Patents

Literature

73results about How to "Save operability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

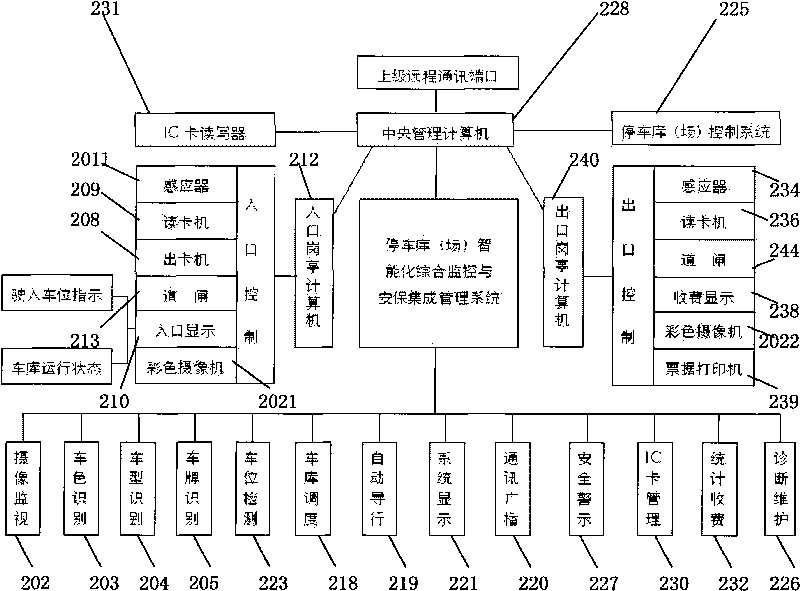

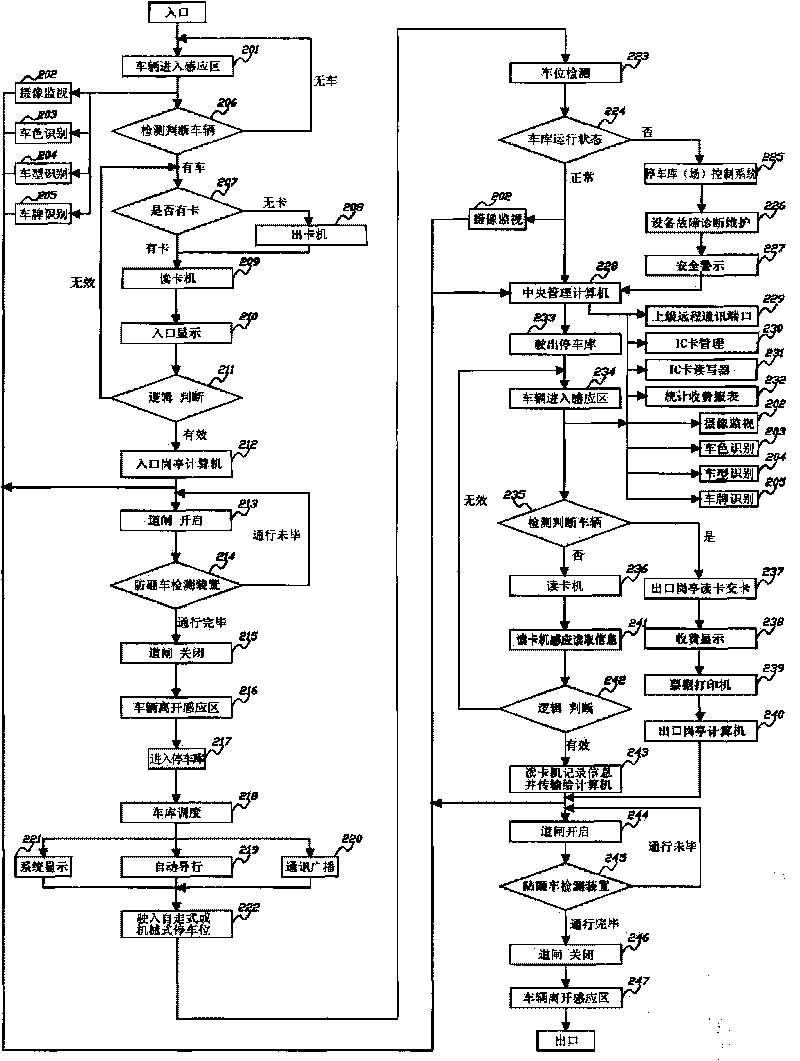

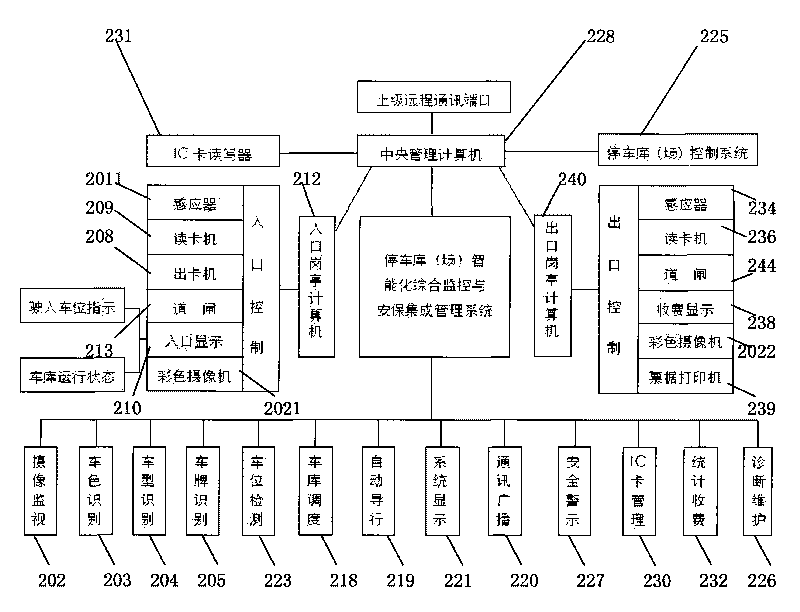

Intelligent comprehensive monitoring and security integrated management system for parking garage

ActiveCN101739841AComplete monitoringPracticalTicket-issuing apparatusIndication of parksing free spacesIntegrated monitoringEconomic benefits

The invention provides an intelligent comprehensive monitoring and security integrated management system for a parking garage. The system solves the comprehensive intelligent management problems of related automatic monitoring, automatic detection, display, different languages and voices, communication, dispatching, guide, digital quantity identification, security, forbidding and passing, charging, statistics, self diagnosis and maintenance and the like of various self-propelled and automatic three-dimensional mechanical parking garages. The system has significant meanings for improving the monitoring, security and management levels of various parking garages, promoting static traffic modernization construction and increasing the social and economic benefits of the parking garages.

Owner:上海久银车库工程有限公司

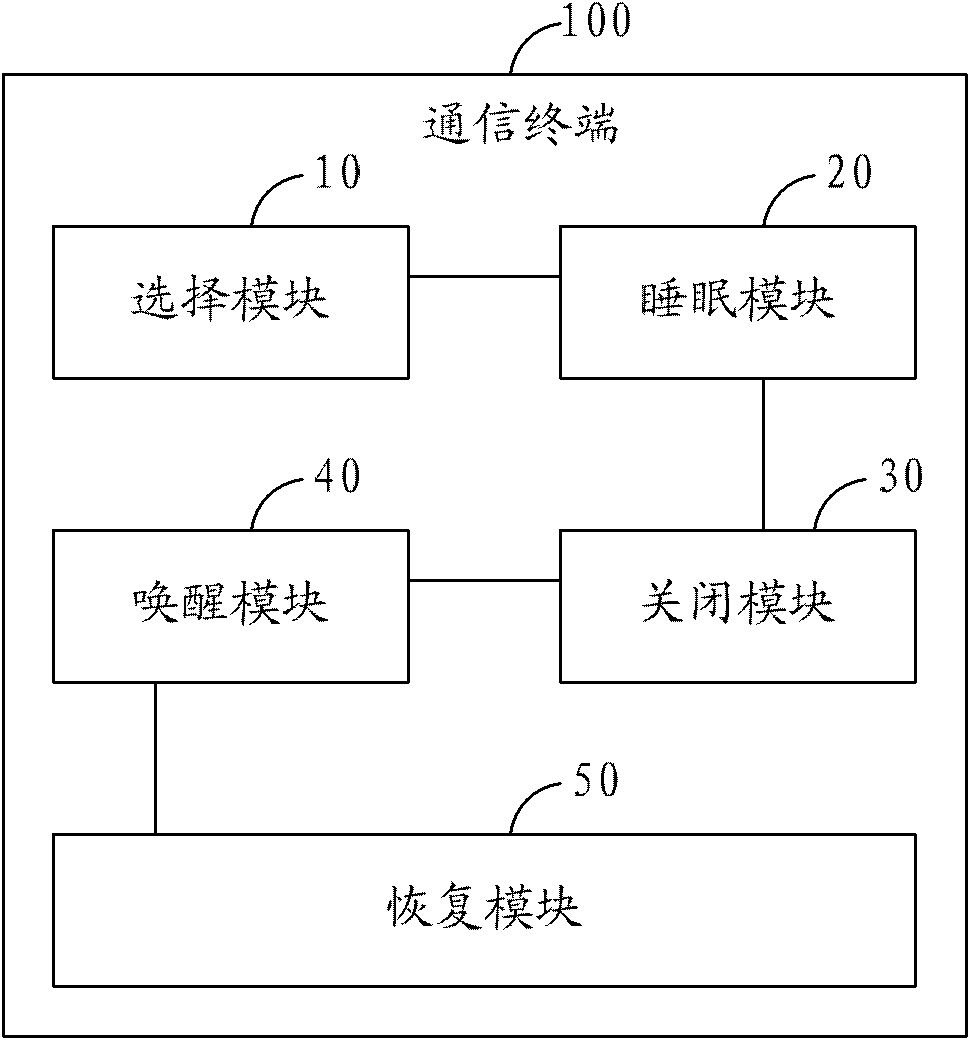

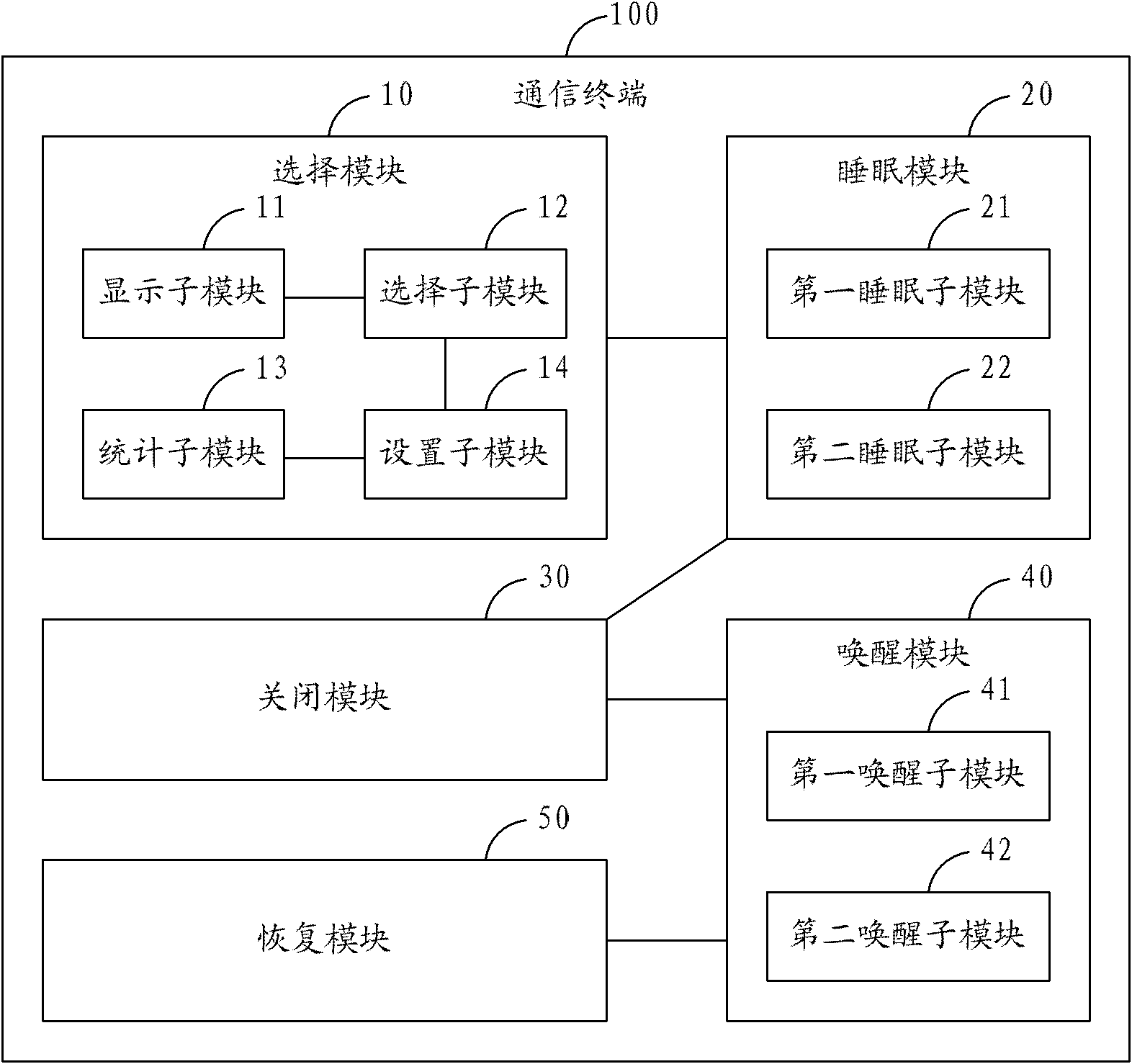

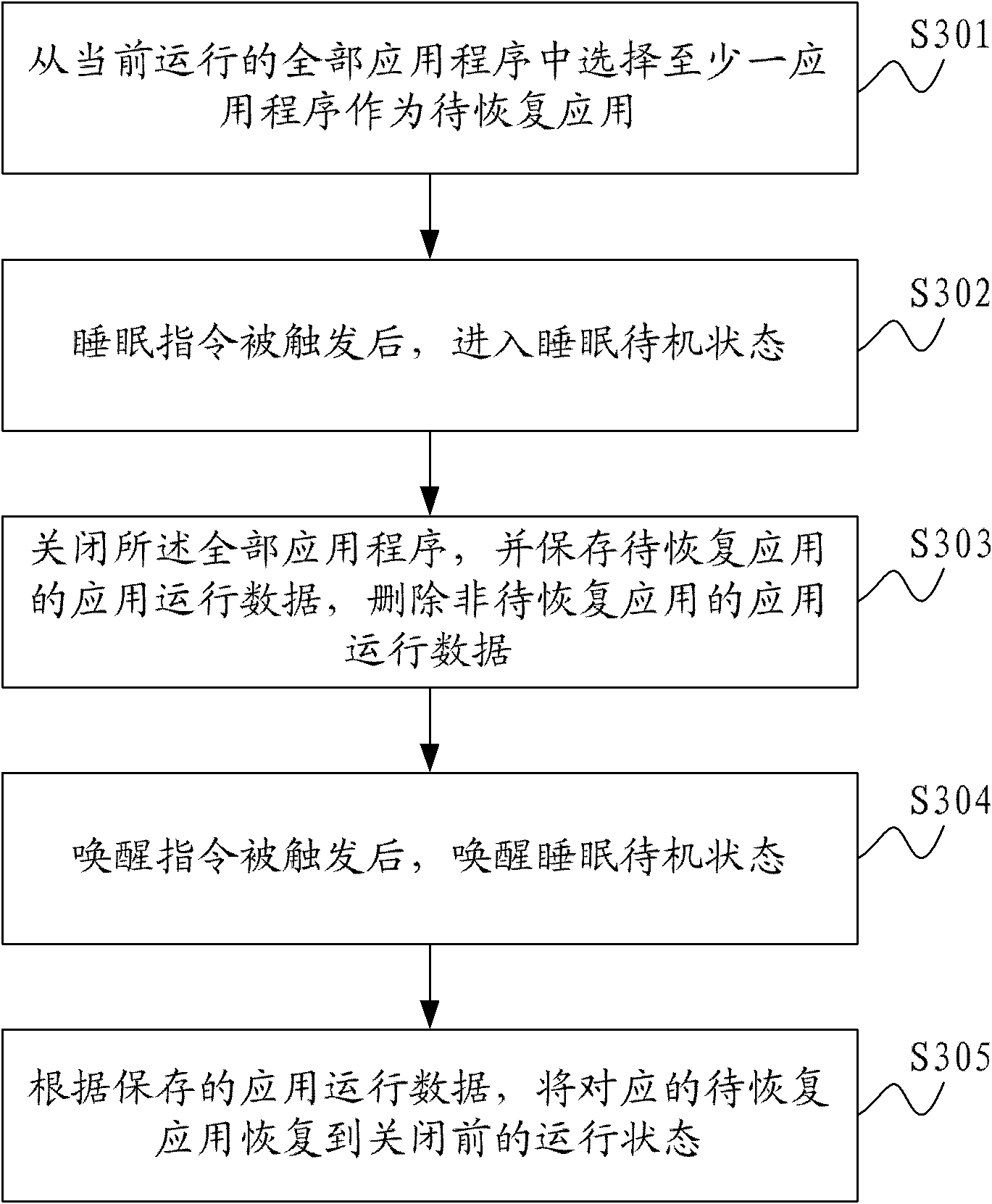

Method for realizing sleep standby and communication terminal

ActiveCN103324549AImprove execution efficiencySave operabilityRedundant operation error correctionSoftware engineering

The invention is suitable for the technical field of communication, and provides a method for realizing sleep standby. The method comprises the following steps: selecting at least one application from all the currently running applications as an application to be restored; entering sleep standby state once the sleep instruction is triggered; closing all applications, saving the application running data of the application to be restored, and deleting the application running data of the applications not to be restored; invoking the sleep standby state once the invoking instruction is triggered; restoring the corresponding application to be restored to the running state before closing, according to saved application running data. Correspondingly, the invention further discloses a communication terminal. Once the sleep standby state is invoked, the application to be restored can be quickly restored, as required by a user, to the running state before closing, so as to save redundant operation steps; the unnecessary memory and cache redundancy can be released, so that the system running efficiency is increased.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

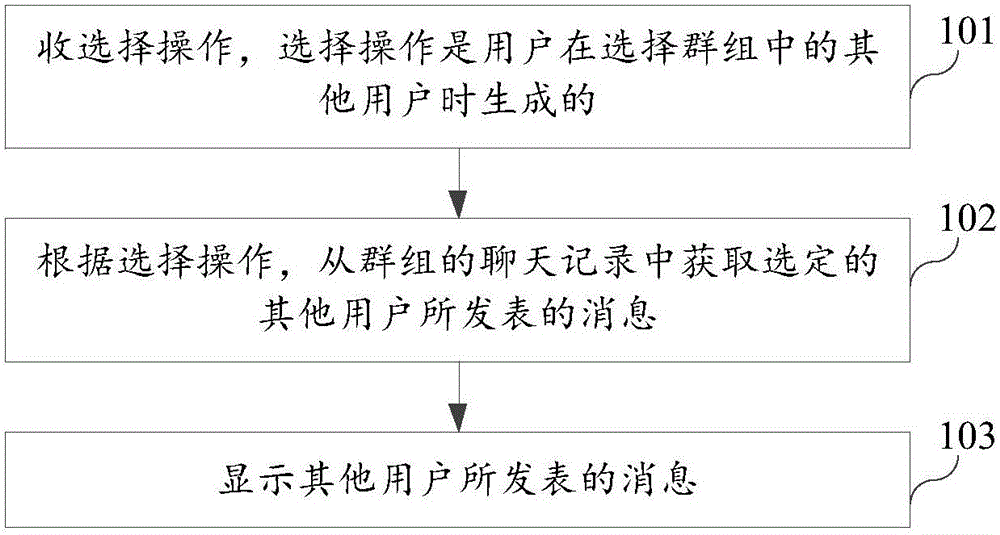

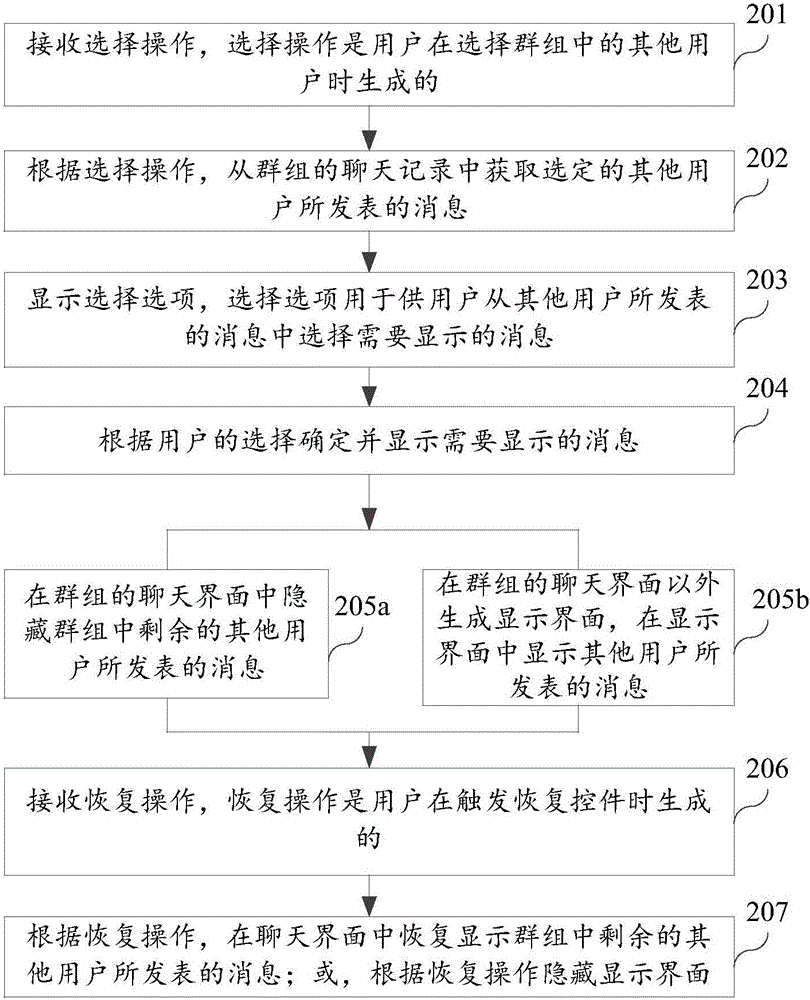

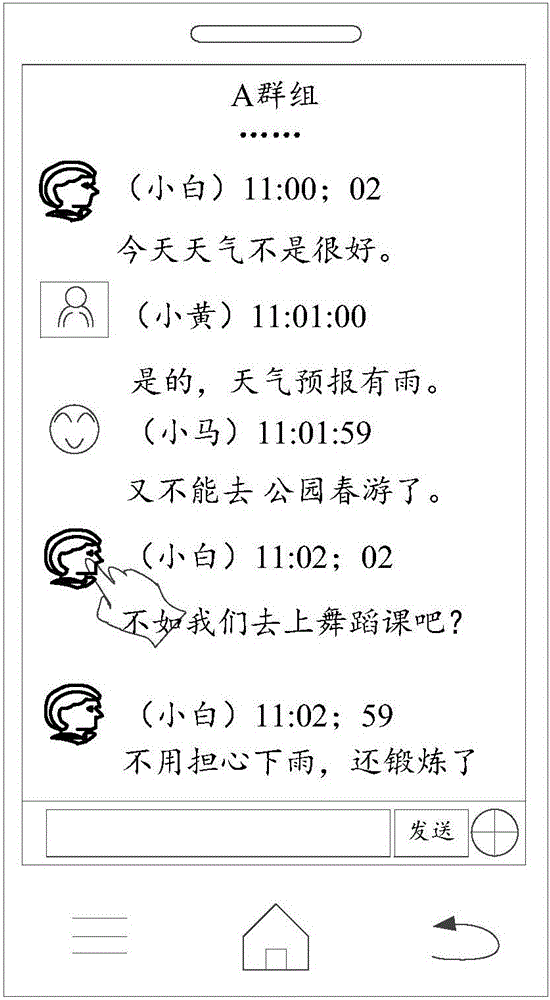

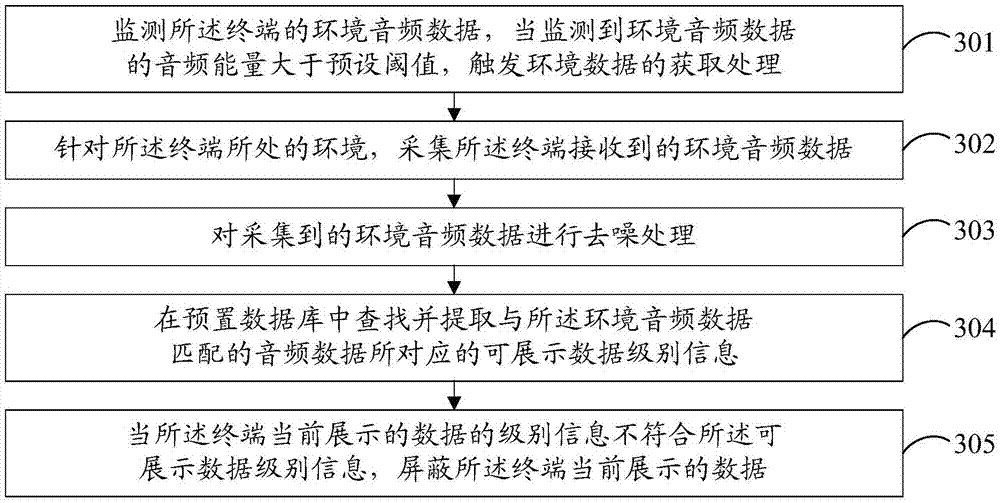

Message display method and device

InactiveCN105892810ASave operabilityShorten the timeInput/output processes for data processingMultimedia

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

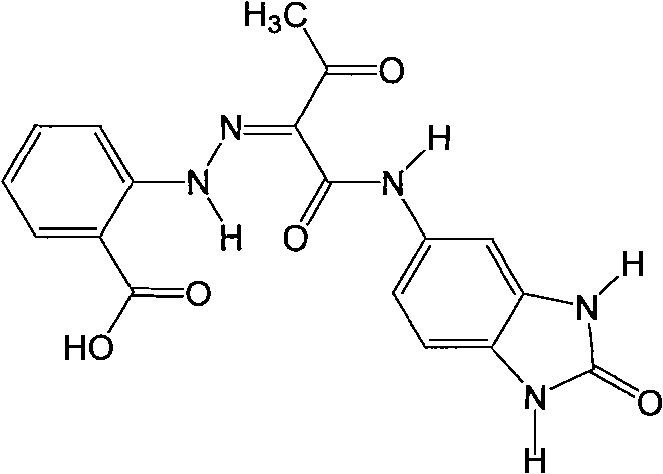

Preparation method of C.I. pigment yellow 151

The invention relates to a preparation method of C.I. pigment yellow 151, which comprises the steps of: taking phthalimide and NaOX as starting materials to prepare strong-basicity solution of o-aminobenzoic acid; dissolving a coupling component 5-acetyl acetamido benzimidazolone (AABI) in the strong-basicity solution without acid precipitation; diazotizing and coupling under a proper pH condition; synthesizing the pigment for once; and optionally pigmenting and surfacing to obtain the C.I. pigment yellow 151. The technology is simplified, the ice use cost is saved, the use level of acid and alkali is greatly reduced, the production waste water is greatly reduced, the good economic benefit is obtained, and the environmental harmfulness is greatly reduced.

