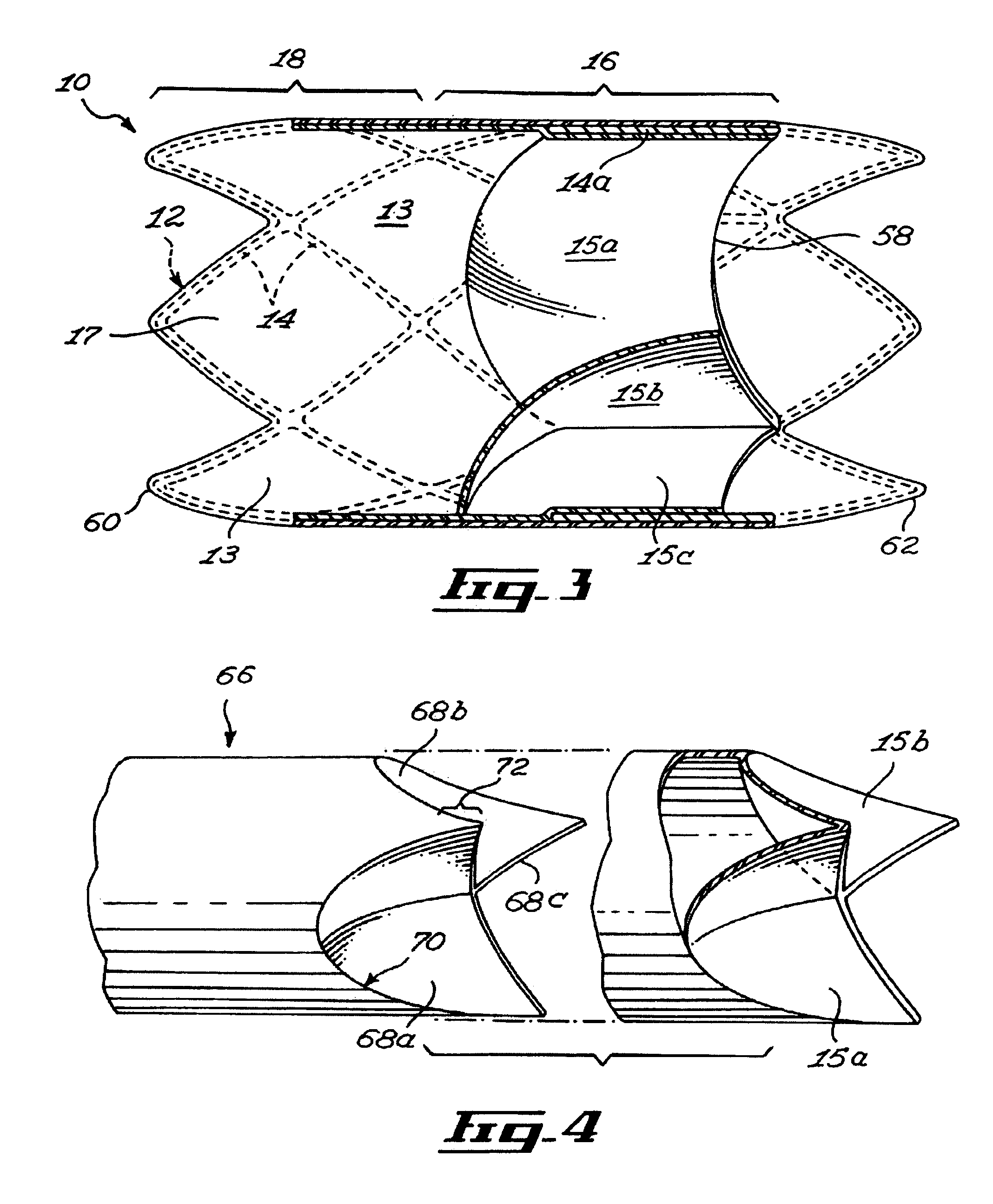

Stent and method of manufacturing same

A stent insertable in a body lumen. The stent includes a scaffold having interlinked struts forming a scaffold first section and a scaffold second section, the scaffold being deformable substantially radially between a scaffold retracted configuration and a scaffold expanded configuration. The struts are configured and sized such that the coefficient of radial compressibility of the scaffold second section is greater than the coefficient of radial compressibility of the scaffold first section and the coupling coefficient between radial and longitudinal strains of the scaffold second section is greater than the coupling coefficient between radial and longitudinal strains of the scaffold first section.

Owner:BAYLIS MEDICAL

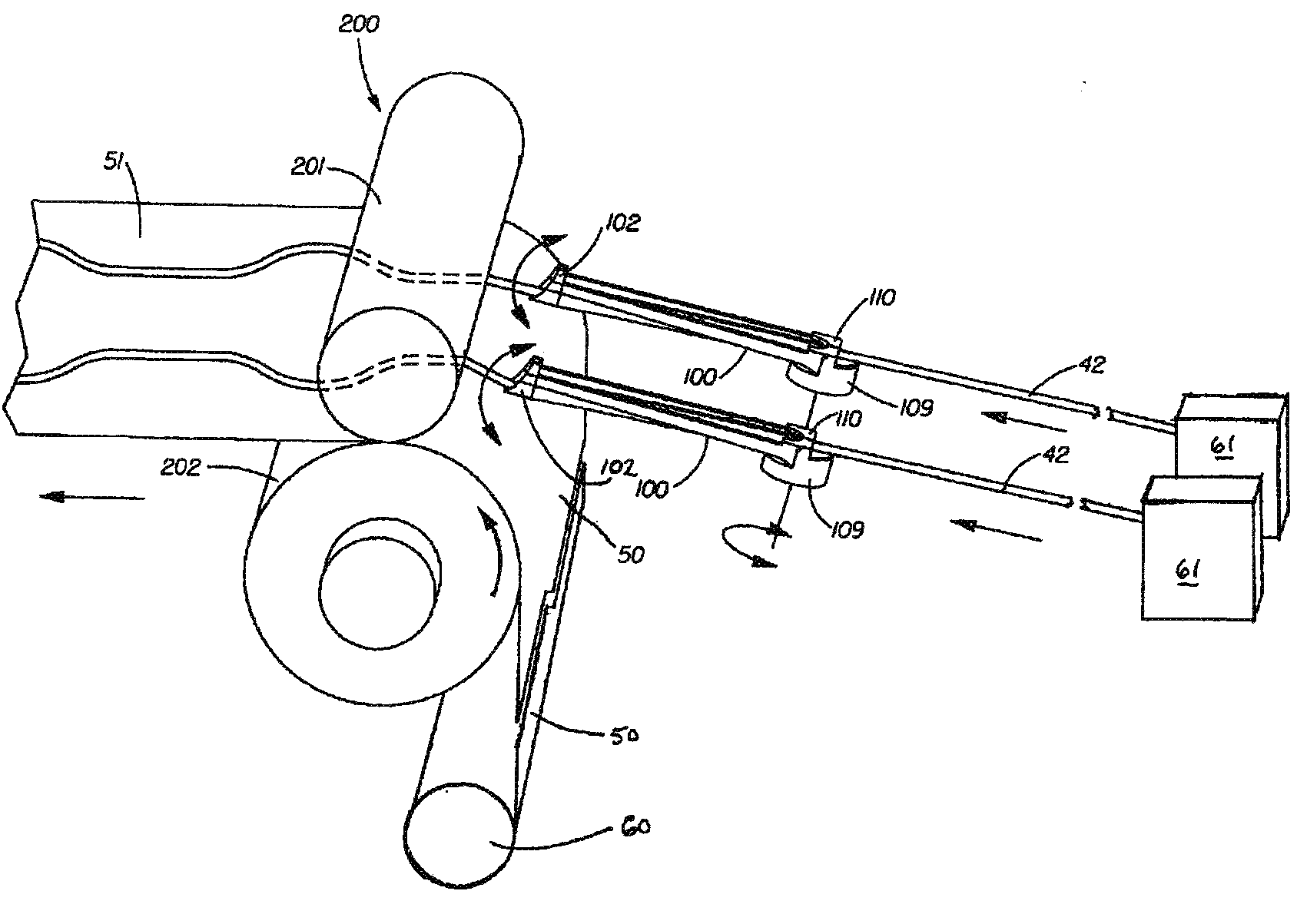

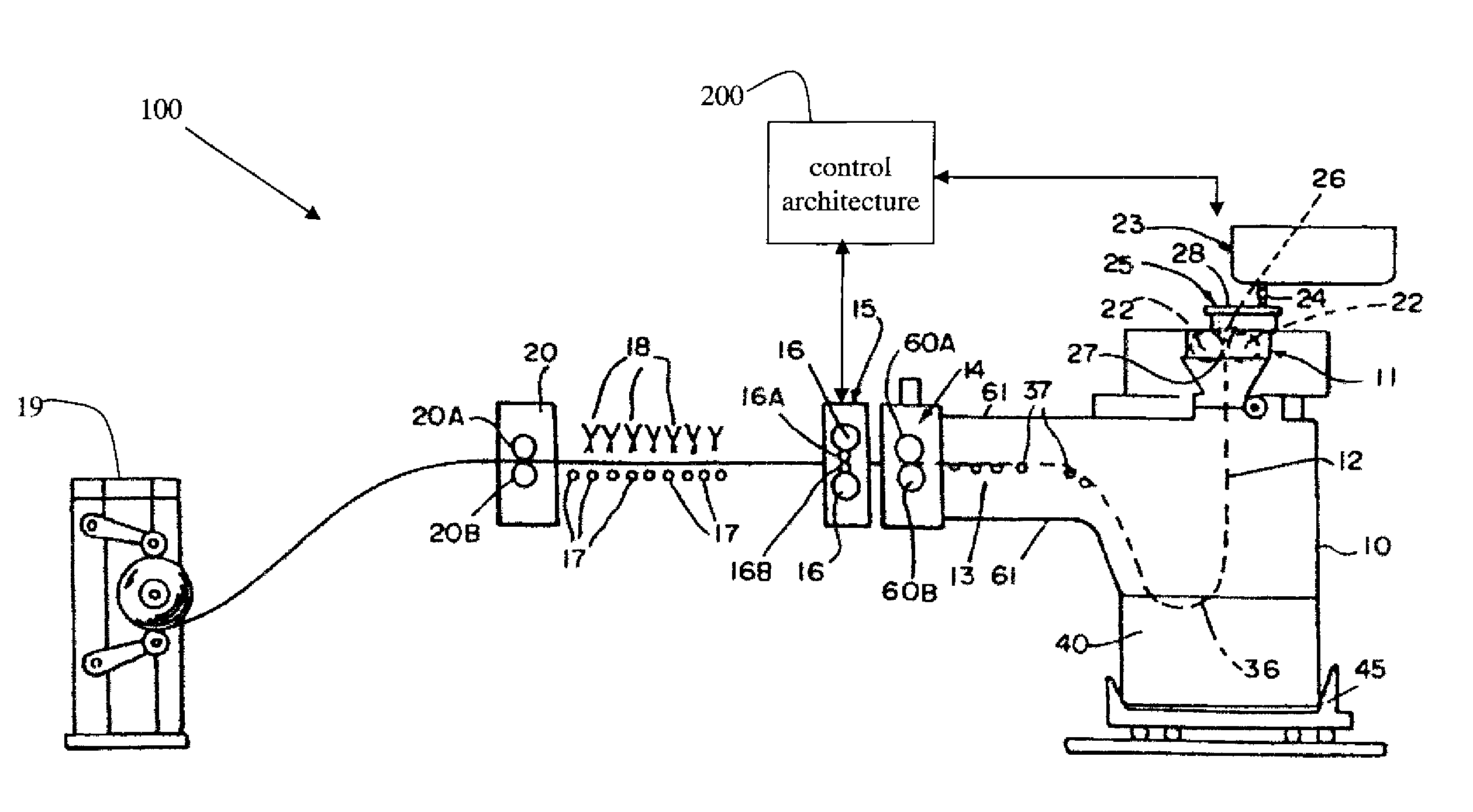

System and Method for High-Speed Continuous Application of a Strip Material to a Moving Sheet-Like Substrate Material at Laterally Shifting Locations

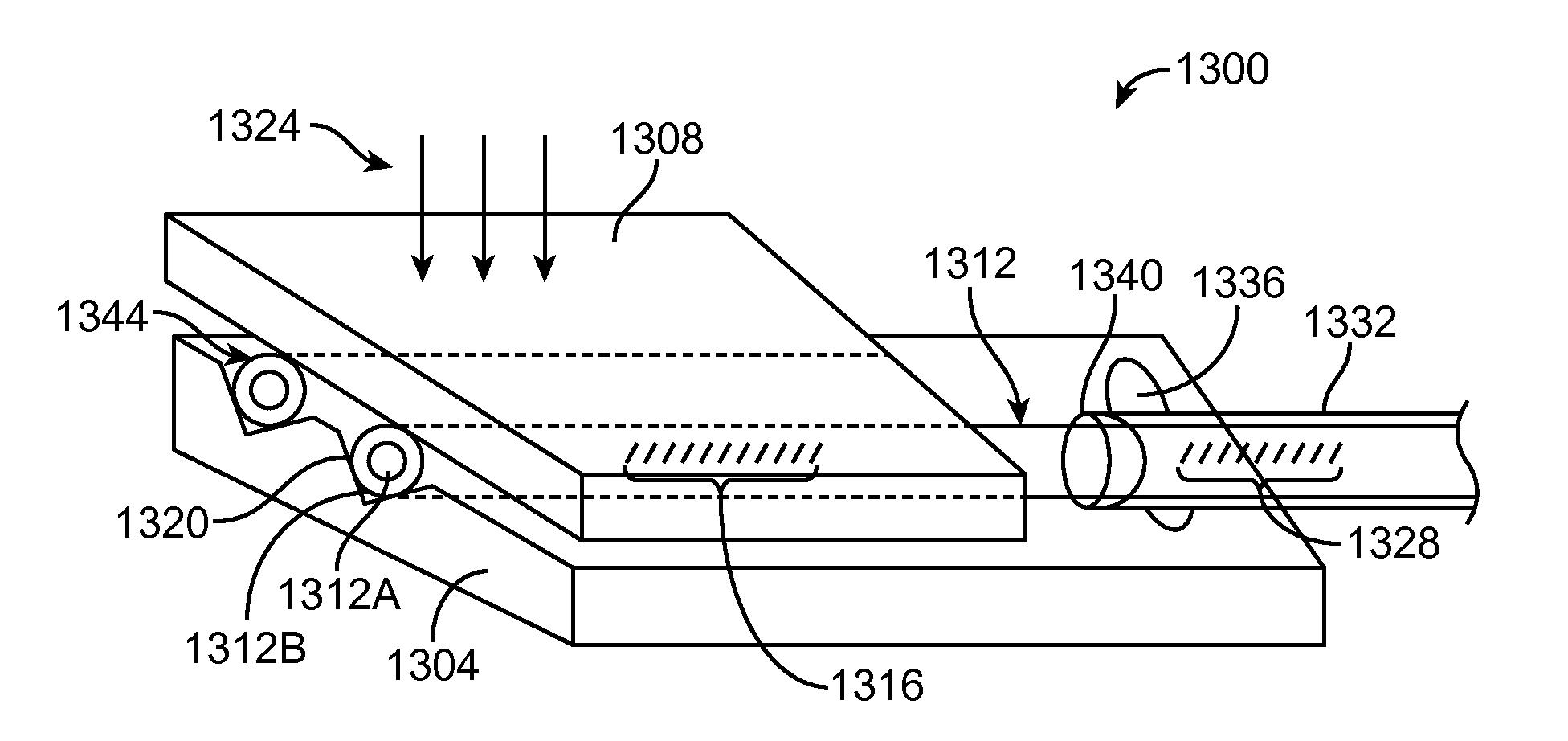

Disclosed are examples of a system for regulating the longitudinal strain in an elastic longitudinal material being applied to a sheet material in continuous fashion. The system may include a continuous supply of the sheet material; a continuous supply of the elastic longitudinal material; first and second feed rollers having a feed nip therebetween through which the elastic longitudinal material passes longitudinally, and downstream first and second joining rollers having a joining nip therebetween through which the sheet material and the elastic longitudinal material pass. The linear velocity of the circumferential surface of at least one of the first or second feed rollers is controlled relative to the linear velocity of the circumferential surface of at least one of the first or second joining rollers, to regulate longitudinal strain in the elastic longitudinal material.

Owner:THE PROCTER & GAMBLE COMPANY

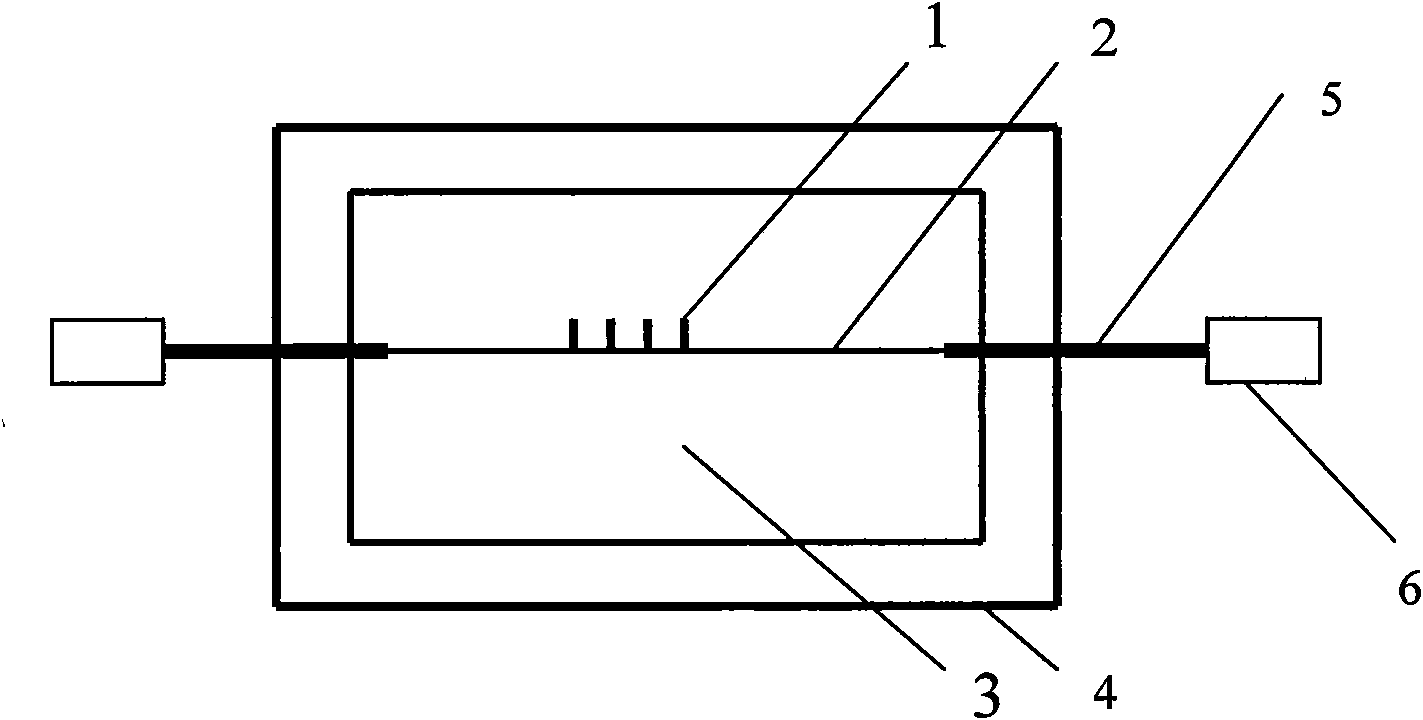

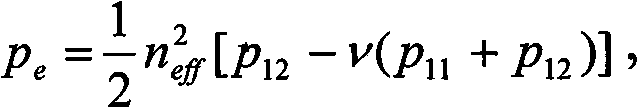

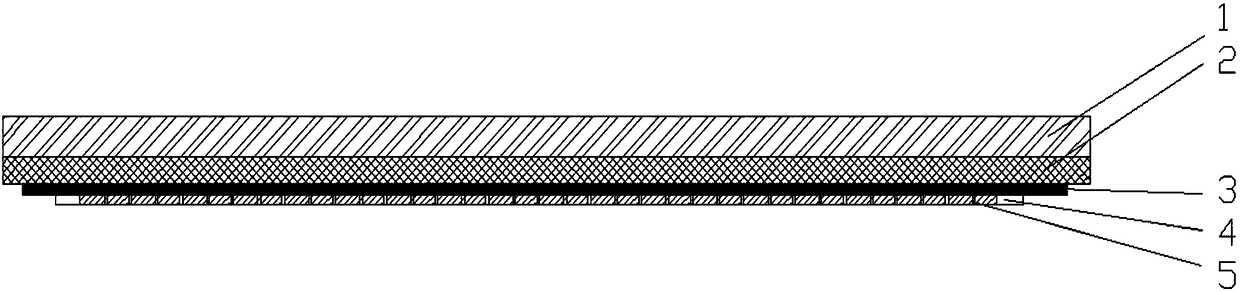

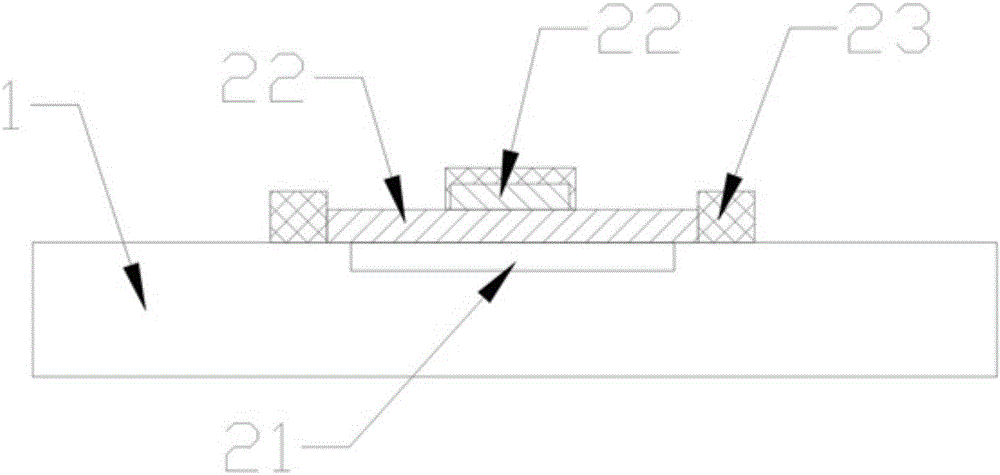

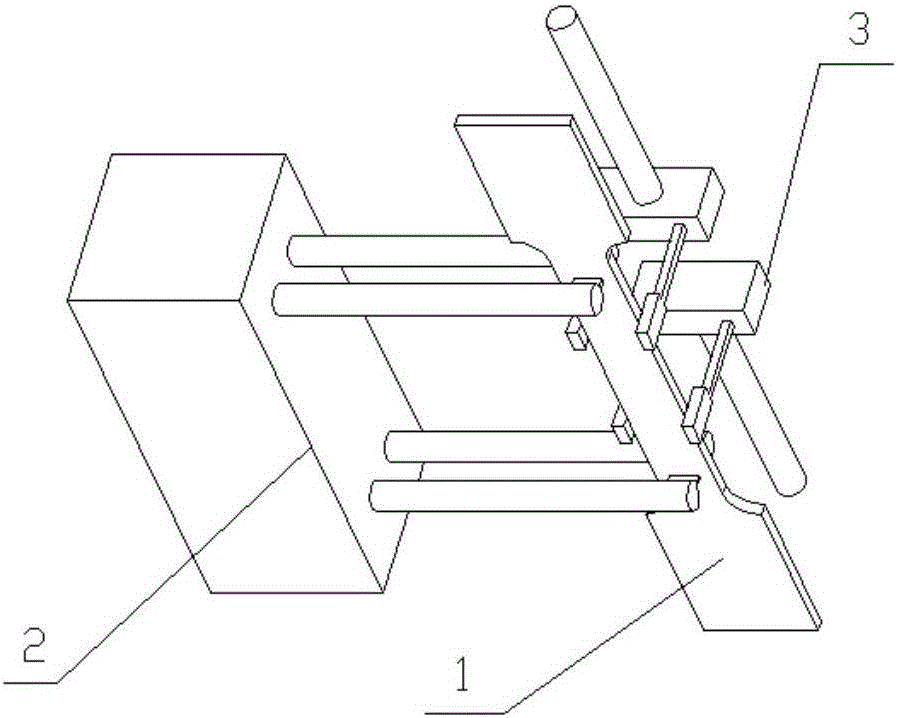

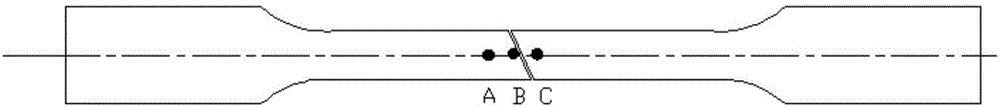

Method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain

The invention provides a method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain. In order to solve the technical problems that as fiber grating sensors are bonded to the surface of a structure through polyimide resin or epoxy resin commonly used in the prior engineering, optic fiber in service is easily destroyed; the optic fiber can get encapsulation protection but cause the concentration of surrounding stress / strain thereof if the optic fiber is directly embedded in a composite-material structure; and thermal residual stress produced in a material-curing process can cause chirp phenomena of fiber grating reflection spectrum to affect the measurement accuracy of grating strain, and the like, the invention provides the method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain. In the method, the fiber grating sensors are embedded in composite-material layers to replace resistance strain gauges commonly used in the field of monitoring structural health; by applying prestress to embedded fiber gratings, the influence of the curing residual stress of composite material on the fiber grating reflection spectrum is reduced so as to avoid the chirp phenomena; and the stability and repeatability of the sensors are improved. In addition, the composite material plays a good role in encapsulating and protecting bare fiber gratings, and meets engineering construction requirement on sensor sensitivity.

Owner:SHENYANG INST OF AERONAUTICAL ENG +1

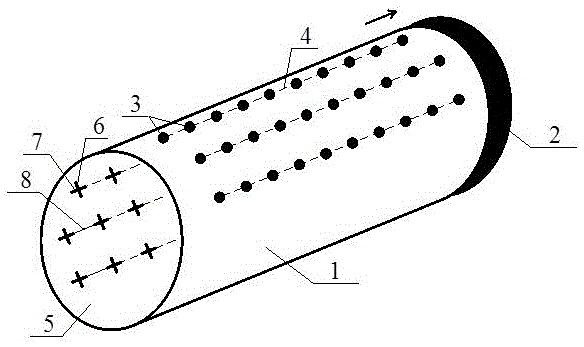

A monitoring method for a surrounding rock and full face tunnel boring machine shield interaction process

ActiveCN105952465AEasy to installAccurate and reliable measurement resultsForce measurement by measuring frquency variationsForce measurement by measuring optical property variationRisk levelTunnel boring machine

The invention provides a monitoring method for a surrounding rock and full face tunnel boring machine shield interaction process. The method comprises the steps of: A, welding and installing pressure boxes to the outer surface of a shield for testing the extrusion force applied to the shield by surrounding rocks directly, placing cables of the pressure boxes in flexible cable-protecting casing pipes, and leading the cables into the shield and connecting the cables to a reading device; B, installing a surface strain sensor in each of the annular direction and the longitudinal direction of each monitoring point on the inner surface of the shield, and inversely calculating the extrusion force applied to the shield by the surrounding rocks according to the principle of elastic mechanics based on the tested annular and longitudinal strains of the inner surface of the shield; C, according to the acquired distribution rules of the extrusion force applied to the shield by the surrounding rocks, calculating the friction force borne by the shield on the premise of linear distribution of the extrusion force between two adjacent measuring points; D, according to the jamming state judging criteria and jamming risk coefficient calculation method, calculating whether the shield is jammed and giving early warning of a jamming risk level. The method solves the problem in monitoring of surrounding rock and shield interaction in a shield type TMB tunneling process, provides basis for the predictive analysis of jamming accidents and is of great importance for the safety of TBM tunneling.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

