Patents

Literature

76 results about "Transverse strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

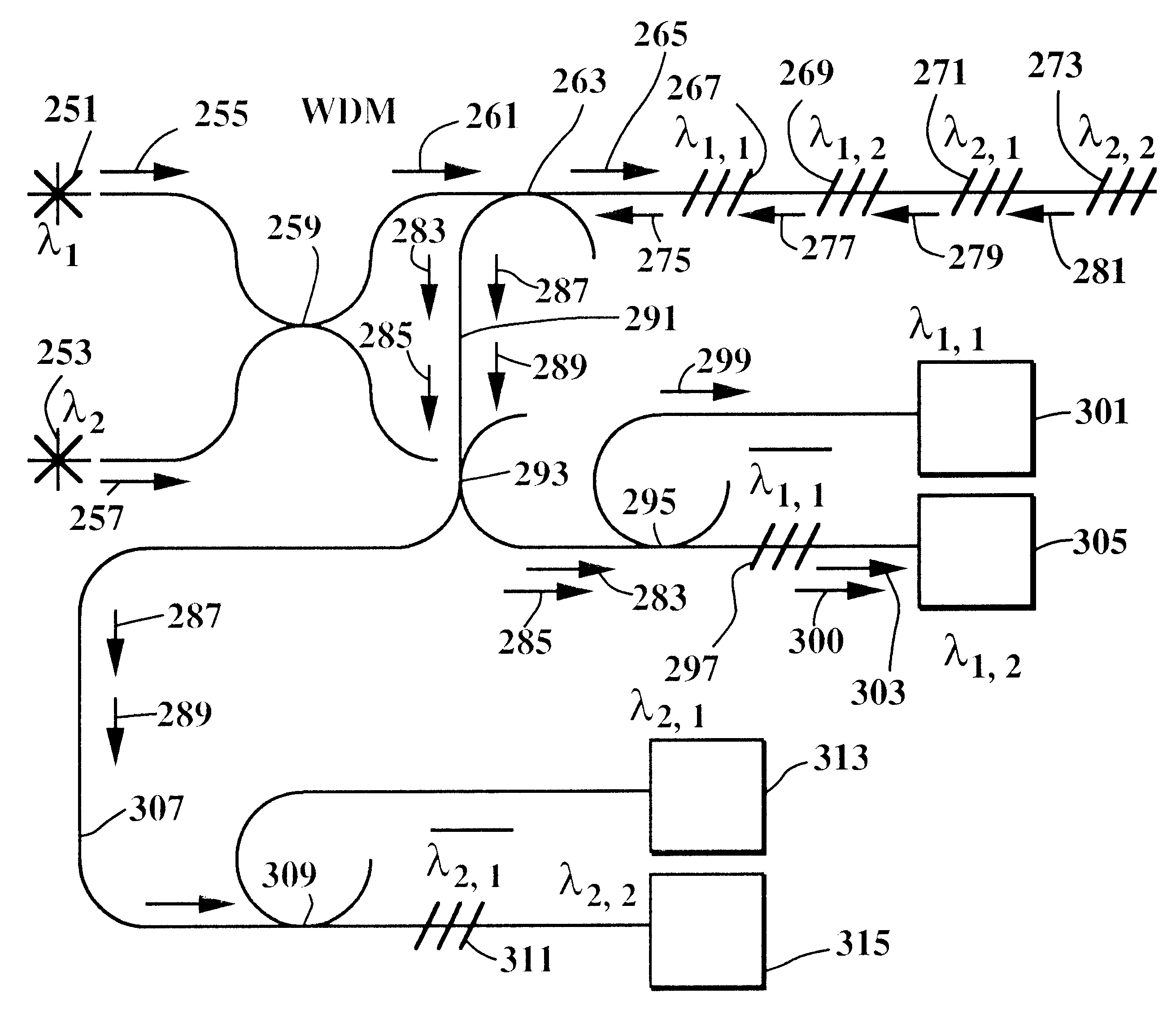

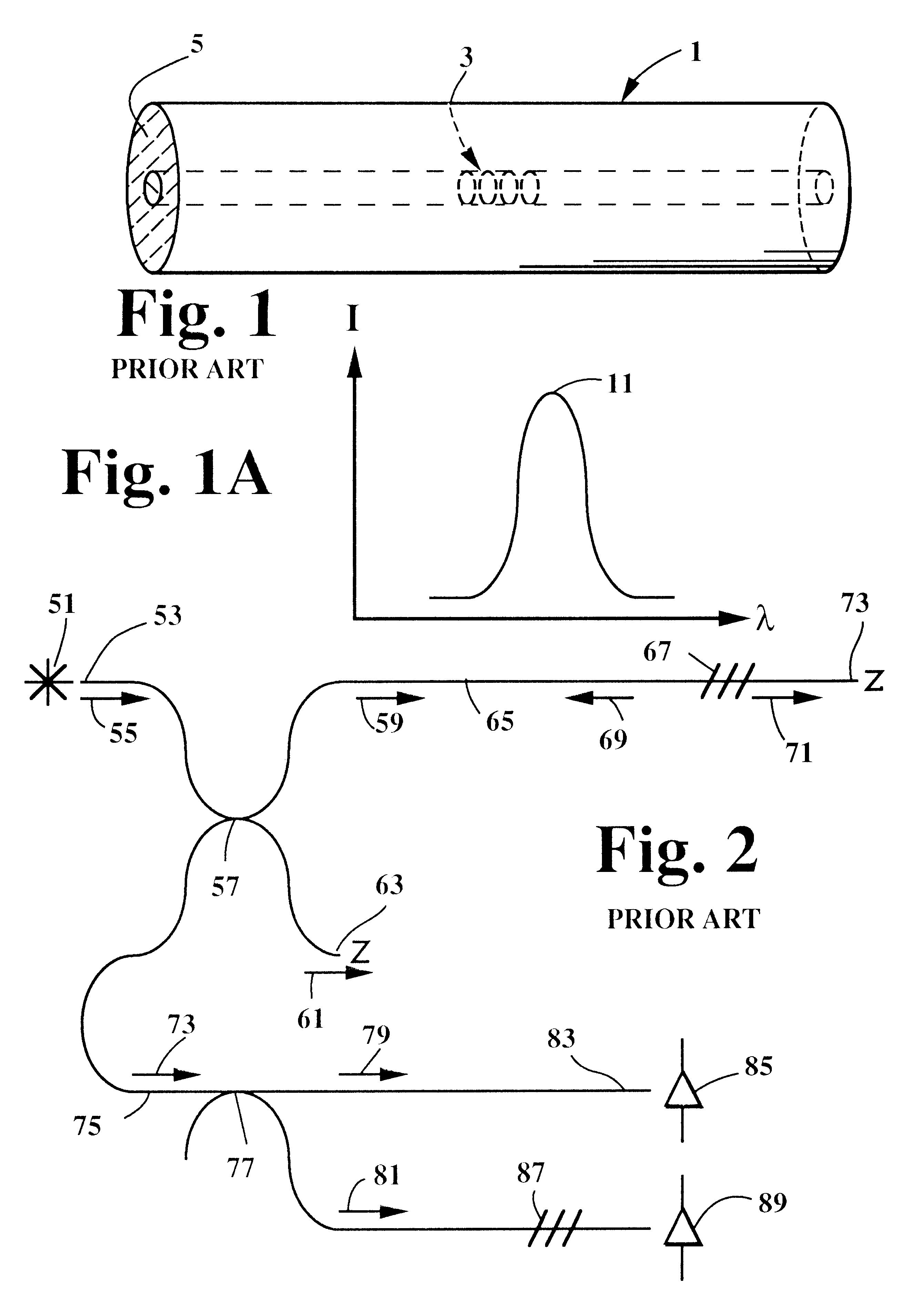

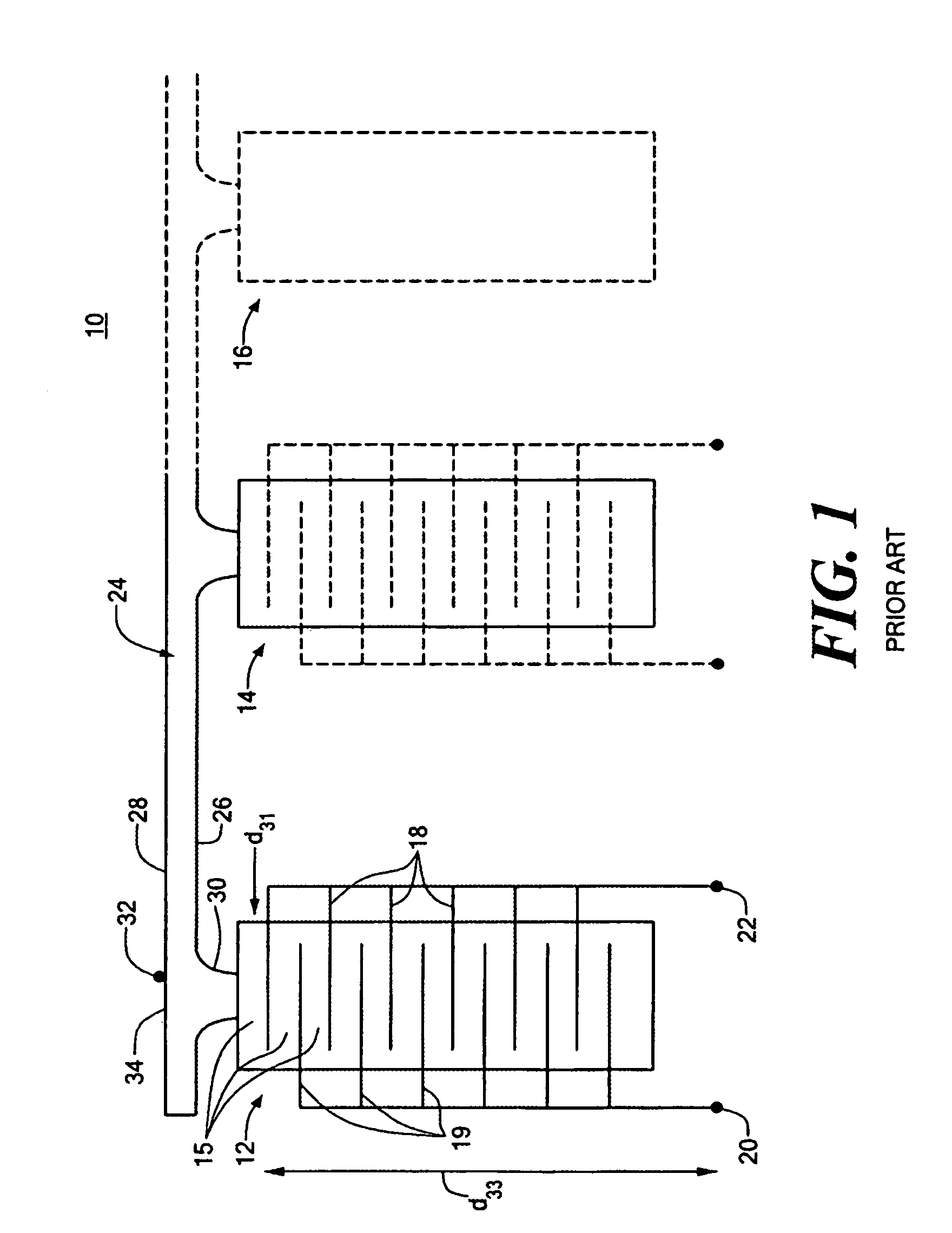

High speed demodulation systems for fiber optic grating sensors

InactiveUS6335524B1Improve speed and accuracyIncrease speedRadiation pyrometryMaterial analysis by optical meansGratingPeak value

Fiber optic grating sensor demodulation systems are described that offer high speed and multiplexing options for both single and multiple parameter fiber optic grating sensors. To attain very high speeds for single parameter fiber grating sensors ratio techniques are used that allow a series of sensors to be placed in a single fiber while retaining high speed capability. These methods can be extended to multiparameter fiber grating sensors. Optimization of speeds can be obtained by minimizing the number of spectral peaks that must be processed and it is shown that two or three spectral peak measurements may in specific multiparameter applications offer comparable or better performance than processing four spectral peaks. Combining the ratio methods with minimization of peak measurements allows very high speed measurement of such important environmental effects as transverse strain and pressure.