Owner:ANSHAN HIFICHEM CO LTD

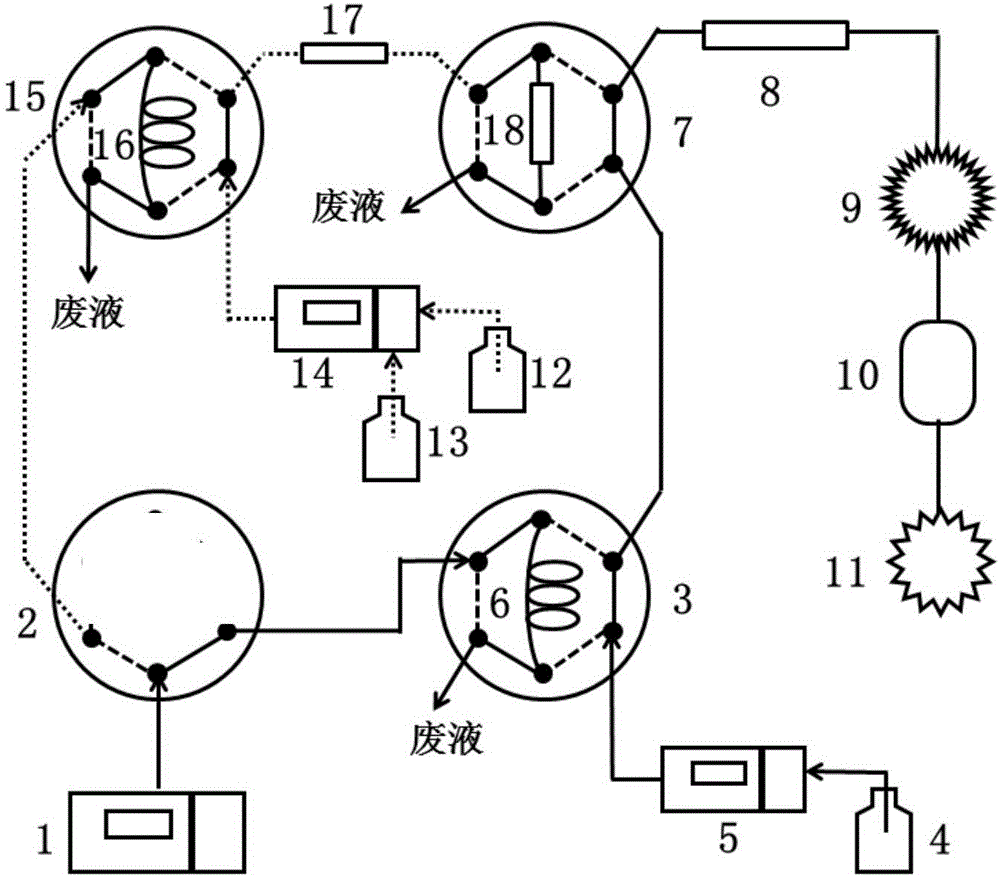

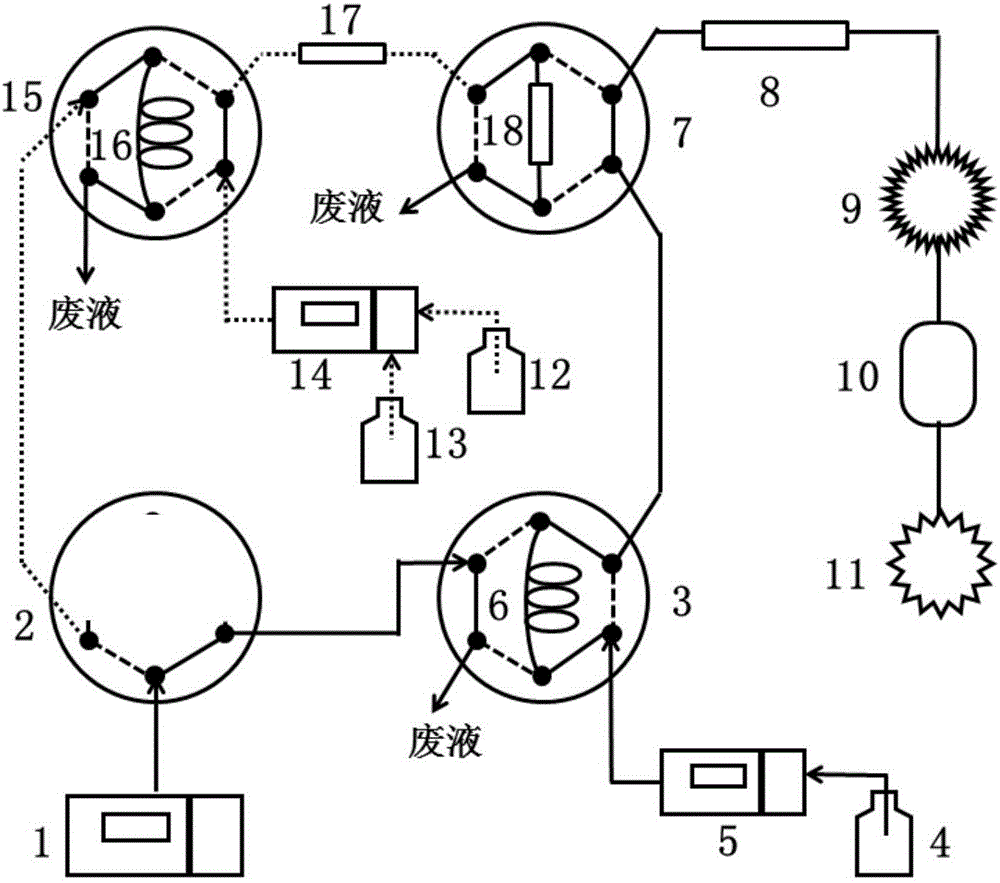

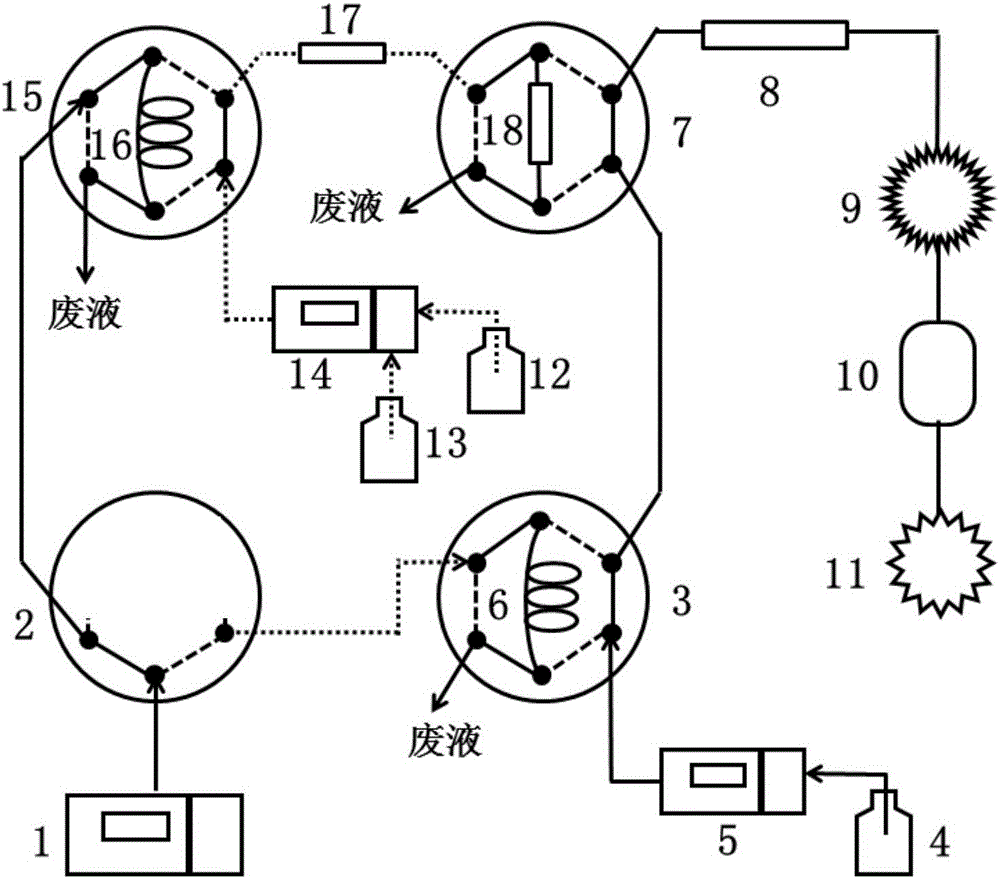

Ion chromatograph based on multi-valve switching and for offline and online analysis and detection method of ion chromatograph

PendingCN106645502ASolution can only do offline ion chromatography analysisSolve the purificationComponent separationChromatographic separationMulti-valve

The invention discloses an ion chromatograph based on multi-valve switching and for offline and online analysis and a detection method of the ion chromatograph. The ion chromatograph comprises an automatic sample feeder, two chromatographic pumps, multiple six-way valves, an online purifying column, an enriching column, a chromatographic separation column, an ultraviolet detector, an inhibitor and an electrical conductance detector. Online switching of offline ion chromatographic analysis and online purifying ion chromatographic analysis can be realized on one ion chromatograph, the problem that conventional ion chromatographs can only conduct offline ion chromatographic analysis or online purifying ion chromatographic analysis is solved, and online switching of analysis systems can be realized according to properties of to-be-analyzed samples, so that convenience and using efficiency of the ion chromatograph are improved greatly, and using cost of the ion chromatograph is lowered. In addition, an online purifying analysis system saves sample pretreatment time and complex operation process; compared with disposable using characteristics of conventional purifying columns, the online purifying column is more environment-friendly through activation and regeneration treatment and recycling, and analysis cost is greatly lowered.

Owner:ANIMAL & PLANT & FOOD INSPECTION CENT OF TIANJIN ENTRY EXIT INSPECTION & QUARANTINE BUREAU +1

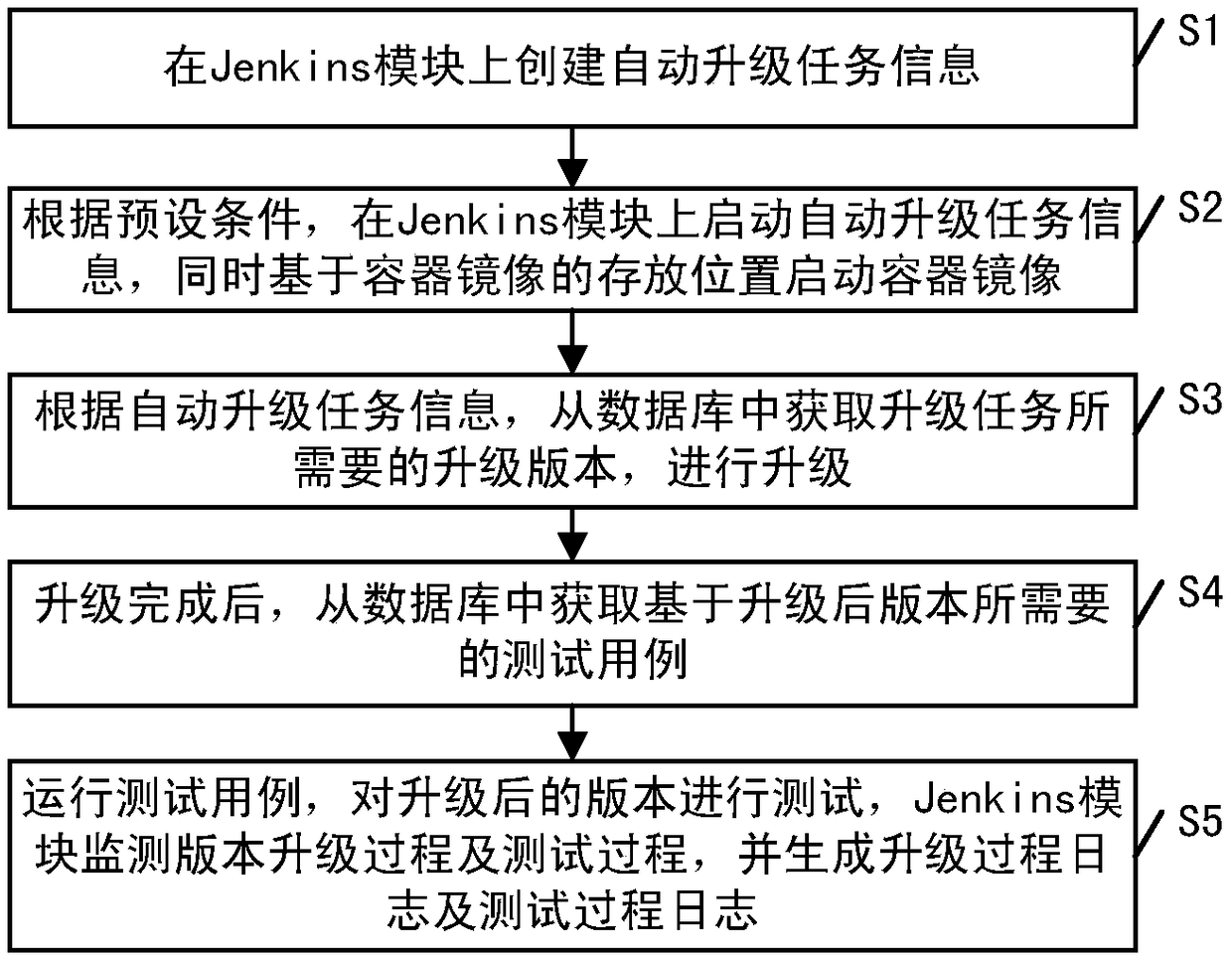

An automatic upgrading and automatic testing method

InactiveCN109002307AReduce the trouble of configuring the environmentReduce demandSoftware testing/debuggingSoftware deploymentTest efficiencyDependability

The invention provides an automatic upgrading and automatic testing method, which creates automatic upgrading task information on a Jenkins module. According to the preset conditions, the automatic upgrade task information is started on the Jenkins module, and the container image is started based on the storage location of the container image. According to the automatic upgrade task information, the upgrade version required by the upgrade task is obtained from the database and upgraded. The test case is run to test the upgraded version. The Jenkins module monitors the version upgrade process and test process, and generates the upgrade process log and test process log. Through the automation of product upgrade test, a lot of manual operation and repetitive operation are saved, and the reliability of product upgrade test is improved. The automation of the whole process greatly improves the test efficiency. On the other hand, through docker containers, mirroring is customized to ensure the conformance of the underlying environment for development and testing.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

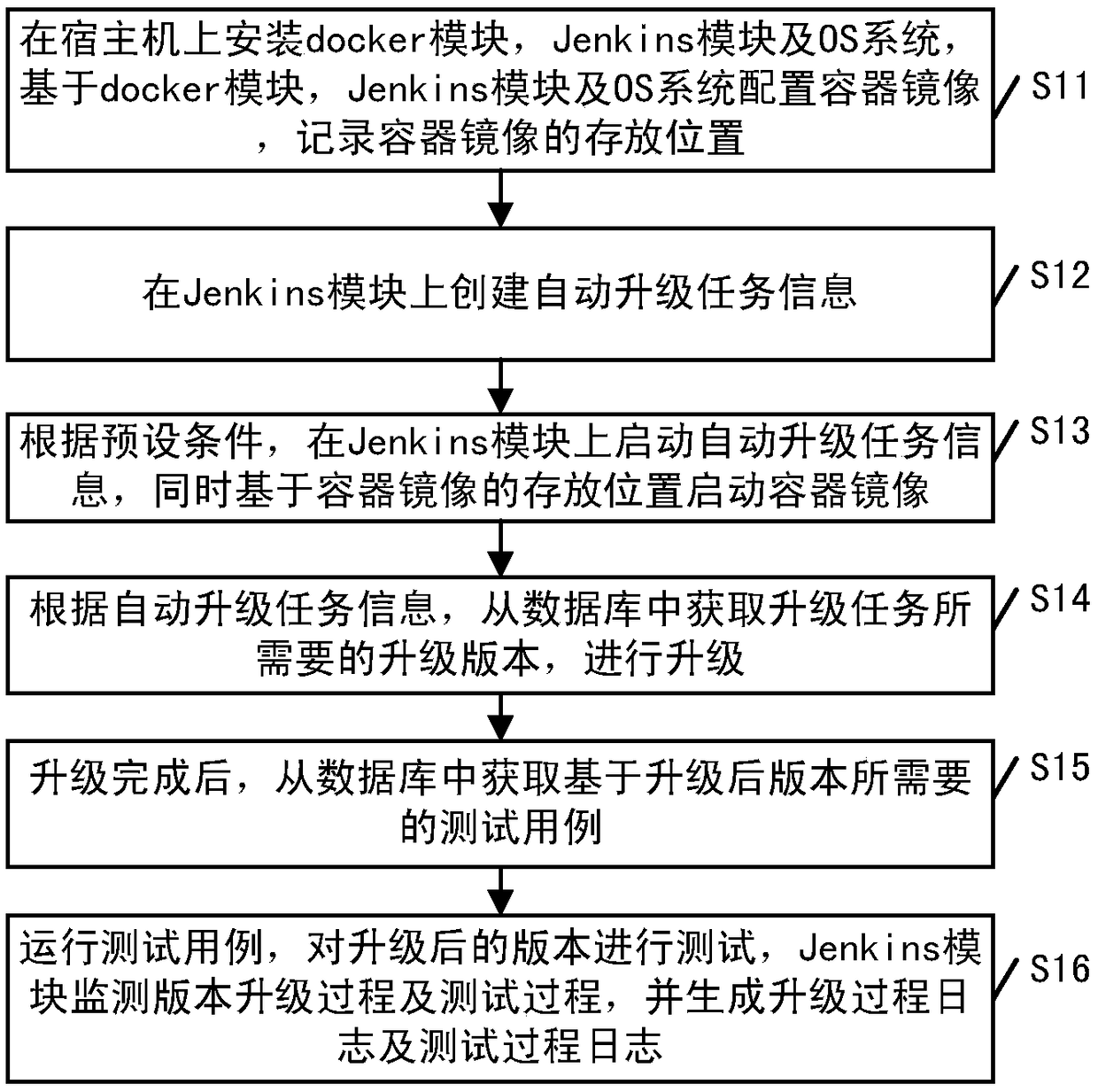

Method for treating pickling wastewater in iron and steel industry

ActiveCN104086030AConcentratesImprove separation efficiencyMultistage water/sewage treatmentWastewaterProcess engineering

The invention discloses a method for treating pickling wastewater in iron and steel industry. The method comprises the following steps: a) introducing pickling wastewater into a regulating tank, a chromium reduction tank and a heavy metal catcher; b) separating heavy metal precipitate produced in reaction from clear liquor through an ultramicro separating machine, carrying out primary fluoride removal on the clear liquor in a fluoride removal filter; c) feeding the mixed solution subjected to primary fluoride removal into a primary precipitating tank for separating non-ferrous precipitate from water, then carrying out secondary fluoride removal on the clear liquor in a fluoride reaction tank; and d) feeding the mixed solution subjected to secondary fluoride removal into a secondary precipitating tank for separating non-ferrous precipitate from water, and emitting the separated clear liquor into a clear water tank for storage. The method has high metal particle separation efficiency, the ultramicro separation machine has concentration effect, so no concentration tank is required for separating the precipitate from the clear liquor to save space and the labor force, the indexes of iron, chromium, nickel, fluoride and the like in the clear liquor emitted from the secondary precipitating tank can all meet the national-level standard requirement.

