Laser cladding powder spraying machine

A laser cladding and spraying machine technology, applied in laser welding equipment, coating, metal material coating process and other directions, can solve the problems of uneven coating, hindering the health of operators, and difficult to complete the spraying equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

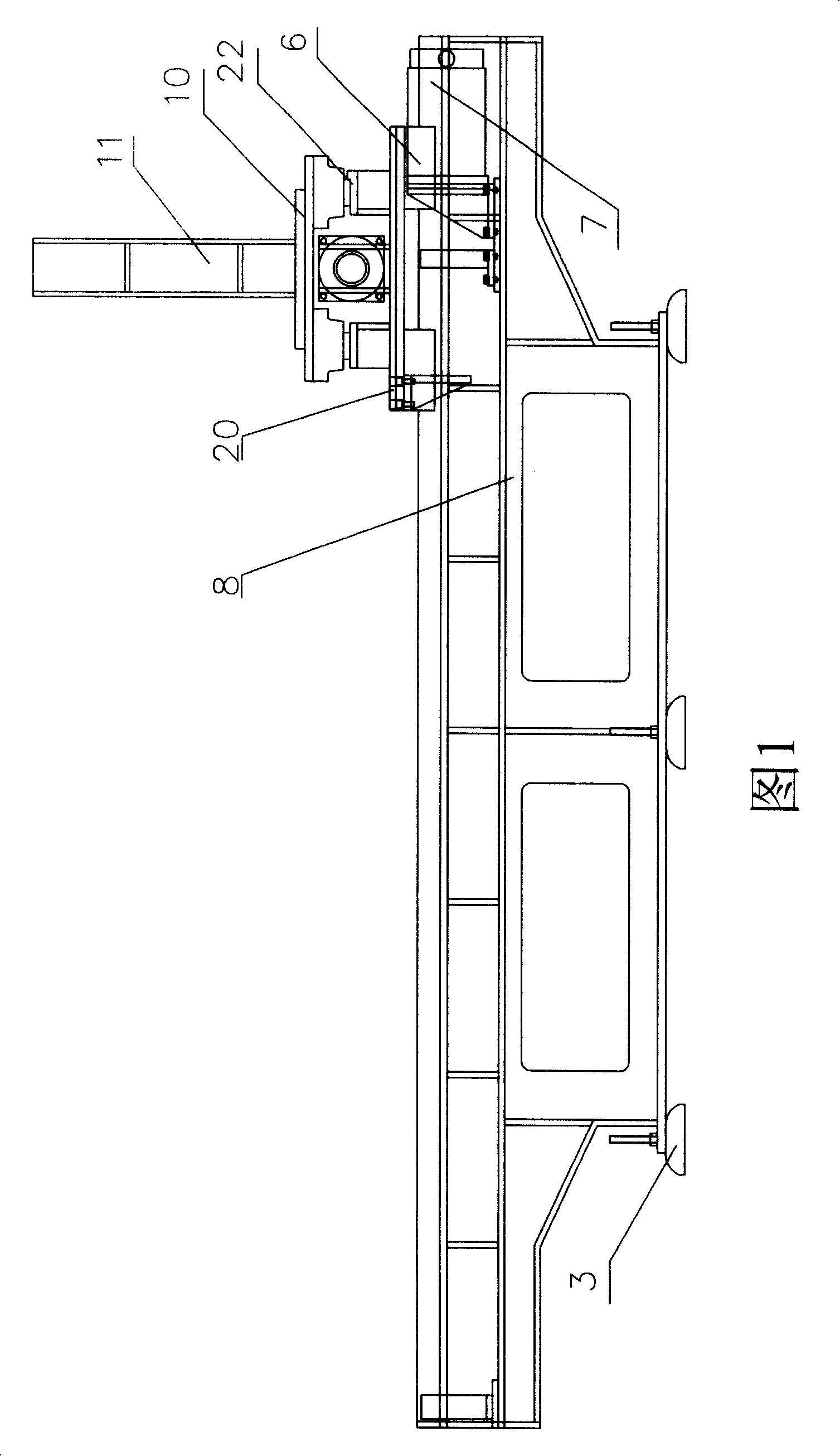

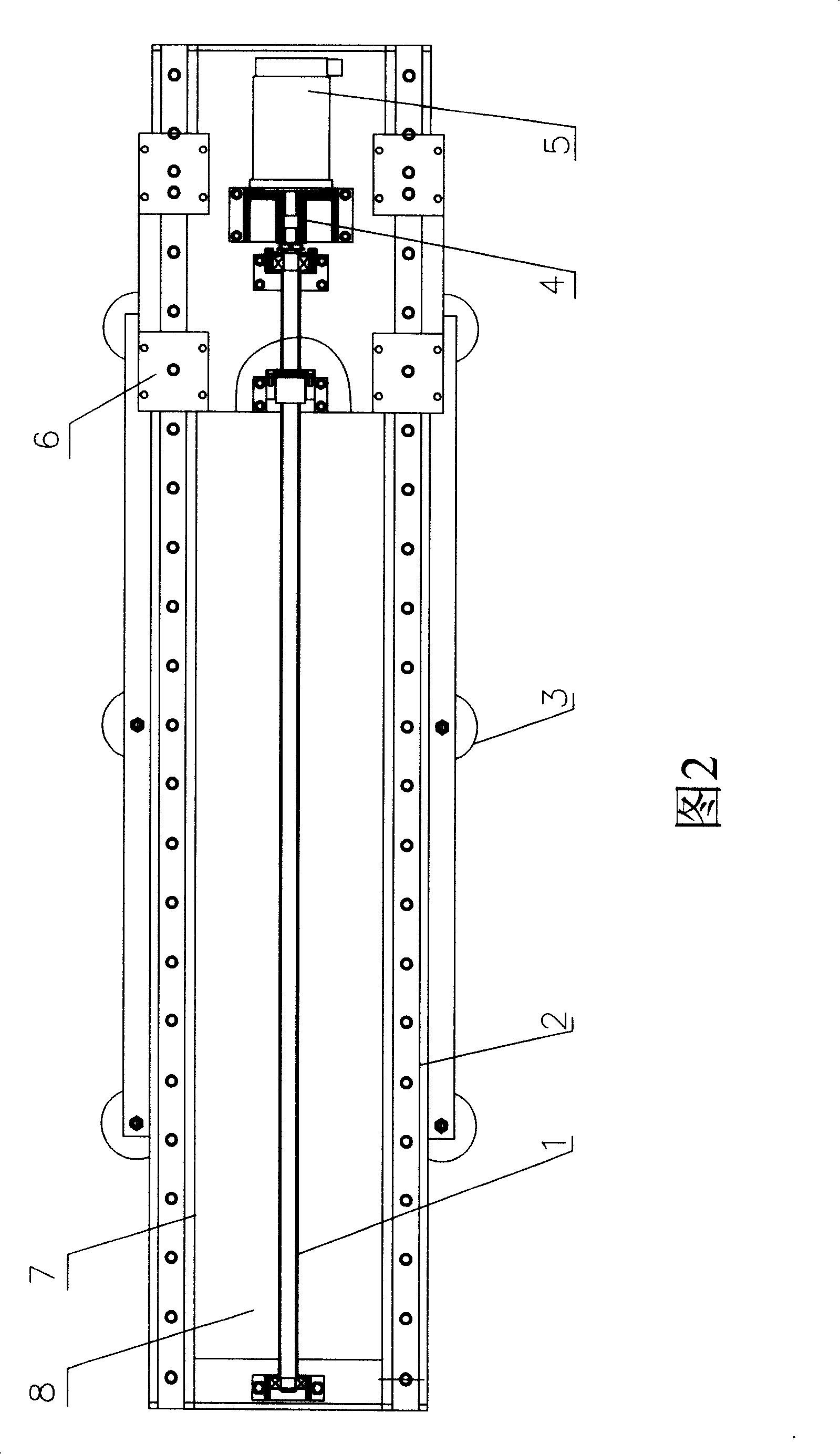

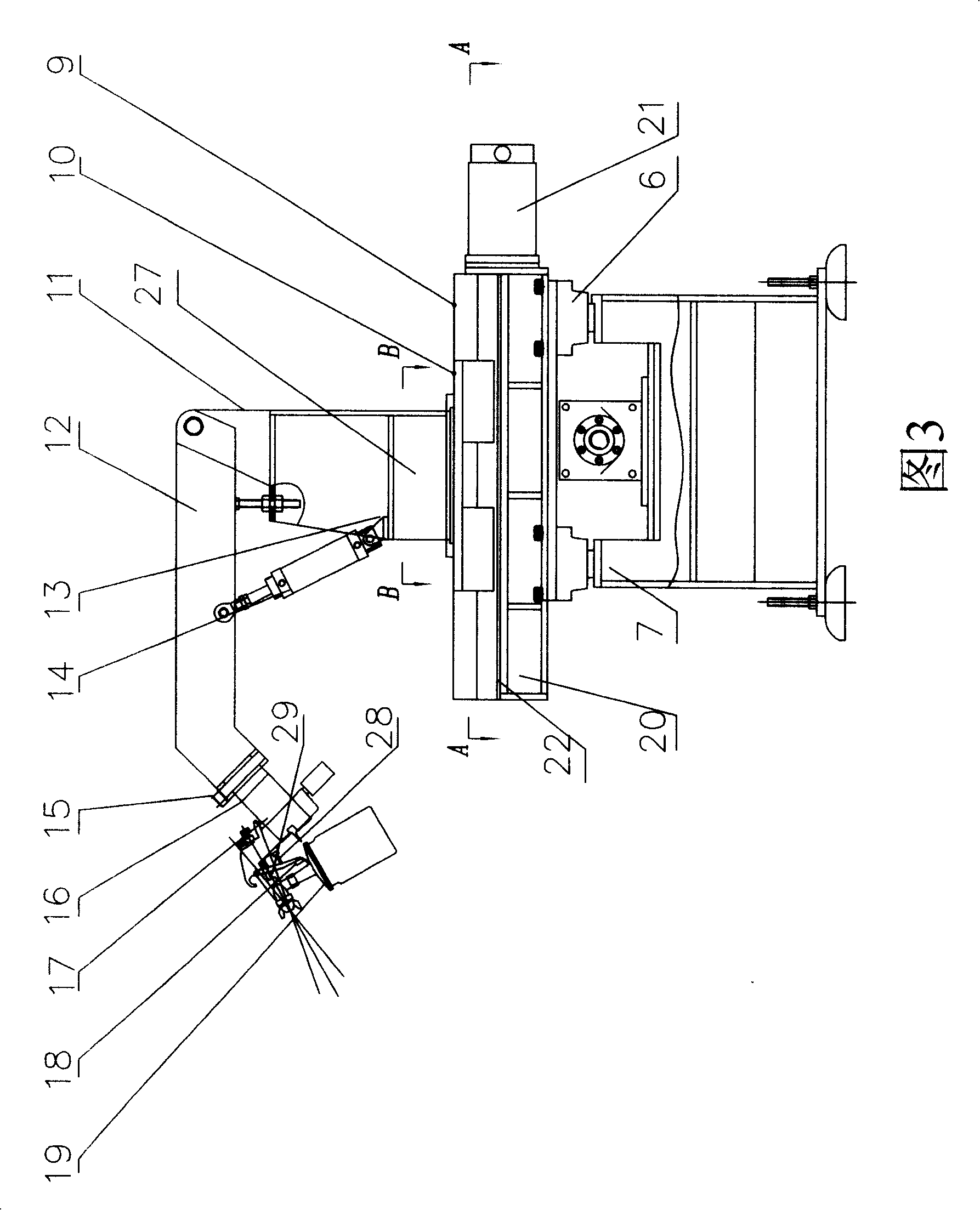

[0023] The laser cladding powder spraying machine includes a machine base, a transmission device, a spraying device, and an air circuit control mechanism. On both sides of the base 8, there are strip-shaped lower rail seats 7, and the lower rail seats 7 are integrated with the base 8. Two linear guide rail pairs 2 are fixedly connected to the upper ends of the lower guide rail seats 7 on both sides with screws.

[0024] The longitudinal ball screw pair 1 is located on the machine base and between the lower guide rail seats 7 on both sides. The two ends of the longitudinal ball screw pair 1 are fixed on the machine base with bearing seats. It is connected in rotation with the longitudinal stepping motor 5 ; the longitudinal ball screw pair 1 is connected in rotation with the nut, and the nut is arranged in the middle of the lower end of the base pedestal 20 below the spray trolley 27 . The four slide blocks 6 that are installed on four corners are fastened under the pedestal 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com