Patents

Literature

30results about How to "Well-designed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for integrating a wide keyboard in a small device

InactiveUS7336263B2Well-designedEasy to useInput/output for user-computer interaction2D-image generationMobile deviceHuman–computer interaction

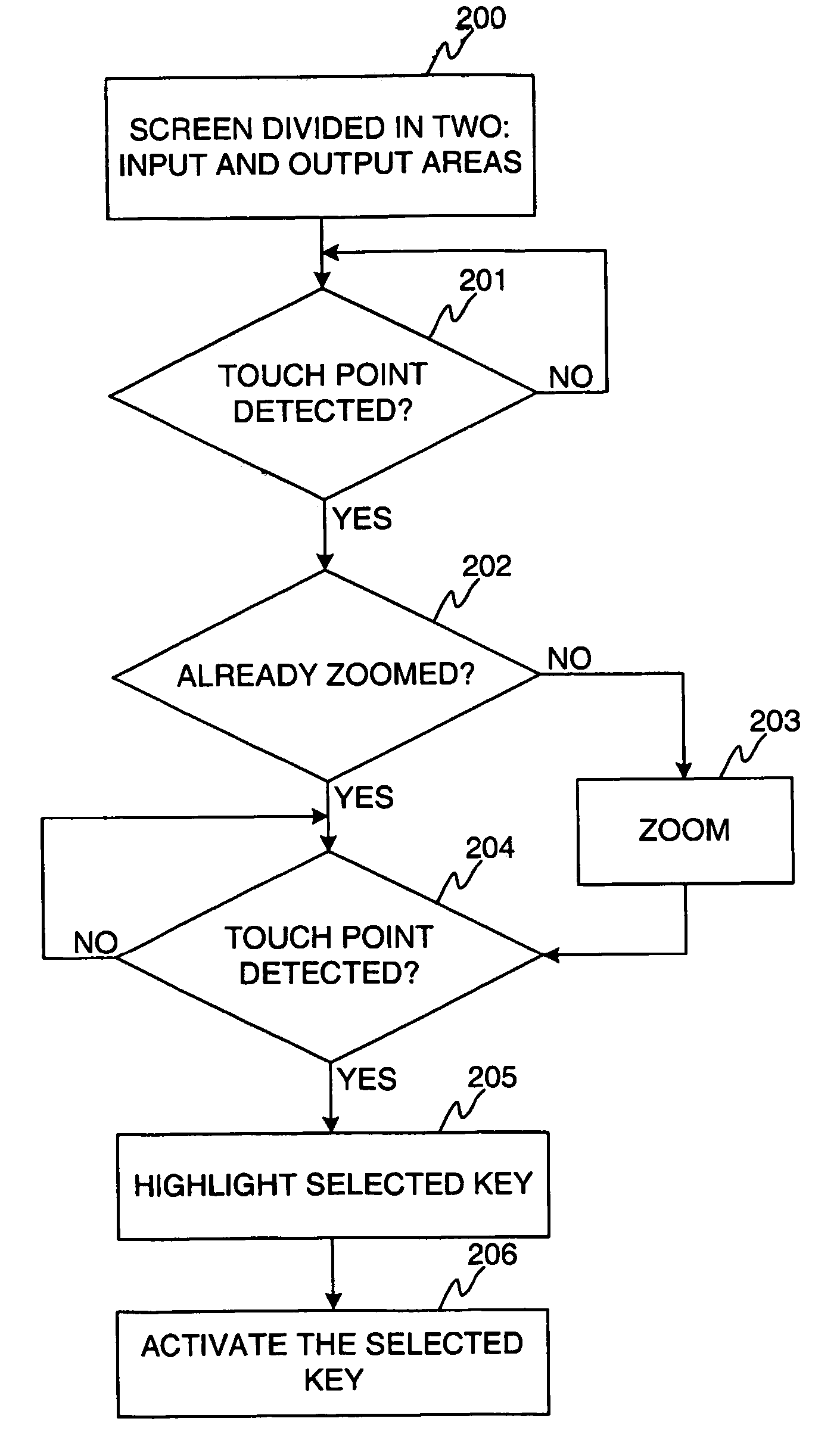

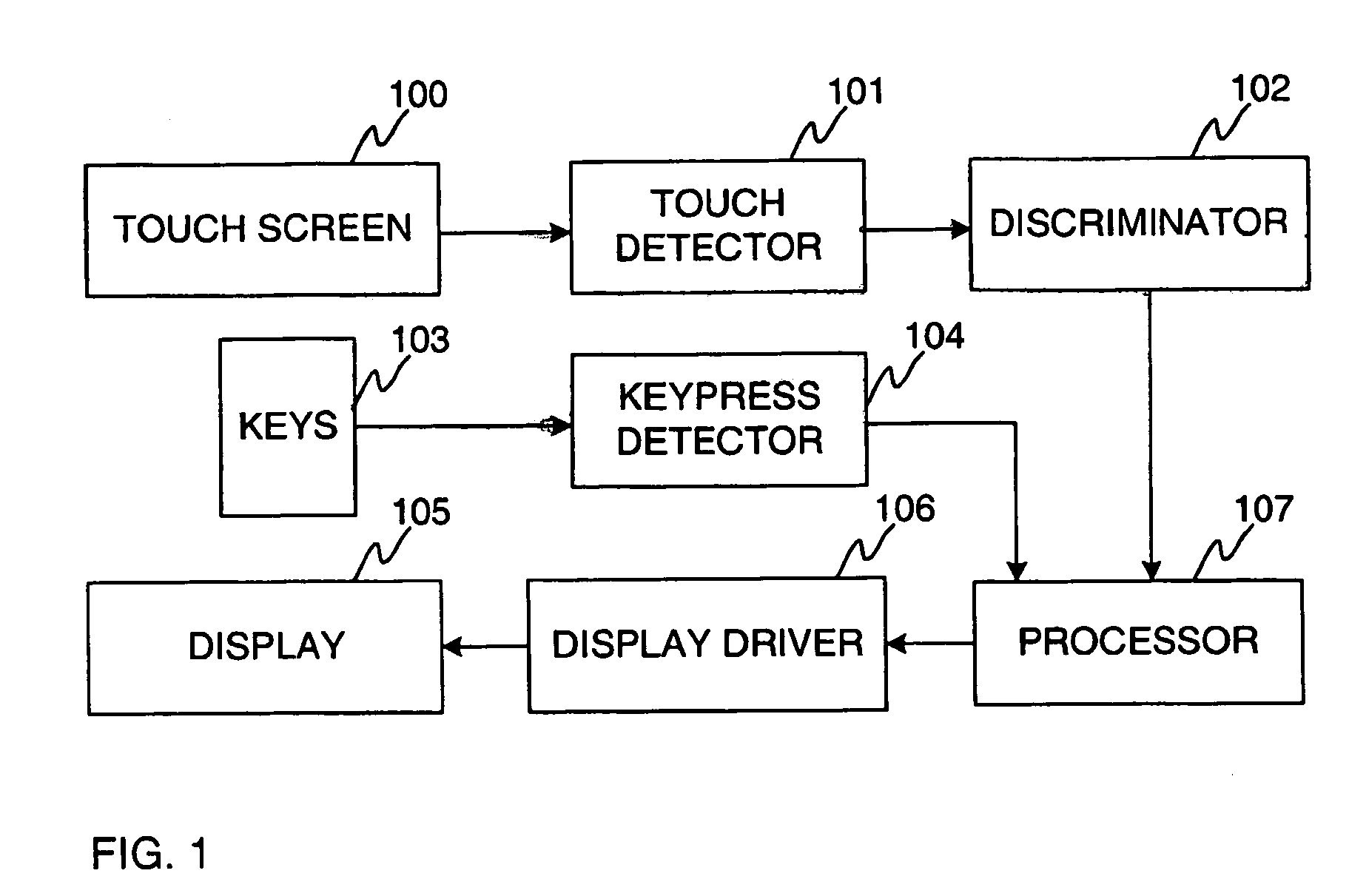

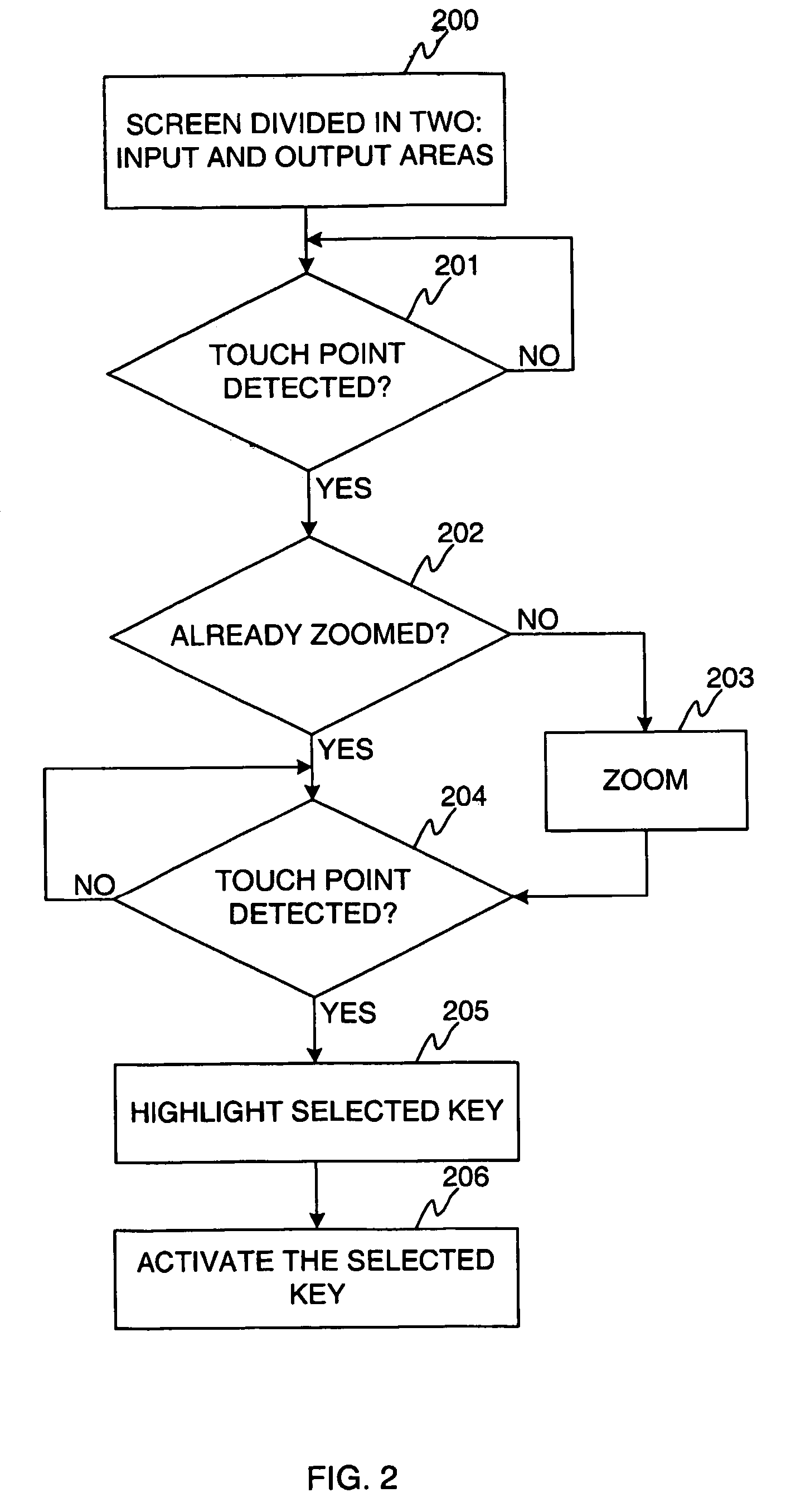

The invention relates to a method and an apparatus for using a wide keyboard including a wide range of keys in small mobile devices. A method relates to operating a mobile device having a touch sensitive display divided in input and output portions. A first location of a tactile input is detected on an input portion of the touch sensitive display displaying a plurality of keys. Next the input portion display view is zoomed by displaying and linearly magnifying the detected tactile input area and it's surrounding. A second location of a tactile input is detected and a key on the location of a second detected tactile input is highlighted. The highlighted key is activated and identified as an input.