Owner:JIANGSU BESITE WATER SCI & TECH

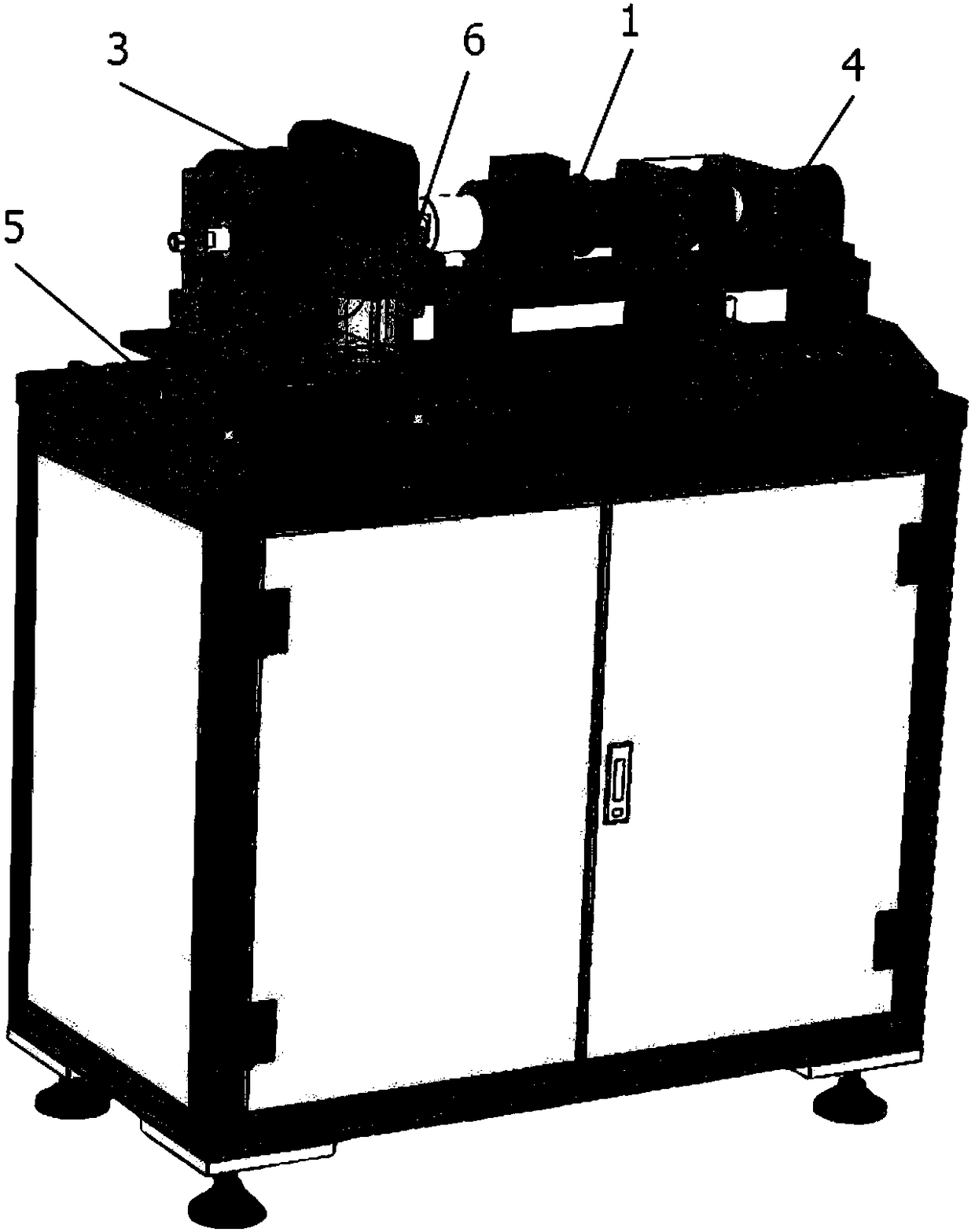

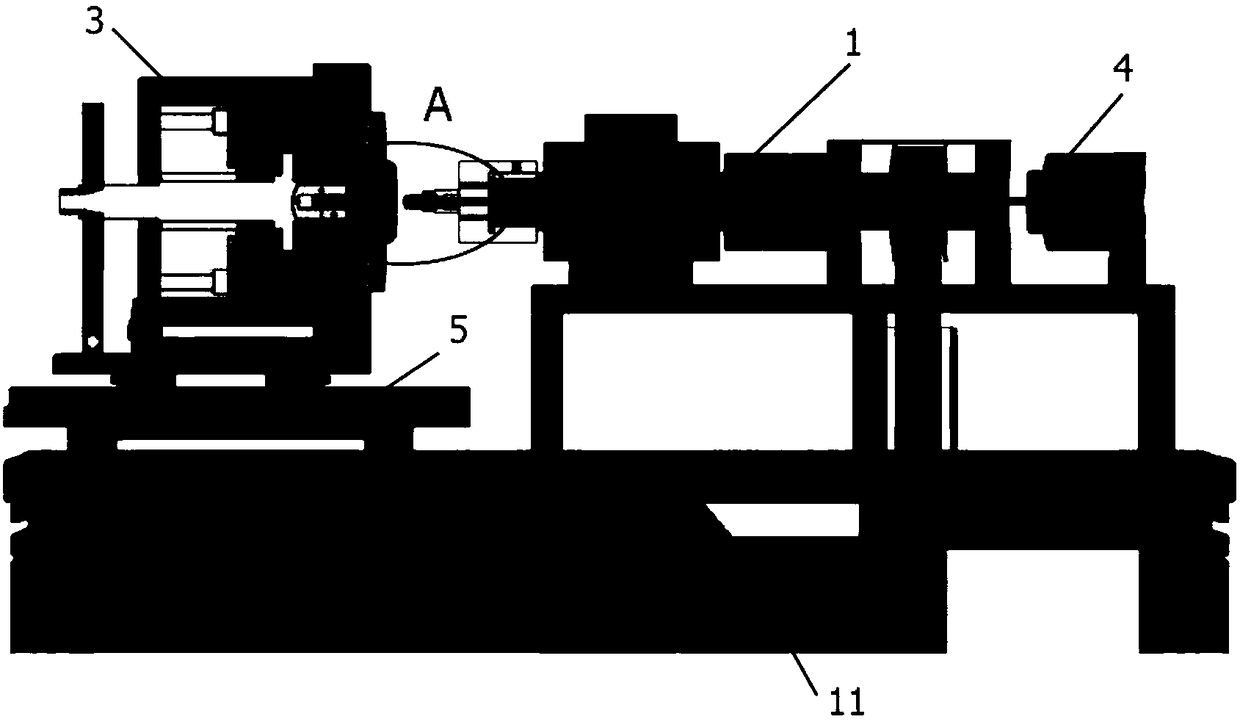

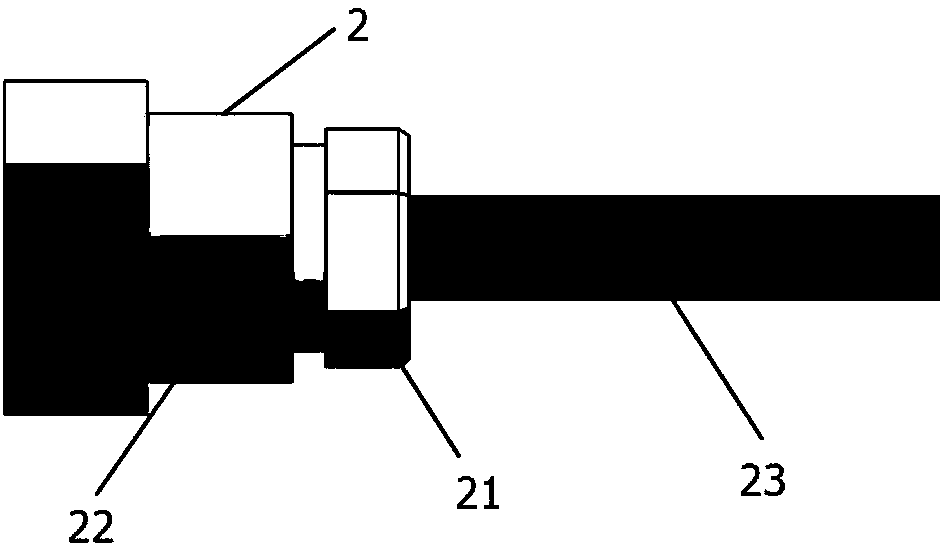

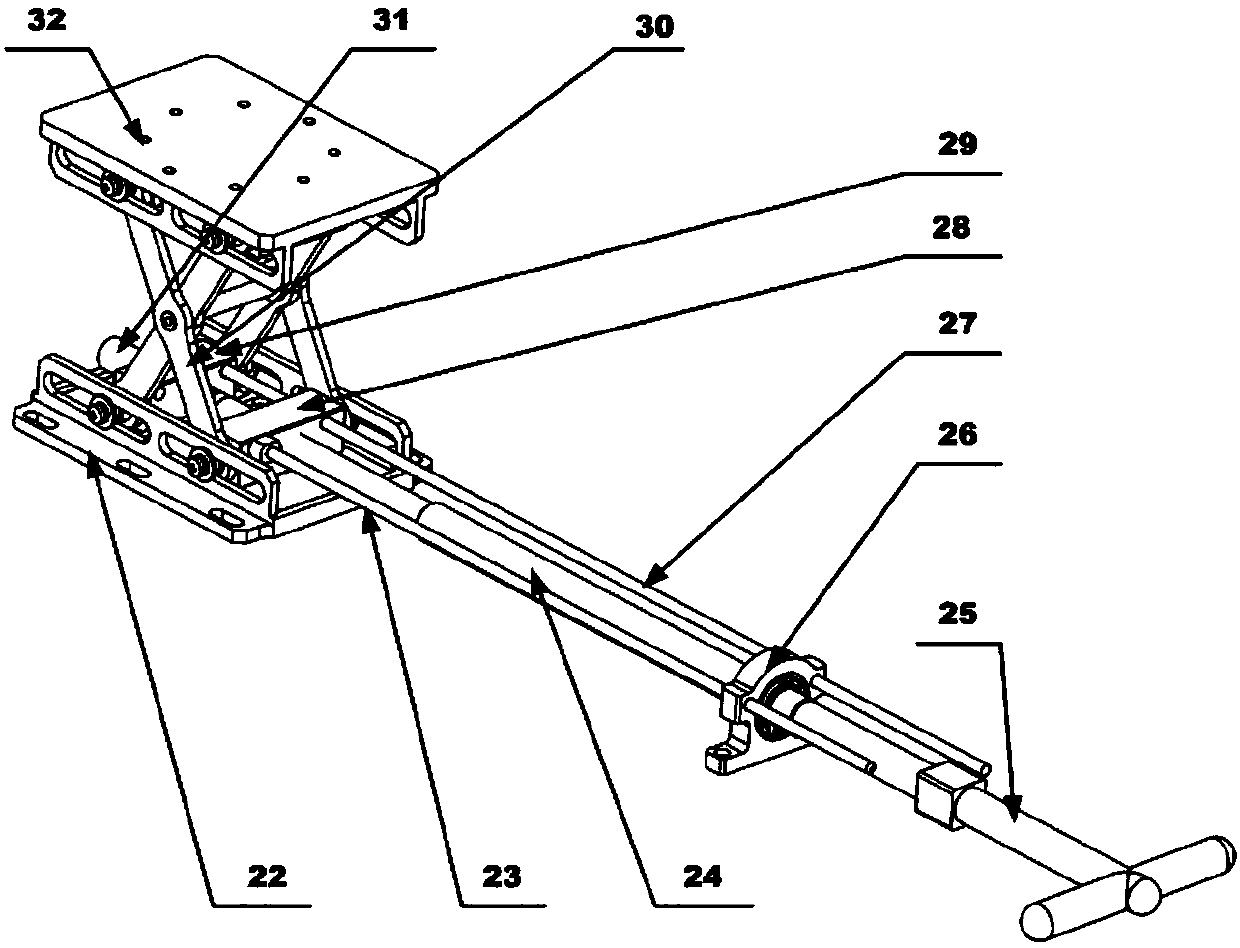

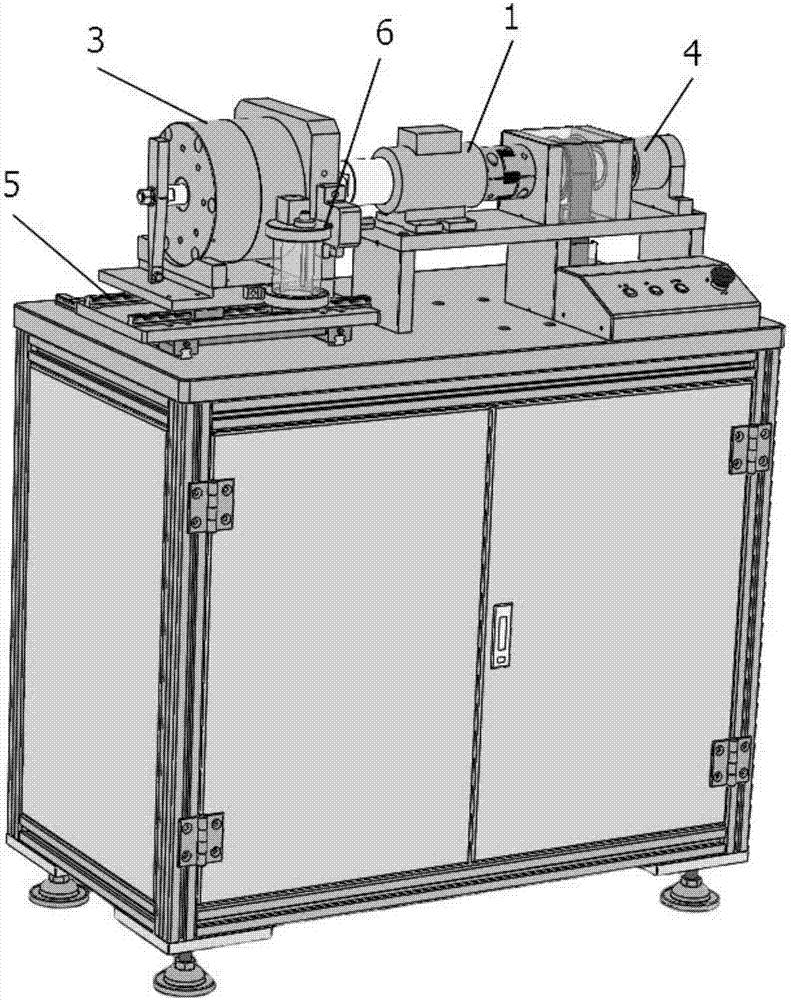

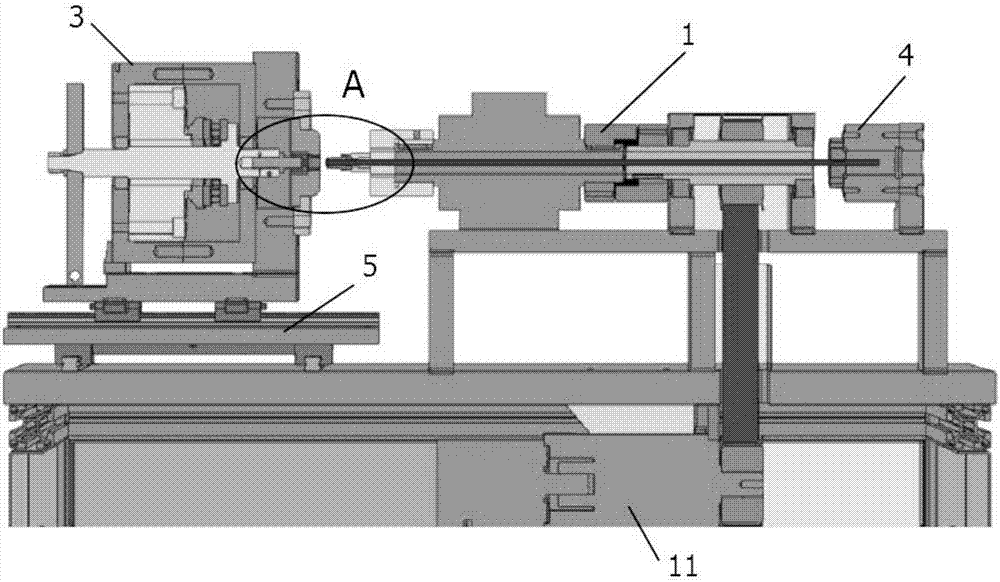

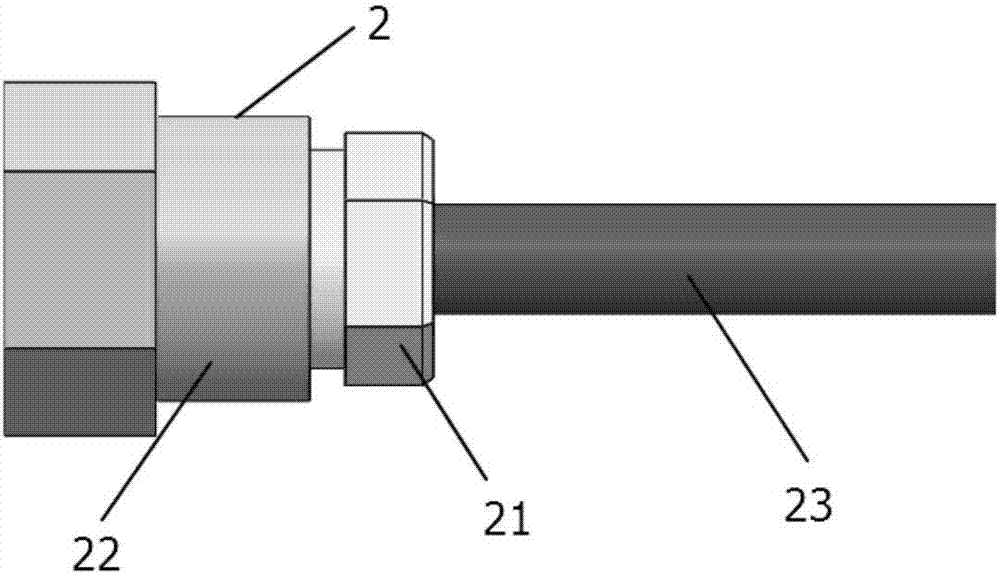

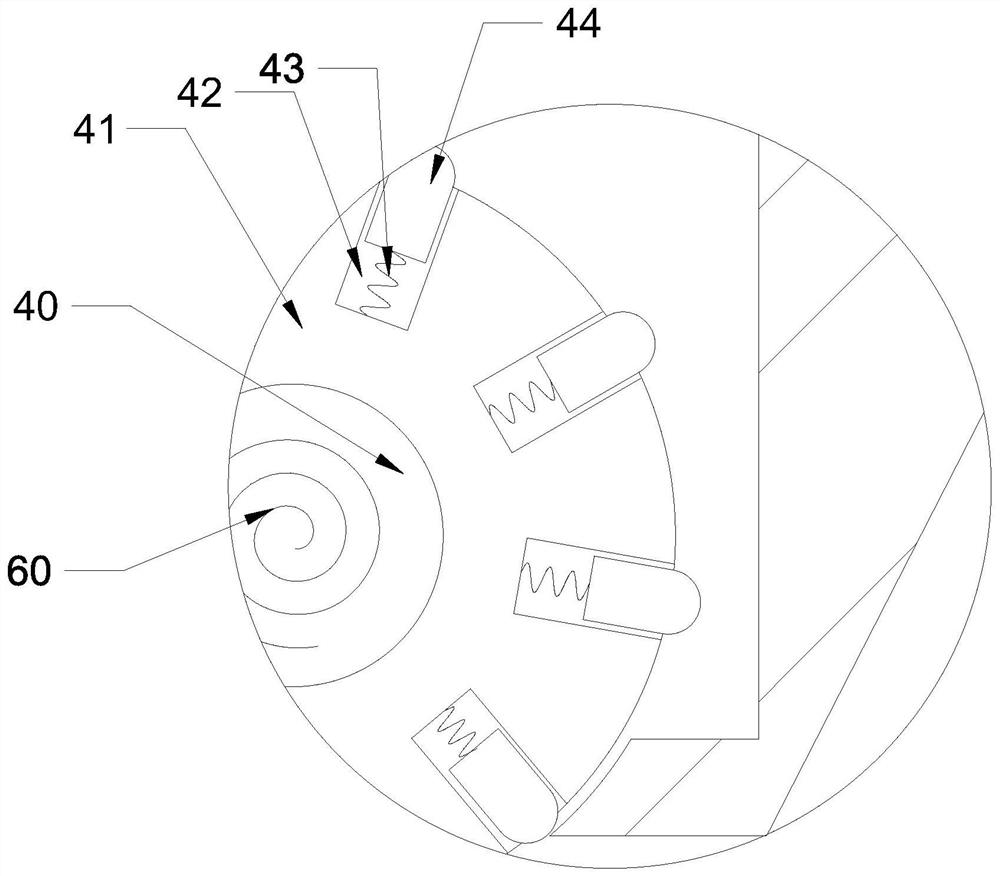

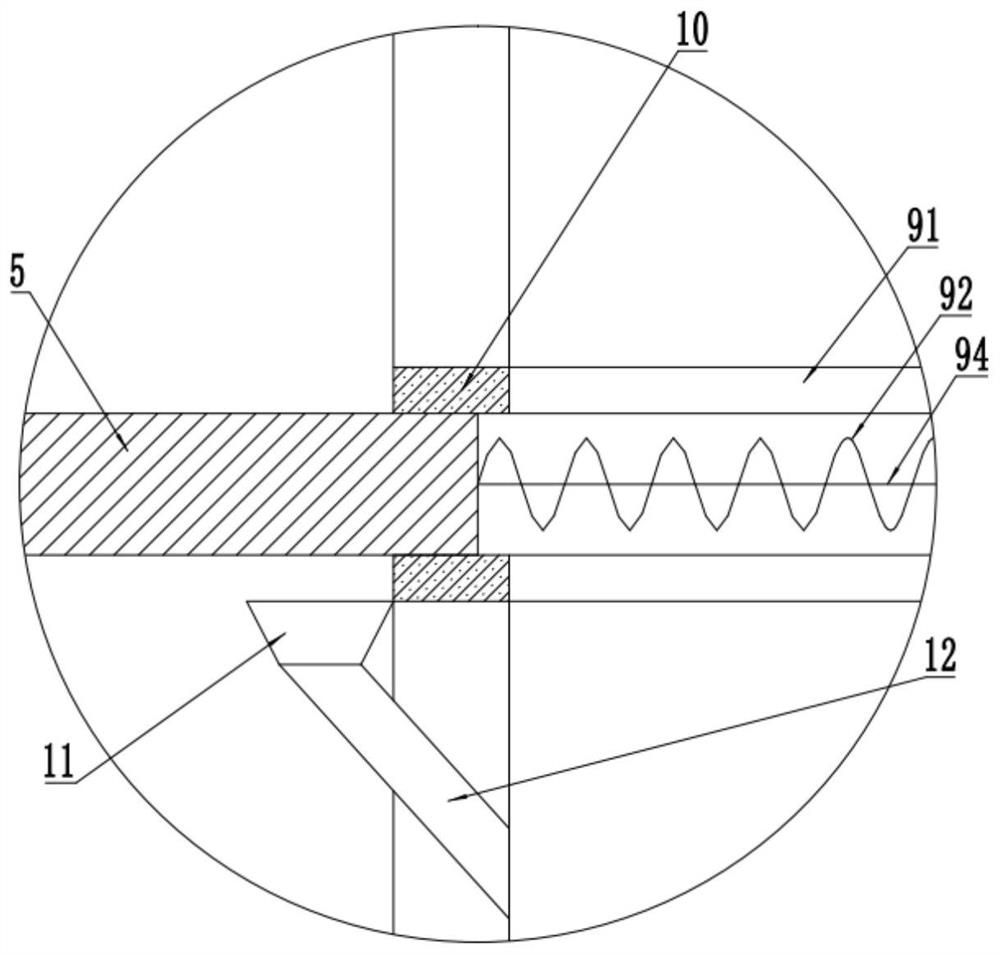

Pre-tightening force measuring device for threaded fastener of oil pipe joint

ActiveCN108181037AQuality improvementRealize one-time detectionMeasurement of torque/twisting force while tighteningForce sensorsCircular coneEngineering

The invention relates to the field of oil pipe joint testing and discloses a pre-tightening force measuring device for a threaded fastener of an oil pipe joint. The device comprises a torque applyingmechanism, an external threaded member of the oil pipe joint coaxially connected to the output end of the torque applying mechanism, an adaption joint which is matched with the external threaded member and comprises separated inner threaded part and conical surface part, and a force conduction and detection mechanism which is connected to the adaption joint and is used for conducting and detectingpretightening force of the external threaded member on the conical surface part, and the force conduction and detection mechanism and an output end of the torque applying mechanism are coaxially arranged. According to the device, through separating and separately fixing the inner threaded part of the adaption joint and the conical surface part, the torque applying mechanism is used to drive the external threaded member to rotate to cooperate with the inner threaded part of the adaption joint, combined with the force conduction and detection mechanism, the pre-tightening force of the oil pipejoint can be directly detected, and the gap of the test in China is filled.

