Food crushing and lifting machine

A technology of elevator and pulverizing mechanism, which is used in food forming, food science, grain processing, etc., can solve the problems of raw material agglomeration, poor pulverization effect, and inability to transport in time, so as to prevent agglomeration and improve food production. Processing efficiency and molding quality, the effect of good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

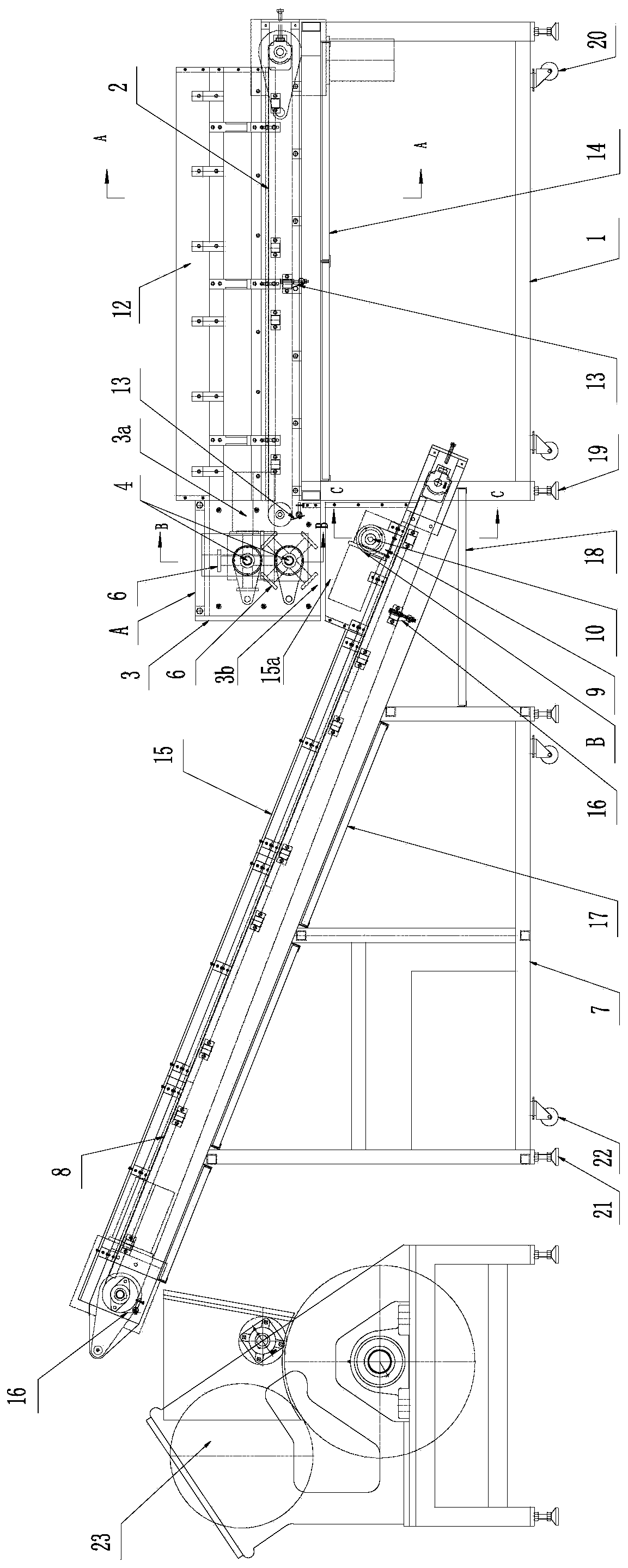

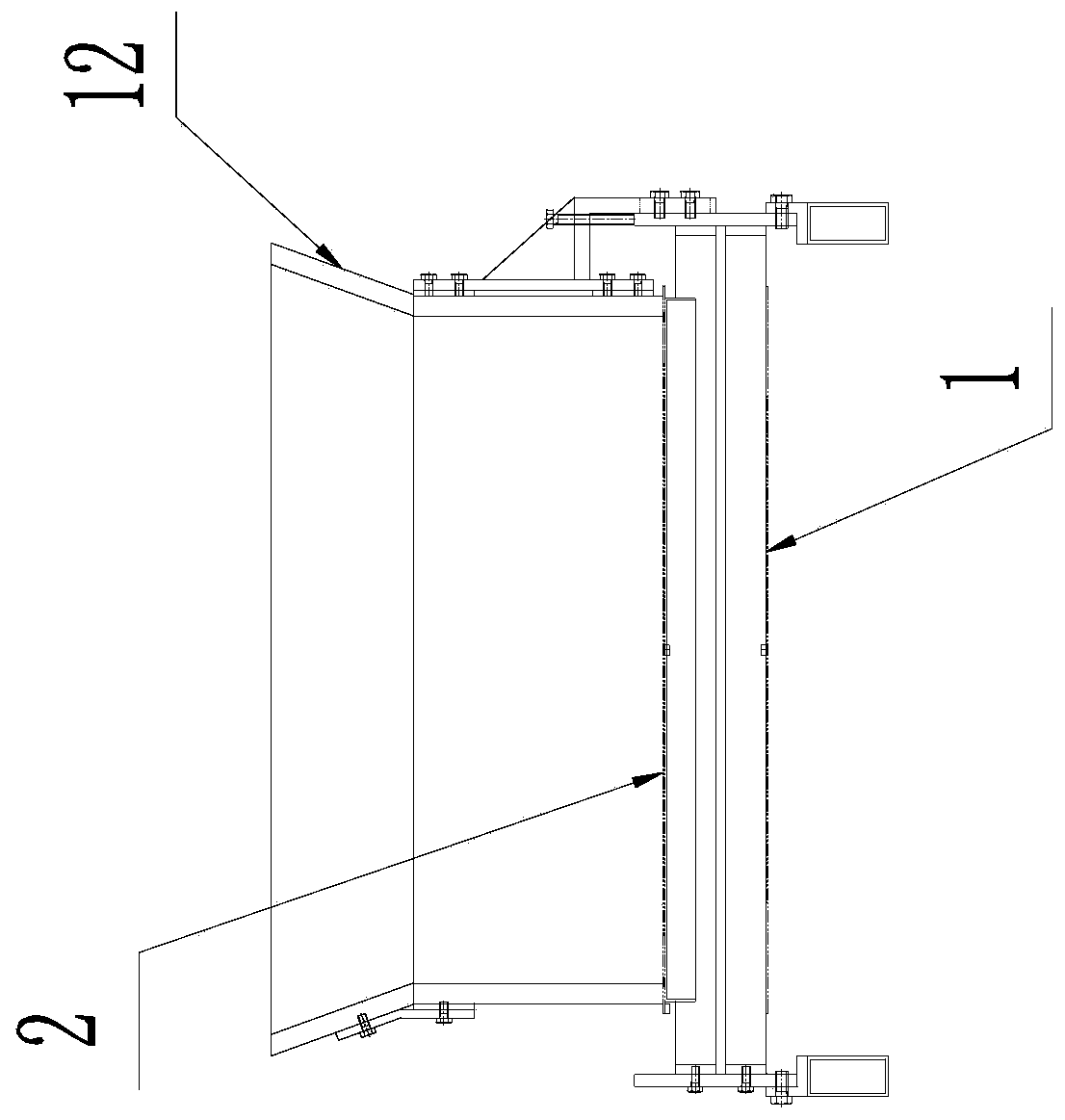