Owner:RPX CORP

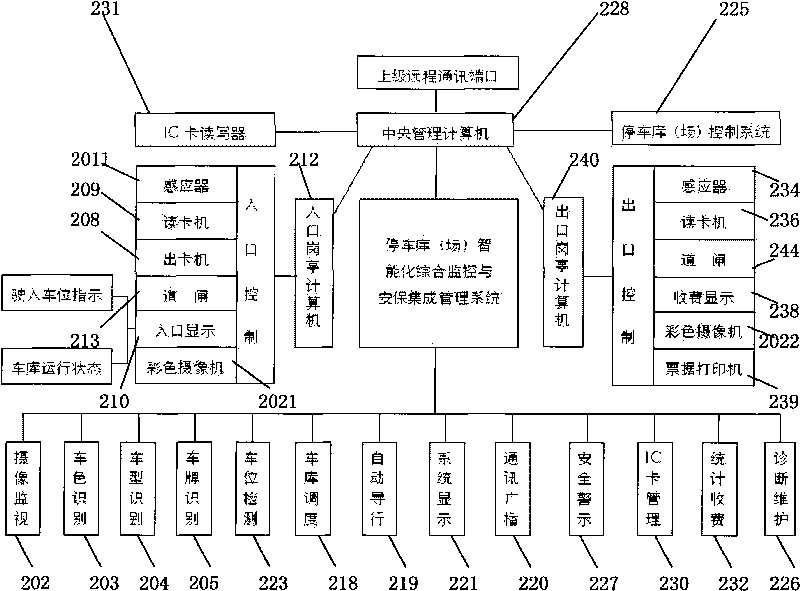

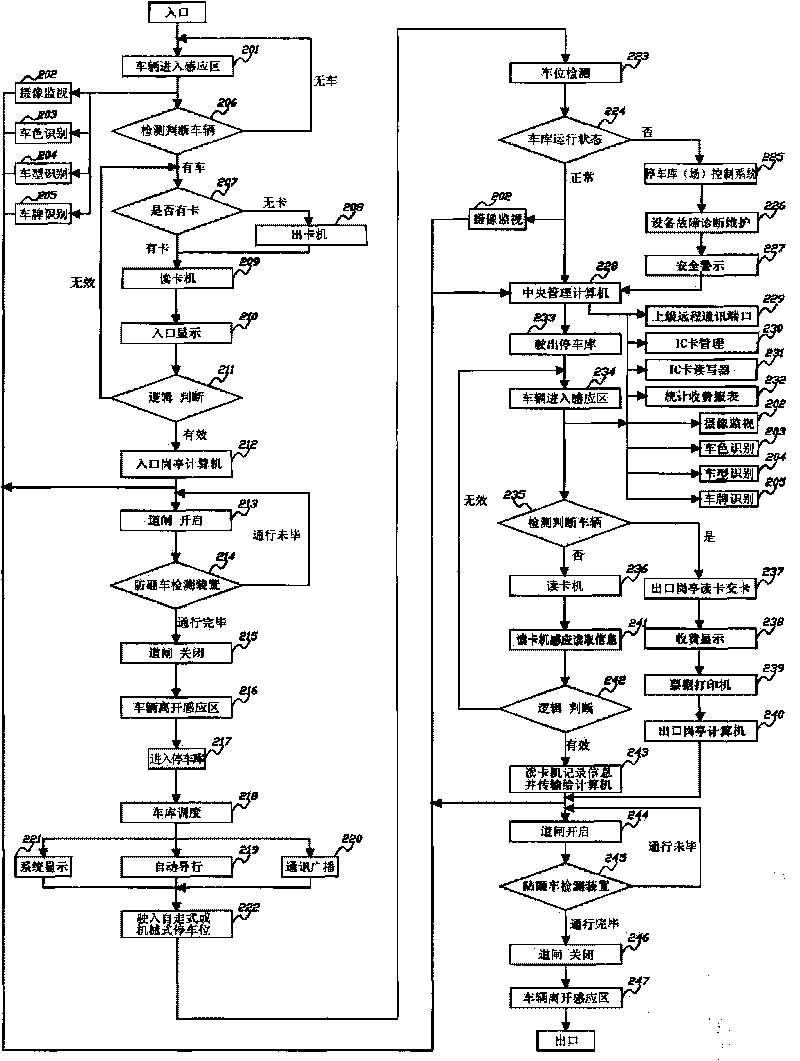

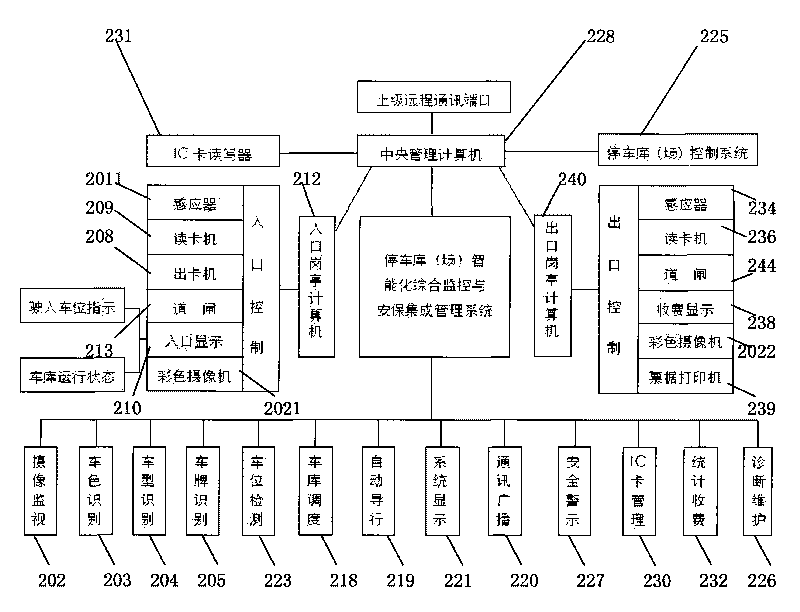

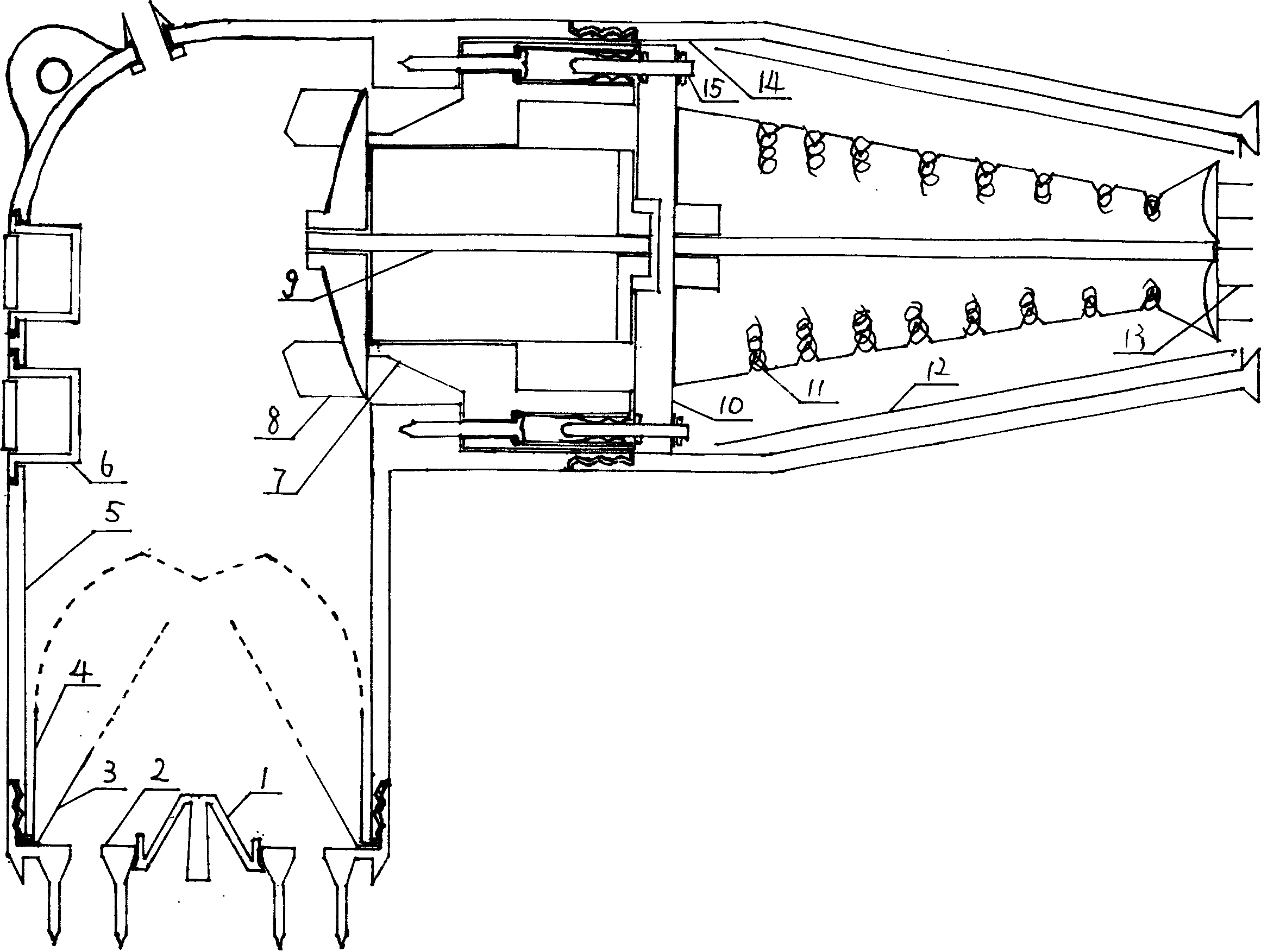

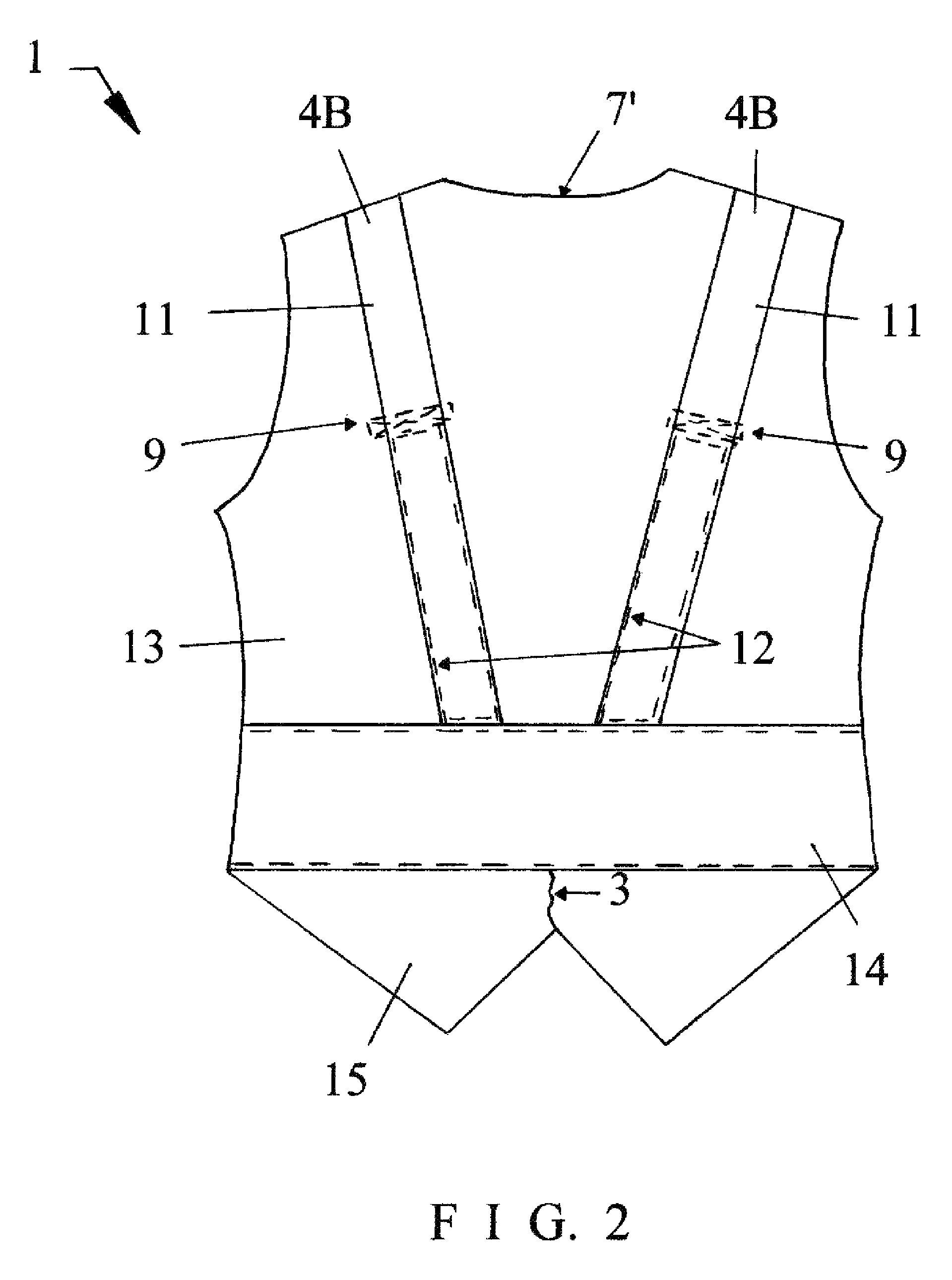

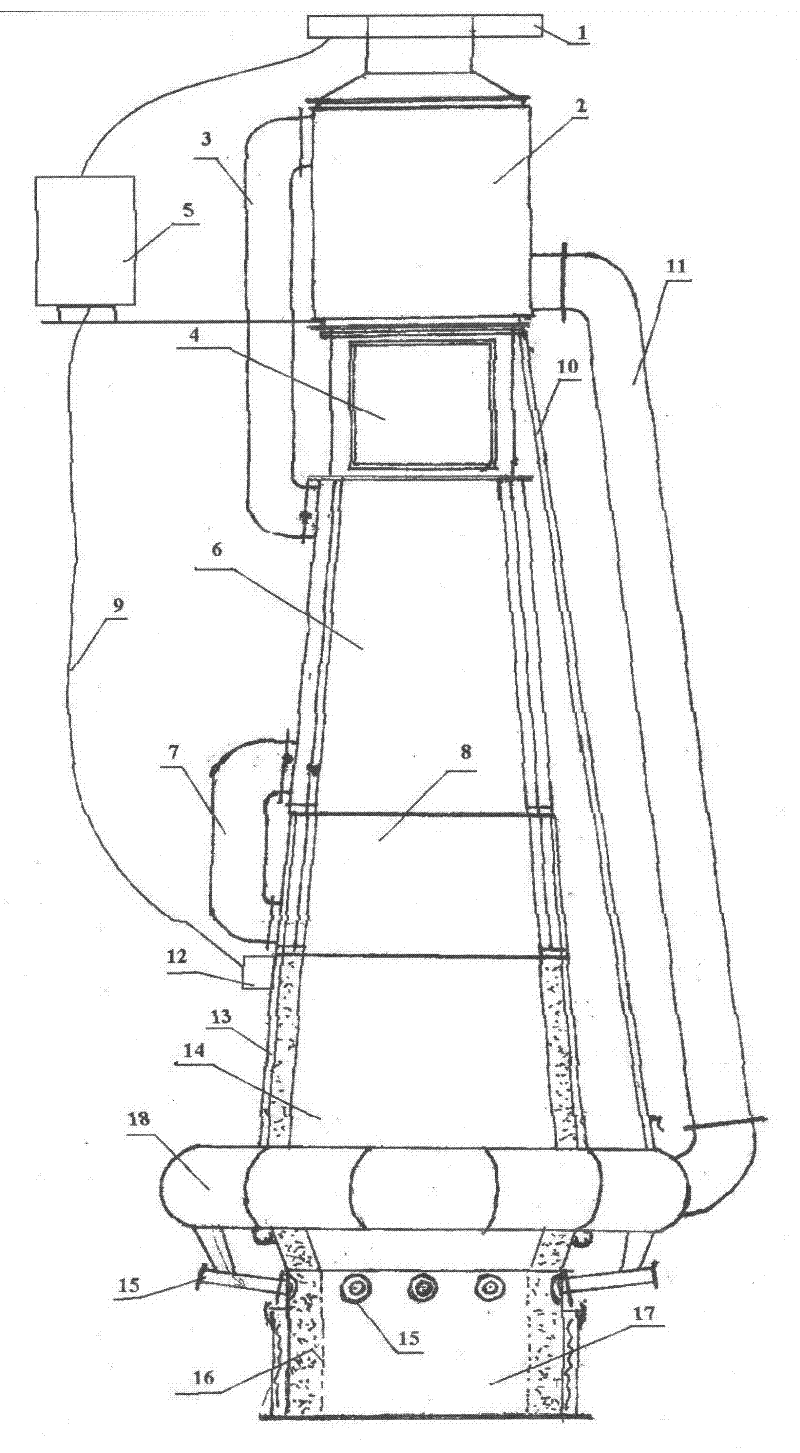

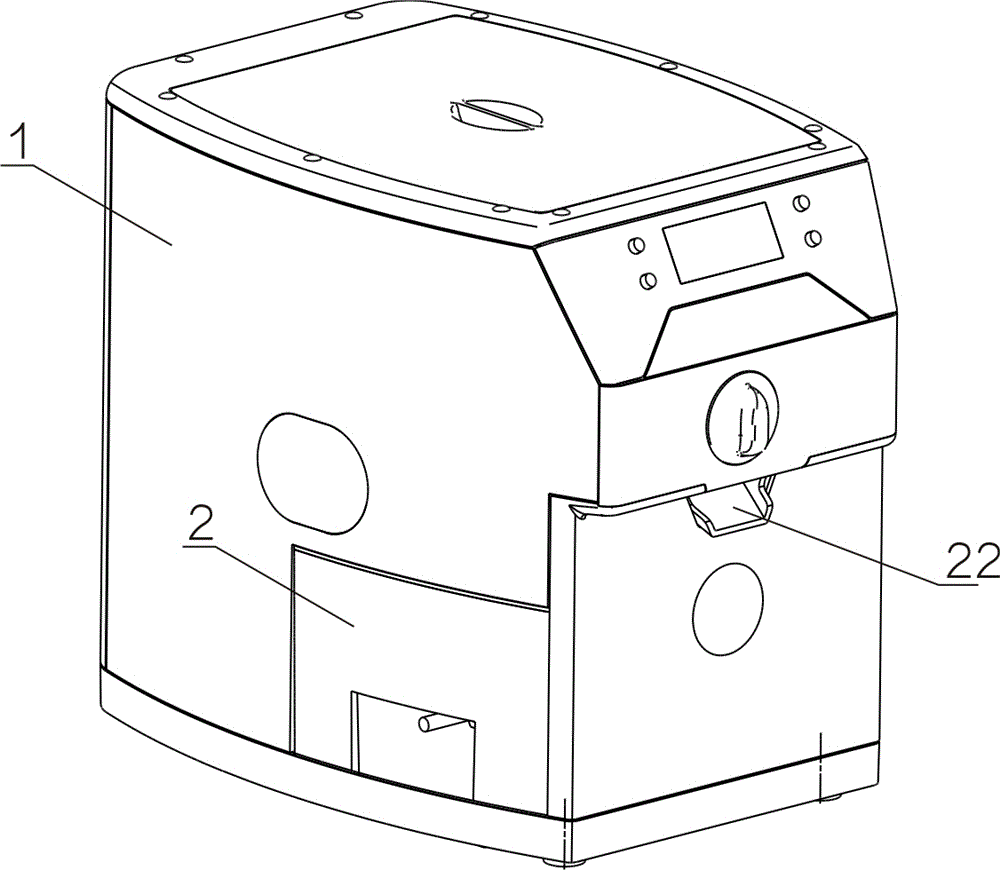

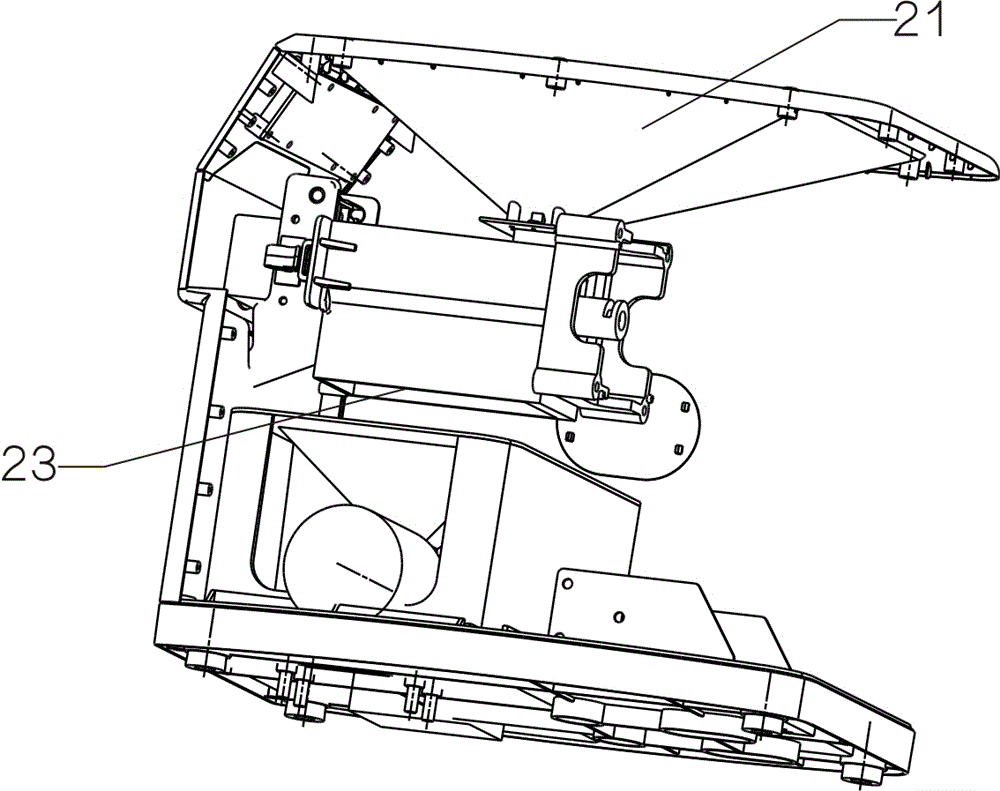

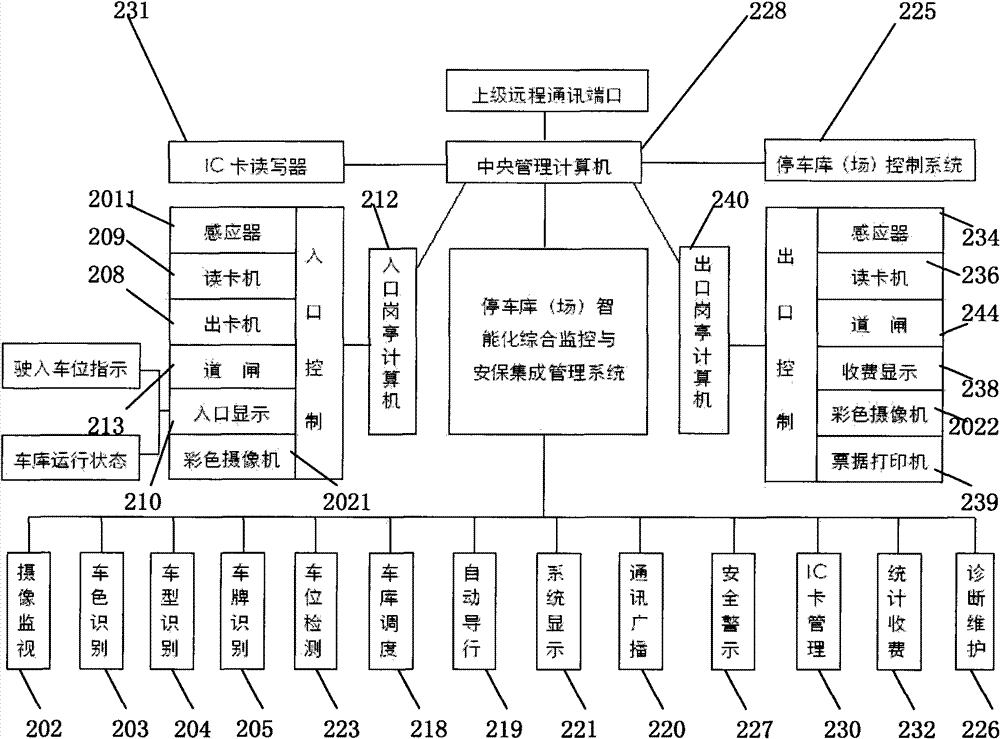

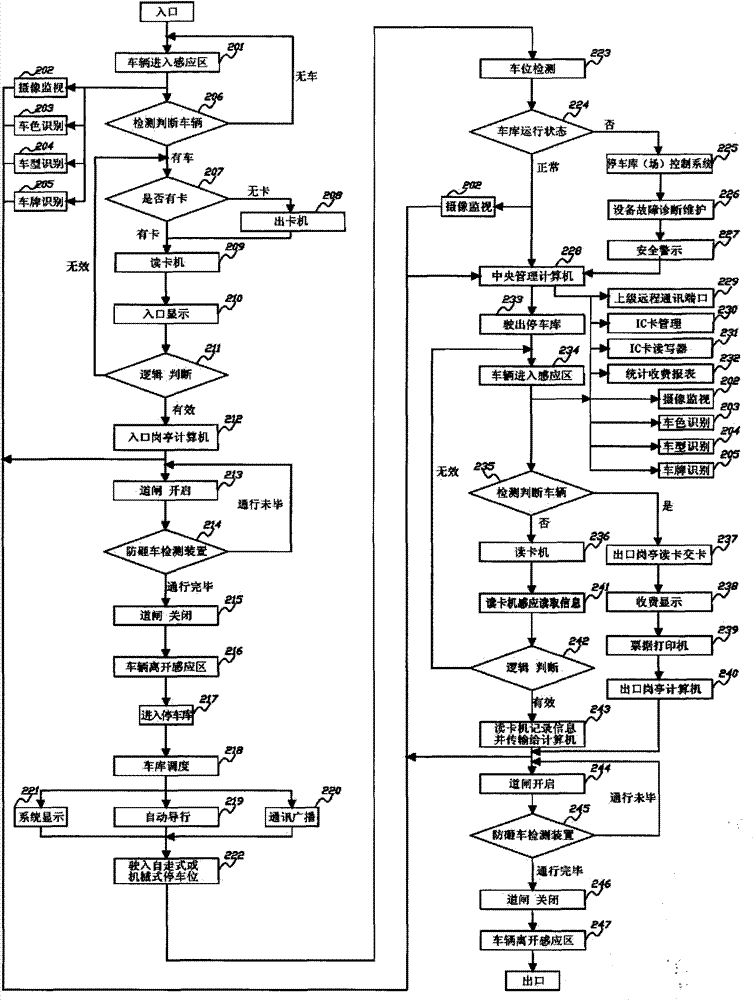

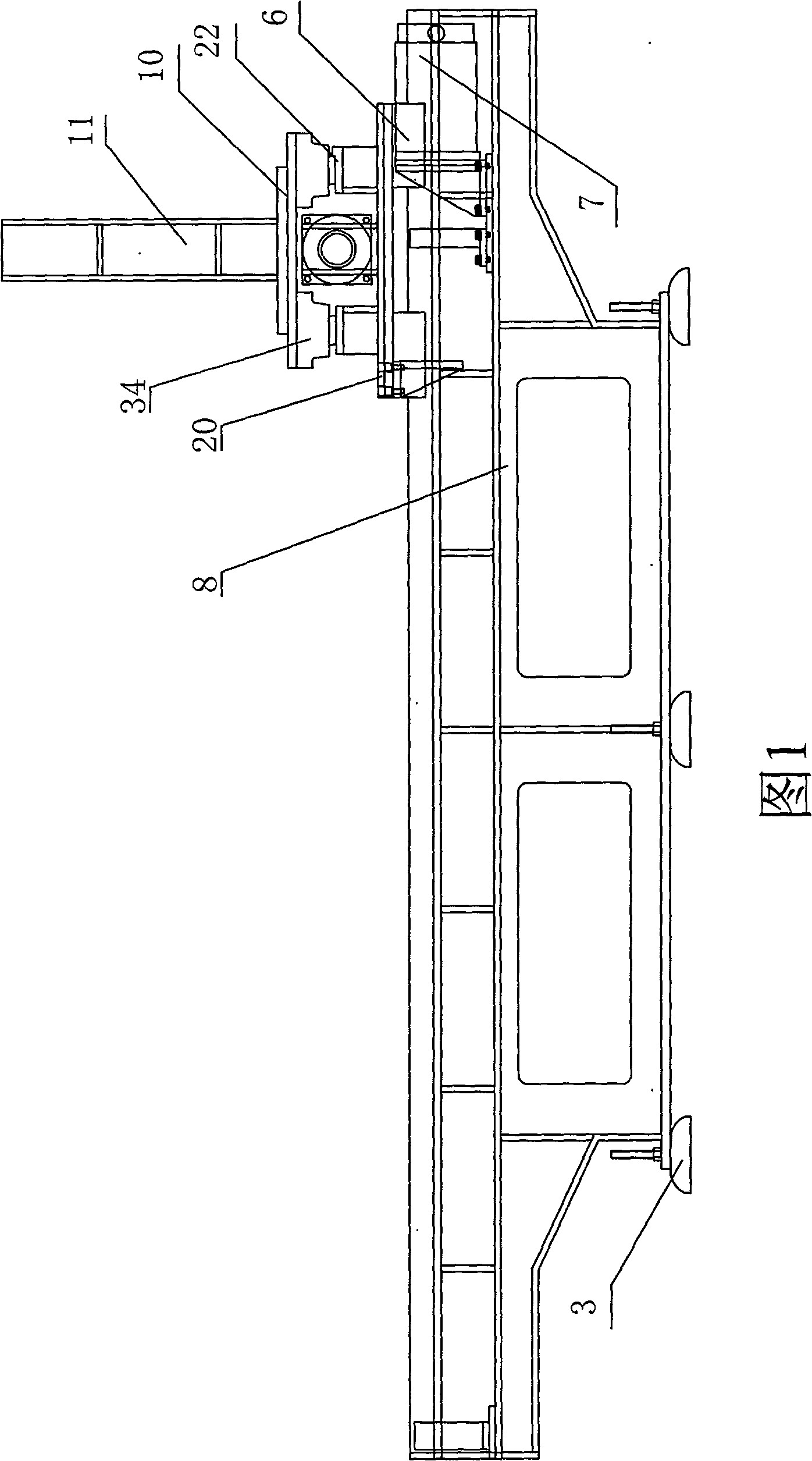

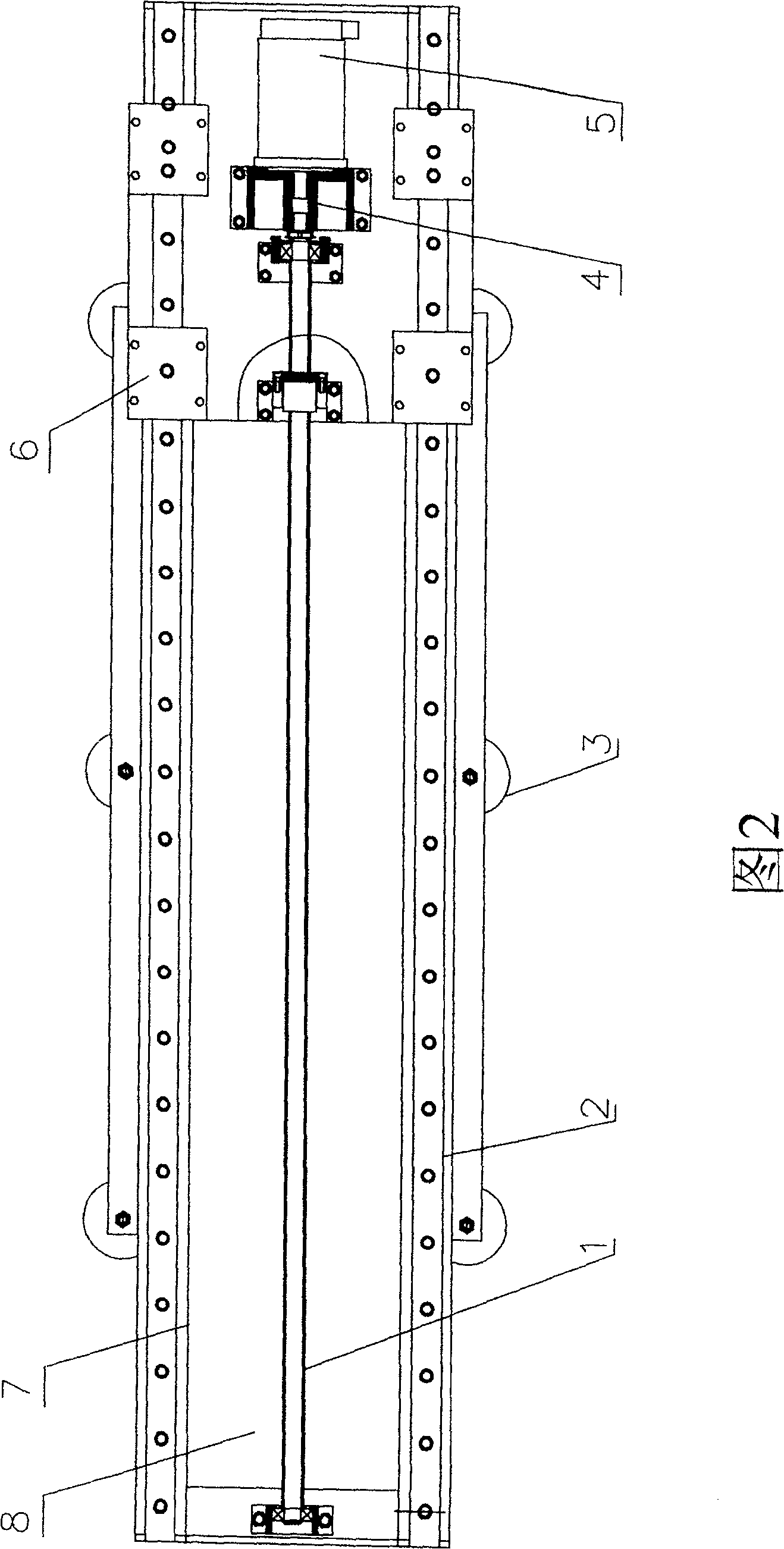

Intelligent comprehensive monitoring and security integrated management system for parking garage

ActiveCN101739841AComplete monitoringPracticalTicket-issuing apparatusIndication of parksing free spacesIntegrated monitoringEconomic benefits

The invention provides an intelligent comprehensive monitoring and security integrated management system for a parking garage. The system solves the comprehensive intelligent management problems of related automatic monitoring, automatic detection, display, different languages and voices, communication, dispatching, guide, digital quantity identification, security, forbidding and passing, charging, statistics, self diagnosis and maintenance and the like of various self-propelled and automatic three-dimensional mechanical parking garages. The system has significant meanings for improving the monitoring, security and management levels of various parking garages, promoting static traffic modernization construction and increasing the social and economic benefits of the parking garages.

Owner:上海久银车库工程有限公司

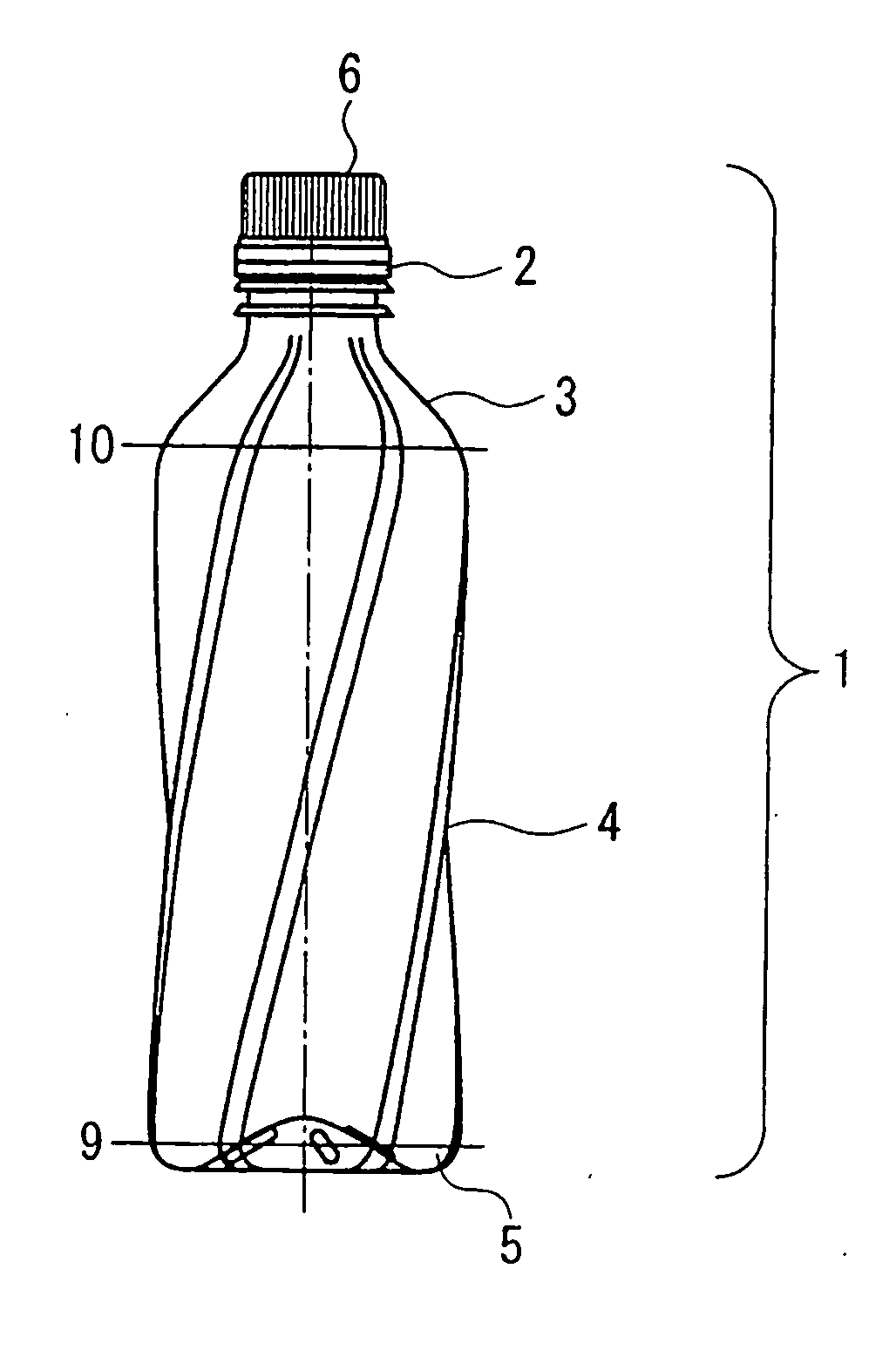

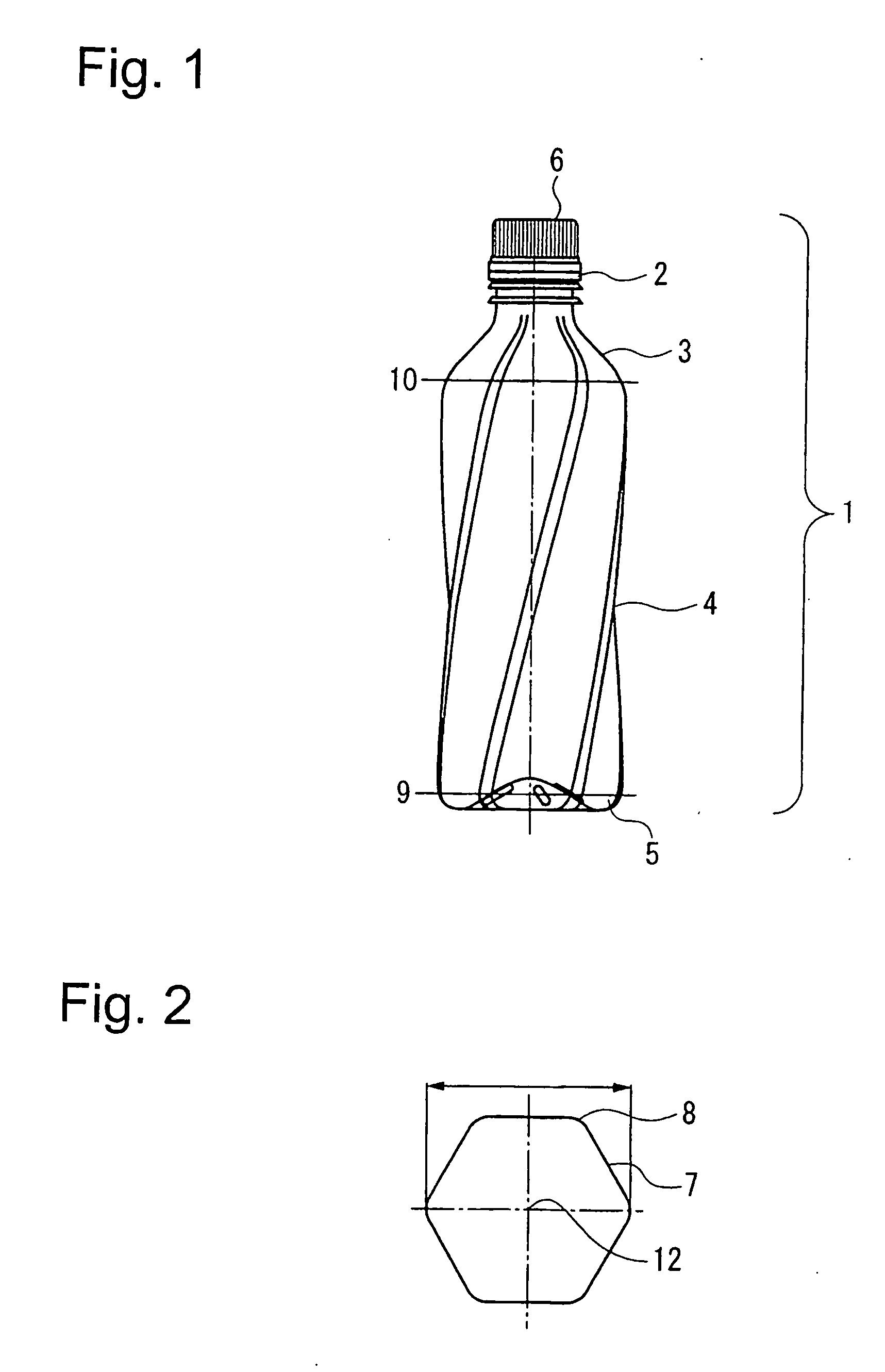

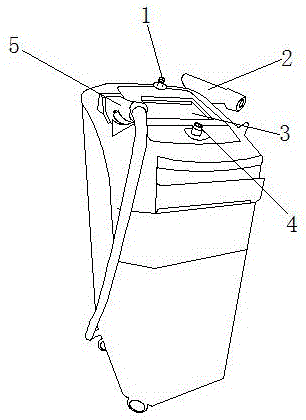

Plastic bottles

InactiveUS20070068894A1Easy to handleAvoid Poor AppearanceBottlesLarge containersEngineeringMechanical engineering

Plastic bottles (1) which are characterized in that: they are composed of neck (2), shoulder (3), body (4) and bottom (5); the cross-sectional shape at the body (3) is a regular polygon, the number of angles of which is an even number of not less than 4 nor more than 32; each angle of the polygon is rounded off by an arc (8) whose radius is not longer than half the radius of a circle circumscribed about the cross-sectional shape at body (3); cross-sectional shapes have the same shape at any portion of body (3); circles circumscribed about the cross-sectional shapes are identical with one another; the circumscribed circles have a center on the vertical central axis of body (3); and the cross-sectional shape of body (3) rotates around said central axis in proportion to height along said central axis.