Owner:上海宏予测试仪器有限公司

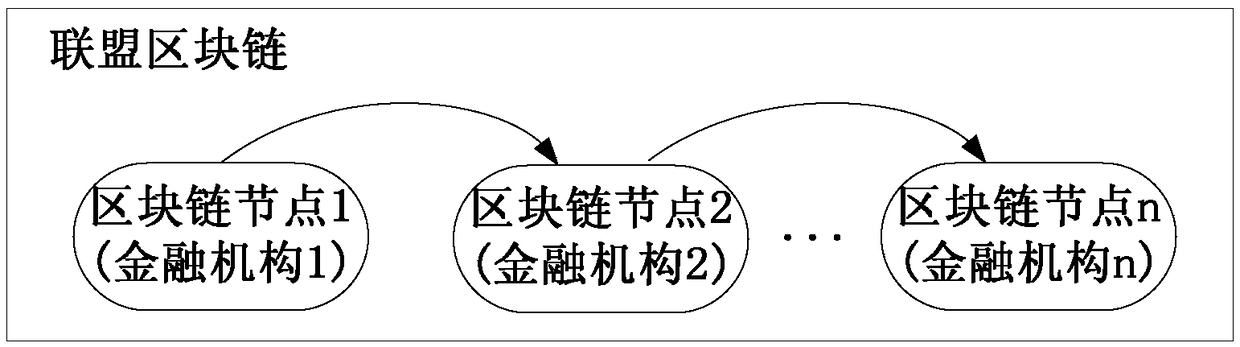

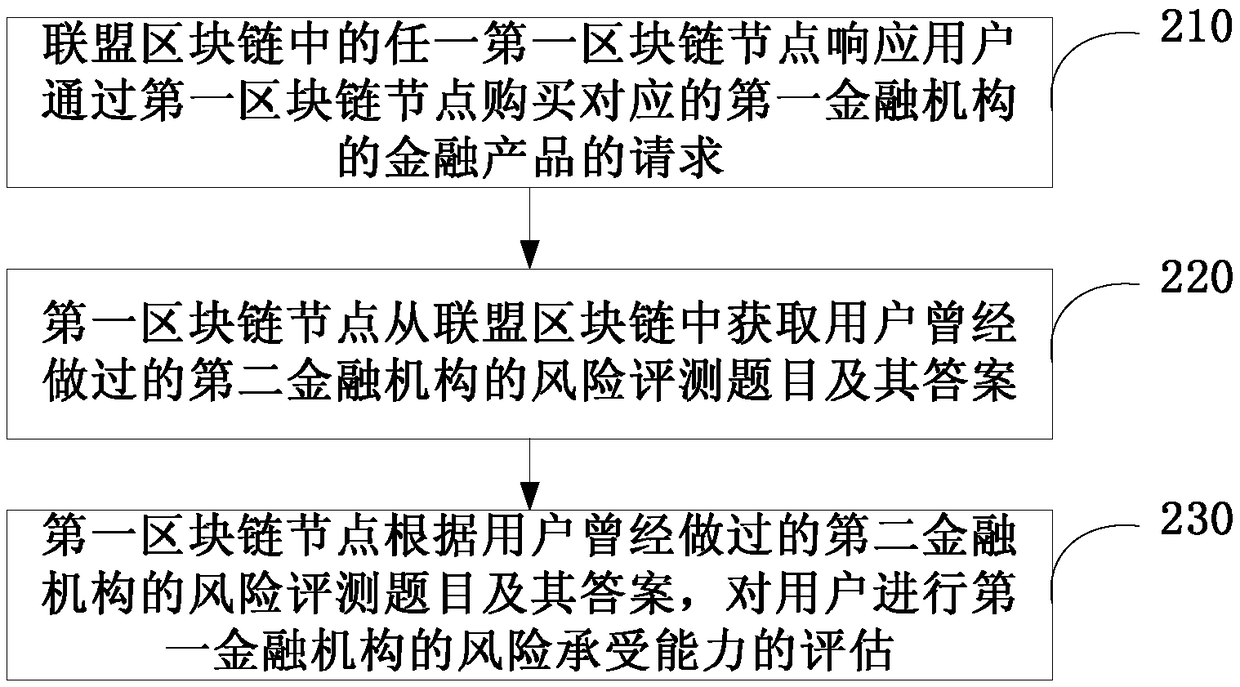

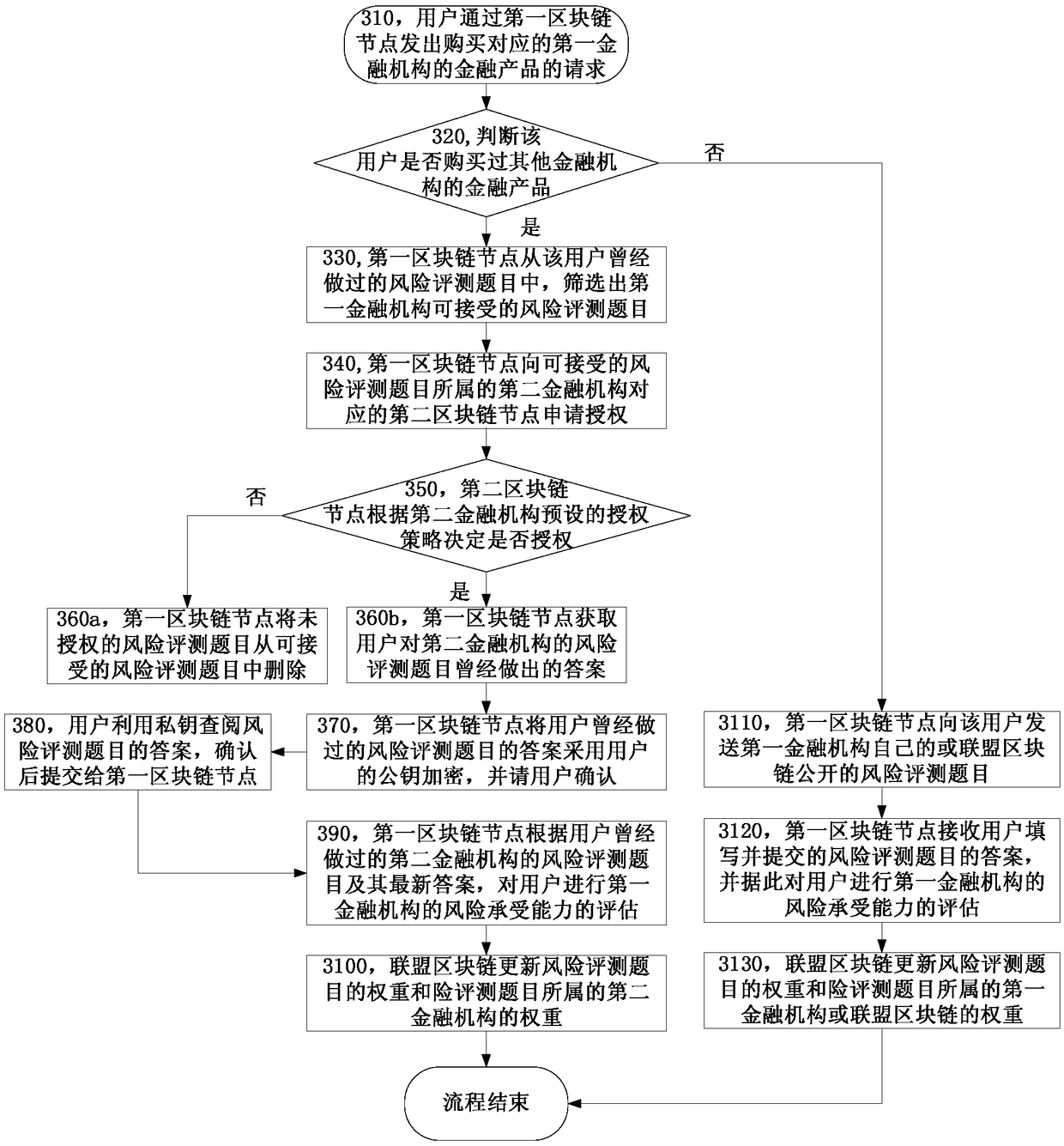

Risk control system and method and computer readable storage medium

The invention proposes a risk control system and method and a computer readable storage medium, and relates to the field of risk control. The system comprises an alliance blockchain which consists ofa plurality of blockchain nodes, wherein each blockchain node is corresponding to one financial institution, and any one first blockchain node in the alliance blockchain is configured to respond to arequest that a user purchases a financial product of the corresponding first financial institution through the first blockchain node; obtaining the risk evaluation questions, answered by the user at one time, of a second financial institution and the answers of the questions from the alliance blockchain; evaluating the risk tolerance of the user for the first financial institution according to therisk evaluation questions, answered by the user at one time, of the second financial institution and the answers of the questions, wherein the evaluation result serves as a reference for judging whether the user is suitable to purchase a financial product of the first financial institution or not. Therefore, the method saves some repeated operation and time for the user in the evaluation process,and improves the evaluation efficiency of the risk tolerance of the user.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

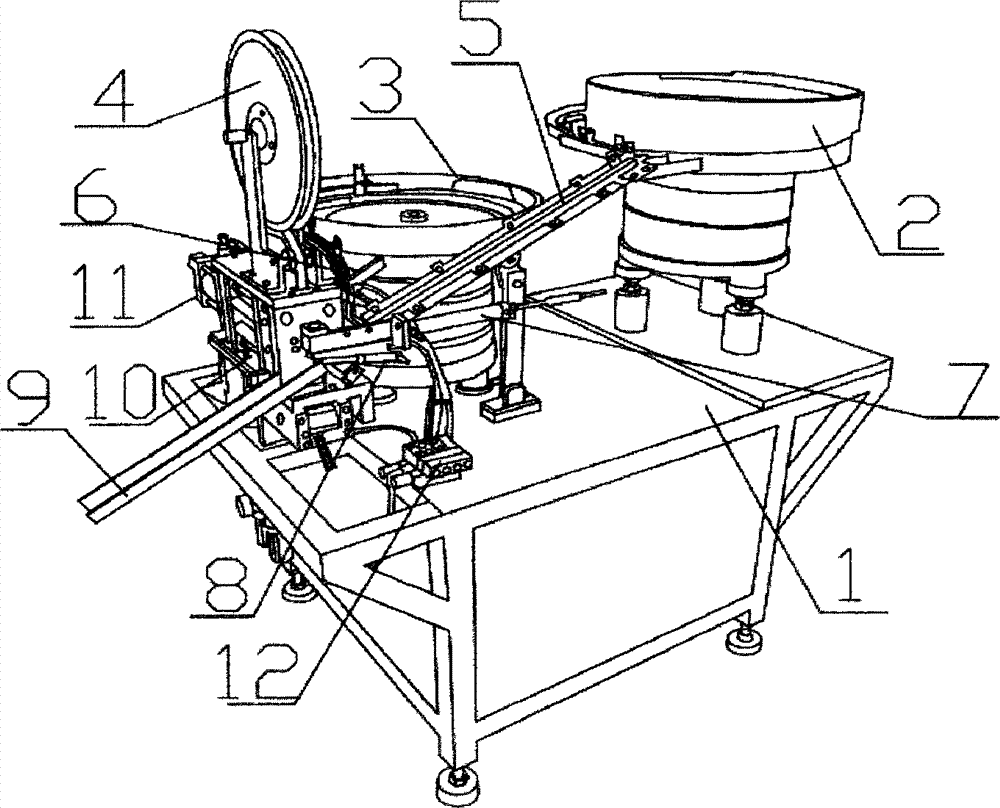

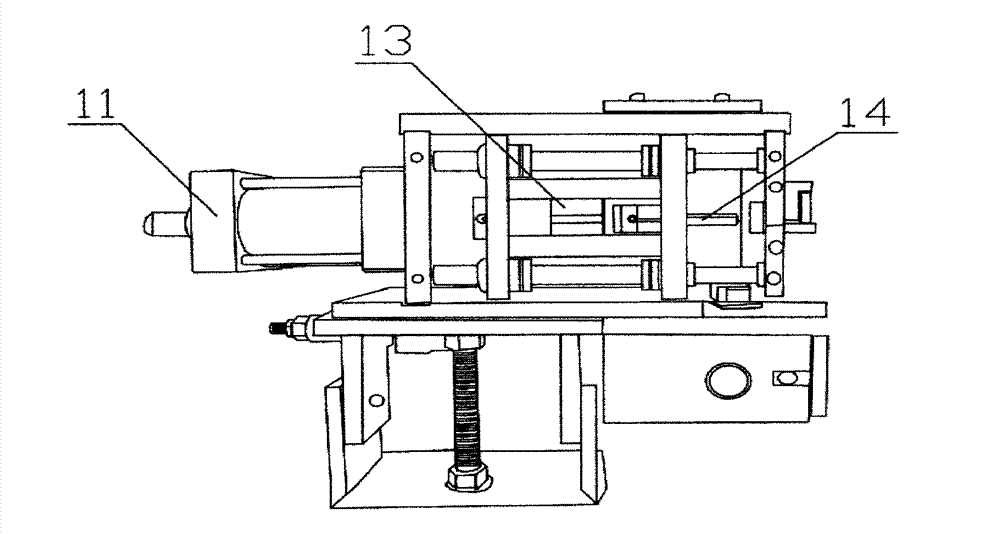

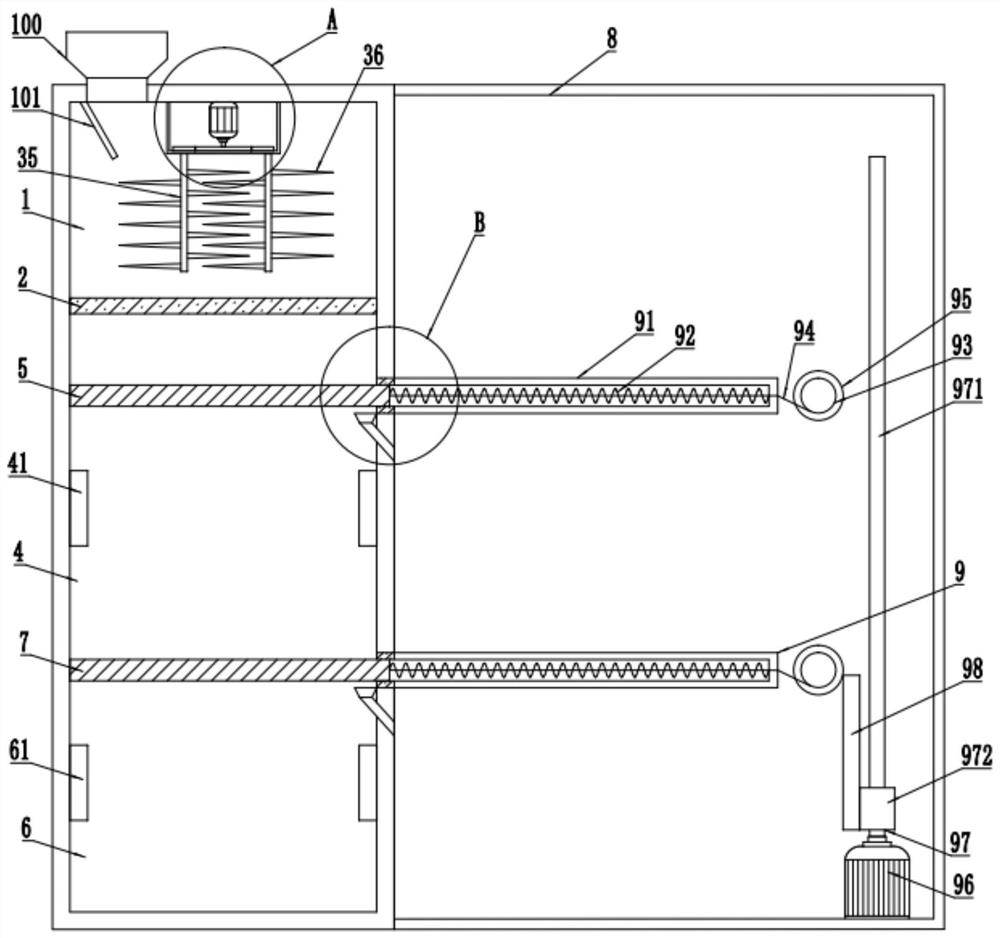

Screw automatic assembly machine

The invention discloses a screw automatic assembly machine and belongs to the field of mechanical equipment for machining and assembling. The screw automatic assembly machine comprises a fixed base and a control electricity box. A first vibration feed plate and a second vibration feed plate are arranged on the top end surface of the fixed base, wherein the first vibration feed plate is used for transporting a metal cylinder and the second vibration feed plate is used for transporting a cone-shaped wedge. A punching assembly mechanism is further arranged on the top of the fixed base. A roll material fixed plate is arranged on the top of the punching assembly mechanism and used for transporting roll materials. The punching assembly mechanism is composed of a punching cylinder and a stamping assembly cylinder. A movable rod of the punching cylinder is provided with a cylindrical punching rod. The punching cylinder is arranged on a movable rod of the stamping assembly cylinder. The stamping assembly cylinder moves to drive the simultaneous movement of the punching rod. The screw automatic assembly machine has the advantages of being capable of achieving intelligent productive process of automatic feeding and automatic material collection, high in stability of production, and capable of saving operation staff and human resources, improving working efficiency and simultaneously guaranteeing safe production.

Owner:南宁燎旺车灯股份有限公司

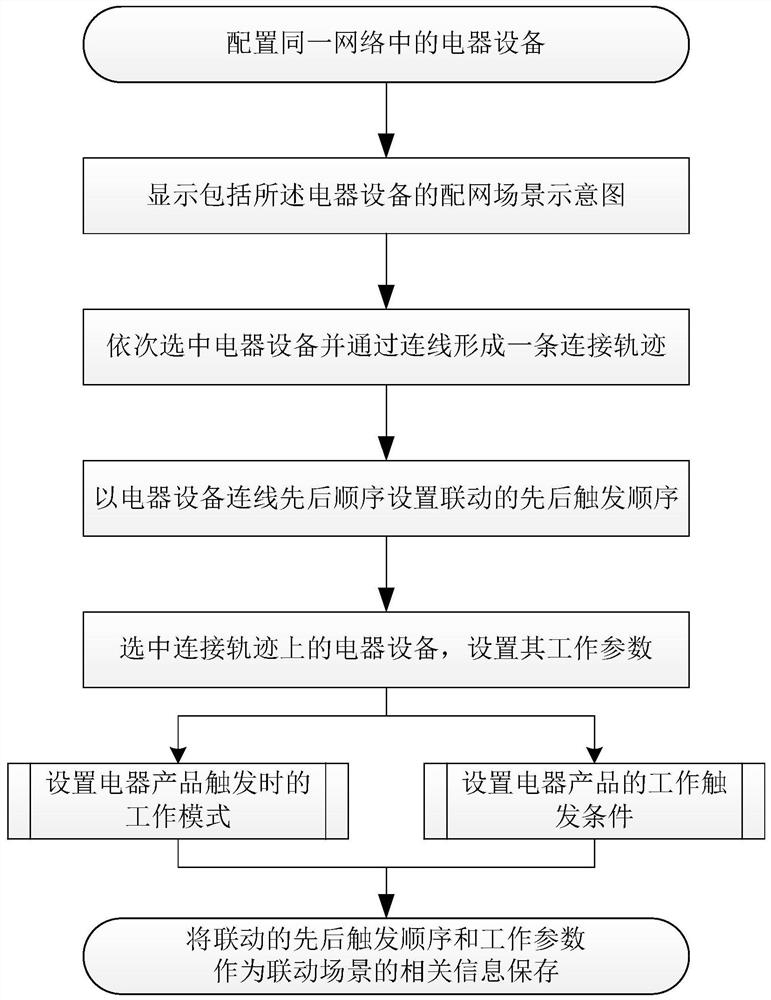

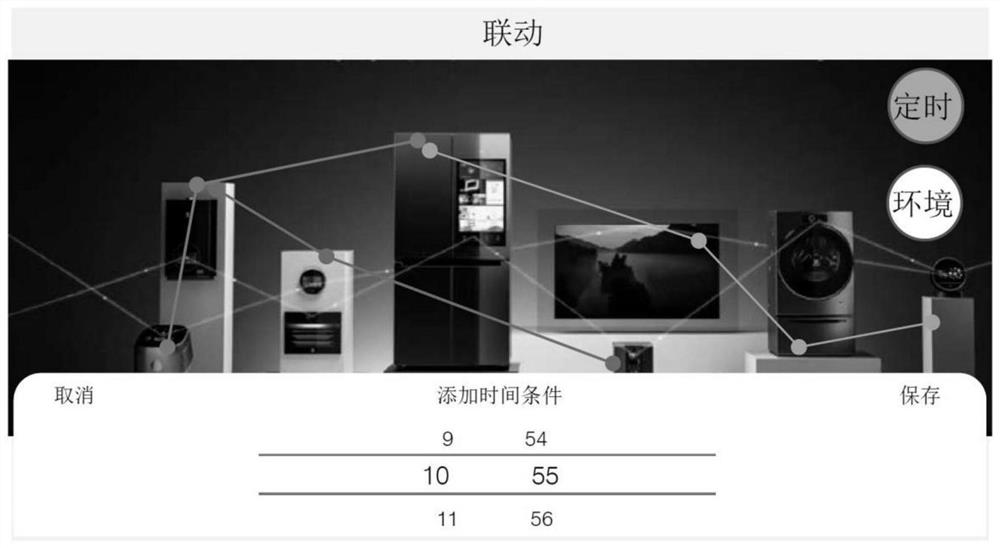

Interaction method for establishing equipment linkage scene, storage medium and electronic equipment

ActiveCN111880501AShorten the timeImprove experienceComputer controlTransmissionSimulationSchematic maps

The invention relates to the technical field of smart home linkage, in particular to an interaction method for establishing an equipment linkage scene, a storage medium and electronic equipment, and solves the problems that the display is not visual enough, the setting process is tedious, the efficiency is low and the time is wasted in the prior art. The method comprises the following steps: in adisplayed distribution network scene schematic diagram comprising electrical equipment configured in the same network, sequentially selecting the electrical equipment through connecting lines to forma connecting track, and setting a sequential triggering sequence for linkage with the electrical equipment in a linkage scene represented by the connecting track according to the sequential order of the connecting lines, selecting the electrical equipment in the connection track to set the working parameters of the electrical equipment in the linkage scene, and finally storing the related information of the linkage scene. According to the invention, the purposes of visual display, simple and rapid linkage scene setting and user experience improvement are achieved, linkage operation steps are reduced, and convenient and rapid operation of intelligent household linkage setting by a user is realized.