Owner:NAGANO KEIKI

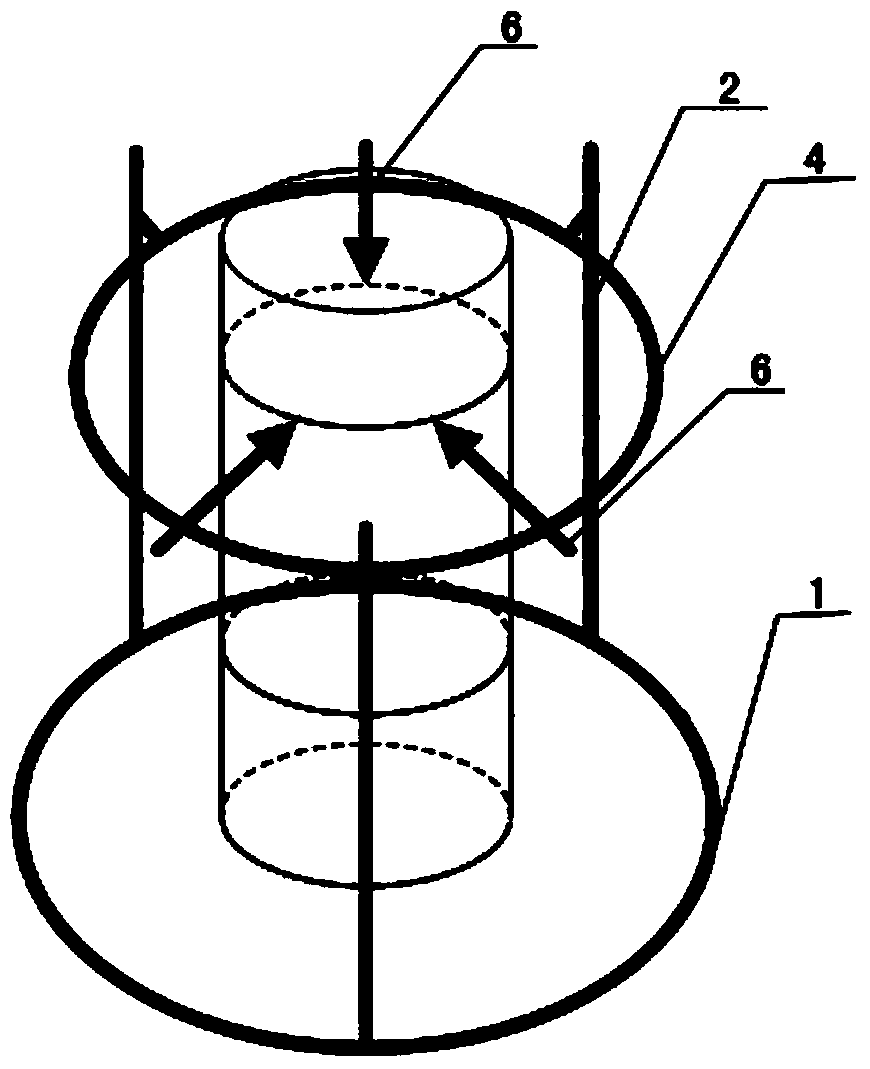

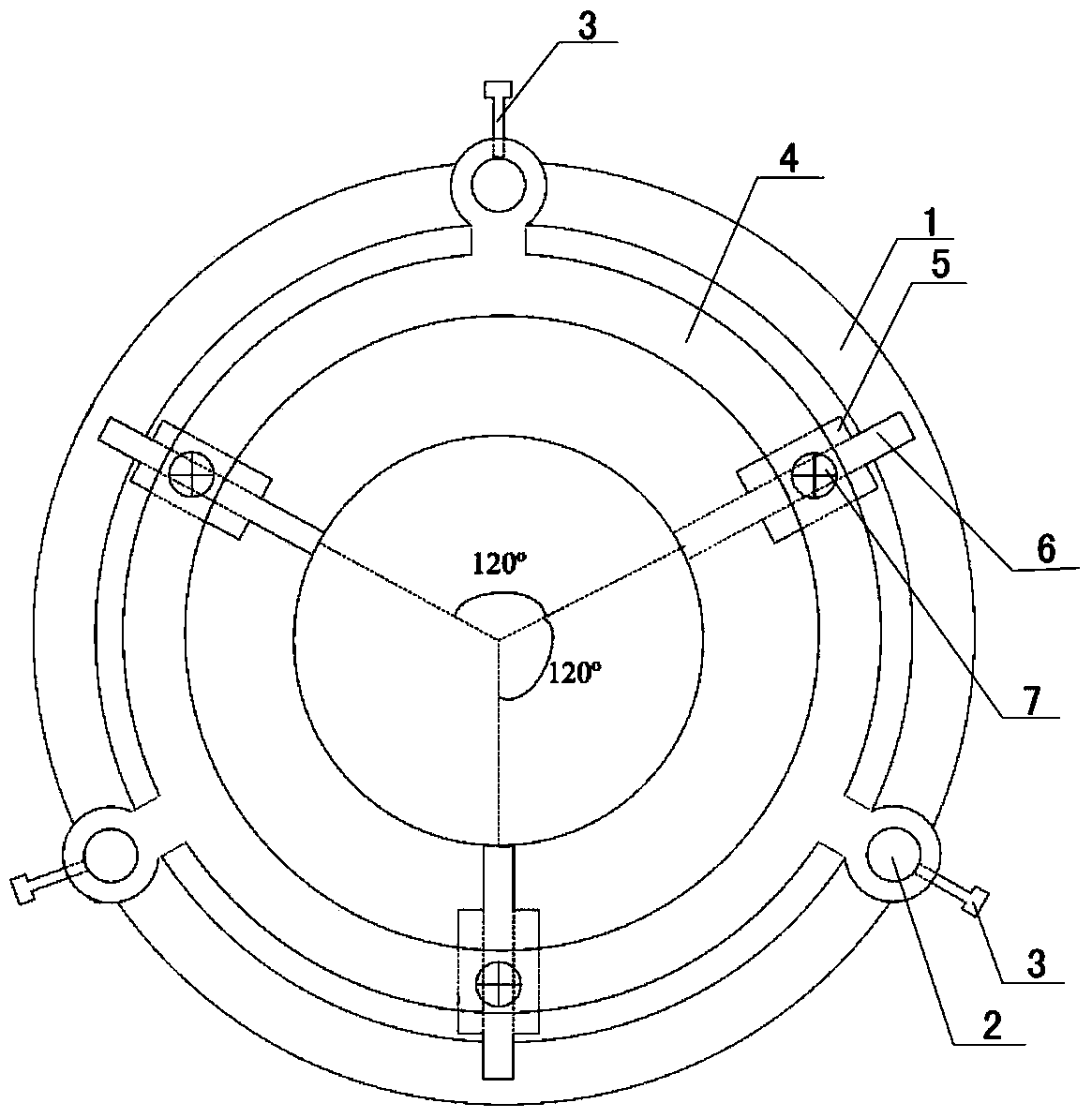

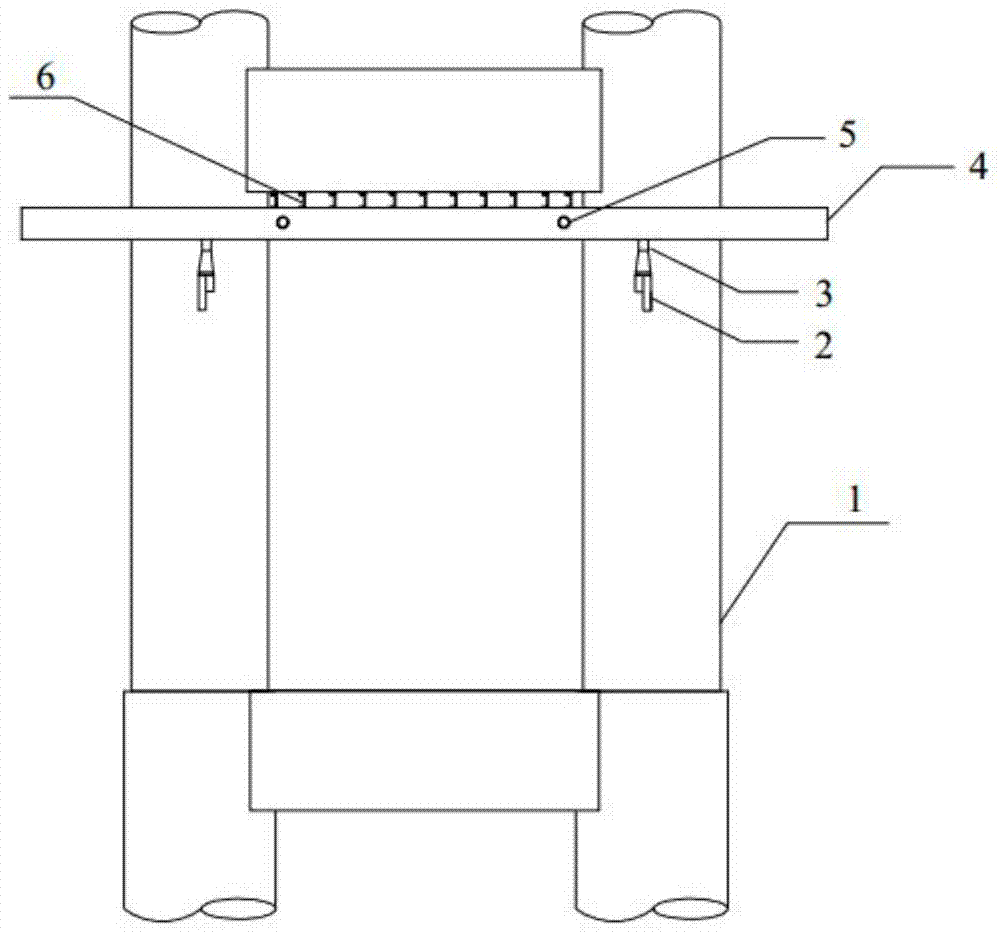

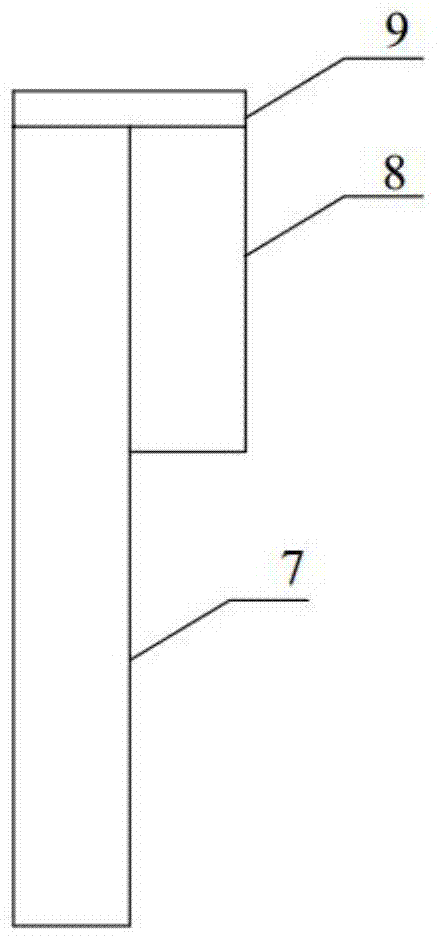

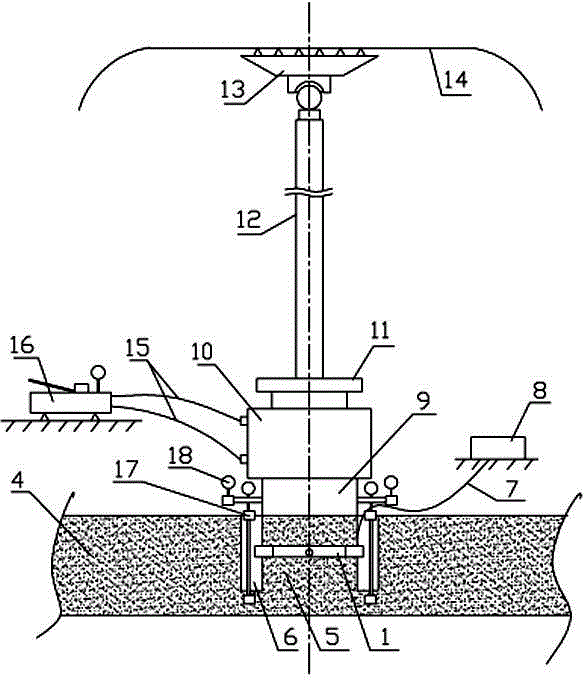

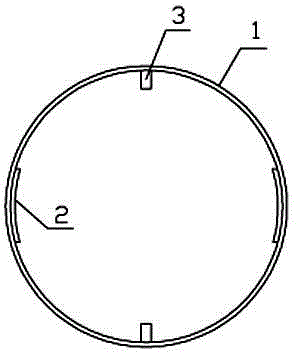

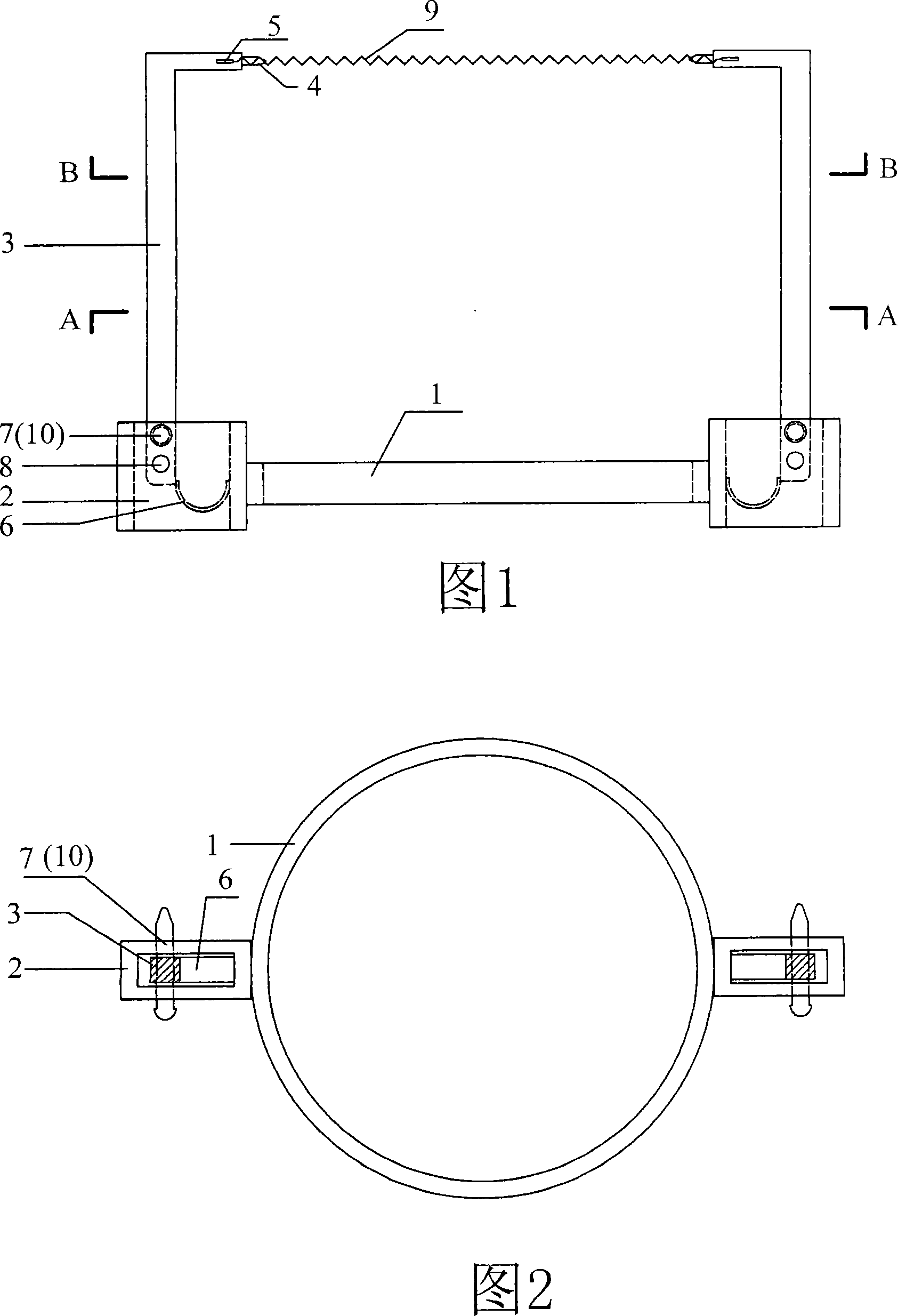

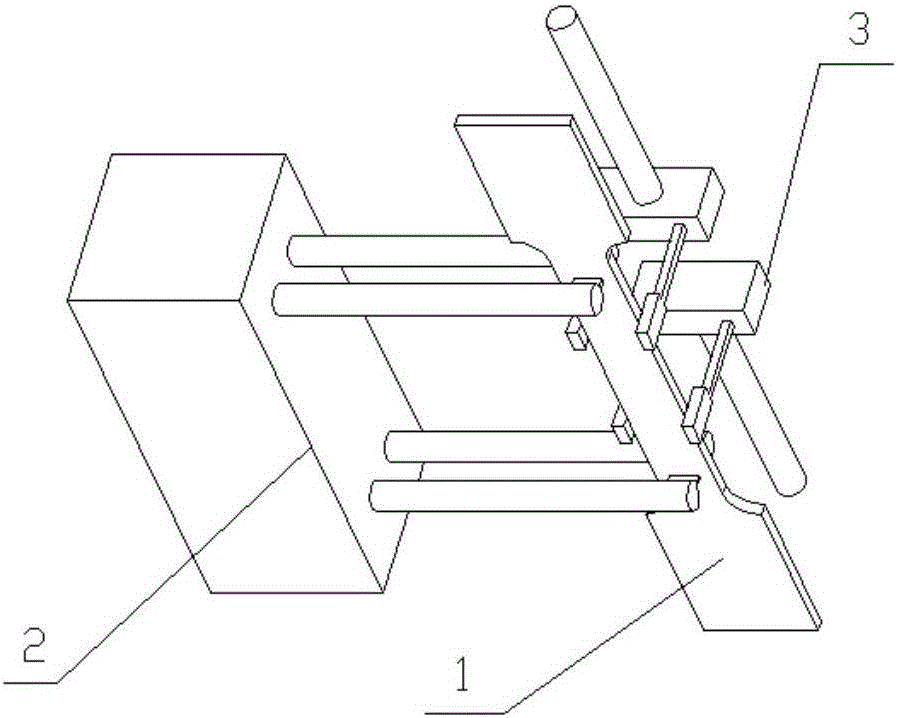

Device for measuring radial deformation of cylindrical test piece

InactiveCN103954262ASolve the measurement problem of radial (transverse) deformationSimple structureMeasurement devicesEngineeringLinear displacement

The invention discloses a device for measuring radial deformation of a cylindrical test piece. The device comprises a base, a stand column, fastening screws, an annular sensor positioning frame and linear displacement sensors, wherein the stand column is installed on the base, the sensor positioning fame is installed on a sliding guide rail of the stand column through the fastening screws, the linear displacement sensors are installed on the sensor positioning fame, the included angle between the axes of every two linear displacement sensors is 120 degrees, sensor portioning sleeves are installed on the linear displacement sensors, sensor positioning screws are installed between the linear displacement sensors and the sensor portioning sleeves, and the linear displacement sensors are LVDT sensors. The device is simple in structure, convenient to operate and low in cost, and achieves the purpose of measuring radial or transverse strain of the cylindrical test piece; accurate centering can be easily achieved, and the force interaction between the device and the test piece does not exist.

