Resource recycling and treatment technology of high-concentration degradation-resistant salt-containing organic waste water

A technology of organic wastewater and treatment process, which is applied in multi-stage water treatment, water/sewage treatment, special compound water treatment, etc. It can solve the problems of difficult long-term stable operation of the process, organic pollution of the membrane system, and low recovery rate of wastewater. The effect of reducing the risk of inorganic salt scaling and good regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

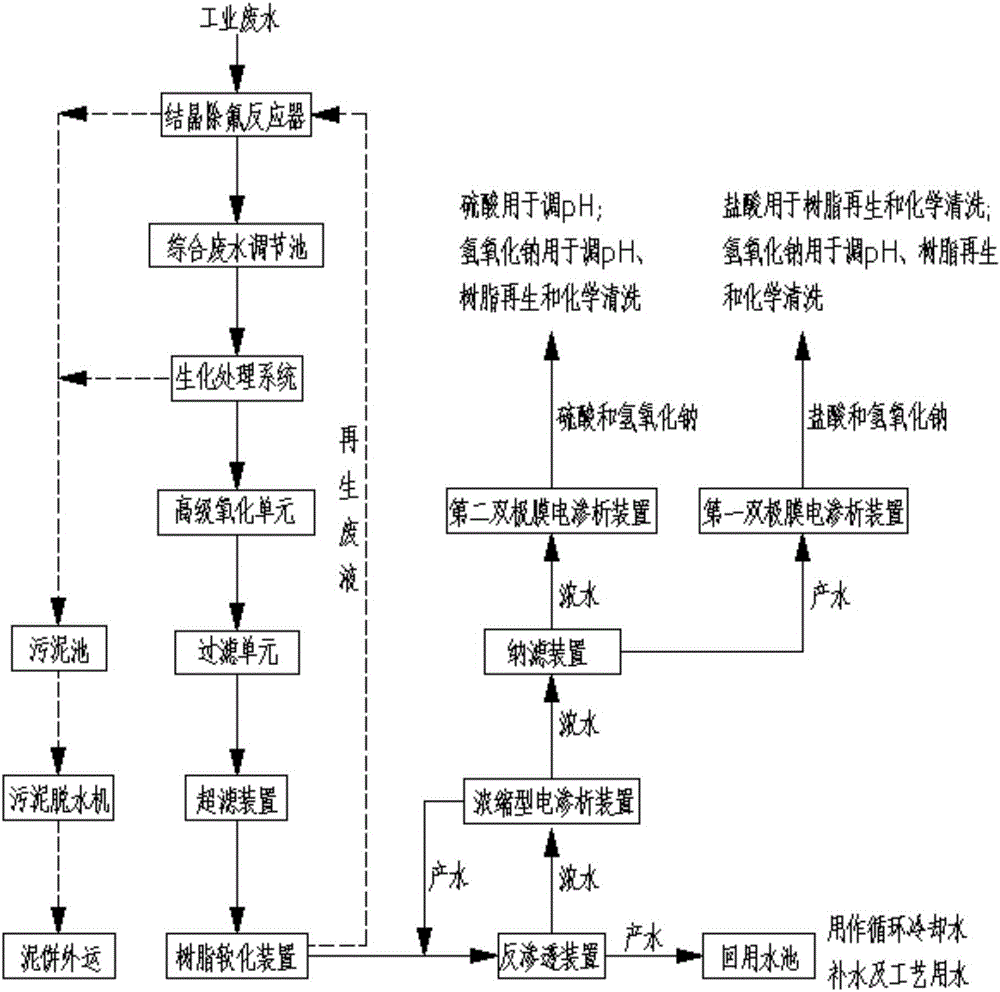

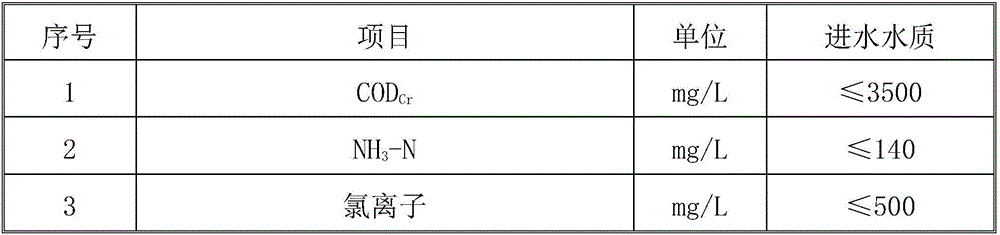

[0078] Adopt the method of the present invention to attach figure 1 The integrated process in the process treats the saline wastewater of an oil refinery, and the water quality indicators are as follows:

[0079] serial number

[0080] The system includes the following steps:

[0081] a. Pretreatment process

[0082] Wastewater first enters the crystallization defluorination reactor for pretreatment. After pretreatment, part of the suspended solids, organic matter and fluoride ions in the wastewater are removed.