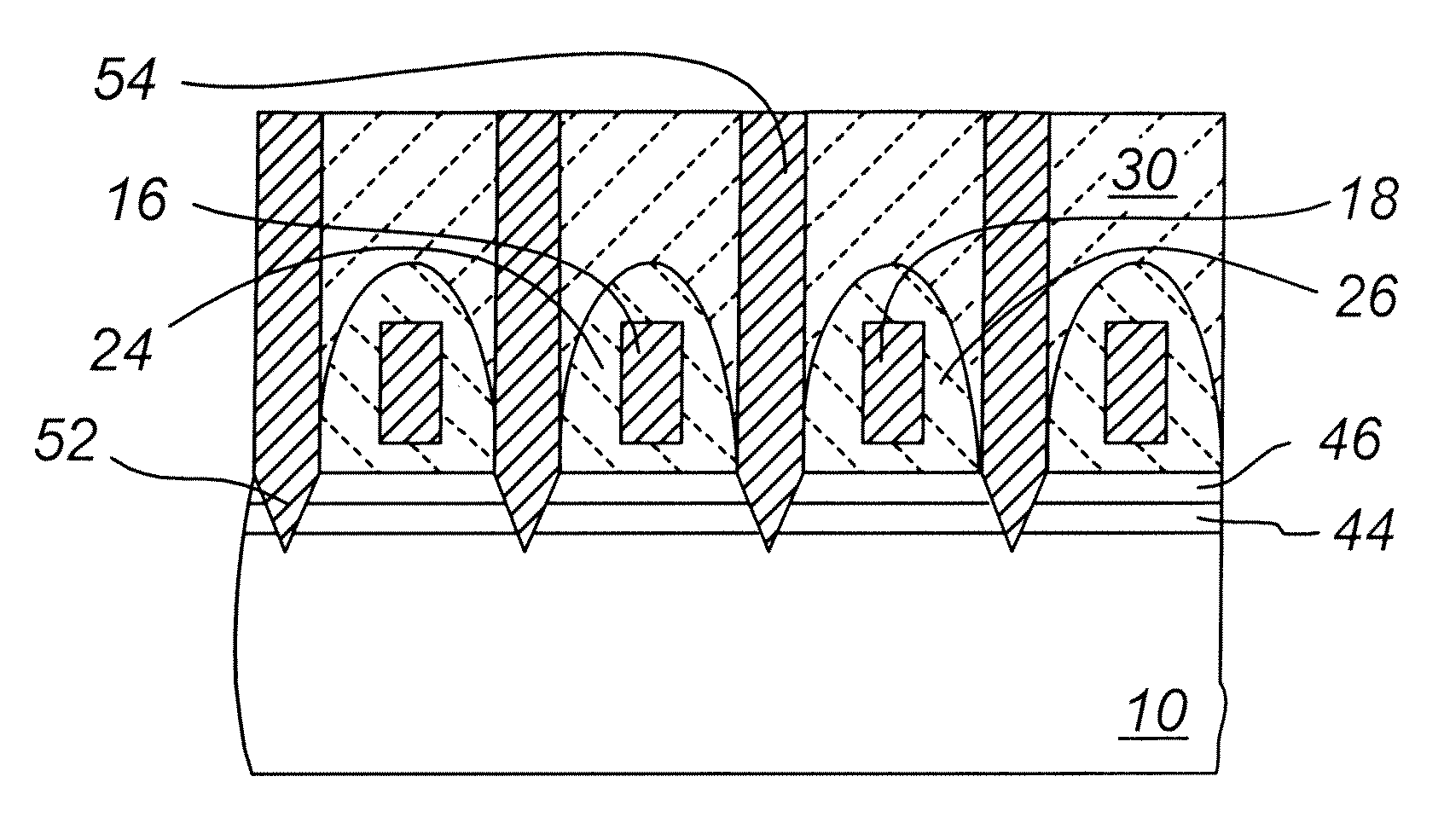

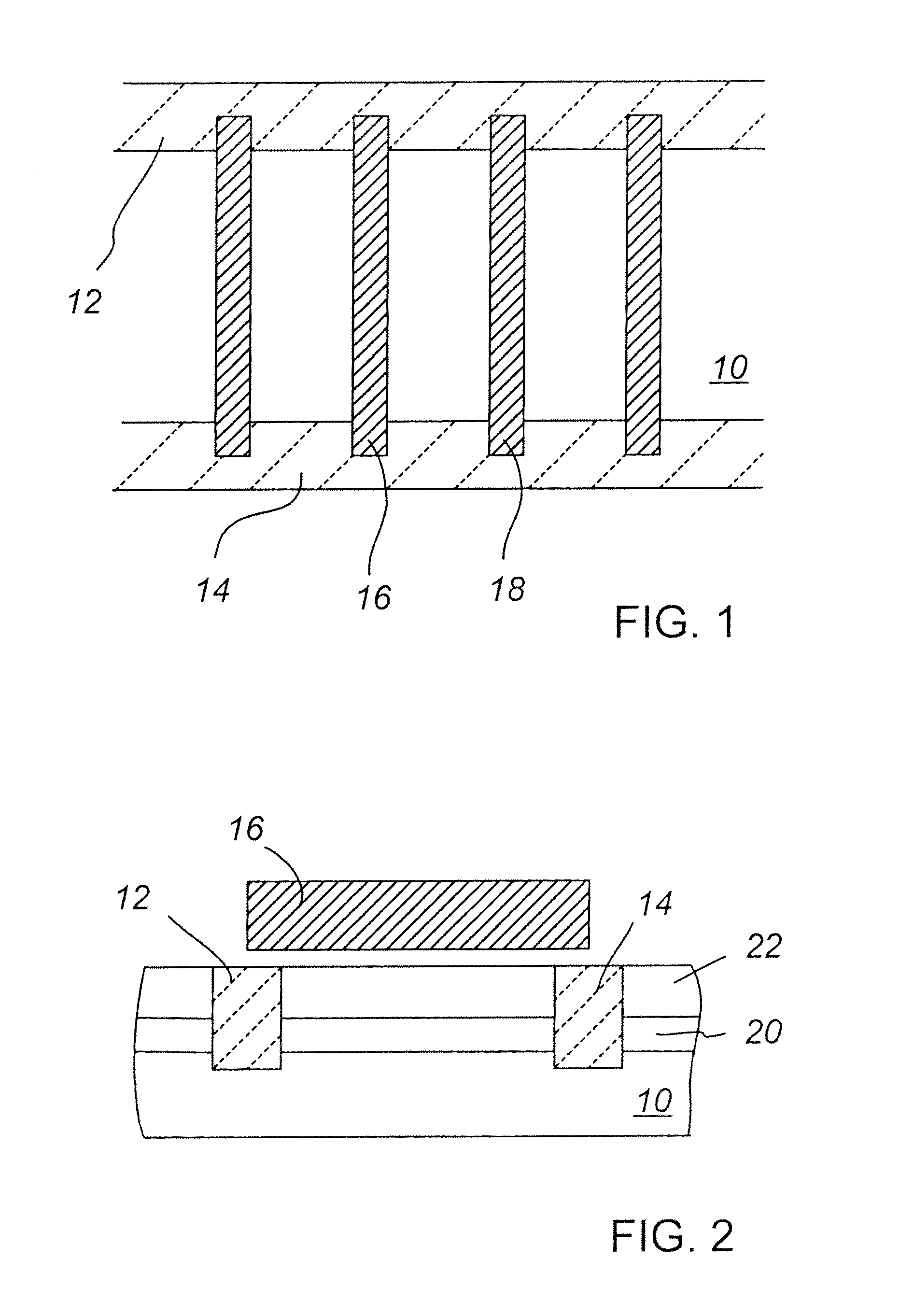

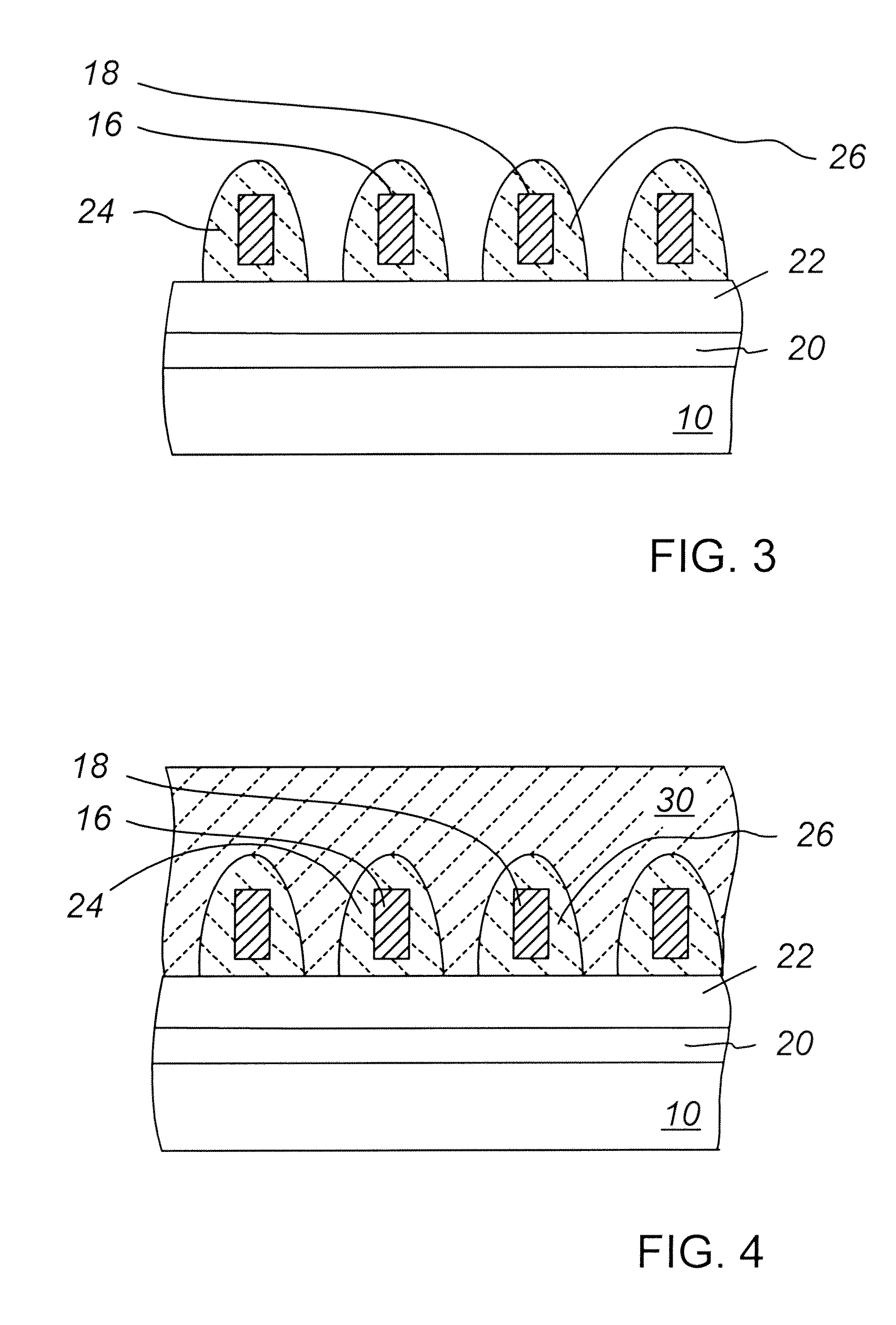

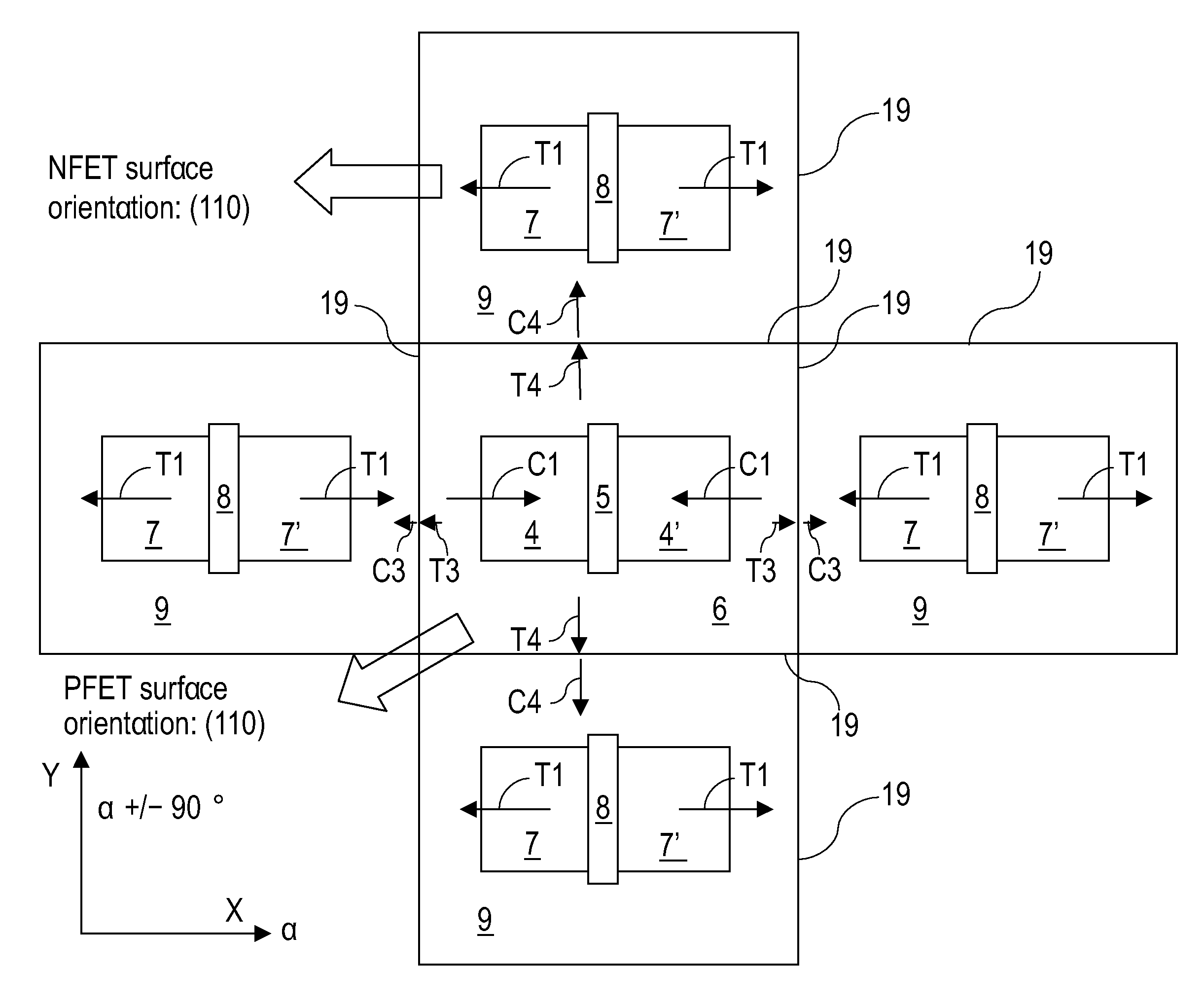

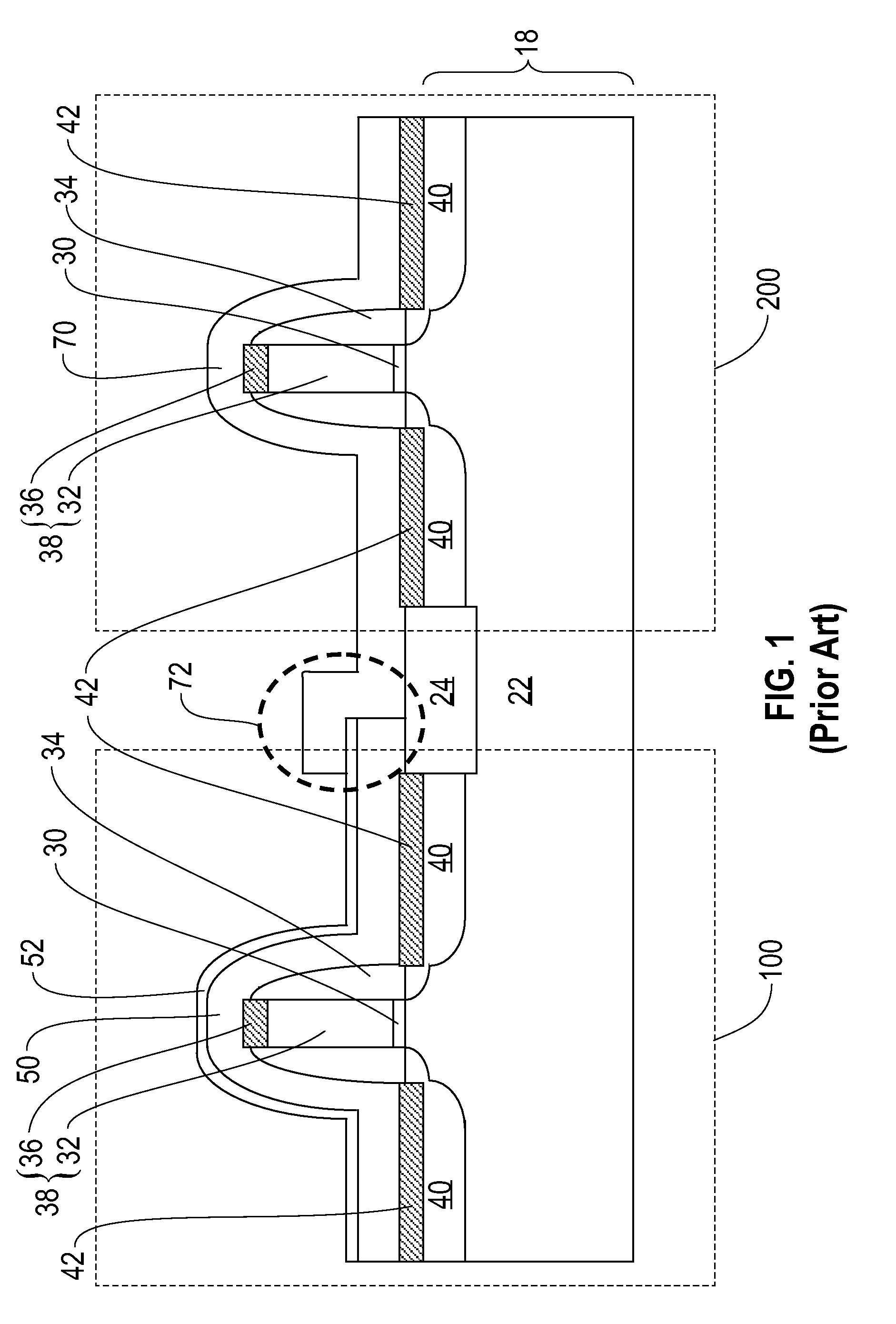

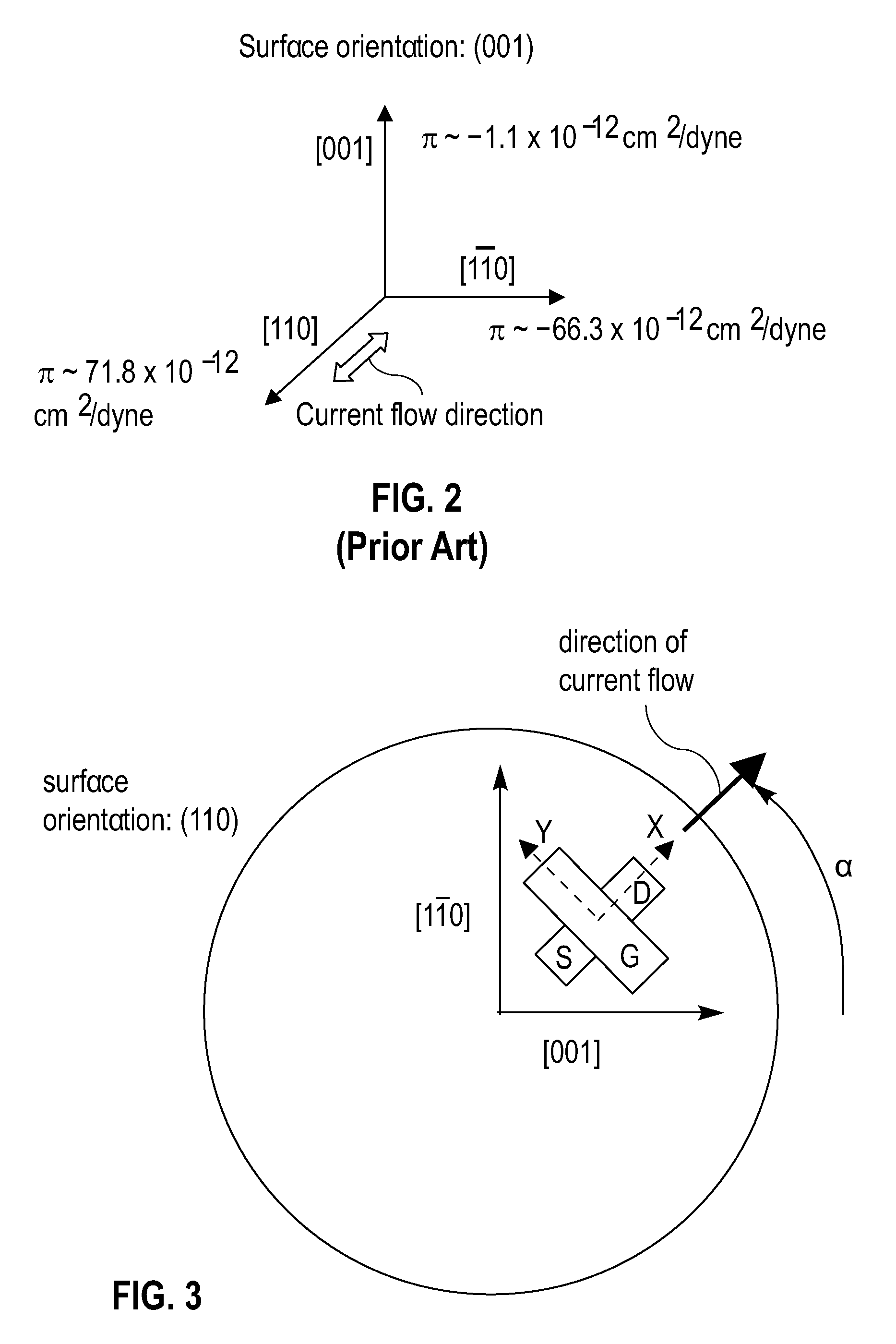

Orientation-optimized PFETS in CMOS devices employing dual stress liners

InactiveUS7525162B2Improve conductivitySolid-state devicesSemiconductor/solid-state device manufacturingIn planeCMOS

Owner:GLOBALFOUNDRIES INC

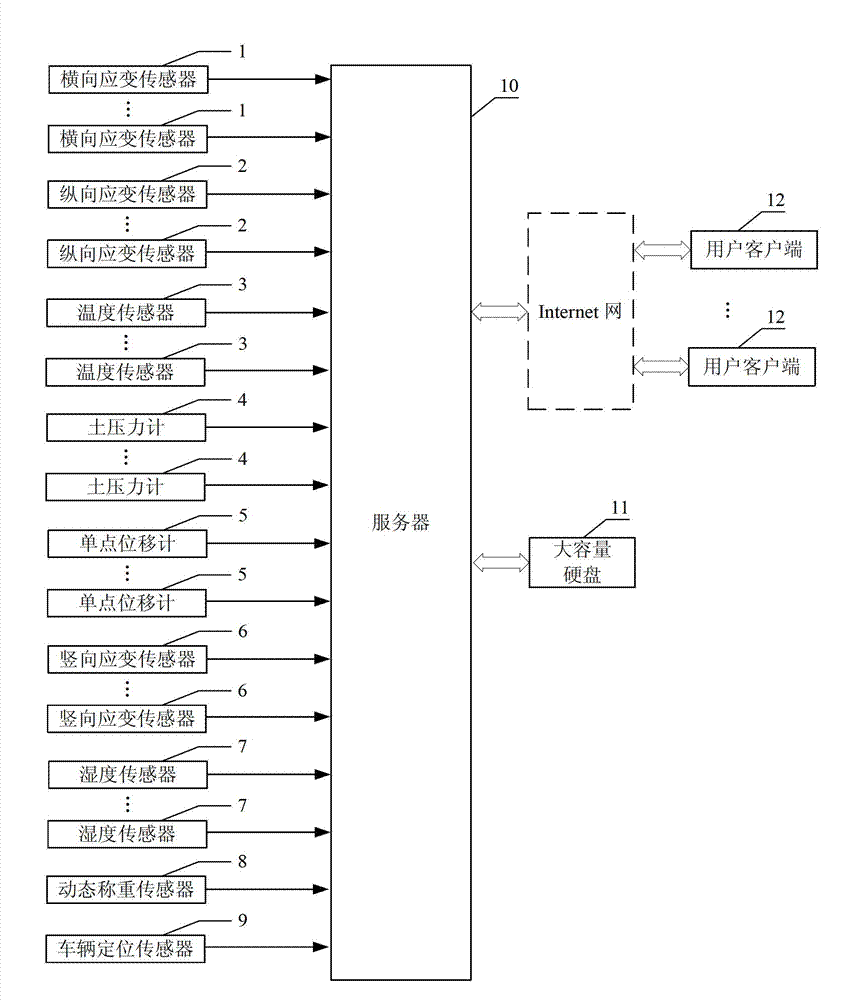

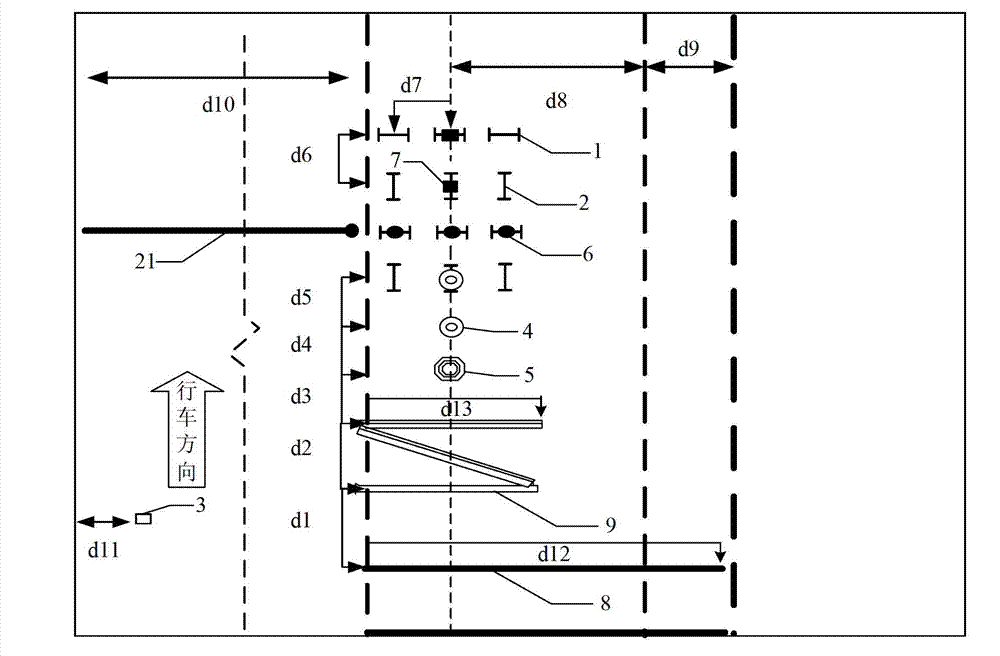

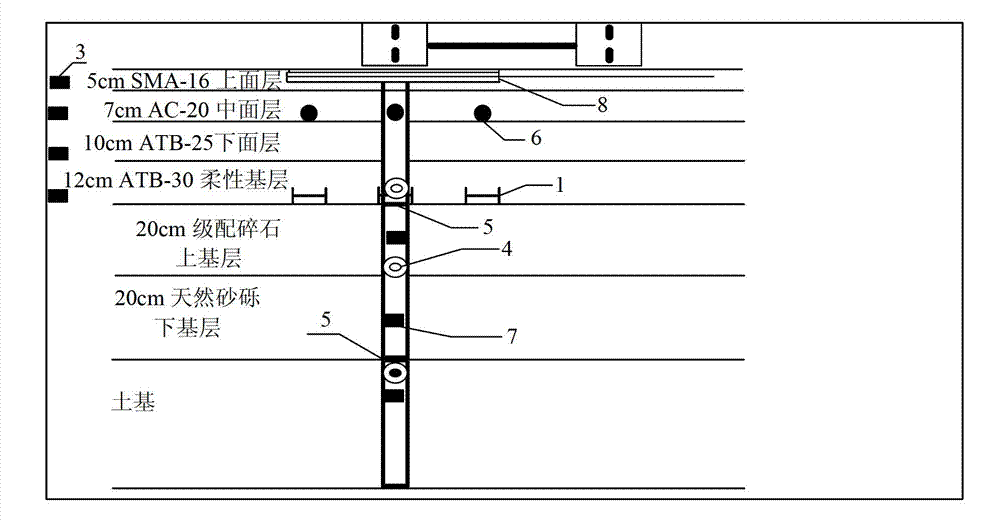

Long-term real-time monitoring system for asphalt pavement structure information based on optical fiber Bragg grating sensor

InactiveCN102900011ARealize evaluationRealize the estimateEmbedding padsRoads maintainenceGratingRoad surface

The invention discloses a long-term real-time monitoring system for asphalt pavement structure information based on an optical fiber Bragg grating sensor and relates to a long-term real-time monitoring system for the asphalt pavement structure information. The long-term real-time monitoring system meets the requirement of long-term real-time monitoring of the asphalt pavement structure information. Various data of the asphalt pavement are acquired by adopting A transverse strain sensors, B longitudinal strain sensors, C temperature sensors, D earth pressure gauges, E single point extensometers, F vertical strain sensors, G humidity sensors, a dynamic weighing sensor and a shaft position sensor and are processed by a server, and thus the long-term real-time monitoring on the asphalt pavement structure information is realized. The long-term real-time monitoring system disclosed by the invention is suitable for long-term real-time monitoring of the asphalt pavement structure information.

Owner:HARBIN INST OF TECH

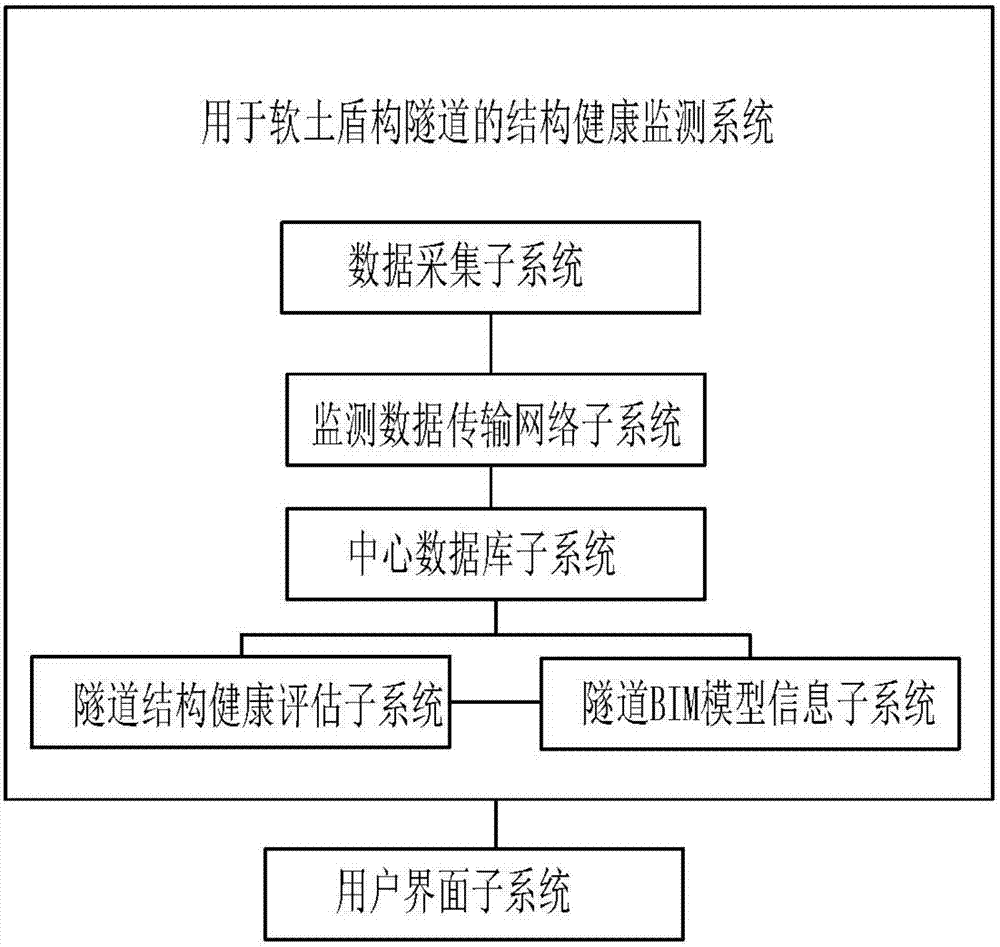

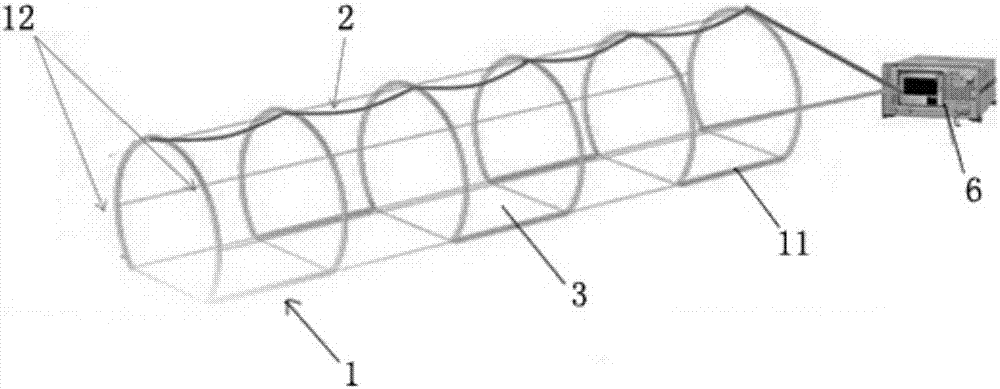

Structure health monitoring system for weak soil shield tunnel

InactiveCN108005725AGuaranteed safe operationFlexible combinationMining devicesStructural health monitoringStructure of the Earth

The invention provides a structure health monitoring system for a weak soil shield tunnel. Monitoring on the interior of the whole line range of a tunnel is conducted aiming at the characteristics ofthe weak soil shield tunnel structure, the requirements for health monitoring of construction and maintenance of the tunnel are met, and the structure health monitoring system comprises a data collection sub system, a monitoring data transmission network sub system, a center database sub system, a tunnel structure health evaluation sub system and a tunnel BIM model information sub system which arein communication connection with one another. The data collection sub system comprises a strain fiber optic sensor and a temperature fiber optic sensor which are arranged in the weak soil shield tunnel, the temperature fiber optic sensor is arranged in the length direction of the weak soil shield tunnel, the strain fiber optic sensor comprises longitudinal strain distributed optic fibers arrangedin the length direction of the weak soil shield tunnel and annular strain distributed optic fibers arranged in the circumferential direction of the weak soil shield tunnel, wherein the longitudinal strain distributed optic fibers and the annular strain distributed optic fibers are connected, and the annular strain distributed optic fibers are arranged at the joints of every two adjacent tunnel duct pieces, and used for collecting and obtaining monitoring data of the weak soil shield tunnel.

