Testing method for automatically measuring thickness thinning rate by adopting tensile testing machine

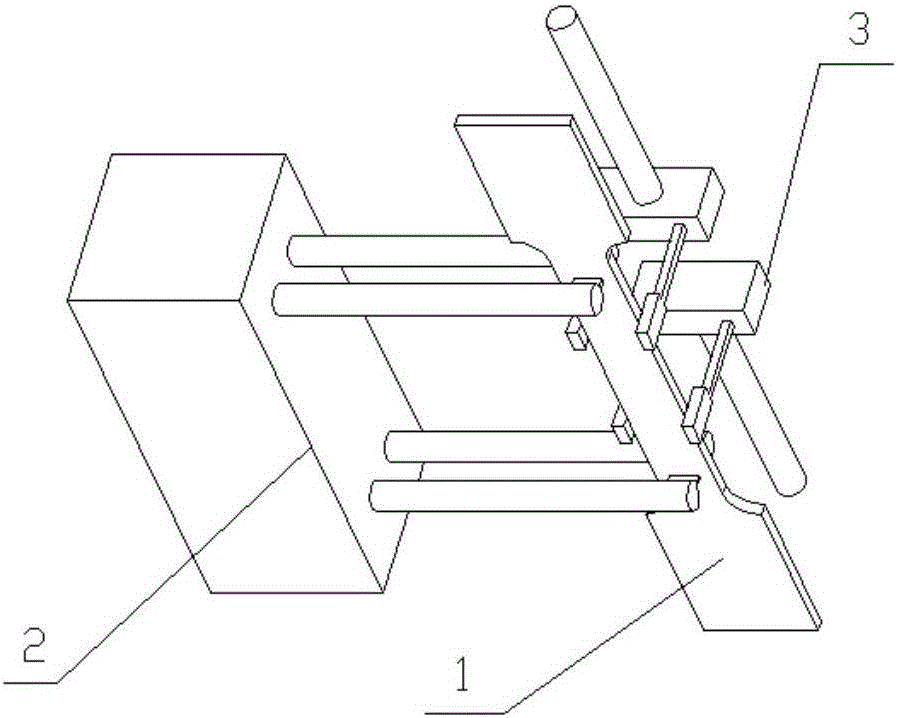

A technology of tensile testing machine and thickness reduction, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. It can solve the problems of many manual measuring points, complicated sample preparation process, unsuitable for large-scale production inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

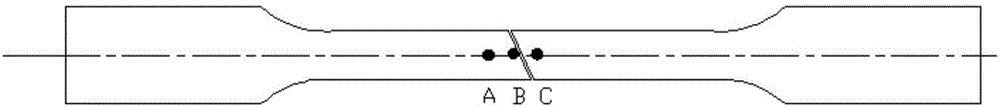

[0078] 1) The test object is a copper alloy, the initial thickness a 0 =5.00mm, initial width b 0 = 19.98mm and initial length L 0 = 50mm.

[0079] 2) Use a plate tensile testing machine with longitudinal and transverse dual extensometers to carry out tensile tests, record the original data of the load, longitudinal extensometer displacement, and transverse extensometer displacement during the test, according to formulas (1) and (2) Calculate the longitudinal strain e L and transverse strain e b .

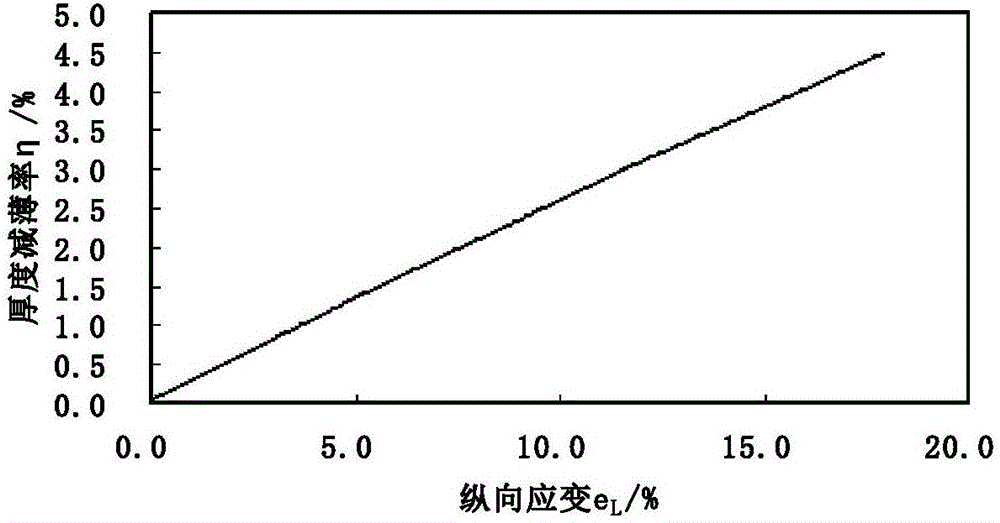

[0080] 3) The longitudinal strain e L and transverse strain e b Substitute into formula (10) to calculate the real-time thickness reduction rate η. According to real-time longitudinal strain e L , Lateral strain e b , Thickness thinning rate η, can draw thickness thinning rate change curve with longitudinal strain and transverse strain, such as Image 6 and Figure 7 shown.

[0081] 4) Draw the stress-longitudinal strain curve, such as Figure 8 As shown, according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com