Boiling type rice husk combustion boiler

A rice husk boiler, boiling technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of incomplete combustion, boiler tube wall wear, combustion characteristics can not be grasped, etc., to achieve the effect of rigorous layout and careful design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

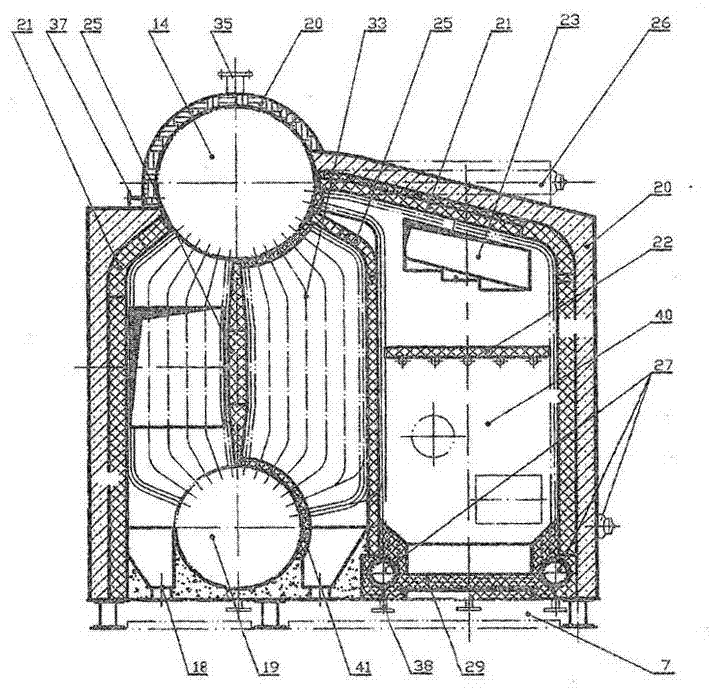

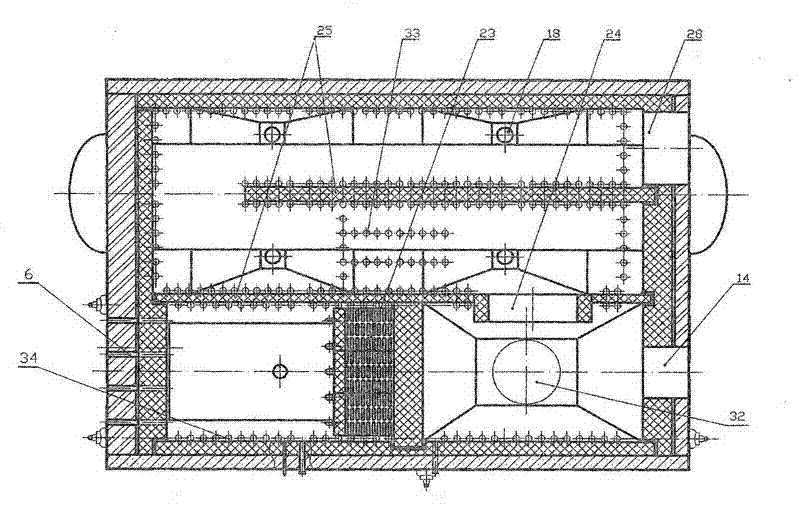

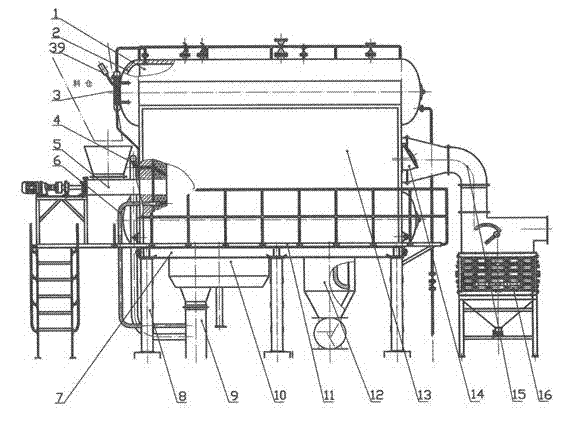

[0019] An example of a boiling rice husk-fired boiler with an evaporation capacity of 4 tons to 30 tons: refer to the drawings: the boiler body including the boiler base column 8 and the boiler base 7 is provided with an upper drum 1, a lower drum 19, Convection heat exchange tube 33, upper header 26, lower header 27, water wall tube 34, boiling bed 29, boiling combustion chamber 40, combustible dust removal chamber 31, refractory furnace wall 21, thermal insulation furnace wall 20, refractory Thermal insulation partition wall 25, explosion-proof door 14, inspection door 30; the upper drum 1 is provided with a safety valve interface 36, a steam interface 35, a drum insulation 2, a high-temperature insulation layer 41, a water inlet 37, a water level gauge 3 and Pressure gauge 39; the lower drum 19 and the lower header 27 are provided with a drain valve interface 38 and a high-temperature insulation layer 41. The upper drum 1, the lower drum 19, the upper header 26, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com