Owner:THE COCA-COLA CO

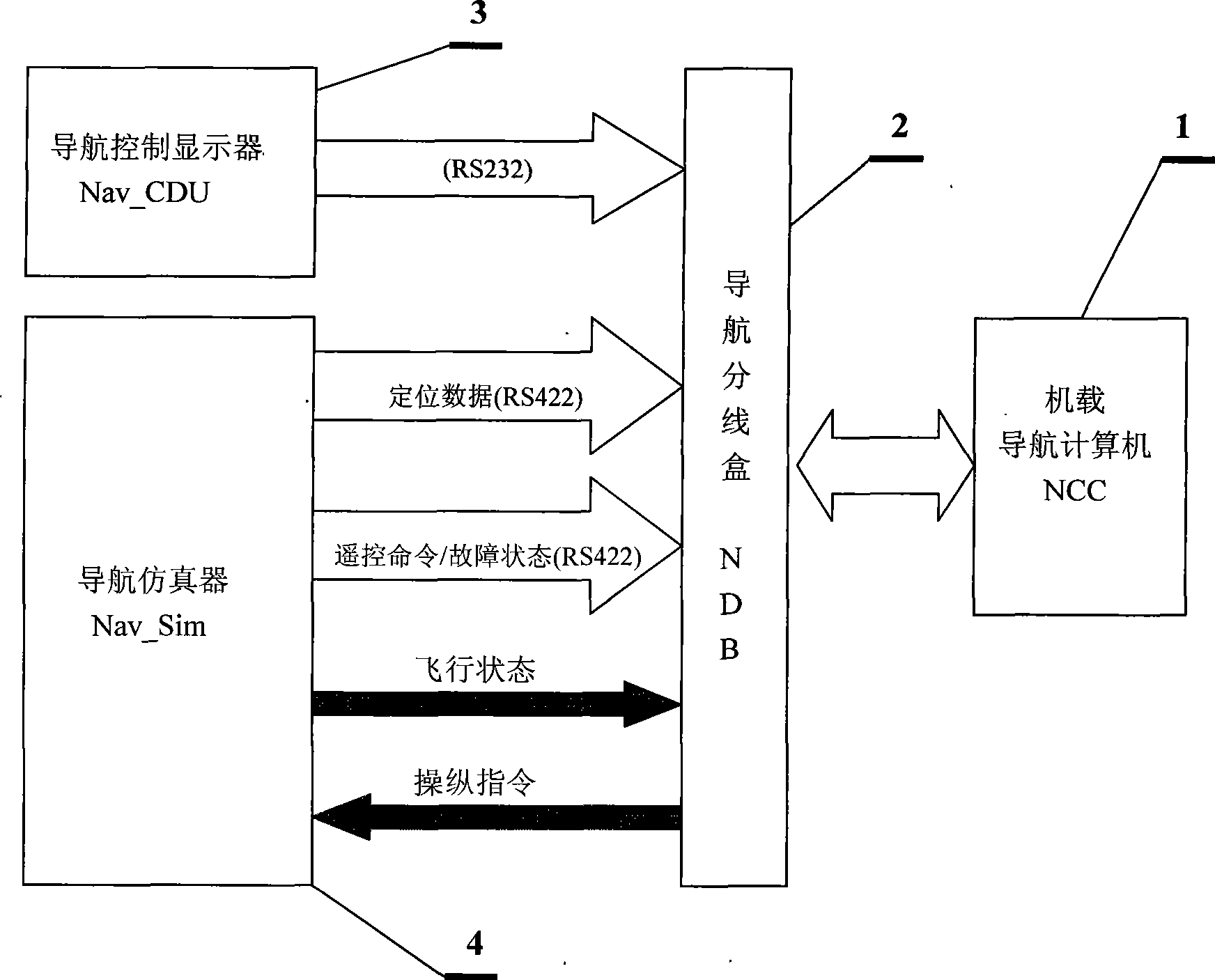

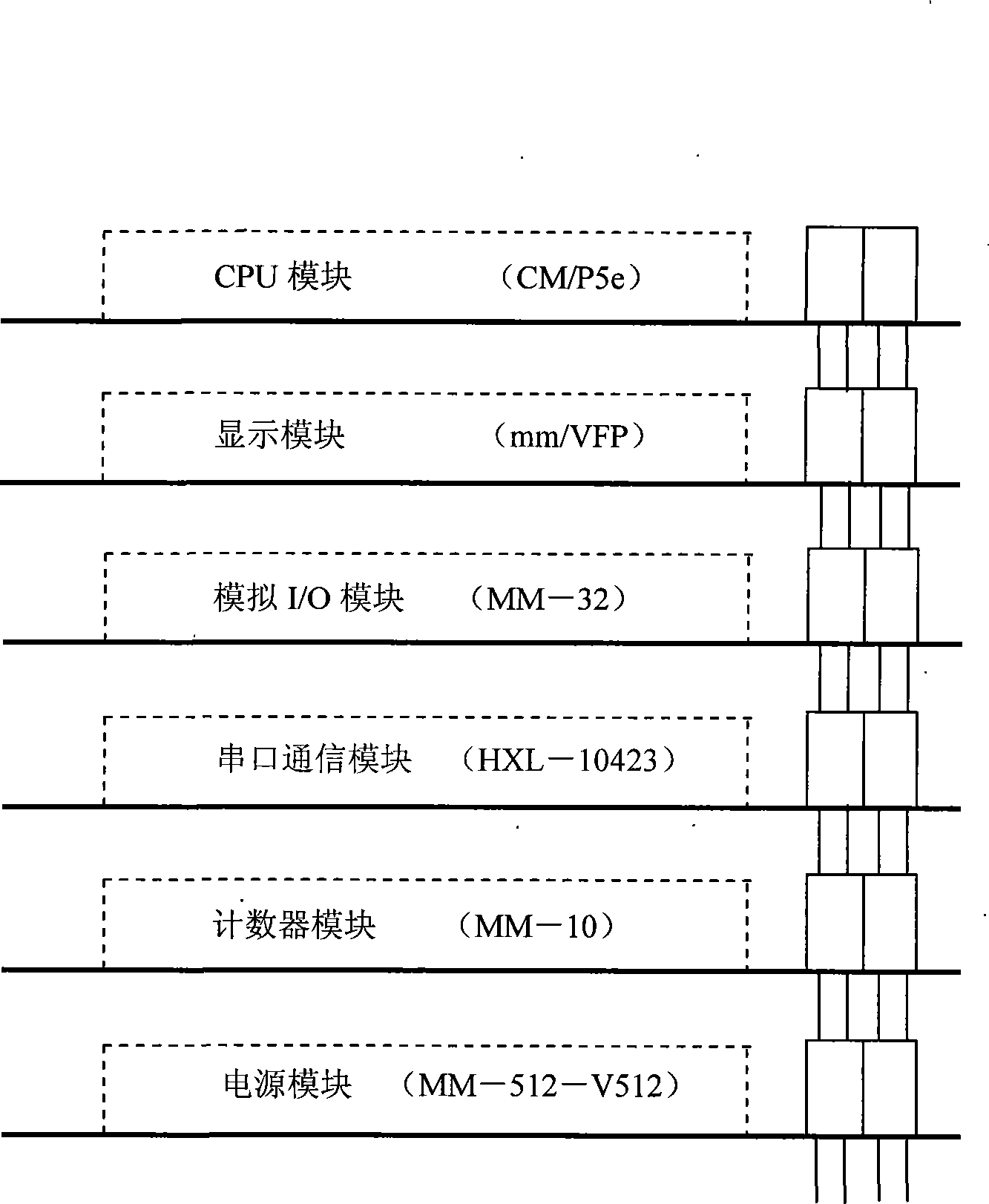

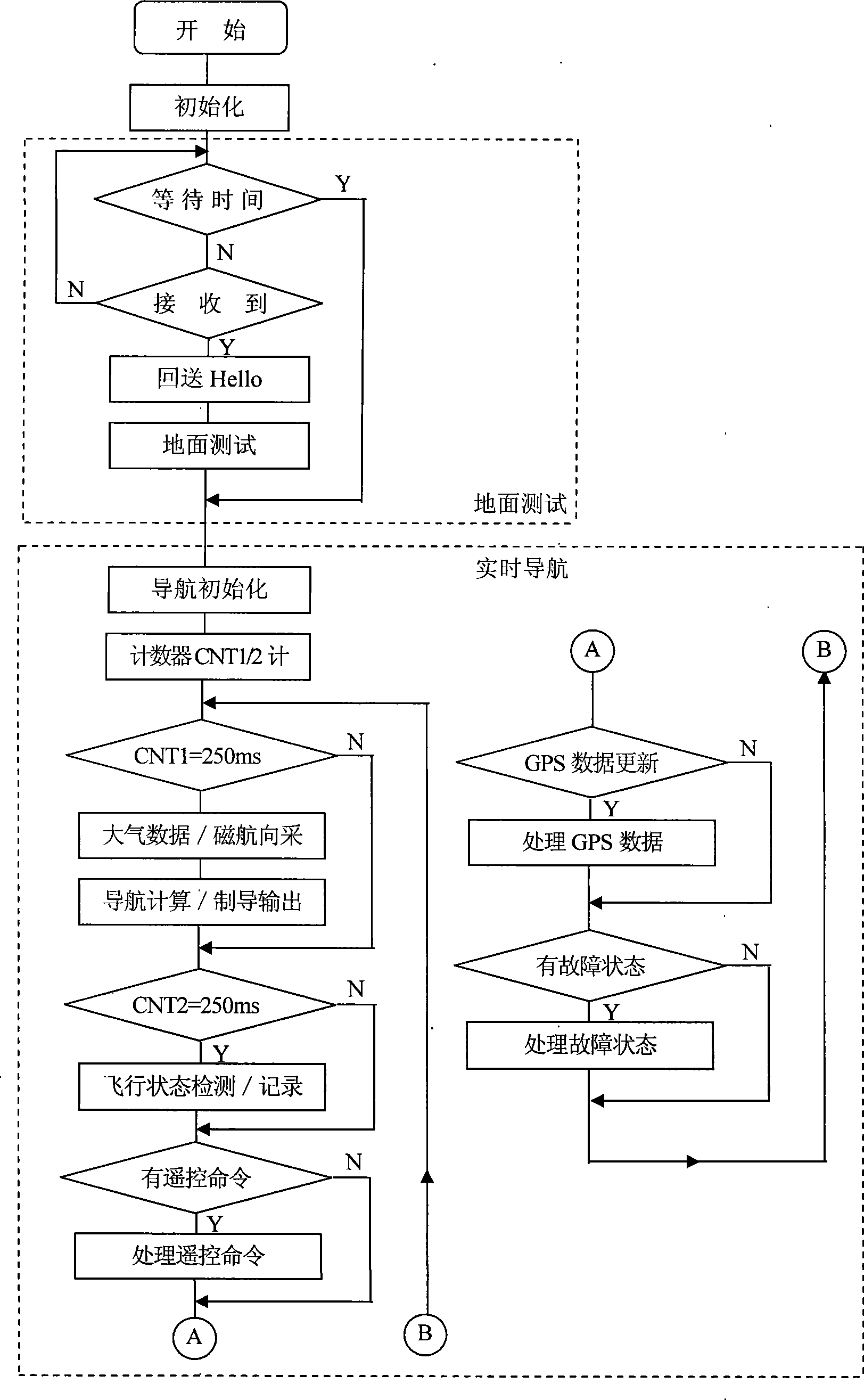

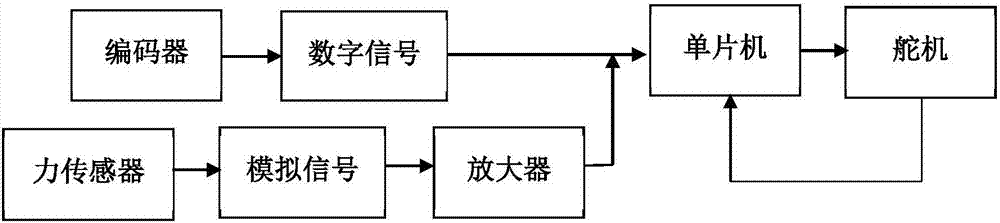

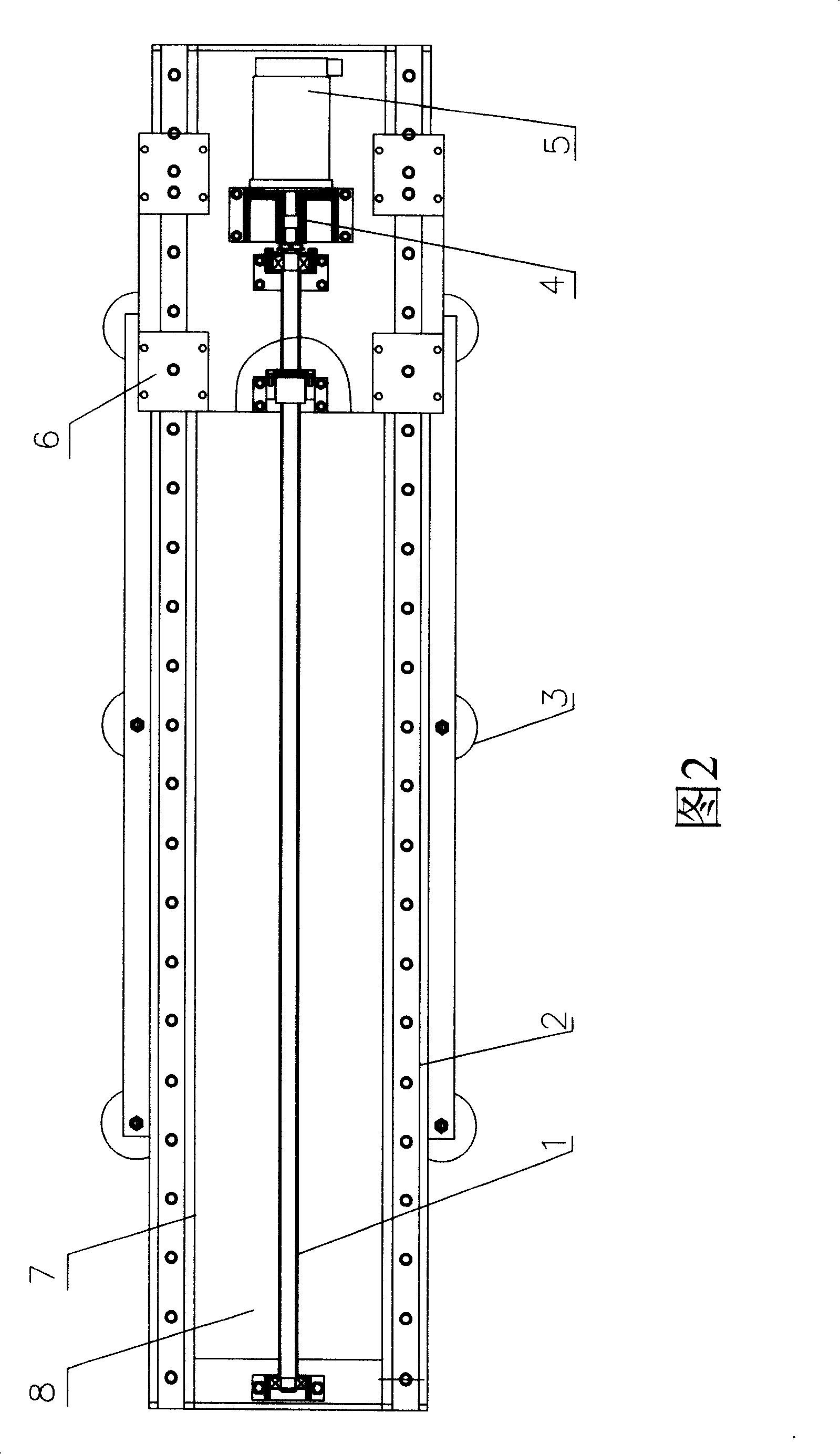

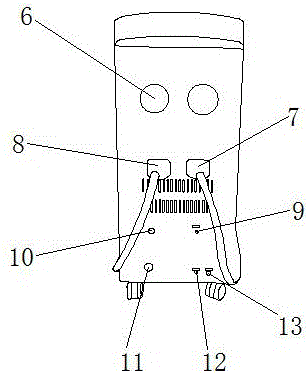

Semi-true object emulation technology apparatus of unmanned coaxal helicopter autonomous navigation system

InactiveCN101435703AStrong advancedWell designedNavigational calculation instrumentsSustainable transportationMarine navigationDisplay device

The invention provides a semi-physical simulation technique device for an autonomous navigation system of an unmanned coaxial helicopter. The device consists of a helicopter-mounted navigation computer, a helicopter-mounted navigation branch box, a navigation control displayer and a navigation simulator, wherein the helicopter-mounted navigation computer is crossed and linked with the navigation simulator by the navigation branch box to form an unmanned helicopter autonomous navigation simulation loop; and the helicopter-mounted navigation computer is also crossed and linked with the navigation control displayer by the navigation branch box to realize the control and test of the helicopter-mounted navigation computer. The device creates a general development platform for the unmanned helicopter navigation system, and can test the function / performance and reliability of the navigation system under conditions of simulating actual flight; the semi-physical simulation technique which the invention relates to has good advanced property, generality and practicability; and the semi-physical simulation environment which the invention relates to has the advantages of careful design, simple structure and good operability. Practice shows that the device reduces the development period and risk of the navigation system, and has good technical and economic benefits.

Owner:BEIHANG UNIV

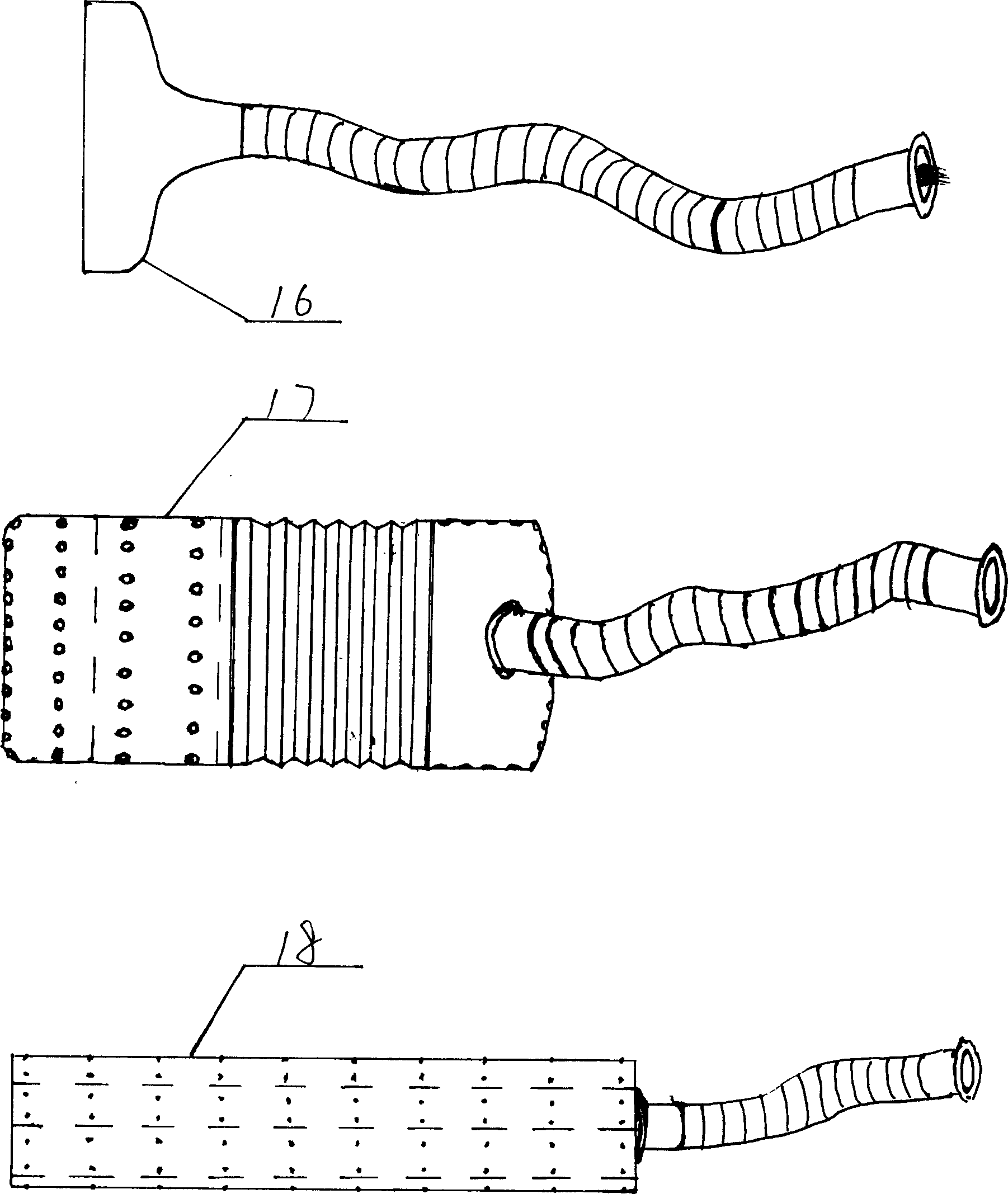

Five-purpose machine acting as hair drier, scurf eliminating comb, small duster, shoes dehumidifier and guilt warmer

The fiver-purpose machine may serve as hair drier, scurf eliminating comb, small duster, shoes dehumidifier and quilt warmer. The machine is one bent circular tube, and has assembled comb type sucking head, circular net, hood net, casing, vane wheel, motor holder, motor, electric heating wire frame, high temperature resisting insulating sleeve, air outlet net and air outlet channel casing. It has two, one coarse and one fine, filtering layers to ensure the normal operation of the motor and avoid dust. It has detachable and exchangeable comb type sucking head, hose sucking head, fine filtering bag, shoes dehumidifying head and quilt warming bat to realize the said functions.