Owner:范鹏贤

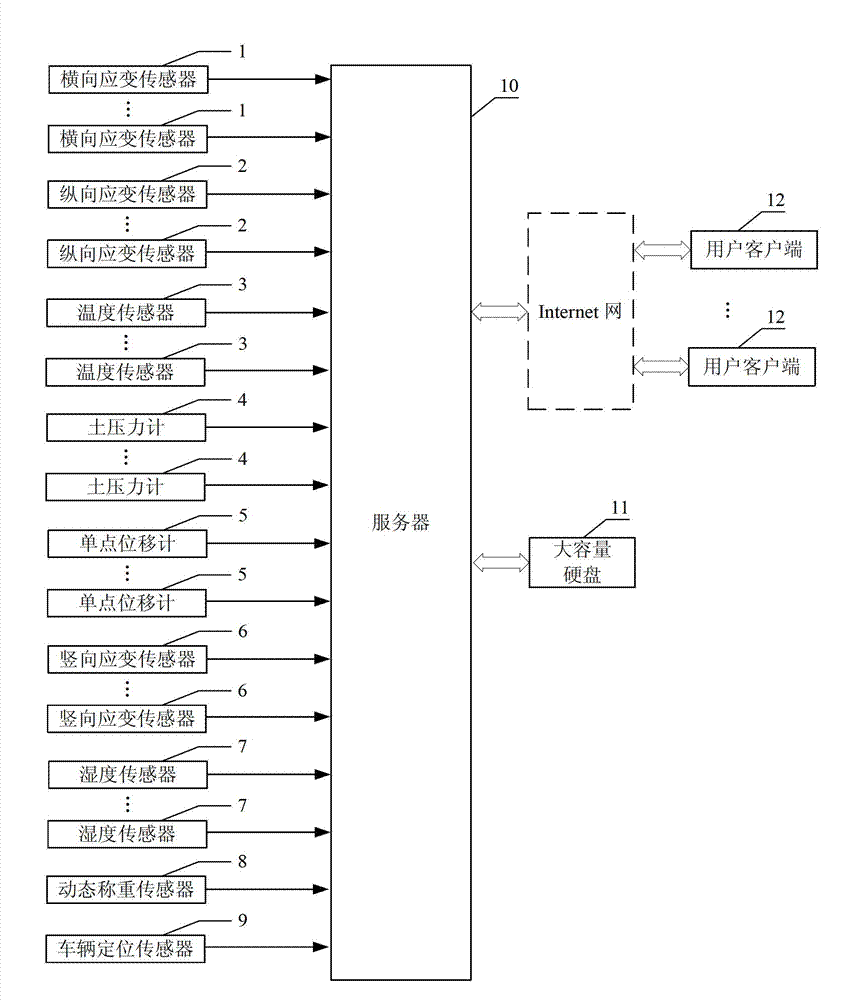

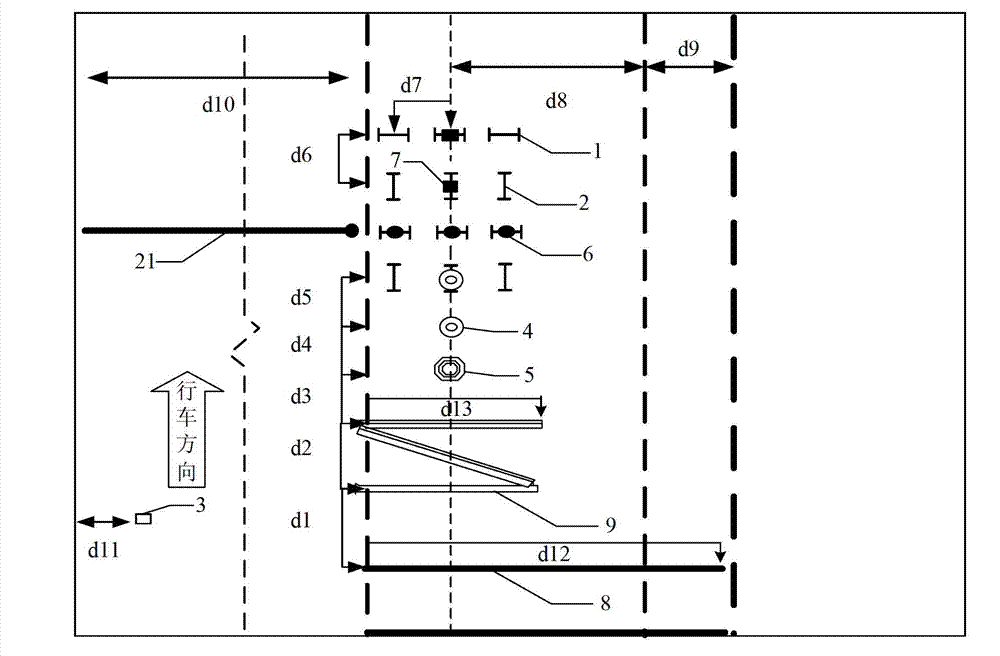

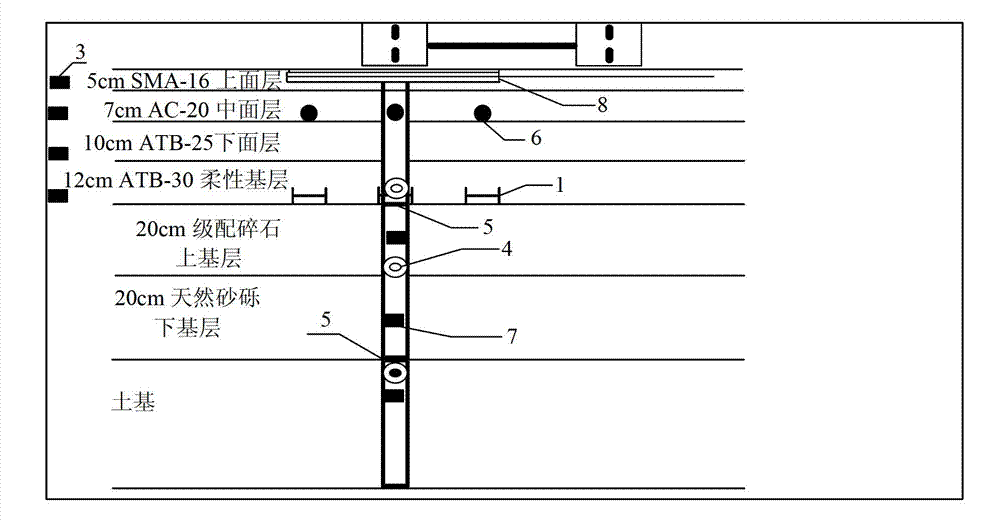

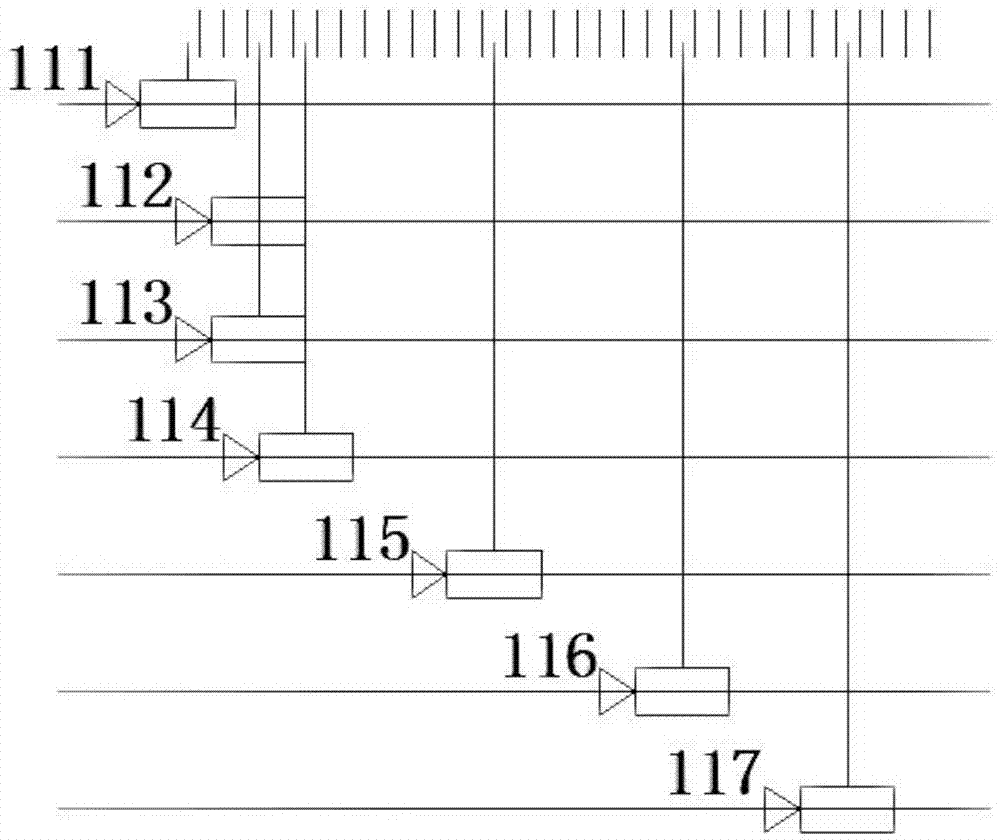

Long-term real-time monitoring system for asphalt pavement structure information based on optical fiber Bragg grating sensor

InactiveCN102900011ARealize evaluationRealize the estimateEmbedding padsRoads maintainenceGratingRoad surface

The invention discloses a long-term real-time monitoring system for asphalt pavement structure information based on an optical fiber Bragg grating sensor and relates to a long-term real-time monitoring system for the asphalt pavement structure information. The long-term real-time monitoring system meets the requirement of long-term real-time monitoring of the asphalt pavement structure information. Various data of the asphalt pavement are acquired by adopting A transverse strain sensors, B longitudinal strain sensors, C temperature sensors, D earth pressure gauges, E single point extensometers, F vertical strain sensors, G humidity sensors, a dynamic weighing sensor and a shaft position sensor and are processed by a server, and thus the long-term real-time monitoring on the asphalt pavement structure information is realized. The long-term real-time monitoring system disclosed by the invention is suitable for long-term real-time monitoring of the asphalt pavement structure information.

Owner:HARBIN INST OF TECH

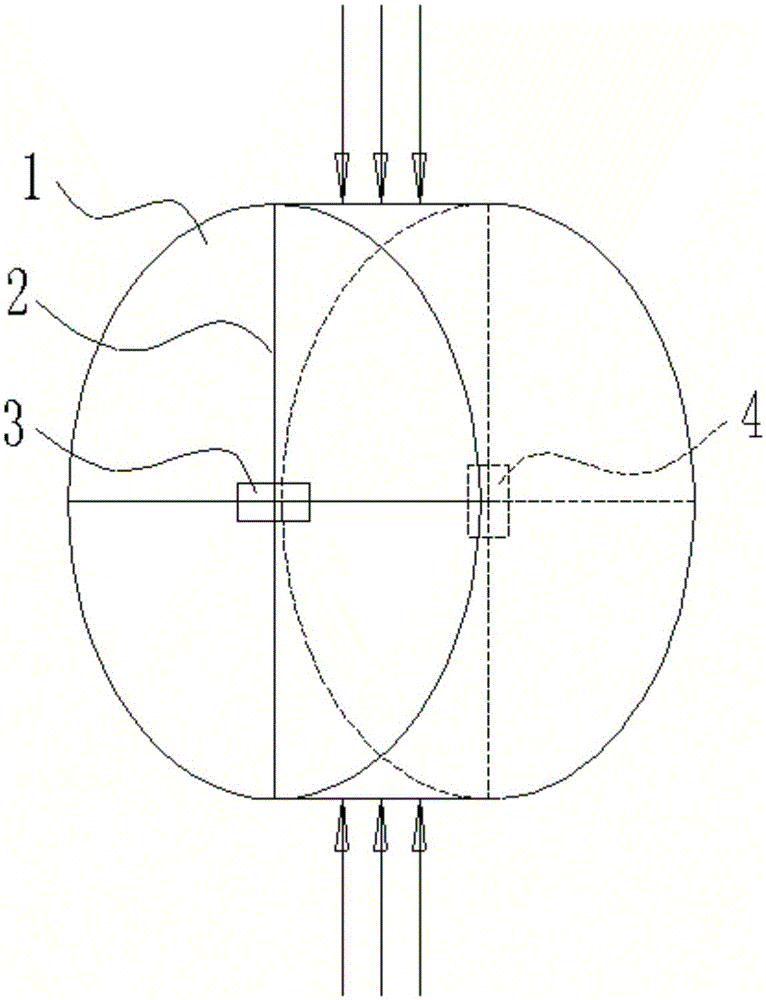

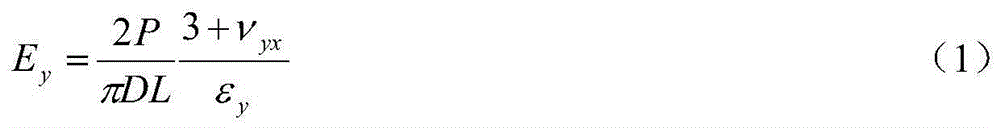

Testing method for one-time measurement of tensile modulus and compression modulus of rock

ActiveCN105158070AThe test method is simple and feasibleThe data is accurate and reliableMaterial strength using tensile/compressive forcesEngineeringRock sample

A testing method for one-time measurement of the tensile modulus and the compression modulus of rock comprises steps as follows: a horizontal strain gauge and a vertical strain gauge are pasted at centers of front and back sides of a disk sample respectively; the disk sample is placed on a press for a Brazilian disk test, the load force P is monitored by a pressure sensor, and the horizontal strain gauge and the vertical strain gauge monitor transverse strain epsilon x and vertical strain epsilon y of the centers of the disk sample respectively; the tensile modulus and the compression modulus of the rock are calculated as per the following formulas shown in the specification, wherein Ex and Ey represent the tensile modulus and the compression modulus of the rock respectively, P is the external load, D is the disk diameter, L is the disk thickness, vyx represents the x-direction transverse deformation coefficient caused by y-direction stress, and epsilon x and epsilon y represent the transverse strain and the vertical strain of the disk centers respectively. The tensile modulus and the compression modulus of the rock can be measured on the same rock sample through one test, the test method is simple and easy to implement, data are accurate and reliable, and results are more scientific.

