Reproduced cheese and preparation method thereof

A technology for processed cheese and cheese, which is applied in the field of processed cheese and its preparation, which can solve the problems of uneven distribution of charred spots, poor melting property, weak stringiness, etc., and achieve excellent melting property, low production cost, and easy preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

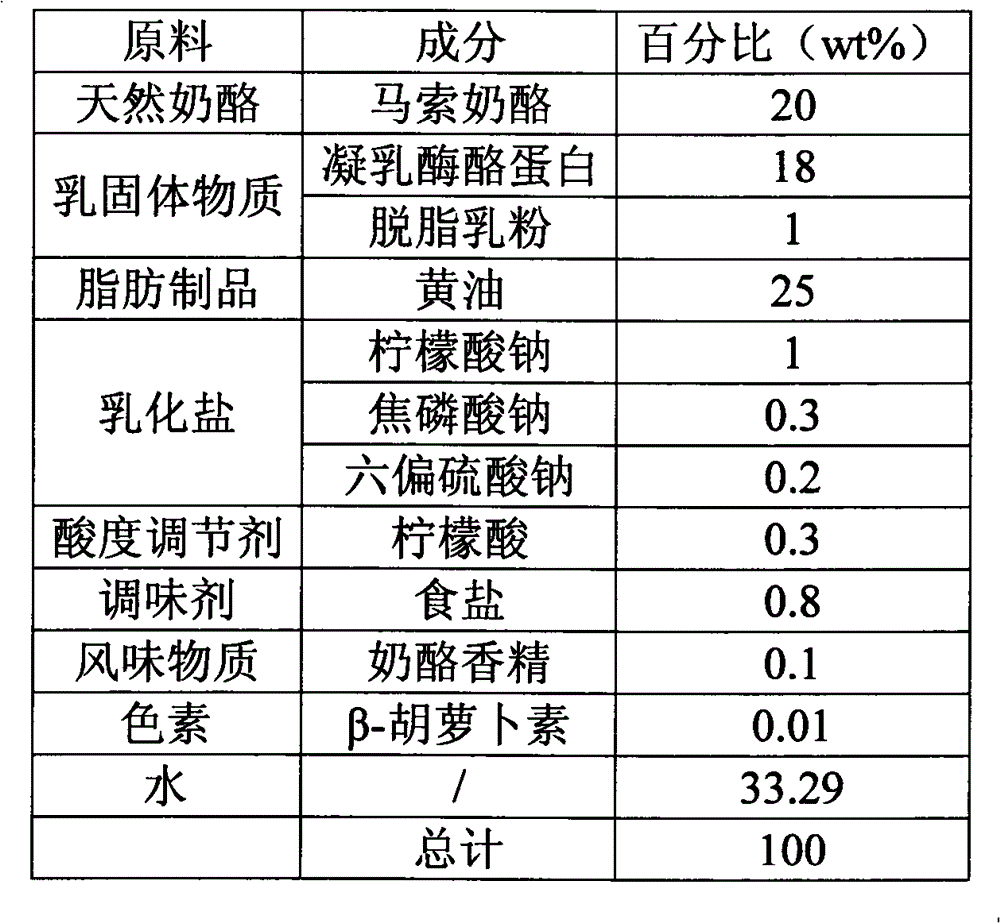

Embodiment 1

[0043] Processed Cheese Ingredients:

[0044]

[0045] Preparation:

[0046] ① According to the above recipe, put all the raw materials except natural cheese and fat products into the melting pot, the number of blades is 2 pieces, and the thickness of the blade is 1mm. Without heating, the temperature was controlled at 20°C, and the premixed slurry was obtained by shearing and stirring at 900 rpm for 4 minutes;

[0047] ② Add natural cheese and fat products, stir at 1500rpm, steam directly to a temperature of 80°C, and then keep warm and emulsify for 10 minutes;

[0048] ③ Cool down to 30°C by air cooling within 1 hour, and then refrigerate at 4°C for 7 days.