Owner:上海纽建信息科技有限公司

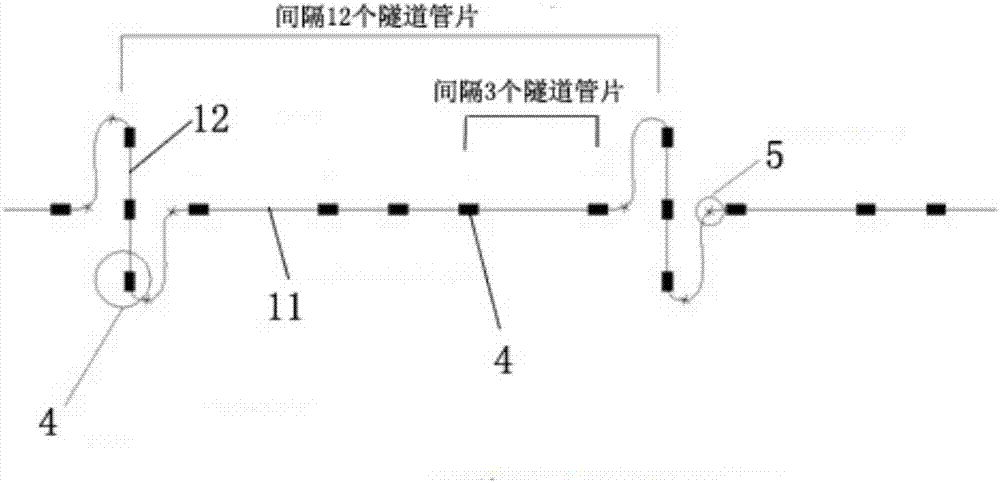

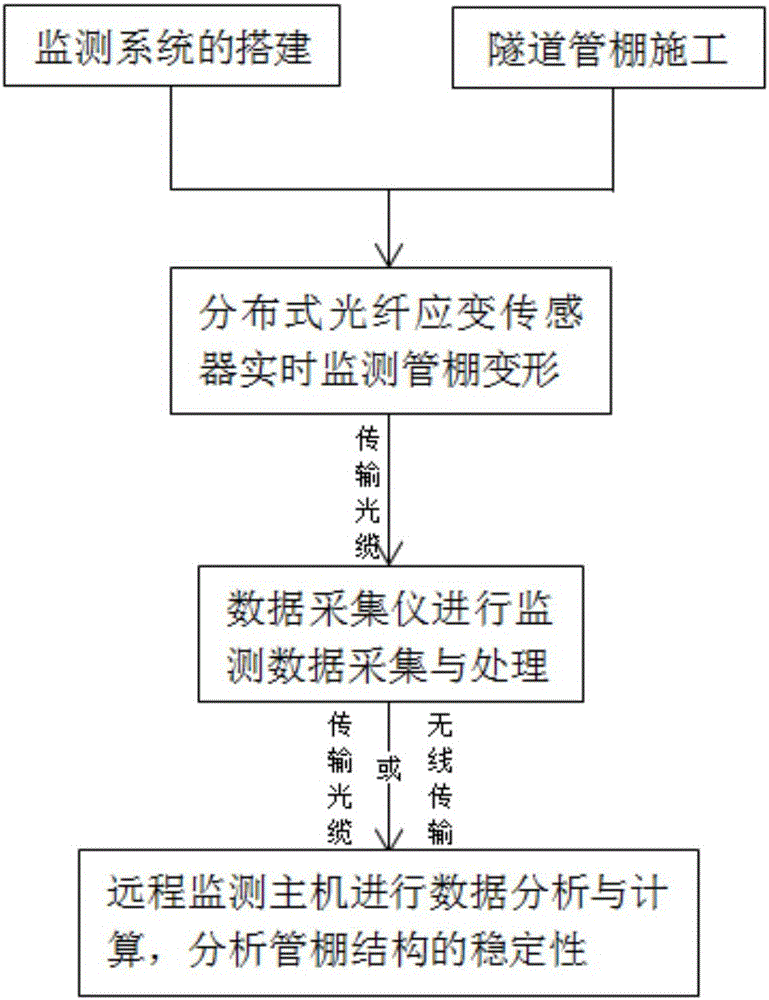

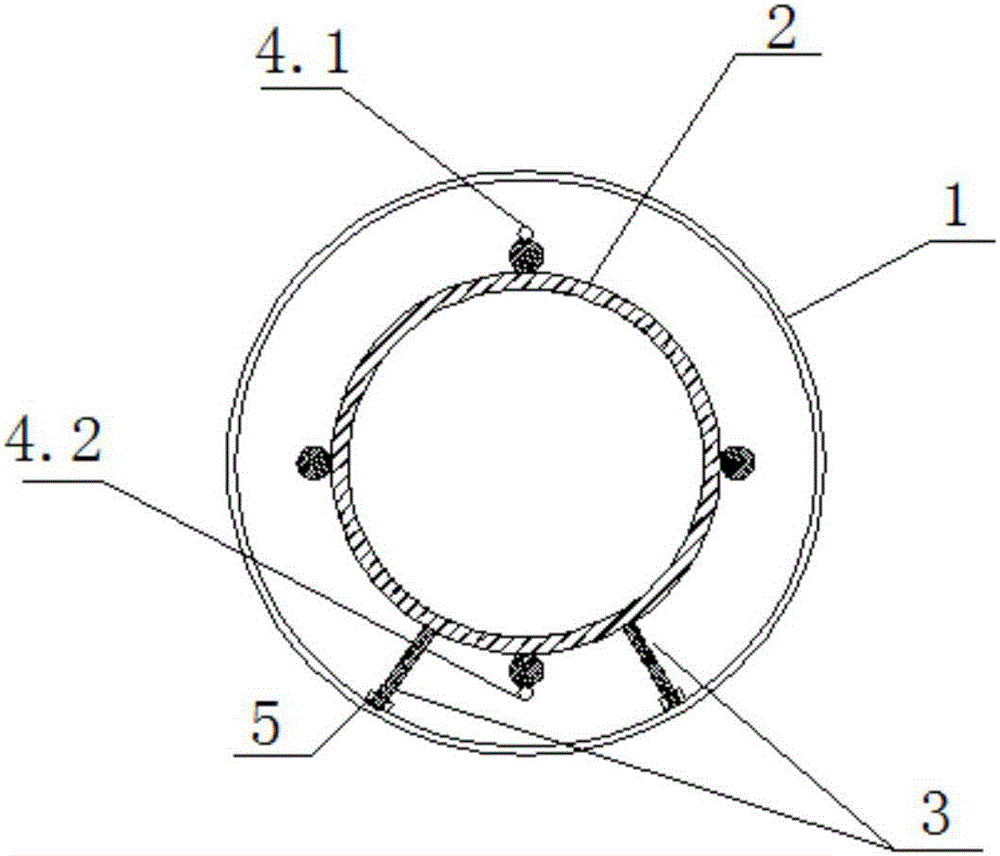

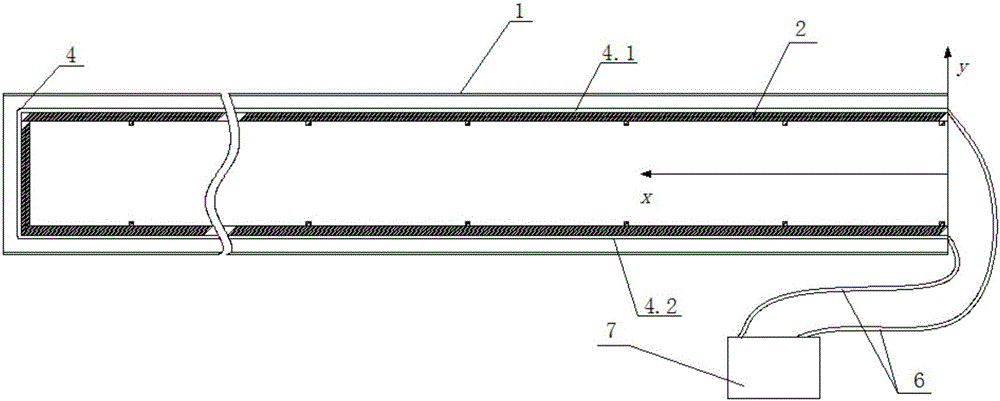

Method for monitoring deformation of tunnel pipe-roof

ActiveCN106524936ARealize onlineRealize dynamic monitoringUsing optical meansDeformation monitoringData acquisition

The present invention relates to a method for monitoring the deformation of a tunnel pipe-roof. The method includes the steps of (1) distributed optical fiber strain sensors laying: attaching distributed optical fiber strain sensors to the upper and lower ends of a steel cage, pushing the steel cage into a steel pipe to be measured, and filling cement mortar in the steel pipe to form a joint force bearing deformable body, (2) Data collection: selecting n measurement sections from the steel pipe to be measured with the measurement section distance being delta xi, monitoring vertical deformation of each section under the effect of vertical loads on a real-time basis by a data acquisition instrument and transmitting the vertical deformation to a monitoring host, and (3) deformation calculation and stability judgment: the monitoring host using Brillouin mediation technology and material mechanics theory to calculate the longitudinal strain difference of each cross section and obtain the deflection wi of the steel pipe to be measured. The monitoring method is quick and easy, the monitoring data is high in precision, and temperature is self-compensating. Monitoring equipment is connected with a data acquisition instrument, through which data is transmitted to a monitoring host, to realize real-time on-line monitoring of the pipe-roof deformation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

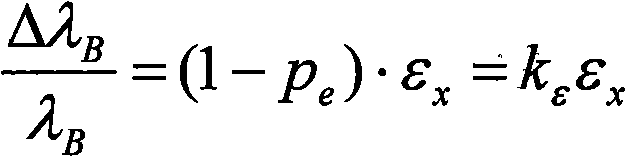

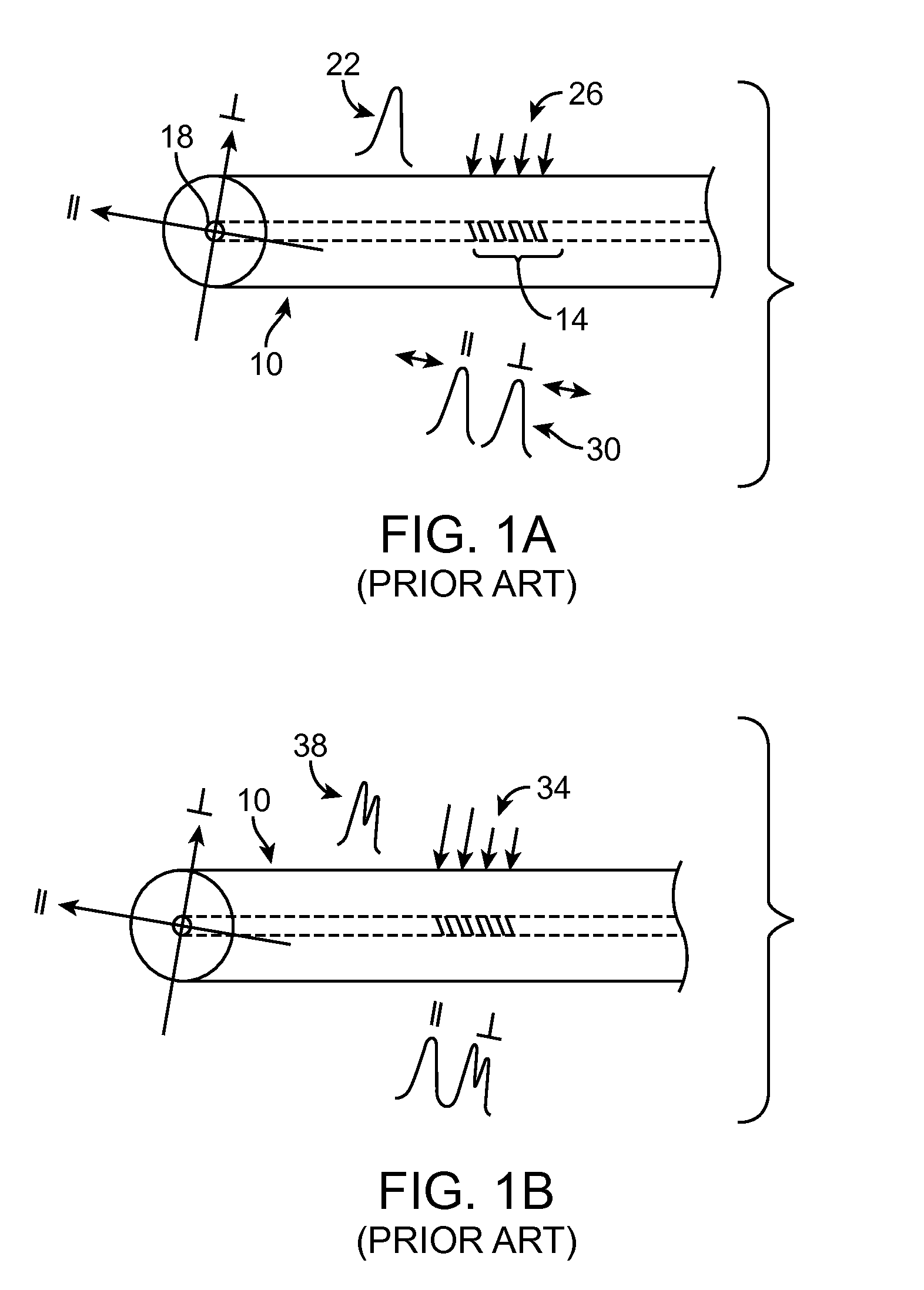

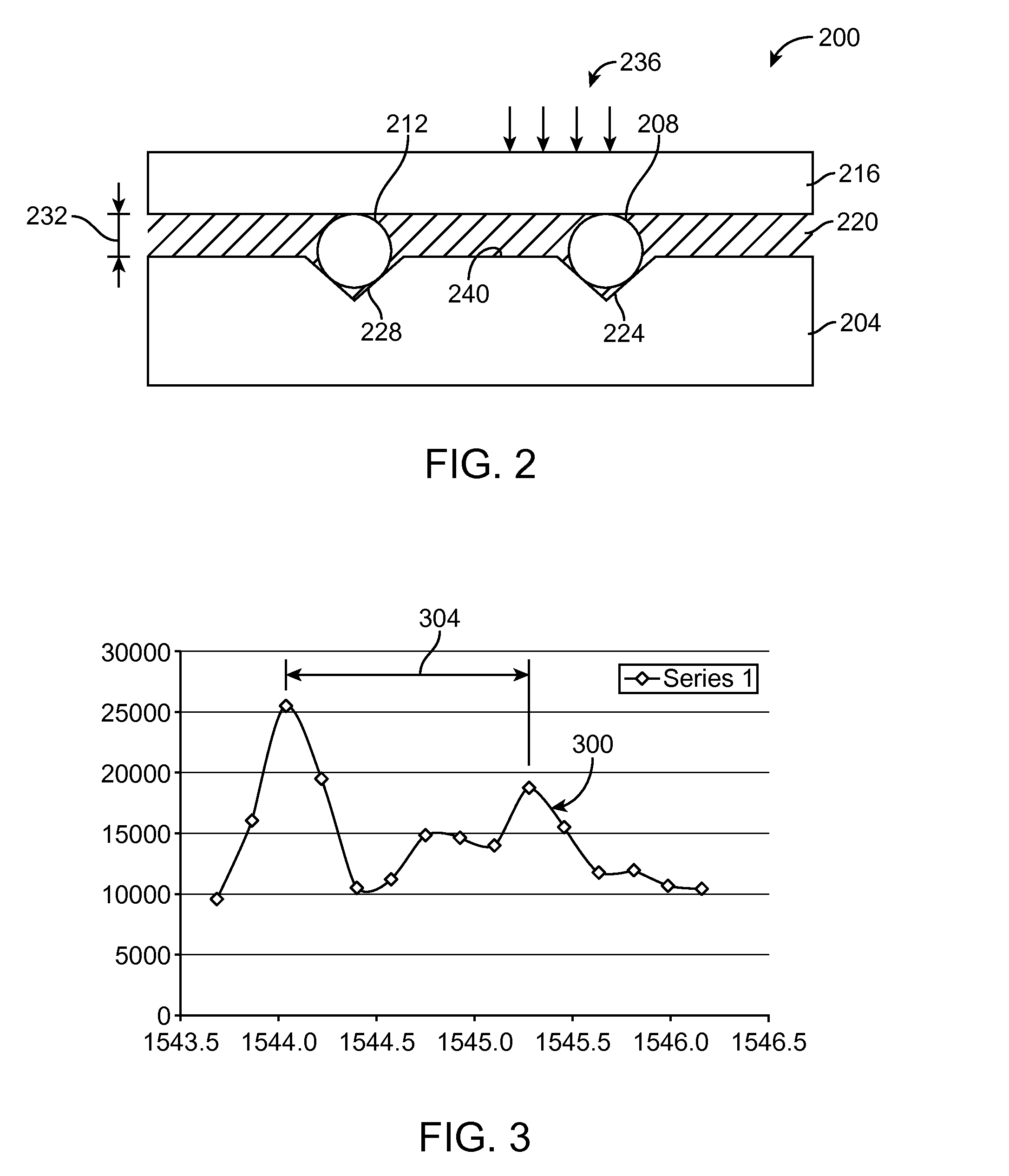

Fiber-Grating Sensors Having Longitudinal-Strain-Inducing Jackets and Sensor Systems and Structures Including Such Sensors

InactiveUS20140321799A1Increased tensile strainIncreases magnitudeForce measurement by measuring optical property variationConverting sensor outputFiberGrating

A sensor comprising an optical fiber that includes a Bragg grating and a longitudinal-strain-inducing (LSI) jacket for inducing longitudinal strain into the optical fiber as a function of a transverse load, i.e., pressure or force. As the LSI jacket induces strain into the optical fiber, the fiber grating deforms, thereby changing the character of light reflected from the grating. The changes in character of the reflected light can be measured using suitable optical instrumentation. Additional physical characteristics that can be measured / sensed using an LSI-jacket-based sensor include moisture content / presence, chemical content / presence, and temperature. A transverse-load-sensing sensor can include transverse-load-applying structures that compress the LSI jacket under transverse load, causing the jacket to controllably elongate and thereby induce longitudinal strain into the optical fiber. Chemical and moisture LSI jackets can comprise materials that swell in the presence of the chemical or moisture.

Owner:WICOR HOLDING

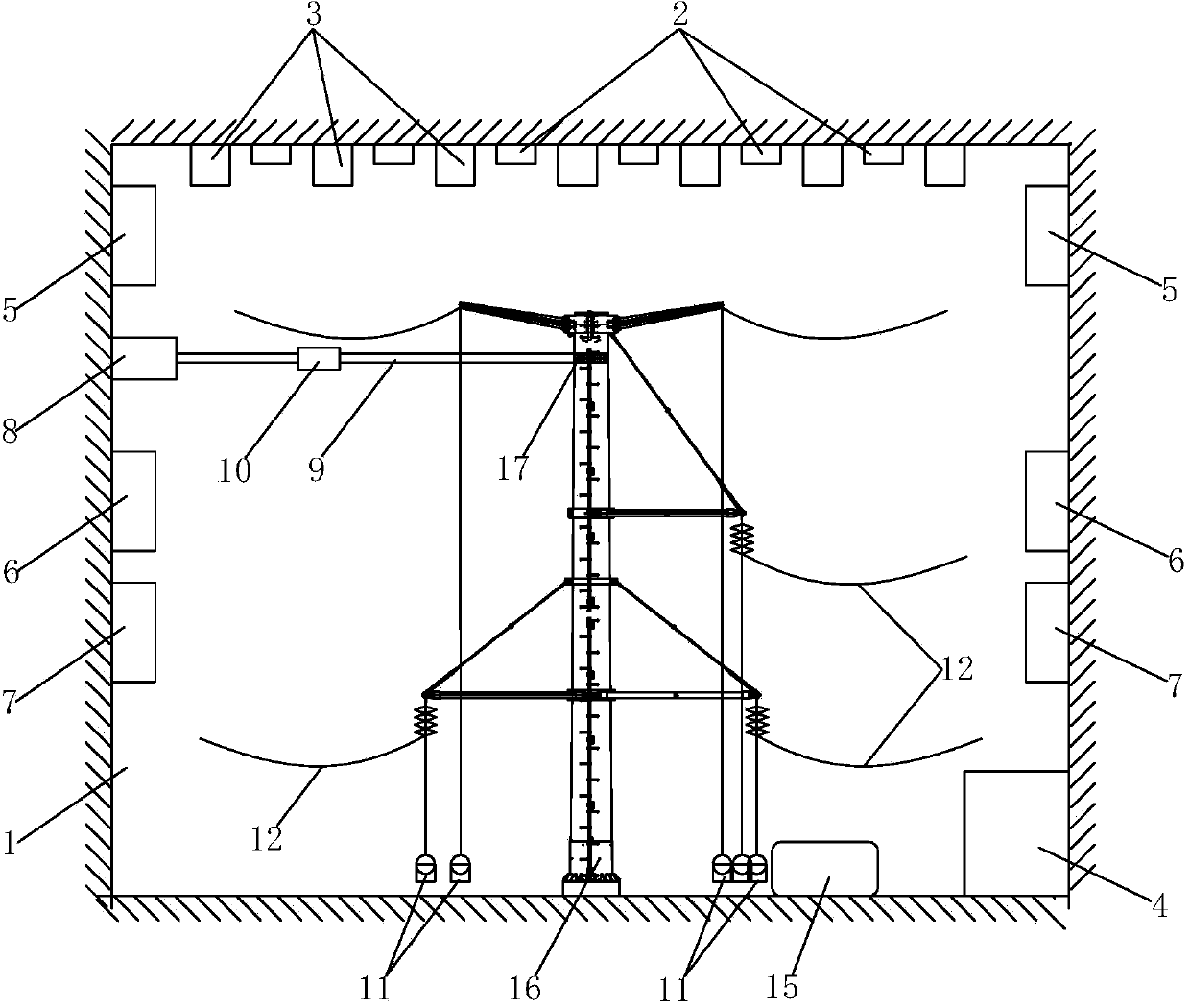

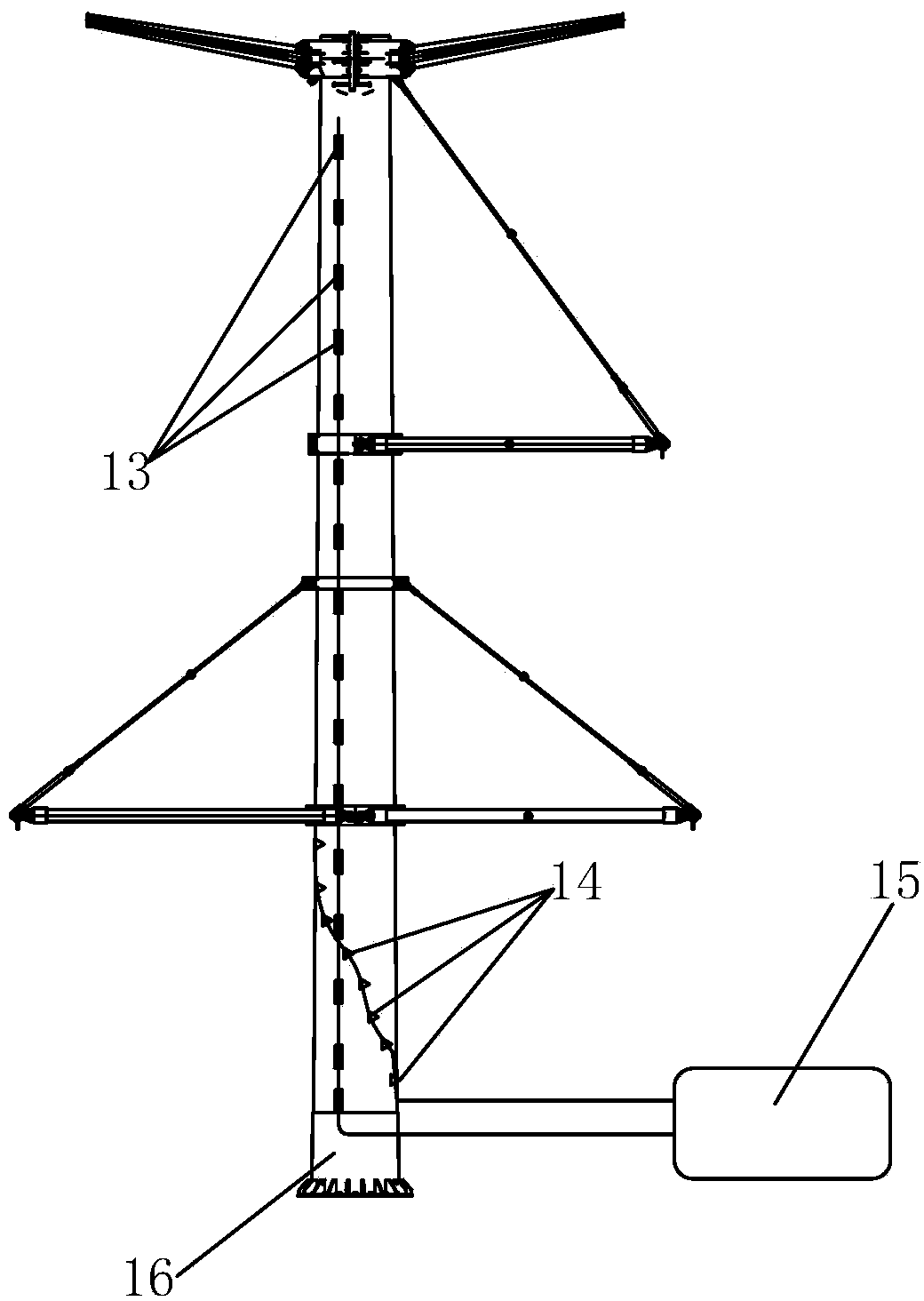

Multiple-factor accelerated aging test device for composite material electric pole

ActiveCN104198358ATest performanceSimple structureWeather/light/corrosion resistanceGratingUltraviolet

The invention discloses a multiple-factor accelerated aging test device for a composite material electric pole. The multiple-factor accelerated aging test device comprises an aging test room, wherein water nozzles and acid, alkali and salt atomizers are arranged on the roof surface of the aging test room; ozone generators, ultraviolet lamps, high-temperature and low-temperature humidity-heat devices, and a tensile machine are arranged on the side walls of the aging test room respectively; the action end of the tensile machine is connected with a traction rod which is provided with a force meter; corresponding to the composite material electric pole to be tested, weights, leads, longitudinal strain gratings, circumferential strain gratings, and a signal detection processor which is electrically connected with the force meter, the longitudinal strain gratings and the circumferential strain gratings respectively, are arranged inside the aging test room. By the cooperation of the water nozzles, the acid, alkali and salt atomizers, the ozone generators, the ultraviolet lamps, the high-temperature and low-temperature humidity-heat devices, the tensile machine, the weights and the leads, various natural environments can be simulated comprehensively, so that the performance of the composite material electric pole can be thoughtfully and correctly tested. The accelerated aging test device is applicable to testing of pole towers.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

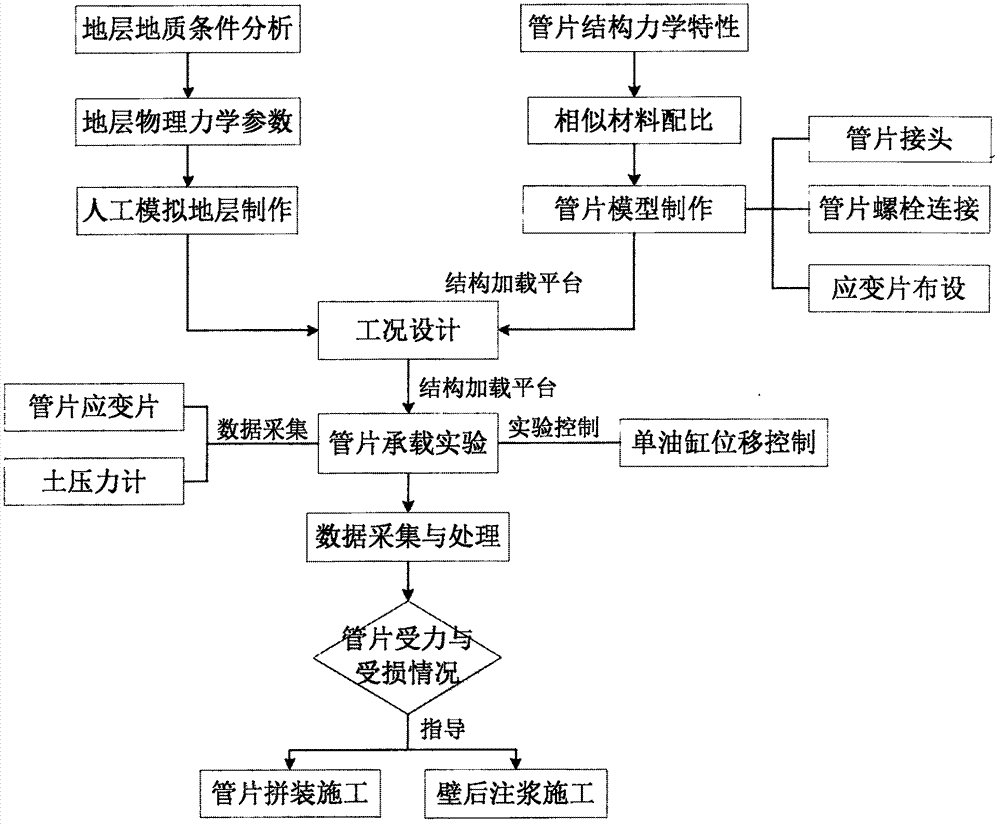

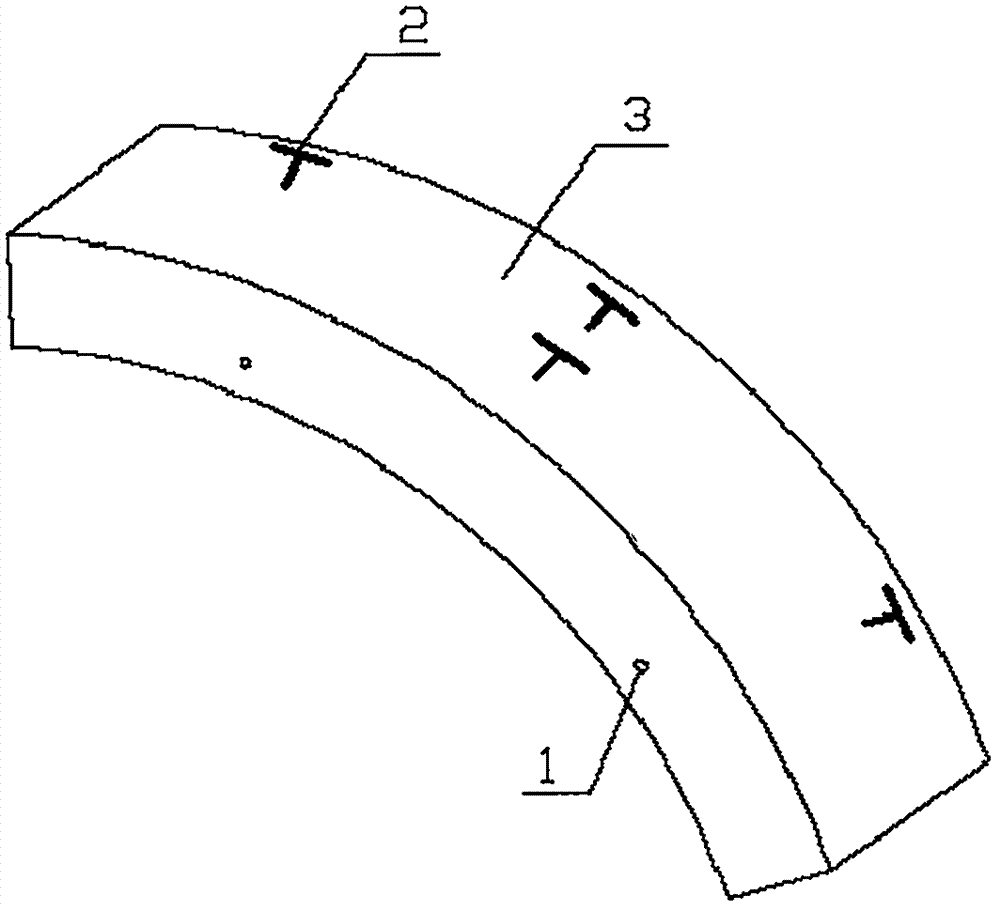

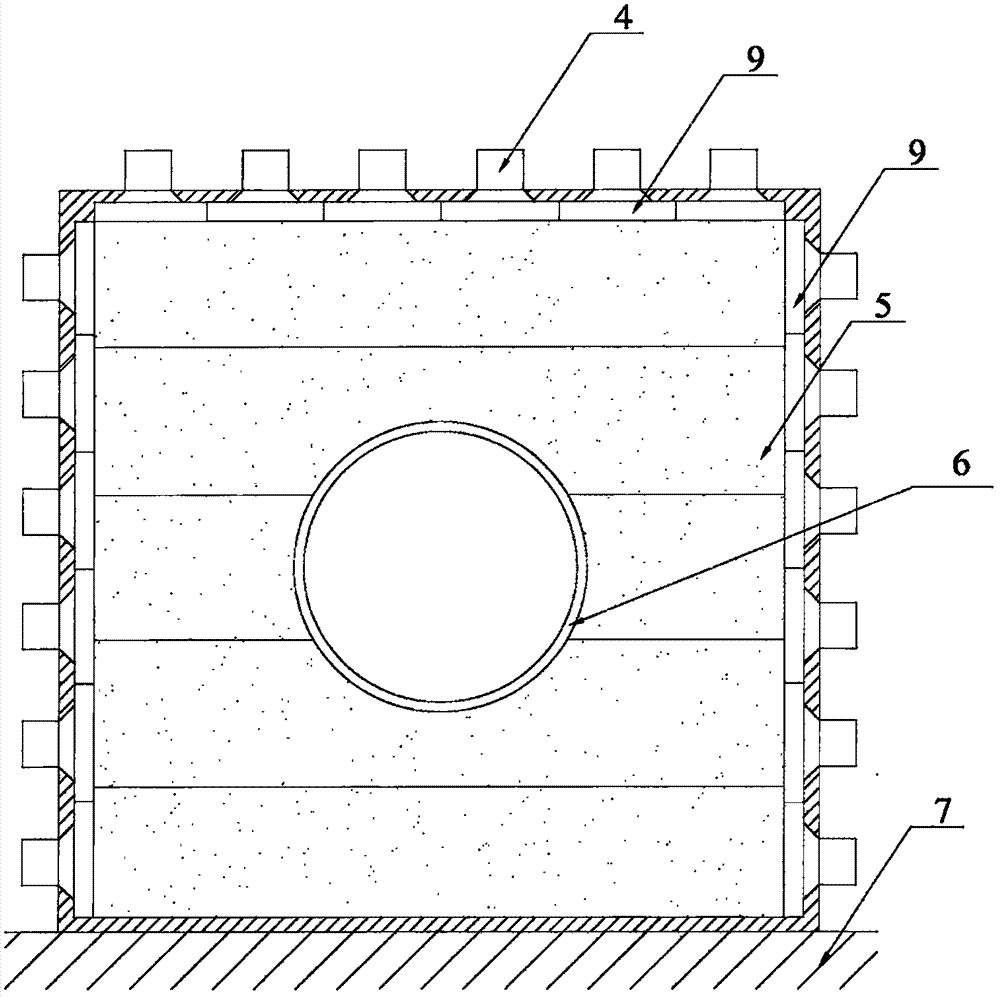

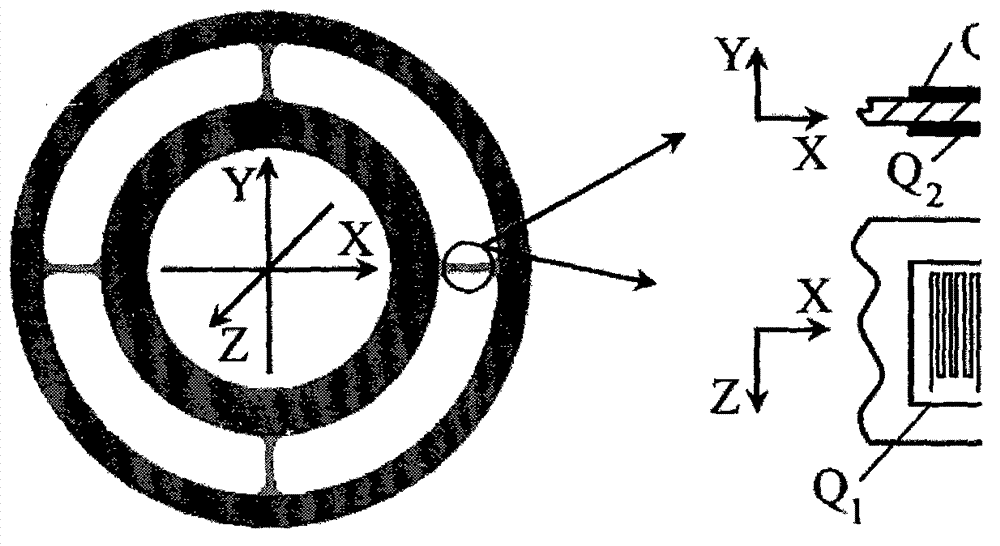

Modeling method for realizing structural mechanical performance of pipe segment three-dimensional loading