Owner:NORTHEASTERN UNIV LIAONING

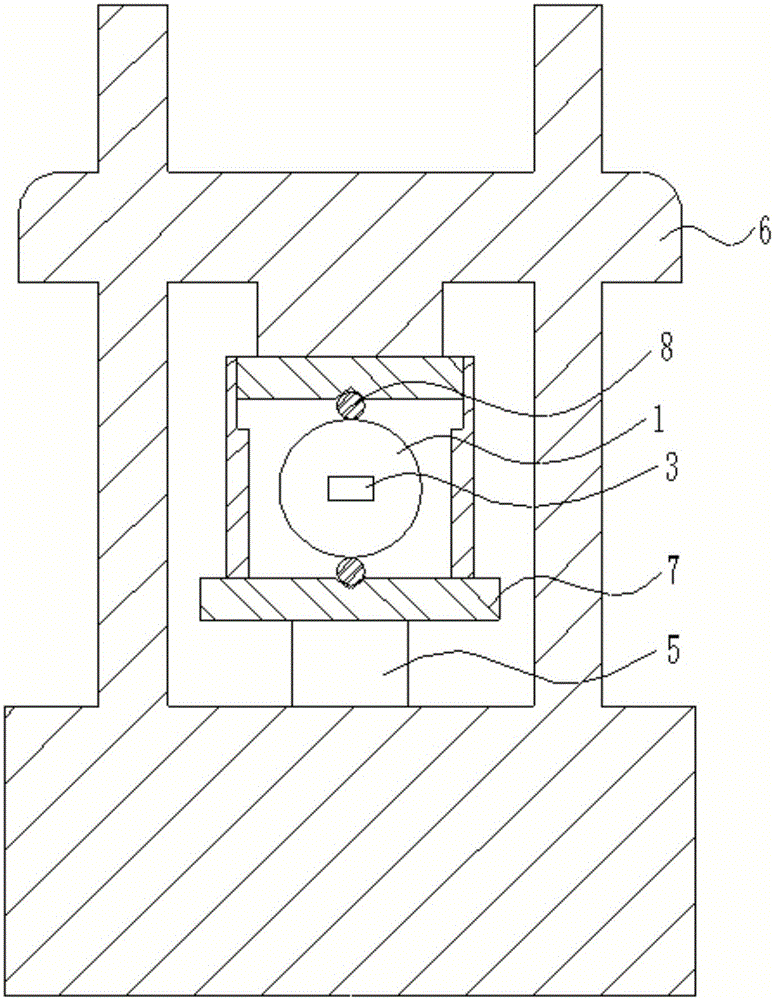

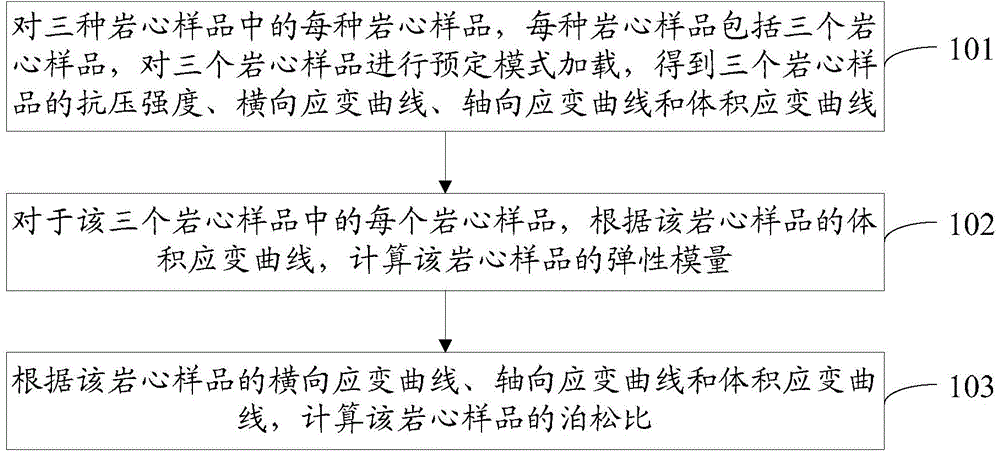

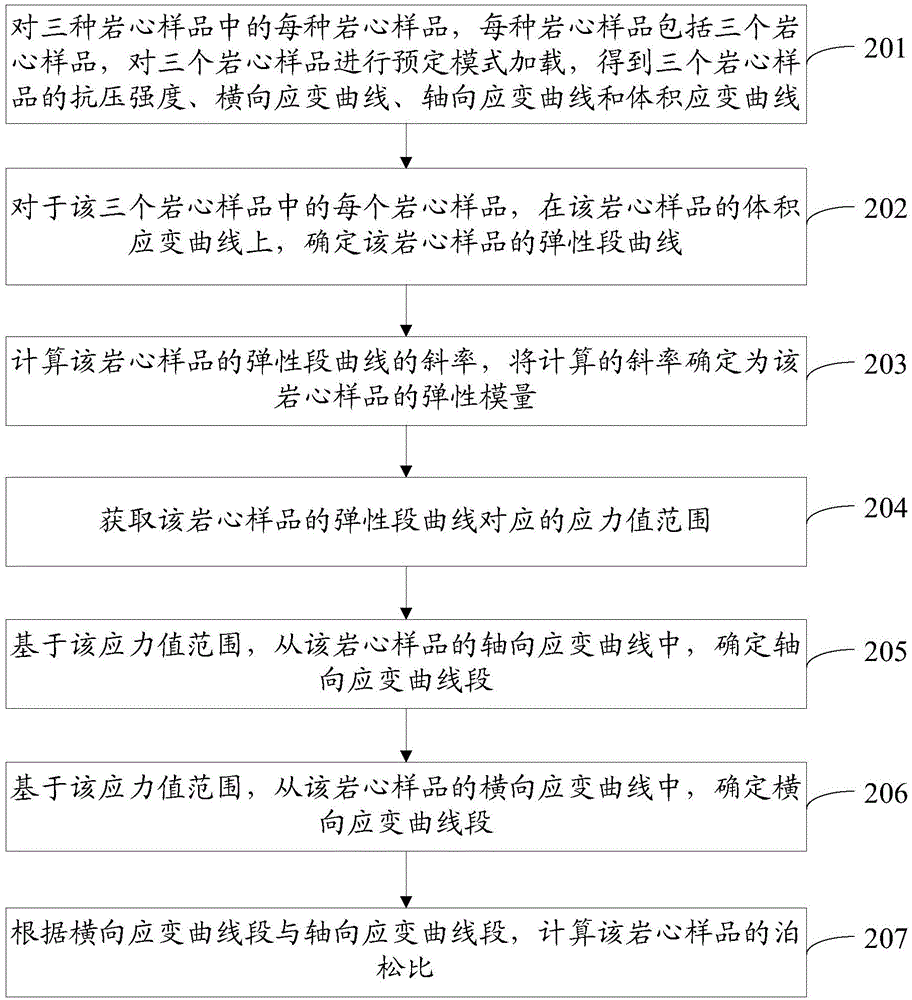

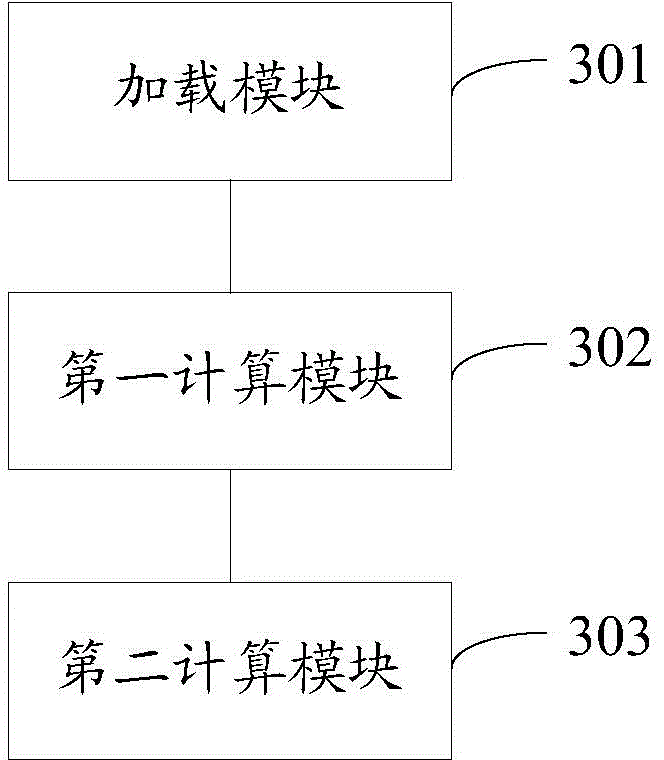

Method and device for measuring shale rock mechanical properties

ActiveCN105628486AAccurate dataPreparing sample for investigationStrength propertiesStress–strain curveCompressive strength

The invention discloses a method and device for measuring shale rock mechanical properties and belongs to the field of petroleum and gas. The method comprises carrying out preset mode loading on all three shale core samples of each type of shale core samples belonging to three types to obtain compressive strength, transverse strain curves, axial strain curves and volumetric strain curves of the three shale core samples, wherein the three types of the shale core samples are obtained through shale sampling along three directions comprising a longitudinal direction, a transverse direction and an inclined direction forming an included angle of 60 degrees with the horizontal direction, calculating elasticity moduli of all the shale core samples of three types of the shale core samples according to the volumetric strain curves of the shale core samples, and calculating a Poisson's ratio according to the transverse strain curve, the axial strain curve and the volumetric strain curve. According to shale specificity, through use of multi-directional sampling and a plurality of loading modes, accurate data is acquired. The method and device are suitable for shale cores.

Owner:PETROCHINA CO LTD

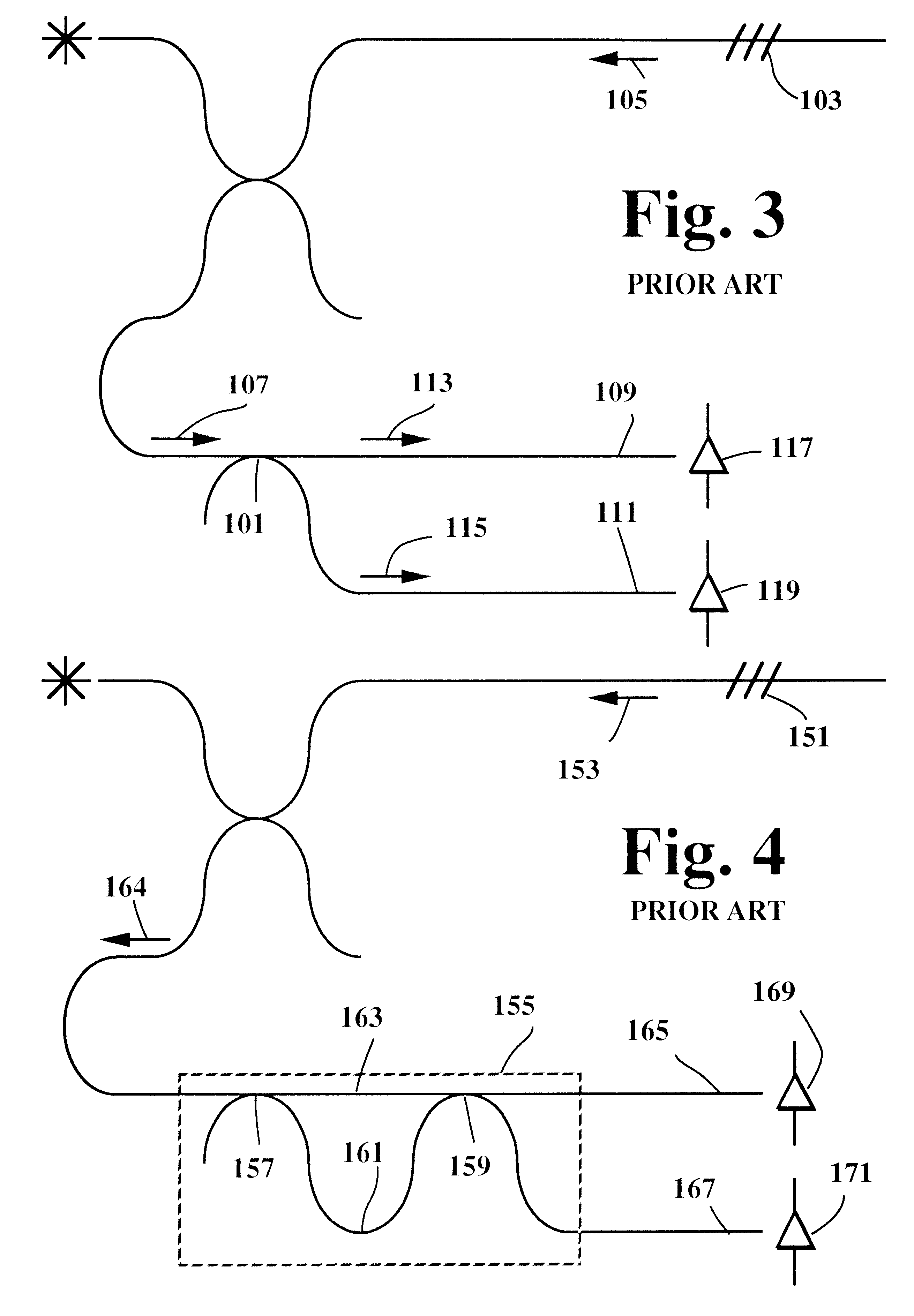

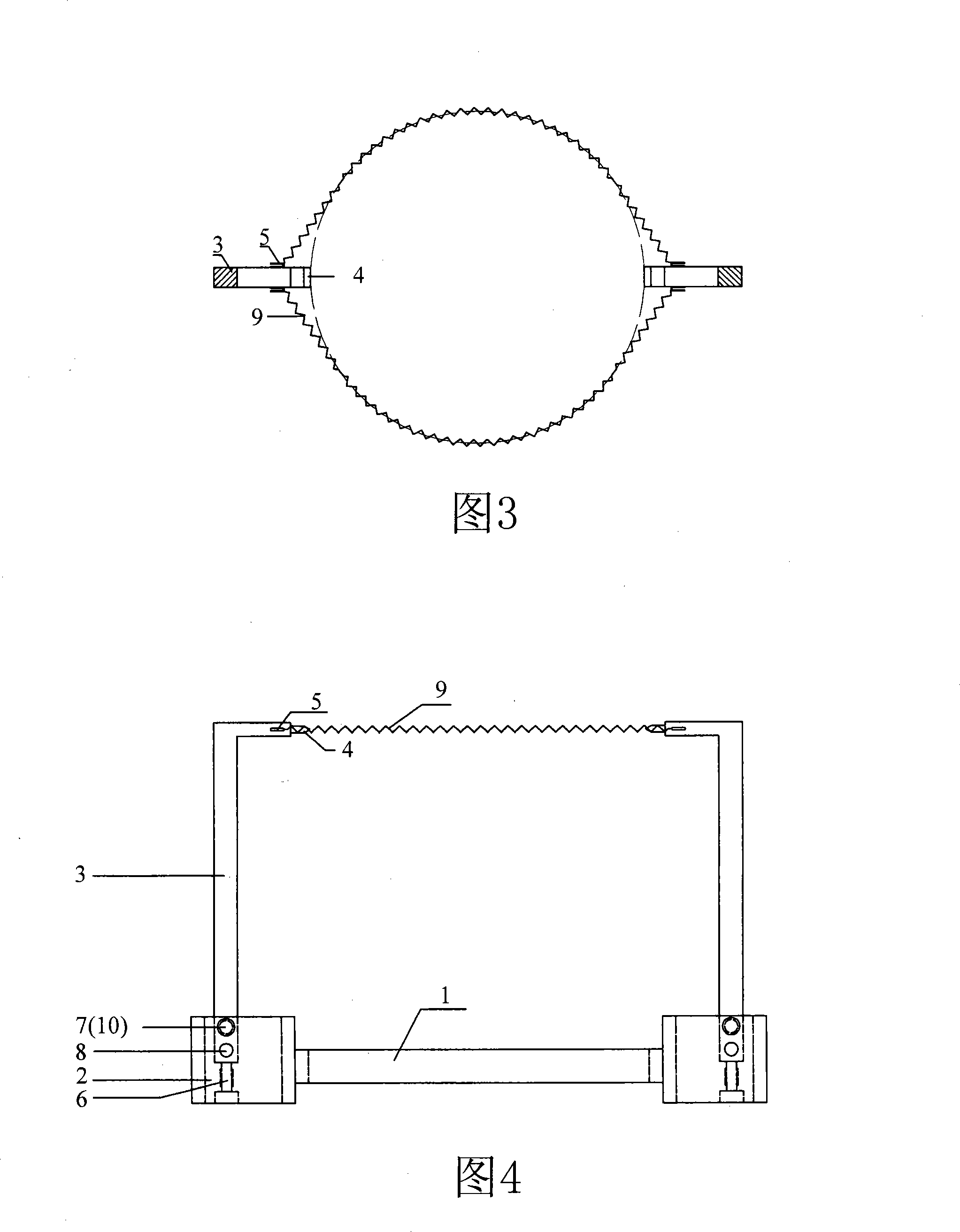

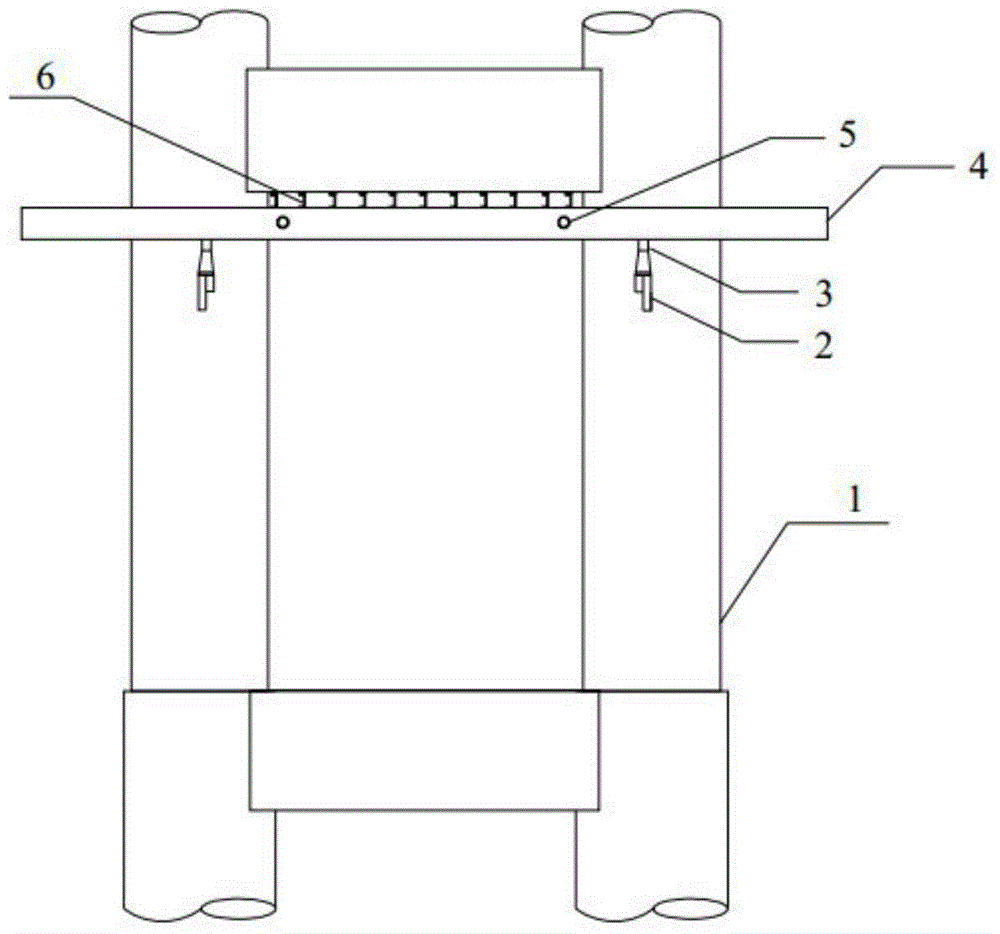

Corbel bracket platform for bridge pier and transverse straining beam synchronous construction and construction method of corbel bracket platform