Owner:仲从宝

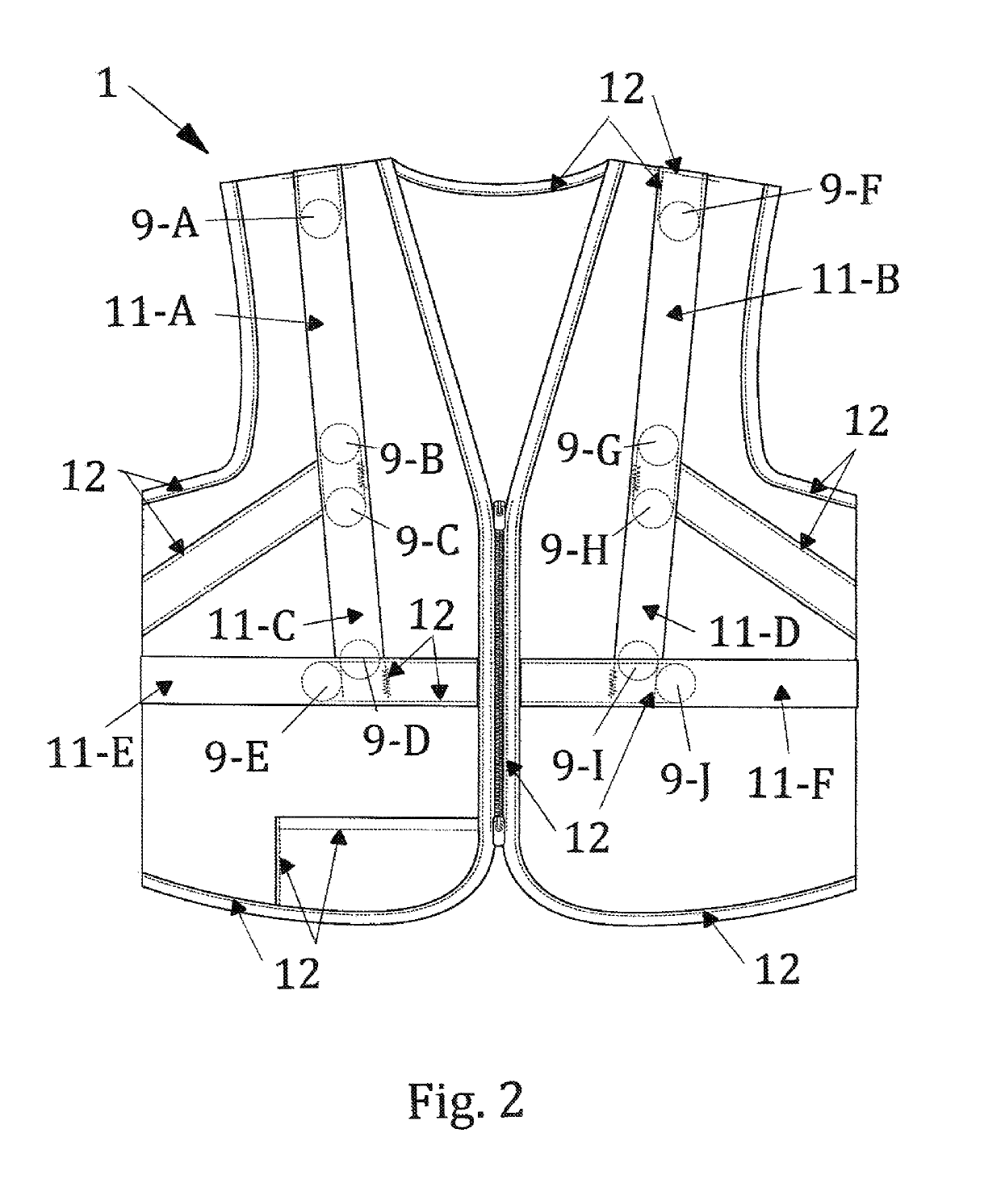

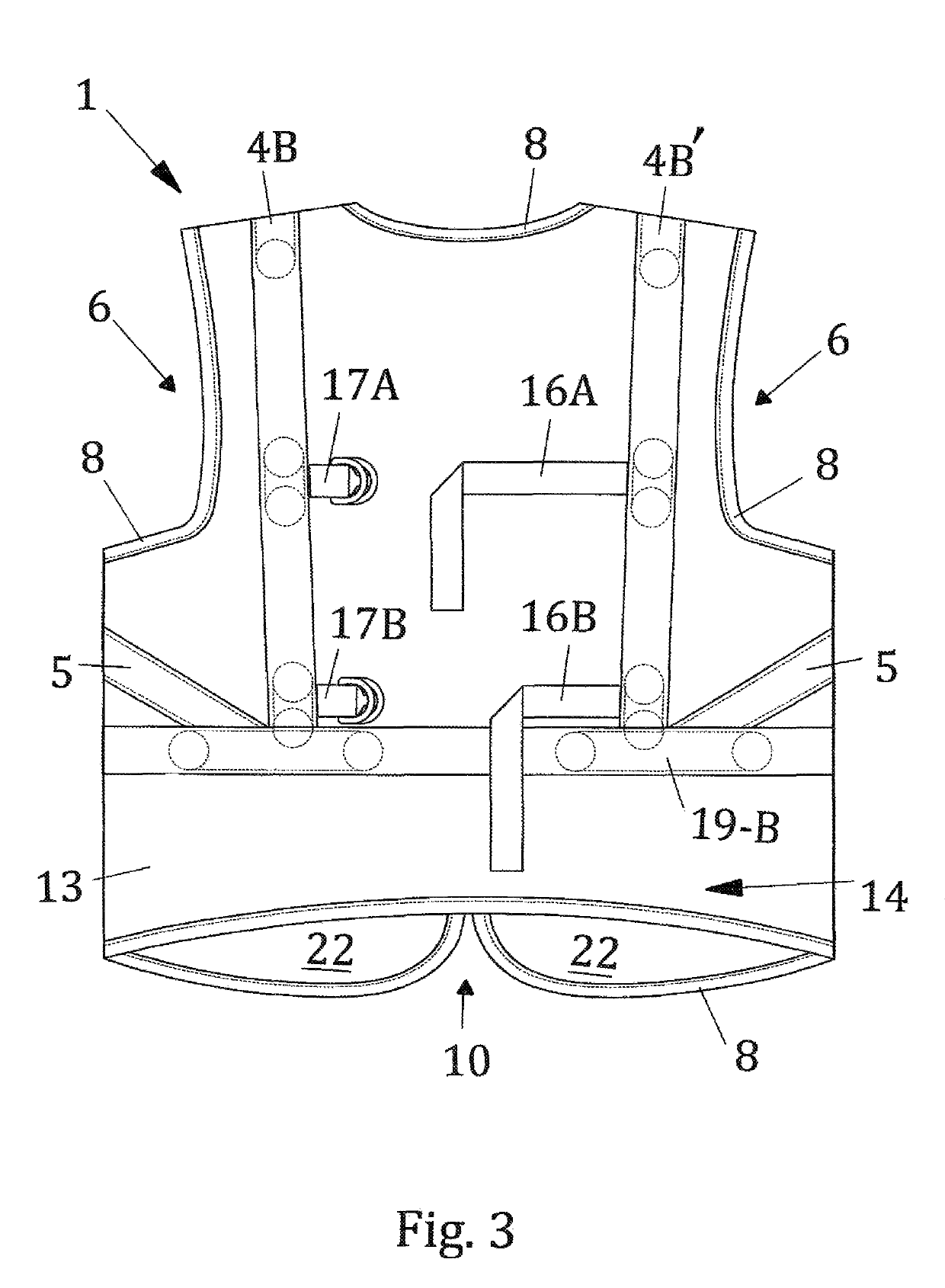

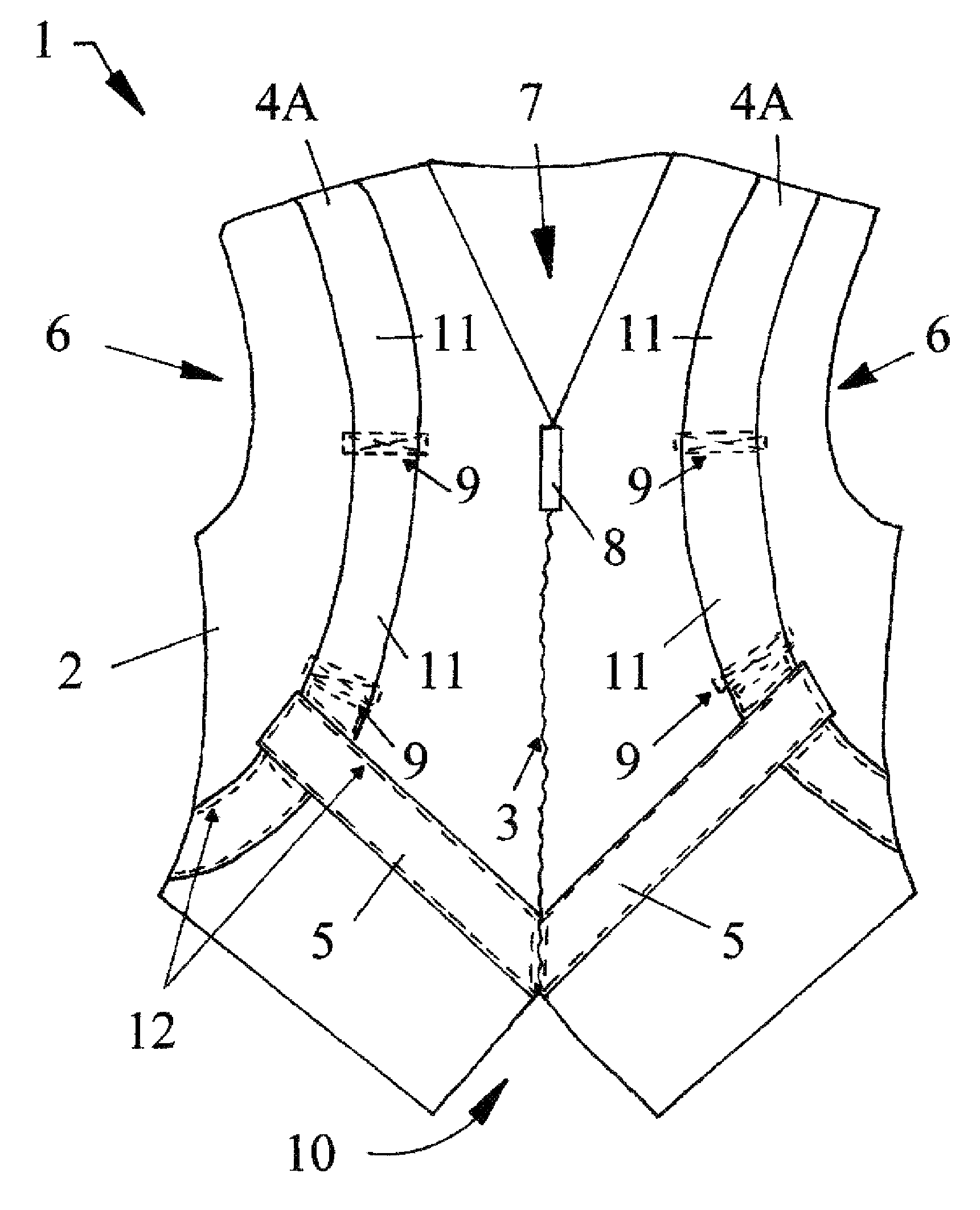

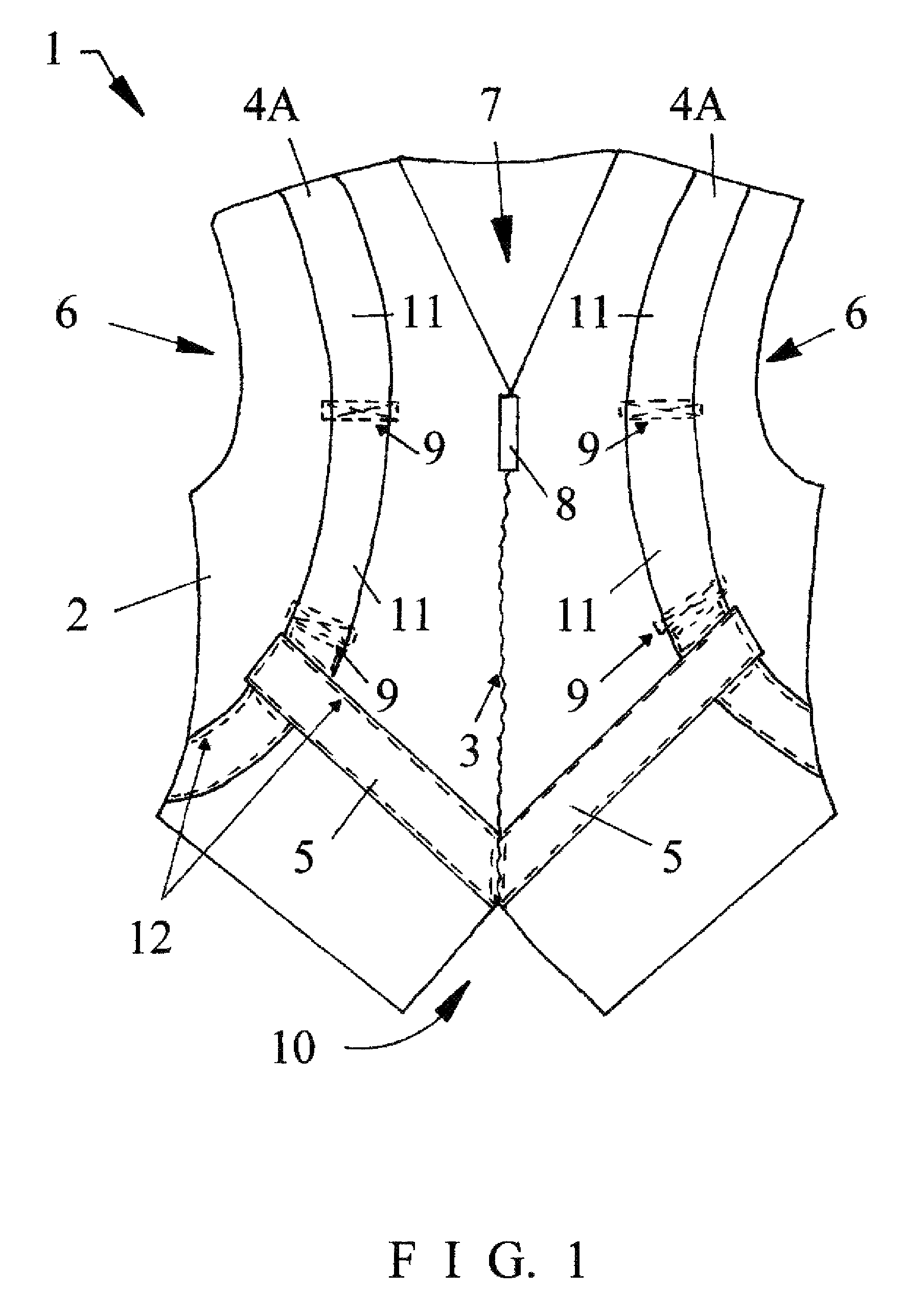

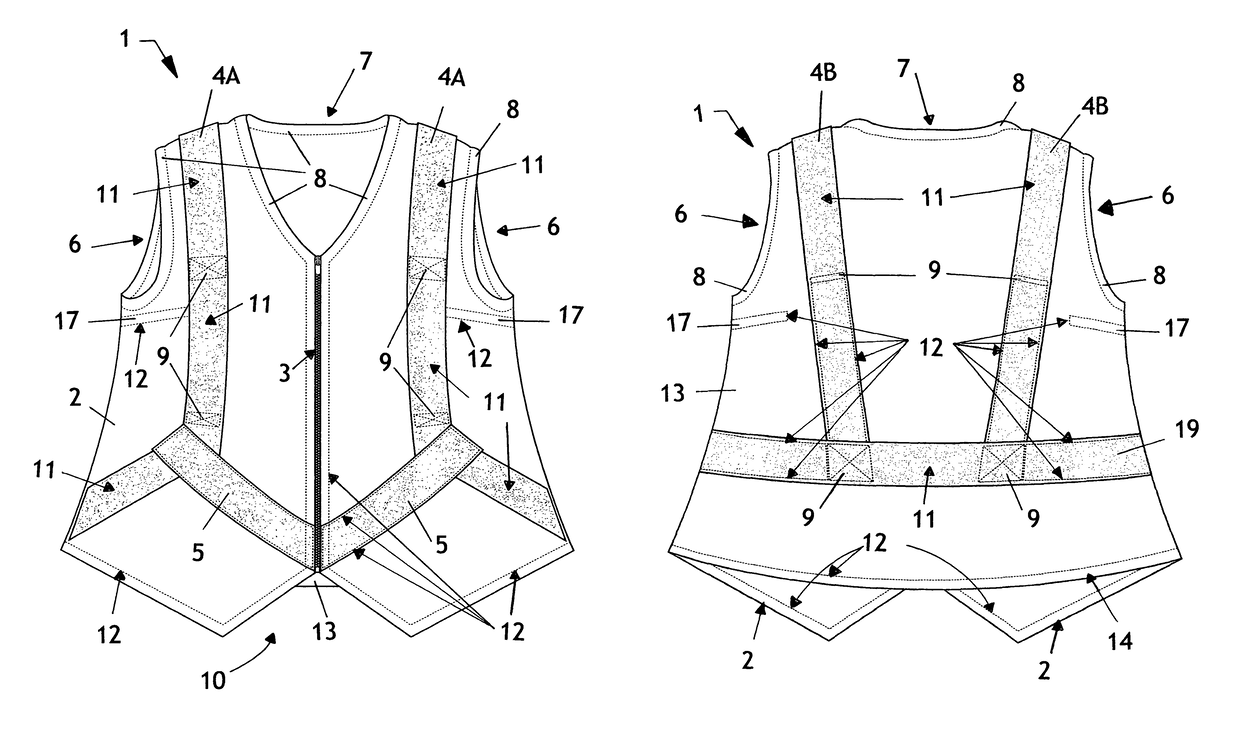

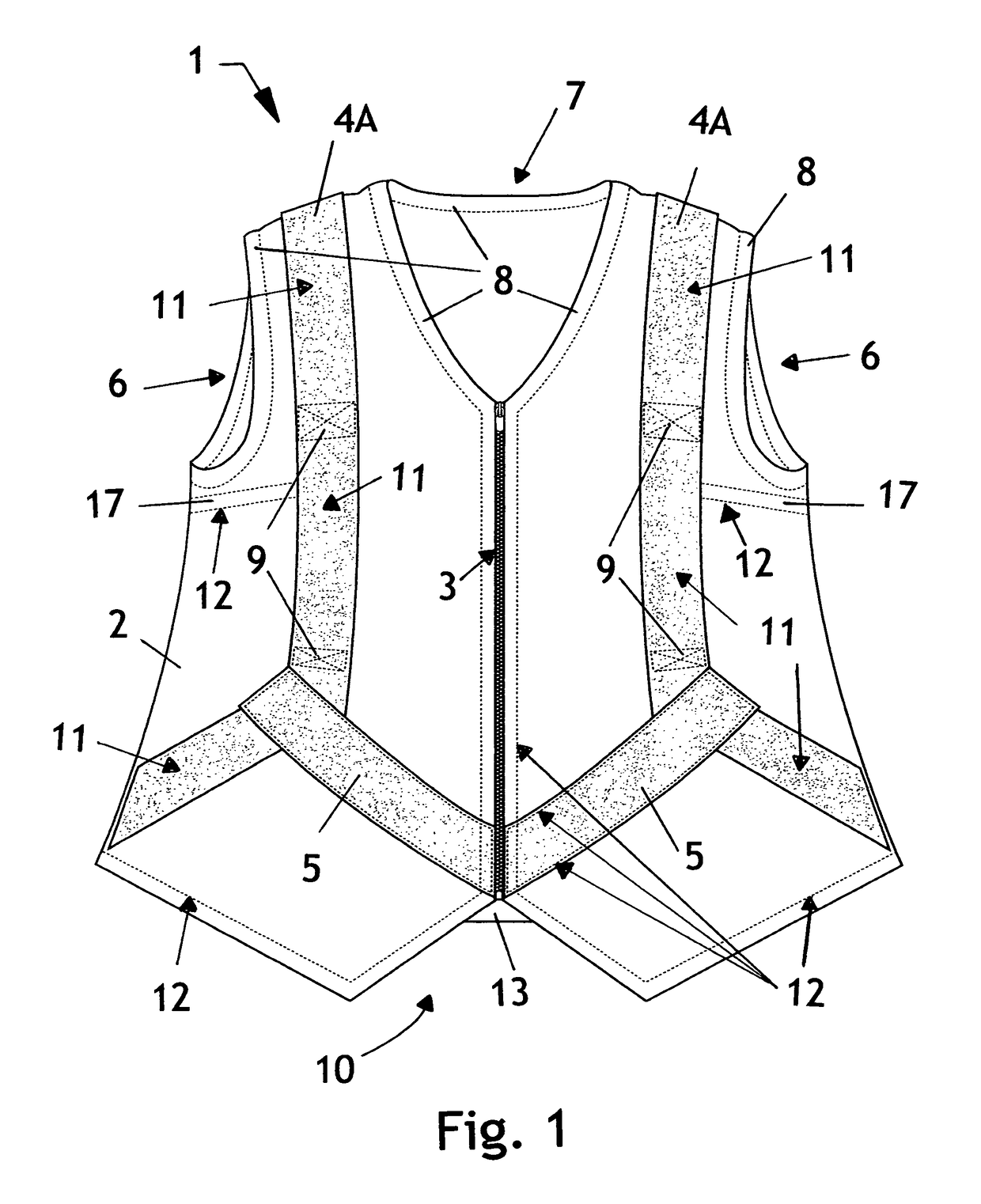

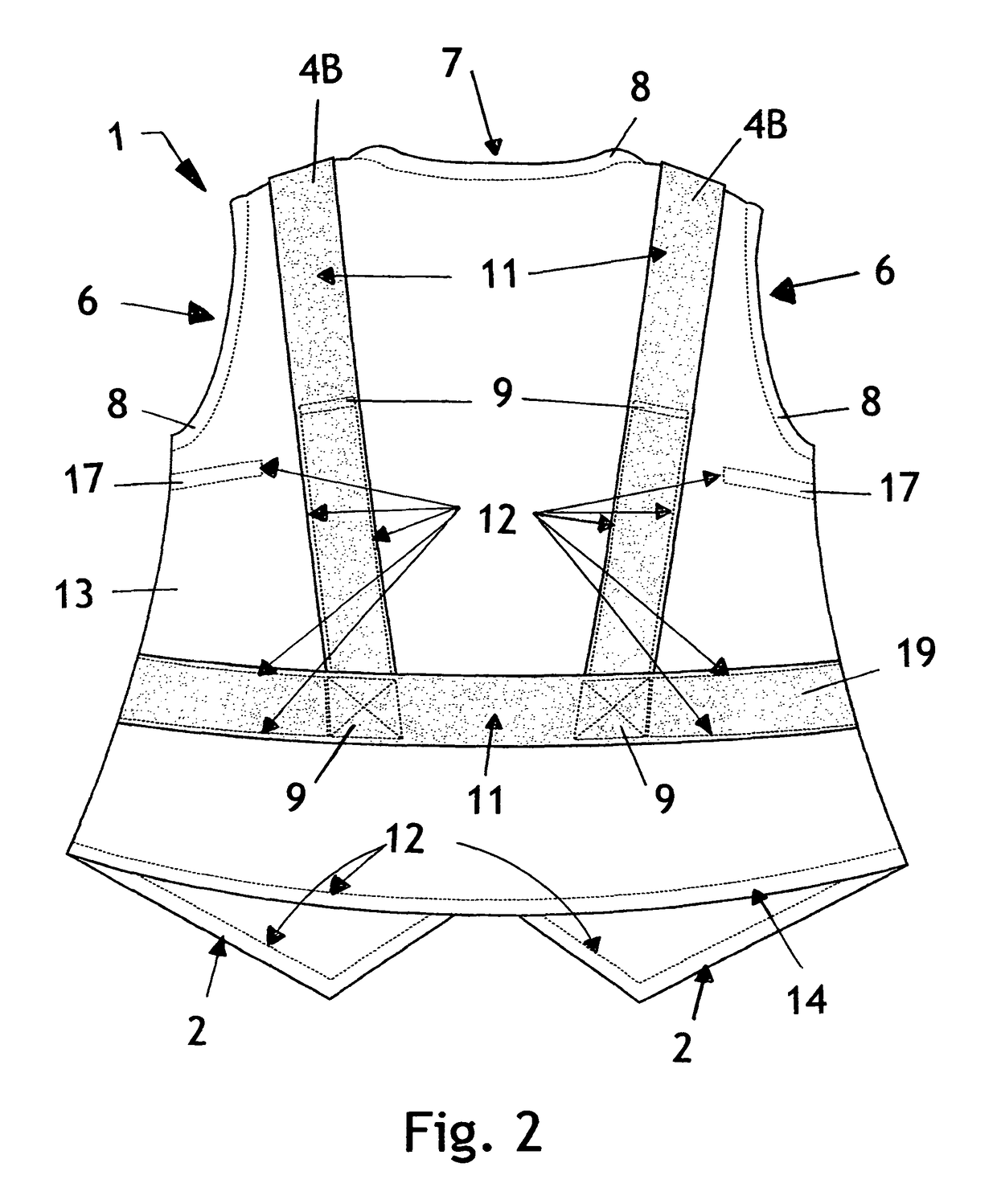

Adjustable manual transfer vest

ActiveUS10420689B1High level of comfort and safetyWell-designedNursing bedsProtective garmentJoint dislocationBody mechanics

A one-piece vest garment having a fashionable appearance wearable in public settings, with an adjustable tapered / secure fit providing efficient manual transfer / lift assistance to caregivers with mobility challenged patients at risk for falling and in need of assistance during standing, walking, sitting, or repositioning activities. It provides secure, steady, and controlled patient lifting while promoting good body mechanics for reduced risk of caregiver shoulder, hand, wrist, and back injury. Since the vest more evenly distributes pressure around a patient's body, in lift maneuvers patient skin tears, bruising, and joint dislocations are reduced. It preferably has four fit-adjusting contour straps and double locking D-ring assemblies, including inner front chest strap, inner front waist strap, exterior back shoulder strap, and exterior lower back strap; a double zippered front closure; and eleven hand grip components, four front, five back, and two side, each fixed with circular stitching for sturdiness and durability during transfer / lift maneuvers.