ActiveCN107301305AAvoid interferenceGeometric CADSpecial data processing applicationsSystems designData acquisition

The invention discloses a modeling method for realizing structural mechanical performance of pipe segment three-dimensional loading. The modeling method mainly includes: analyzing and remodeling geological conditions; making a stratum model; making a contraction rule pipe segment model; designing a pipe segment monitoring system; performing different loading model experiments on pipe segments; collecting and analyzing data. By adopting the method, pipe segment structural mechanical characteristic experiments on working conditions of horizontal and vertical different loading, of pipe segment rings, pipe segment axial geostress difference and pipe segment staggering and eccentric loading in different geological environments can be realized, real simulation of pipe segment loading environment is realized through stratum remodeling, pipe segment structure is processed by utilizing gypsum to realize detailed construction of the pipe segment structure, joint screwed connection is realized, annular and longitudinal strain gauges are distributed for whole-ring pipe segments to realize monitoring of internal force of the pipe segments, and technical support is provided for subsequent shield pipe segment assembling and wall posterior grouting parameter setting.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

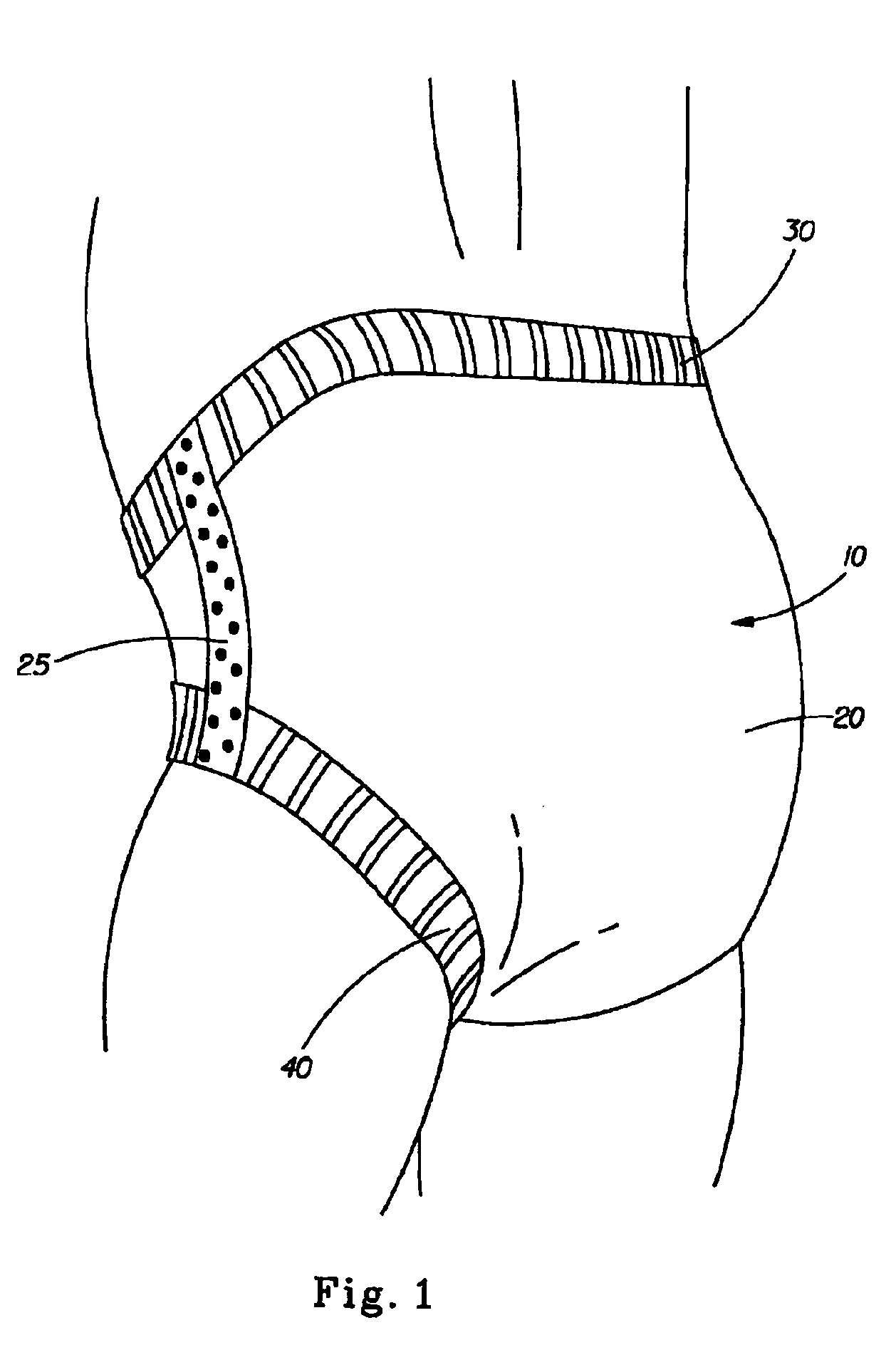

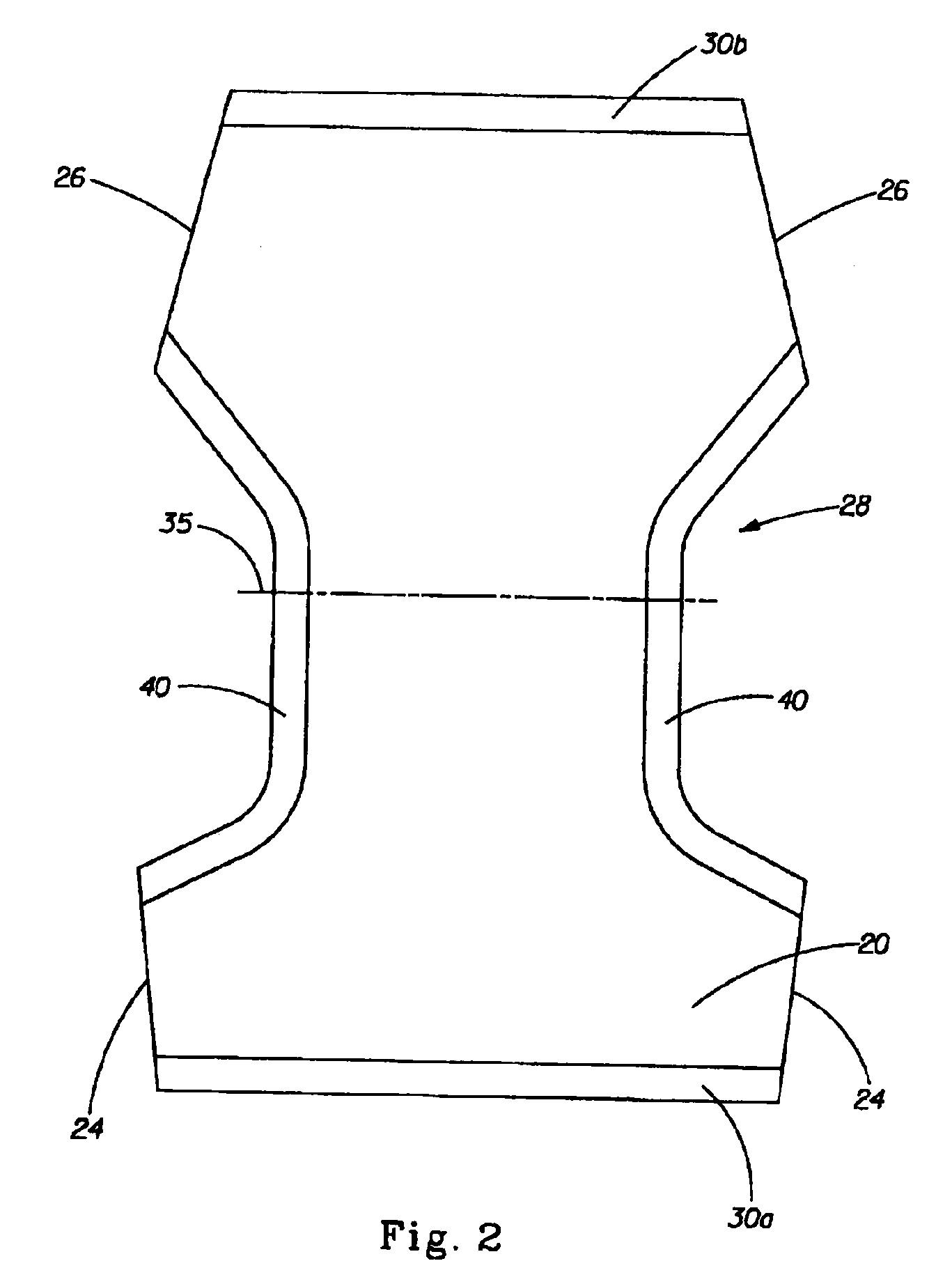

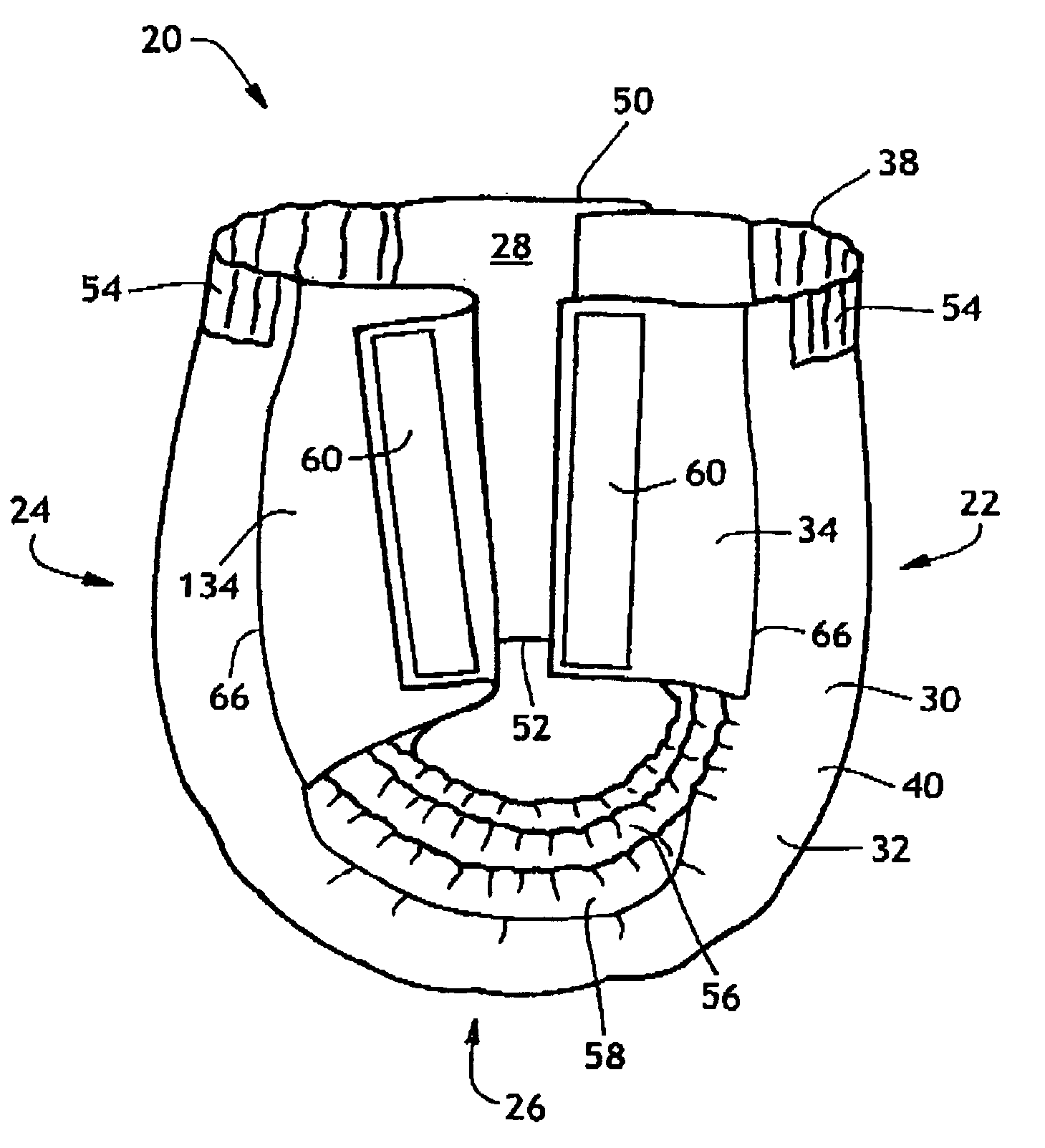

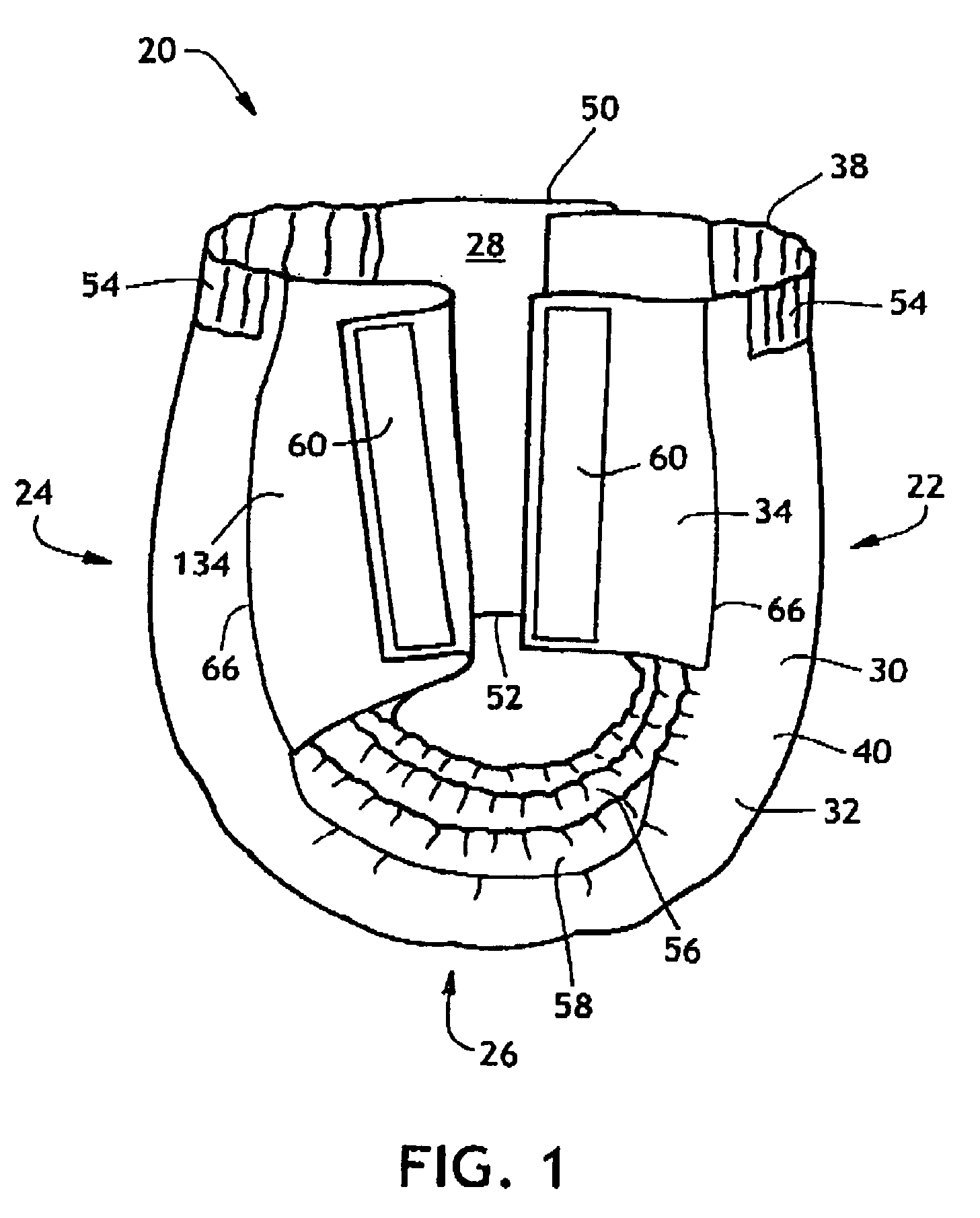

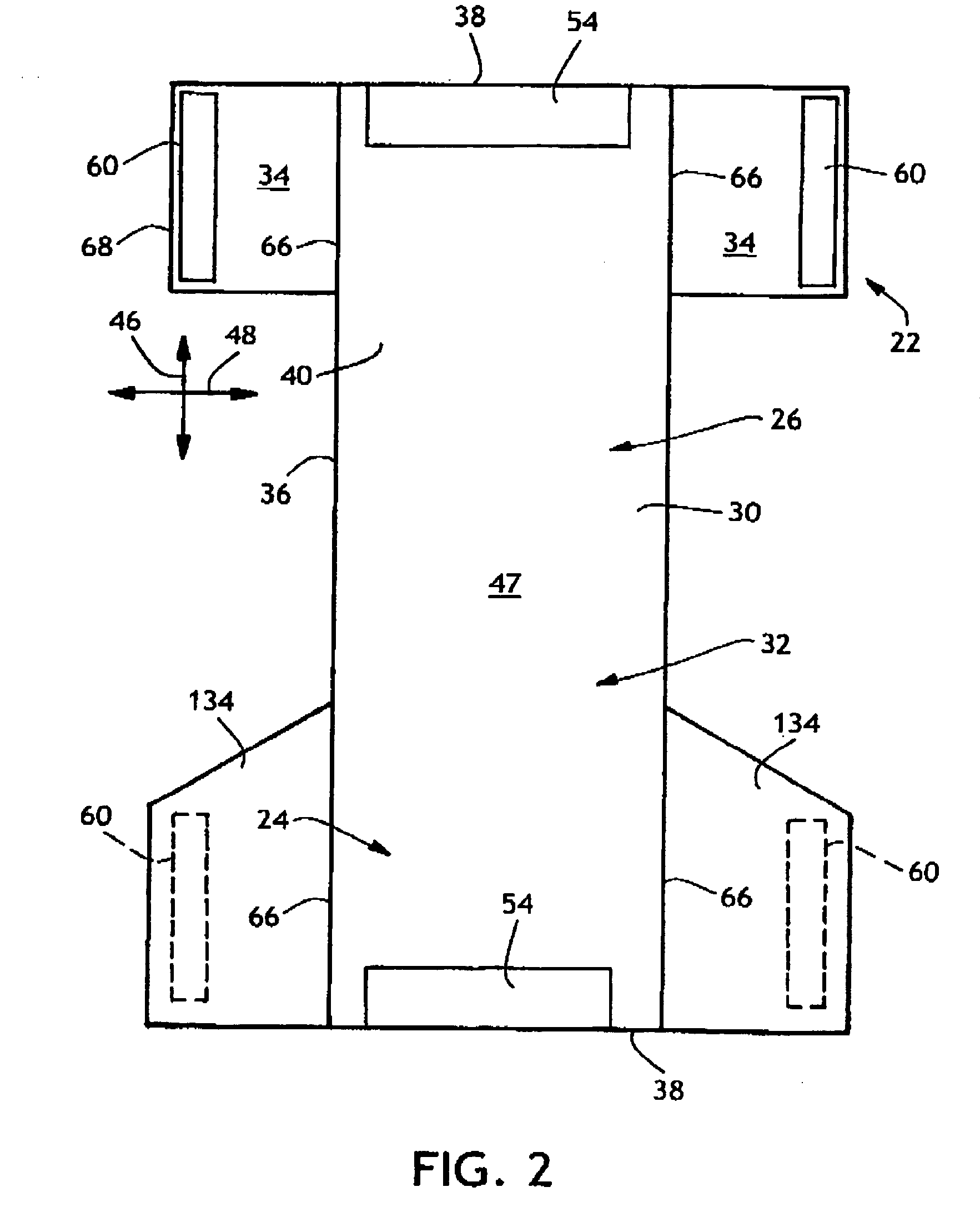

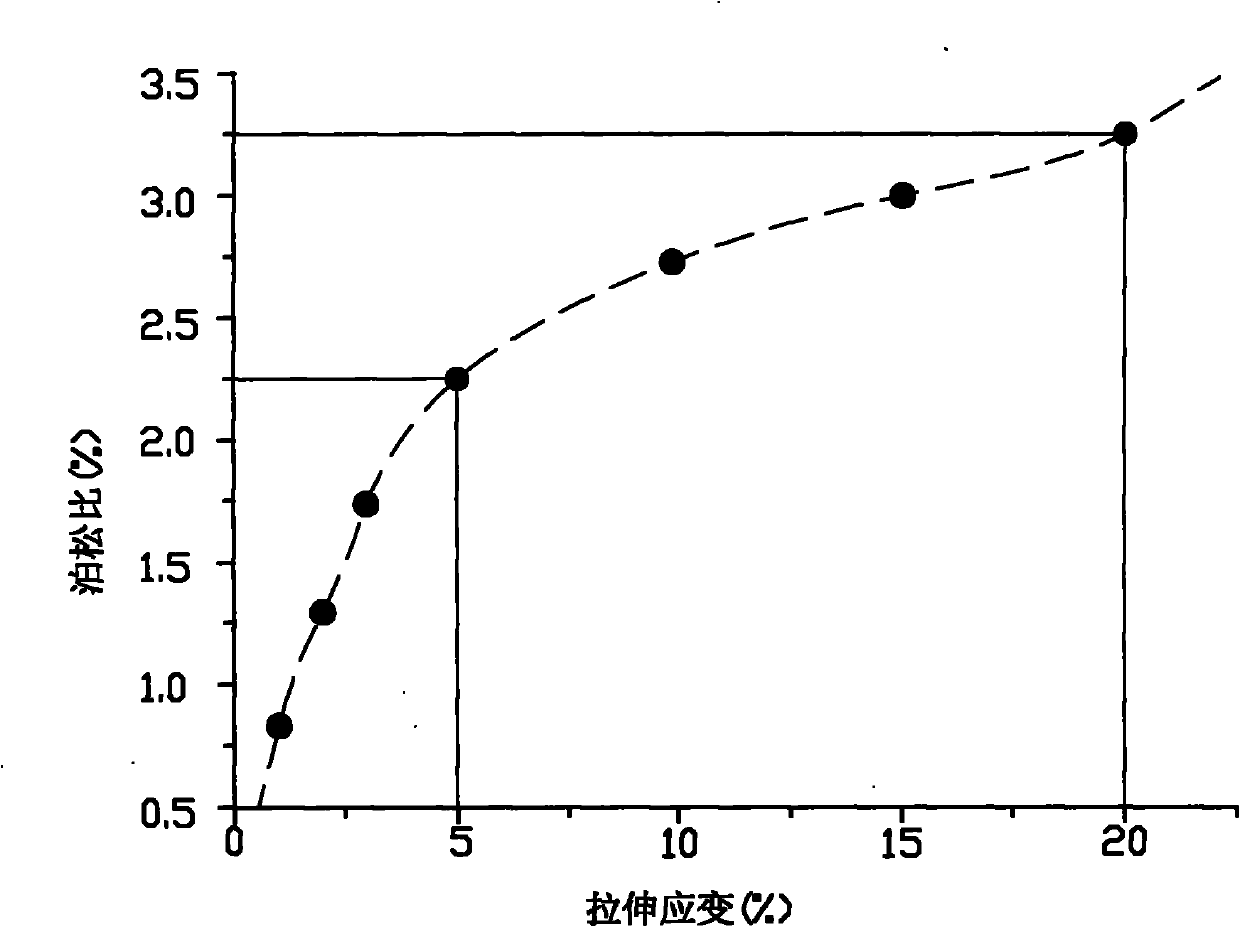

Absorbent article featuring a laminated material with a low Poisson's Ratio

Disclosed is an absorbent article defining a longitudinal direction and a lateral direction perpendicular to the longitudinal direction, the absorbent article including an outercover, the outercover comprising a laminated material including two layers; an absorbent body disposed adjacent the outercover; and a graphic associated with the outercover, wherein the laminated material exhibits a Poisson's Ratio less than 1.0 at 4 percent longitudinal strain using ASTM-E132. The laminated material optimally exhibits a Poisson's Ratio less than 0.75 at 4 percent longitudinal strain using ASTM-E132. The laminated material more optimally exhibits a Poisson's Ratio less than 0.4 at 4 percent longitudinal strain using ASTM-E132.

Owner:KIMBERLY-CLARK WORLDWIDE INC

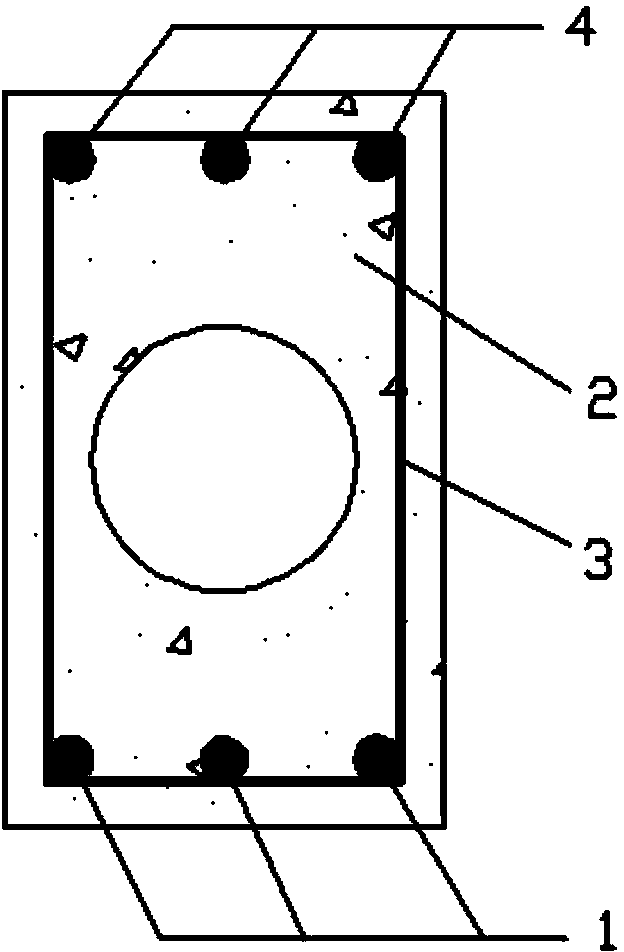

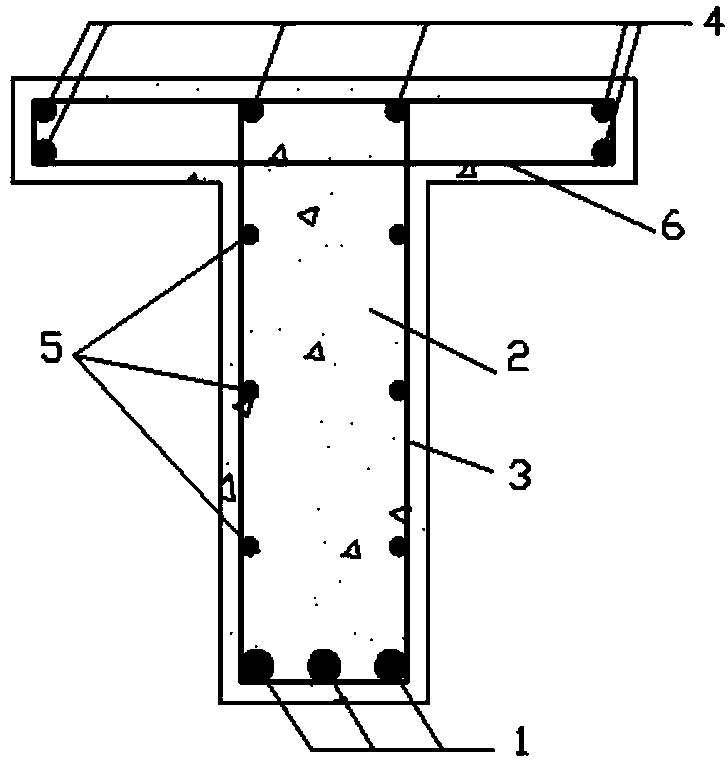

FRP (Fiber Reinforced Plastic) bar and fiber high-strength concrete beam component

The invention relates to an FRP (Fiber Reinforced Plastic) bar and fiber high-strength concrete beam component. The FRP (Fiber Reinforced Plastic) bar and fiber high-strength concrete beam component comprises fiber high-strength concrete and an FRP bar framework cast in the fiber high-strength concrete, wherein the cross section of the beam component is solid rectangular, hollow rectangular, T-shaped or box-shaped; for the solid rectangular or hollow rectangular cross section, the FRP bar framework consists of longitudinal strained FRP bars, FRP stirrup bars and longitudinal erected FRP bars, and the longitudinal strained FRP bars and the longitudinal erected FRP bars are attached to the inner sides of the FRP stirrup bars and bundled together; for the T-shaped cross section and the box-shaped cross section, the FRP bar framework consists of longitudinal strained FRP bars, FRP stirrup bars, erected FRP bars, girder web distributed FRP bars and top plate stressed FRP bars, the longitudinal strained FRP bars are attached to the inner sides of the FRP stirrup bars, the distributed FRP bars are attached to the inner sides of the FRP stirrup bars, the erected FRP bars are attached to the inner sides of the top plate stressed FRP bars, and the top plate stressed FRP bars are connected with the FRP stirrup bars to form effective connection.