Owner:GREE ELECTRIC APPLIANCES INC

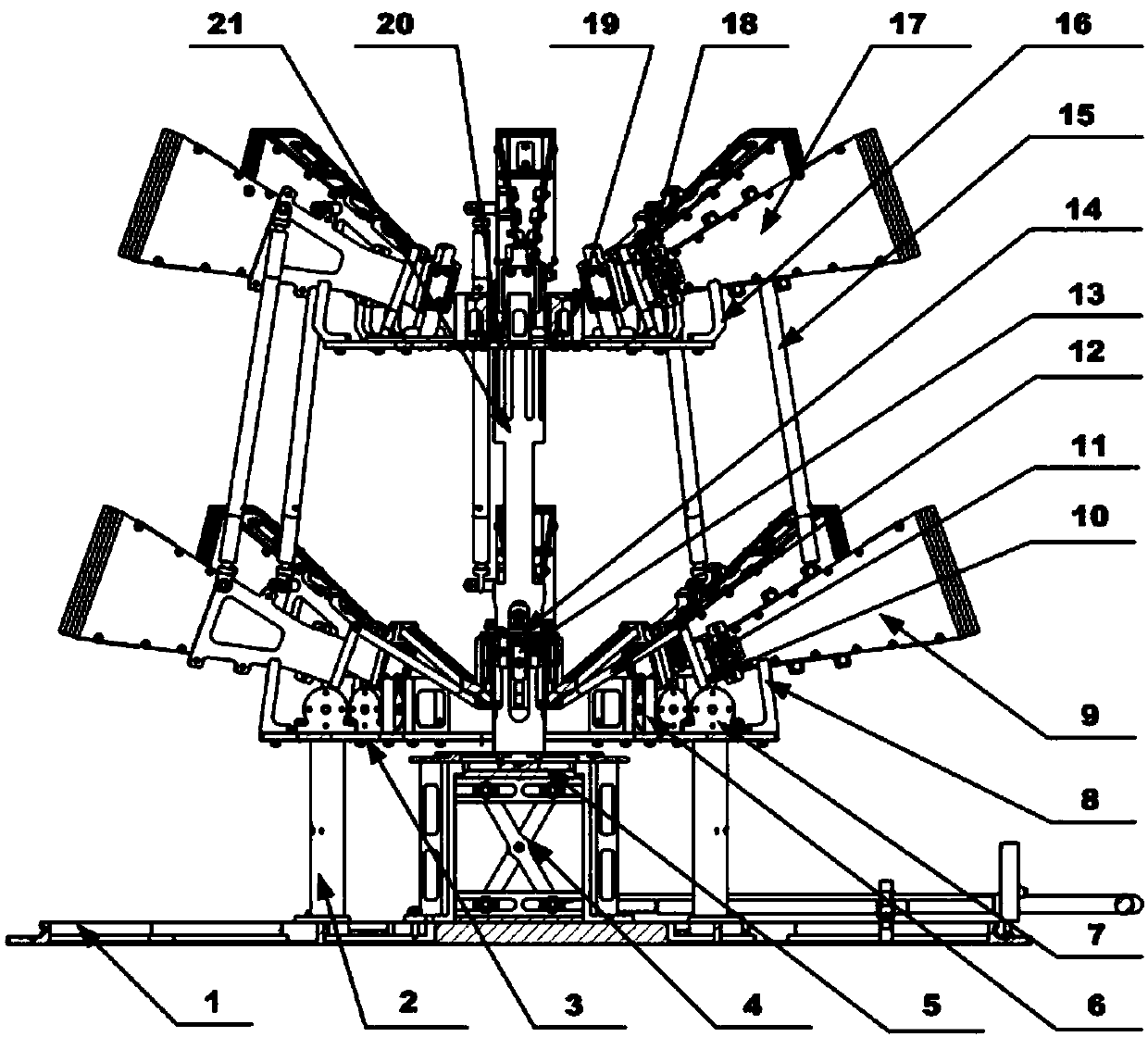

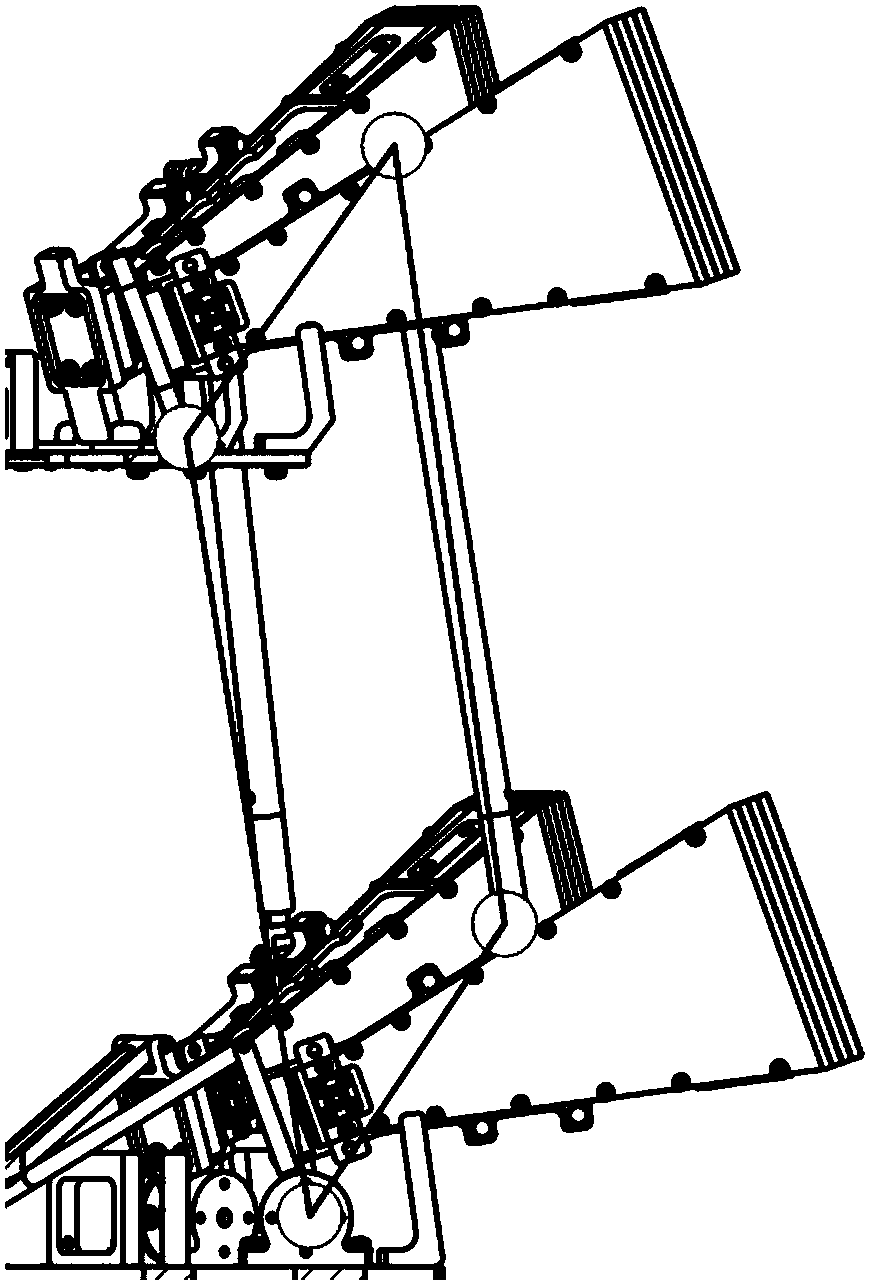

Device for rapidly realizing antenna pitching angle adjustment

Owner:GUILIN CHANGHAI DEV

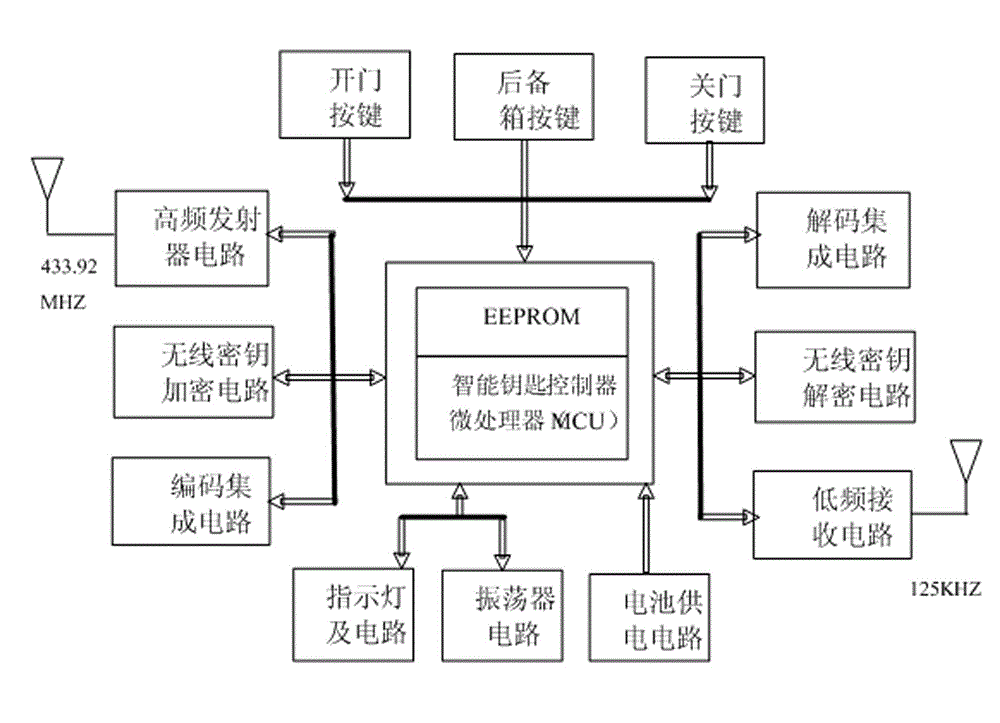

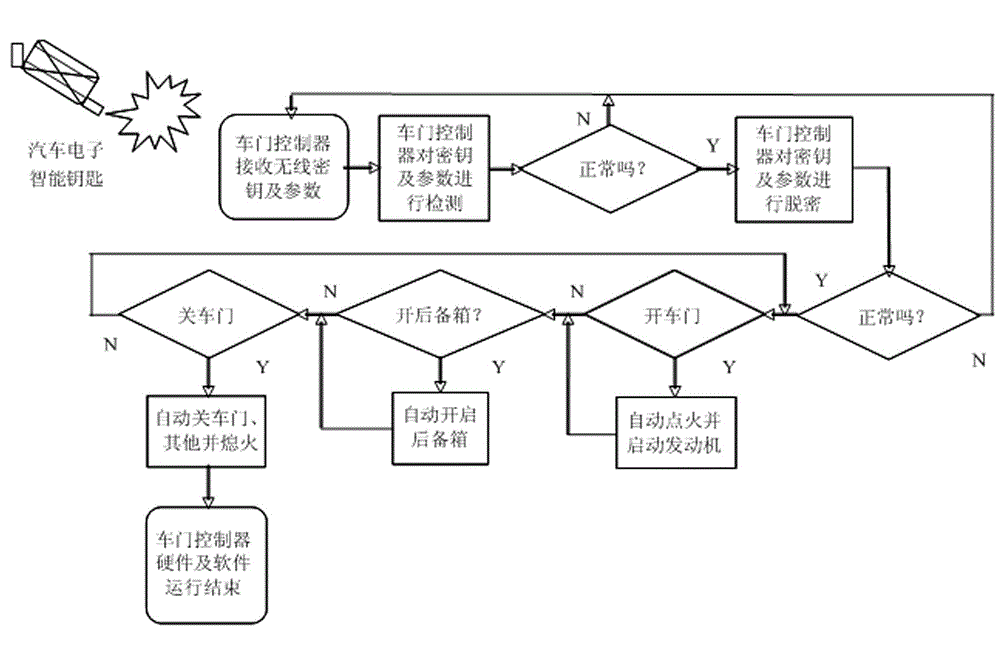

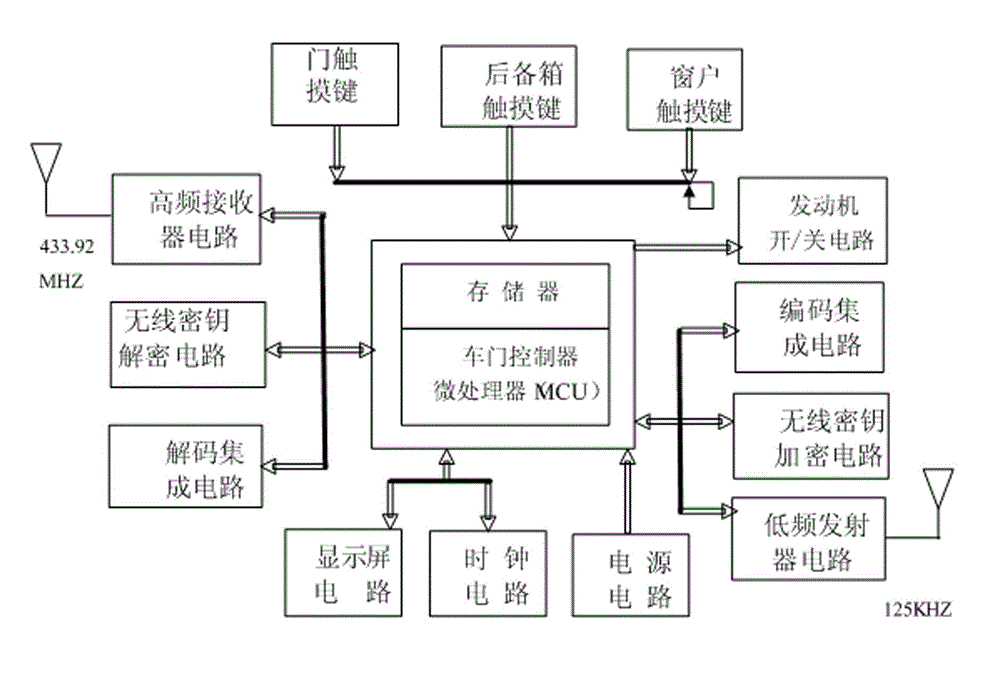

Electronic intelligent key and vehicle door automatic controller used in vehicle

ActiveCN103150801AImprove intelligenceHigh degree of automationIndividual entry/exit registersIn vehicleCold winter

The invention provides an electronic intelligent key and a vehicle door automatic controller used in a vehicle. Compared with the prior art, the electronic intelligent key and the vehicle door automatic controller have the advantage of completely changing a four-step method comprising vehicle door opening, key insertion, automobile power-on, and engine ignition start-up of an original automobile. A user can send a wireless encryption key and a key parameter (within an effective wireless receiving range) to the vehicle far away from the automobile by pressing a one-touch vehicle door opening key of the electronic intelligent key, and when receiving the unique wireless encryption key and the key parameter, the vehicle quickly judges whether the wireless encryption key and the key parameter are correct or not, and enables an engine of the vehicle to be automatically started if the wireless encryption key and the key parameter are correct. Therefore, the operation steps and operation time can be saved, and the vehicle can be cooled and heated in advance in hot summer and cold winter so as to improve the comfort and coziness of a driver as well as the intelligentization and automation degree of the vehicle.

Owner:兴科迪科技(泰州)有限公司

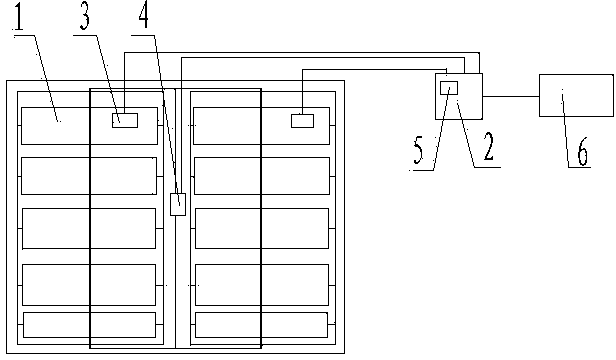

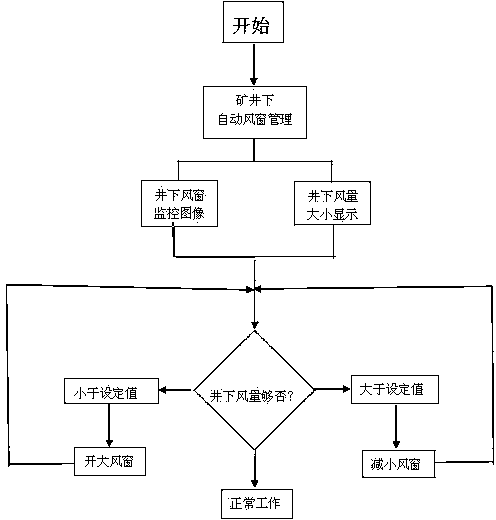

Remote intelligent adjusting wind window

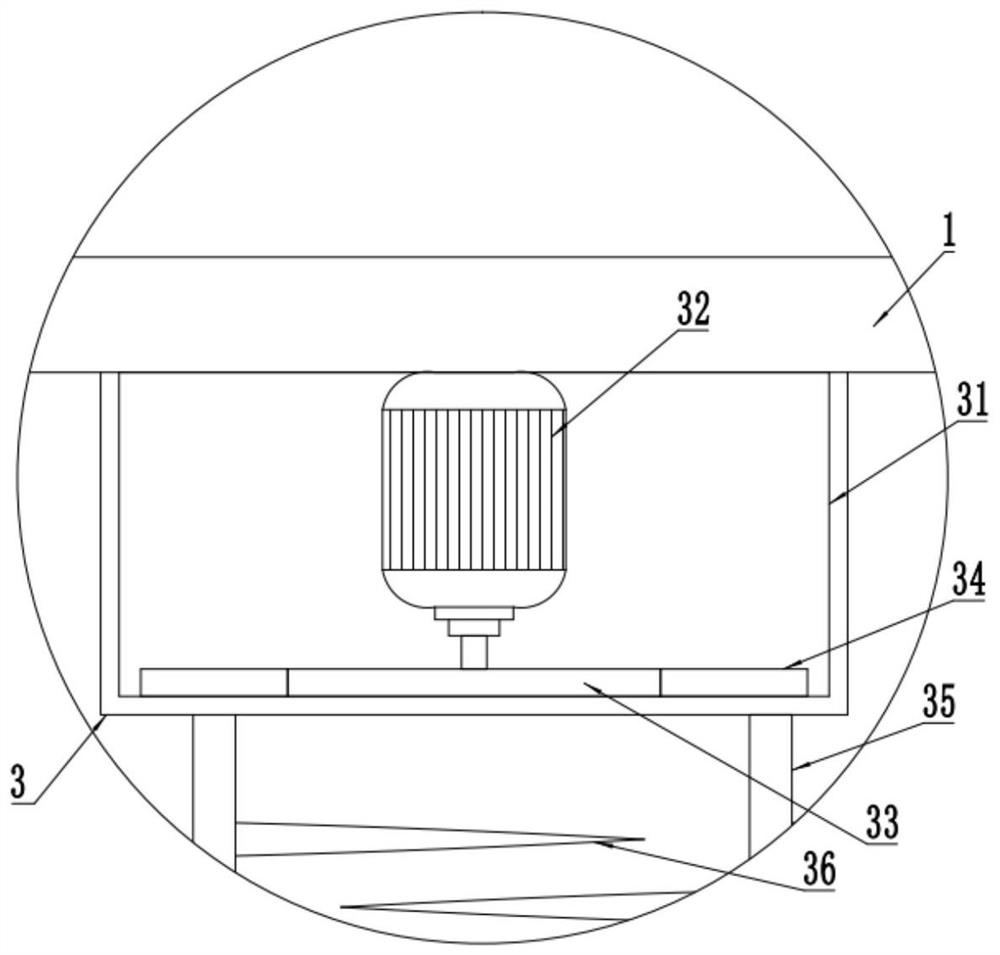

InactiveCN103726865AEnsure safetyAchieve regulationTunnel/mines ventillationCommunication interfaceElectric control

The invention relates to a remote intelligent adjusting wind window, comprising an adjustable louvered window (1), an automatic wind window electric control gear (2), a wind speed sensor (3), a miniature explosion-proof motor (4), an R485 communication interface (5) and a dispatching room (6), wherein the adjustable louvered window (1) is connected with the wind speed sensor (3); the wind speed sensor (3) is connected with the automatic wind window electric control gear (2); the miniature explosion-proof motor (4) is connected with a rotating shaft on the adjustable louvered window (1); the miniature explosion-proof motor (4) is connected with the automatic wind window electric control gear (2); the R485 communication interface (5) is arranged on the automatic wind window electric control gear (2) and is connected with the dispatching room (6). With the remote intelligent adjusting wind window, the safety of operators is ensured, the operators and working hours are saved, the cost is reduced, and underground coal mine ventilation accidents can be greatly reduced.

Owner:DATONG COAL MINE GRP CO LTD HENGAN EQUIP CO LTD

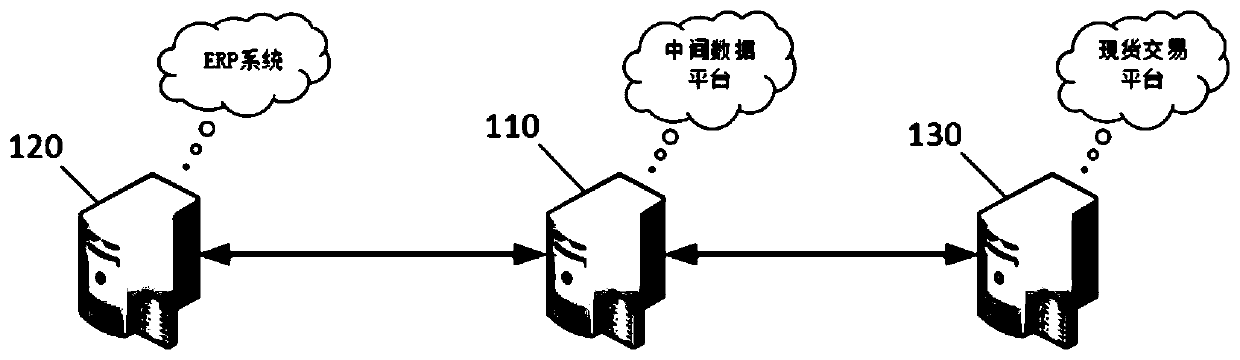

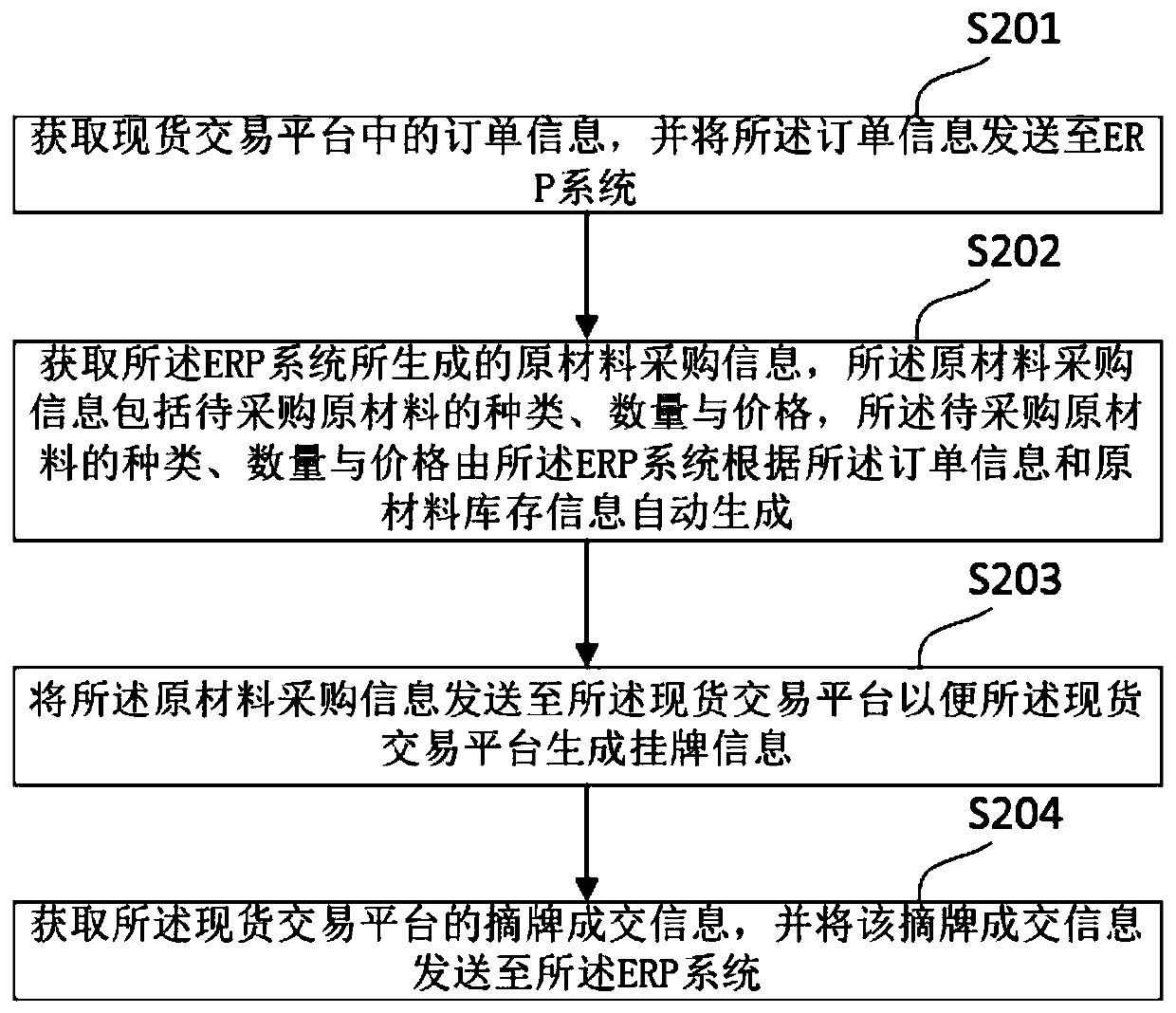

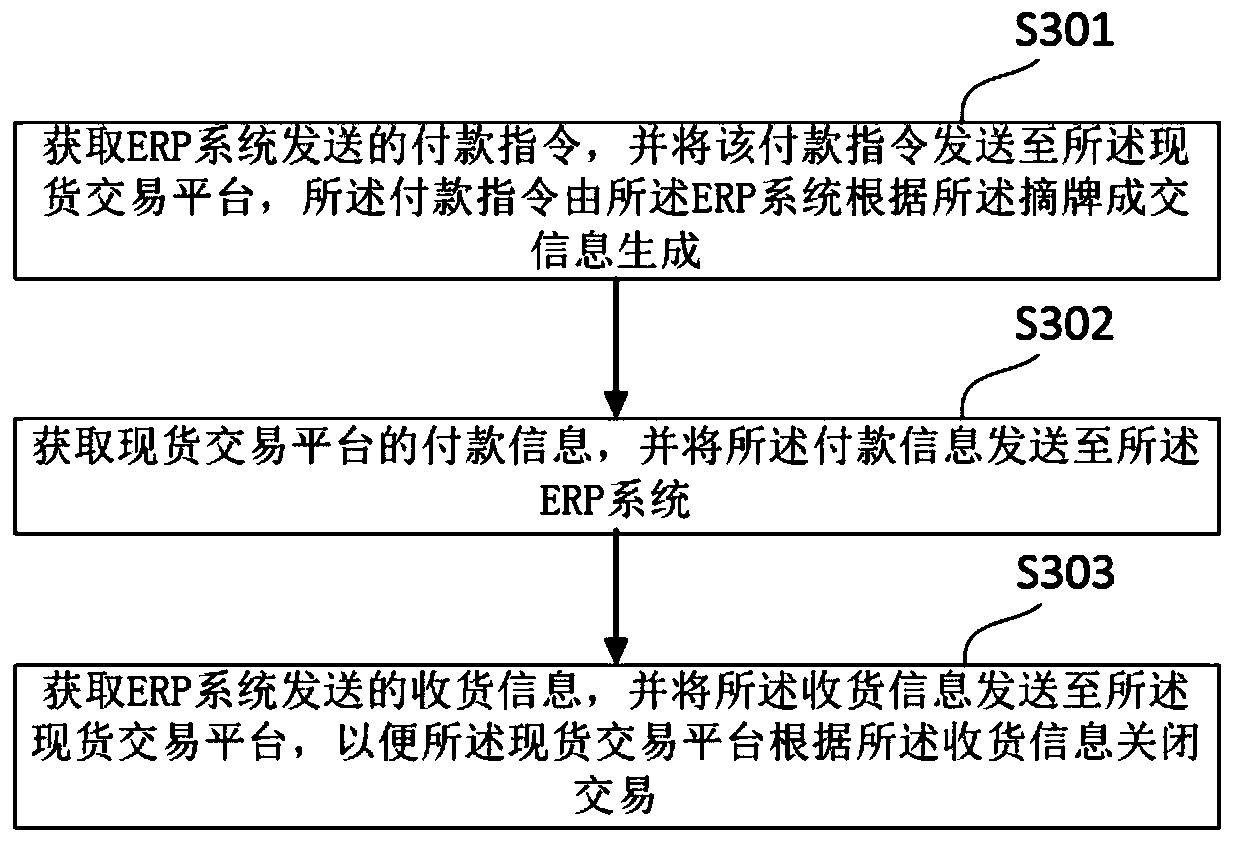

Enterprise ERP and e-commerce platform data connection method and system, and computer device

ActiveCN109978443ASave operabilitySave operating timeBuying/selling/leasing transactionsLogisticsData connectionButt joint

The invention relates to an enterprise ERP and e-commerce platform data connection method and system, and a computer device. The enterprise ERP and e-commerce platform data connection method comprisesthe following steps: obtaining order information in an industrial e-commerce platform, and sending the order information to an ERP system; raw material purchasing information generated by the ERP system is acquired, the raw material purchasing information comprises types, quantities and prices of to-be-purchased raw materials, and the types, quantities and prices of the to-be-purchased raw materials are automatically generated by the ERP system according to the order information and the raw material inventory information; the raw material purchasing information is sent to the industrial e-commerce platform so that the industrial e-commerce platform can generate listing information; and obtaining card picking transaction information of the industrial e-commerce platform, and sending the card picking transaction information to the ERP system. According to the enterprise ERP and e-commerce platform data butt joint method, data butt joint of the ERP system and the industrial e-commerce platform can be automatically achieved, and the operation time of a user is saved.