Owner:FOSTER CATHY J +1

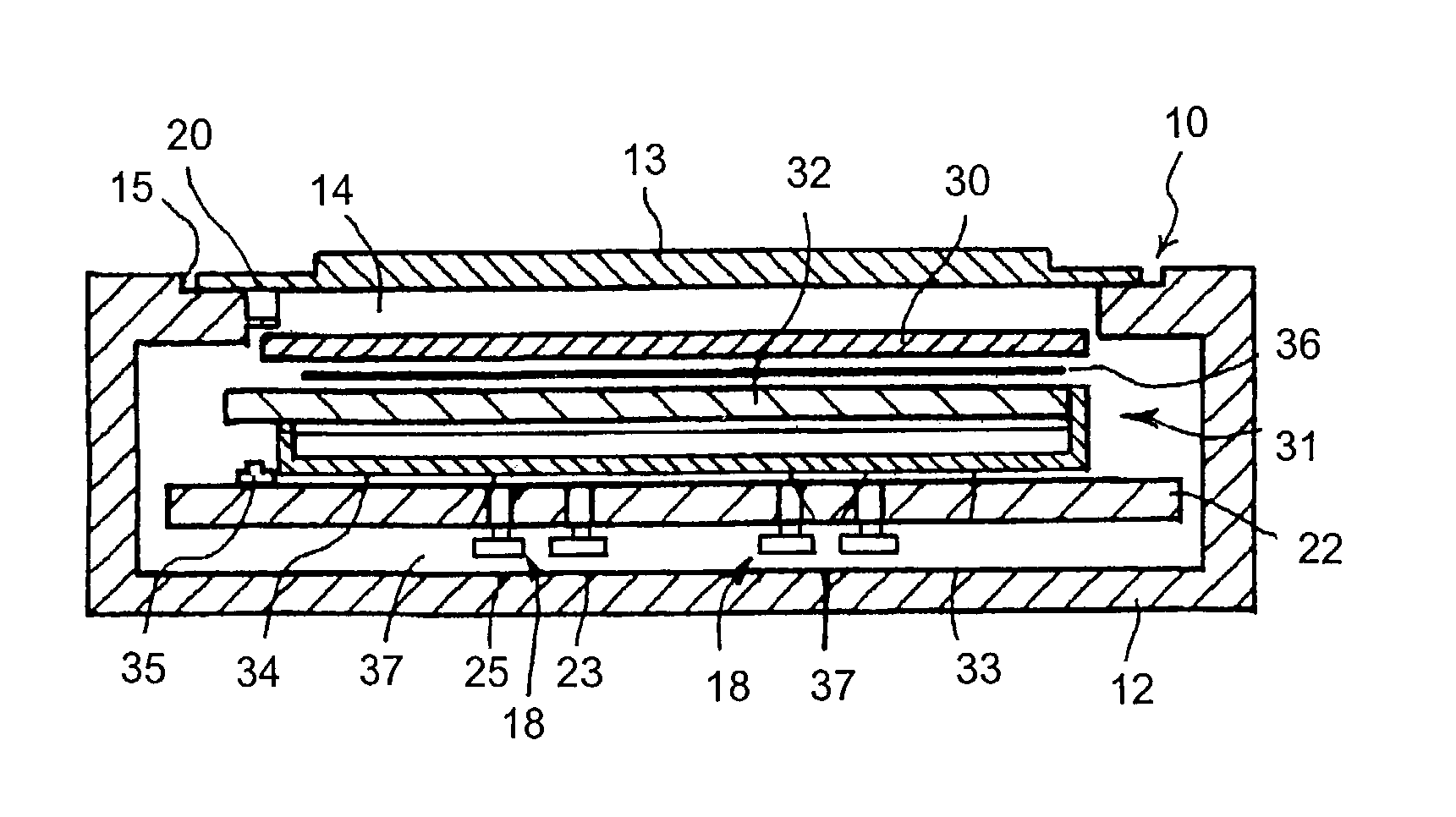

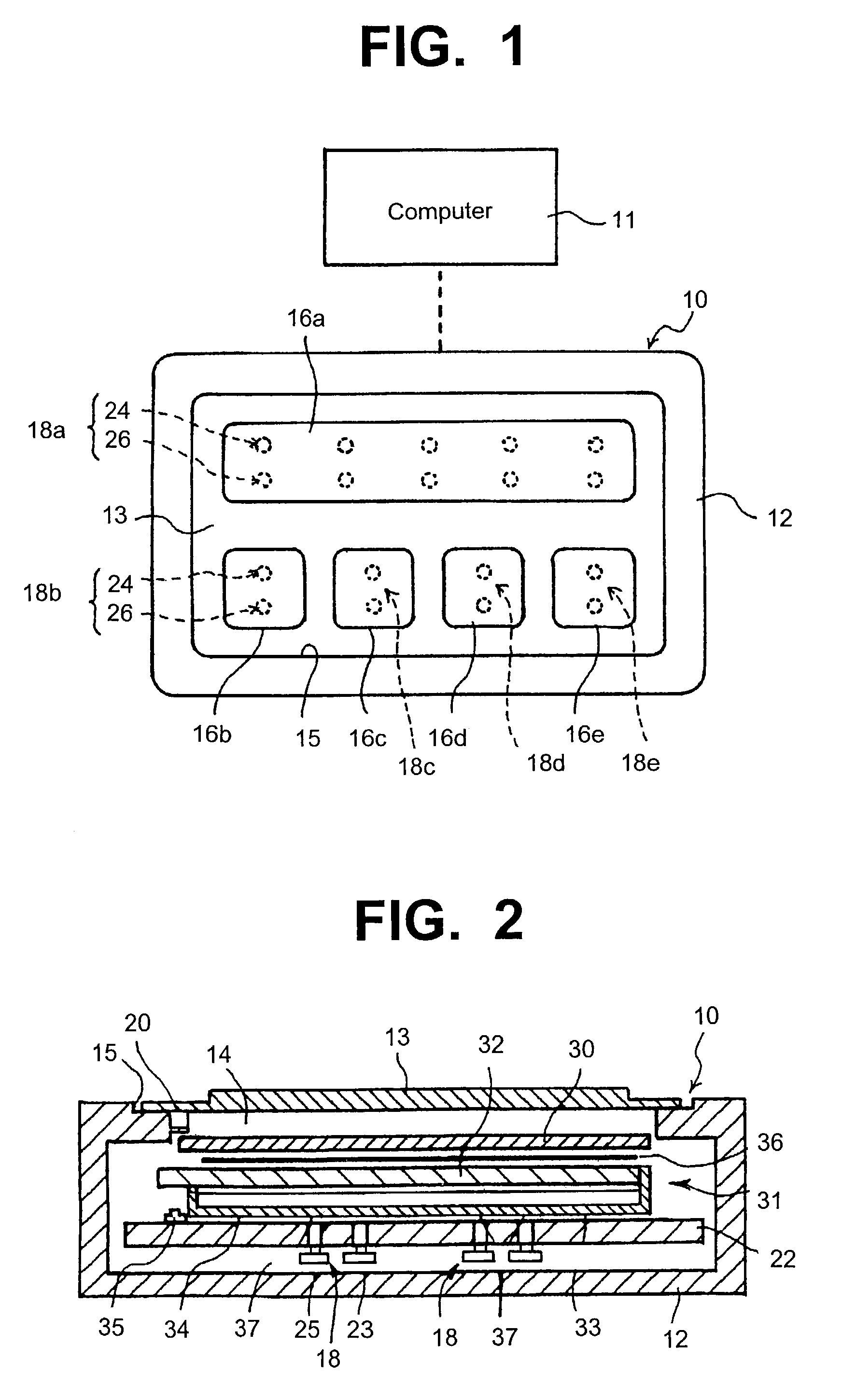

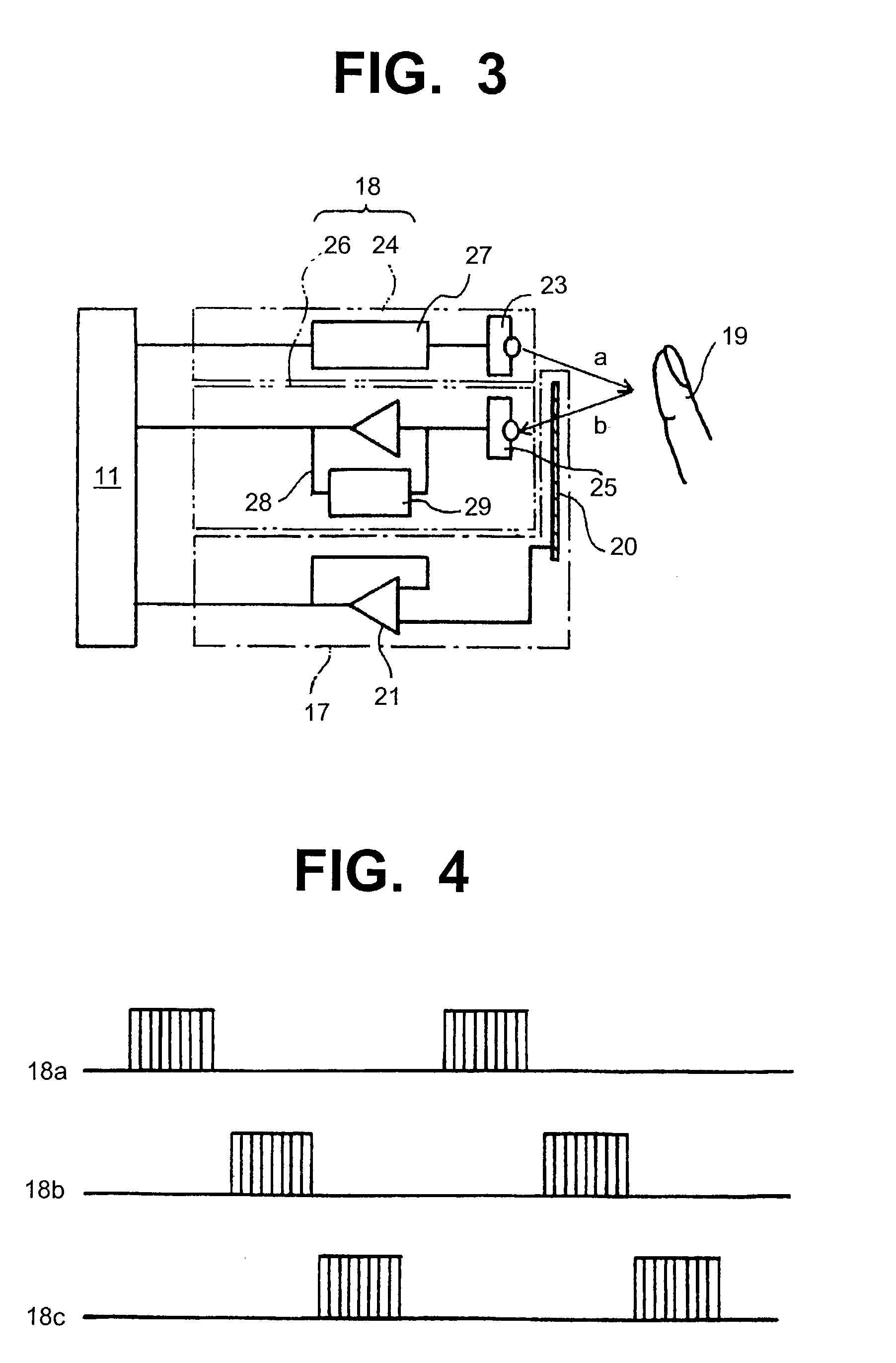

Touch-type input apparatus

InactiveUS7138986B2Avoid failureWell-designedInput/output for user-computer interactionEmergency casingsHome applianceLight signal

A touch-type input apparatus which is used for operating equipment such as electric home appliances, is durable and well-designed, and prevents malfunction is disclosed. The touch-type input apparatus includes a translucent touch operation panel, touch detection means, light detection means, a light reception unit, and input determination means. The touch detection means detects a touch on the touch operation panel. The light detection means includes a light emission unit and a light reception unit. The light emission unit is provided on the rear surface side of the touch operation panel and transmits a unique light signal through the touch operation panel. The light reception unit detects a reflected unique light signal which is transmitted from the light emission unit and is reflected on a front surface side of the touch operation panel. The input determination means determines the intended input operation based on detection signals supplied from the touch detection means and the light detection means.

Owner:SMK CORP

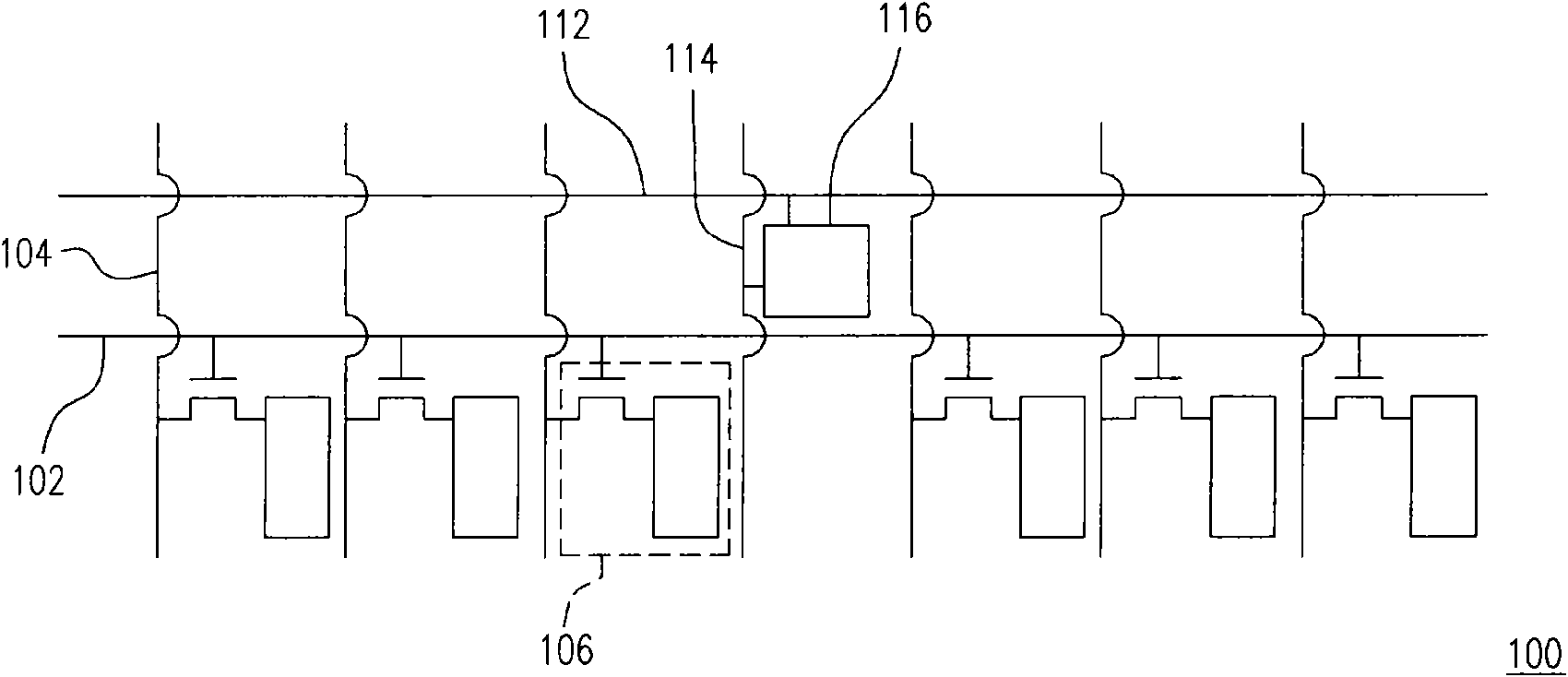

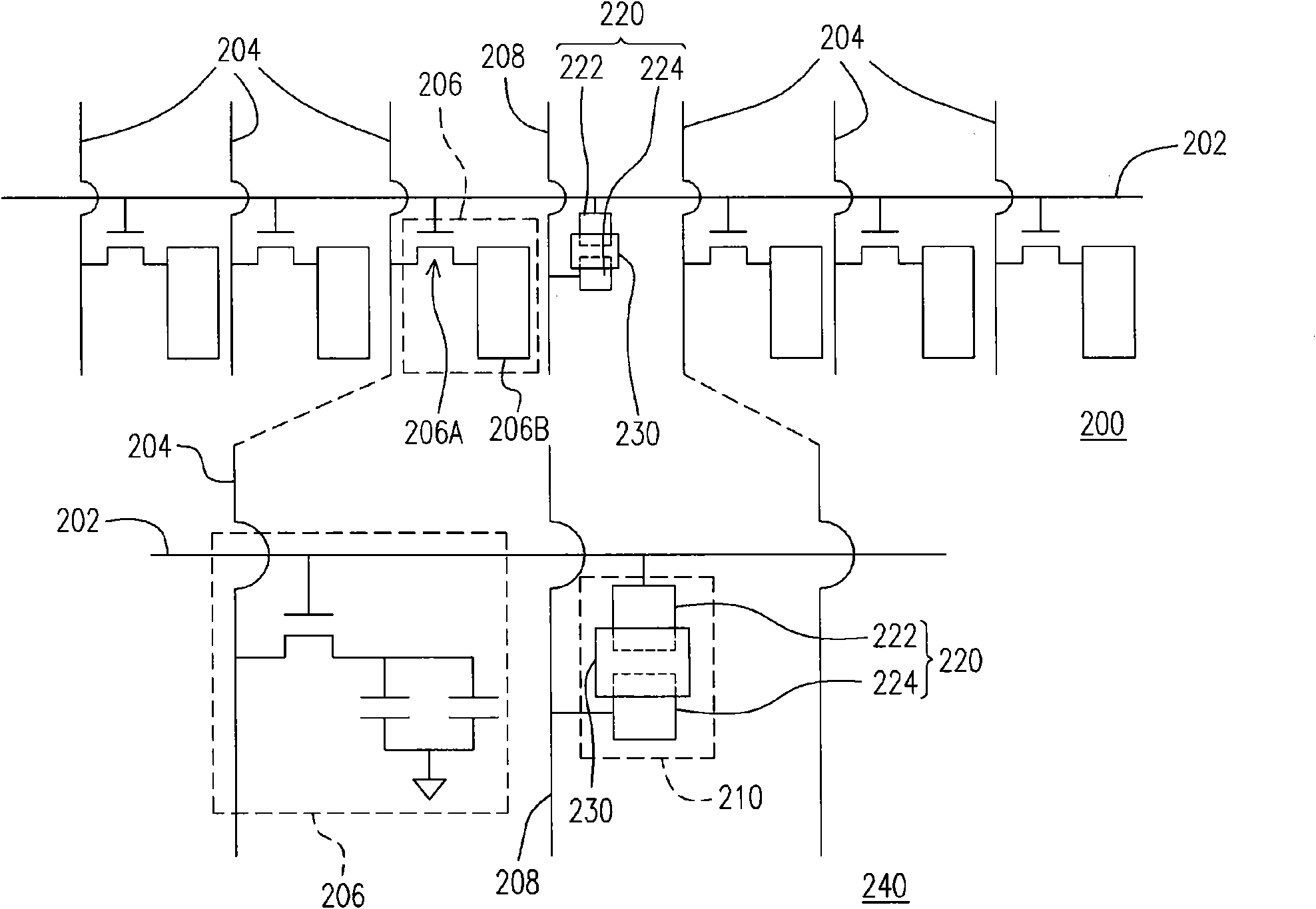

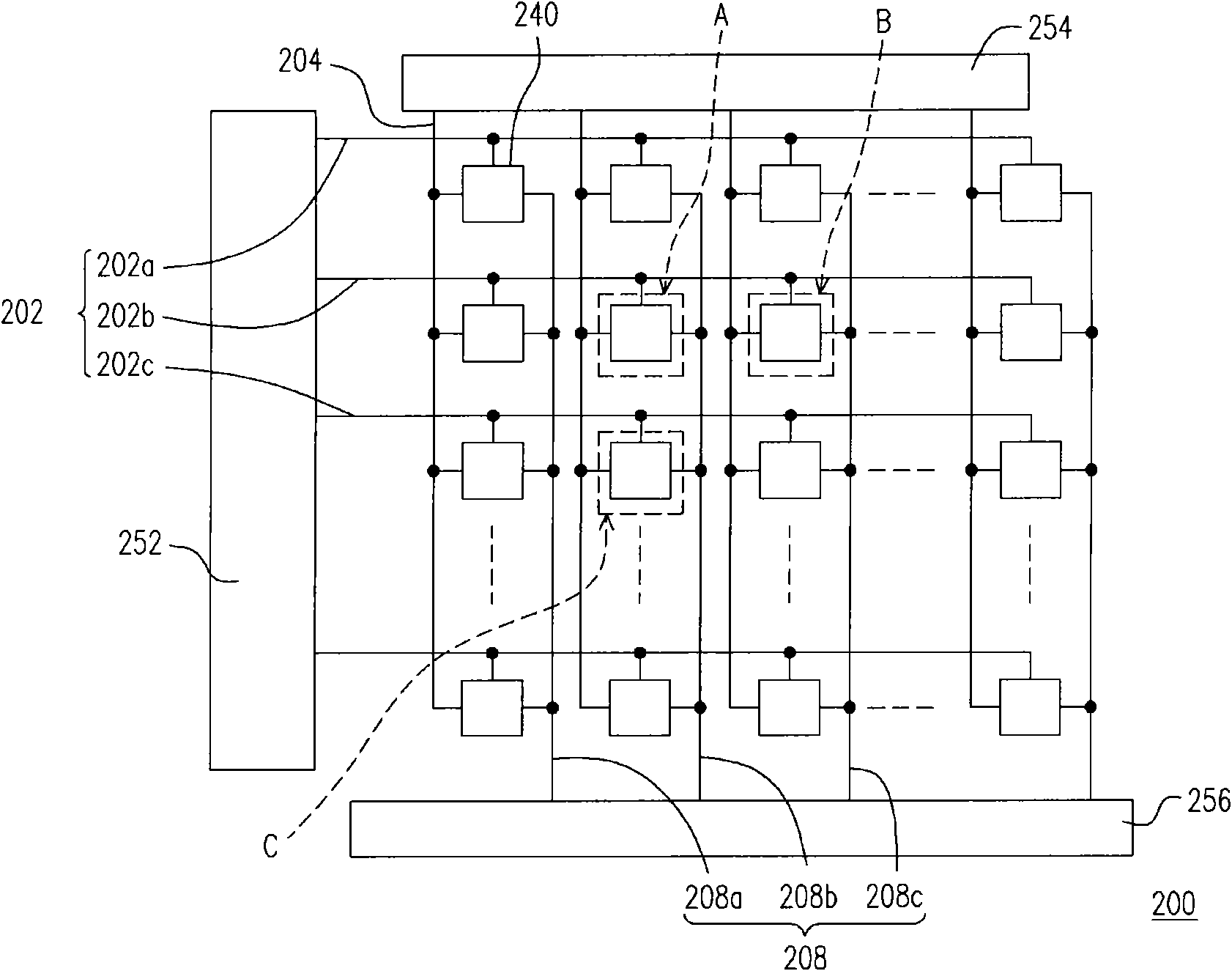

Touch control type display panel

InactiveCN101807127ASimplify wiring layoutWell designedInput/output processes for data processingSignal linesScan line

The invention relates to a touch control type display panel which comprises at least one sensing signal line, at least one touch control sensing assembly, a plurality of scan lines, a plurality of data lines and a plurality of pixel units, wherein the scan lines and the data lines intersect; the pixel units are electrically connected with the scan lines and the data lines; the sensing signal line is positioned among the pixel units; each touch control sensing assembly comprises a sensing pad group and a signal transmission part; the sensing pad group comprises a first pad and a second pad which are separated from each other; the first pad is electrically connected with the scan lines; the second pad is electrically connected with the sensing signal lines; the signal transmission part is positioned above the sensing pad group; when the position of the touch control sensing assembly is pressed, the signal transmission part is directly in contact with the first pad and the second pad; and when the position of the touch control sensing assembly is not pressed, the first pad and the second pad are electrically insulated.

Owner:WINTEK CORP

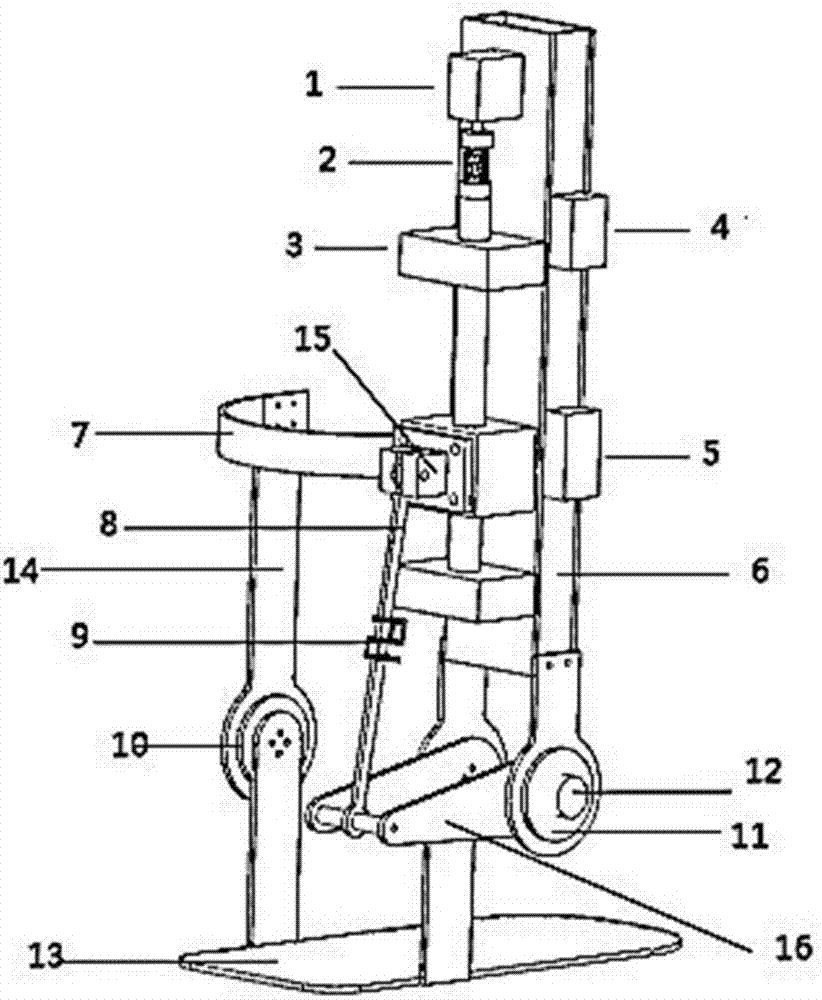

Ankle rehabilitation exoskeleton device

InactiveCN106880469ACompact structureWell designedDiagnosticsChiropractic devicesWeaknessVIT signals

The invention provides an ankle rehabilitation exoskeleton device, which comprises the following devices: a signal transmission device, a control device, a driving device, a transmission device and a memory device, wherein the signal transmission device comprises a force sensor and a rotation sensor; the force sensor is used for detecting pressure signals of the transmission device and the rotation sensor is used for detecting a rotation direction of the transmission device; the control device is used for controlling the driving device to run in accordance with signals received from the signal transmission device, wherein the signals of the signal transmission device include the pressure signals and rotation direction signals; the driving device, under the control of the control device, is used for driving the transmission device and for outputting transmission data; the transmission device, under the driving of the driving device, is transmitted; and the memory device is used for receiving and keeping transmission data outputted from the driving device in real time. The ankle rehabilitation exoskeleton device provided by the invention has the advantages of being compact in structure, delicate in design, small in volume, low in cost and convenient to wear; external force weakness and direction can be adjusted in real time in accordance with exercise situation of a user; and by arranging data recording, analysis and statistic can be conducted on an ankle recovery situation, so that personalized treatment is achieved.