Owner:ZHENGZHOU UNIV

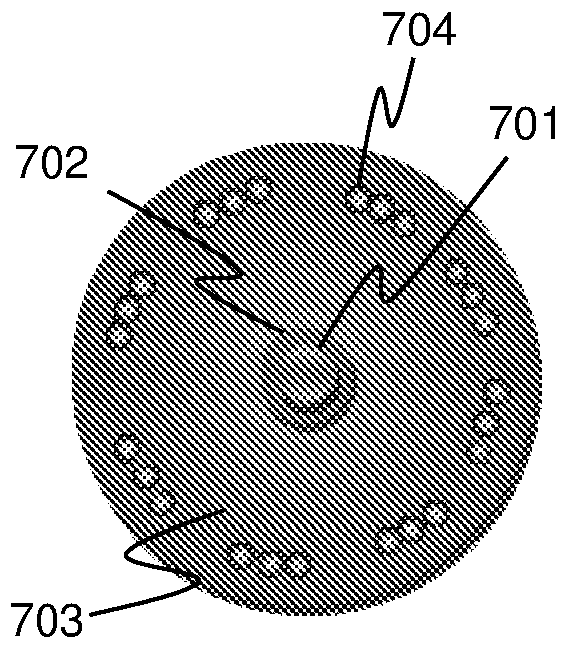

Fibre optic cable with tuned transverse sensitivity

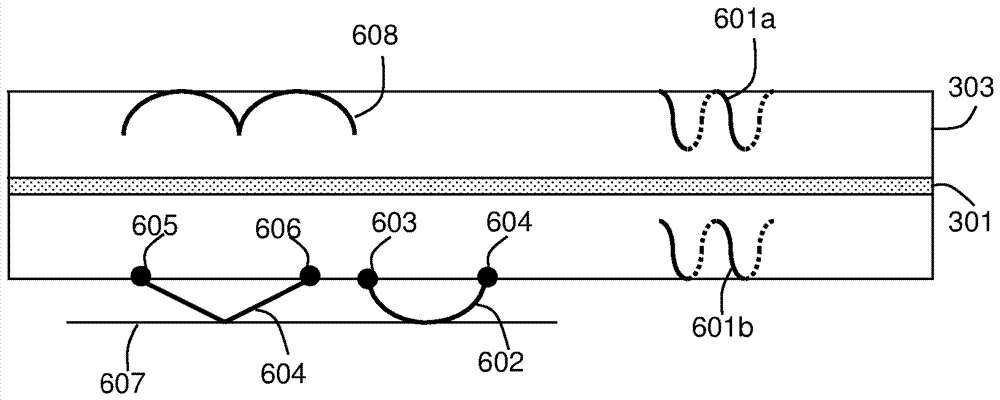

InactiveCN107003192ASubsonic/sonic/ultrasonic wave measurementForce measurement by measuring optical property variationFiberDistributed acoustic sensing

This application relates to a fibre optic cable structure suitable for use as a sensing fibre optic for distributed acoustic sensing and having an improved sensitivity to transverse pressure waves. The application describes a fibre optic cable (300) having a longitudinal cable axis and comprising at least one optical fibre (301). The cable also comprises a compliant core material (303) mechanically coupled to the optical fibre(s), possible via a buffer (302) such that a longitudinal force acting on the compliant core material induces a longitudinal strain in the optical fibre(s). At least one deformable strain transformer (304) is coupled to the compliant core material and configured such that a force acting on the strain transformer in a direction transverse to the cable axis results in a deformation of the strain transformer thereby applying a longitudinal force to the compliant core material.

Owner:OPTASENSE HLDG LTD

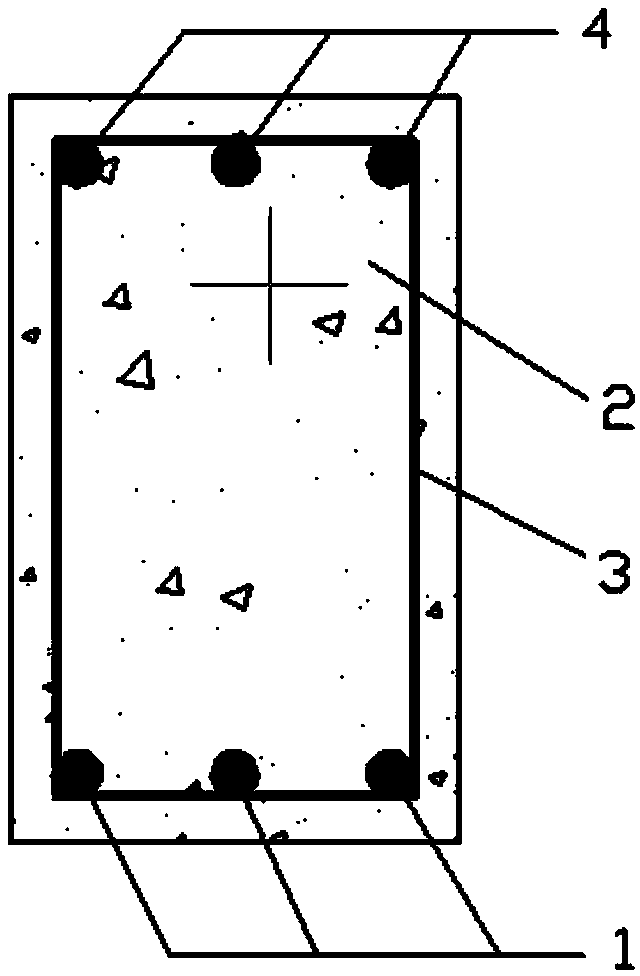

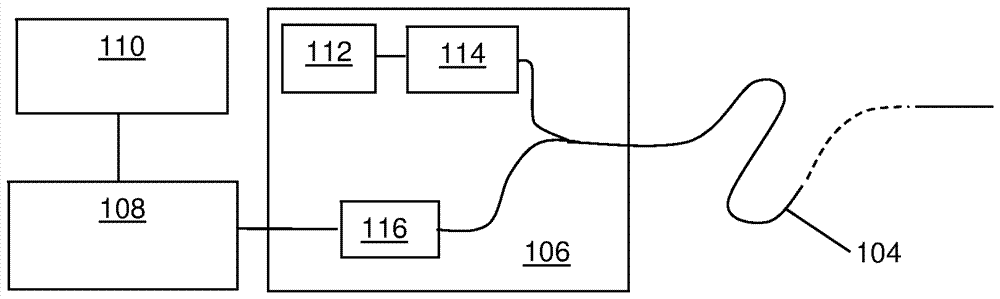

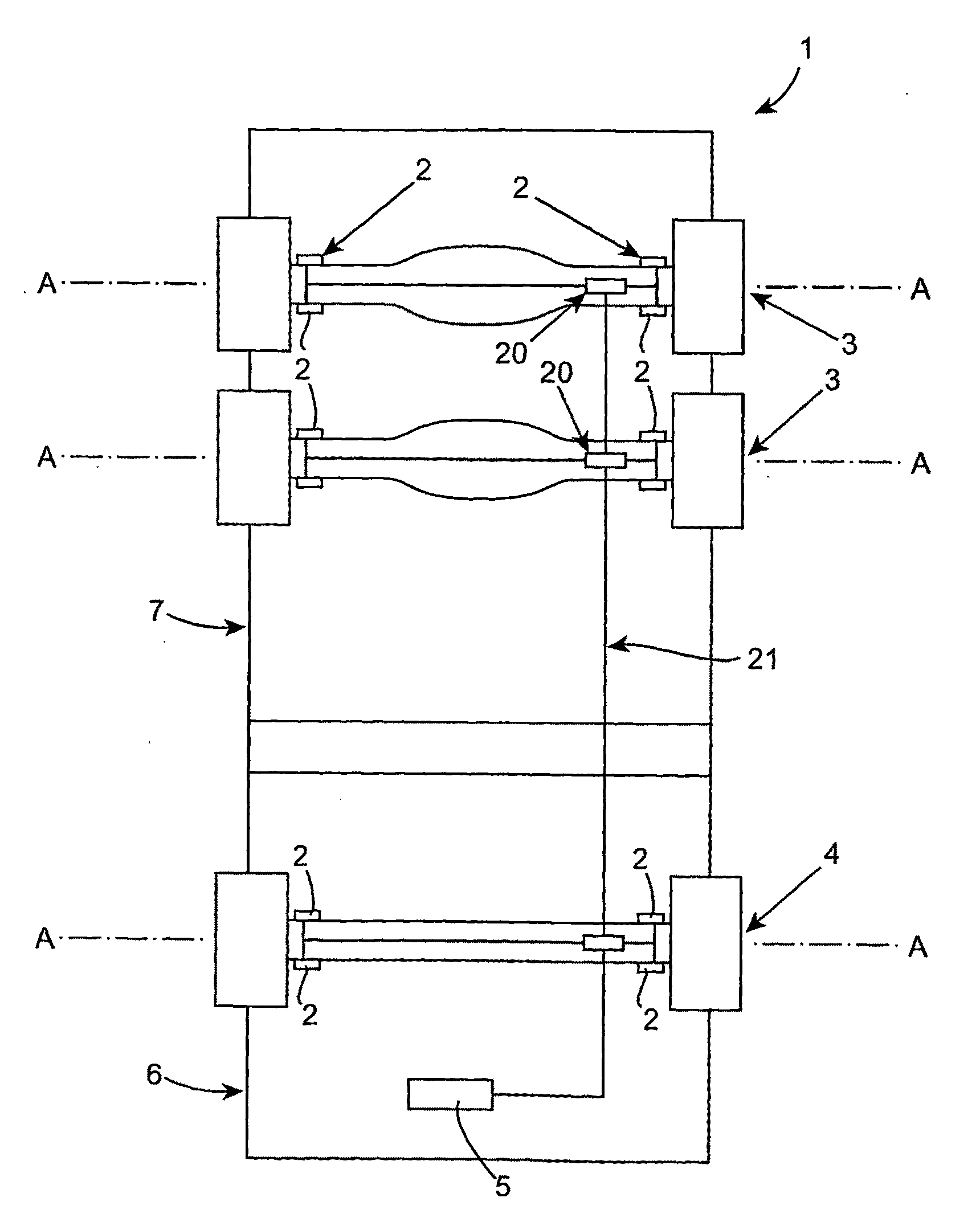

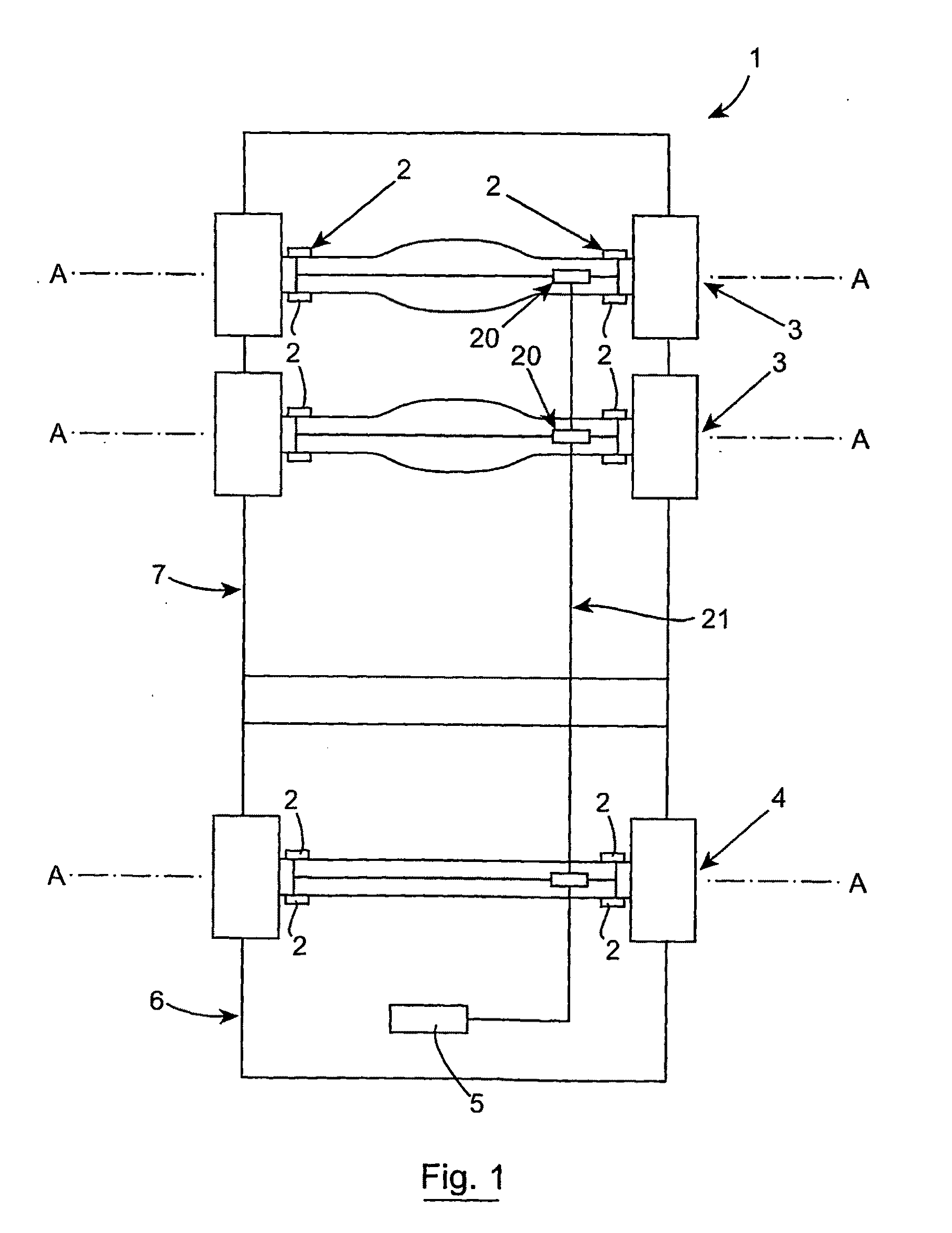

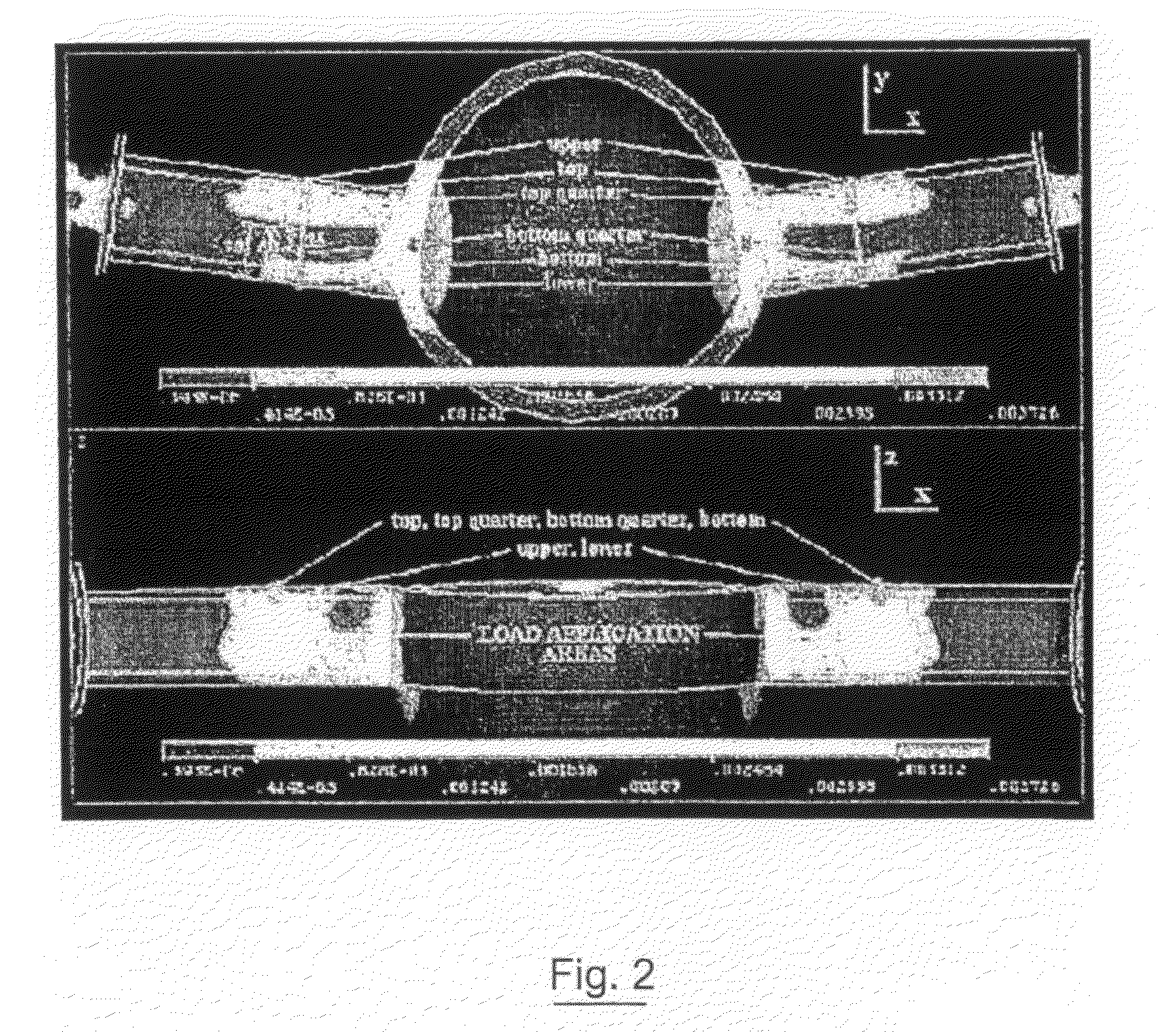

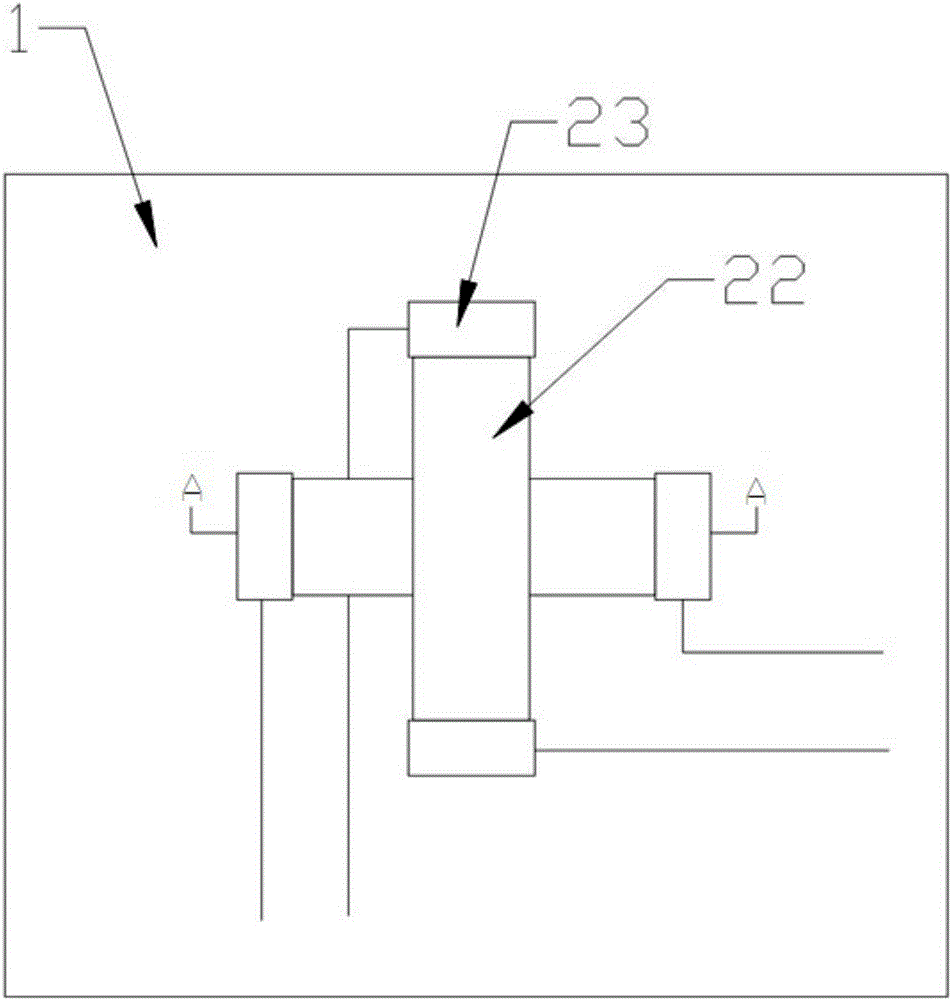

System for Determining a Vehicle Load

A system (1) for determining a load of a vehicle such as a HGV. The system (1) comprises a plurality of strain gauges (2) mounted on each axle (3, 4) of the HGV. Each strain gauge (2) is arranged parallel to the longitudinal axis A-A of the axles (3, 4) to measure the strain exerted on each axle (3, 4) in a direction substantially parallel to the longitudinal axis A-A of each axle (3, 4). The strain gauges (2) are mounted on the axles (3, 4) at locations on the axles (3, 4) at which the axles (3, 4) exhibit a substantially linear strain-load relationship. These locations are determined, by performing a finite element analysis of the axles (3, 4). The system (1) also comprises a master control unit (5), carried on-board the HGV5 for calculating the HGV load responsive to the longitudinal strain measured by the strain gauges (2). The load exerted by the HGV on the road surface may then be calculated responsive to the calculated HGV load. The strain gauges (2) may be employed to measure in real-time the longitudinal strain exerted on the nodes (3, 4) of the HGV while the HGV is moving, and the master control unit (5) may be employed to calculate in real-time the HGV load while the HGV is moving. The system (1) further comprises a transmitter for transmitting information from the HGV to a central server at a location remote from the HGV.

Owner:TRINITY COLLEGE DUBLIN

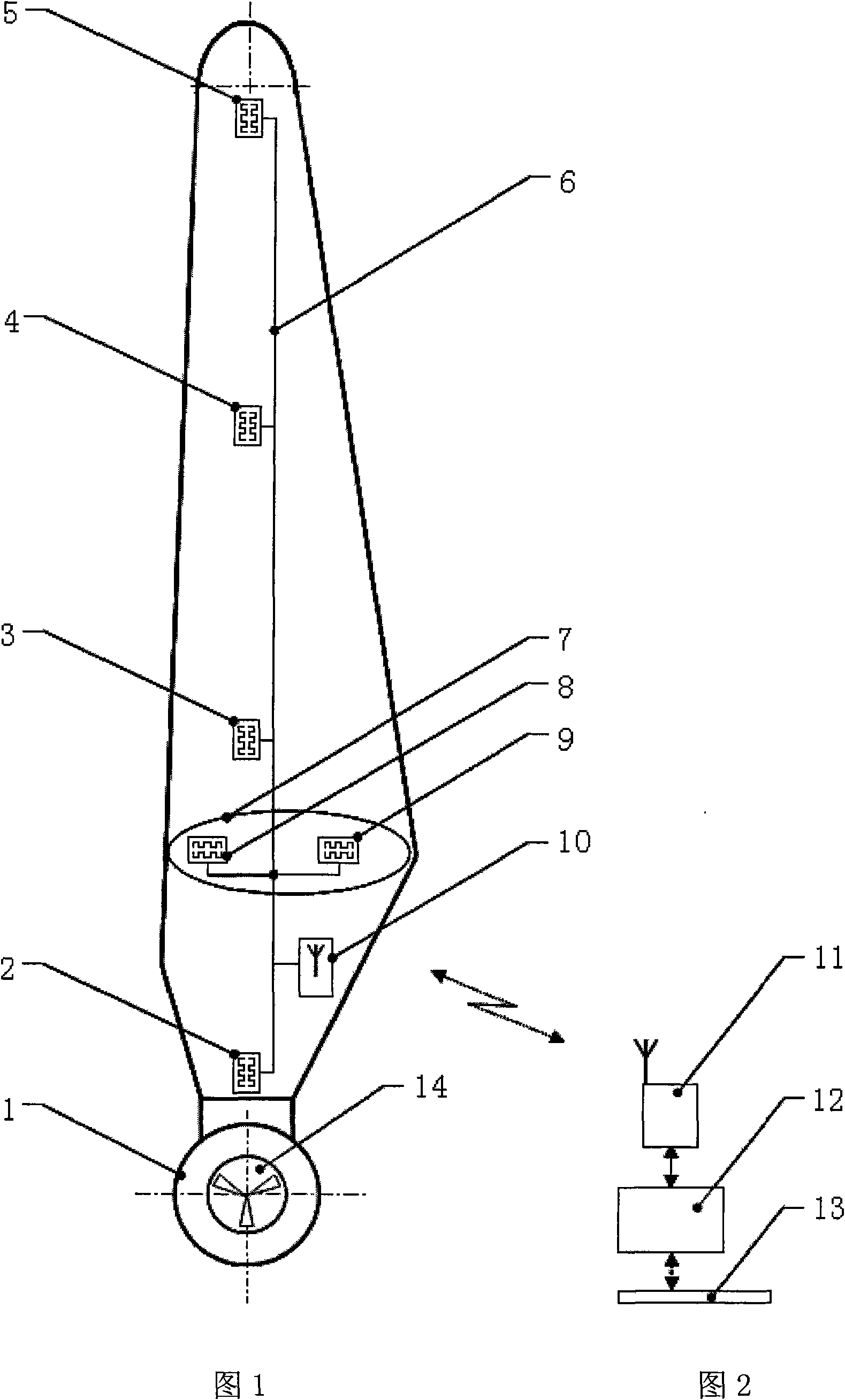

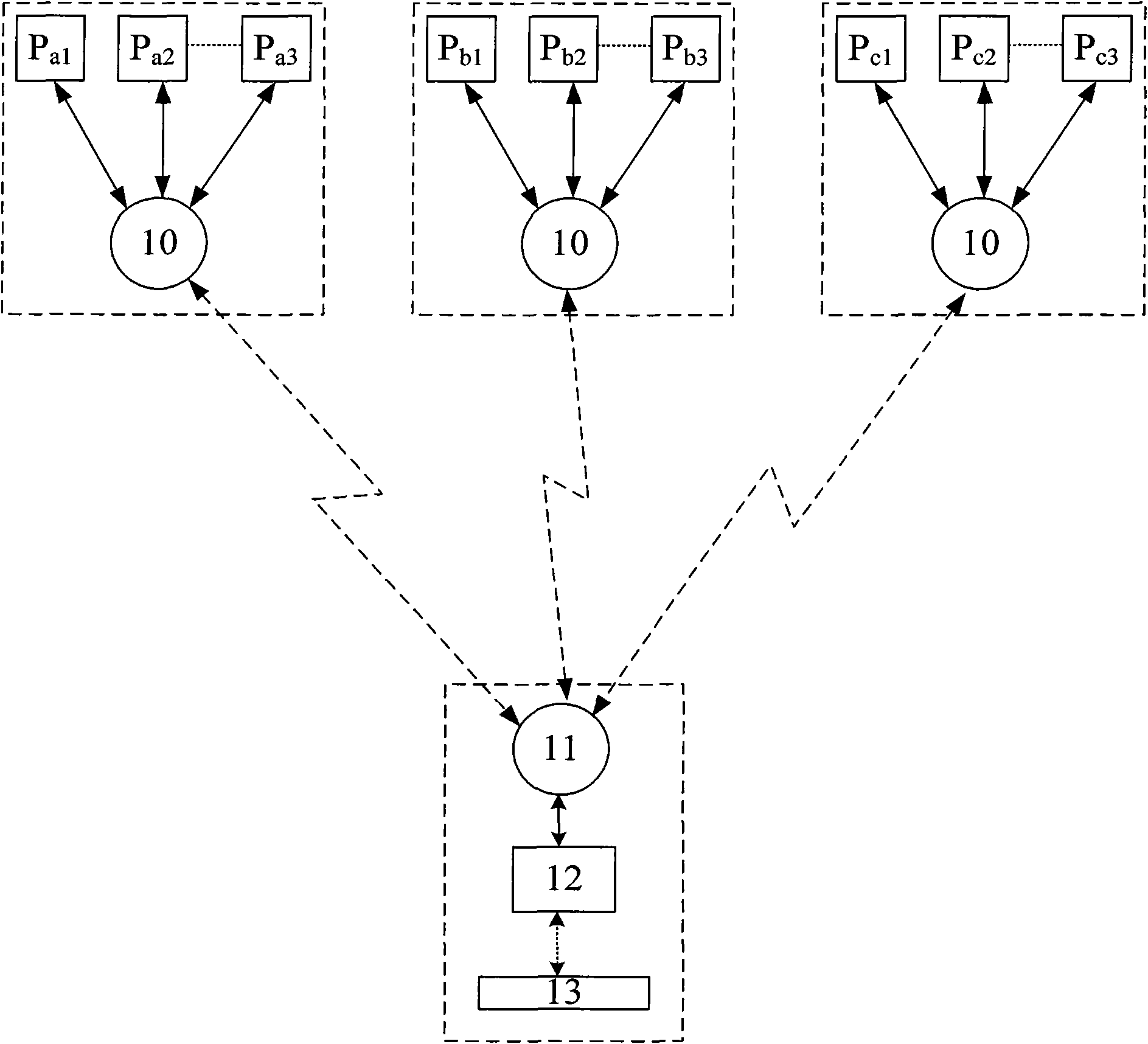

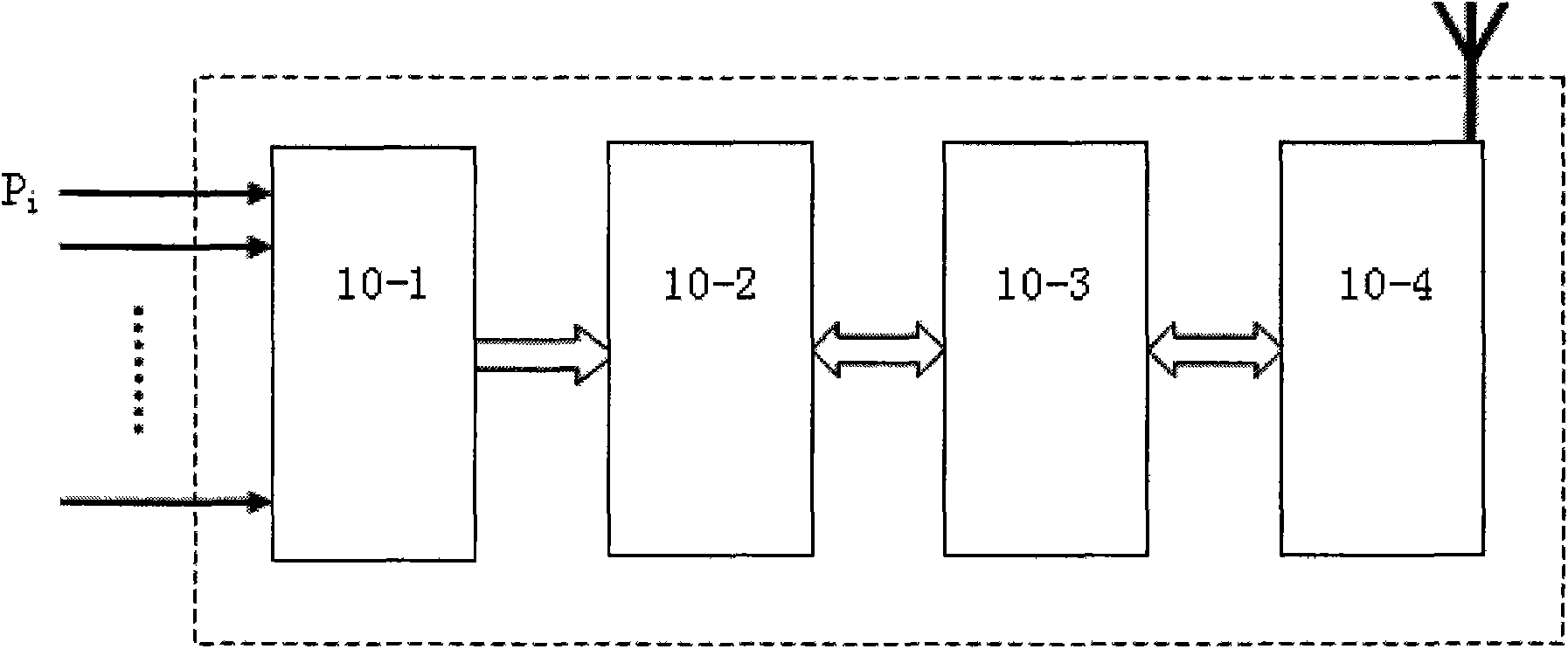

Online real-time monitoring method for dynamic deflection deformation of wind driven generator blade

InactiveCN101982724AGuaranteed real-time accessThe method is simple and reliableTransmission systemsElectrical/magnetic solid deformation measurementWind drivenEngineering

The invention relates to an online real-time monitoring method for dynamic deflection deformation of a wind driven generator blade. When the blade is deformed, a longitudinal strain detection strain sheet and a transverse strain detection strain sheet input signals of the blade to a differential half-bridge signal detection and conditioning module for detecting and conditioning a strain analog signal of a strain sheet of a detected point respectively, the signals are converted into digital quantity by an analog-to-digital converter, the digital quantity is coded by a microprocessor, a wireless transmitting / receiving module transmits the signals, and the wireless transmitting / receiving module receives control instructions sent by monitoring instrument equipment; the monitoring instrument equipment processes, stores and displays the detected data and transmits the detected data through an interface; and a control center performs blade deformation reconstruction according to the detected data to obtain fatigue degree of the blade so as to achieve the goal of real-time detection of the blade. The method realizes long-term monitoring of online deformation of the rotary blade, and acquires the working condition of the rotary blade at the current moment from a data terminal by wireless data transmission technology. The combination of a wind driven generator and a storage battery ensures long-term operation of a monitoring system and data transmission thereof and effectively ensures real-time acquisition of the working condition data of the rotary blade.