Owner:东莞市大易产业链服务有限公司

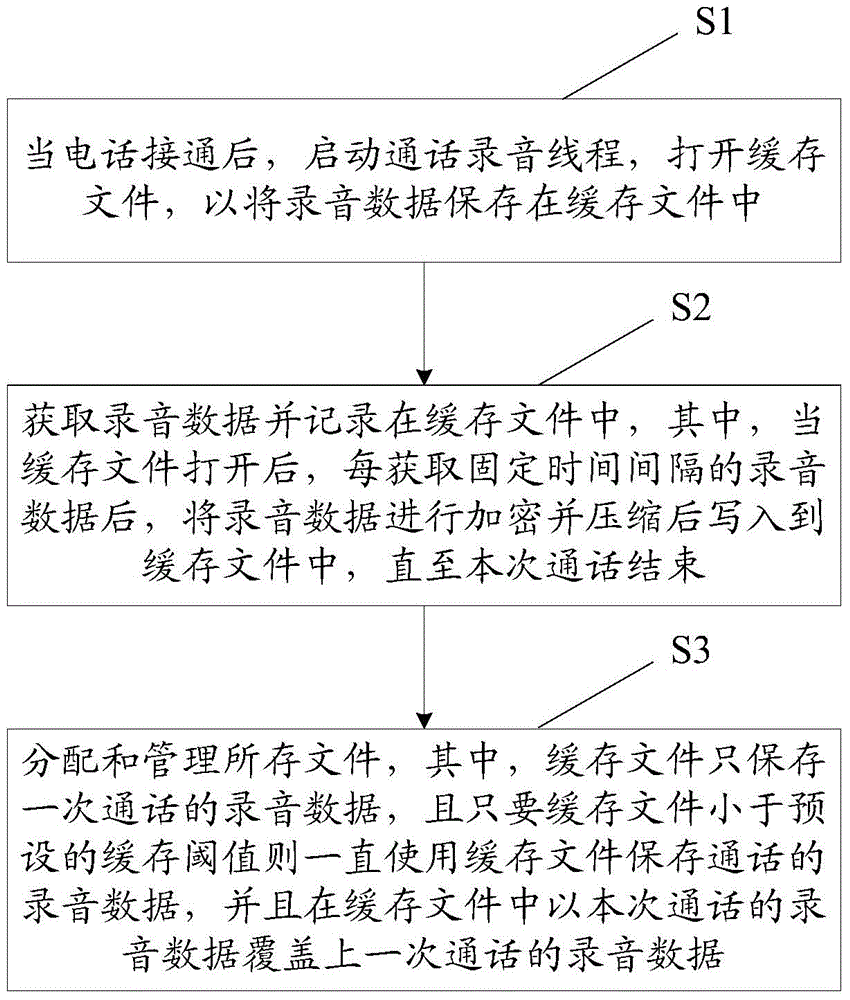

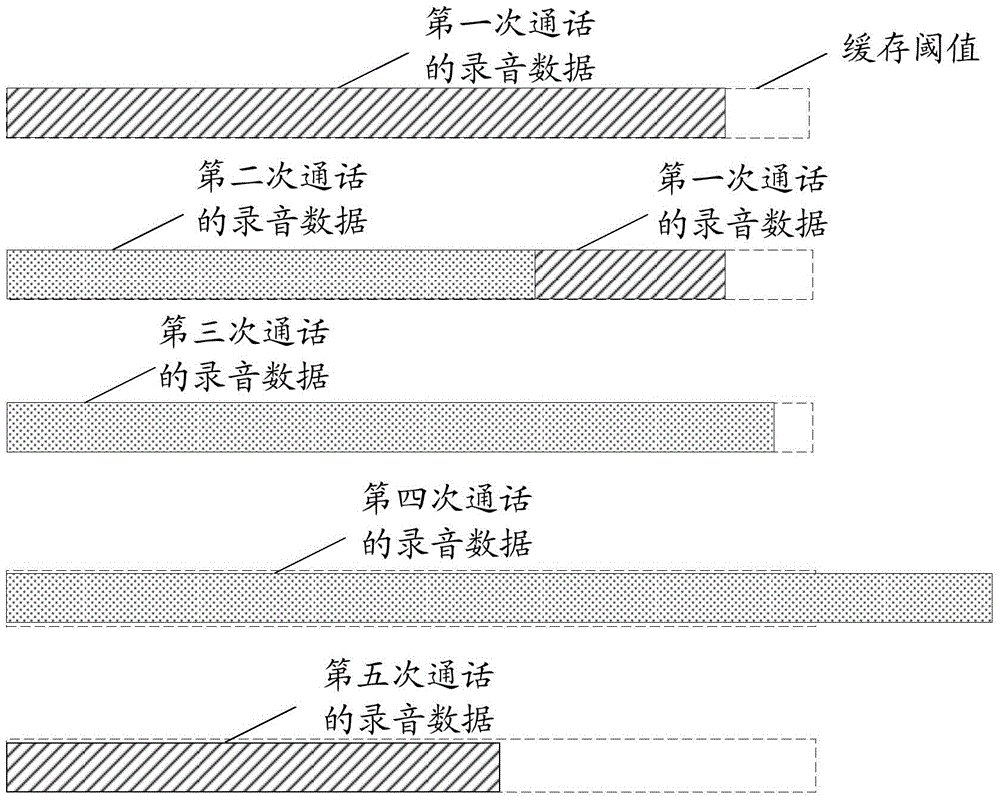

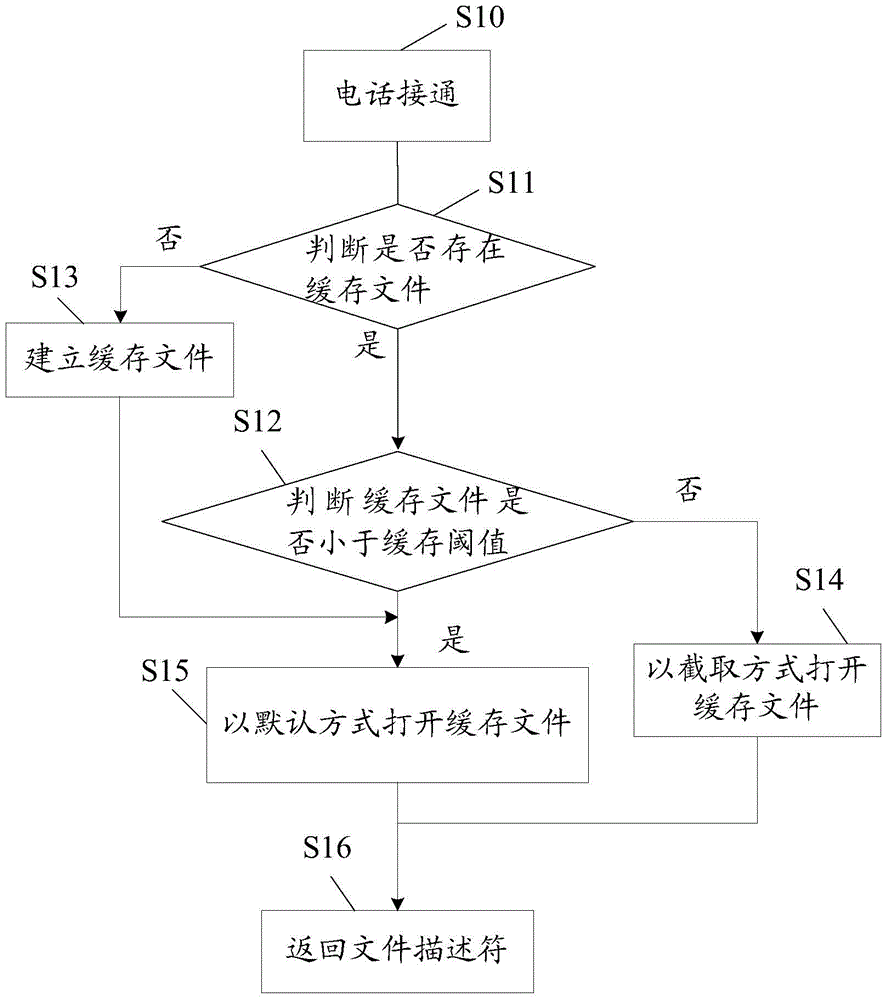

Caching method for call record and communication device

ActiveCN104580647AEnsure safetyDoes not increase in size infinitelySubstation equipmentSpecial data processing applicationsFile allocationCommunication device

The invention discloses a caching method for a call record and a communication device. The caching method comprises the following steps that after a call is put through, a call recording thread is started, and a cache file is opened so that record data can be stored in the cache file; the record data are obtained and recorded in the cache file, wherein under the condition that the cache file is opened, after the recording data within a fixed time interval are obtained every time, the recording data are encrypted and compressed and written into the cache file, and the process is ended until the call is ended; the cache file is distributed and managed, wherein the cache file only stores call data of one call, as long as the cache file is smaller than a preset caching threshold value, the cache file is used for storing call records all the time, and in the cache file, the record data of the call covers the record data of a last call. In this way, by the adoption of the caching method for the call record and the communication device, recording can be conducted automatically, the file distribution time is shortened, the time of deleting the cache data of a last call is shortened, and the operation of deleting the cache data of the last call is easier.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

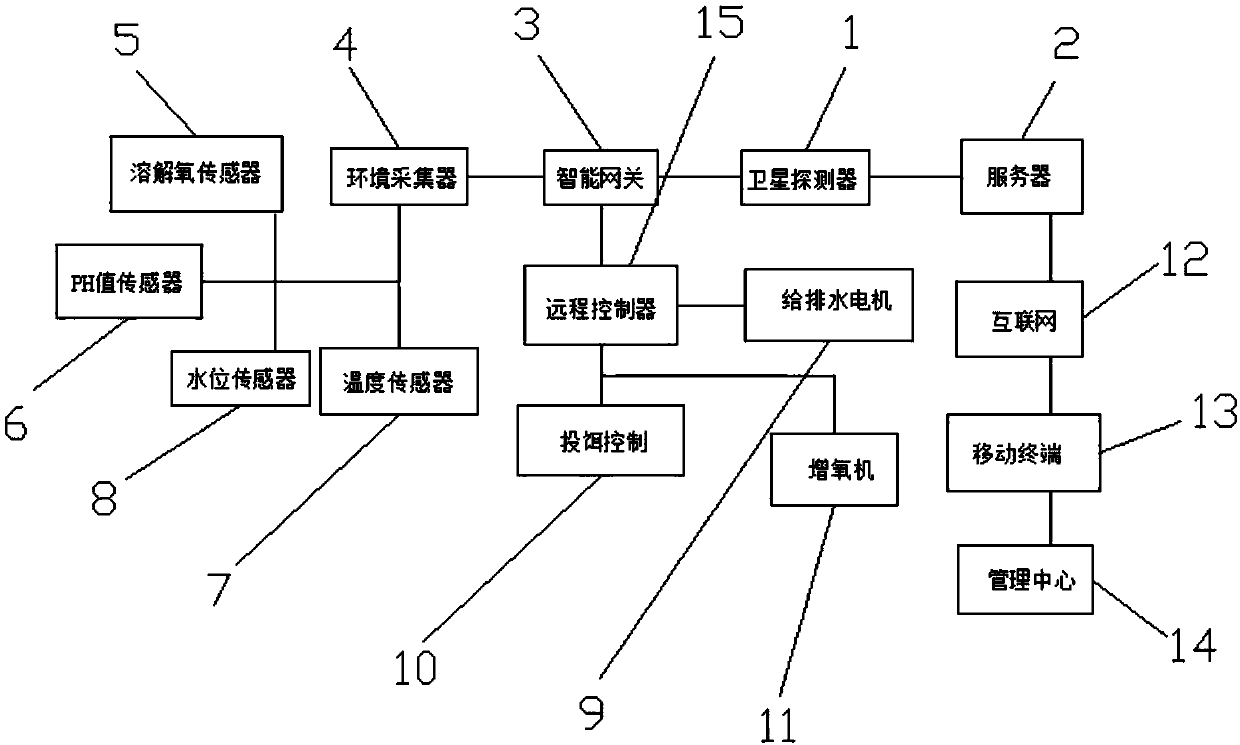

Aquaculture system based on internet of things

InactiveCN107683816ALimit lossSave operabilityClimate change adaptationPisciculture and aquariaData acquisitionWater quality

The invention discloses an aquaculture system based on the internet of things. The aquaculture system structurally comprises a satellite detector, the satellite detector comprises a server and an intelligent gateway, the server is connected with the satellite detector, and the intelligent gateway is connected with the satellite detector; the intelligent gateway comprises an environment collector and a remote controller, an environment detector is connected with the intelligent gateway, and the remote controller is connected with the intelligent gateway; the environment collector comprises a dissolution sensor, a PH value sensor, a temperature sensor and a water level sensor. Aiming at the features of the diversity, variability, remote dispersion and the like of an aquaculture environment object, the systematic scheme of remote data collection and information distributing of a measurement and control technology can save a large amount of artificial operation and power consumption for auser, the loss caused due to fish diseases is avoided, the death rate is reduced, and through long-term continuous monitoring, adjusting and controlling of water quality, the aquaculture yield can beobviously increased.

Owner:ZHUHAI LINGCHUANG INTELLIGENT INTERNET OF THINGS INST CO LTD

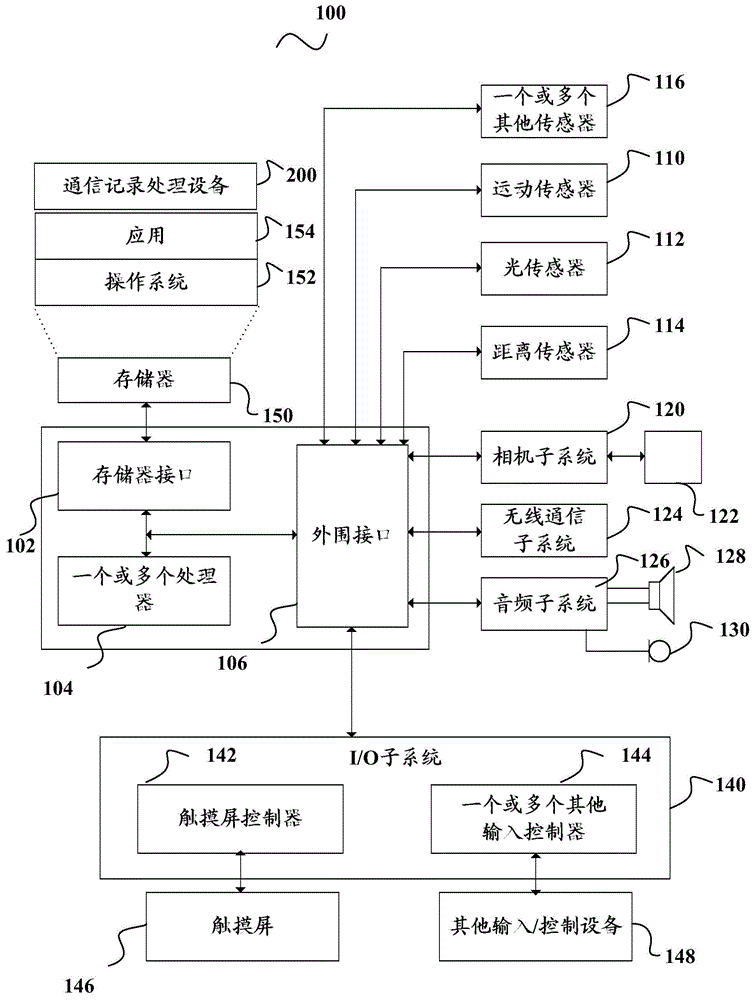

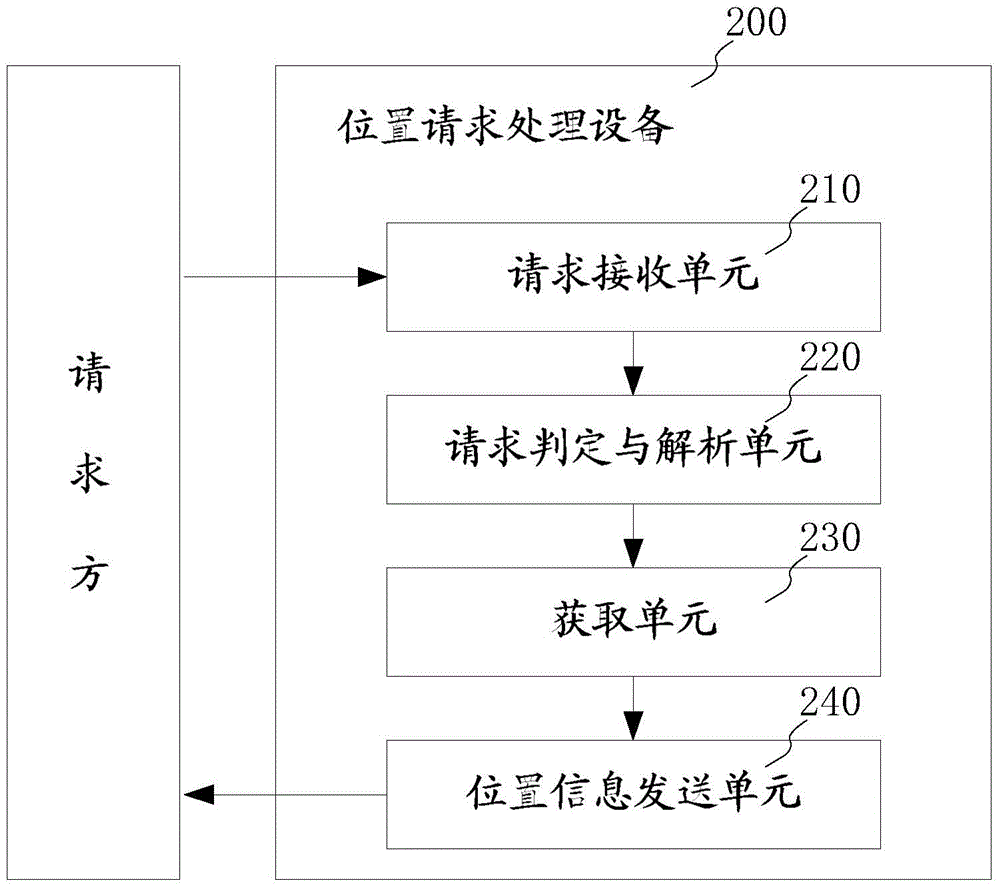

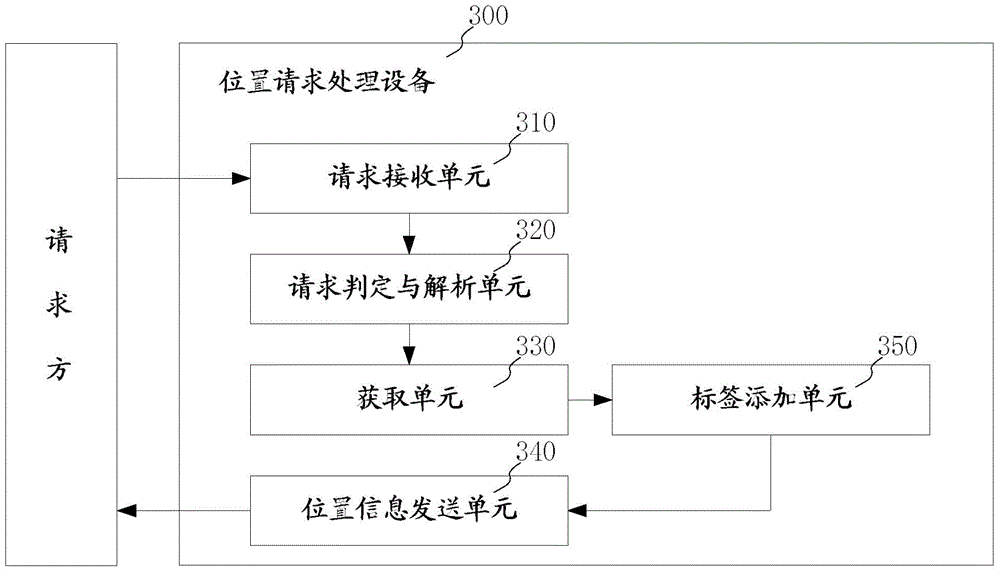

Position request processing equipment and method and position information acquiring equipment and method

ActiveCN104320760AIntendedSatisfy needsMessaging/mailboxes/announcementsLocation information based serviceInformation processingGeolocation

The invention discloses position request processing equipment and method, position information acquiring equipment and method, a mobile terminal and a position information processing system. The position request processing equipment and method and the position information acquiring equipment and method are aimed to overcome the problem that the prior art is incapable of actively acquiring the geographic positions of the other users. The position information acquiring equipment comprises a request sending unit suitable for sending position request information to a requested party in a predetermined form, a reply receiving unit suitable for receiving reply information from the requested party, a reply judging and analyzing unit suitable for judging whether the reply information is position reply information and analyzing the reply information if the reply information is position reply information, and a storage unit suitable for storing position information of the requested party in the analyzed result. The position request processing equipment comprises a request receiving unit, a request judging and analyzing unit, an acquiring unit and a position information sending unit. The position request processing equipment and method and the position information acquiring equipment and method can be used for the communication field.

Owner:厦门黑谷网络科技股份有限公司

Measuring device for threaded fasteners of oil pipe joints

ActiveCN107957310AQuality improvementRealize one-time detectionMeasurement of fluid loss/gain rateMeasurement of torque/twisting force while tighteningFriction torqueEngineering

The invention belongs to the oil pipe joint performance testing field and discloses a measuring device for threaded fasteners of oil pipe joints. The measuring device comprises a torque application mechanism, an external screw thread component of an oil pipe joint, a conversion connector, and a force conduction and detection mechanism; the external threaded component of the oil pipe joint is coaxially connected with the output end of the torque applying mechanism; the conversion connector is matched with the external threaded component and includes an internal screw thread portion and a conical surface portion which are separated from each other; the force conduction detection mechanism is connected with the conversion connector; the force conduction and detection mechanism is used for conducting and detecting a pre-tightening force and a friction torque which are applied to the conical surface portion by the external screw thread component during a tightening process; an oil pipe is arranged in the external screw thread component; one end of the oil pipe is connected with the external screw thread component through the torque application mechanism, and the other end of the oil pipe is connected with a pipe torque detection mechanism; the pipe torque detection mechanism is used for detecting a pipe torque introduced into the oil pipe during the tightening process; and the forceconduction and detection mechanism, the pipe torque detection mechanism and the output end of the torque application mechanism are coaxially arranged. The device of the invention has the advantages of compact structure, simple operation, easiness in popularization and popularization.

Owner:上海宏予测试仪器有限公司

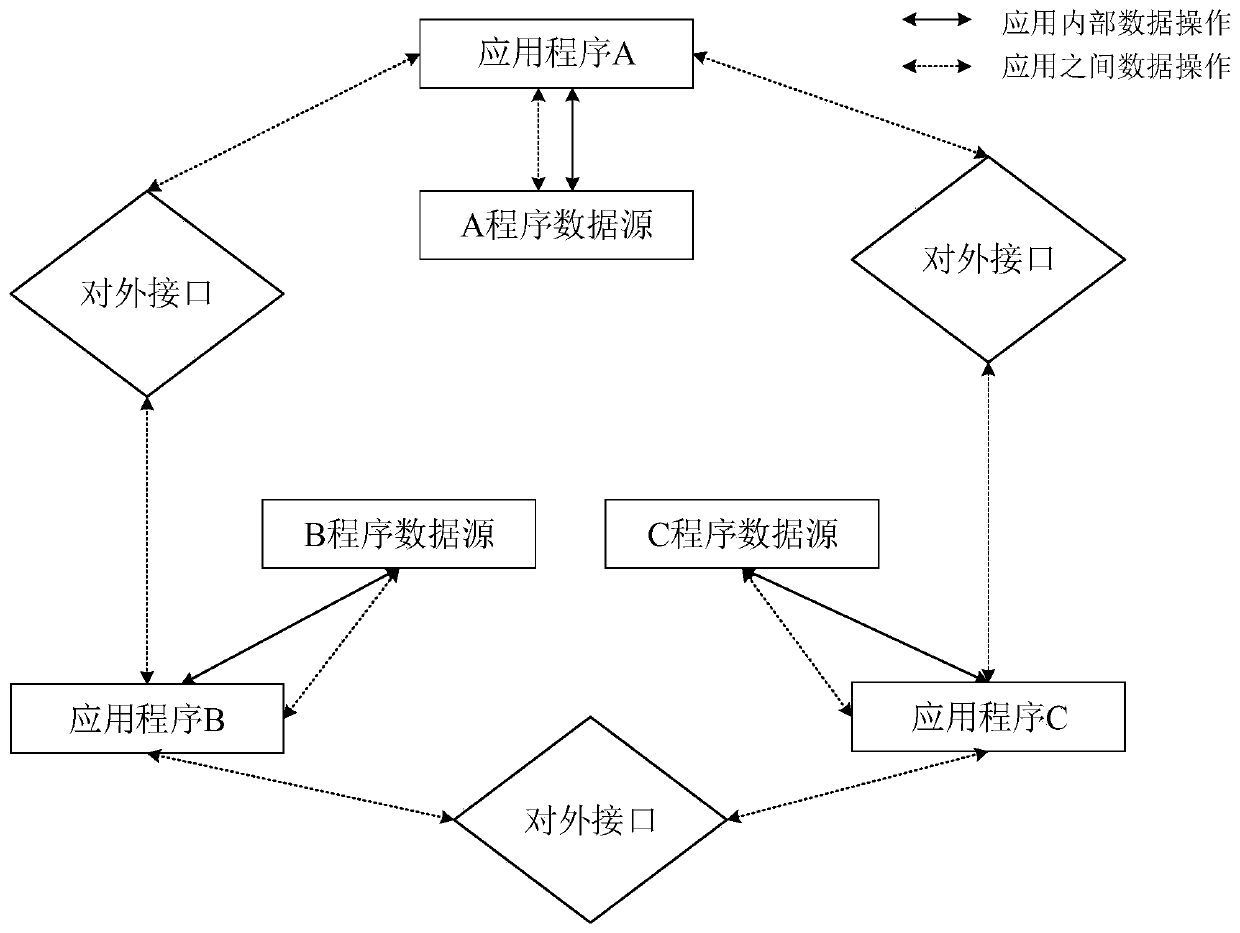

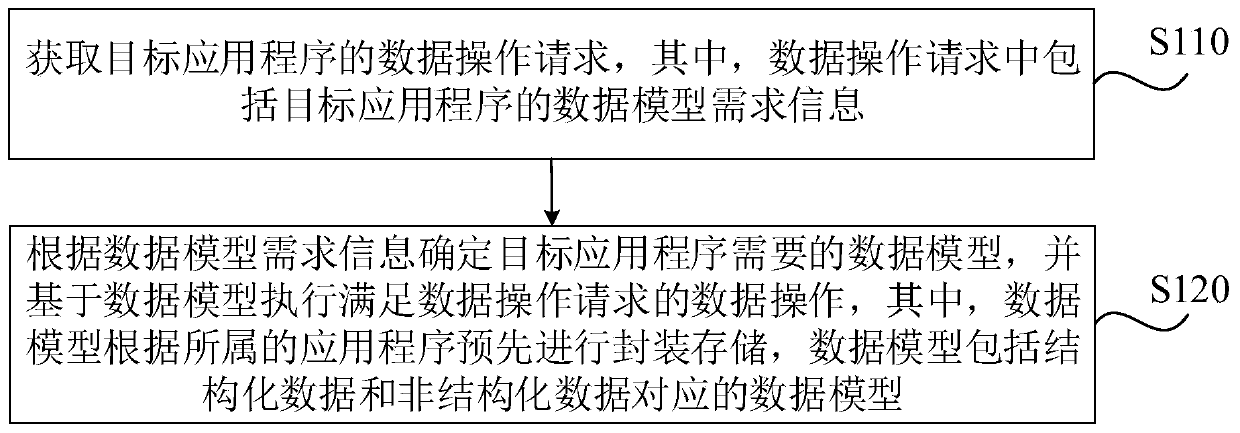

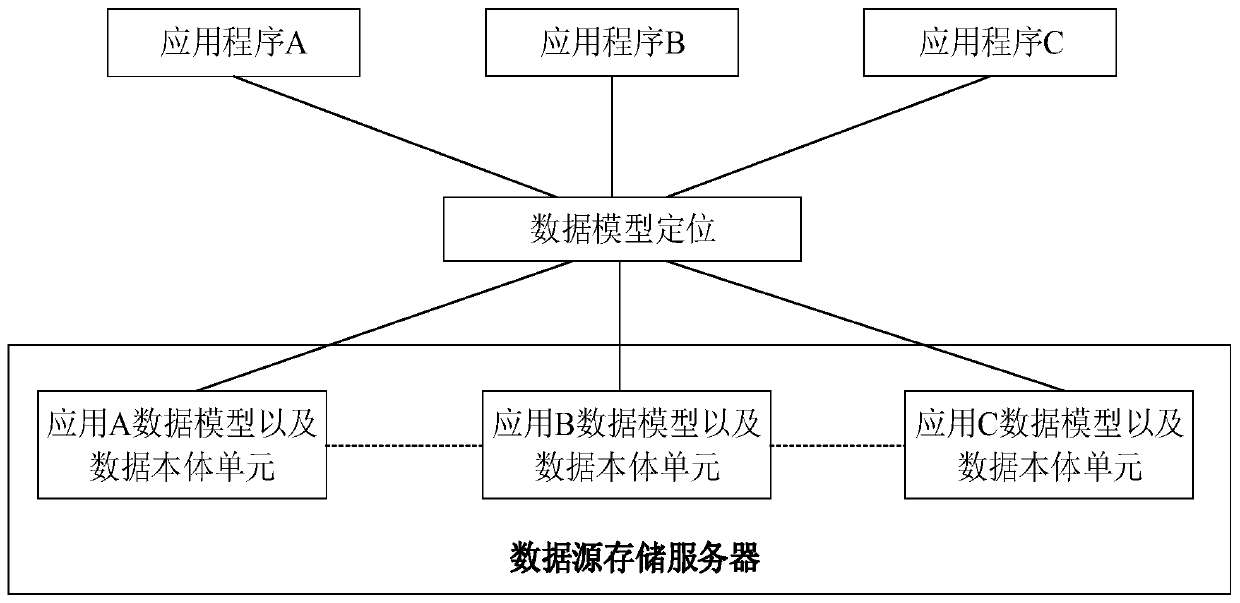

Data operation method and device of application program, server and medium

ActiveCN110096543AImprove development efficiencyImprove data securityDatabase management systemsSpecial data processing applicationsData operationsData source

The embodiment of the invention discloses a data operation method and device of an application program, a server and a medium, and the method comprises the steps: obtaining a data operation request ofa target application program, the data operation request comprising data model demand information of the target application program; and determining a data model required by the target application program according to the data model demand information, and executing a data operation meeting the data operation request based on the data model, the data model being pre-encapsulated and stored in a server according to the application program to which the data model belongs, and the data model comprising a data model corresponding to structured data and unstructured data. According to the embodiment of the invention, isolation based on the data source and the application program body is realized, the application program development efficiency is improved, the data security of the application program is improved, and the method and the device are suitable for structured data and unstructured data at the same time.