[0049] ④Use a cutting machine to cut into 3.5mm3 Granular, packaged and frozen at -18°C.

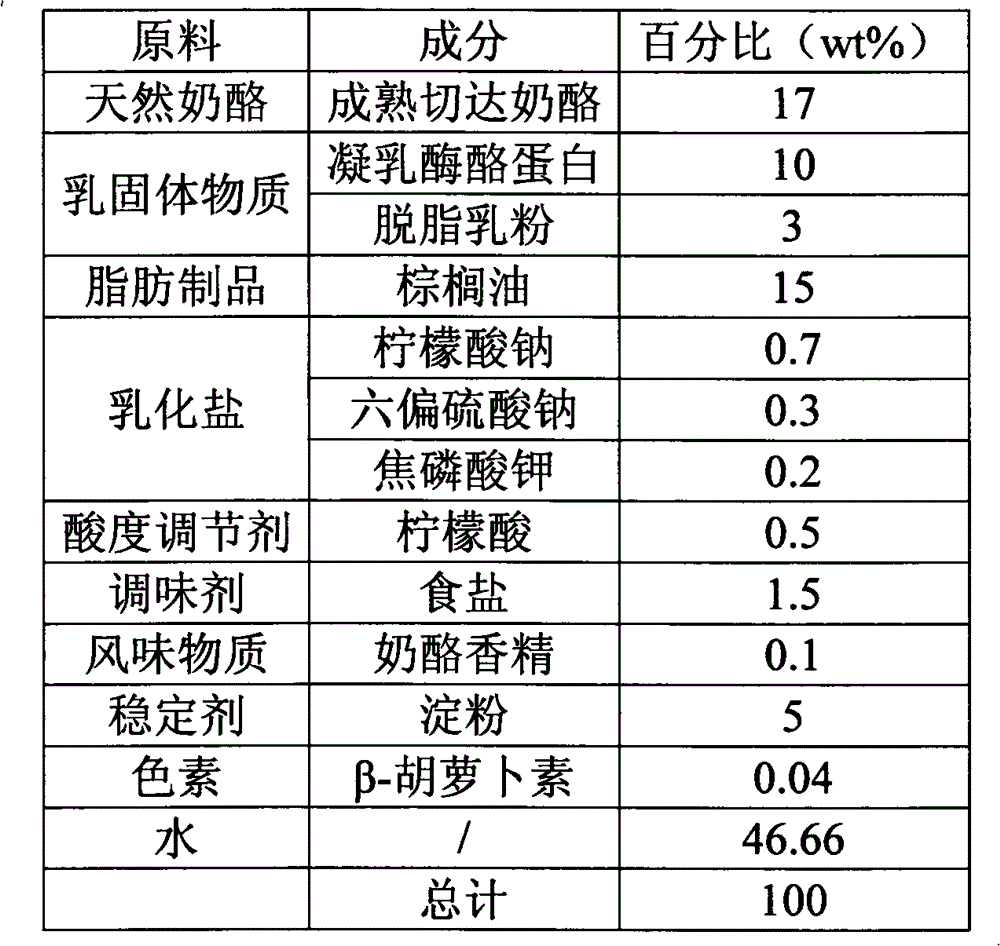

Embodiment 2

[0051] Processed Cheese Ingredients:

[0052]

[0053] Preparation:

[0054] ① According to the above formula, put all the raw materials except natural cheese and fat products into the melting pot, the number of blades is 3 pieces, and the thickness of the blade is 0.5mm. Without heating, the temperature is controlled at 25°C, and the premixed slurry is obtained by shearing and stirring at 1800rpm for 2min;

[0055] ② Add natural cheese and fat products, stir at 1800rpm, steam directly to a temperature of 90°C, and then keep warm and emulsify for 12 minutes;

[0056] ③Water cooling to 30°C within 1 hour, and then refrigerated at 2°C for 2 days.

[0057] ④Use a cutting machine to cut into 2mm 3 Granular, packaged and frozen at -18°C.