Owner:TONGJI UNIV

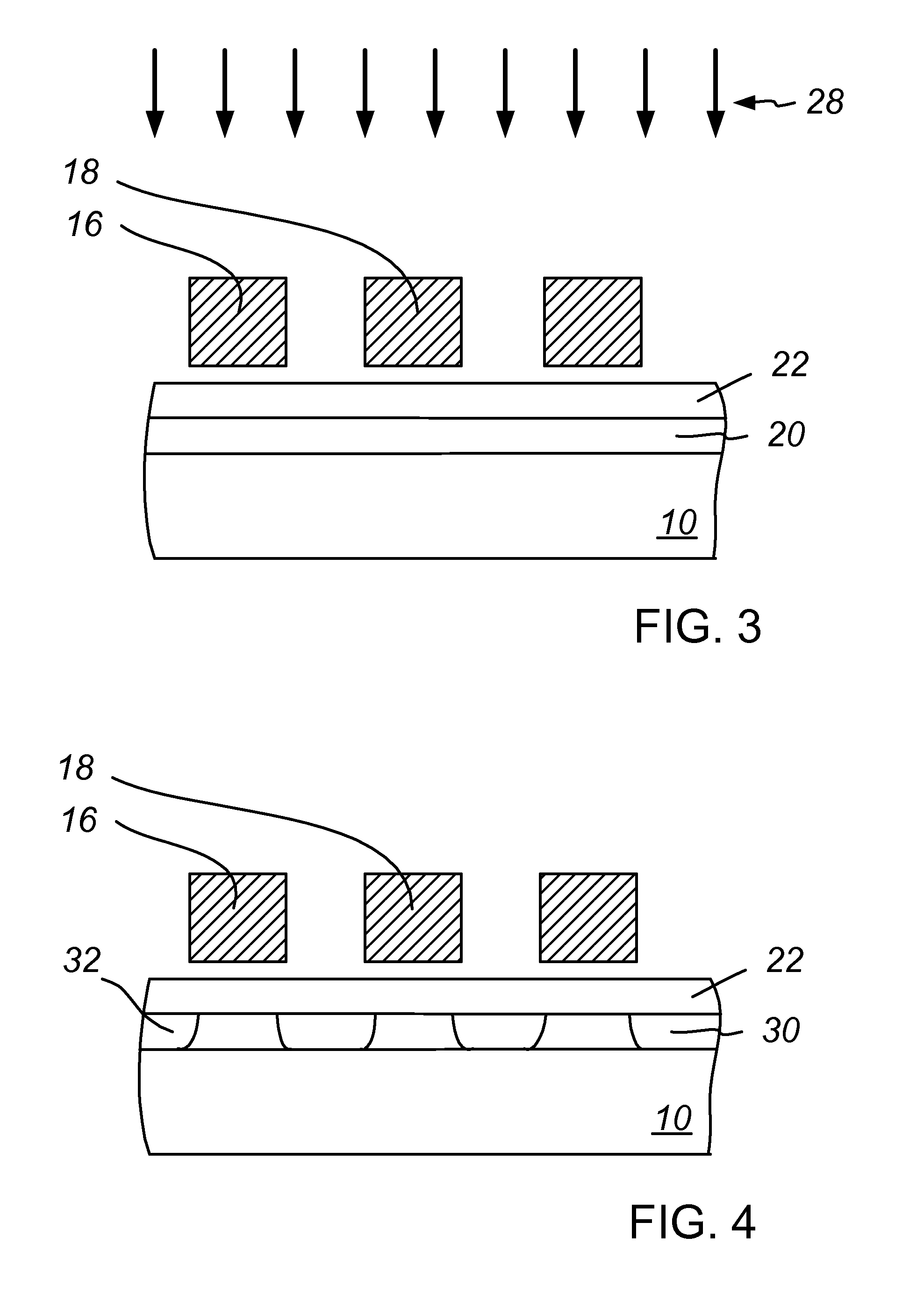

Biaxial Strained Field Effect Transistor Devices

ActiveUS20110230026A1Semiconductor/solid-state device detailsSolid-state devicesDielectricSurface layer

A process for forming contacts to a field effect transistor provides edge relaxation of a buried stressor layer, inducing strain in an initially relaxed surface semiconductor layer above the buried stressor layer. A process can start with a silicon or silicon-on-insulator substrate with a buried silicon germanium layer having an appropriate thickness and germanium concentration. Other stressor materials can be used. Trenches are etched through a pre-metal dielectric to the contacts of the FET. Etching extends further into the substrate, through the surface silicon layer, through the silicon germanium layer and into the substrate below the silicon germanium layer. The further etch is performed to a depth to allow for sufficient edge relaxation to induce a desired level of longitudinal strain to the surface layer of the FET. Subsequent processing forms contacts extending through the pre-metal dielectric and at least partially into the trenches within the substrate.

Owner:ACORN TECH INC

Device and method for measuring strain

ActiveCN102087101AEasy to measureEasy to operateMaterial nanotechnologyNanosensorsCarbon nanotubeStrain gauge

The invention provides a device for measuring strain. The device for measuring the strain comprises a strain gauge, a clamping device, and a transverse strain recorder, wherein the clamping device is used for clamping and extending the strain gauge, the longitudinal strain of the strain gauge is generated in the extension direction, and the transverse strain of the strain gauge is generated in the direction vertical to the extension direction; the transverse strain recorder is used for measuring the transverse strain of the strain gauge; the strain gauge comprises a carbon nano tube membrane structure which comprises a plurality of carbon nano tubes; the carbon nano tubes are arranged along the preferred orientations of a first direction and a second direction, and the carbon nano tubes which are directionally arranged along the preferred orientation of the first direction and the carbon nano tubes which are arranged along the directional preferred orientation of the second direction are overlapped and intersected; an included angle between the first direction and the second direction is formed; the included angle is more than 0 degree and less than 180 degrees; and during using, the strain gauge is arranged on the clamping device along the direction of a bisector of the included angle between the first direction and the second direction. The invention also provides a method for measuring the strain by using the device for measuring the strain.

Owner:TSINGHUA UNIV +1

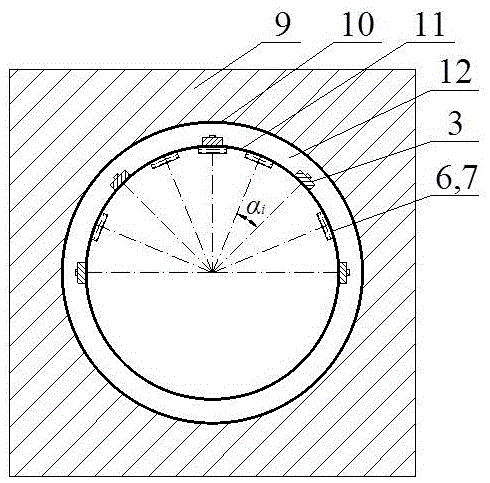

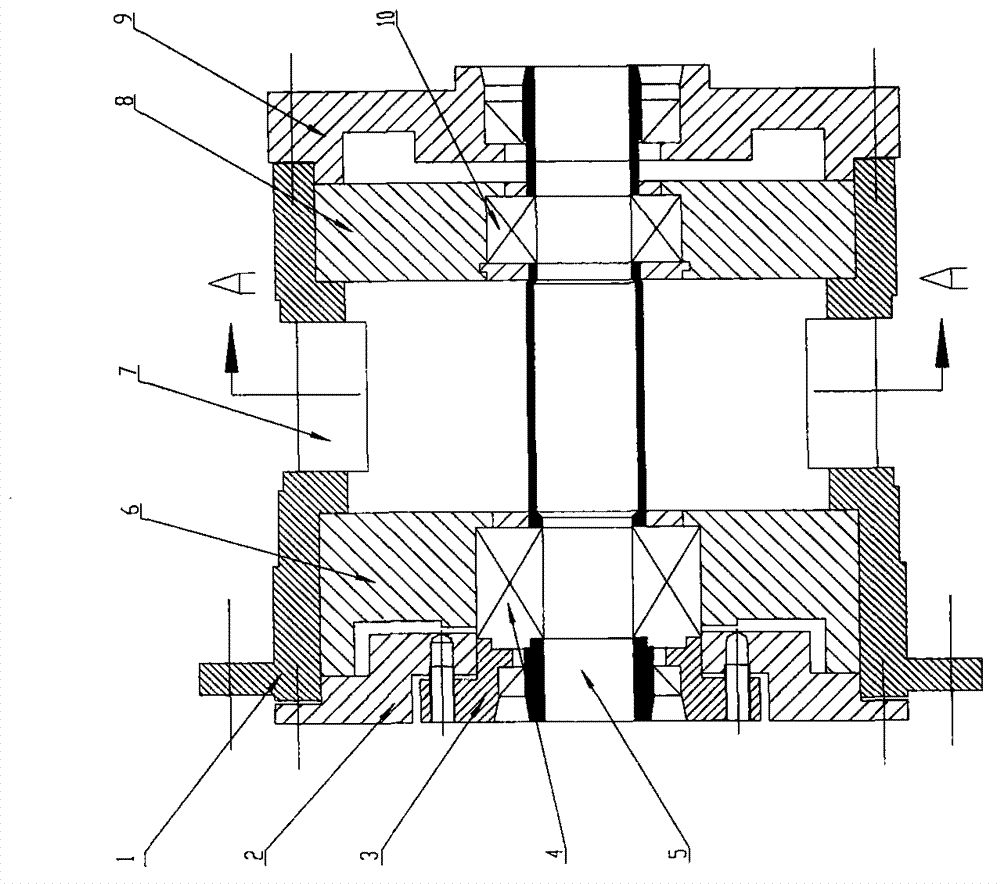

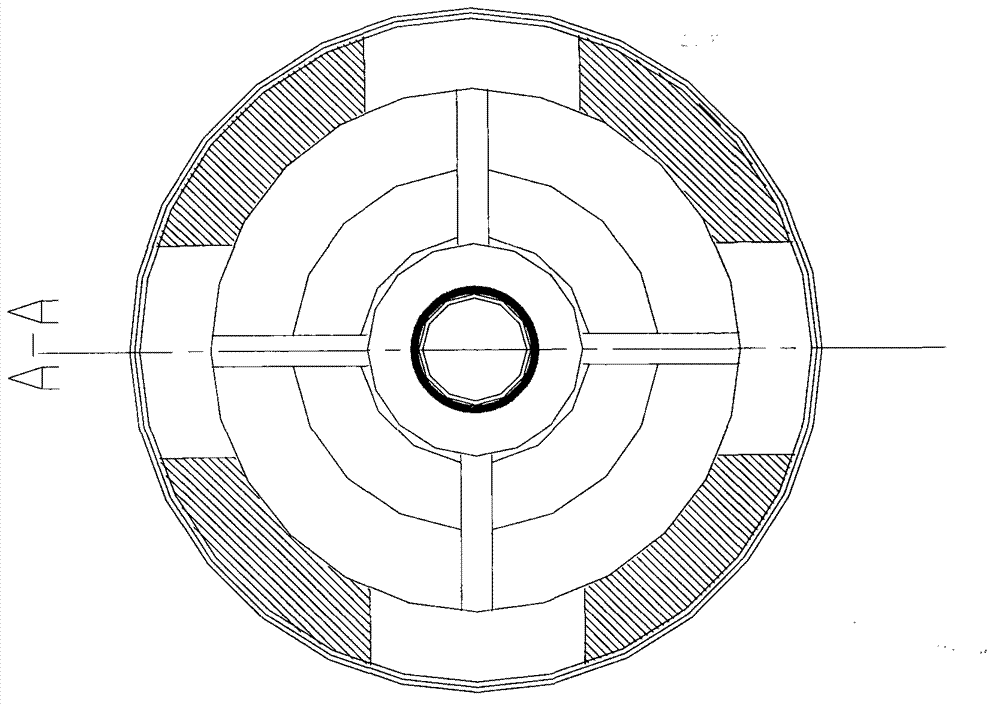

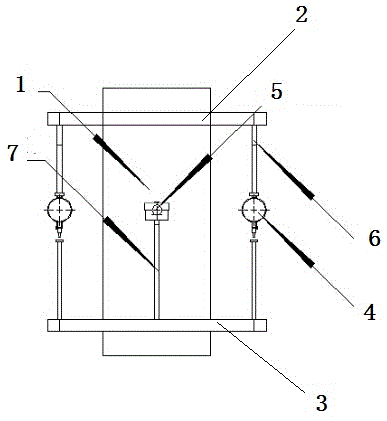

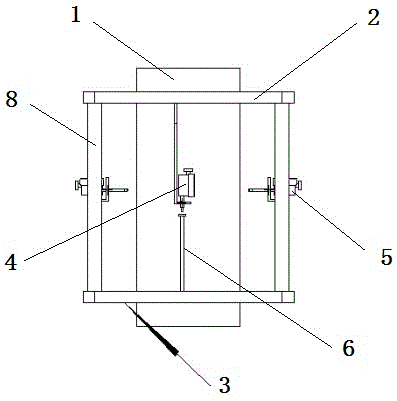

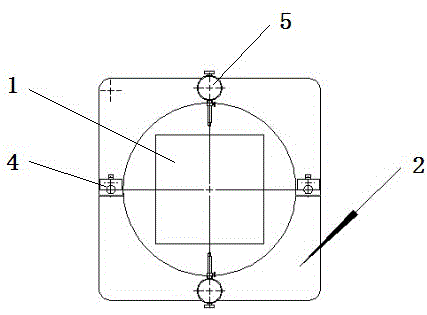

Device for measuring radial force of transient-state hydraulic power of centrifugal pump and measuring method thereof

ActiveCN102901598ASimple structureLow priceApparatus for force/torque/work measurementForce/torque/work measurement apparatus calibration/testingTransient stateMeasurement device

The invention provides a device for measuring radial force of transient-state hydraulic power of a centrifugal pump and a measuring method thereof, and discloses a measuring device. The measuring device comprises a shell 1, a back fixed ring 2, a compaction plate 3, a tight bearing 4, a shaft cavity 5, tight bearing elastic supports 6, an operation hole 7, loosened bearing elastic supports 8, a loosened bearing 9 and a front fixed ring 10, wherein outer rings of the tight bearing 4 and the loosened bearing 9 are connected and fixed with the shell 1 of the device by four elastic supports 6 and 8 respectively; the elastic supports are distributed at intervals of 90 degrees; a longitudinal strain plate and a transverse strain plate are respectively arranged on each side; for calibration, an object of which the mass is known is placed at the front end of a pump shaft, output signals of a circuit are amplified, acquired and output in a combined mode, and data of the device in each direction are recorded. The mass of the object arranged at the front end of the pump shaft is changed and is measured for many times by using the same method, so that the calibration of the device and the conversion of a measuring value are realized.

Owner:JIANGSU UNIV

Method of testing Poisson's ratio of concrete

ActiveCN104931352AEasy and fast testingAvoiding the pitfalls of lossy strain gaugesMaterial strength using tensile/compressive forcesConversion coefficientsStructural engineering

The invention relates to a method of testing Poisson's ratio of concrete. The method includes: performing testing by pressurizing in static elastic modulus test, selecting a concrete specimen of specified size, selecting a specified test area on the concrete specimen and a test scheme, placing transverse strain gauges at the centers of two opposing sides of the concrete specimen, placing longitudinal strain gauges at positions, determined distances away from the upper and lower end faces, on two longitudinal sides of the concrete specimen, precisely measuring and recording transverse deformation and longitudinal deformation, and calculating the Poisson's ratio of the concrete through the transverse deformation, the longitudinal transformation and a conversion coefficient. The method has the advantages that measuring is precise and fast, testing cost is lowered and repeatability is good.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

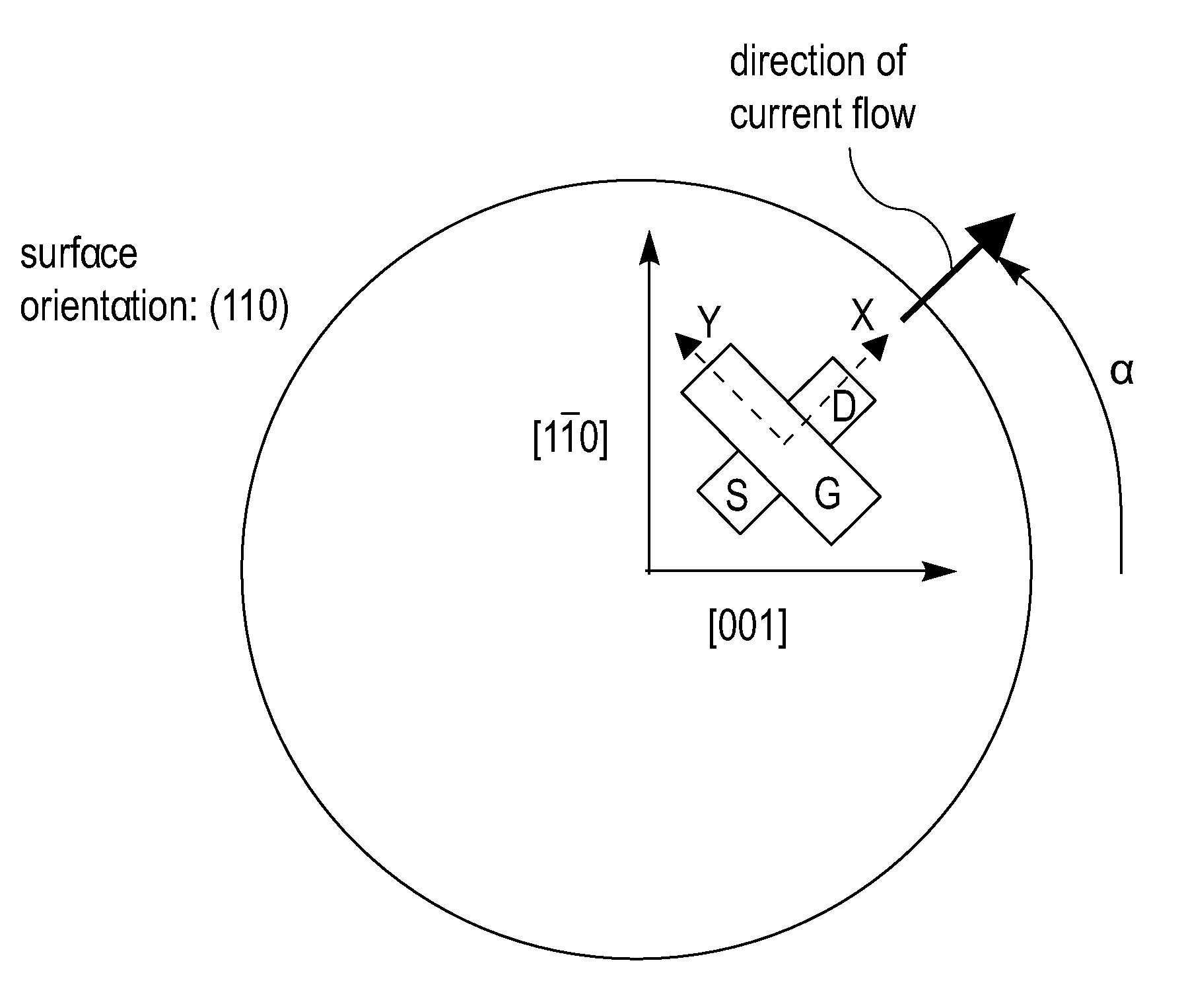

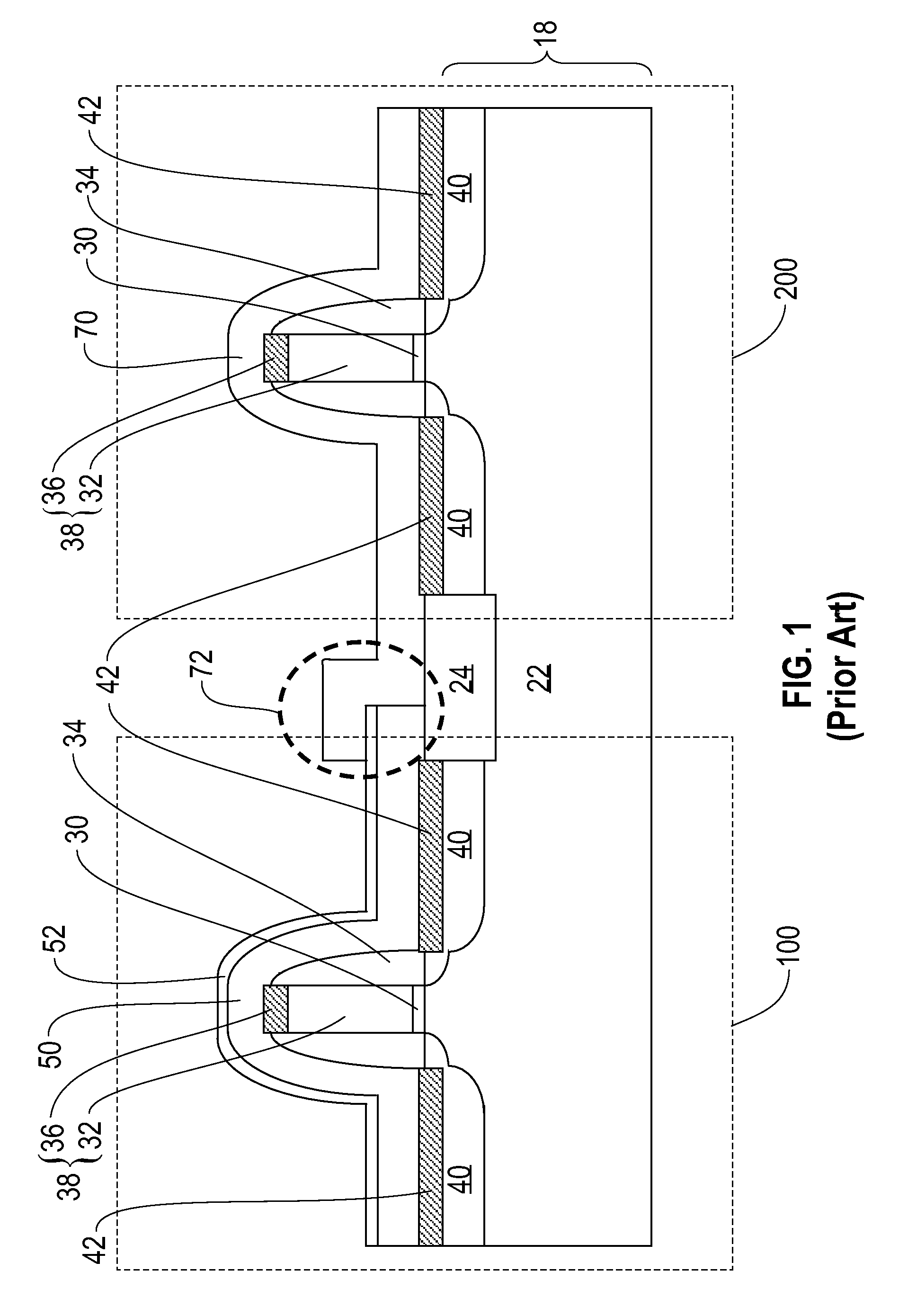

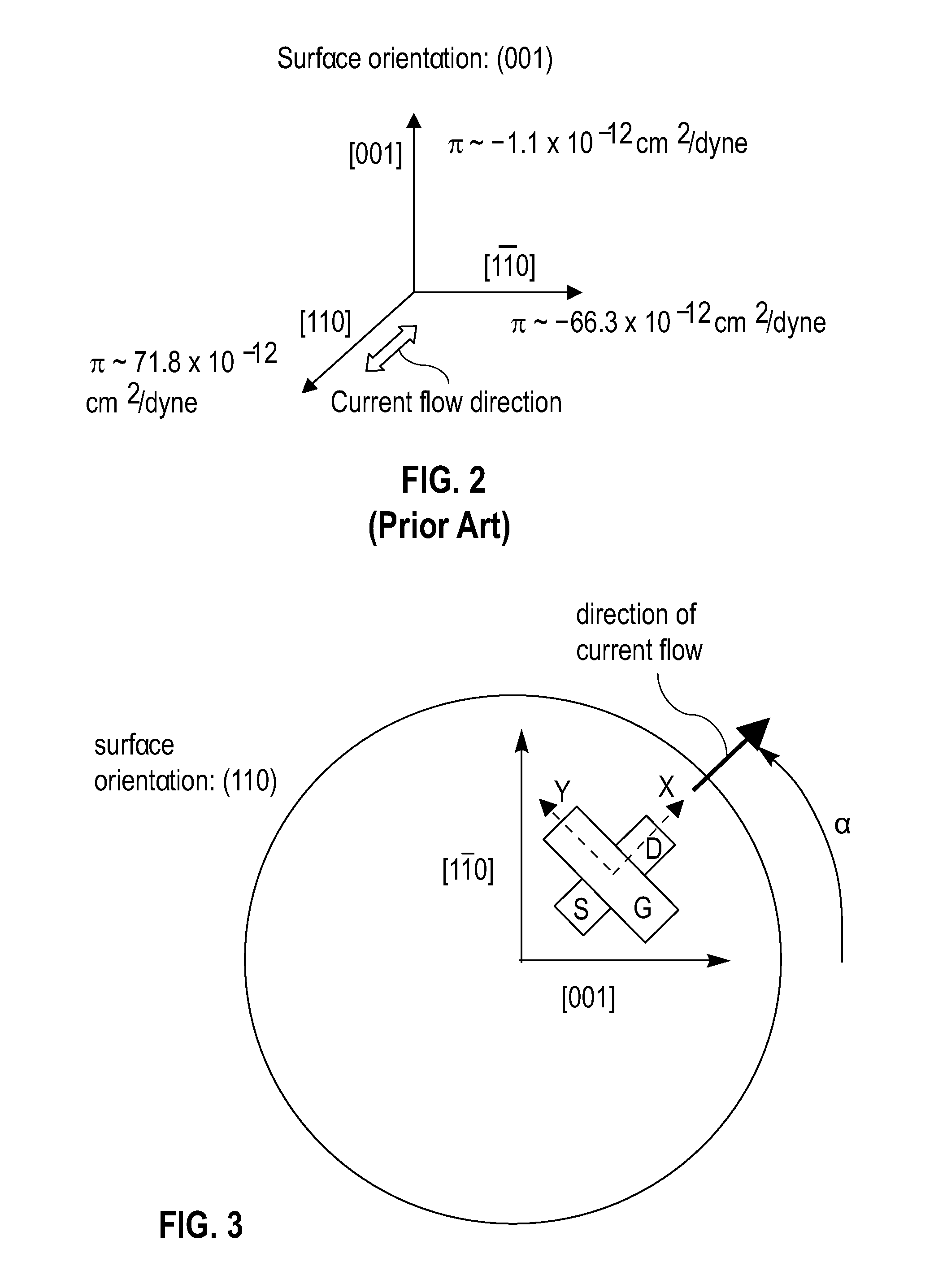

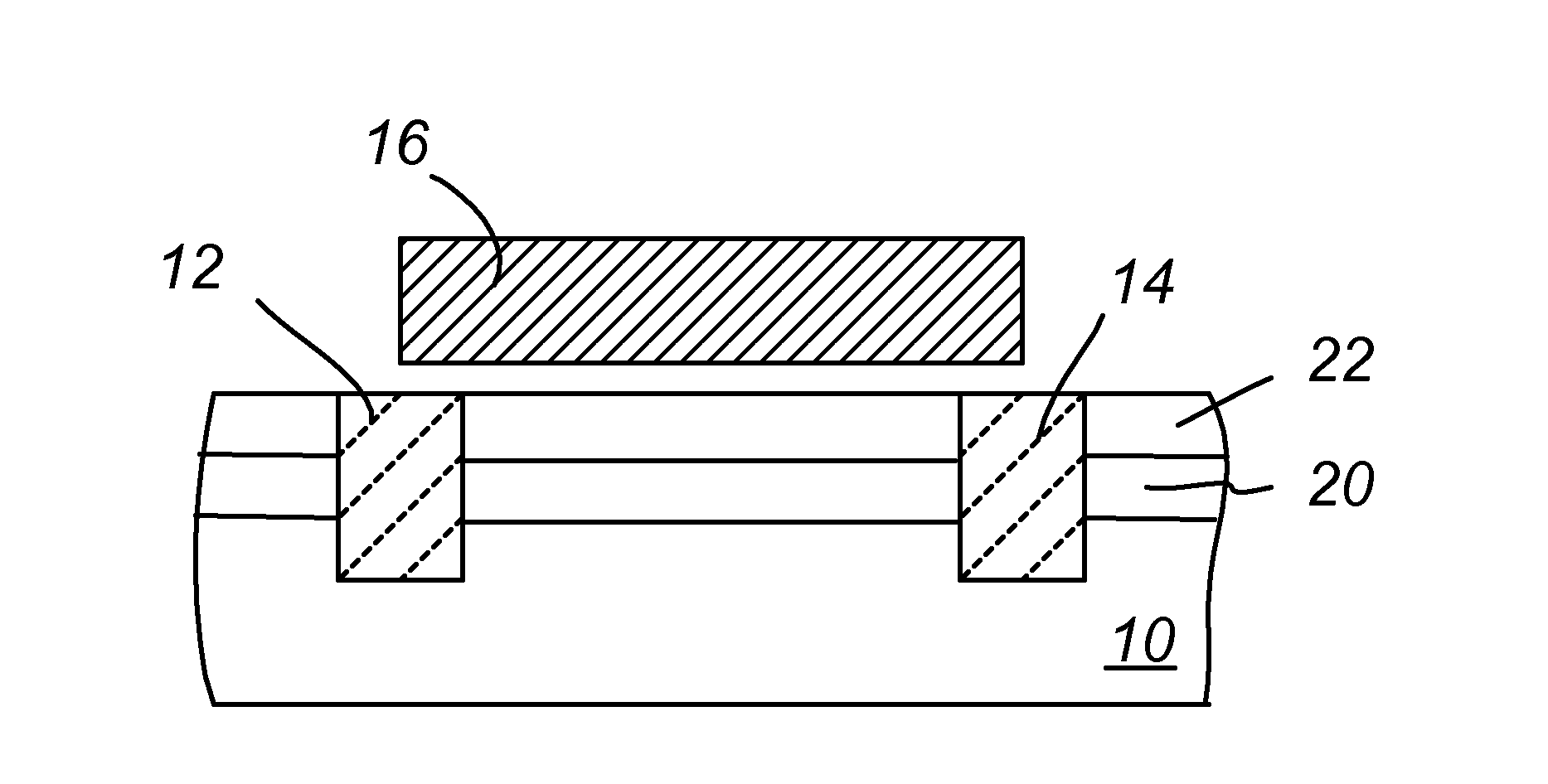

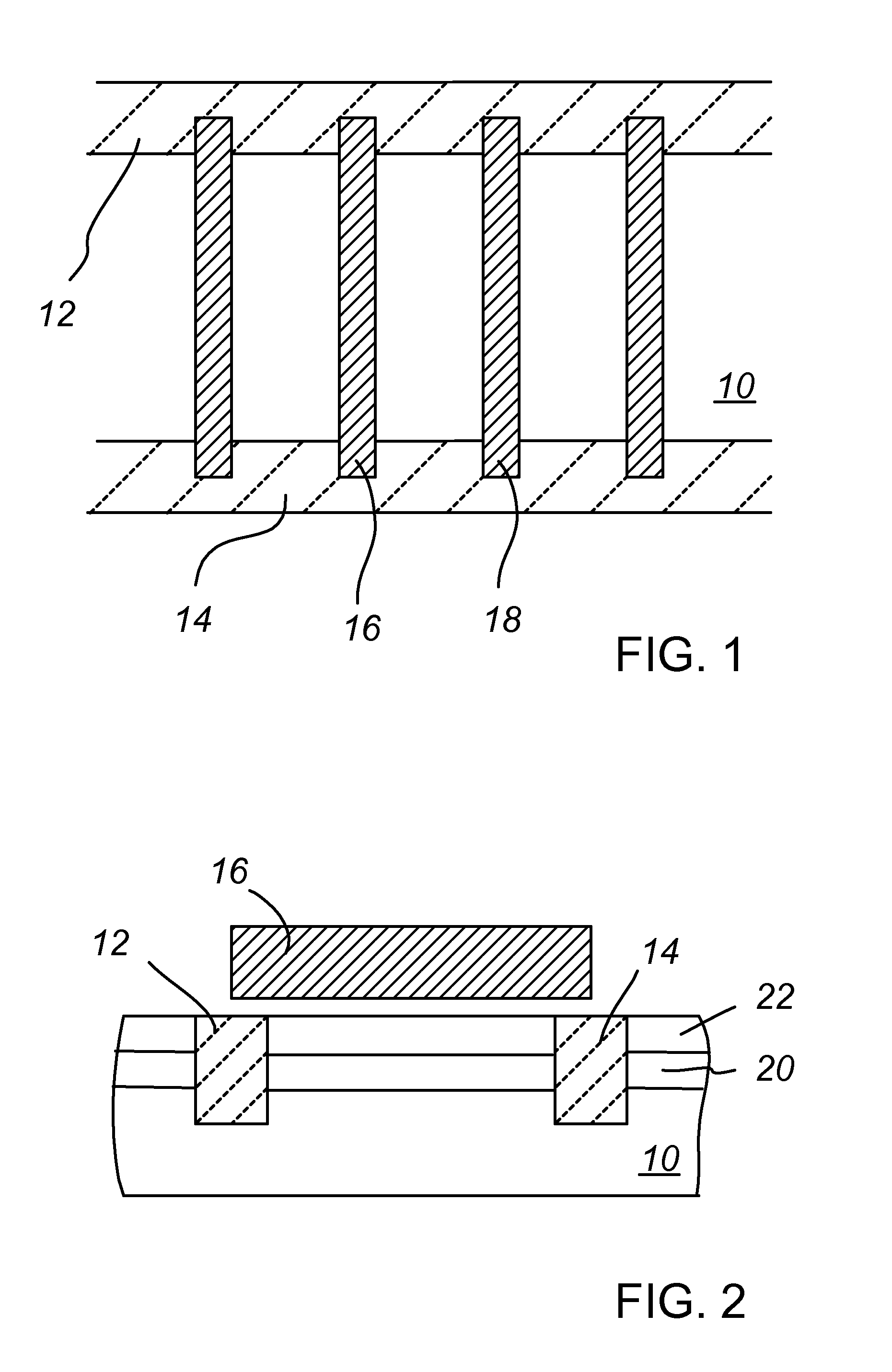

Orientation-optimized pfets in CMOS devices employing dual stress liners

InactiveUS20090065867A1Minimize tensile stressBig advantageSolid-state devicesSemiconductor/solid-state device manufacturingCMOSTensile strain

A PFET is provided on a silicon layer having a (110) surface orientation and located in a substrate. A compressive stress liner disposed on the gate and source / drain regions of the PFET generates a primary longitudinal compressive strain along the direction of the PFET channel. A tensile stress liner disposed on at least one NFET located transversely adjacent to the PFET generates a primary longitudinal tensile strain along the direction of the NFET channel. A secondary stress field from the at least one NFET tensile liner generates a beneficial transverse tensile stress in the PFET channel. The net benefits of the primary compressive longitudinal strain and the secondary tensile transverse stress are maximized when the azimuthal angle between the direction of the PFET channel and an in-plane [1 10] crystallographic direction in the (110) silicon layer is from about 25° to about 55.