Owner:SHANGHAI JIAO TONG UNIV

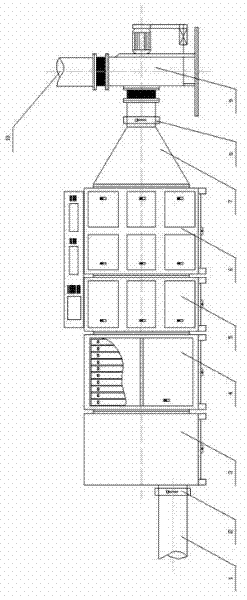

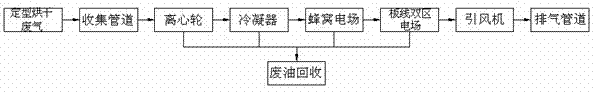

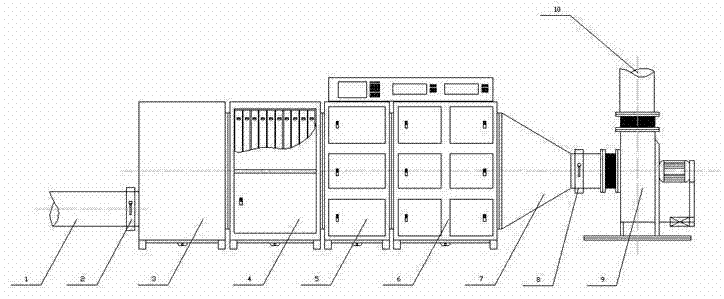

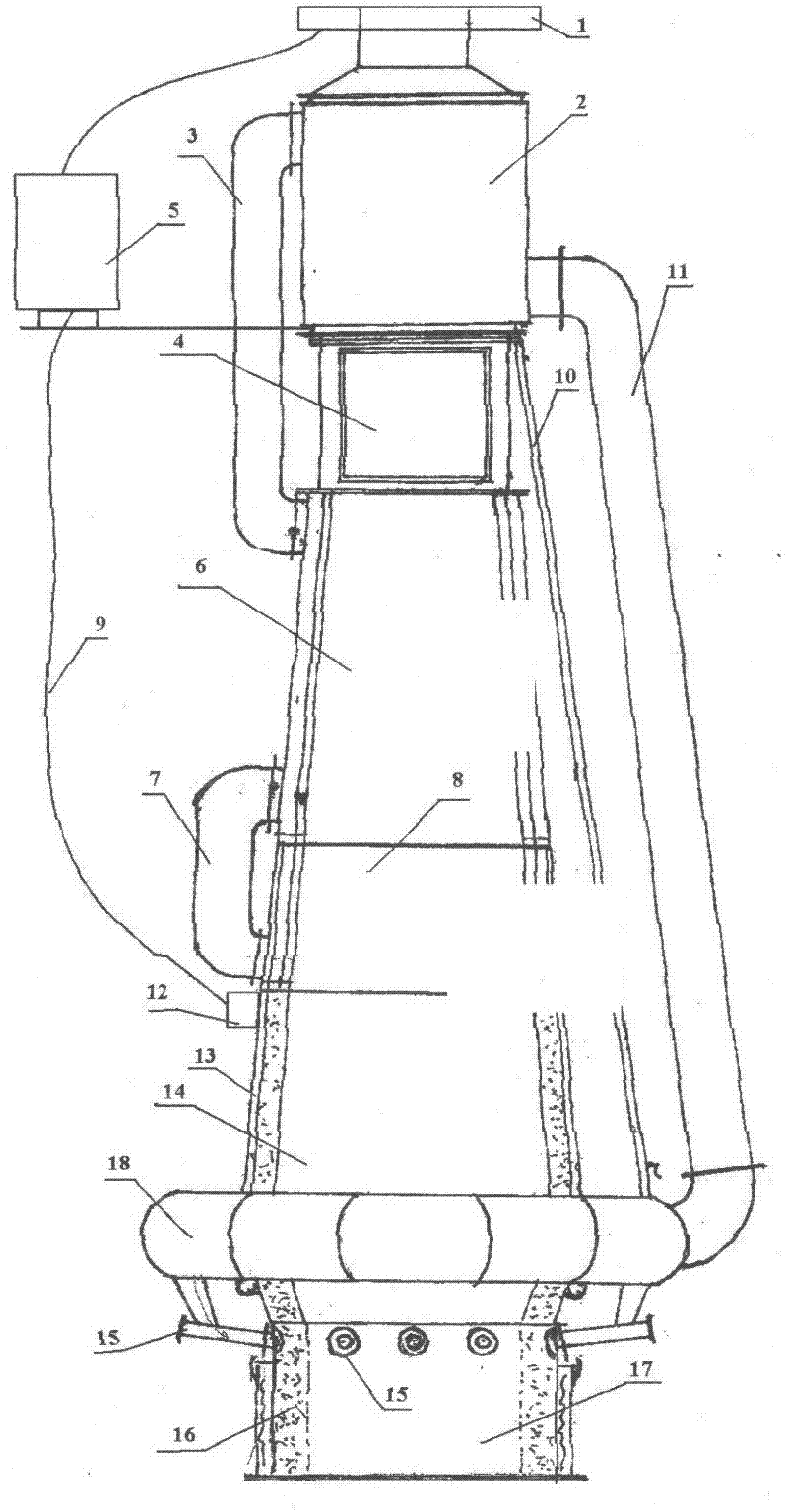

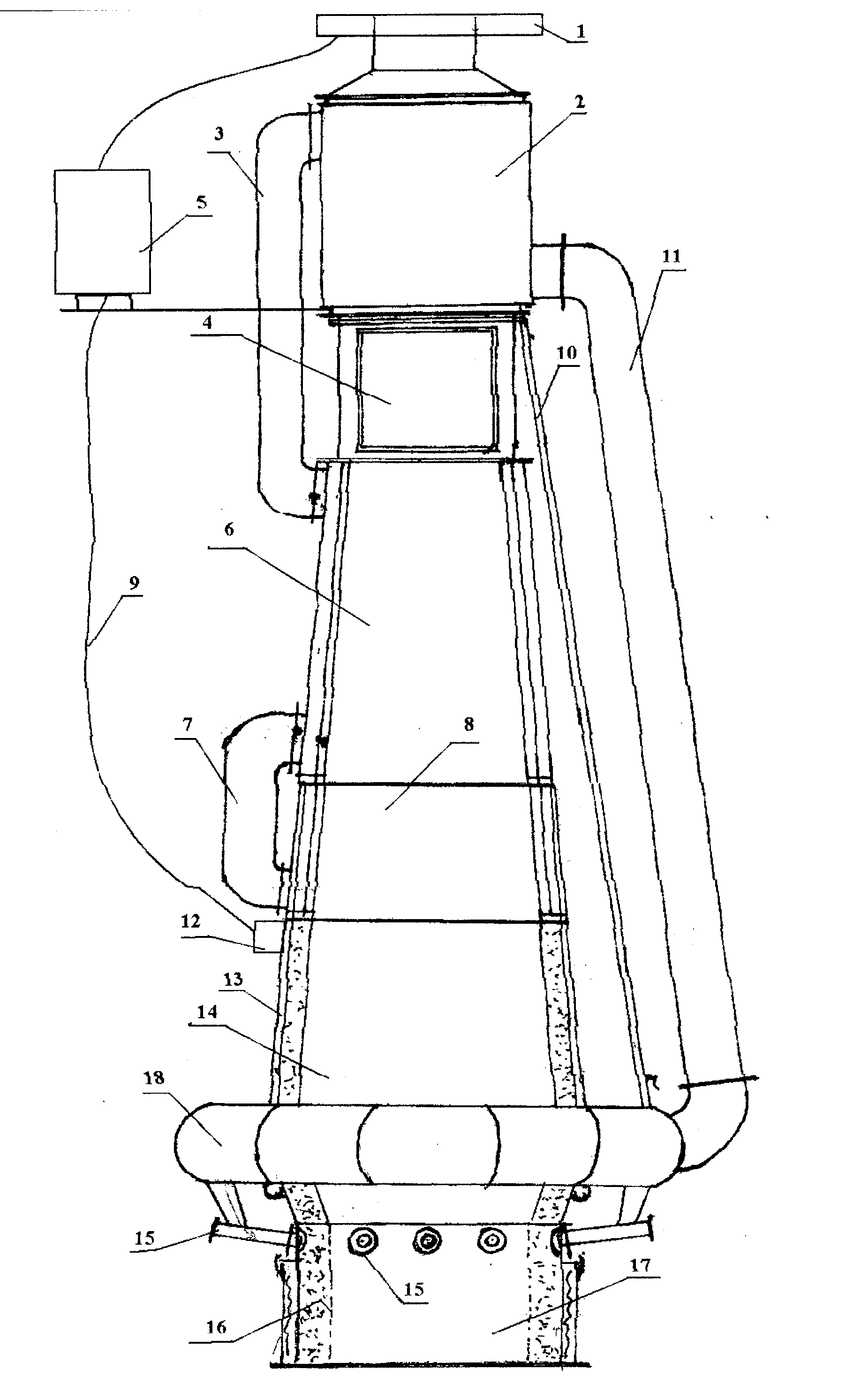

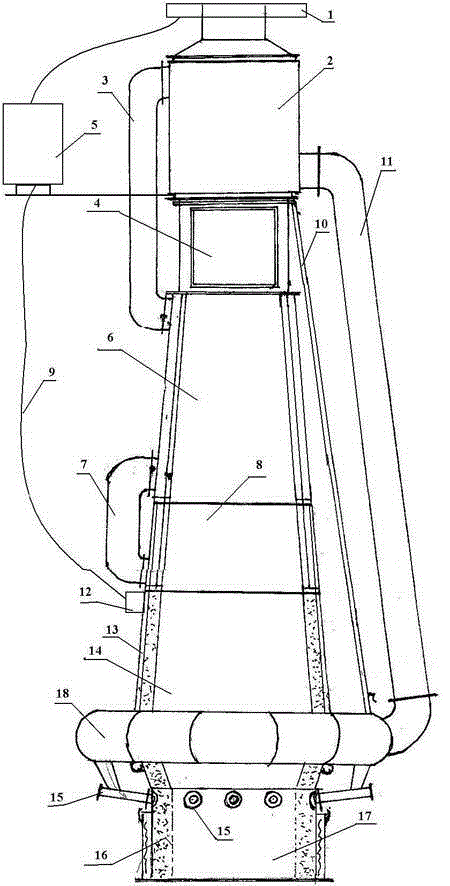

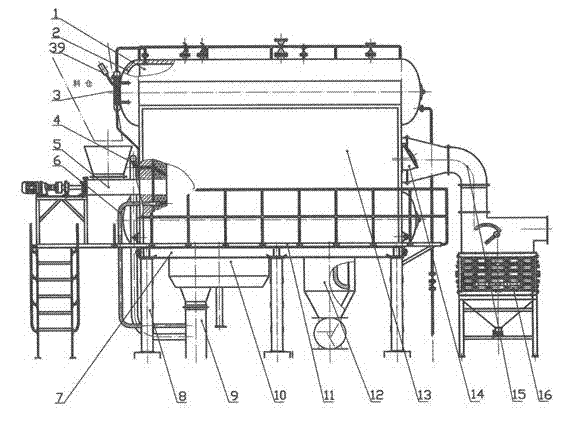

Device for treatment of waste drying gas from sizing in textile dyeing and finishing and process for the same

InactiveCN102553719AImprove securityIncrease humidityExternal electric electrostatic seperatorFiberParticulates

The invention discloses a device for treatment of waste drying gas from sizing in textile dyeing and finishing and process for the same. The device comprises a collecting duct, a front fire resisting damper, a centrifugal wheel, a condenser, a honeycomb electric field, a plate line double-area electric field, a stream guidance duct, a rear fire resisting damper, a draught fan and a discharge duct which are connected in sequence, wherein the centrifugal wheel is installed on the electric machine. After being gathered by the collecting duct, the waste gas firstly enters into the centrifugal wheel for humidification and most of the oil drop and fiber with larger grain size are intercepted; the waste gas treated by the centrifugal wheel is cooled in the condenser and then enters the honeycomb electric field for pretreatment; after that, the oil gas enters the plate line double-area efficient purifying electric field for further treatment; finally the gas goes through the stream guidance duct and is discharged by the draught fan after coming up to the standard. The device of the invention integrates the advantages of several waste oil gas treatment technologies, has high purification efficiency, and can be widely used for the treatment of waste drying gas from sizing machine in the textile dyeing and finishing industry.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

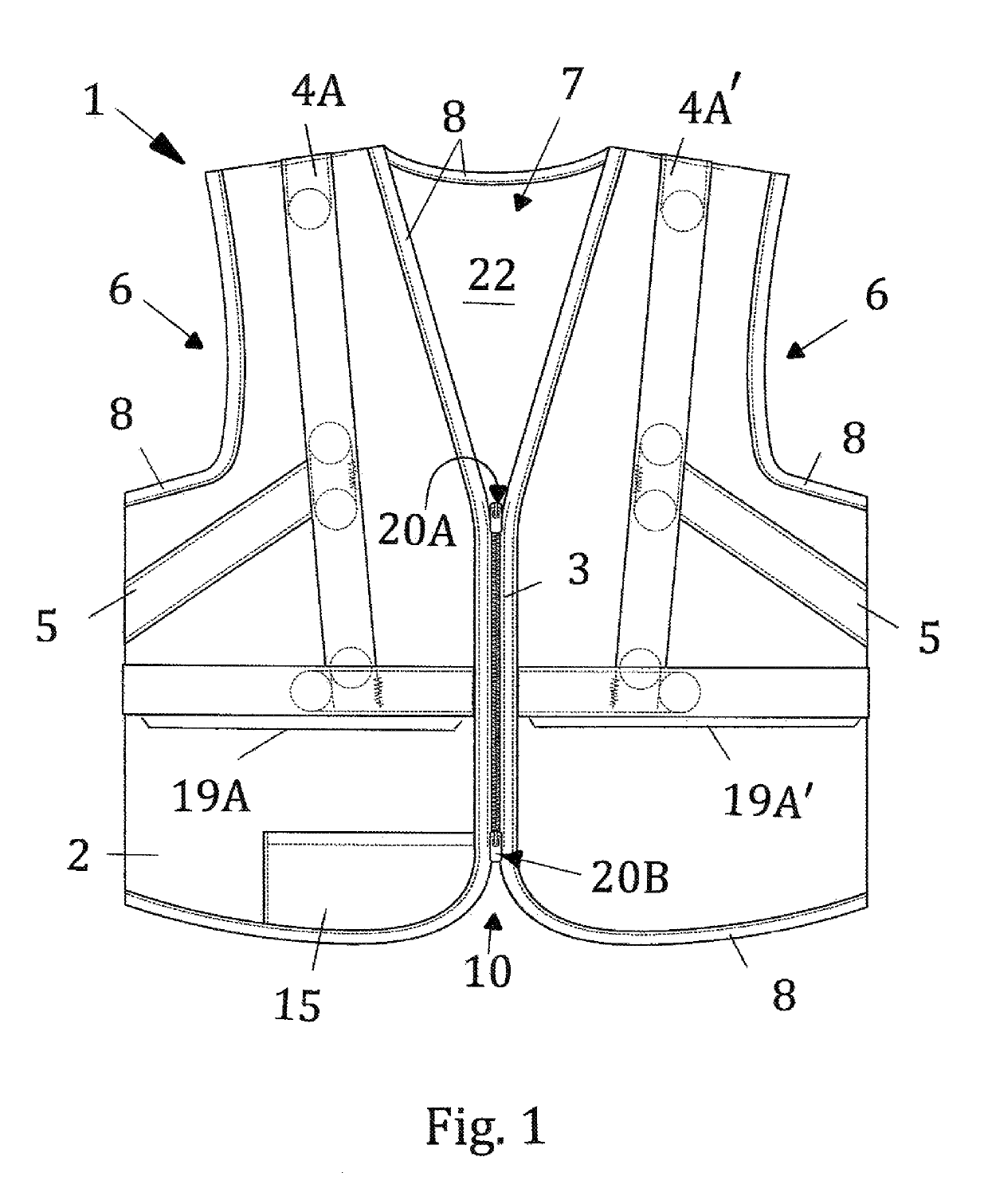

Manual transfer vest

ActiveUS9015880B1High level of comfortHigh level of safetyNursing bedsProtective garmentEngineeringInjury prevention

A manual transfer vest which aids in compensating for fatigue, pain, loss of strength, mobility, and energy in the daily life of a patient or individual / caregiver assisting the patient. It comprises soft, lightweight, and preferably washable material that enwraps the patient's torso, and also has at least two vertically-extending and non-adjustable hand-grip lift components with sturdy and durable construction and attachment. In most embodiments, six hand-grip lift components are used, with two upper front hand-grips preferably situated bilaterally in the clavicle / upper chest area of the patient, or the shoulder area, two lower front hand-grips situated bilaterally in the abdominal / mid-section area of the patient, and two upper back hand-grips located near the shoulders. For vest durability during repeated patient lifting, reinforcement lining material is also secured to the front exterior of the vest diagonally below hand-grips. Overall, the manual transfer vest promotes safety in preventing injuries, thereby reducing medical costs.

Owner:CAUTHEN PEGGY S +1

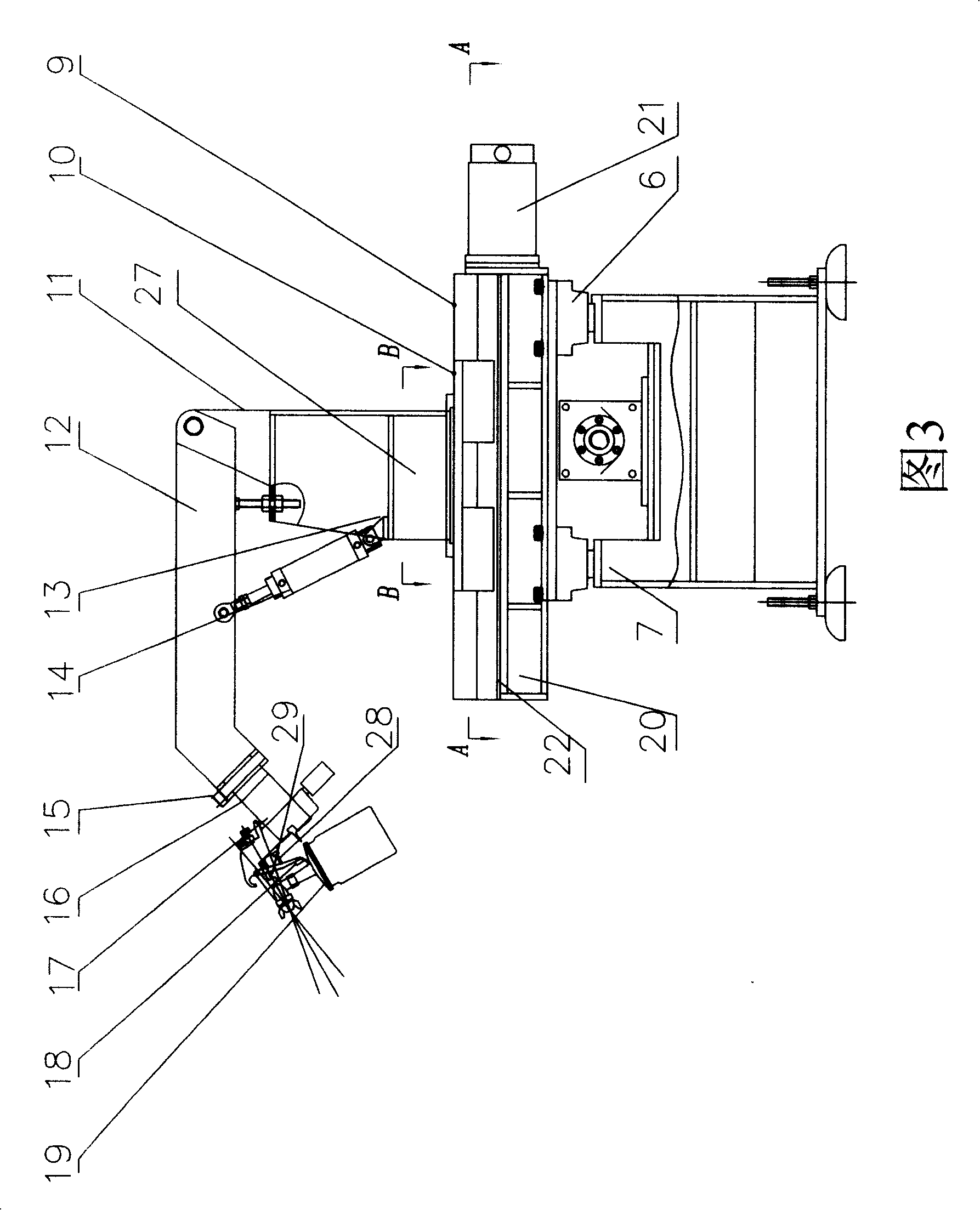

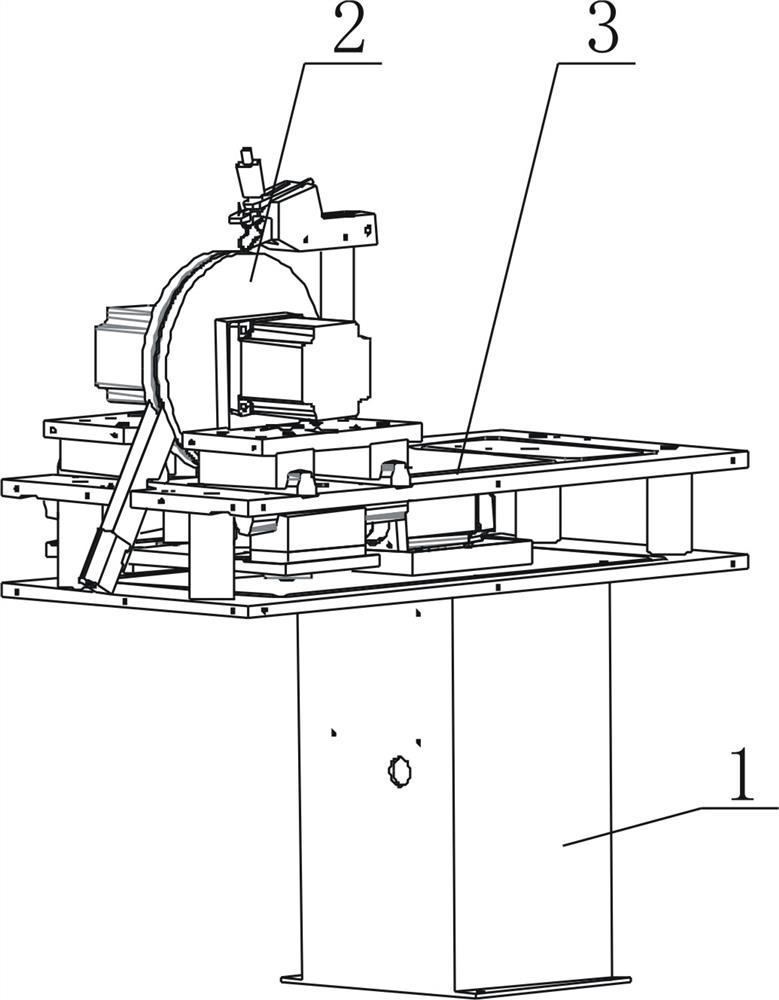

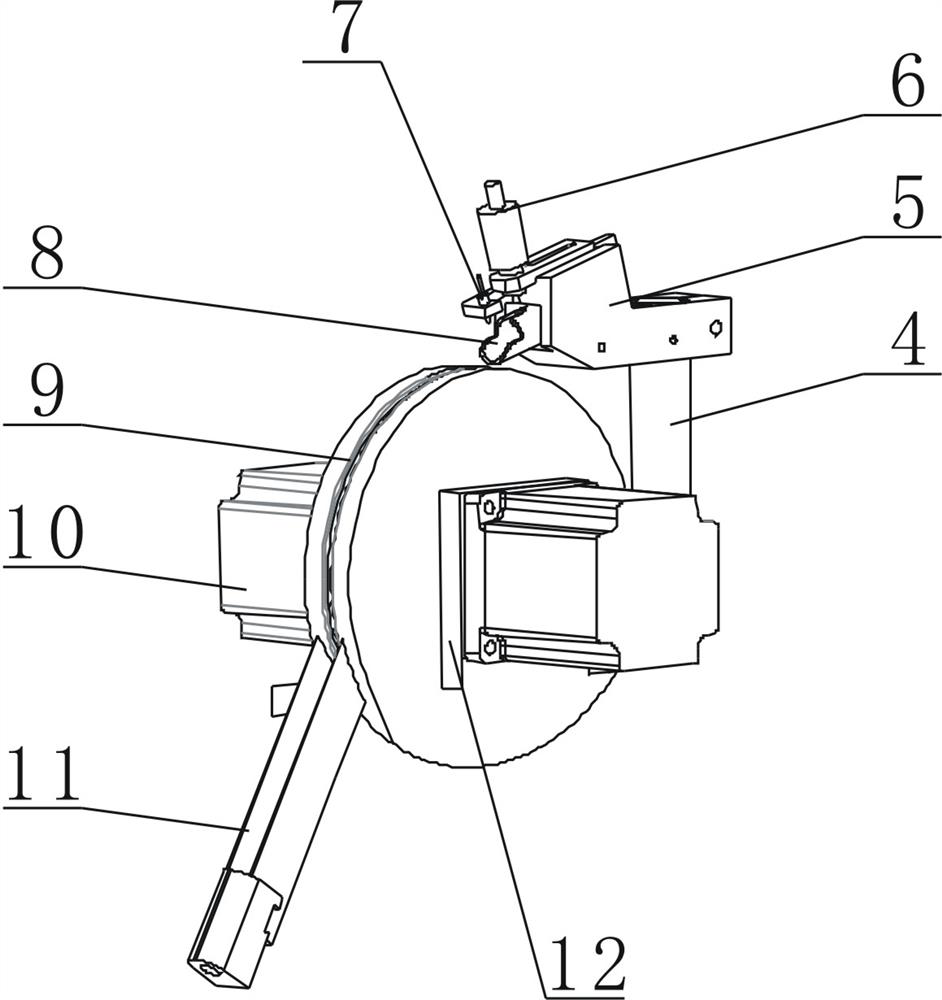

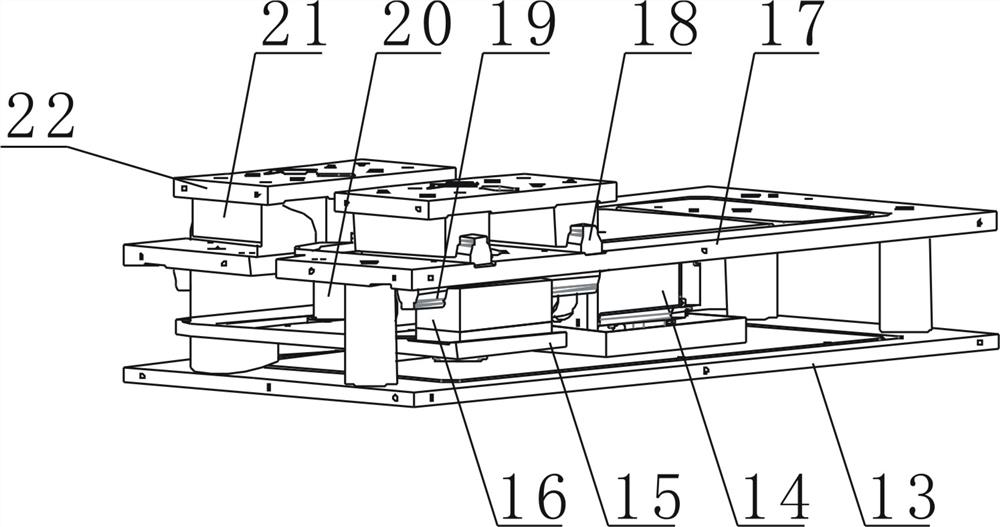

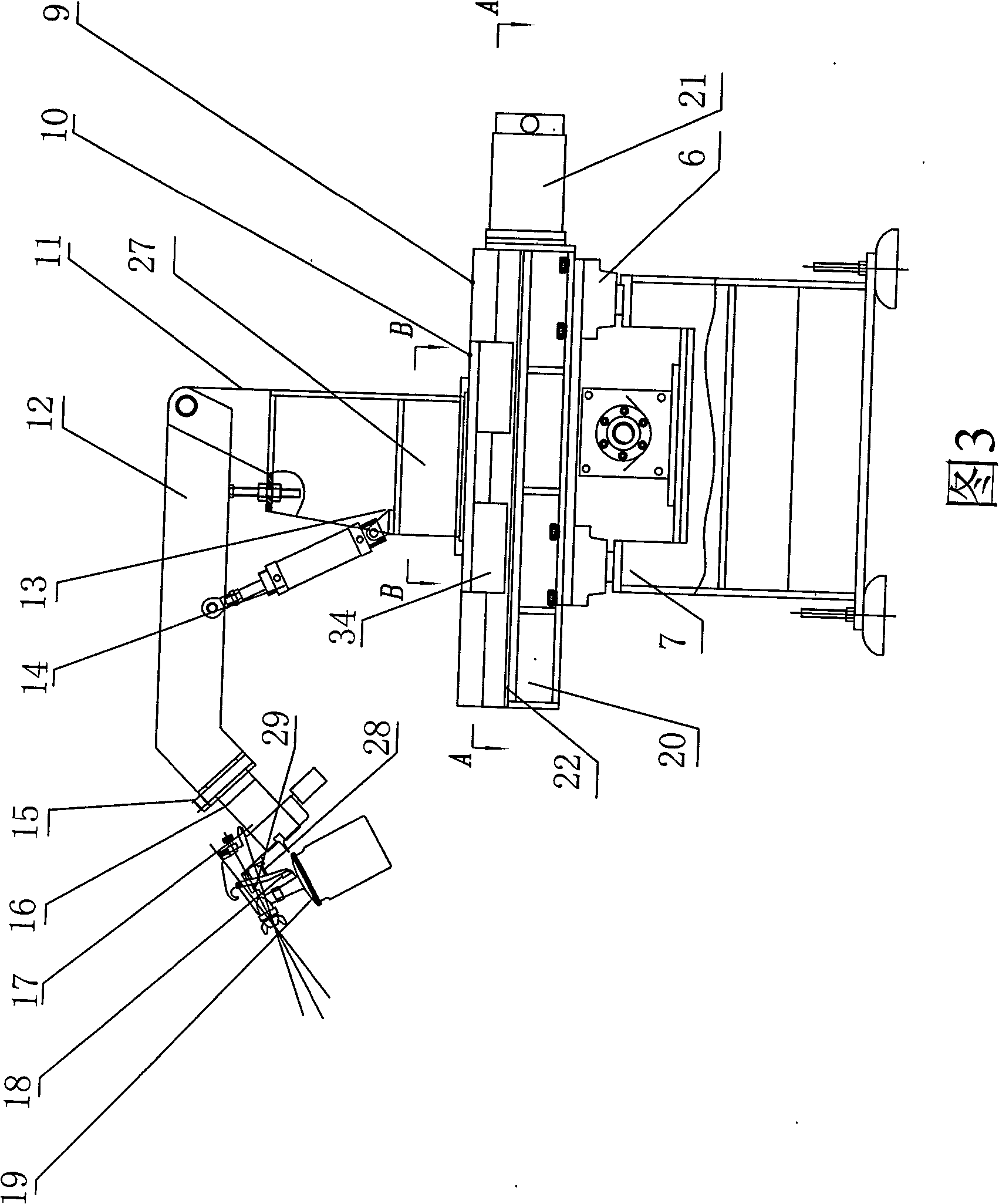

Laser cladding powder spraying machine

InactiveCN101161863AKeep healthyIngenious ideaMetallic material coating processesLaser beam welding apparatusMachine controlAutomatic control

A laser cladding powder spraying machine comprises a transmission device, a spraying device and a gas path control mechanism; a fixed ring is arranged above a base of a spraying car; a rotary ring is connected with the upper part of the fixed ring; a locking keep plate is connected between the fixed ring and the rotary ring; a spraygun vertical wall is fixed on the rotary ring and is in flexible connection with a transverse arm through a pin roll; the middle of the spraygun vertical wall is provided with a cylinder block; the top of a cylinder piston rod is fixed on the middle of the transverse arm. The front end of the transverse arm is provided with an angle adjusting device and is tightly connected with the mounting bracket of a spraygun; a biaxial cylinder and a spraygun are arranged above the mounting bracket; the top of the piston rod in the lower part of the biaxial cylinder is tightly connected with a spray hooker. The invention is skillful in design, reasonable in structure, simple in operation and automatic in the whole machine control; as the spraying car can operate vertically and horizontally and the rotary ring of the base rotates according to specific conditions, the transverse arm can move up and down when spraying; the spraygun can have multi-angle rotation and can complete multi-angle spatial spraying; as the invention has automatic control, uniform spraying, superior quality and high working efficiency, the health of operators can be fully ensured.