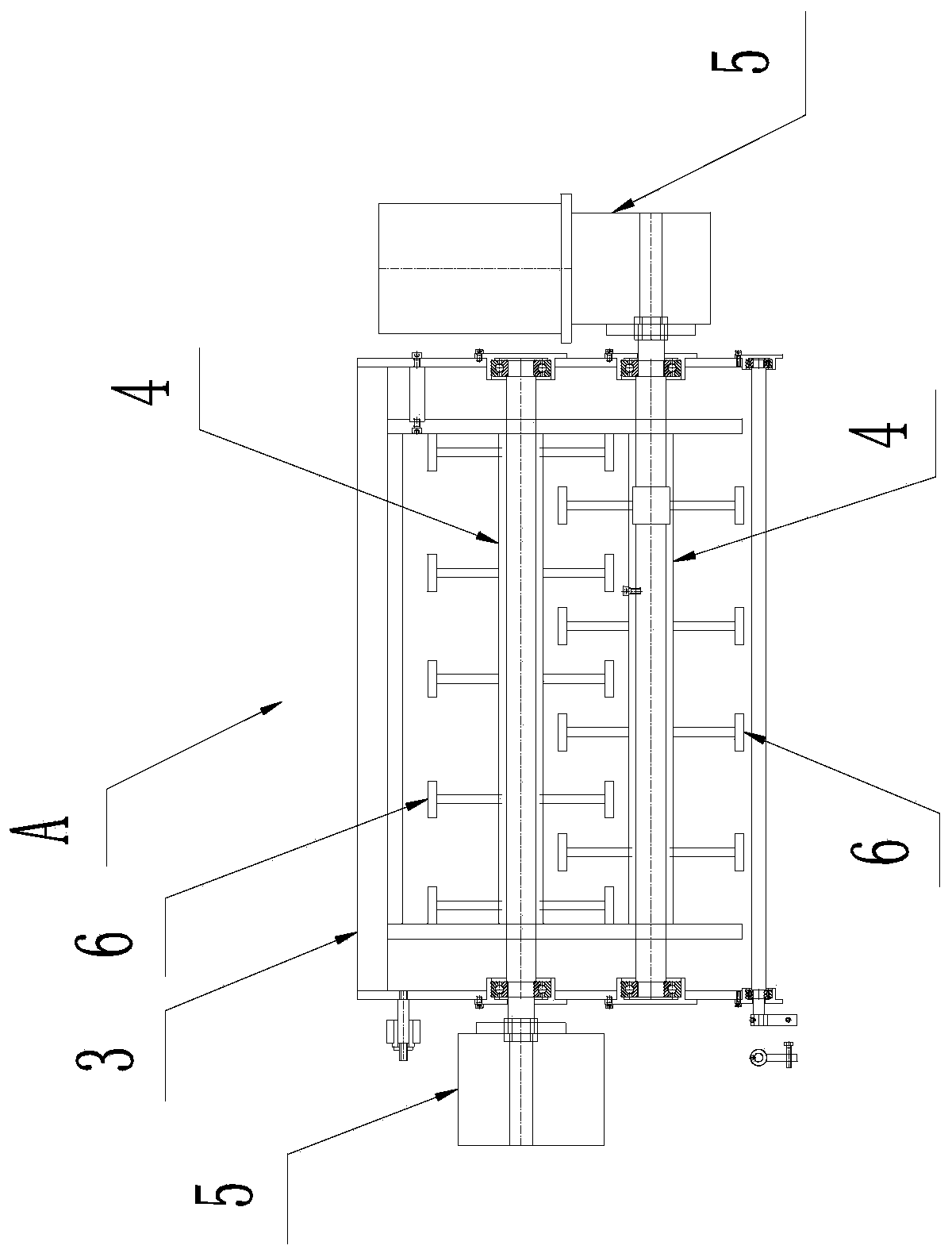

[0034] Embodiment: combine below Figure 1~Figure 4 Shown, this specific implementation mode provided by the present invention is described in detail as follows:

[0035] The food crushing elevator provided by the present invention is specifically composed of two parts: a crushing mechanism and a lifting mechanism. The first is the crushing mechanism, combined with figure 1 and figure 2 As shown, it consists of a crushing mechanism support 1, a crushing mechanism circulating transmission belt 2 arranged thereon and its driving mechanism, a double-roller crushing mechanism A, two rollers fixed on the crushing mechanism support 1 and located on both sides of the crushing mechanism circulating transmission belt 2 Block baffle plate 12, be arranged on the pulverization mechanism support 1 and two pulverization mechanism scrapers 13 that are against the bottom of the pulverization mechanism circulating transmission belt 2 and be fixed on the pulverization mechanism support 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com