Owner:软通智慧科技有限公司

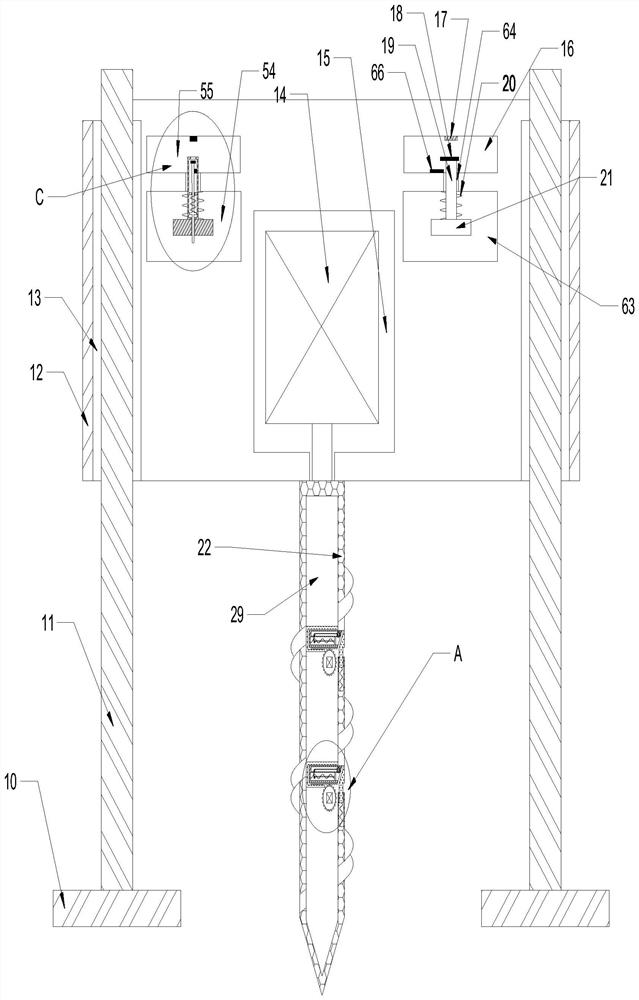

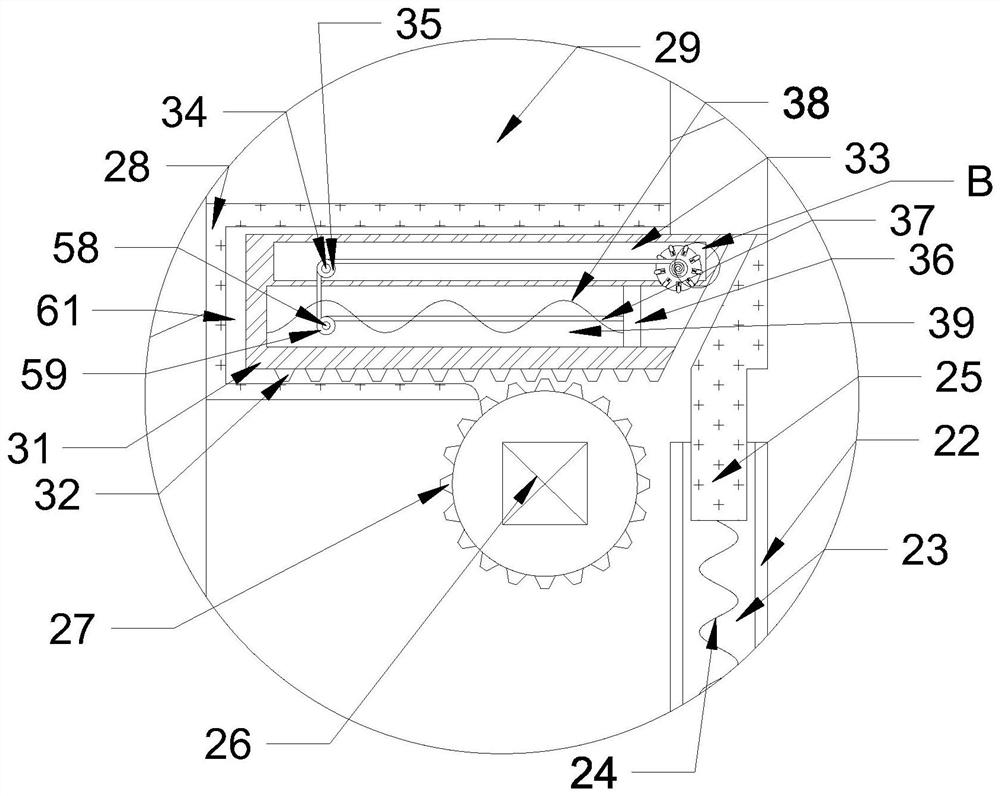

Soil detection sampling equipment

InactiveCN111999105AAvoid affecting data accuracySave operabilityWithdrawing sample devicesSoil scienceAgricultural engineering

The invention provides soil detection sampling equipment, belongs to the field of detection, and solves the problems that soil needs to be taken out of most of existing soil sampling tools manually. The soil detection sampling equipment comprises a sliding block, a soil punching device arranged below the sliding block, a sampling control device arranged in the upper left portion of soil punching,and a punching control device arranged in the upper right portion of the soil punching device. When the sliding block is pressed to enable a worm to move downwards, soil sampling can be carried out, and when the worm is pulled out of the soil, the sampled soil can be pushed out of an external space, so that pollution and influence on data precision due to the fact that the soil needs to be manually buckled out of the sampling cavity during sampling are avoided, meanwhile, operation and time are saved, and the working efficiency is improved.

Owner:陈福斌

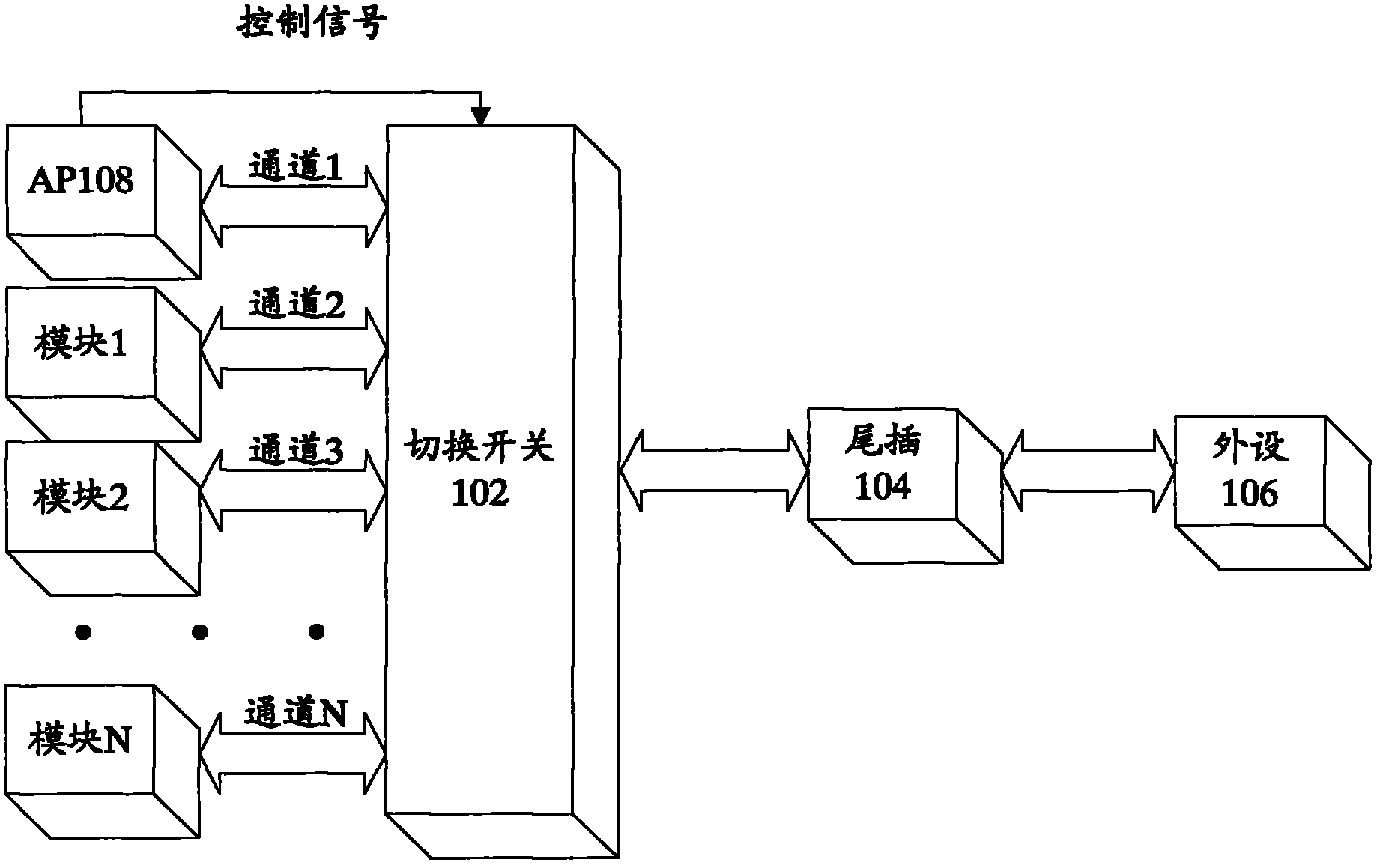

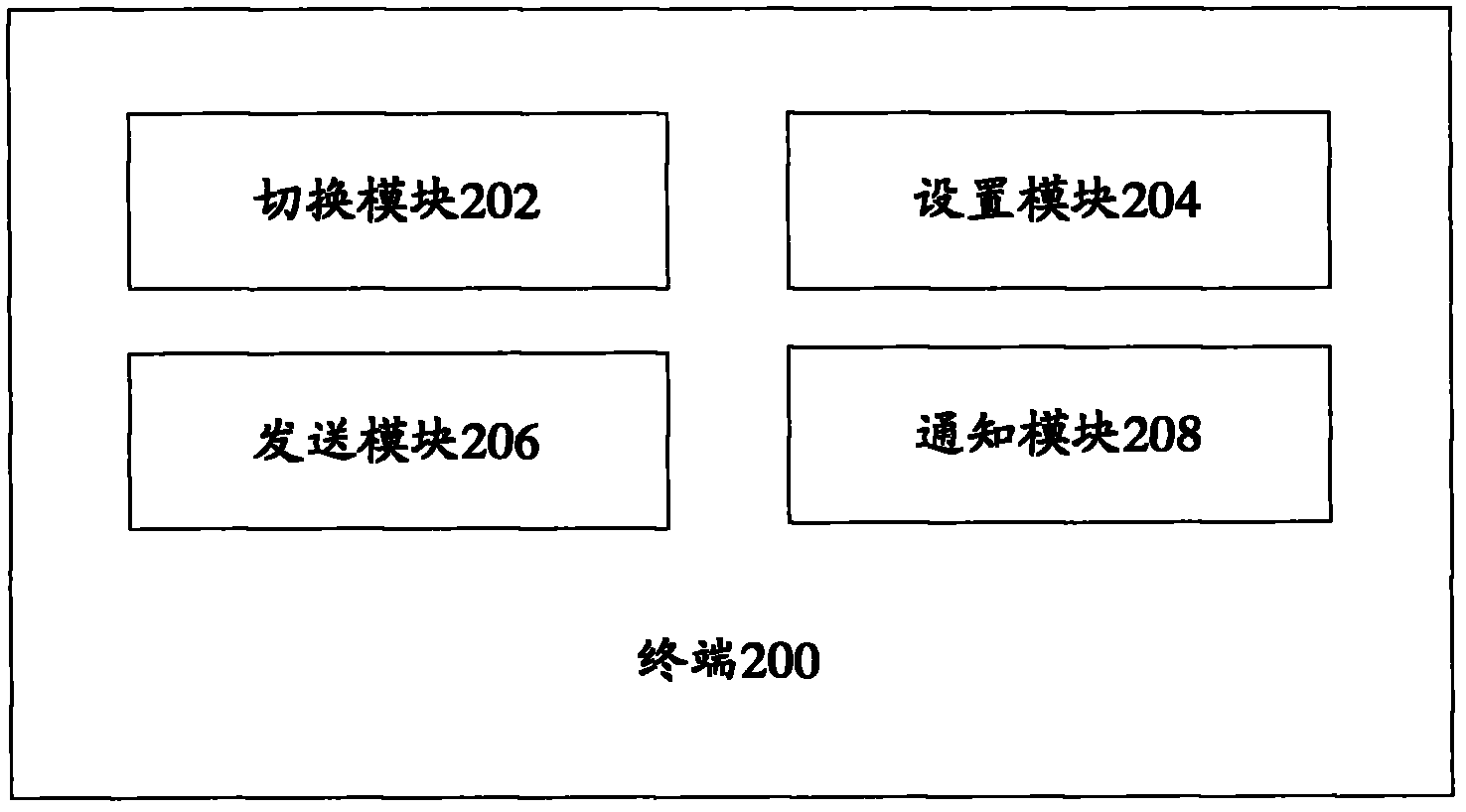

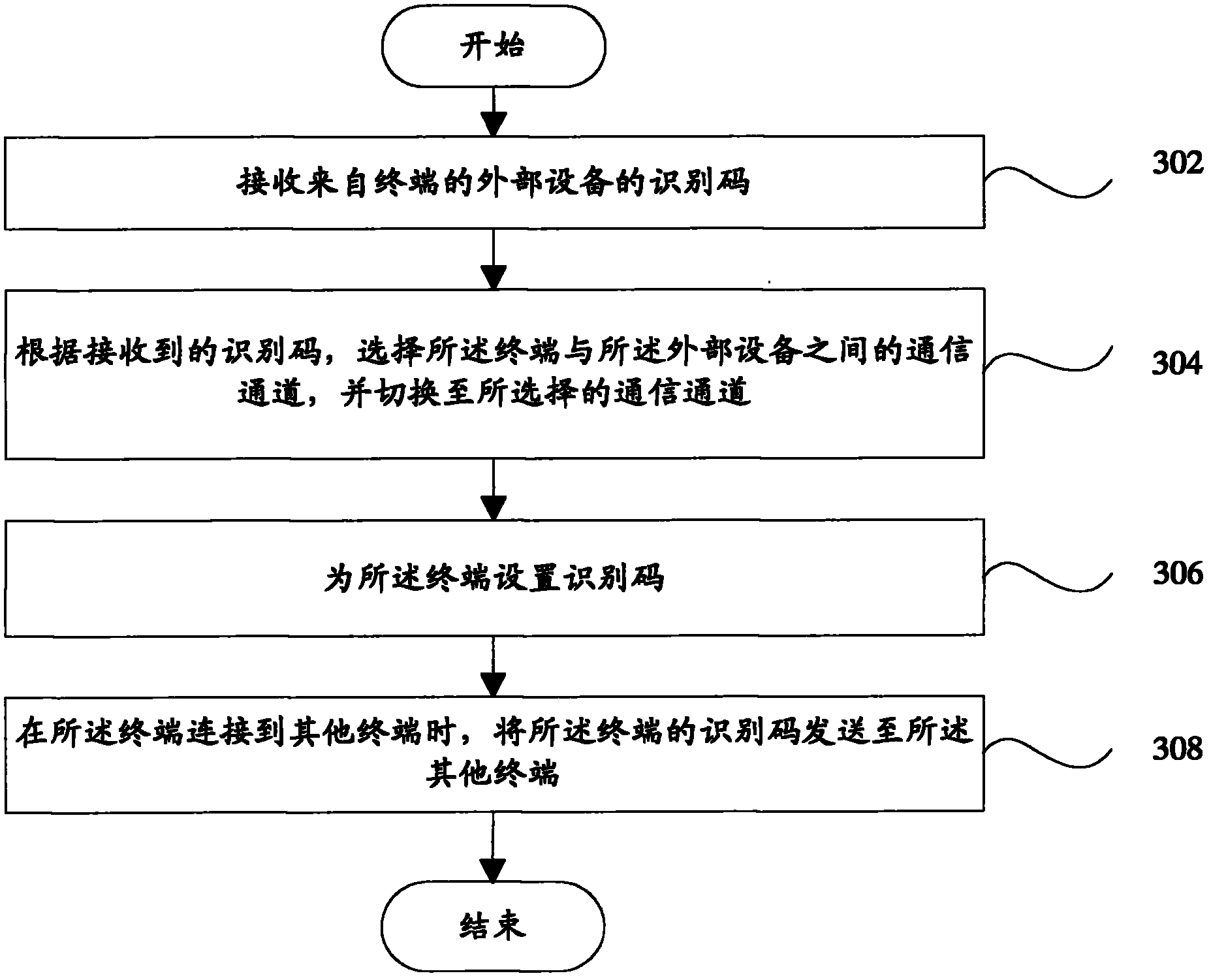

Terminal and communication channel switching method

The invention provides a terminal and a communication channel switching method. The terminal comprises a switching module, wherein the switching module is used for receiving an identification code from external equipment of the terminal, selecting a communication channel between the terminal and the external equipment according to the received identification code, and switching to the selected communication channel. In the technical scheme, the corresponding communication channels can be automatically switched according to different identification codes, for example, when an earphone with different identification codes accesses the terminal, different network modules are switched by using the switching module.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

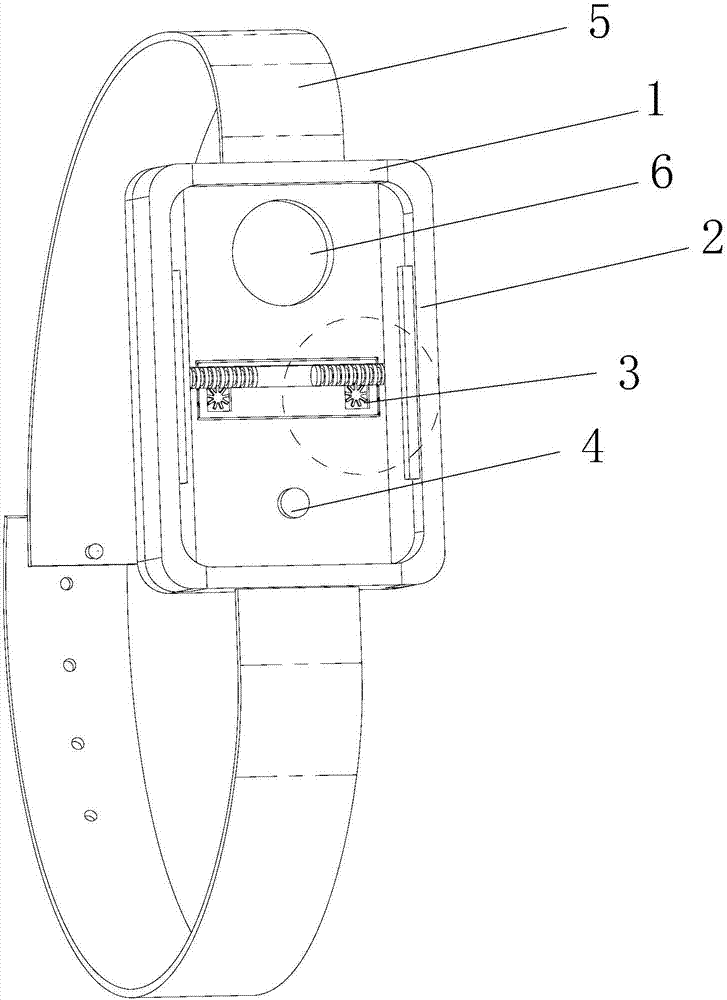

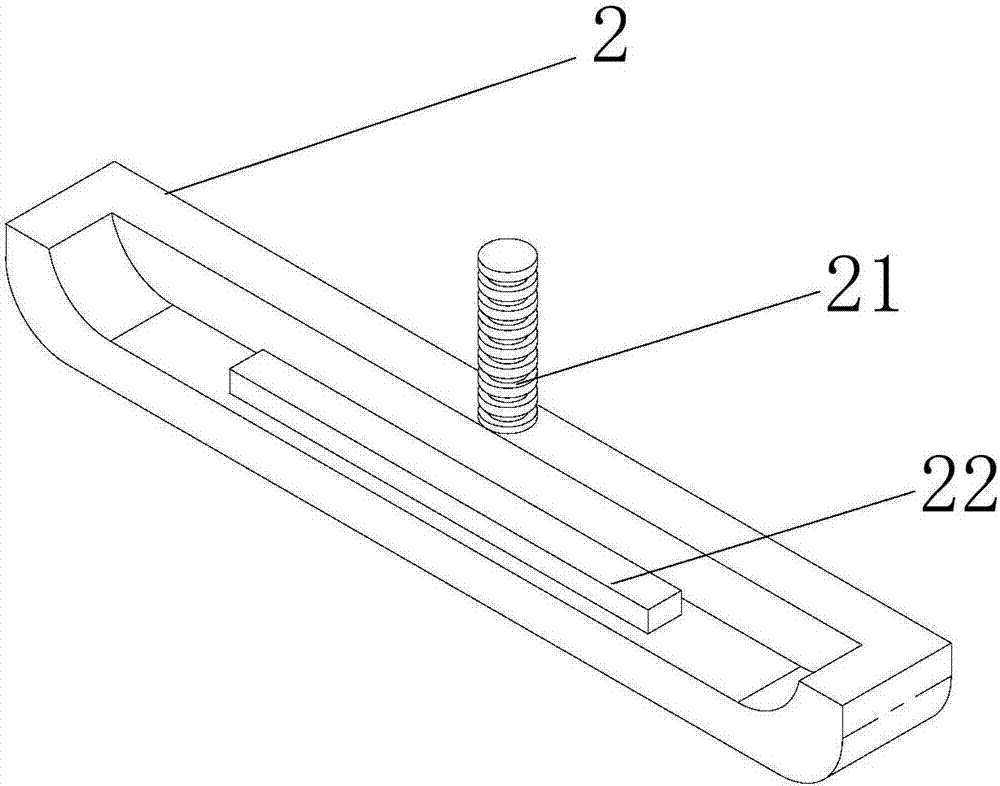

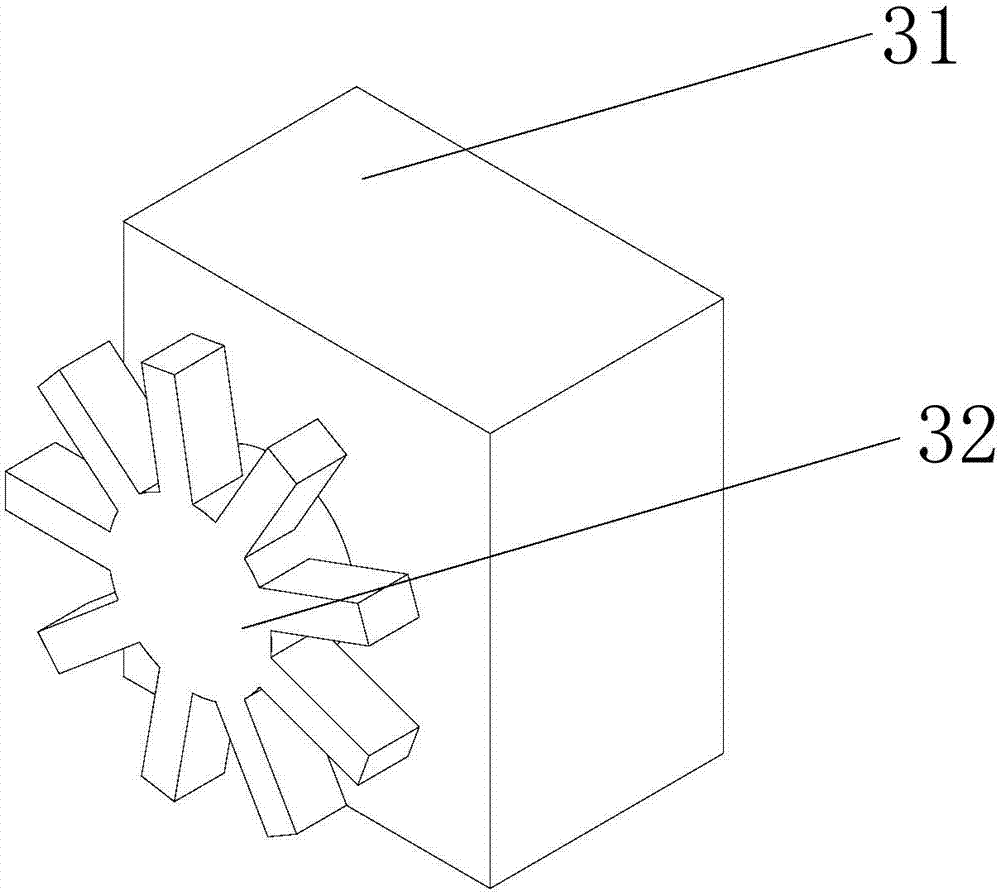

Bluetooth headset holding structure, Bluetooth headset and smart watch

ActiveCN107135439AEasy to storeSave operabilityEarpiece/earphone attachmentsClockwork casesElectric signalEmbedded system

The invention discloses a Bluetooth headset holding structure, a Bluetooth headset and a smart watch. The Bluetooth headset holding structure comprises a housing for holding the Bluetooth headset; a clamping mechanism for clamping the Bluetooth headset and a driving mechanism for driving the clamping mechanism are arranged on the housing; a conductive post is further arranged on the housing; the conductive post is used for contacting with a conductive contact on the Bluetooth headset, obtaining a first electrical signal that an answering key of the Bluetooth headset is triggered and a second electrical signal that the Bluetooth headset is put into the housing, and sending the first electrical signal and the second electrical signal to the driving mechanism; and the driving mechanism is used for driving the clamping mechanism to move after the first electrical signal is received such that the clamping mechanism releases the Bluetooth headset, and driving the clamping mechanism to move to an opposite direction after the second electrical signal is received to clamp the Bluetooth headset. By automatically releasing the Bluetooth headset when triggering the answering key of the Bluetooth headset, and clamping the Bluetooth headset when the Bluetooth headset is put into the housing, the Bluetooth headset holding structure is convenient for a user to take and place, the operating steps and time when a telephone is answered are saved, and the experience and comfortable feeling are enhanced.