Owner:BEIJING DALU TIANRUI LASER ENG TECHCO

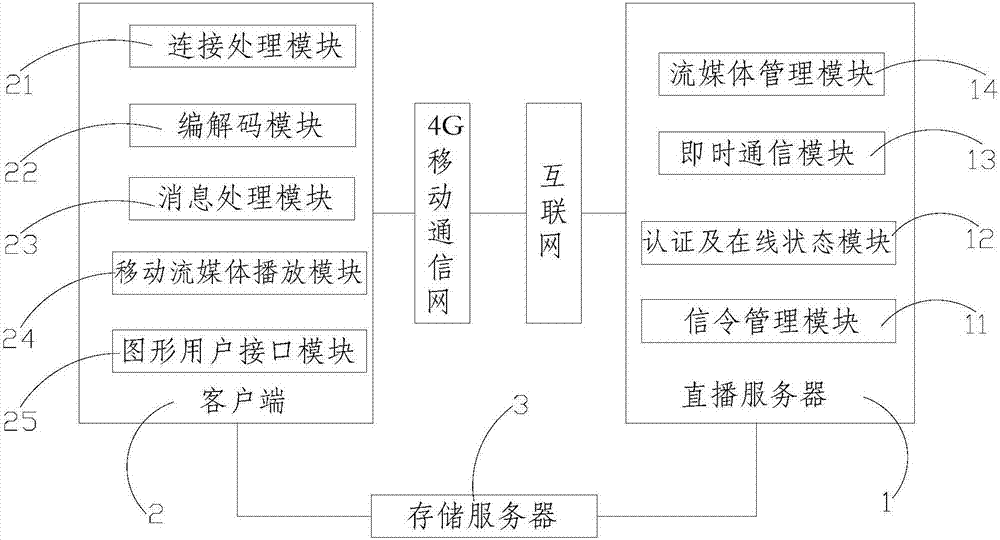

Mobile Internet live broadcasting platform

The invention relates to a mobile Internet live broadcasting platform comprising a live broadcasting server and a client, wherein the client is connected with the live broadcasting server via a mobile Internet. The platform also comprises a storage server respectively in communication connection with the client and the live broadcasting server and used for storing programs played by the live broadcasting server and videos after live broadcasting. The mobile Internet live broadcasting platform provided by the invention has the beneficial effect as follows: the platform adopts an XMPP protocol and expansion protocols thereof, RTP, RTCP and RSTP to achieve bidirectional interaction of mobile streaming media playing of the mobile phone and the video.

Owner:北京颐和正新科技有限公司

Manual transfer vest

ActiveUS9642400B1High level of comfort and safetyBetter accommodateNursing bedsProtective garmentEngineeringPatient comfort

A manual transfer vest which aids in compensating for fatigue, pain, loss of strength, mobility, and energy in the daily life of patients and / or individuals / caregivers assisting them. It comprises soft, lightweight, and preferably washable material that enwraps the patient's torso, and also has at least seven non-adjustable hand-grip lift components with sturdy and durable construction and attachment. In some preferred embodiments, nine hand-grip lift components are used, with six hand-grip lift components preferably situated bilaterally on the vest front, and three hand-grip lift components situated on the vest back. For vest durability during repeated patient lifting, reinforcement lining stitching is secured adjacent to or near at least one end of all hand-grips lift components. Interior adjustment ties, padded neck and armhole openings, mesh fabric, and a collar may also contribute to patient comfort. Overall, the manual transfer vest promotes safety in preventing injuries, thereby reducing medical costs.

Owner:CAUTHEN PEGGY S +1

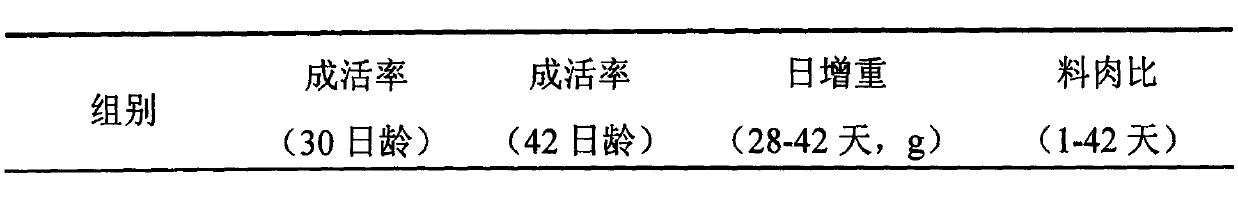

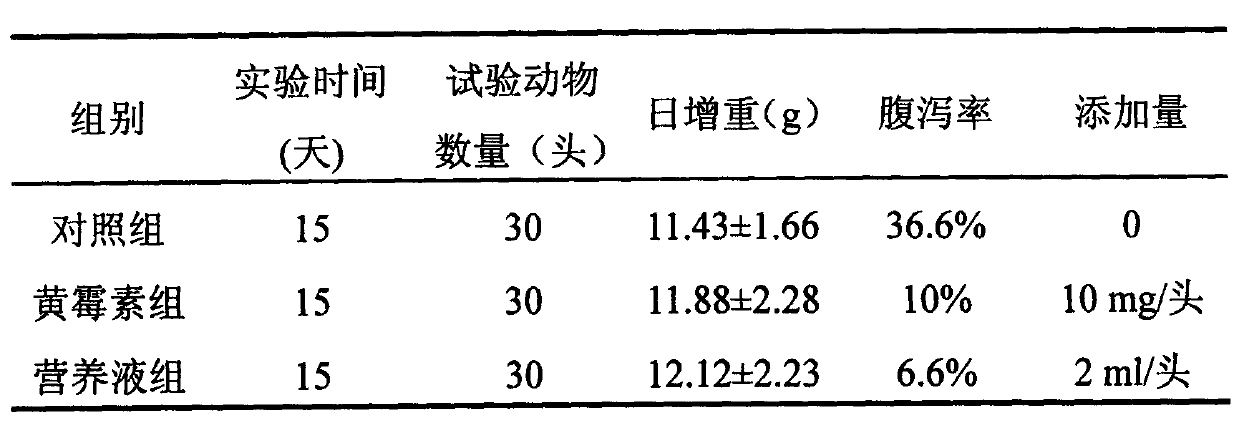

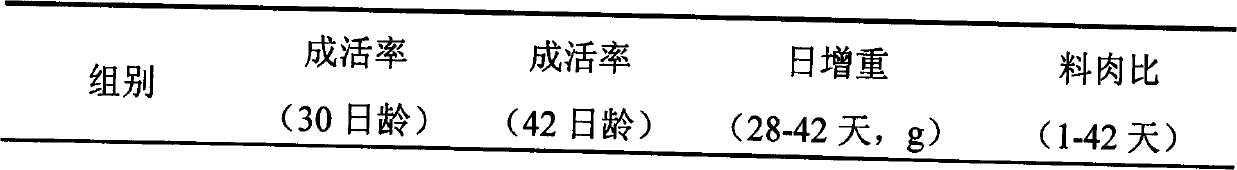

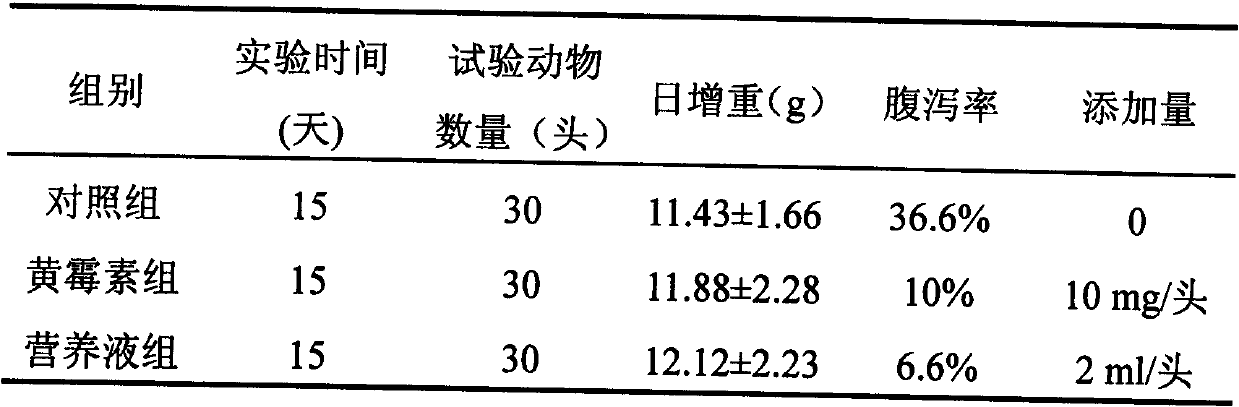

Nutritional health liquid for porket, and preparation method and application method thereof

ActiveCN102726622AComprehensive design considerationsStrong targetingAnimal feeding stuffConjugated linoleic acidPrecipitation

A nutritional health liquid for porket is prepared from antibody protein, conjugated linoleic acid, glucose, Twain-80, egg white, vitamin E, xanthan gum and distilled water. The preparation method of the nutritional health liquid includes steps of: extracting immunoglobulin IgG using a low temperature absolute ethyl alcohol precipitation method; evenly mixing the raw materials into a mixture; placing the mixture in an emulsifying machine and emulsifying the mixture into an emulsion; irradiating the emulsion by UV; and filling to obtain finished products. A usage method of the nutritional health liquid is as below: the porket orally takes 2ml immediately after birth, and then orally takes 0.5ml 7 days later until weaning. The main function of the nutritional health liquid is to repair and enhance the immune system of porket, and provide energy, vitamin and functional unsaturated fatty acids for early-stage porket; and the nutritional health liquid has excellent effects on valetudinarianism caused by inadequate milk of sow or weaning in early stage, so as to really focus on health of porket in the perspectives of immunity enhancement and nutrition strengthening.

Owner:上海国龙生物科技有限公司

Two-in-one multifunctional beauty device

InactiveCN106110495AWell designedReasonable structureElectrotherapyLight therapyLiquid-crystal displayKey switch

A two-in-one multifunctional beauty device provided by the present invention comprises a beauty device body, an LED liquid crystal display screen is arranged on the upper plane of the beauty device body, and an emergency switch and a key switch are arranged above and below the LED liquid crystal display screen respectively. An E-light manual tool and a laser manual tool are arranged at the two sides of the LED liquid crystal display screen respectively, and a radiating fan, an E-light manual tool socket, a laser manual tool socket, a water adding port, a pedal switch interface, a power supply interface, an overflow port and a drainage port are arranged on the backside of the beauty device body separately. The two-in-one multifunctional beauty device has the characteristics of being excellent in design, reasonable in structure, beautiful in appearance and reliable in performance, being convenient to use, etc., can effectively treat the exogenous pigmentation and the endogenous pigment lesion formed by mixed pigments, has the functions and technical indexes reaching the international advanced level, and is an upgrade product of the current national similar devices.

Owner:合肥安博罗医疗器械有限公司

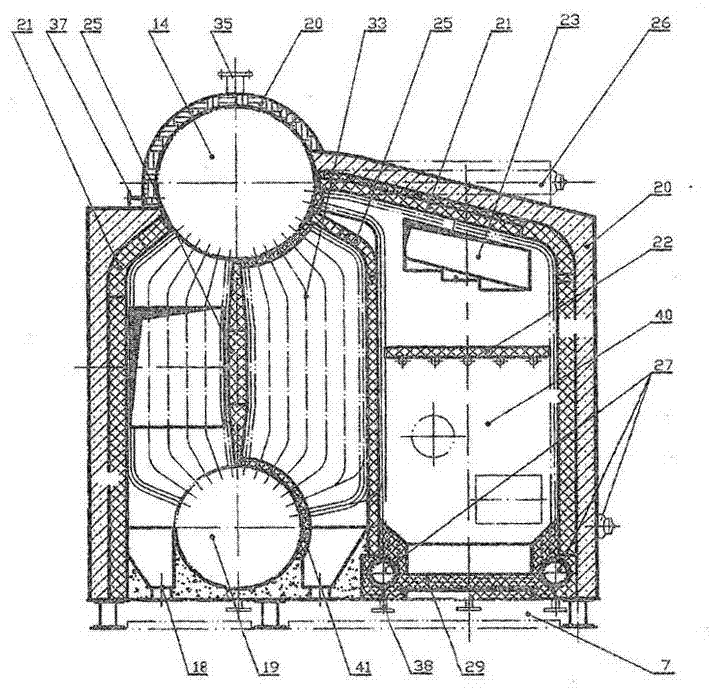

A high-temperature energy-saving hot blast melting furnace

The invention relates to a high-temperature energy-saving hot air smelting furnace which comprises a combustion chamber, a melting chamber, a small air container and a large air container, wherein the combustion chamber is positioned at the lowest part; the inner wall of the combustion chamber is provided with a fire-resistant layer; the melting chamber is positioned at the upper pat of the combustion chamber and is of a cylindrical structure; the outer wall of the cylindrical structure is wrapped by a temperature reduction layer, and the inner wall of the cylindrical structure is filled withthe fire-resistant layer; an air control device is arranged between the combustion chamber and the melting camber; the small air container is positioned at the upper part of the melting chamber; the large air container is positioned above the small air container; the small air container is externally provided with a small air pipeline; and one end of the small air pipeline is communicated with the small air container, and the other end of the small air pipeline is communicated with the large air container. For the high-temperature energy-saving hot air smelting furnace, the heat efficiency ofthe device is high through a hot air pipeline for the melting furnace, the unique and complex hot air flow structure in the furnace strengthens the full utilization of heat energy, the heat transfer speed is rapid, and the heating efficiency is high.

Owner:QINGDAO FURUIXIANG SMELTING EQUIP MFG

Formula of traditional Chinese medicine incense powder

InactiveCN112274608AImprove spiritEnhance positive energyHeavy metal active ingredientsNervous disorderChemistryChinese herbs

The invention discloses a formula of a traditional Chinese medicine incense powder. The formula is prepared from the following raw material components in percentage by weight: 5% of agastache rugosus,10% of sandalwood, 3% of clove, 2% of fennel, 5% of murraya paniculata, 5% of cassia twig, 5% of galangal, 3% of realgar, 3% of cinnabar, 4% of amber, 7% of jasmine flower, 6% of rose, 6% of folium artemisiae argyi, 7% of pericarpium citri reticulatae, 6% of acorus tatarinowii, 5% of rhizoma kaempferiae, 5% of rhizoma nardostachyos, 8% of agilawood and 5% of licorice. Nineteen Chinese herbal medicines are adopted, monarch, minister, assistant and guide are adopted during blending, balance of warm and cold and rising and falling of medicine properties in the body are emphasized, and thereforethe effects of inducing resuscitation with fragrance, refreshing the mind, calming the nerves and promoting qi circulation to remove dampness are achieved, and the formula is universally suitable formodern people who work and live under high pressure at present. In addition to medical effects, the formula also has extremely high artistic value through exquisite process, elaborate design and perfect accessories.

Owner:西安华玳生物科技有限公司

Traceless direction treatment mechanism

PendingCN112173637AIncrease the level of automationWell designedControl devices for conveyorsPackagingEngineeringMechanical engineering

The invention discloses a traceless direction treatment mechanism. The traceless direction treatment mechanism comprises a supporting square pipe, a roller guide assembly and an automatic debugging assembly. The automatic debugging assembly is installed at the upper end of the supporting square pipe, the roller guide assembly is arranged in the automatic debugging assembly in a protruding manner,and the roller guide assembly is used for guide treatment of rollers. Rollers vibrated out by a vibration mechanism are orderly arranged into a straight line to enter the roller guide assembly, the roller guide assembly orderly conducts direction treatment processing on the rollers and sends the rollers to the next procedure for assembly work, and the automatic debugging assembly can complete exchange between different models of the rollers. The roller guide assembly internally comprises a stand column, a rotary disc and a V-shaped discharging port. By arranging the supporting square pipe, theroller guide assembly and the automatic debugging assembly, the problems that traditional equipment cannot automatically complete the guide and supply effects of rollers, the process precision is low, and equipment debugging is inconvenient are solved.

Owner:龚培生

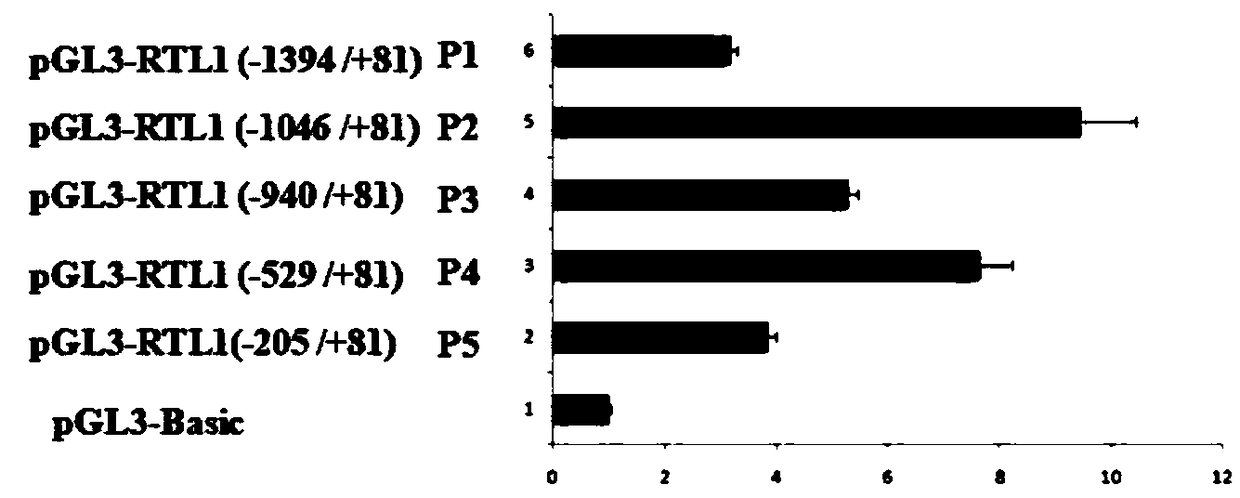

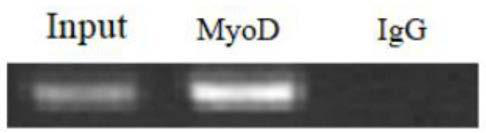

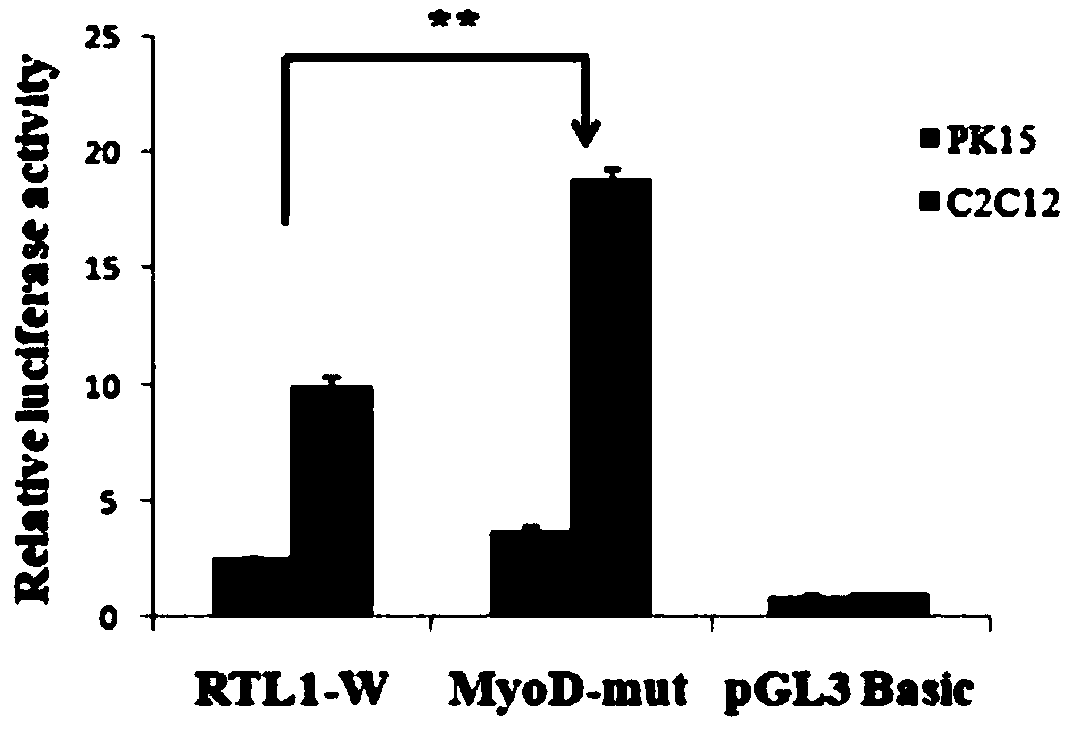

Application of transcription factor MyoD in regulation and control of pig RTL1 gene expression

ActiveCN109467595AGood application prospectWell designedAnimals/human peptidesVector-based foreign material introductionMutantResearch Object

The invention provides application of a transcription factor MyoD in regulation and control of pig RTL 1 gene expression. RTL1 is used as a research object, recombinant plasmids of pig RTL1 gene promoter dual-luciferase reporter gene are constructed, and a core promoter region of RTL1 is found; then the interaction between a transcription factor MyoD and the core promoter region of RTL1 is verified; subsequently, a MyoD overexpression vector and synthetic small interfering RNA are constructed to detect the influence of MyoD on RTL1; and a mutant fluorescent expression vector MyoD-mut of a transcription factor MyoD binding site is also constructed to detect luciferase activity after transfecting PK15 and C2C12 cells. The invention confirms for the first time the influence of the transcription factor MyoD on regulation and control of transcription of an RTL1 gene, brings deeper cognition for regulation and control of expression of RTL1, and has a good application prospect when the transcription factor MyoD is applied to improvement of meat quality traits and research on a molecular regulation mechanism of muscle development of livestock.

Owner:INST OF ANIMAL SCI & VETERINARY HUBEI ACADEMY OF AGRI SCI

Chinese-character '1-2-3' input method

InactiveCN1219245COvercome Difficult Splitting ProblemsLess rote contentInput/output processes for data processingChinese charactersAlgorithm

A Chinese character "1-2-3" input method features that the first stroke and the number of strokes for each part are combined with numerals 1-10 to form 10 regions, whose code numbers are 0-9, so 10 numeral keys can be used to code all the Chinese characters. Its advantage is to easily master it.

Owner:胡兴家

Rice nutrition powder extraction equipment and operation method thereof

The invention discloses rice nutrition powder extraction equipment and an operation method thereof to mainly solve the problem of resources waste due to the fact that embryos having nutrient values are abandoned along with bran and are not fully utilized during rice milling through the existing similar products. According to the rice nutrition powder extraction equipment, rice bud grains and rice bud films after unshelling are milled, the number of grains milled from rice buds and rice bud films is greater than or equal to 180 meshes, thick and thin powder of the milled rice bud films are respectively screened, and the rice buds and the rice bud films smaller than 180 meshes are milled continuously. The rice nutrition powder extraction equipment is provided with a rice milling equipment and a nutrient powder milling powder extraction equipment; the nutrient powder milling powder extraction equipment which is flexibly arranged in the rice milling equipment is corresponding to a bran outlet of the rice milling equipment; the nutrient powder milling powder comprises a receiving box and a nutrient powder milling powder extraction device which is arranged inside the receiving box.