[0083] Pretreatment effluent: turbidity ≤ 130NTU, COD ≤ 1700mg / L, effluent flows into the comprehensive wastewater regulating tank for water quality and quantity regulation.

[0084] b. Biochemical treatment process

[0085] The biochemical treatment process unit adopts anaerobic-anoxic-aerobic (A 2 O) process, COD, nitrogen, and phosphorus are removed from wastewater.

[0086] After the biochemical treatment unit, the COD of the wastewater is ≤170mg / ...

Embodiment 2

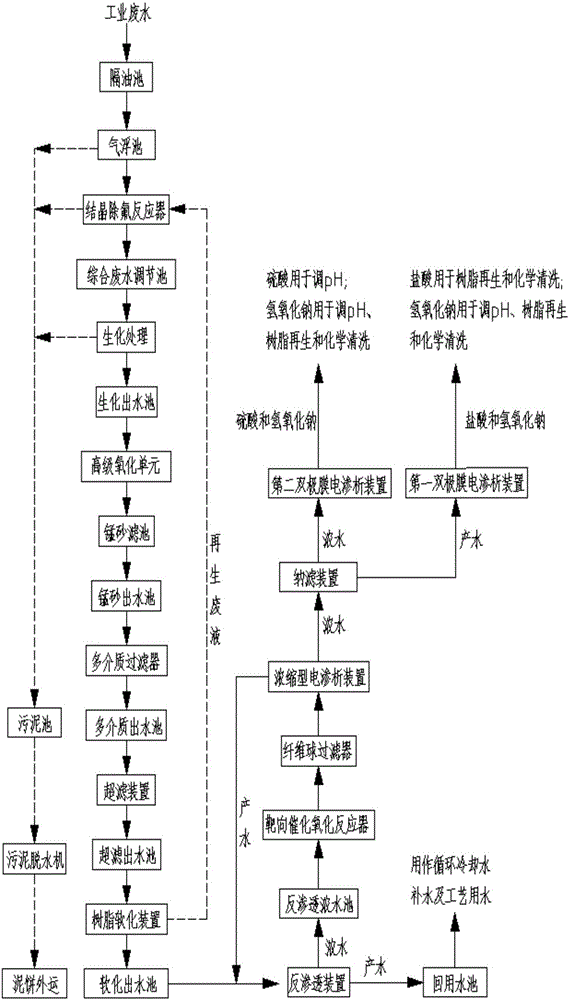

[0101] Adopt the method of the present invention to attach figure 2 The integrated process in the process treats wastewater from a coking plant, and the water quality indicators are as follows:

[0102]

[0103]

[0104] The system includes the following steps:

[0105] a. Pretreatment process

[0106] The wastewater first enters the grease trap, the air flotation tank, and the crystallization defluorination reactor for pretreatment. After pretreatment, part of the oil, suspended solids, fluoride ions and organic matter in the wastewater are removed.

[0107] Pretreatment effluent: turbidity ≤ 30NTU, COD ≤ 2400mg / L, effluent flows into the comprehensive wastewater regulating tank for water quality and quantity regulation.

[0108] b. Biochemical treatment process

[0109] The biochemical treatment process unit adopts anaerobic-anoxic-aerobic (A 2 O) process, COD, nitrogen, and phosphorus are removed from wastewater.

[0110] After the biochemical treatment unit, t...

Embodiment 3

[0126] Adopt the method of the present invention to attach figure 2 The integrated process flow in the paper treats a certain coal gas waste water. The water quality indicators are as follows:

[0127]

[0128]

[0129] The system includes the following steps:

[0130] a. Pretreatment process

[0131] The wastewater first enters the grease trap, the air flotation tank, and the crystallization defluorination reactor for pretreatment. After pretreatment, part of the oil, suspended solids, fluoride ions and organic matter in the wastewater are removed.

[0132] Pretreatment effluent: turbidity ≤ 25NTU, COD ≤ 3000mg / L, effluent flows into the comprehensive wastewater regulating tank for water quality and quantity regulation.

[0133] b. Biochemical treatment process

[0134] The biochemical treatment process unit adopts anaerobic-anoxic-aerobic (A 2 O) process, COD, nitrogen, and phosphorus are removed from wastewater.

[0135] Biochemical treatment effluent: COD≤200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com