Owner:GLOBALFOUNDRIES INC

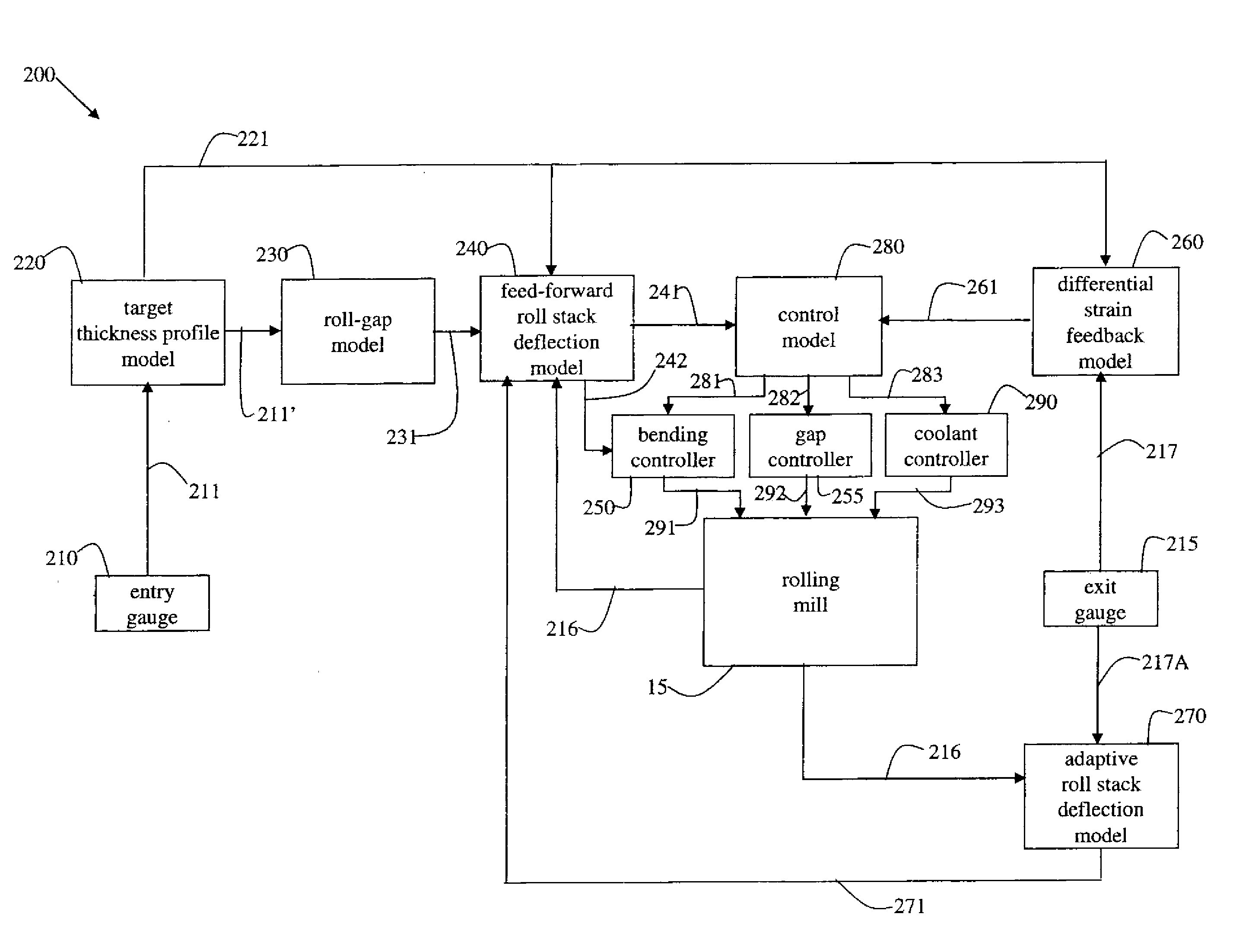

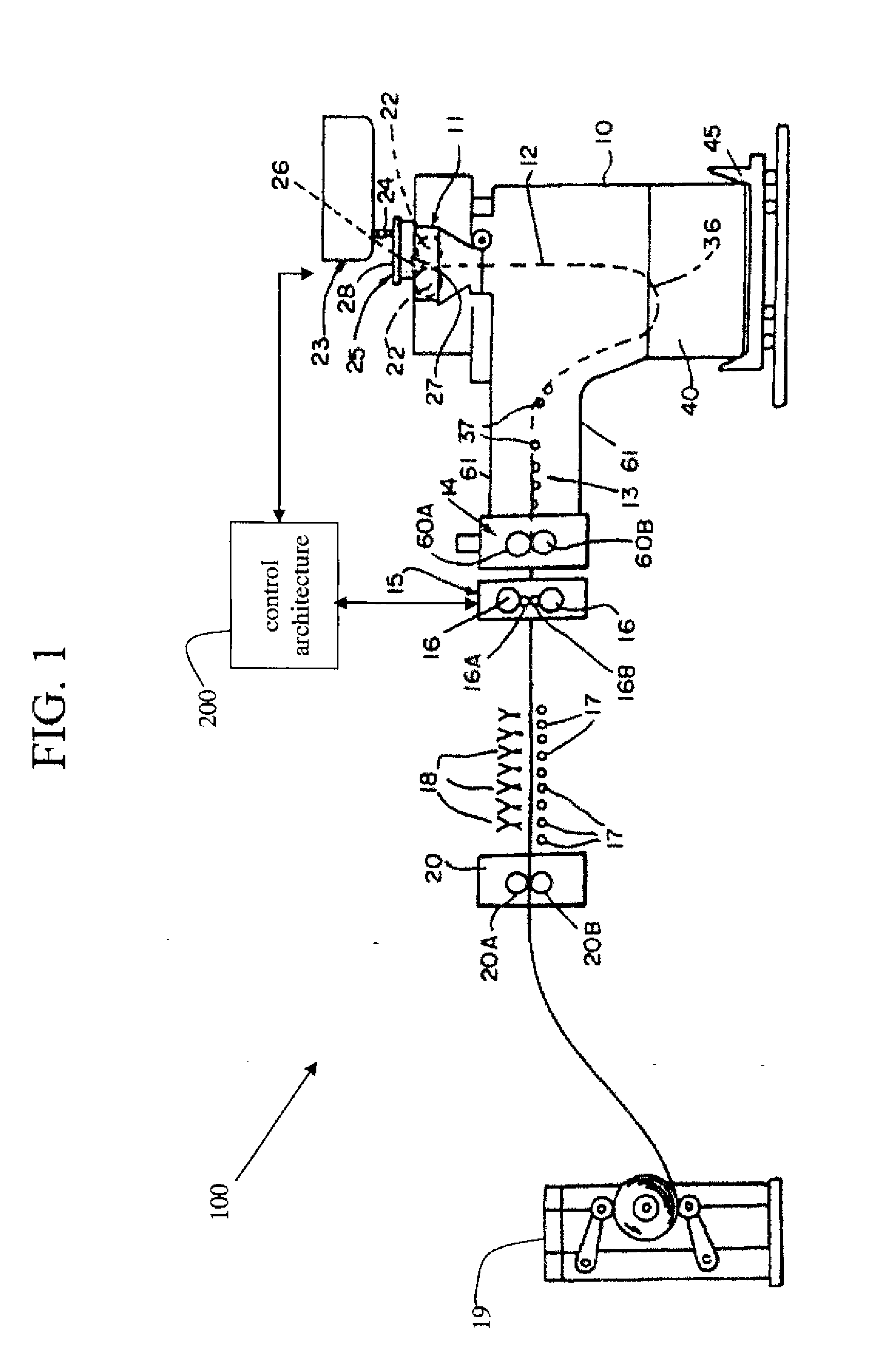

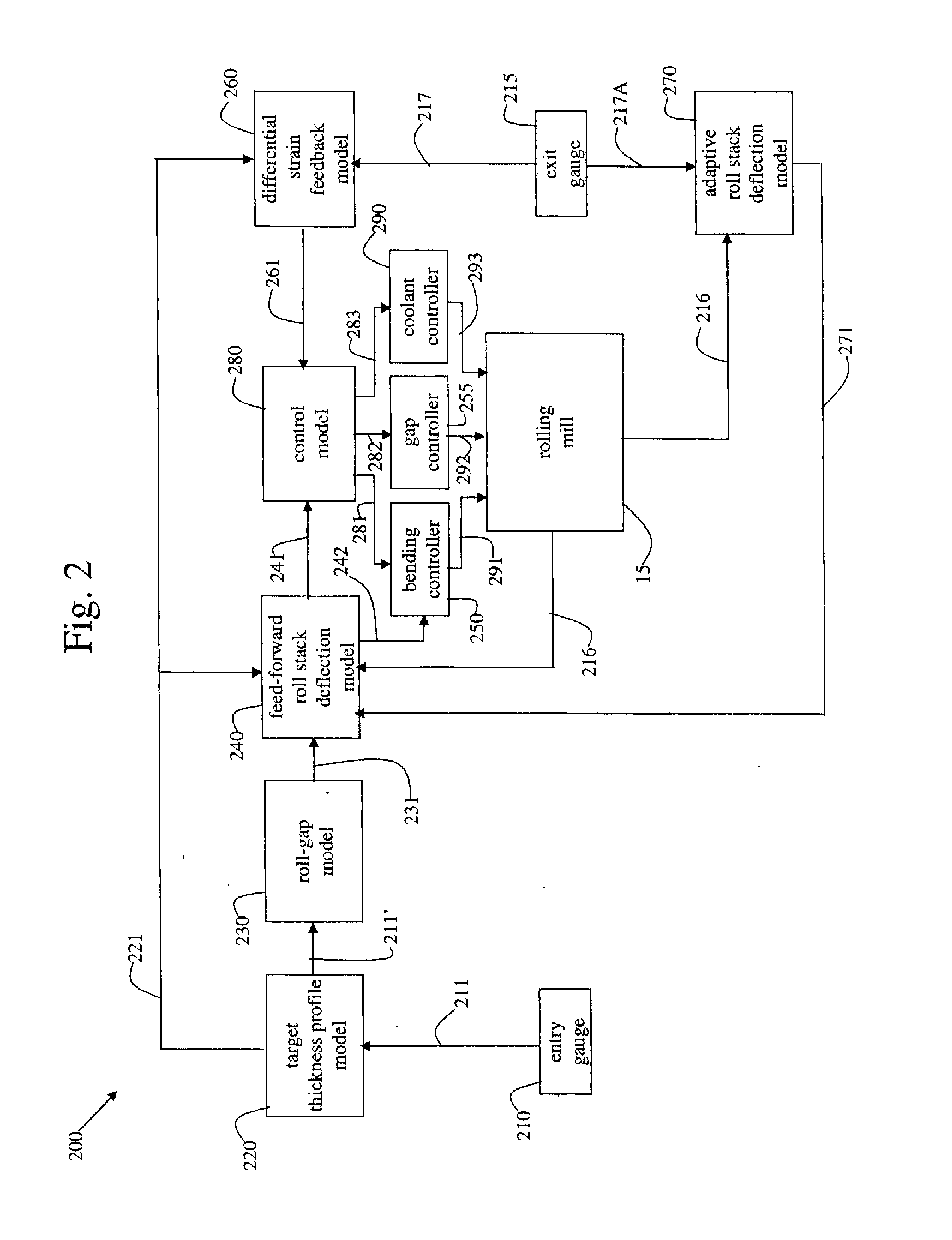

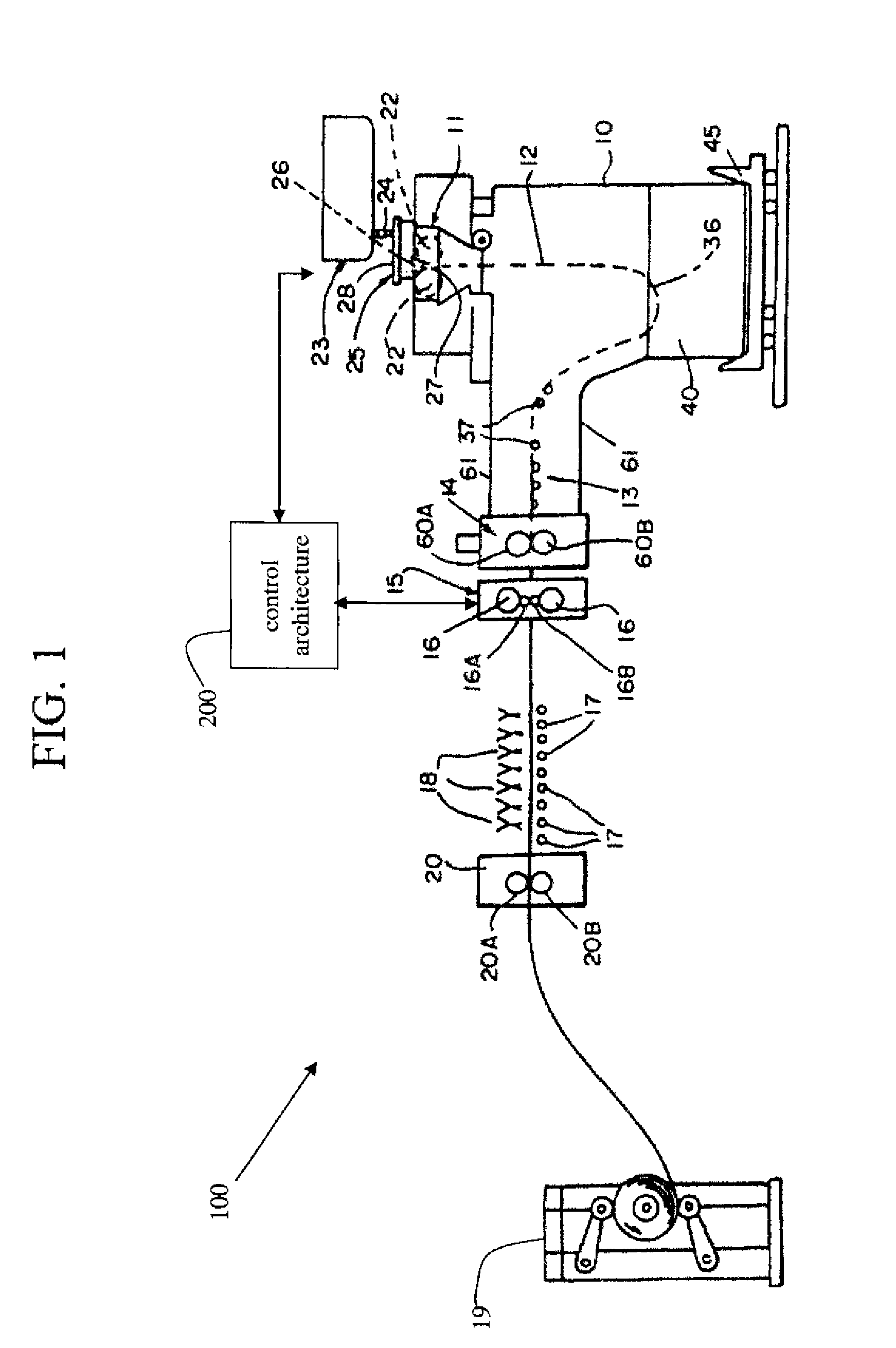

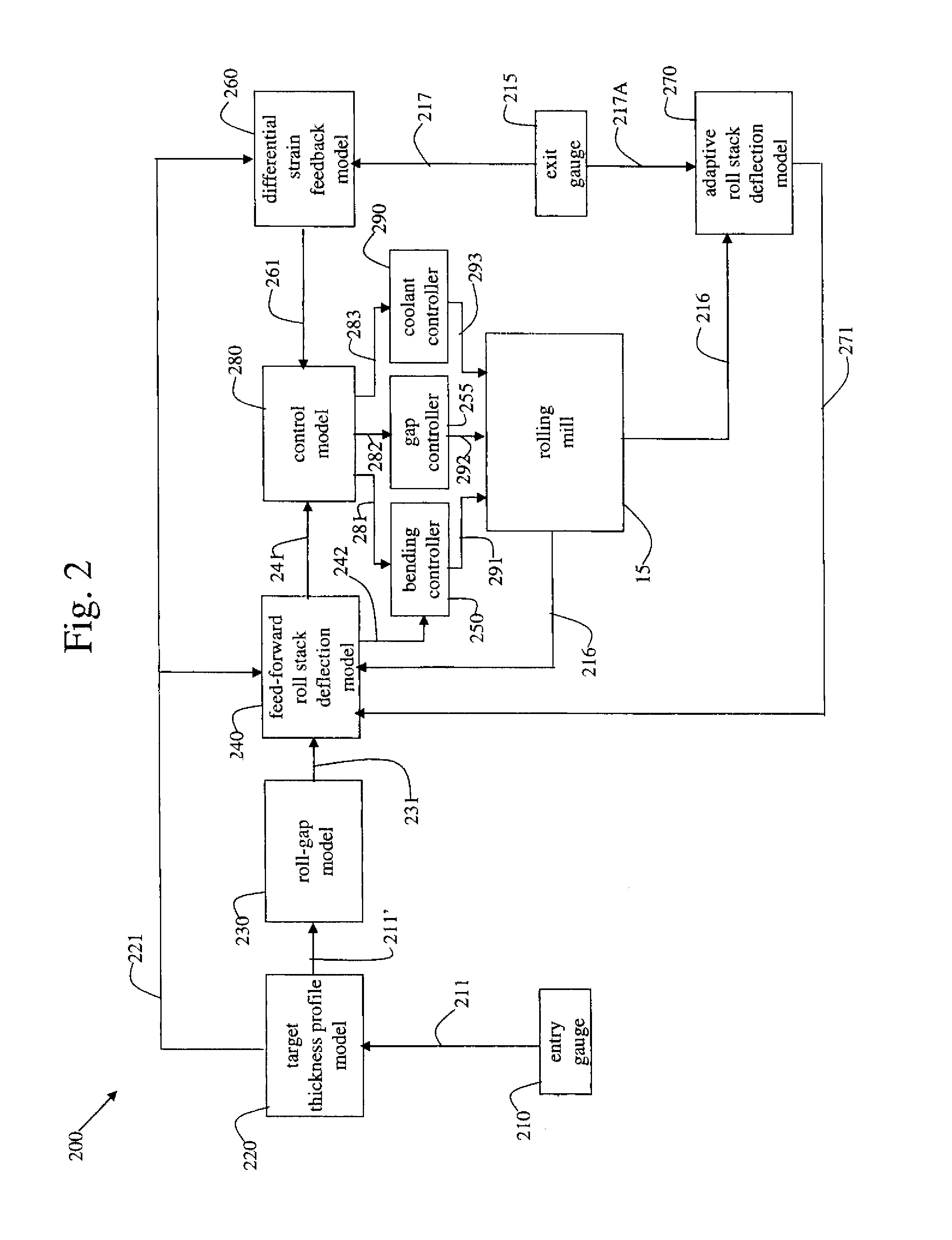

Method and plant for integrated monitoring and control of strip flatness and strip profile

ActiveUS20070220939A1Reduce tensionSusceptible to bucklingRoll force/gap control deviceMetal rolling stand detailsIntegrated monitoringControl signal

Apparatus and method of controlling strip geometry in casting strip having a rolling mill. A target thickness profile is calculated as a function of the measured entry thickness profile of the strip while satisfying profile and flatness operating requirements. A differential strain feedback from longitudinal strain in the strip is calculated by a control system by comparing the exit thickness profile with the target thickness profile, and a control signal is generated to control a device capable of affecting the geometry of the strip processed by the hot rolling mill. A feed-forward control reference and / or sensitivity vector may also be calculated as a function of the target thickness profile, and used in generating the control signal sent to the control device. The control device may be selected from one or more of the group consisting of a bending controller, gap controller and coolant controller.

Owner:NUCOR CORP

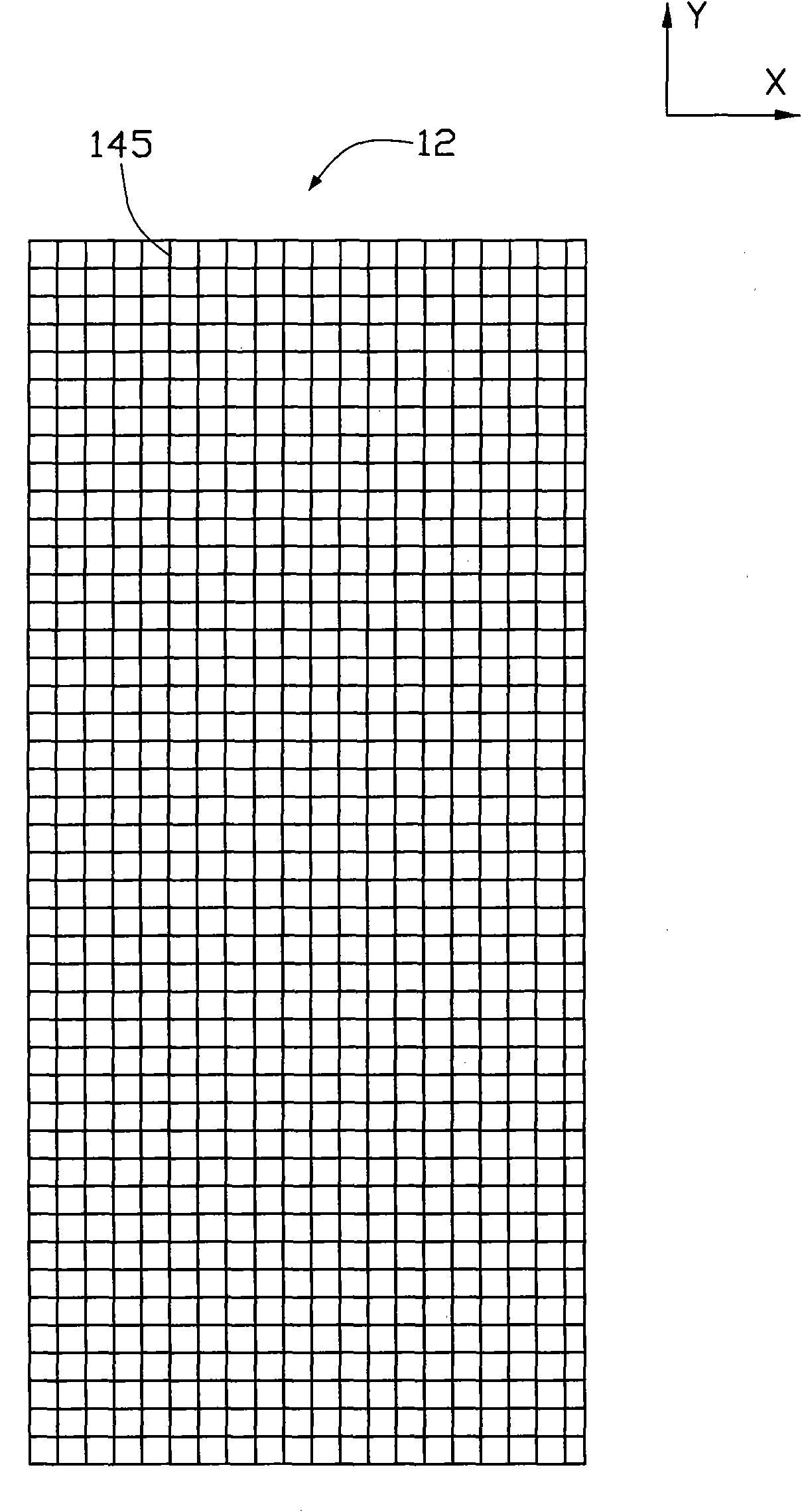

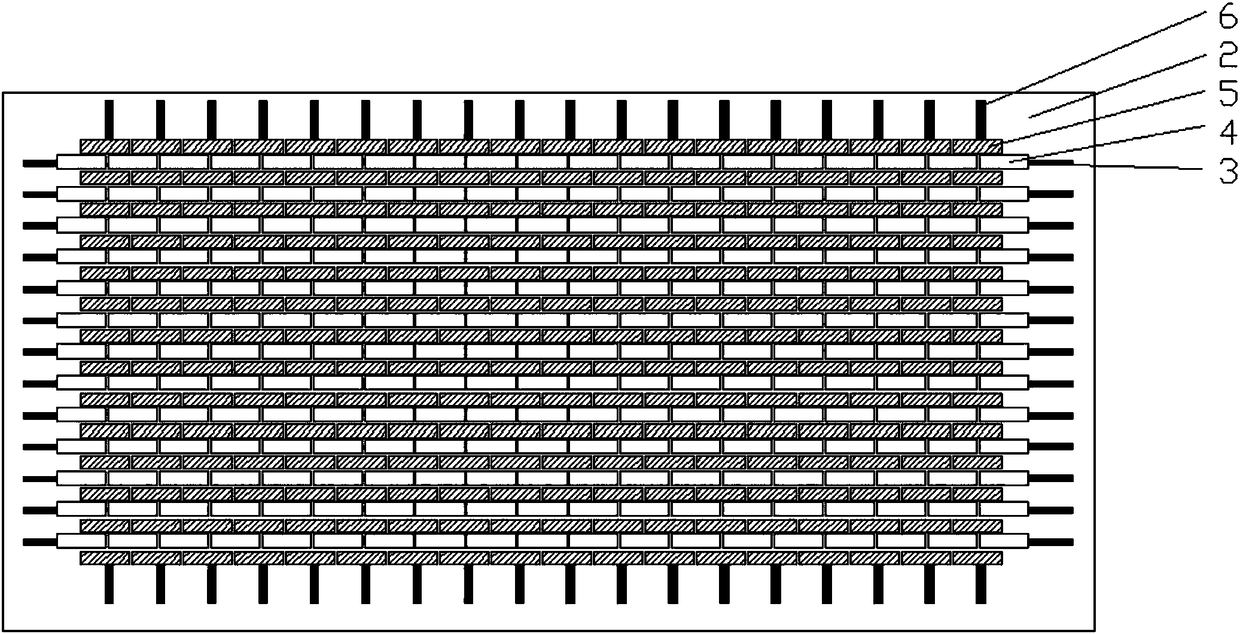

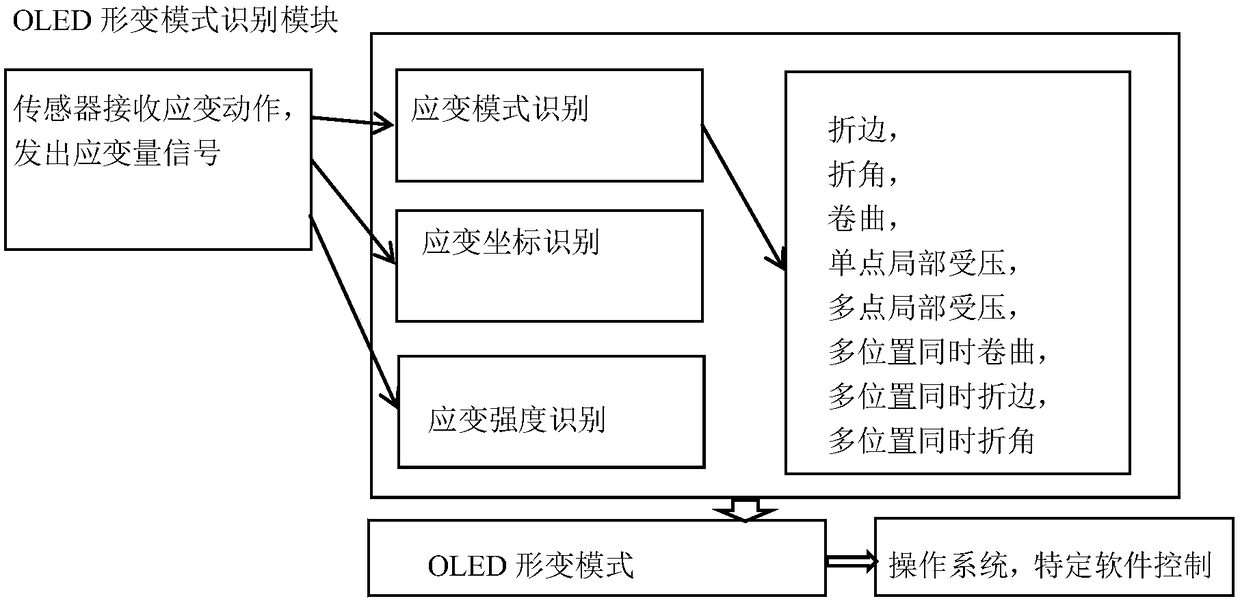

Flexible display deformation sensing system

ActiveCN108571925AElectrical/magnetic solid deformation measurementIdentification meansSensor arrayDisplay device

The invention relates to a flexible OLED (Organic Light Emitting Diode) display deformation sensing system, which comprises a sensor substrate layer attached to the back of a flexible display, whereinthe sensor substrate layer is provided with a sensor array layer, and the sensor array layer is provided with a plurality of leading-out wires. The sensor array layer comprises a strain sensor matrixformed by a transverse array and a longitudinal array, wherein the transverse array is composed of a plurality of transverse strain sensors, the longitudinal array is composed of a plurality of longitudinal strain sensors, each transverse strain sensor is provided with a transverse leading-out wire, and each longitudinal strain sensor is provided with a longitudinal leading-out wire. The transverse array sensor capture longitudinal strain point coordinates and strain values, and the longitudinal array sensors capture transverse strain point coordinates and strain values. The sensor layer cancapture a deformation mode and a deformation device of the display screen in real time. The flexible deformation action of the OLED display is captured into a digital signal so as to be used for controlling the display, a data interaction action and other control actions.