Owner:彭攀桦

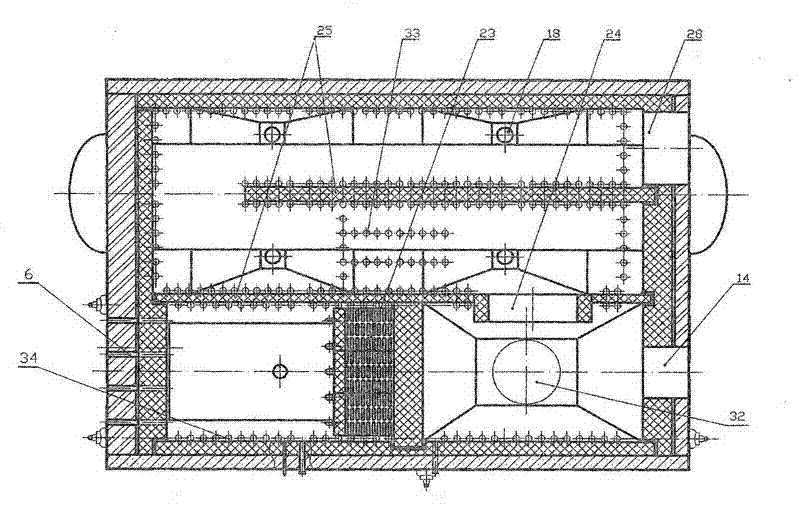

Intelligent comprehensive monitoring and security integrated management system for parking garage

ActiveCN101739841BComplete monitoringPracticalTicket-issuing apparatusIndication of parksing free spacesIntegrated monitoringEconomic benefits

The invention provides an intelligent comprehensive monitoring and security integrated management system for a parking garage. The system solves the comprehensive intelligent management problems of related automatic monitoring, automatic detection, display, different languages and voices, communication, dispatching, guide, digital quantity identification, security, forbidding and passing, charging, statistics, self diagnosis and maintenance and the like of various self-propelled and automatic three-dimensional mechanical parking garages. The system has significant meanings for improving the monitoring, security and management levels of various parking garages, promoting static traffic modernization construction and increasing the social and economic benefits of the parking garages.

Owner:上海久银车库工程有限公司

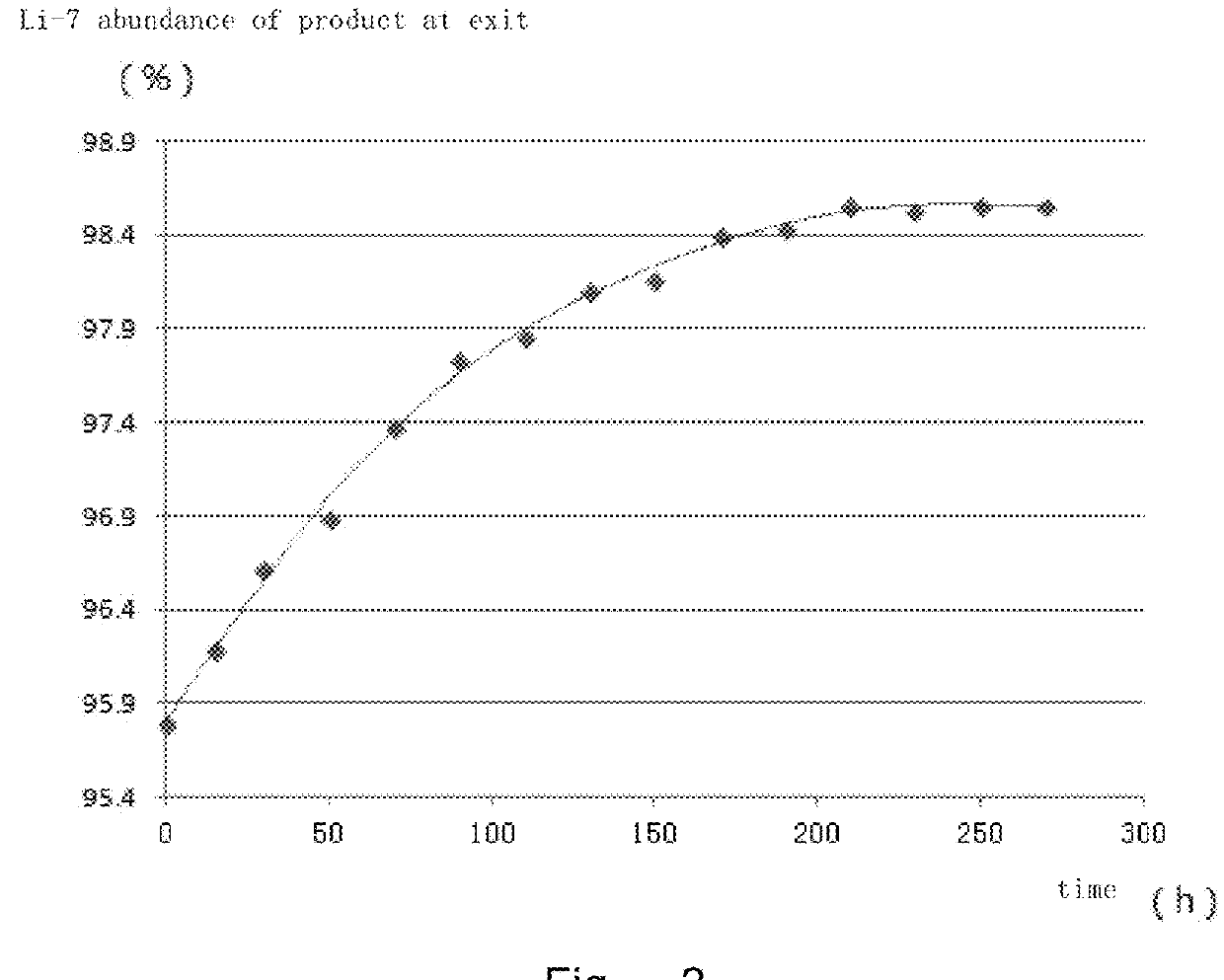

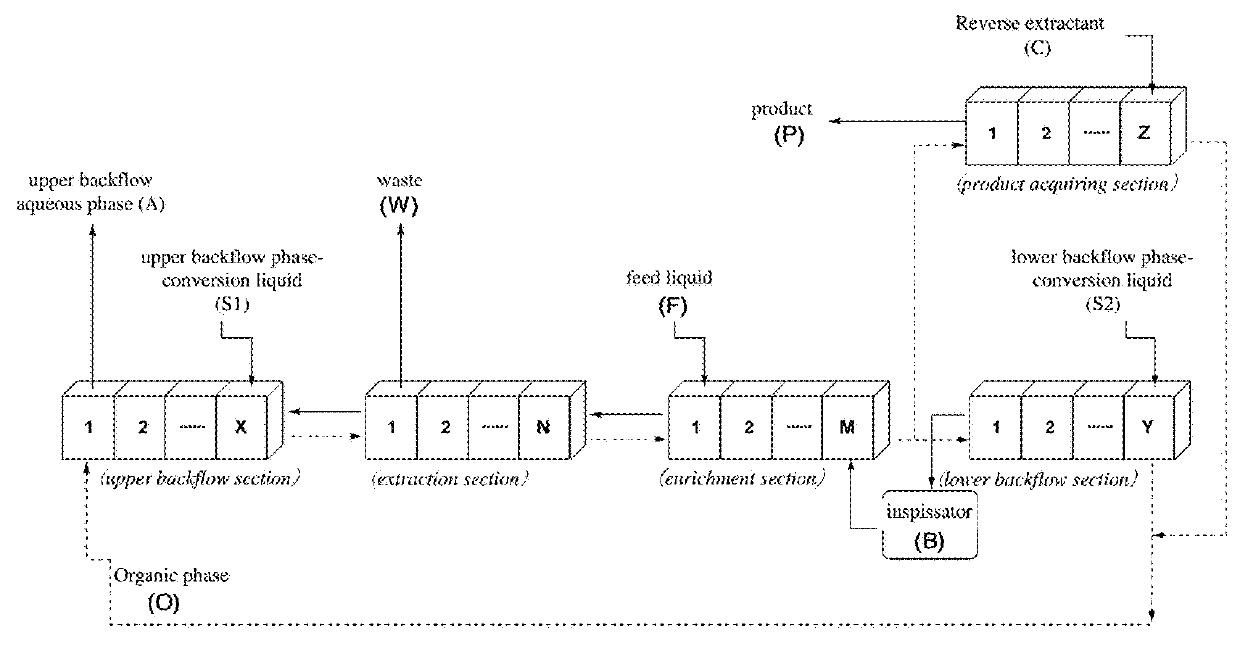

Backflow cascade novel process for producing lithium-7 isotope

ActiveUS9963760B2Improve efficiencyHigh abundanceIsotope separationRecovering materialsPhase conversionLithium

Provided is a backflow cascade novel process for producing a lithium-7 isotope. The process comprises an upper backflow section, an extraction section, an enrichment section, a lower backflow section, and a product acquiring section. Upper backflow phase-conversion liquid and lower backflow phase-conversion liquid are respectively added to the upper backflow section and the lower backflow section, and upper backflow phase-conversion liquid and lower backflow phase-conversion liquid of the lithium material are controlled; the product is precisely acquired in the product acquiring section; an organic phase is added to the upper backflow section, and is recycled in the lower backflow section. By means of cascade connection with a high-performance liquid separator, environmental protection, high efficiency, and multi-level enrichment of the lithium-7 isotope are achieved, and a high-abundance lithium-7 isotope product is obtained.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Laser cladding powder spraying machine

InactiveCN100535188CKeep healthyIngenious ideaMetallic material coating processesLaser beam welding apparatusMachine controlAutomatic control

A laser cladding powder spraying machine comprises a transmission device, a spraying device and a gas path control mechanism; a fixed ring is arranged above a base of a spraying car; a rotary ring is connected with the upper part of the fixed ring; a locking keep plate is connected between the fixed ring and the rotary ring; a spraygun vertical wall is fixed on the rotary ring and is in flexible connection with a transverse arm through a pin roll; the middle of the spraygun vertical wall is provided with a cylinder block; the top of a cylinder piston rod is fixed on the middle of the transverse arm. The front end of the transverse arm is provided with an angle adjusting device and is tightly connected with the mounting bracket of a spraygun; a biaxial cylinder and a spraygun are arranged above the mounting bracket; the top of the piston rod in the lower part of the biaxial cylinder is tightly connected with a spray hooker. The invention is skillful in design, reasonable in structure, simple in operation and automatic in the whole machine control; as the spraying car can operate vertically and horizontally and the rotary ring of the base rotates according to specific conditions, the transverse arm can move up and down when spraying; the spraygun can have multi-angle rotation and can complete multi-angle spatial spraying; as the invention has automatic control, uniform spraying, superior quality and high working efficiency, the health of operators can be fully ensured.

Owner:BEIJING DALU TIANRUI LASER ENG TECHCO

High-temperature energy-saving hot air smelting furnace

The invention relates to a high-temperature energy-saving hot air smelting furnace which comprises a combustion chamber, a melting chamber, a small air container and a large air container, wherein the combustion chamber is positioned at the lowest part; the inner wall of the combustion chamber is provided with a fire-resistant layer; the melting chamber is positioned at the upper pat of the combustion chamber and is of a cylindrical structure; the outer wall of the cylindrical structure is wrapped by a temperature reduction layer, and the inner wall of the cylindrical structure is filled withthe fire-resistant layer; an air control device is arranged between the combustion chamber and the melting camber; the small air container is positioned at the upper part of the melting chamber; the large air container is positioned above the small air container; the small air container is externally provided with a small air pipeline; and one end of the small air pipeline is communicated with the small air container, and the other end of the small air pipeline is communicated with the large air container. For the high-temperature energy-saving hot air smelting furnace, the heat efficiency ofthe device is high through a hot air pipeline for the melting furnace, the unique and complex hot air flow structure in the furnace strengthens the full utilization of heat energy, the heat transfer speed is rapid, and the heating efficiency is high.

Owner:QINGDAO FURUIXIANG SMELTING EQUIP MFG

Novel smelting furnace structure

InactiveCN106679415ATake advantage ofImprove thermal efficiencyCrucible furnacesCombustion chamberEngineering

The invention relates to a novel smelting furnace structure which comprises a combustion chamber, a smelting chamber, a small air container and a large air container. The combustion chamber is located at the bottommost part, and a fire-resisting layer is arranged on the inner wall of the combustion chamber. The smelting chamber is located at the upper portion of the combustion chamber and is of a cylindrical structure. The outer wall of the cylindrical structure is wrapped by a cooling layer, and the inner wall of the cylindrical structure is filled with a fire-resisting layer. An air control device is arranged between the combustion chamber and the smelting chamber. The small air container is located at the upper portion of the smelting chamber, and the large air container is located above the small air container. A small air pipeline is arranged at the outer portion of the small air container. One end of the small air pipeline communicates with the small air container, and the other end of the small air pipeline communicates with the large air container. According to the novel smelting furnace structure, the heat efficiency of the equipment is high through the hot air pipeline, sufficient utilization on heat energy is enhanced through an unique and complex hot air flowing structure in a furnace, the heat transfer speed is high, and the heating efficiency is high.

Owner:杨配媛

Boiling type rice husk combustion boiler

InactiveCN102927562AWell-designedRigorous layoutFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberMixed type

The invention discloses a boiling type rice husk combustion boiler which comprises a boiler body, a refractory furnace wall heat-insulation system, an electric control system, an air blasting system, an air mixed type screw feeder, a boiling type combustor and an induced draught system. The boiler body is of an energy-saving type full steel structure of the boiling type rice husk combustion boiler and is composed of an upper boiler barrel, a lower boiler barrel, an upper collecting box, a lower collecting box, a water wall tube, a convection heat exchanging pipe and a downcomer, the upper boiler barrel and the lower boiler barrel are communicated with each other through the water wall tube, the convection heat exchanging pipe and the downcomer, and the upper collecting box and the lower collecting box are communicated with each other through the water wall tube, the convection heat exchanging pipe and the downcomer; a steam connector, a safety valve connector and a pressure meter connector are arranged above the upper boiler barrel, a water level gauge connector is arranged at the front end of the upper boiler barrel, and a water inlet connector is arranged at the rear of the upper boiler barrel; a pollution discharge connector is arranged below the lower boiler barrel; the boiling type combustor is arranged on the lower portion of the boiler body, and a boiling bed is arranged at the bottom of the boiling type combustor; and the air mixed type screw feeder is arranged on the boiling type combustor. The boiler is simple and rigorous in whole structure, anti-abrasive, anti-explosive, thorough in combustion, high in heat utilization, long in service life and applicable to various enterprises, especially food processing enterprises.

Owner:CHANGDE JINYUAN BOILER MFG

Nutritional health liquid for porket, and preparation method and application method thereof

ActiveCN102726622BComprehensive design considerationsStrong targetingAnimal feeding stuffBiotechnologyWeaning

A nutritional health liquid for porket is prepared from antibody protein, conjugated linoleic acid, glucose, Twain-80, egg white, vitamin E, xanthan gum and distilled water. The preparation method of the nutritional health liquid includes steps of: extracting immunoglobulin IgG using a low temperature absolute ethyl alcohol precipitation method; evenly mixing the raw materials into a mixture; placing the mixture in an emulsifying machine and emulsifying the mixture into an emulsion; irradiating the emulsion by UV; and filling to obtain finished products. A usage method of the nutritional health liquid is as below: the porket orally takes 2ml immediately after birth, and then orally takes 0.5ml 7 days later until weaning. The main function of the nutritional health liquid is to repair and enhance the immune system of porket, and provide energy, vitamin and functional unsaturated fatty acids for early-stage porket; and the nutritional health liquid has excellent effects on valetudinarianism caused by inadequate milk of sow or weaning in early stage, so as to really focus on health of porket in the perspectives of immunity enhancement and nutrition strengthening.

Owner:上海国龙生物科技有限公司

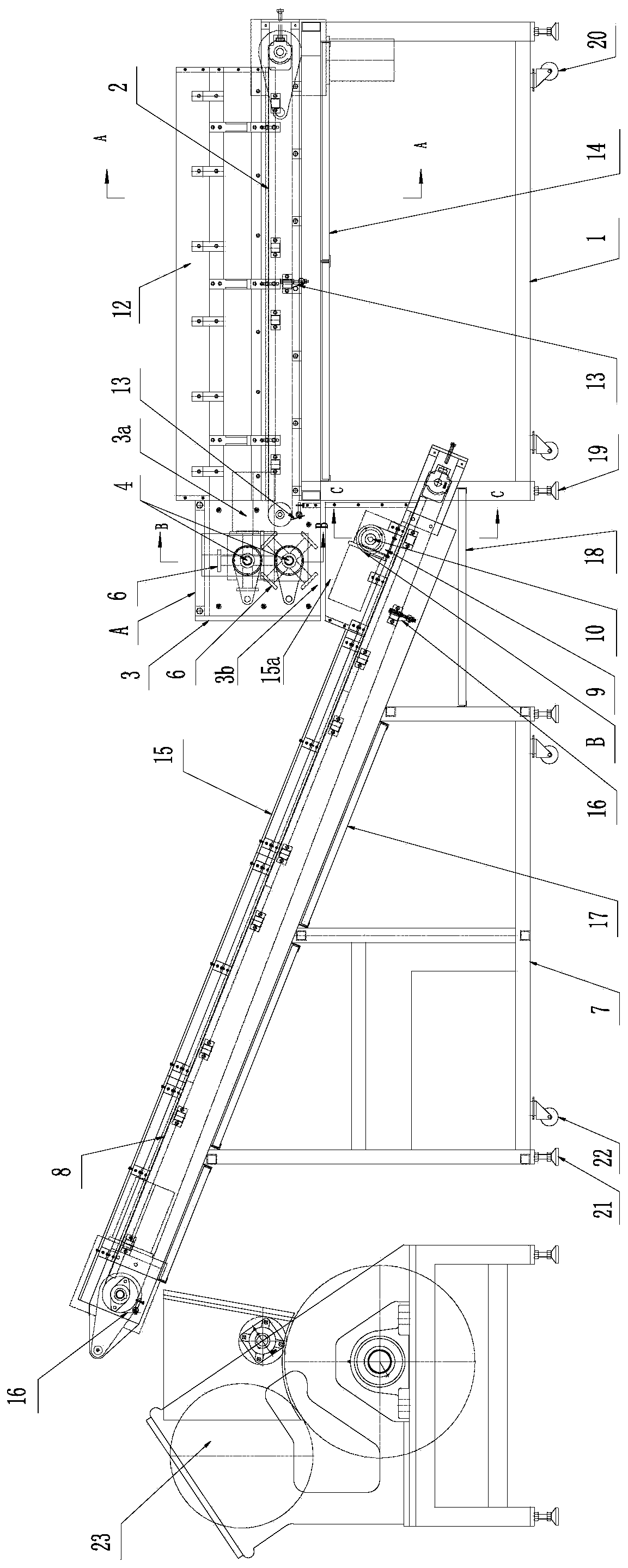

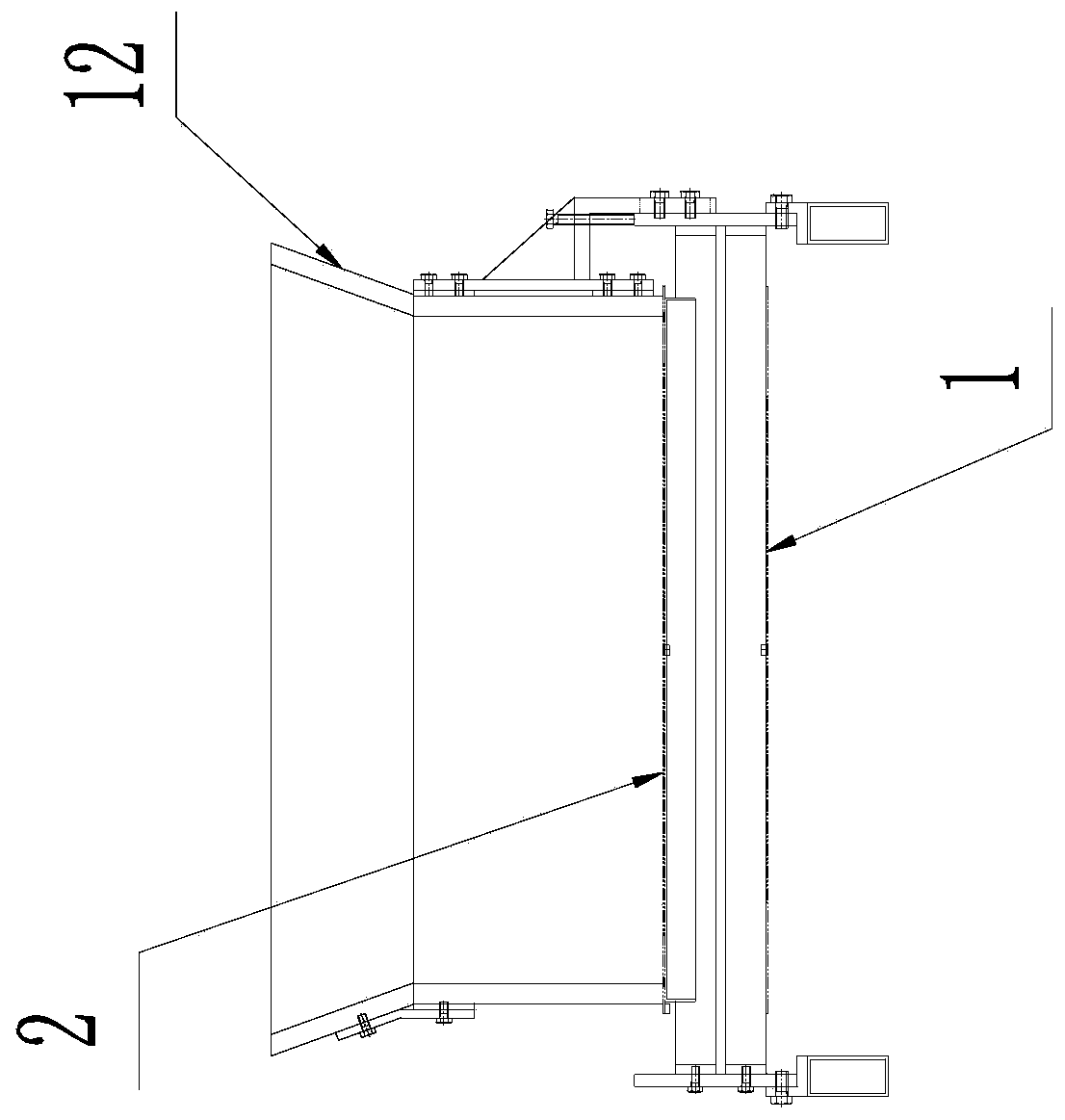

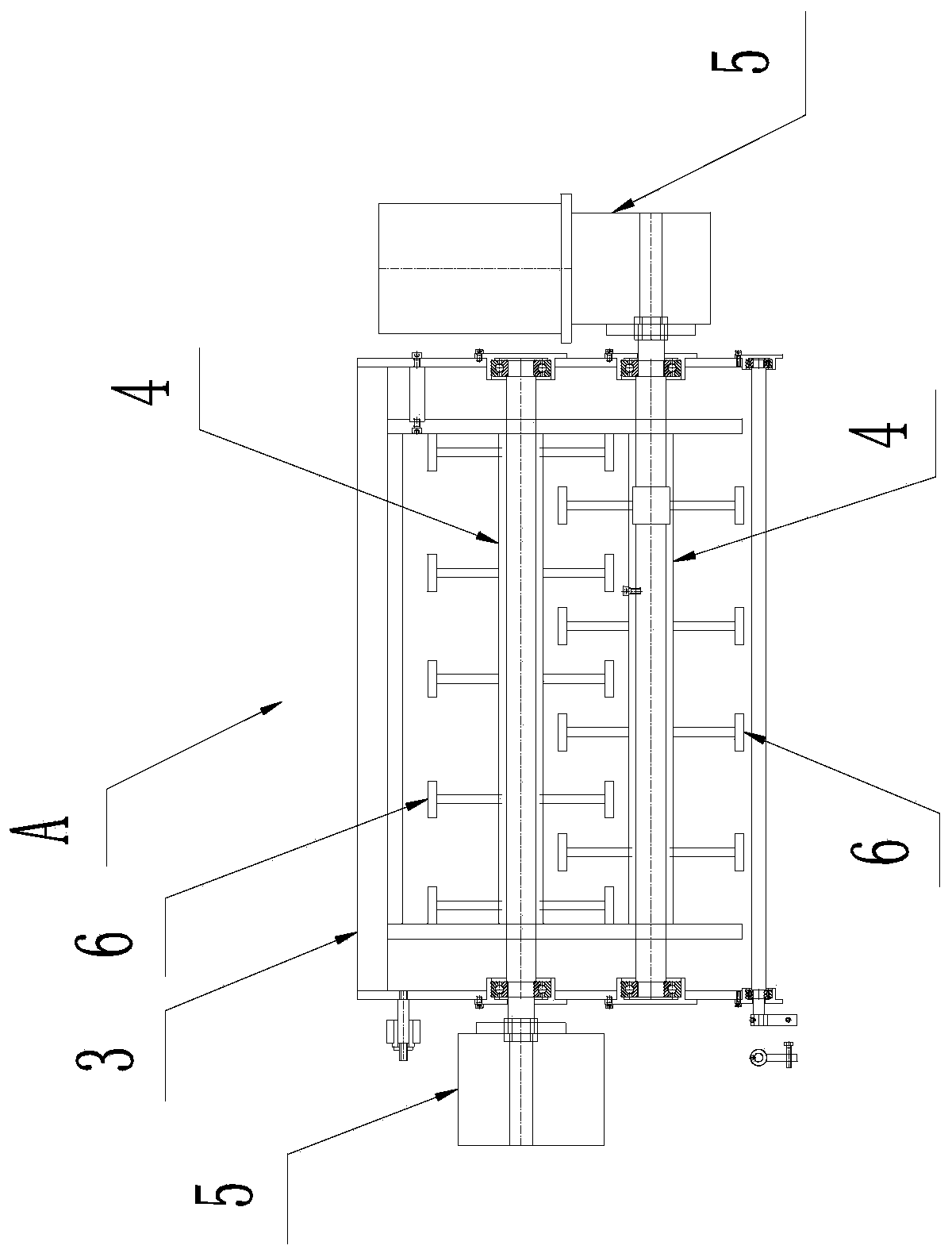

Food crushing and lifting machine

PendingCN110201751ASmooth connectionImprove structural stabilityFood shapingGrain treatmentsEngineeringSugar

The invention discloses a food crushing and lifting machine. The food crushing and lifting machine is characterized by comprising a crushing mechanism and a lifting mechanism; the crushing mechanism comprises a crushing mechanism bracket, a crushing mechanism circulating conveying belt, a driving mechanism and a double-roller crushing mechanism,; the crushing mechanism circulating conveying belt,the driving mechanism and the double-roller crushing mechanism are arranged on the crushing mechanism bracket; the double-roller crushing mechanism comprises two roller shafts which are pivotally arranged in a tank body and are vertically arranged, and roller shaft driving speed reducing motors which are respectively connected with the roller shafts and drive the roller shafts to rotate; a plurality of radial driving hammers are arranged on each roller shaft in the length direction; a feeding inlet for allowing the tail end of the crushing mechanism circulating conveying belt to extend into isformed in the tank body, and a discharging opening is formed in the bottom of the tank body; the lifting mechanism comprises a lifting mechanism support, a lifting mechanism circulating conveying belt arranged on the lifting mechanism support in an inclined mode and a driving mechanism of the lifting mechanism circulating conveying belt, and the lower end of the conveying belt is located below the discharging opening of the tank body; and a screw separating mechanism which stretches across the corresponding conveying belt is further arranged on the lifting mechanism support. The device disclosed by the invention is specially designed to be used for crushing energy rods and sugar-containing food raw materials and then feeding the raw materials into a single-group roller extruding machine,so that the crushing effect is good, and the working efficiency is high.

Owner:苏州姑苏食品机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com