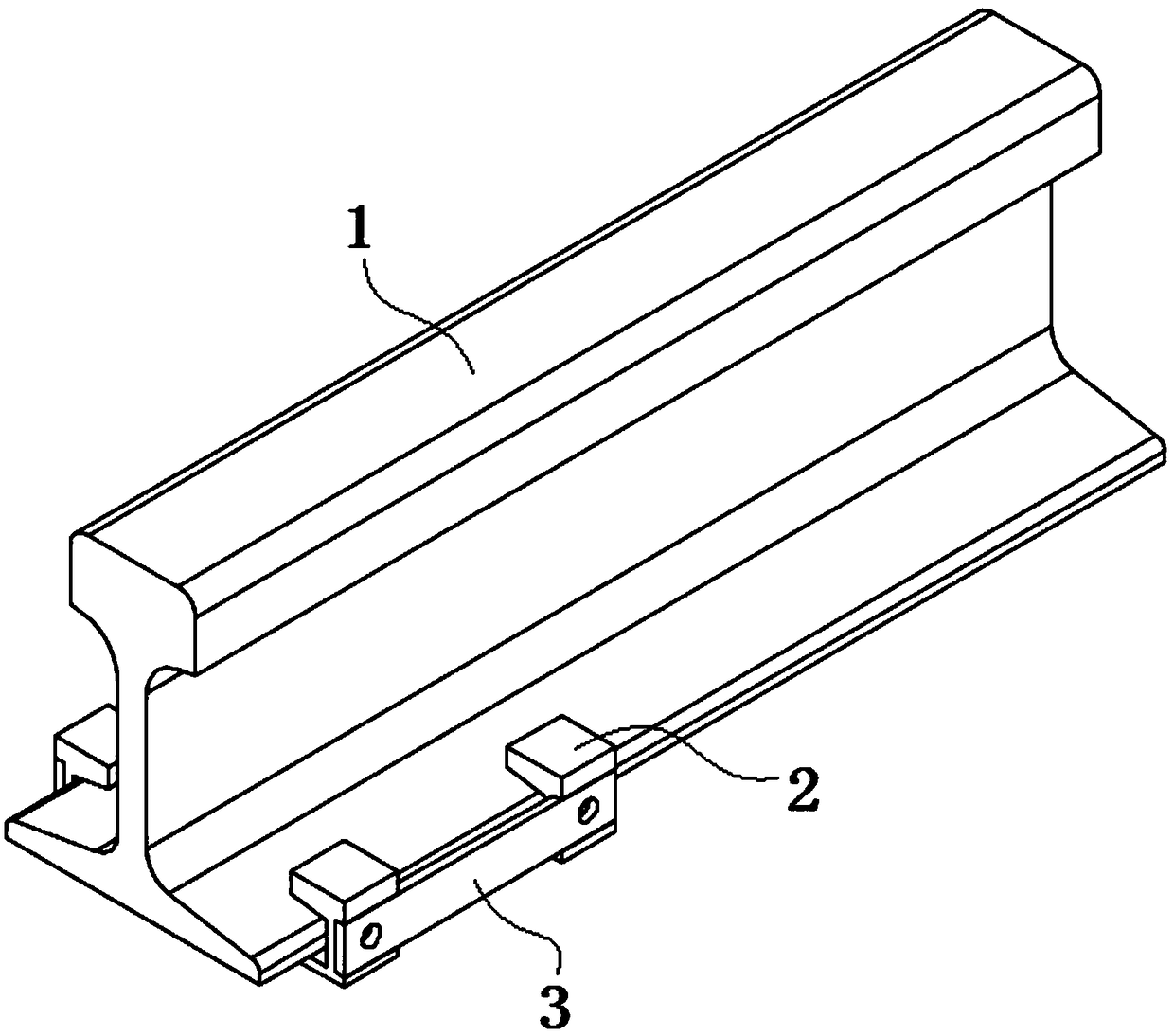

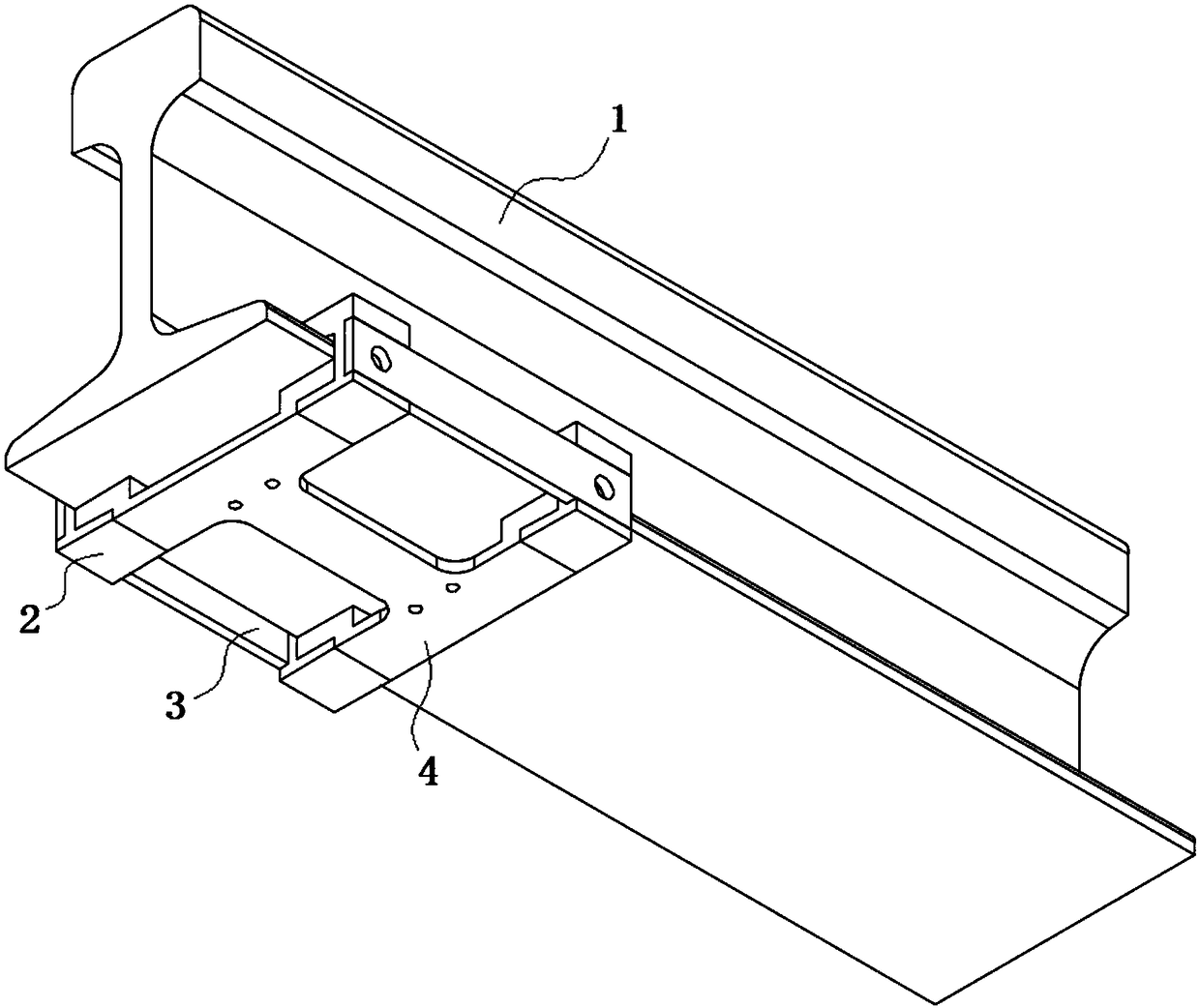

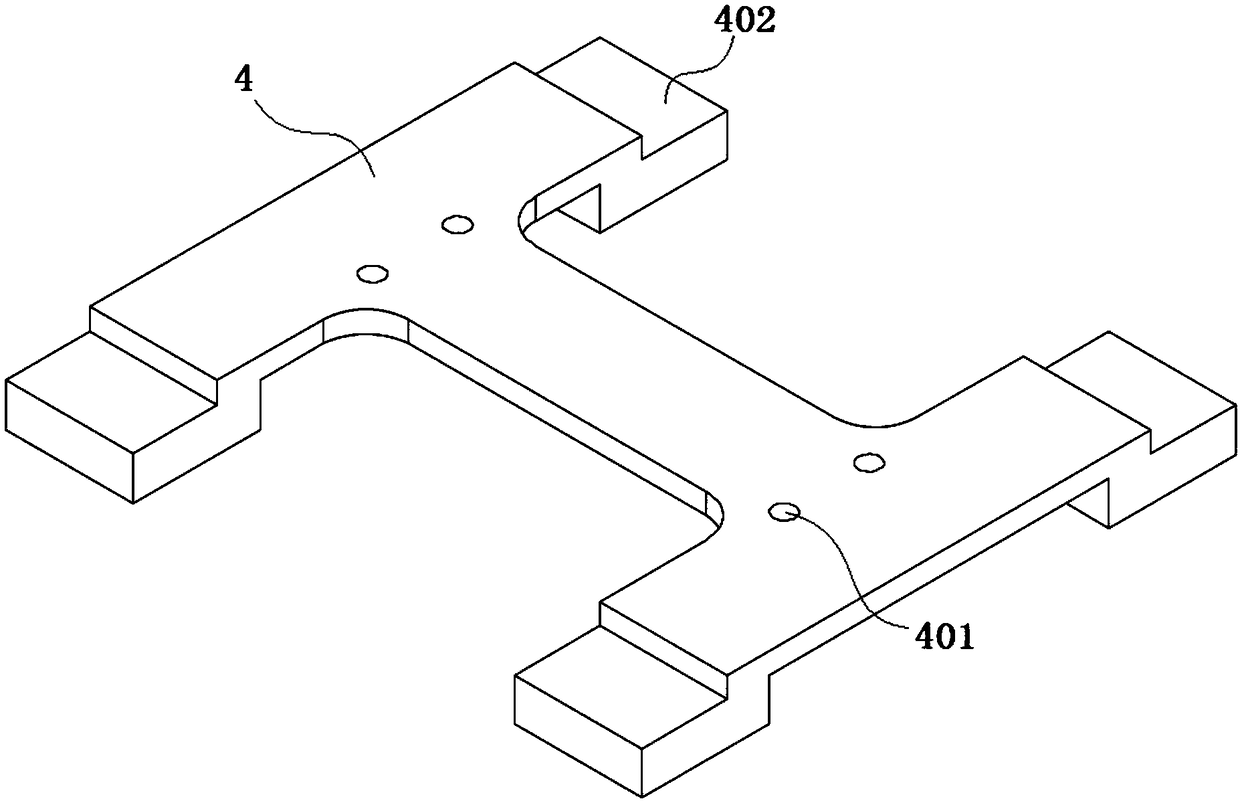

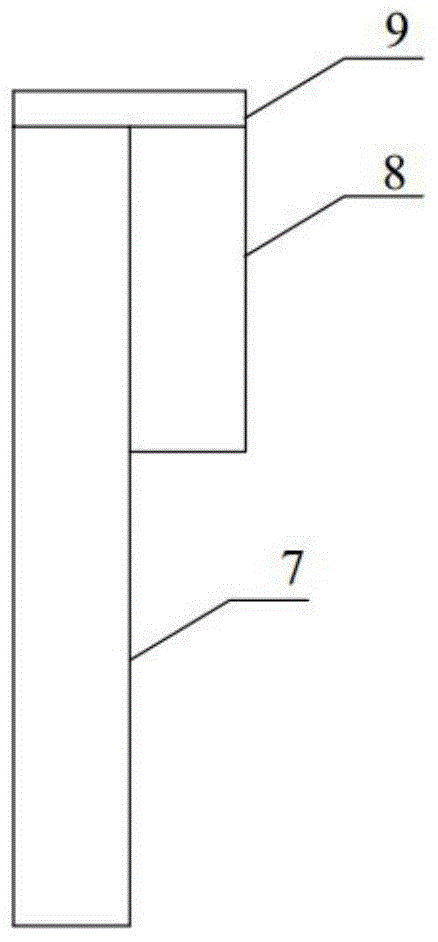

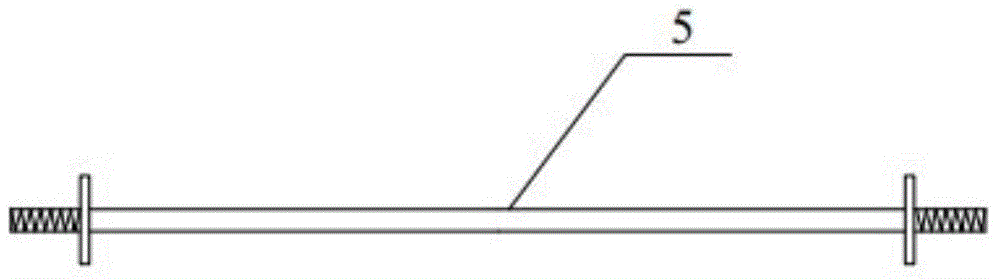

ActiveCN103882813AMeet the structural stress requirementsUse less materialBridge erection/assemblyCorbelColumn model

The invention discloses a corbel bracket platform for bridge pier and transverse straining beam synchronous construction. The corbel bracket platform is characterized in that the positions, with the equal height, in the middle of semicircular steel molds on the two sides of the upper portion of a pier column model (1) are respectively provided with a corbel (2) in a welding mode, jacks (3) are installed on the corbels (2), I-beams (4) are placed on the jacks (3) in the horizontal direction, the I-beams (4) on the two sides of the pier column model (1) are connected together through pulling rods (5) and fastened on the pier column model (1), and distributive beams (6) are placed between the I-beams (4) at equal intervals. The invention further discloses a construction method of the corbel bracket platform. According to the corbel bracket platform, synchronous construction of a pier column and a transverse straining beam is achieved, the construction cycle period of components below a bridge is shortened, and the bridge construction progress is accelerated. Meanwhile, compared with a traditional construction scheme, the input material cost is low, materials of the platform of the transverse training beam can be completely recycled for coping beam construction, and the circulating utilization rate of the materials is high.

