Biological agent for removing odors of slurry-spraying granulation tail gas

A biological agent and spray granulation technology, applied in the biological field, can solve the problems of poor regeneration ability of adsorbent, large amount of waste, complicated process parameters, etc., and achieve the reduction of enterprise burden, low cost of carrier raw materials, and simple operation process parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A biological preparation for removing the peculiar smell of spray granulation tail gas, which is prepared according to the following steps:

[0030] Step 1) put the straw into the pulverizer, and pass through a 100-mesh sieve after crushing to obtain straw powder; put the slag into the pulverizer, pass through a 50-mesh sieve after crushing, and obtain the slag powder; Calcium, clay and phosphoric acid solution were added to the reaction kettle according to the mass ratio of 4:10:2:1:15, stirred at 300rpm for 15min, and then entered into the drum granulator for granulation, and the particle size was controlled to be 1mm, and then placed at 95°C , and dried for 1 hour to obtain an adsorption carrier; the concentration of the phosphoric acid solution was 0.1mol / L; the particle diameters of the calcium fluoride and clay were 100 mesh;

[0031] Step 2) Trichoderma reesei ATCC56765 seed liquid (1 × 10 8 cfu / ml) according to the inoculation amount of 6% volume ratio, transfe...

Embodiment 2

[0034] A biological preparation for removing the peculiar smell of spray granulation tail gas, which is prepared according to the following steps:

[0035] Step 1) put the straw into the pulverizer, and pass through a 100-mesh sieve after crushing to obtain straw powder; put the slag into the pulverizer, pass through a 50-mesh sieve after crushing, and obtain the slag powder; Calcium, clay and phosphoric acid solution were added to the reaction kettle according to the mass ratio of 7:15:3:2:20, stirred at 300rpm for 15min, and then entered into the drum granulator for granulation, the particle size was controlled to be 1mm, and then placed at 95°C , dried for 1 hour to obtain an adsorption carrier; the concentration of the phosphoric acid solution was 0.1mol / L; the particle size of the calcium fluoride and clay was 100 mesh;

[0036] Step 2) Trichoderma reesei ATCC56765 seed liquid (1 × 10 8 cfu / ml) according to the inoculation amount of 6% volume ratio, transferred to the fe...

Embodiment 3

[0039] The exhaust gas from the spraying and granulation workshop in Fufeng was selected for treatment. The composition of the exhaust gas after spraying is as follows: H 2 S is 112mg / Nm 3 , SO 2 127g / Nm 3 , NOx is 109mg / Nm 3 , the temperature is 35℃, the space velocity is 5000h -1 ; Then enter the reaction chamber equipped with biological agents for tail gas odor treatment, the treatment time is 60min;

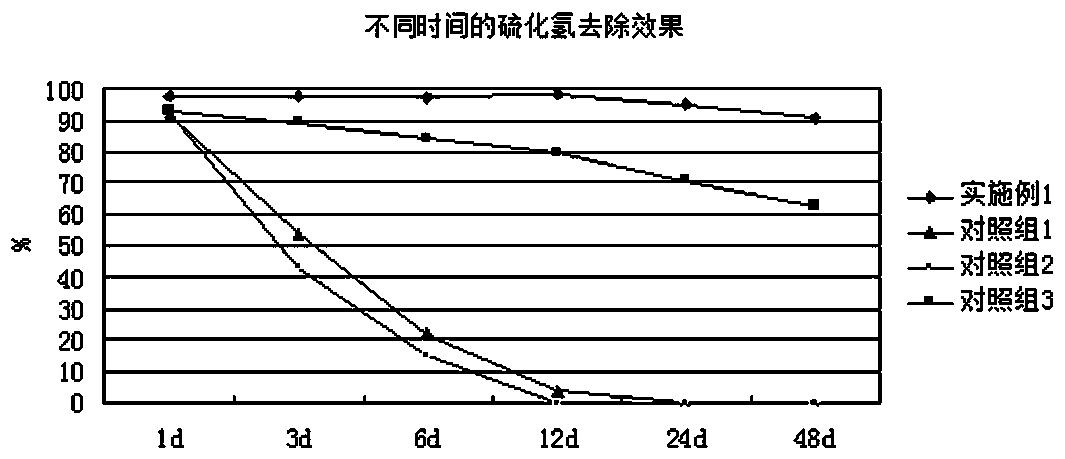

[0040] Set up the control group: control group 1: only use carrier, do not add compound fermentation liquid, the rest is the same as embodiment 1; control group 2: adopt conventional activated carbon adsorbent; control group 3: use diatomite as the carrier, and the rest are the same as embodiment 1 . See Table 1 for details:

[0041] group h 2 S (mg / Nm 3 )

[0042] The present invention adsorbs the tail gas through the adsorption carrier, and then removes the pollutants in the tail gas through a microbial reaction, so that the adsorption carrier can be e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com