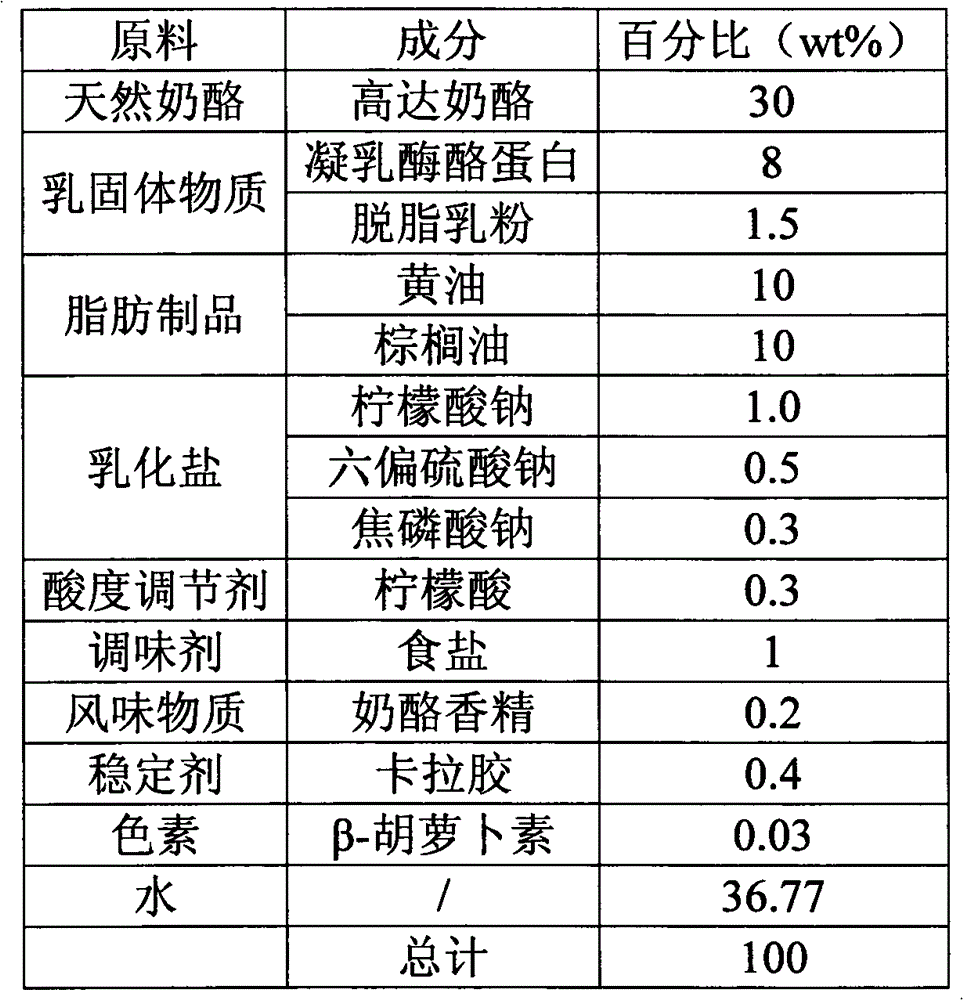

Embodiment 3

[0059] Processed Cheese Ingredients:

[0060]

[0061] Preparation:

[0062] ① According to the above recipe, put all the raw materials except natural cheese and fat products into the melting pot, the number of blades is 4 pieces, and the thickness of the blade is 1.5mm. Without heating, the temperature is controlled at 30°C, and the premixed slurry is obtained by shearing and stirring at 1000rpm for 5min;

[0063] ② Add natural cheese and fat products, stir at 1000rpm, steam directly to a temperature of 95°C, and then keep warm and emulsify for 8 minutes;

[0064] ③Water cooling to 25°C within 1 hour, and then refrigerated at 6°C for 4 days.

[0065] ④Use a cutting machine to cut into 5mm 3 Granular, packaged and frozen at -18°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com