Owner:CHINA RAILWAY ERJU 1ST ENG +1

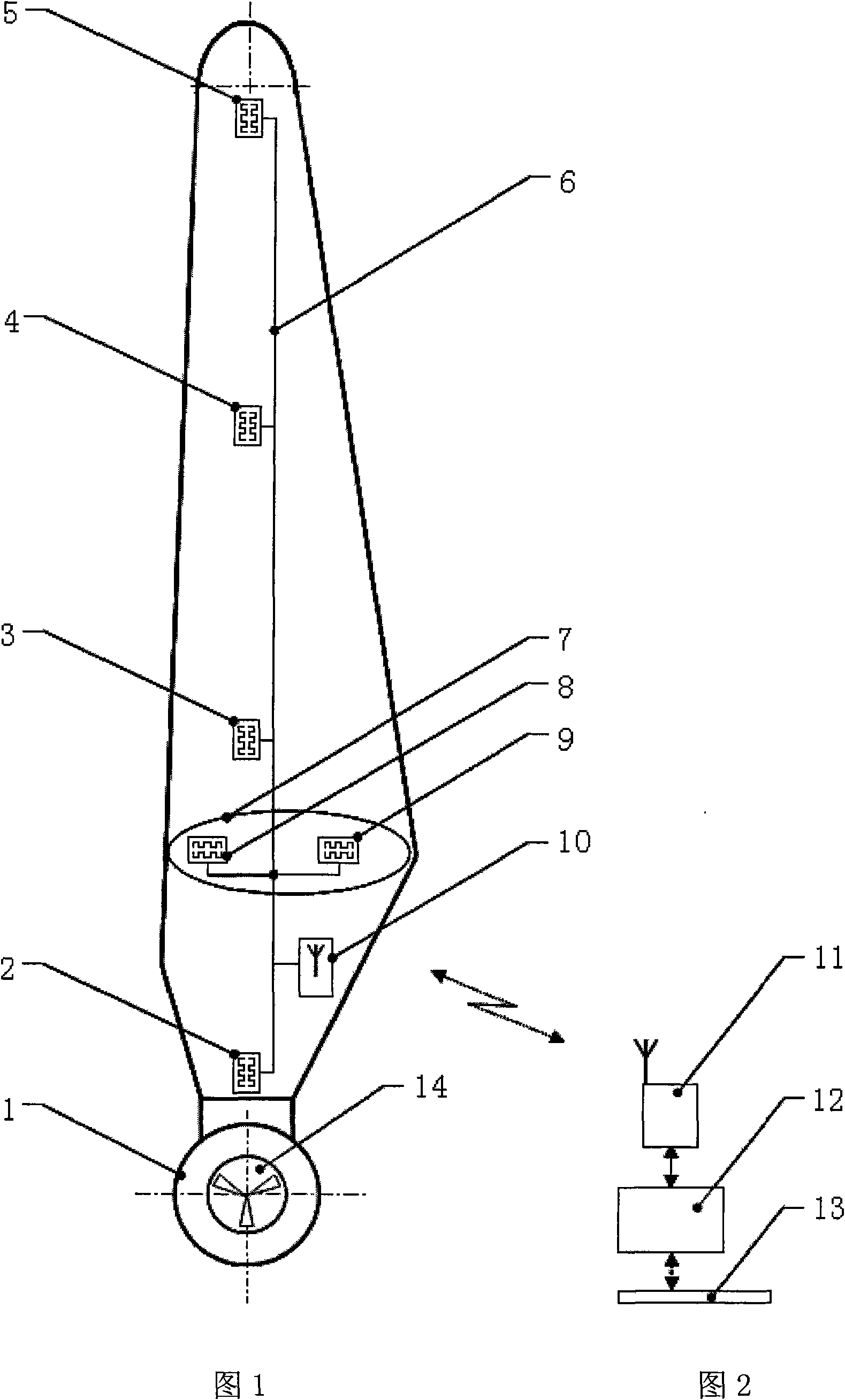

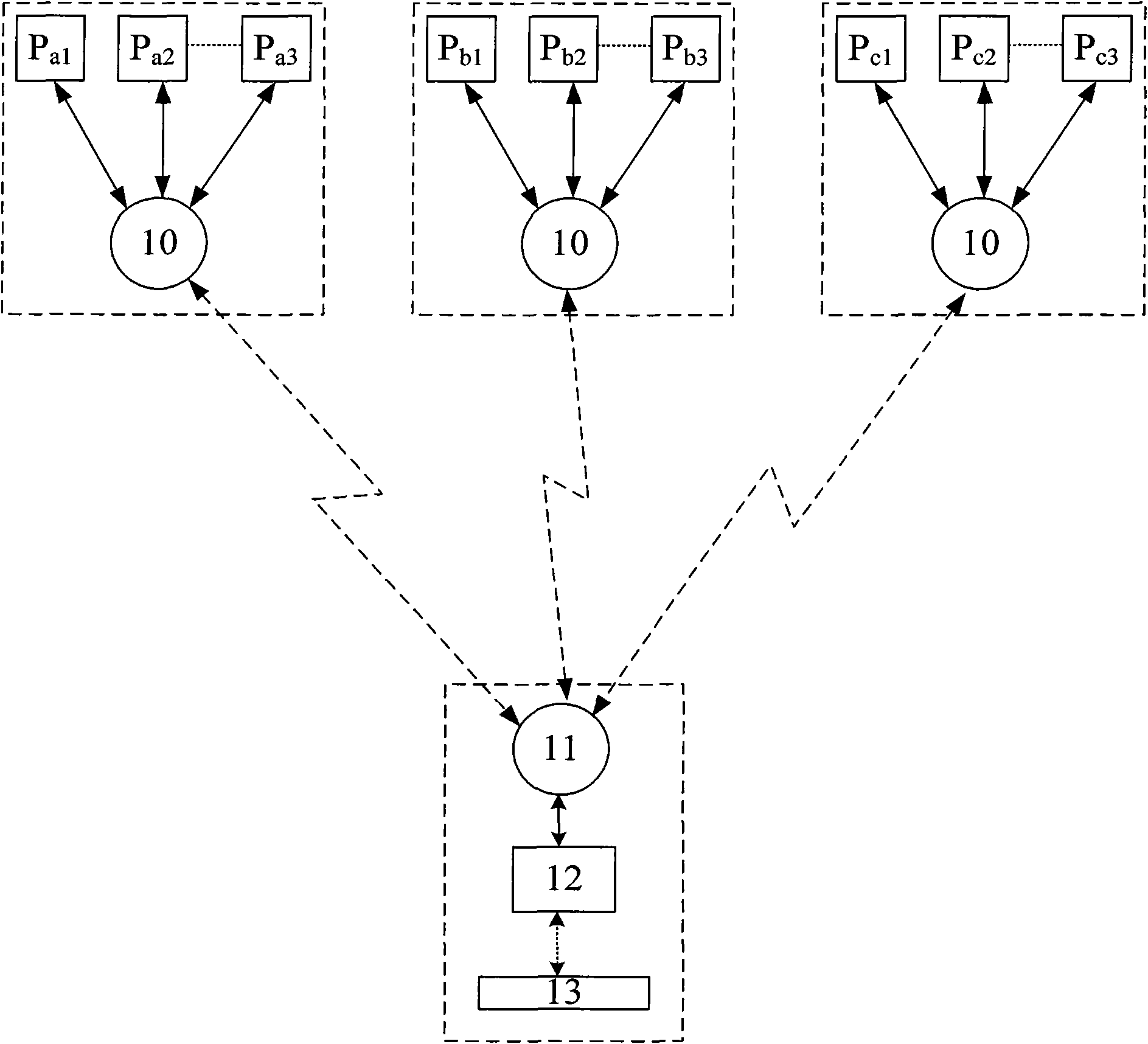

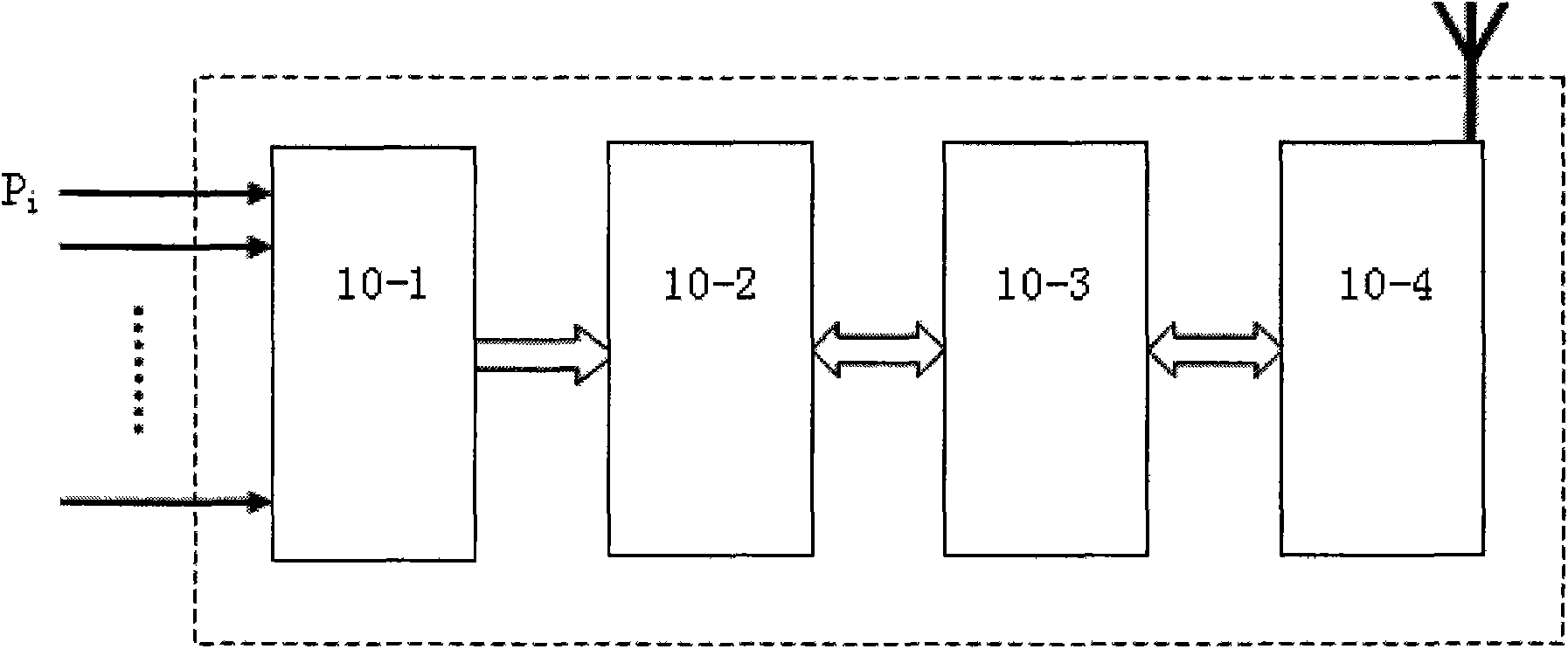

Online real-time monitoring method for dynamic deflection deformation of wind driven generator blade

InactiveCN101982724AGuaranteed real-time accessThe method is simple and reliableTransmission systemsElectrical/magnetic solid deformation measurementWind drivenEngineering

The invention relates to an online real-time monitoring method for dynamic deflection deformation of a wind driven generator blade. When the blade is deformed, a longitudinal strain detection strain sheet and a transverse strain detection strain sheet input signals of the blade to a differential half-bridge signal detection and conditioning module for detecting and conditioning a strain analog signal of a strain sheet of a detected point respectively, the signals are converted into digital quantity by an analog-to-digital converter, the digital quantity is coded by a microprocessor, a wireless transmitting / receiving module transmits the signals, and the wireless transmitting / receiving module receives control instructions sent by monitoring instrument equipment; the monitoring instrument equipment processes, stores and displays the detected data and transmits the detected data through an interface; and a control center performs blade deformation reconstruction according to the detected data to obtain fatigue degree of the blade so as to achieve the goal of real-time detection of the blade. The method realizes long-term monitoring of online deformation of the rotary blade, and acquires the working condition of the rotary blade at the current moment from a data terminal by wireless data transmission technology. The combination of a wind driven generator and a storage battery ensures long-term operation of a monitoring system and data transmission thereof and effectively ensures real-time acquisition of the working condition data of the rotary blade.

Owner:TONGJI UNIV

Field rock mass poisson ratio test method

InactiveCN104483199AFully reflect the real stateLow costMaterial strength using tensile/compressive forcesElectrical/magnetic solid deformation measurementElectrical resistance and conductanceBedrock

The invention discloses a field rock mass poisson ratio test method. The method comprises the steps of firstly digging a test flat hole in a mountain, drilling a cylindrical test piece on bedrock on the bottom surface of the test flat hole by utilizing a hollow drill bit, and symmetrically perforating test holes in the bottom of an annular groove at the periphery of the test piece; sleeving the test piece with an elastic steel lantern ring provided with a steel contact and a strain plate, connecting a strain plate test line and a resistance strain gauge, and calculating transverse deformation of the test piece by virtue of test; fixing the top surface of the test piece together with a test flat hole top plate sequentially through a pressure plate, a jack, a reducing connector steel plate, a combined force transfer rod and a hinge anchor, installing measuring points in bolt holes in two sides of the pressure plate and in the test holes in the bottom of the annular groove, and installing a dial indicator above the measuring point; calculating vertical deformation of the test piece after the load test; then calculating a corresponding transverse strain value and a vertical strain value, and calculating the poisson ratio of the test piece according to the transverse strain value and the vertical strain value. The field rock mass poisson ratio test method has advantages that the implementation method is simple and rapid, the measurement data is accurate and reliable, and the real condition of the rock mass can be comprehensively reflected.