Owner:GEER TECH CO LTD

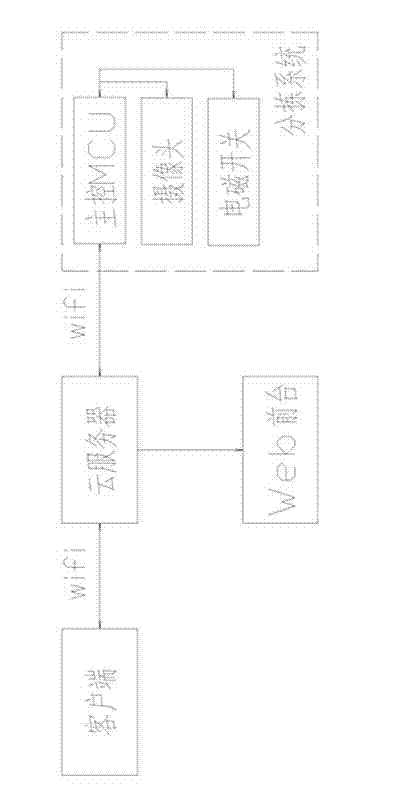

Information security management system

The invention discloses an information security management system, which is characterized in that the system comprises a client-side capable of generating two-dimensional codes, wherein the client-side is connected with a cloud server through a WiFi (wireless fidelity) network, a sorting system is also connected with the cloud server through the WiFi network, and comprises a master control unit MCU, the MCU is capable of controlling a plurality of electromagnetic switches matched with a conveying belt of the sorting system, and is also capable of controlling a camera, and the cloud server is also connected with a Web foreground through the WiFi network. The information security management system is capable of protecting client information, is convenient and safe in operation and is capable of automatically realizing information updating.

Owner:FUJIAN EADING CORE INTELLIGENT TECH

Seawater selective chromogenic culture media for VP (Vibrio Parahaemolyticus) and authenticating and counting method thereof

InactiveCN104293880AGrow fastEasy to identifyMicrobiological testing/measurementAgainst vector-borne diseasesFiltrationVibrio parahemolyticus

The invention discloses a method adopting seawater selective chromogenic culture media to perform quick separation, authentication, counting and analyzing on the VP (Vibrio Parahaemolyticus) in the marine environment. The method comprises the specific steps as follows: firstly, preparing a seawater selective chromogenic culture flat plate for the VP; secondly, taking a certain amount of seawater sample and filtering by a filter membrane with the filtration diameter of 0.22 mum; thirdly, horizontally adhering the filter membrane with sterilized tweezers to the seawater selective chromogenic culture flat plate obtained in the first step for culture at 28 DEG C; fourthly, counting the statistics of the bacterial colony which is claret-colored. According to the method provided by the invention, the blanks of quick authentication and counting of pathogenic bacteria VP in the present marine environment are filled, and enriched culture is not required, the testing time is short, and the result is accurate and reliable.

Owner:TIANJIN UNIV

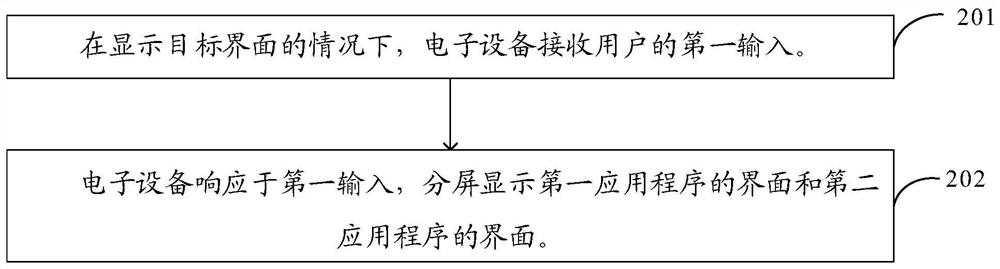

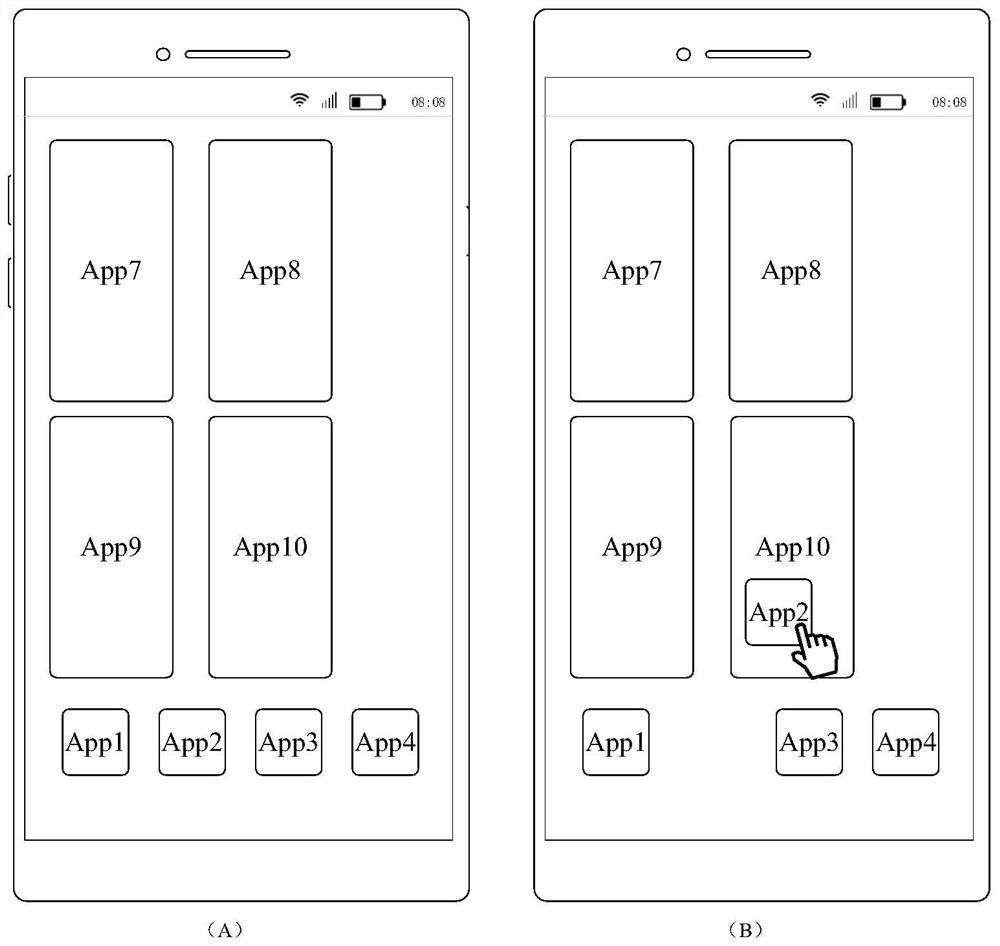

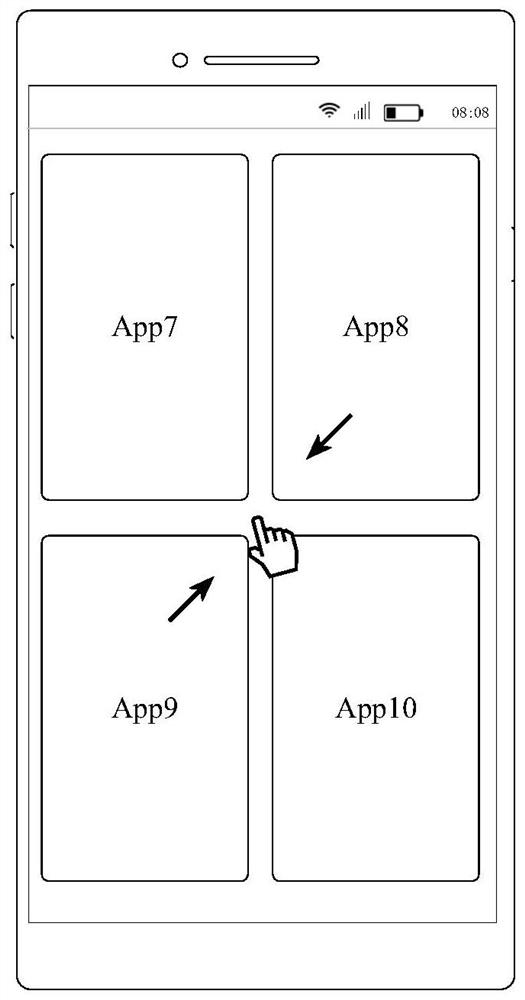

Screen splitting method and device and electronic equipment

PendingCN113703624ASimplify the split-screen processImprove the efficiency of split screen displayExecution for user interfacesDigital output to display deviceComputer hardwareSoftware engineering

The invention discloses a screen splitting method and device and electronic equipment, belongs to the technical field of communication, and can solve the problem that the efficiency of screen splitting display of the electronic equipment is low. The method comprises the steps that under the condition that a target interface is displayed, first input of a user is received, the target interface comprises at least two identifiers, each identifier indicates one application program, and the first input is input of the user to a first identifier and a second identifier in the at least two identifiers; in response to the first input, an interface of the first application program and an interface of the second application program are displayed in a split-screen mode, the first application program is the application program indicated by the first identifier, and the second application program is the application program indicated by the second identifier.

Owner:VIVO MOBILE COMM HANGZHOU CO LTD

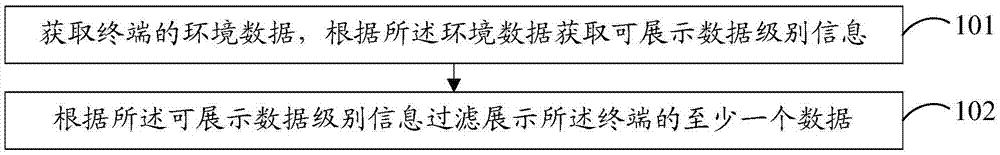

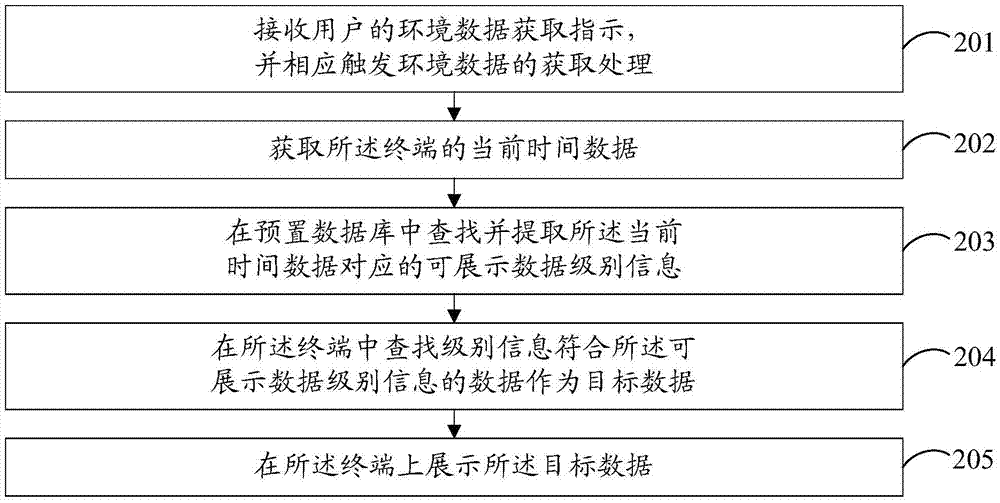

Data processing method and device as well as terminal

InactiveCN106899867AReduce processing loadEasy accessSelective content distributionComputer terminalEnvironmental data

The embodiment of the invention provides a data processing method, comprising the following steps: acquiring the environmental data of a terminal, and acquiring the displayable data level information based on the environmental data; and filtering at least one data that displays the terminal according to the displayable data level information. According to the data processing method provided by the embodiment of the invention, the user can conveniently and quickly acquire the data that meets the requirements, and the operation and time consumed by the user when filtering the data can be saved; and meanwhile, the processing load of the terminal can be saved, and the data filtering efficiency can be increased.

Owner:BEIJING QIHOO TECH CO LTD +1

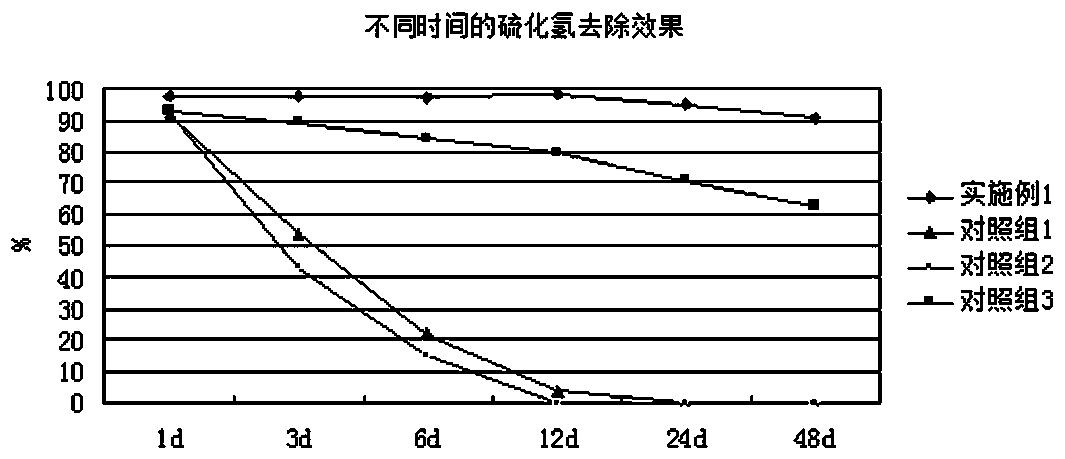

Biological agent for removing odors of slurry-spraying granulation tail gas

PendingCN109971650AReduce the risk of contaminationSymbiotic balanceFungiGas treatmentSpray GranulationSlag

The invention belongs to the field of biotechnology and discloses a biological agent for removing odors of slurry-spraying granulation tail gas. The biological agent is prepared according to the following steps: stirring and mixing a compound fermentation broth and an adsorption carrier in a mass ratio being (3-5):(5-7), then, performing drying at the drying temperature of 22 DEG C until the moisture content is 10wt% after drying, and carrying out packaging to obtain the biological agent. The adsorption carrier of the biological agent is prepared from main raw materials of slag and straw to adsorb odors of tail gas, and the adsorbed tail gas can be absorbed and utilized by strains in the biological agent, so that the purpose of removing the odors of the tail gas is achieved.

Owner:许传高

White spirit raw material crushing, cooking and cooling device

ActiveCN112126545ASuitable temperatureSpread evenlyAlcoholic beverage preparationGrain treatmentsEngineeringMechanical engineering

One or more embodiments of the invention provide a white spirit raw material crushing, cooking and cooling device. The white spirit raw material crushing, cooking and cooling device comprises a crushing cavity; a feeding hopper is arranged on one side of the top end of the crushing cavity and used for feeding raw materials; a filter plate is fixed in the middle in the crushing cavity; a crushing assembly is fixed at the top end in the crushing cavity and used for crushing the raw materials; a cooking cavity is arranged below the crushing cavity; a first partition plate is transversely insertedinto the communication position between the crushing cavity and the cooking cavity; the crushed raw materials are cooked in the cooking cavity through a heating device; the cooling cavity is formed below the cooking cavity; a second partition plate is transversely inserted into the communication position between the cooking cavity and the cooling cavity; and the cooked raw materials are cooled bythe cooling device in the cooling cavity. Through a control mechanism in a control cavity, the second partition plate and the first partition plate can be sequentially driven to be pulled away and penetrate into the control cavity, the second partition plate and the first partition plate can be sequentially and automatically reset, and therefore multi-procedure matched switching operation is achieved.

Owner:ANHUI SHUANLUN VINO

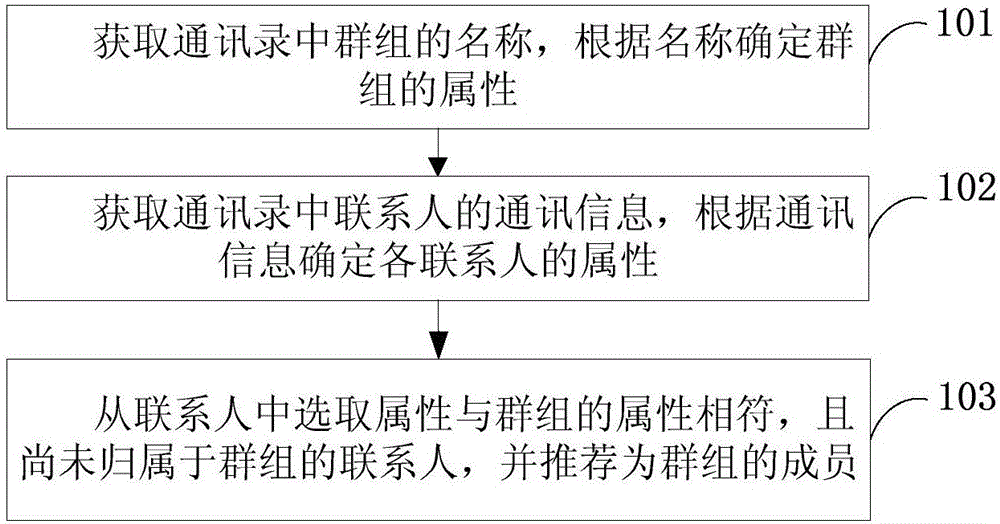

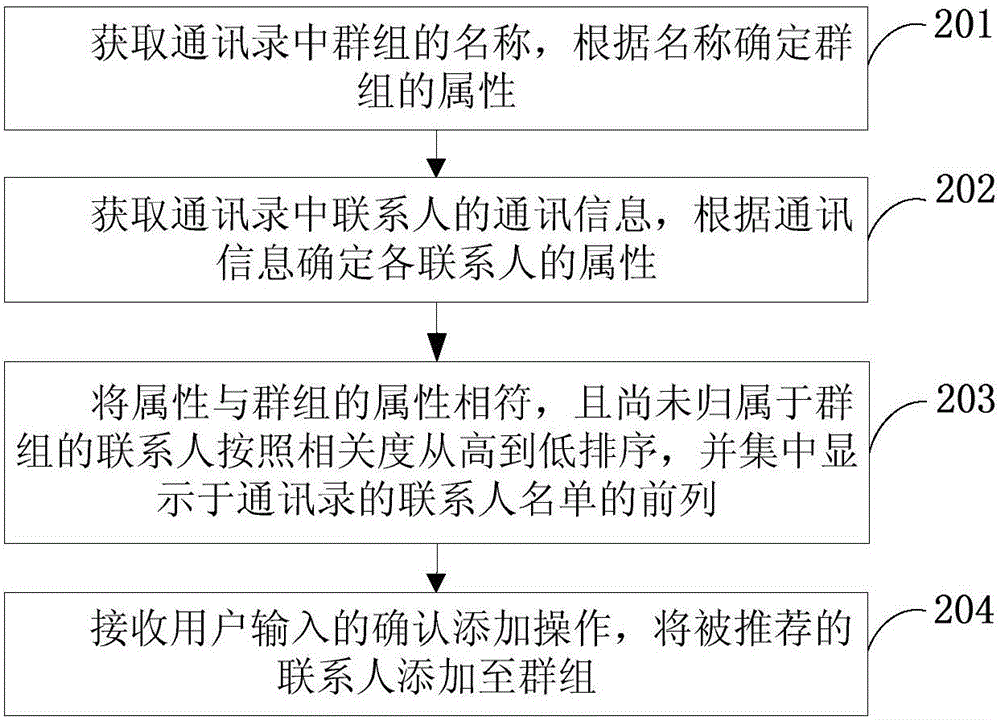

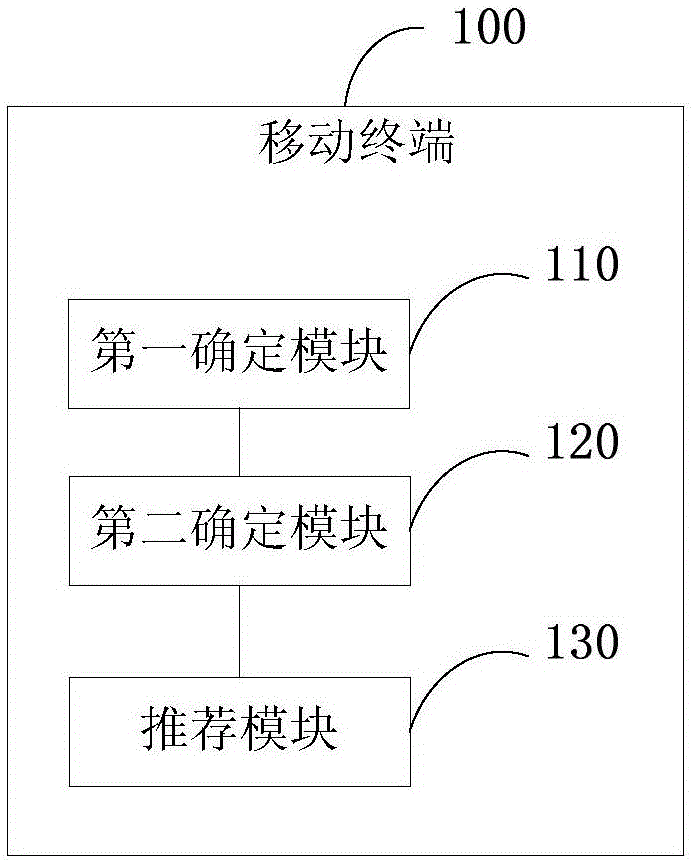

Method for recommending group members in address book, and mobile terminal

InactiveCN106453784AImprove user experienceRealize intelligent personalized recommendationSubstation equipmentPersonalizationAddress book

The invention relates to the field of mobile communication, and provides a method for recommending group members in an address book, and a mobile terminal, used for realizing the method. In the embodiment of the invention, the name of a group in the address book and communication information of contact persons are obtained; thereby, attributes of the group and the various contact persons are respectively determined; the contact persons, whose attributes accord with the attribute of the group, and not belonging to the group, are selected and recommended as members of the group; therefore, intelligent personalized recommendation of new members of the group is realized; the operation step and the operation time for adding the new members of the group are saved for users; therefore, the adding process is relatively rapid and intelligent; and the use experience of users is effectively improved.

Owner:VIVO MOBILE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com