High-temperature energy-saving hot air smelting furnace

A smelting furnace and hot air technology, applied in the direction of furnaces, crucible furnaces, furnace types, etc., can solve the problems of small smelting equipment, poor structure, poor heating efficiency, and low energy utilization rate, and achieve good melting effect, The effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

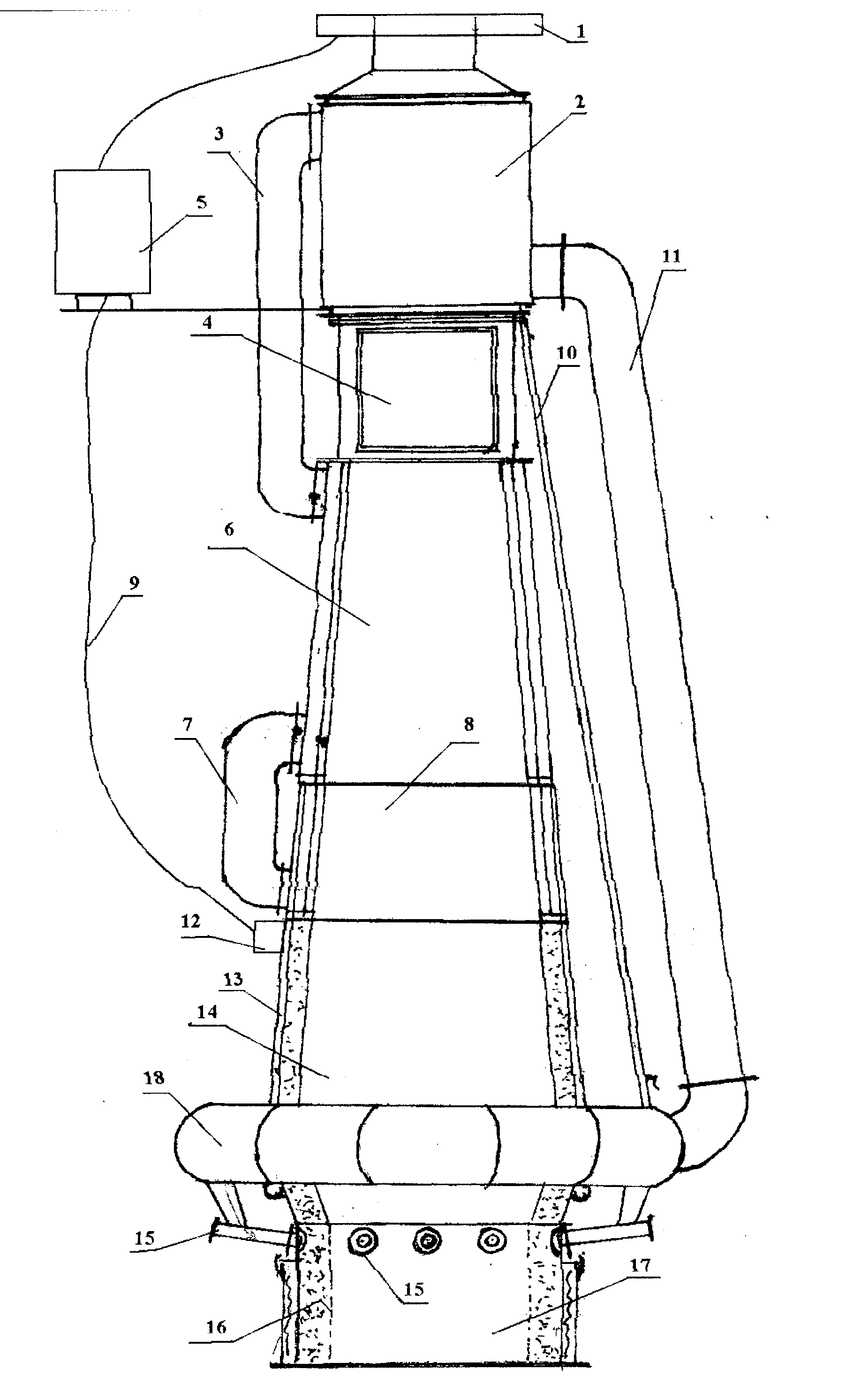

[0021] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

[0022] Referring to the accompanying drawings, the present invention includes a combustion chamber 17, a melting chamber 14, a small wind bladder 8 and a large wind bladder 6. The combustion chamber 17 is located at the bottom, and its inner wall is provided with a refractory layer 16. The sides of the combustion chamber 17 There is a slag outlet. The melting chamber 14 is located on the upper part of the combustion chamber 17 and has a cylindrical structure. The outer wall of the cylindrical structure is wrapped by a cooling layer 13, and its inner wall is filled with a refractory layer 16. Between the combustion chamber 17 and the melting chamber 14, a The wind control device 18 is provided with a regulating valve 15 outside the wind control device 18, and the regulating valve 15 is used to adjust the magnitude of the wind force and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com