Owner:上海敏传智能科技有限公司

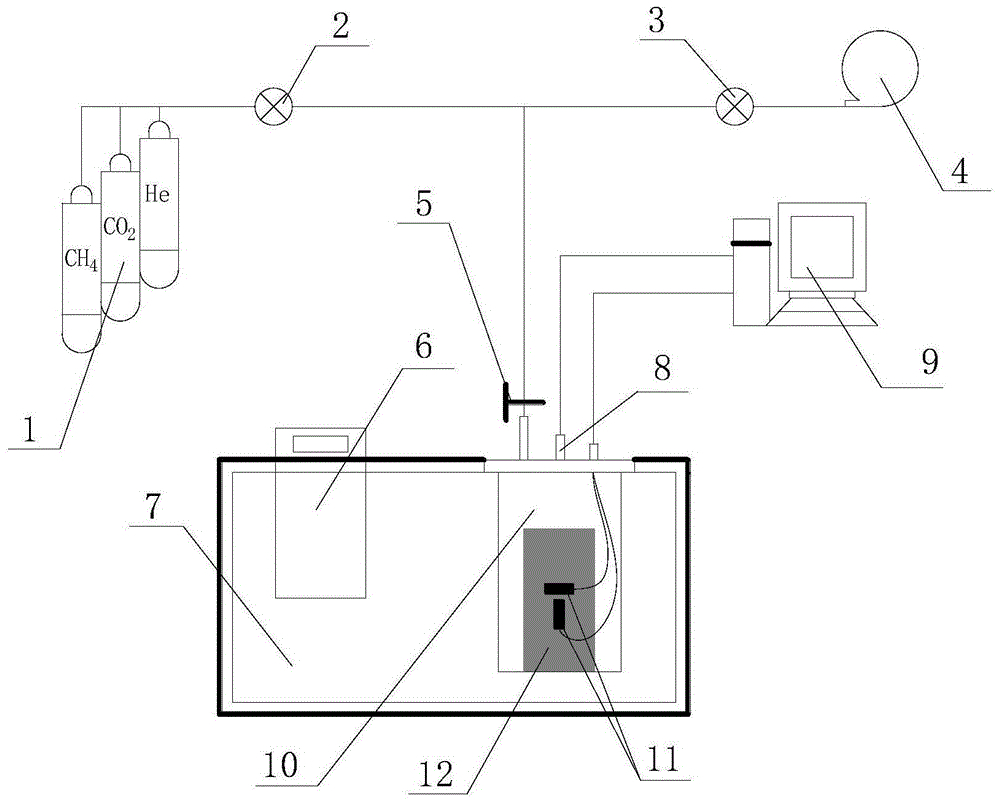

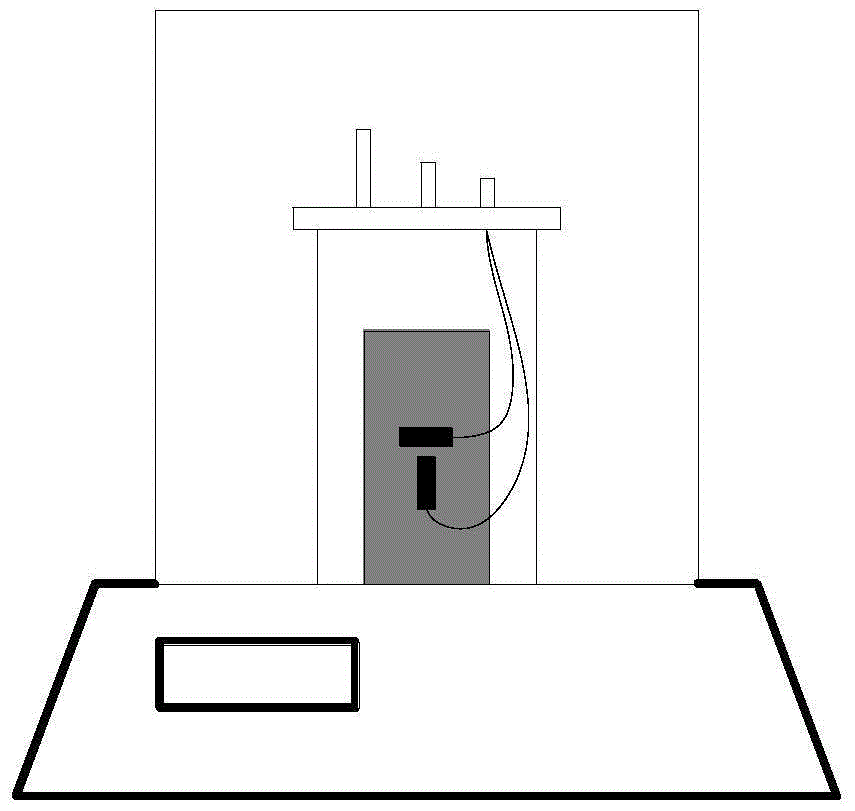

Test method for measuring rock mass constant temperature adsorption and monitoring rock mass strain and instrument

InactiveCN105043920AAvoiding Difficulties in High-Precision CalibrationImprove reliabilityStrength propertiesWeighing by absorbing componentAdsorption equilibriumParticle size measurement

Belonging to testing methods and instruments for rock mass constant temperature and rock mass strain, the invention relates to a test method for measuring rock mass constant temperature adsorption and monitoring rock mass strain and an instrument. According to the test method, rock mass constant temperature adsorption capacity is measured by an indirect gravitational method, at the same time, transverse and longitudinal strain gauges can be pasted to a side of a tested sample, the strain condition of the rock sample is monitored while the rock sample reaches adsorption equilibrium, thus being convenient to analyze the relation between rock mass adsorption and rock mass microscopic stress. A plurality of adsorption tanks are added, also adsorption test is carried out on rock samples in different particle size ranges at the same time, the rock mass sample particle size measurement range is wide, and the particle size test range covers 100micrometer-20mm. The test method calculates the sample adsorbing capacity by high precision balance weighing, which is different from the previous volumetric method for measurement of adsorbing capacity. The method can be used for determining the adsorbing capacity of rock to gas in laboratories, test enterprises and government departments. The test instrument is single, has few joints, enhances the system airtightness, and has the characteristics of simple operation, simple and reliable calculation method, and high accuracy.

Owner:CHINA UNIV OF MINING & TECH

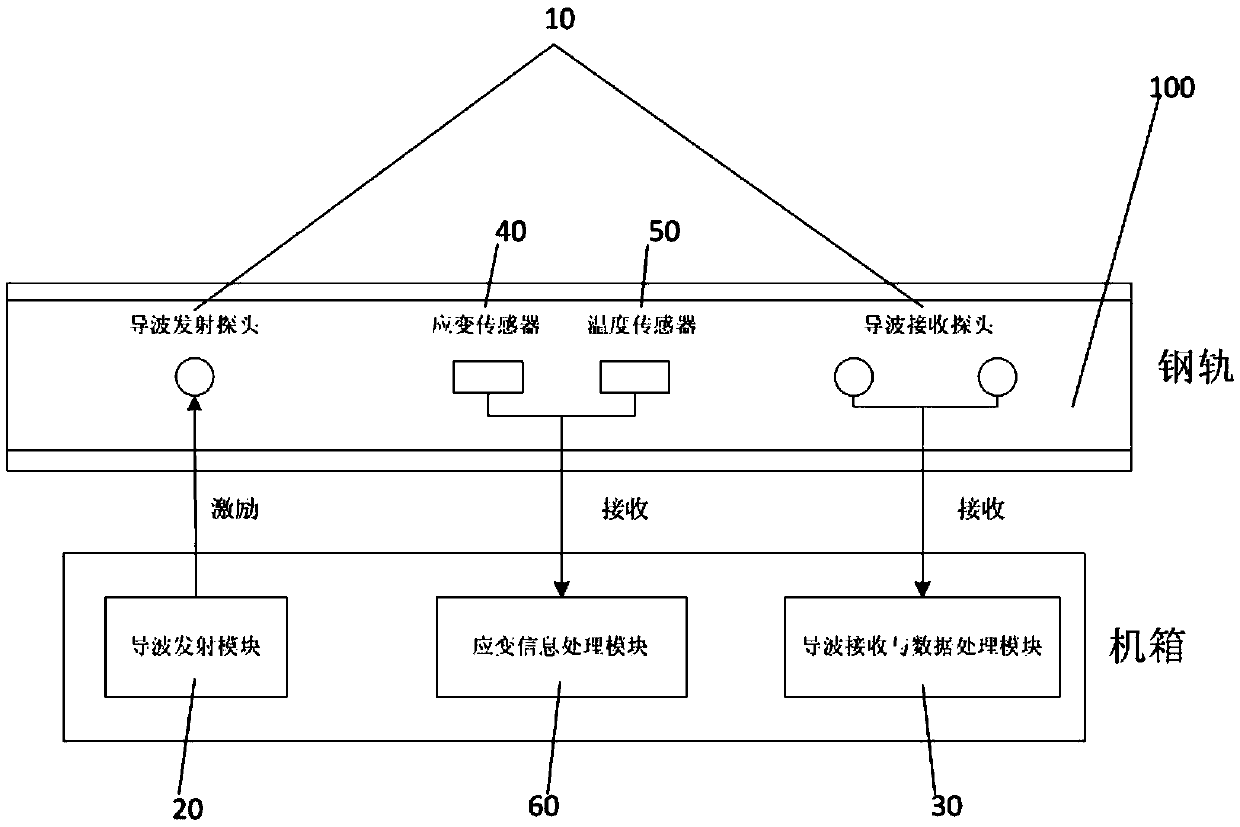

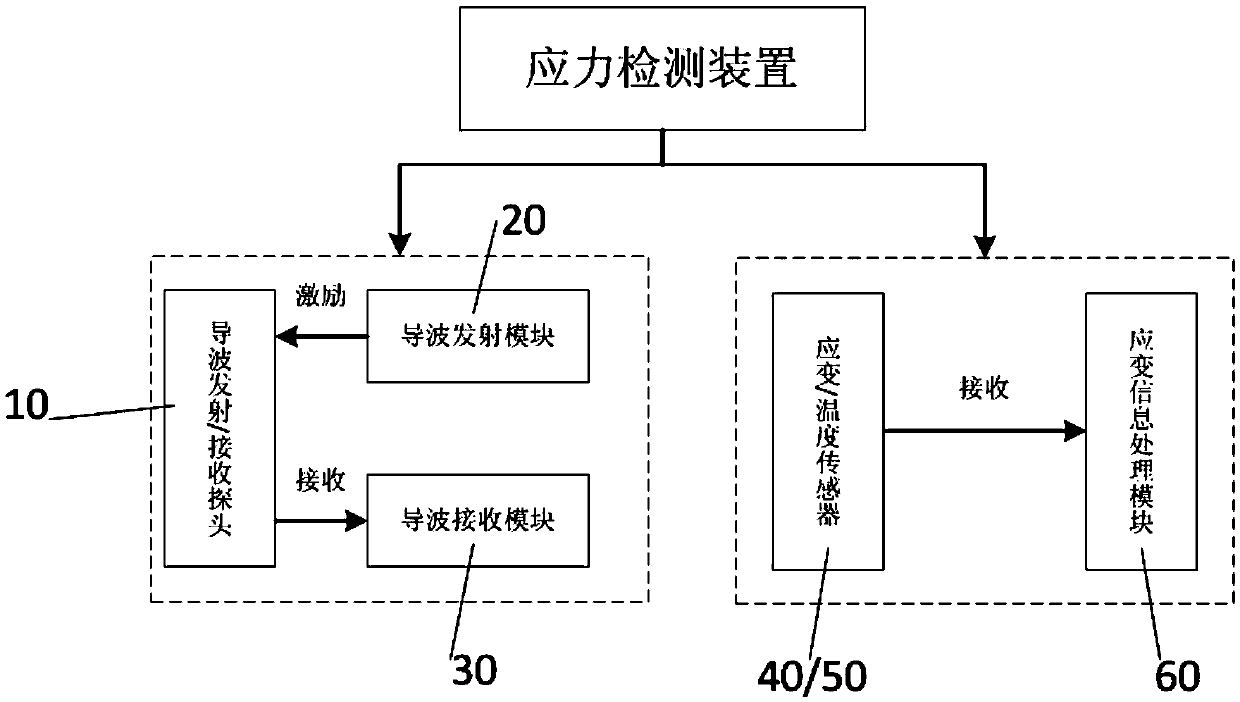

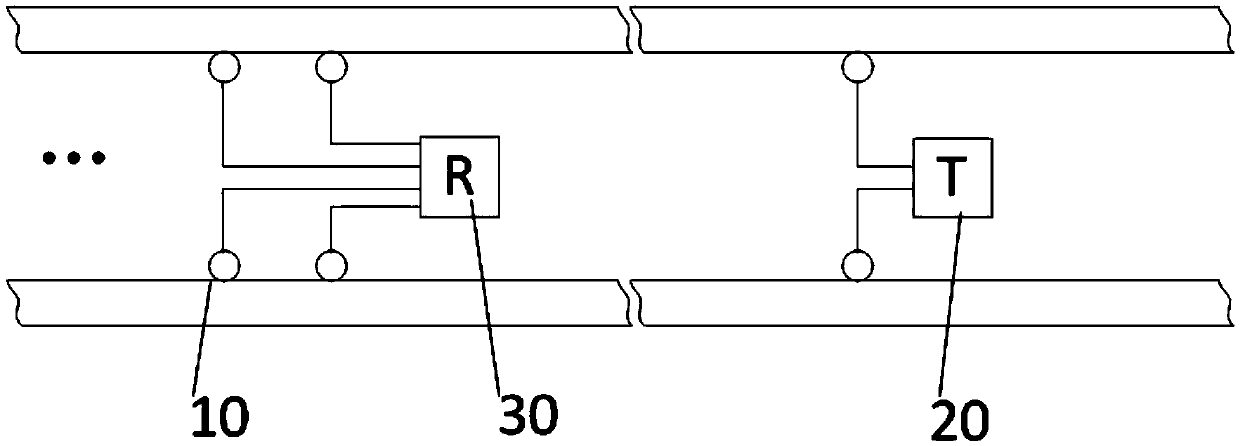

Seamless steel rail stress detection device and method based on ultrasonic guided waves and strain gauge

ActiveCN105564459ASimplify the calibration processReal-time precise measurementRailway auxillary equipmentRailway profile gaugesInformation processingUltrasonic guided wave

The invention provides a seamless steel rail stress detection device and method based on ultrasonic guided waves and a strain gauge. The device comprises guided wave group speed measurement probes, a guided wave emitting module, a guided wave receiving and data processing module, a strain sensor, a temperature sensor and a strain information processing module, wherein the probes, the strain sensor and the temperature sensor are distributed along the same steel rail, the probes and the temperature sensor are used for measuring a guided wave group speed value and a temperature value of the steel rail, the strain sensor is used for measuring a longitudinal strain value of the steel rail and measures a current strain value of the steel rail when the guided wave group speed value and the rail temperature meet a preset function relation with longitudinal stress being 0, the current strain value is taken as an initial value of the system, the rail temperature meeting the function is taken as a locked rail temperature, the temperature sensor and the strain sensor measure real-time temperature and real-time strain in actual measurement of the longitudinal stress, the real-time strain and the initial value of the system are compared, steel rail length change is obtained, the real-time temperature and the locked rail temperature are compared, then temperature change is obtained, and accordingly, a longitudinal stress value is obtained.

Owner:CHINA RAILWAYS CORPORATION +1

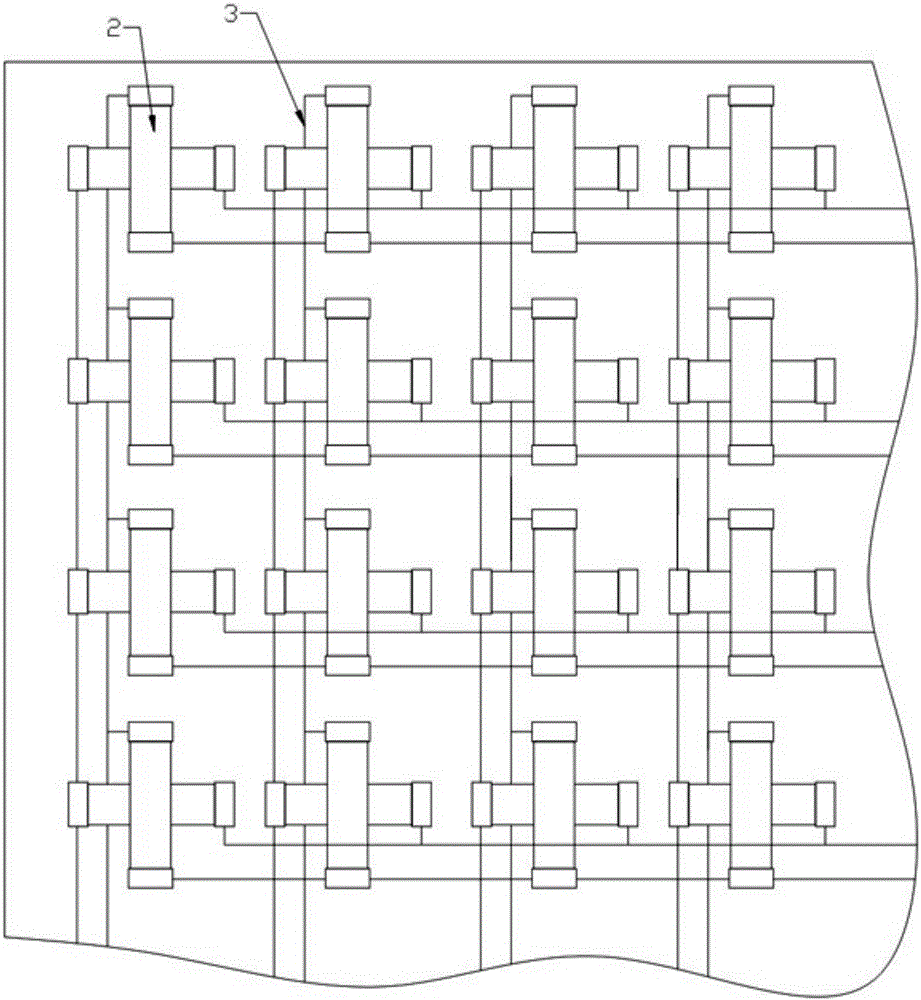

Graphene strain sensor array

The invention discloses a graphene strain sensor array. The graphene strain sensor array comprises an array circuit board and array circuits arranged on the array circuit board, and the array circuit board is provided with a plurality of graphene strain sensing units connected with the array circuits; the graphene strain sensing units are used for converting collected signals into strain values by means of a signal collecting and processing system; each graphene strain sensing unit comprises two sensing films which are arranged crisscross, wherein each sensing film is formed by attaching a graphene layer and an elastic polymer layer, and electrodes are arranged at the two ends of each sensing film. According to the graphene strain sensor array with the structure, the transverse and longitudinal strain changes can be sensed simultaneously, the application range of the sensor array is greatly widened, and therefore a graphene strain sensor achieves more diversified development.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

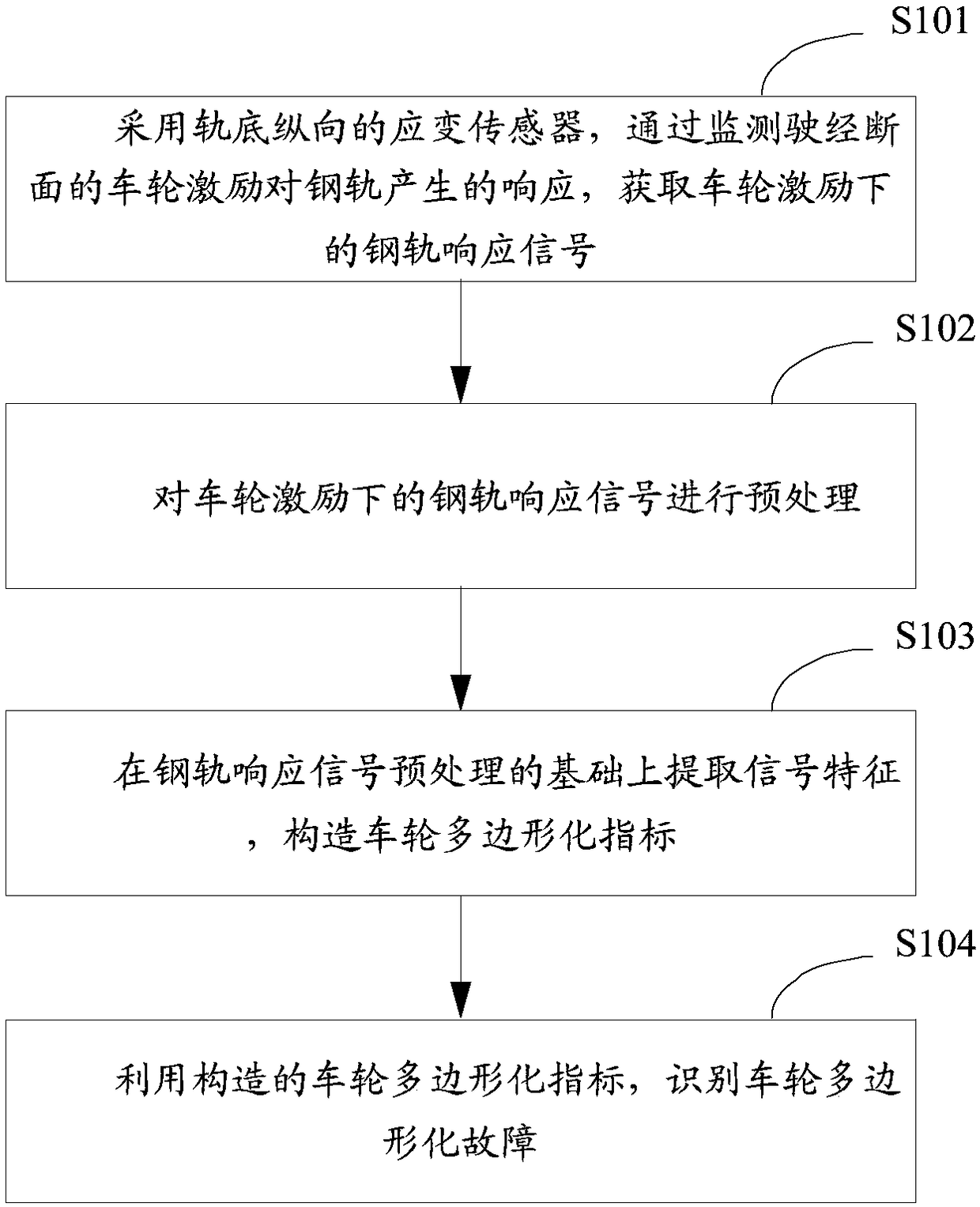

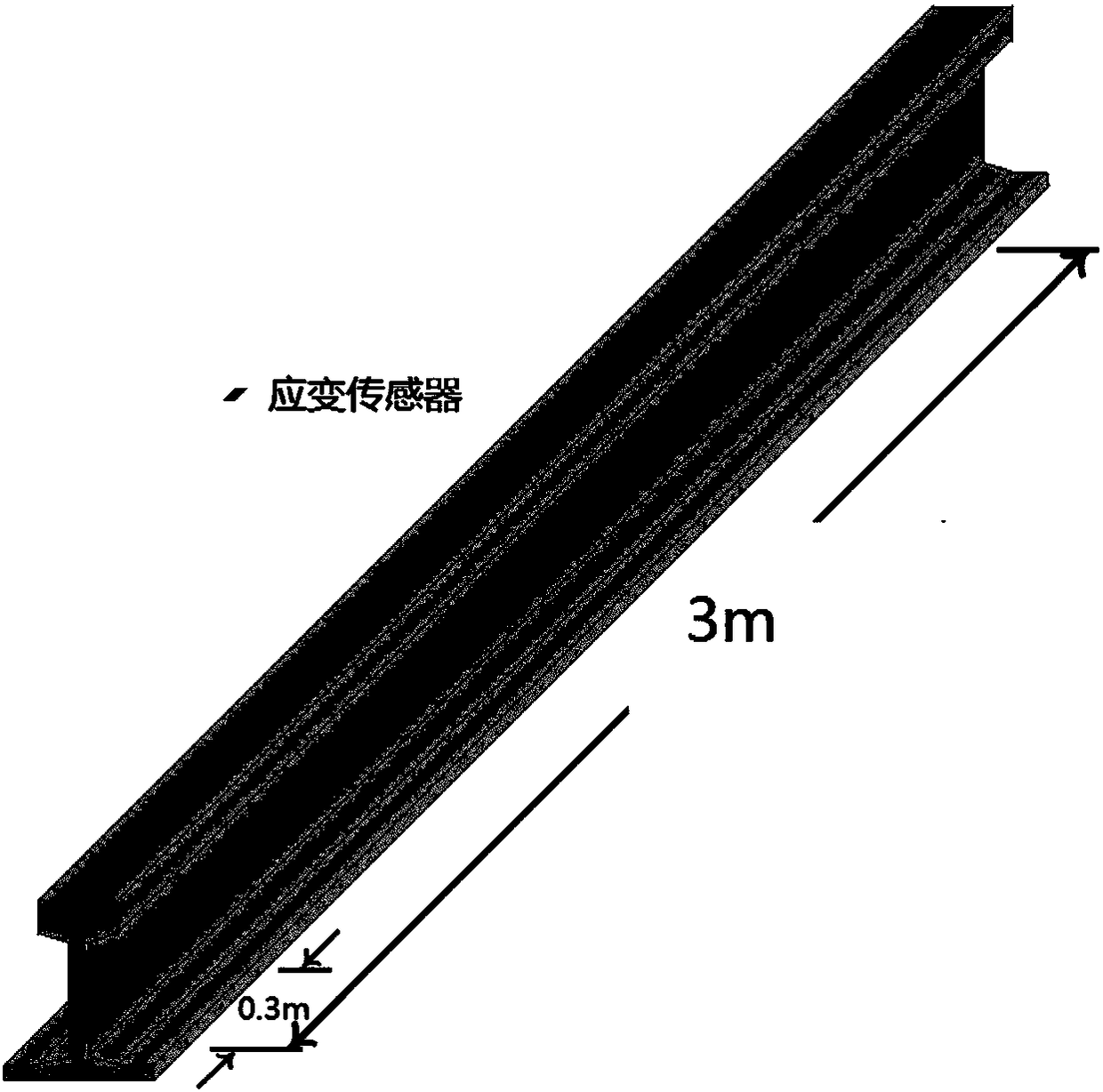

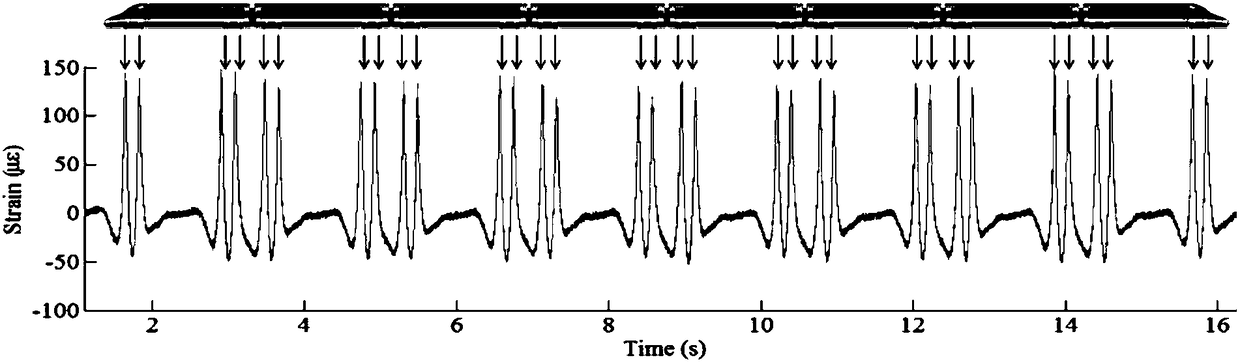

Method and apparatus for identifying polygonization of high speed train wheels

InactiveCN108734060AImproved operation and maintenance efficiencyCharacter and pattern recognitionEngineeringState evolution

The invention is applicable to the technical field of wear identification of high speed train wheels, and provides a method and apparatus for identifying the polygonization of high speed train wheels.The method comprises the following steps: using a longitudinal strain sensor at the bottom of a rail to obtain a steel rail response signal under wheel excitation by monitoring the response generatedby the wheel excitation on a travelling section to the steel rail; preprocessing the steel rail response signal under wheel excitation; extracting signal features on the preprocessing basis of the steel rail response signal to construct a wheel polygonization index; and identifying a wheel polygonization fault by using the constructed wheel polygonization index. The method and apparatus providedby the invention have two advantages: on one hand, online identification of the polygonization state of the high speed train wheels is achieved, and wheel fault early warning is provided, and on the other hand, the state evolution of the high speed train wheels is tracked to guide the wheel repair work. On the basis of the high-efficiency identification algorithm software developed in the invention, a timely and effective detection and repair measure can be taken on the wheel having the polygonization fault.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST

Transistor with longitudinal strain in channel induced by buried stressor relaxed by implantation

ActiveUS20140199813A1Relieve pressureSemiconductor/solid-state device manufacturingSemiconductor devicesSurface layerField-effect transistor

Processes for making field effect transistors relax a buried stressor layer to induce strain in a silicon surface layer above the buried stressor layer. The buried stressor layer is relaxed and the surface layer is strained by implantation into at least the buried stressor layer, preferably on both sides of a portion of the surface layer that is to be stressed. For example, implanting ions through the surface silicon layer on either side of the gate structure of the preferred FET implementation into an underlying stressor layer can induce strain in a channel region of the FET. This process can begin with a silicon or silicon-on-insulator substrate with a buried silicon germanium layer having an appropriate thickness and germanium concentration. Other stressor materials can be used.

Owner:ACORN TECH INC

Method and plant for integrated monitoring and control of strip flatness and strip profile

ActiveUS7849722B2Reduce tensionSusceptible to bucklingRoll force/gap control deviceMetal rolling stand detailsIntegrated monitoringControl system

Apparatus and method of controlling strip geometry in casting strip having a rolling mill. A target thickness profile is calculated as a function of the measured entry thickness profile of the strip while satisfying profile and flatness operating requirements. A differential strain feedback from longitudinal strain in the strip is calculated by a control system by comparing the exit thickness profile with the target thickness profile, and a control signal is generated to control a device capable of affecting the geometry of the strip processed by the hot rolling mill. A feed-forward control reference and / or sensitivity vector may also be calculated as a function of the target thickness profile, and used in generating the control signal sent to the control device. The control device may be selected from one or more of the group consisting of a bending controller, gap controller and coolant controller.

Owner:NUCOR CORP

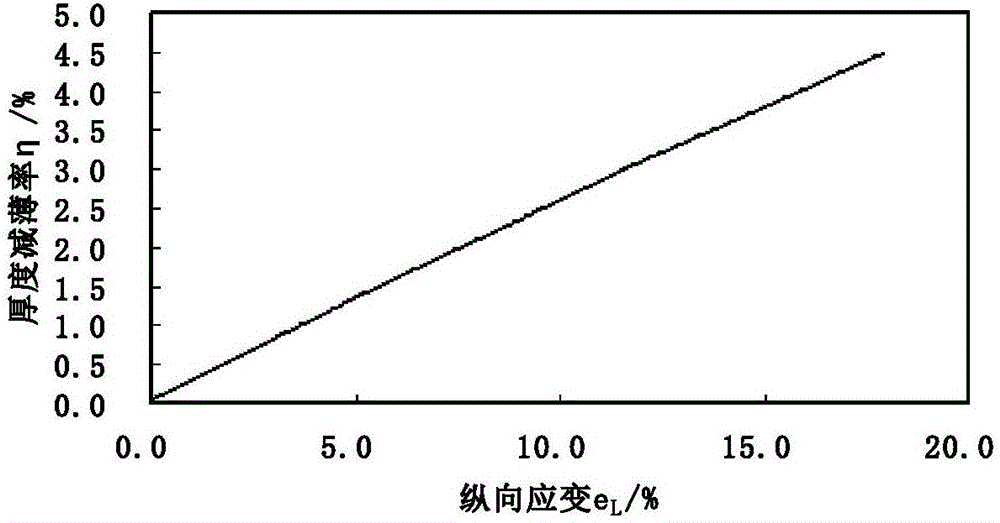

Testing method for automatically measuring thickness thinning rate by adopting tensile testing machine

InactiveCN106644712ASuitable for mass inspectionWell designedMaterial strength using tensile/compressive forcesTest sampleMicrometer

The invention discloses a testing method for automatically measuring a thickness thinning rate by adopting a tensile testing machine. The tensile testing machine is a tensile testing machine with longitudinal and transverse extensometers; the testing method comprises the following steps: 1) testing an original initial thickness a0, an initial width b0 and an initial length L0 of a test sample; 2) clamping the test sample to be tested onto the tensile testing machine with the longitudinal and transverse extensometers and recording instant sizes L and b of the test sample to be tested in a length direction and a width direction in a whole tensile testing process; solving real-time longitudinal strain eL and transverse strain eb respectively; 3) calculating the instant thickness thinning rate of the tensile test sample; 4) setting a maximum force total elongation rate Agt and a maximum force plastic elongation rate Ag, and calculating to obtain a maximum force total thinning rate and a maximum force plastic thinning rate; 5) defining a thinning rate at a fractured minimum thickness part after testing as a fractured thinning rate etau; testing a minimum thickness au of a necking region of a fractured test sample through a point micrometer; calculating the fractured thinning rate etau. The testing method disclosed by the invention is convenient and rapid and is suitable for large-batch inspection.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com