Owner:YELLOW RIVER ENG CONSULTING

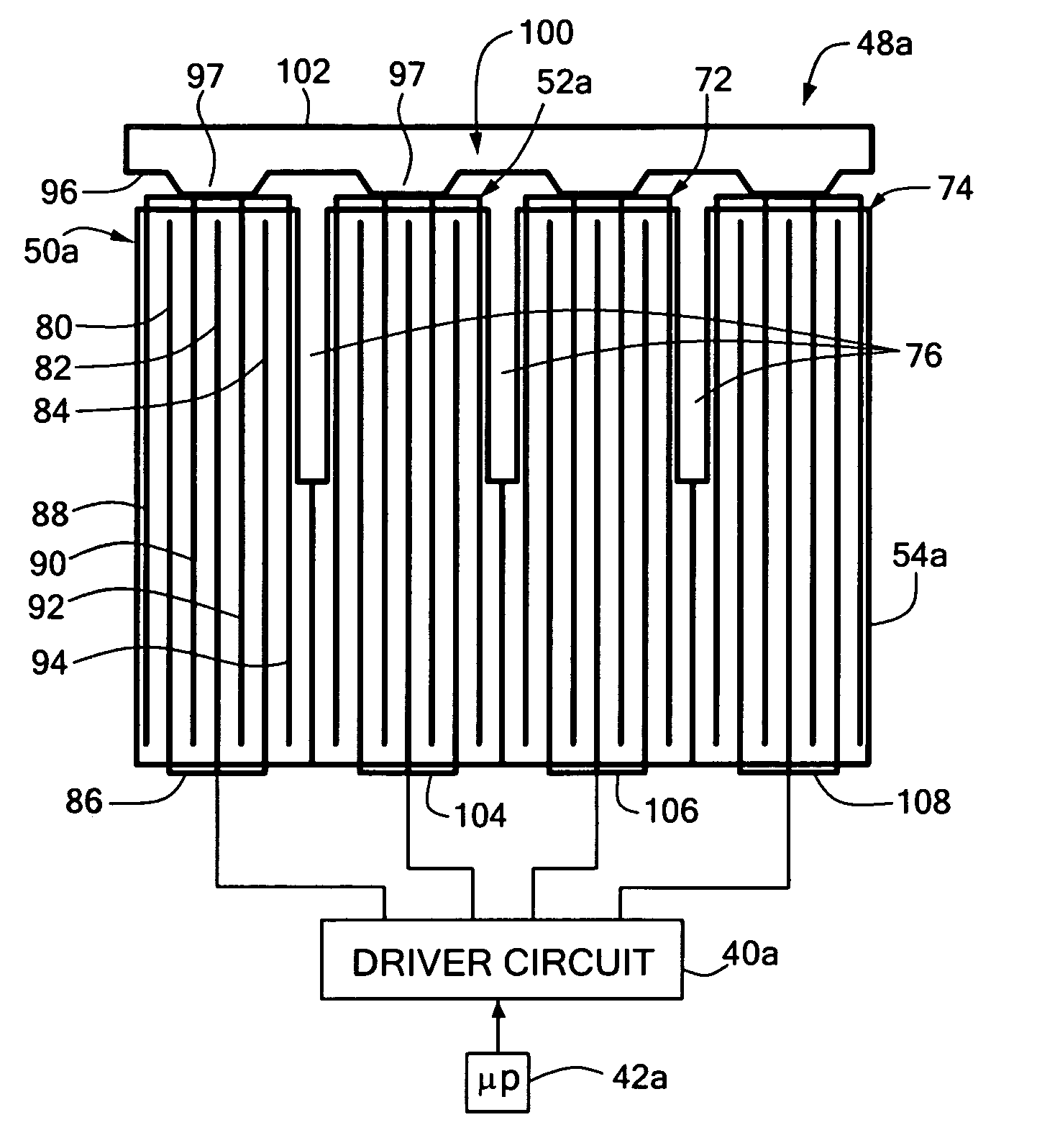

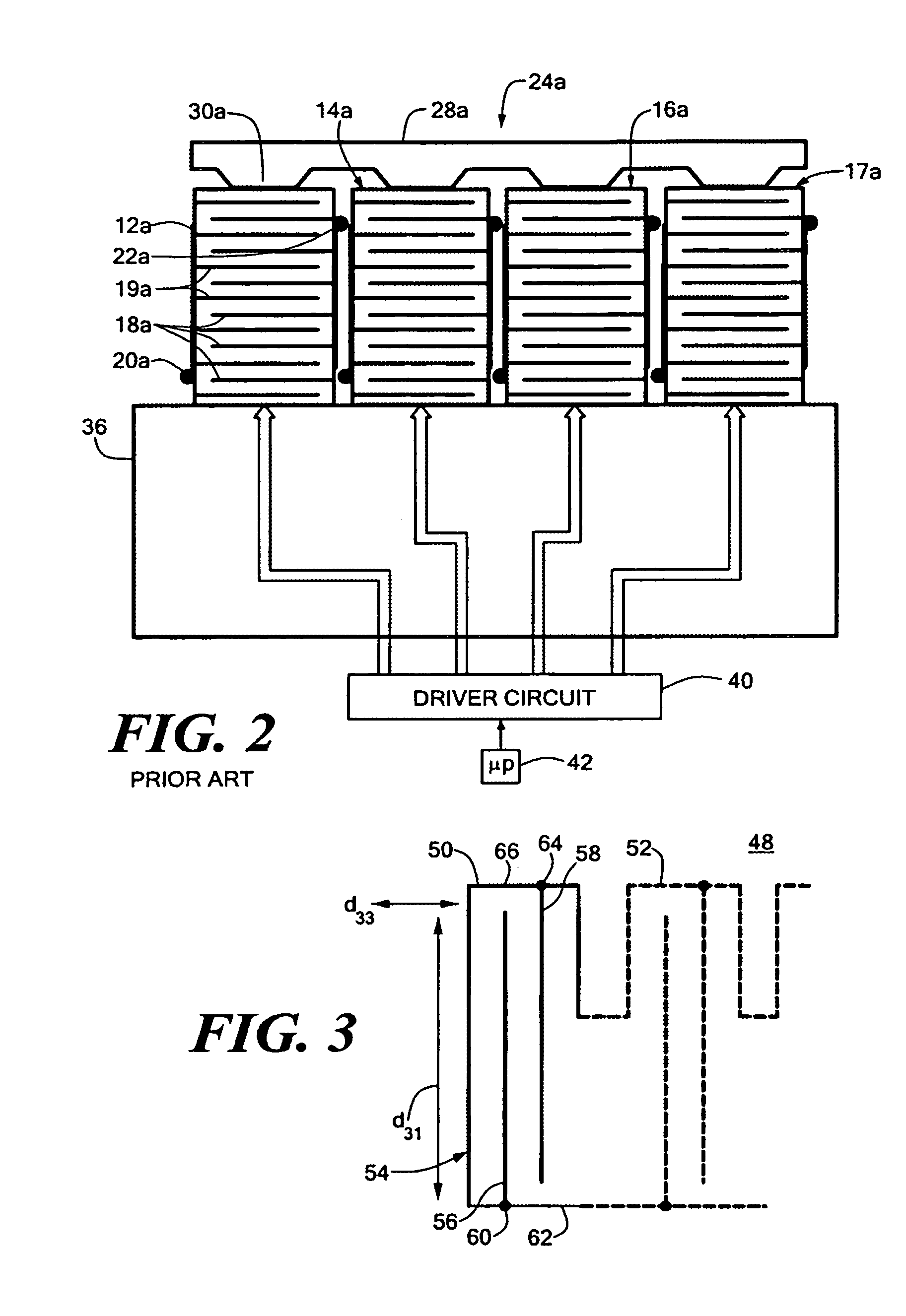

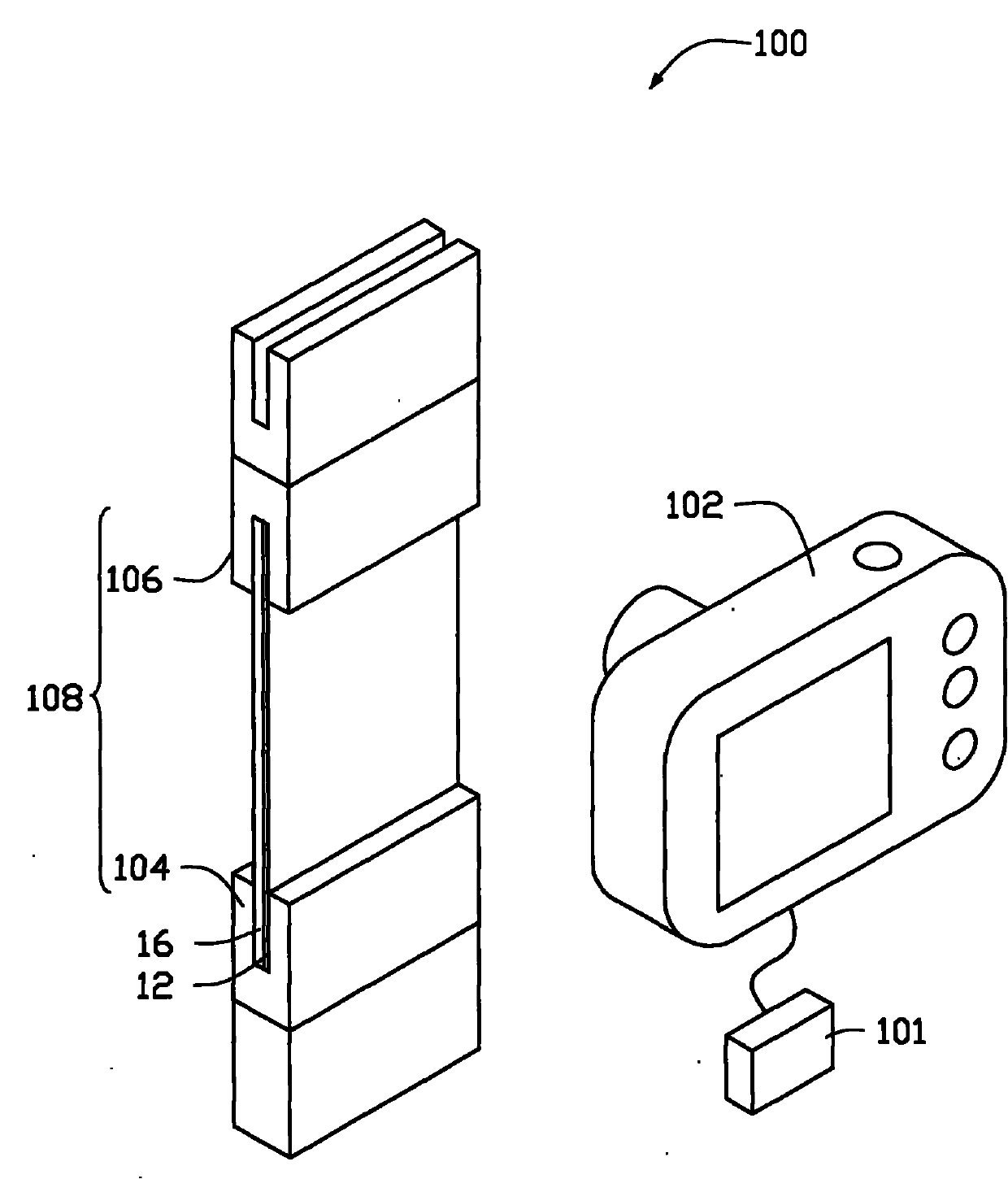

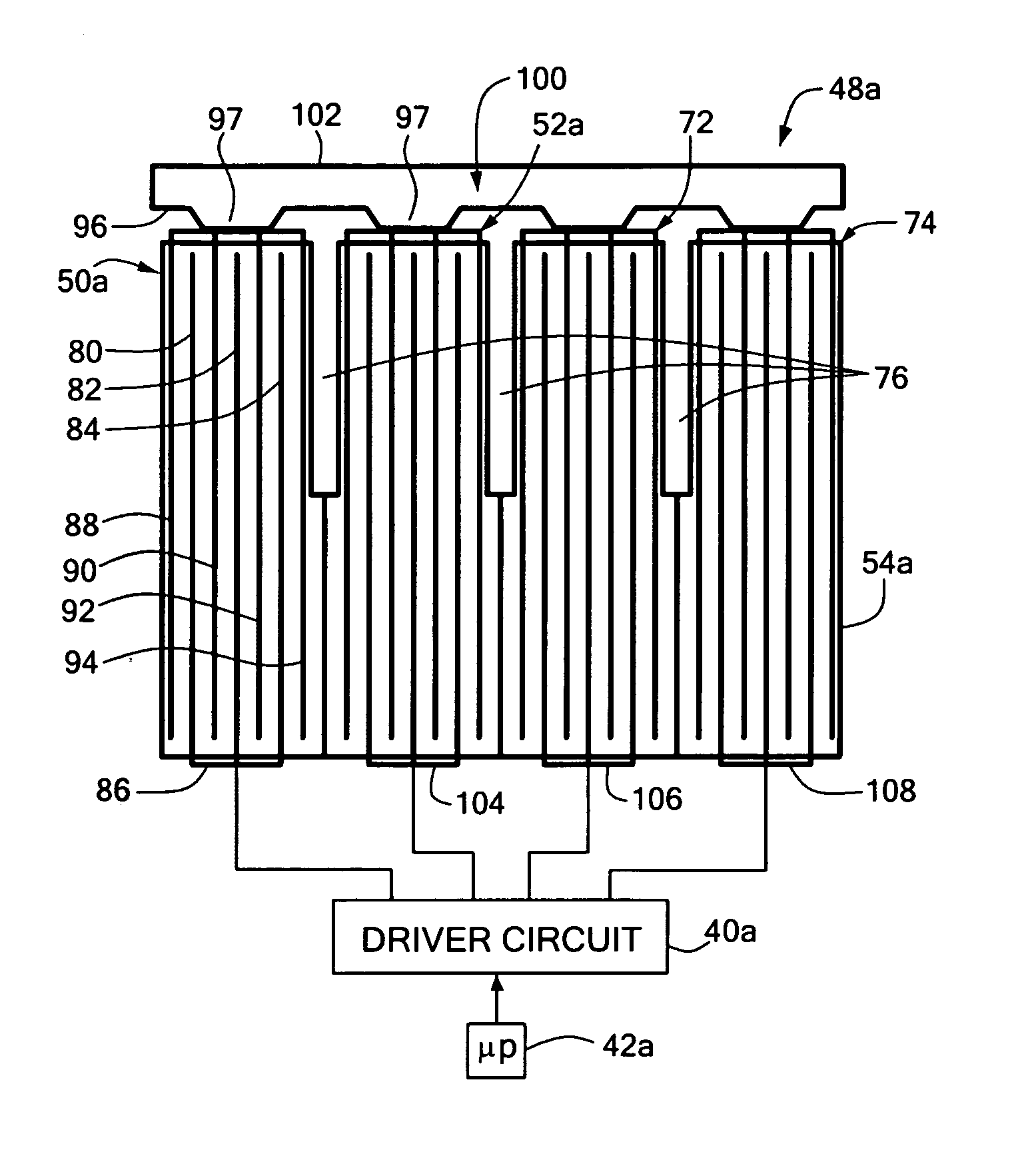

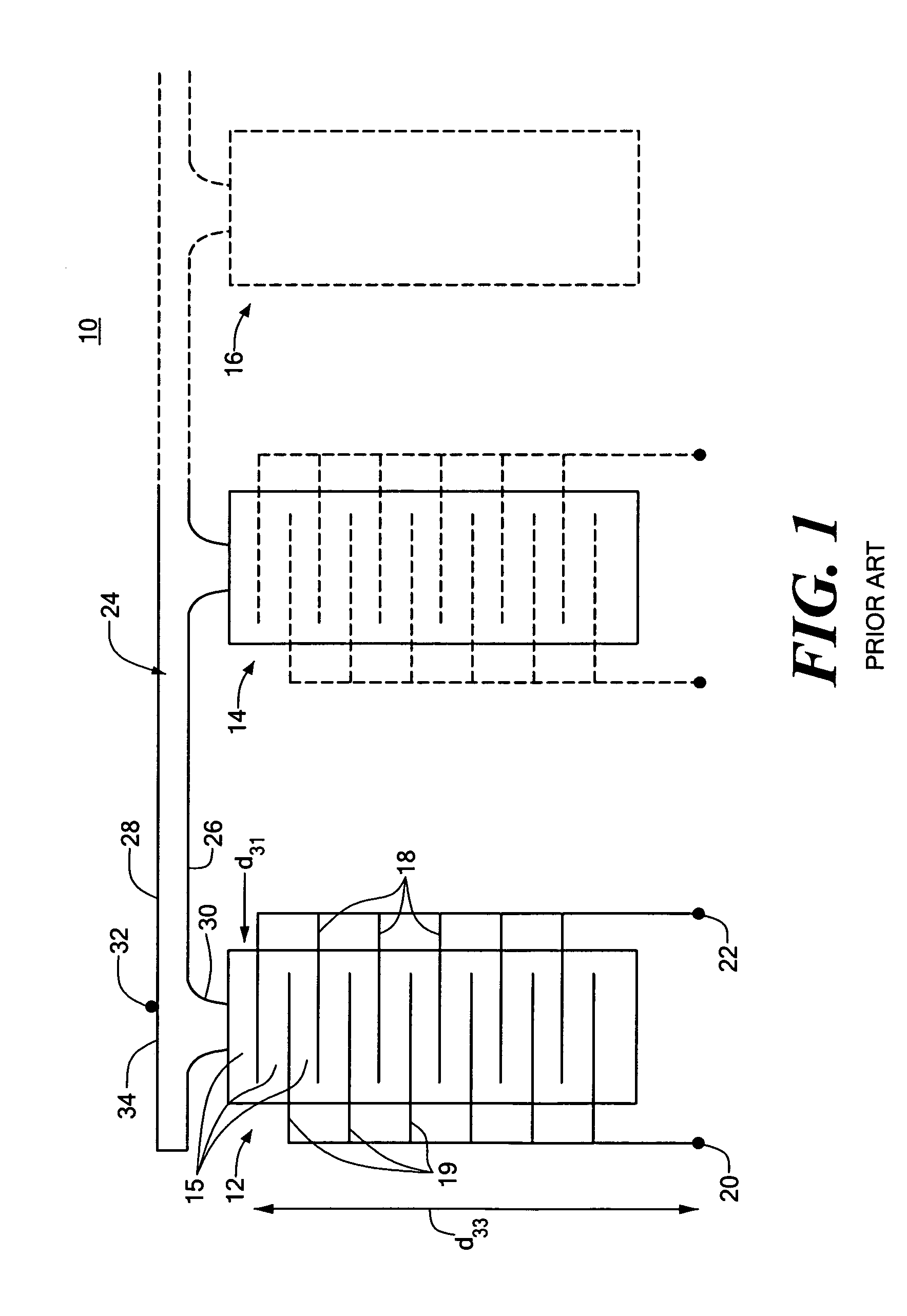

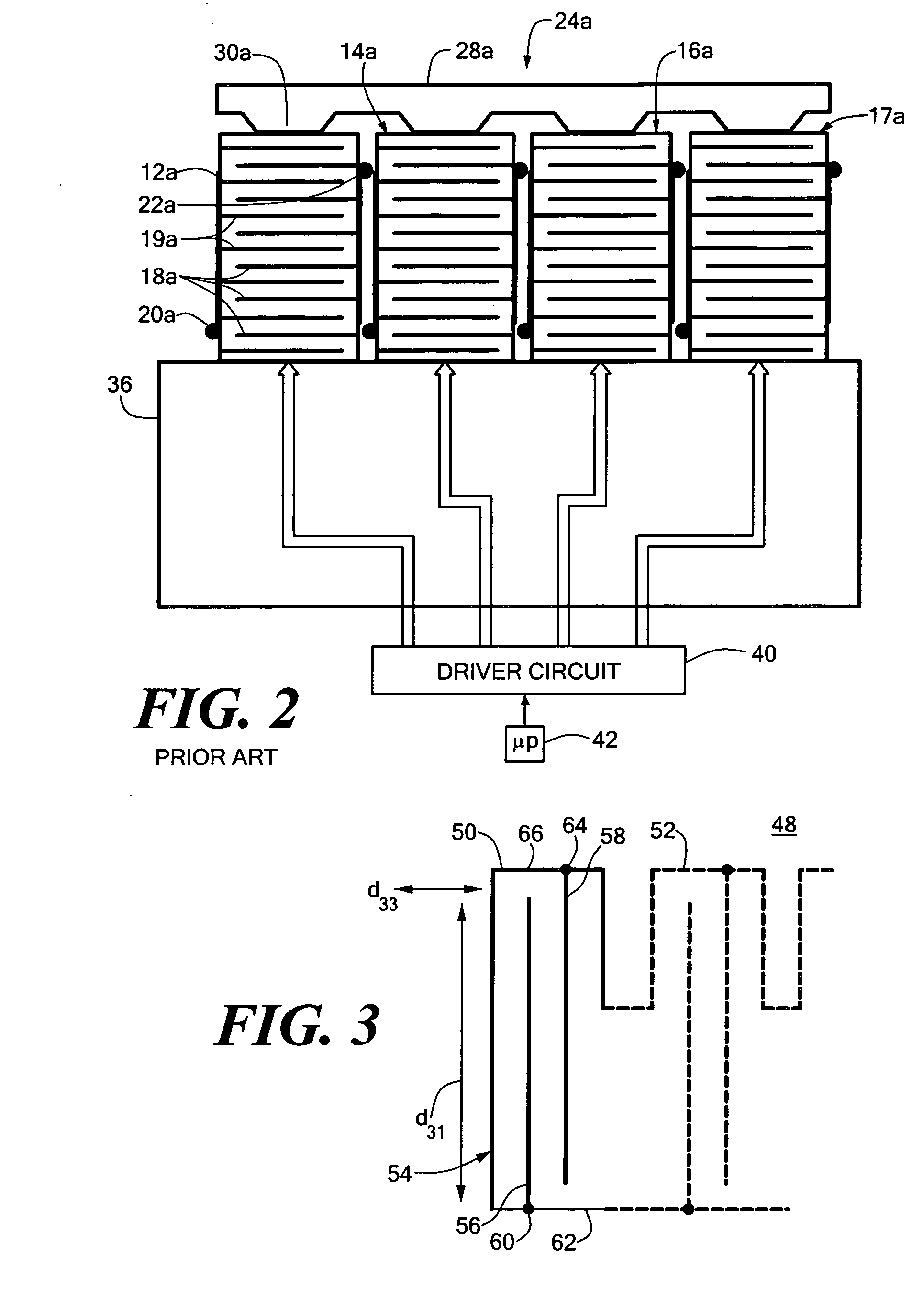

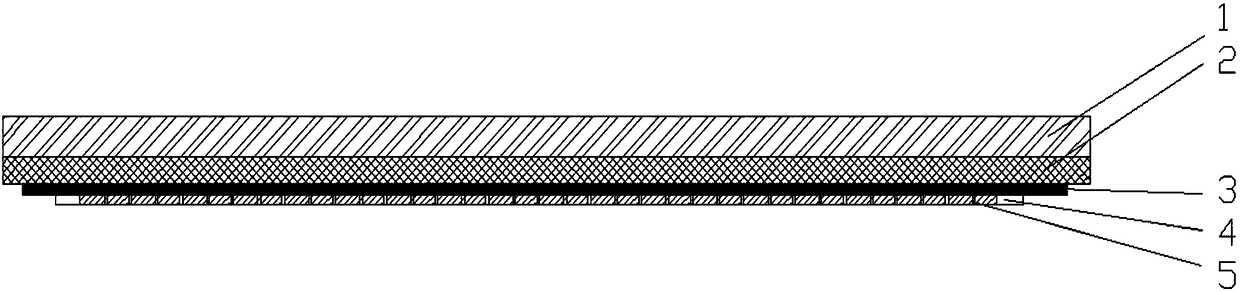

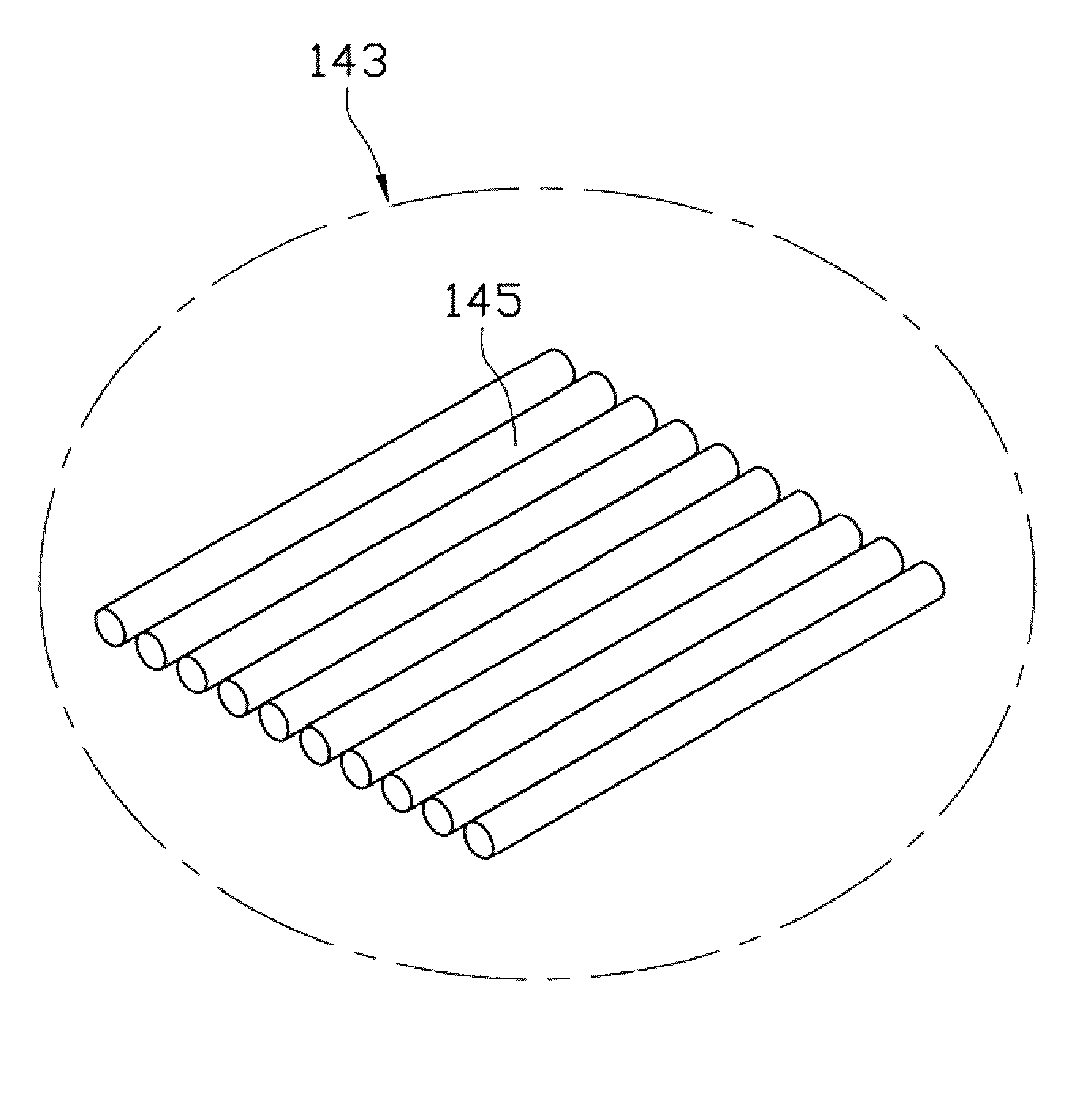

Transverse electrodisplacive actuator array

A transverse electrodisplacive actuator array for controlling the optical phasing of a reflective surface includes a support structure; a plurality of electrodisplacive actuator elements extending from a proximate end at the support structure to a distal end; each actuator element including at least one addressable electrode and one common electrode spaced from the addressable electrode and extending along the direction of said proximate and distal ends along the transverse d31 strain axis; a reflective member having a reflective surface and a mounting surface mounted on the actuator elements; and a plurality of addressable contacts and at least one common contact for applying voltage to the addressable and common electrodes to induce a transverse strain in addressed actuator elements to effect an optical phase change in the reflective surface at the addressed actuator elements.

Owner:NORTHROP GRUMMAN SYST CORP

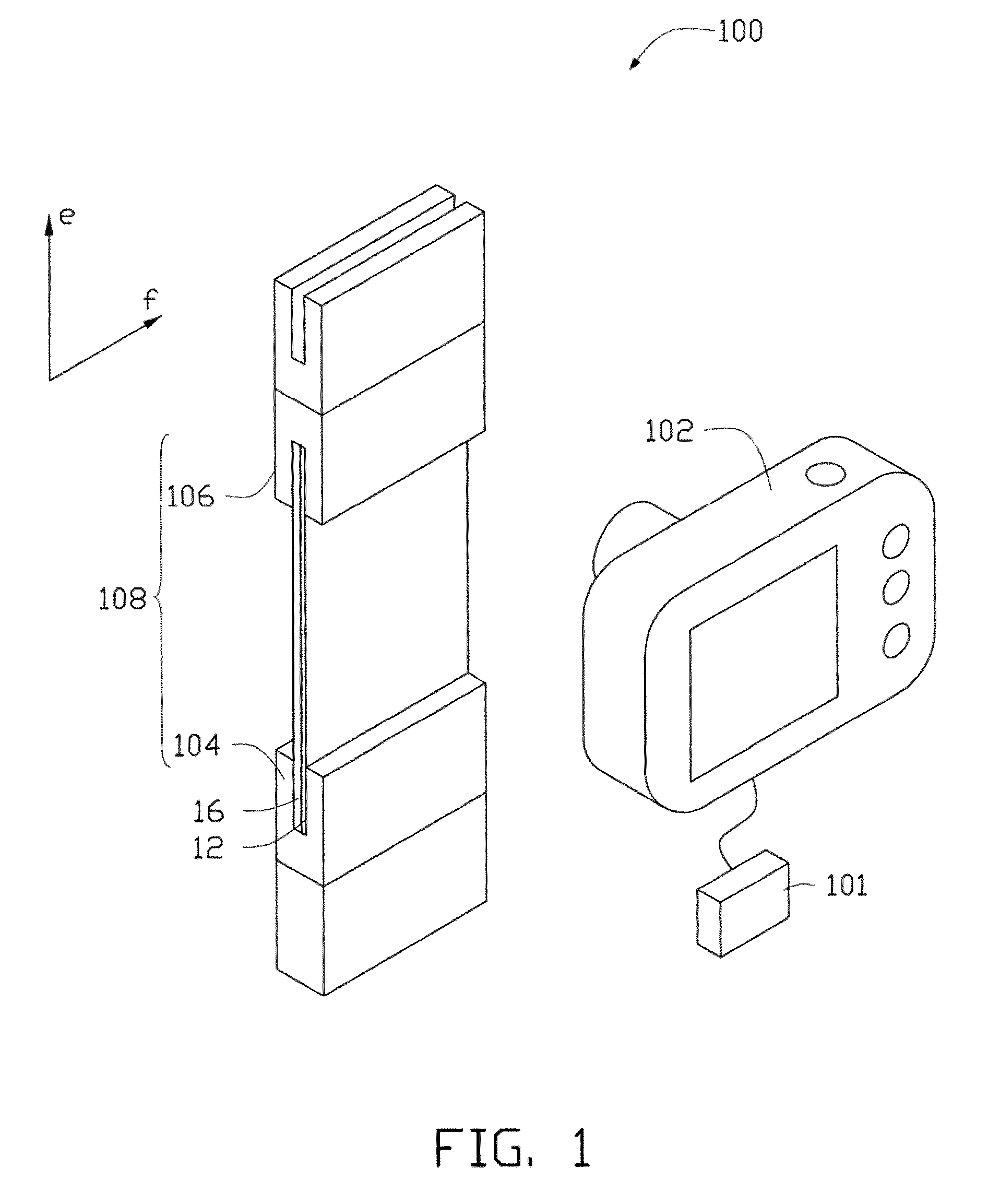

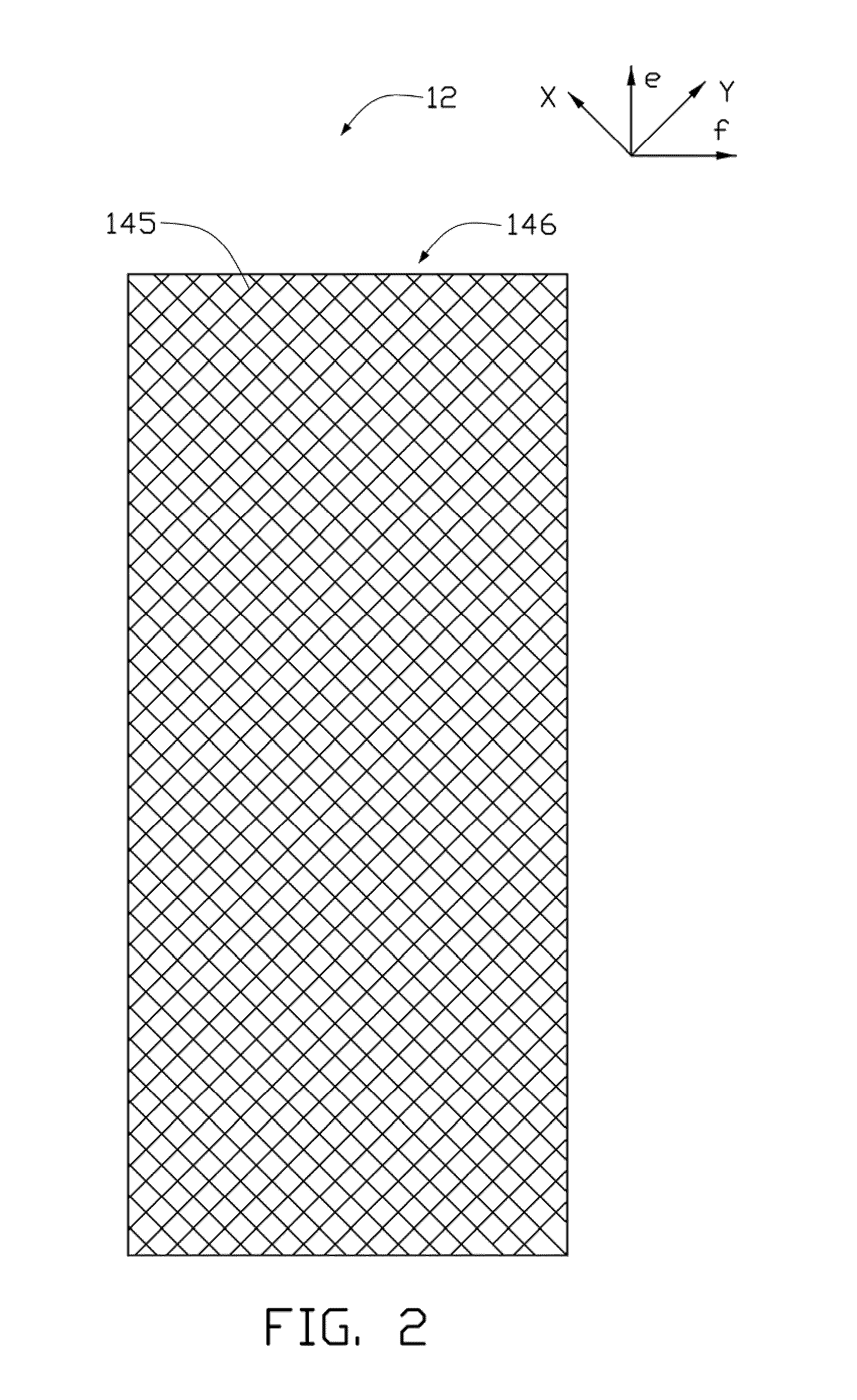

Device and method for measuring strain

ActiveCN102087101AEasy to measureEasy to operateMaterial nanotechnologyNanosensorsCarbon nanotubeStrain gauge

The invention provides a device for measuring strain. The device for measuring the strain comprises a strain gauge, a clamping device, and a transverse strain recorder, wherein the clamping device is used for clamping and extending the strain gauge, the longitudinal strain of the strain gauge is generated in the extension direction, and the transverse strain of the strain gauge is generated in the direction vertical to the extension direction; the transverse strain recorder is used for measuring the transverse strain of the strain gauge; the strain gauge comprises a carbon nano tube membrane structure which comprises a plurality of carbon nano tubes; the carbon nano tubes are arranged along the preferred orientations of a first direction and a second direction, and the carbon nano tubes which are directionally arranged along the preferred orientation of the first direction and the carbon nano tubes which are arranged along the directional preferred orientation of the second direction are overlapped and intersected; an included angle between the first direction and the second direction is formed; the included angle is more than 0 degree and less than 180 degrees; and during using, the strain gauge is arranged on the clamping device along the direction of a bisector of the included angle between the first direction and the second direction. The invention also provides a method for measuring the strain by using the device for measuring the strain.

Owner:TSINGHUA UNIV +1

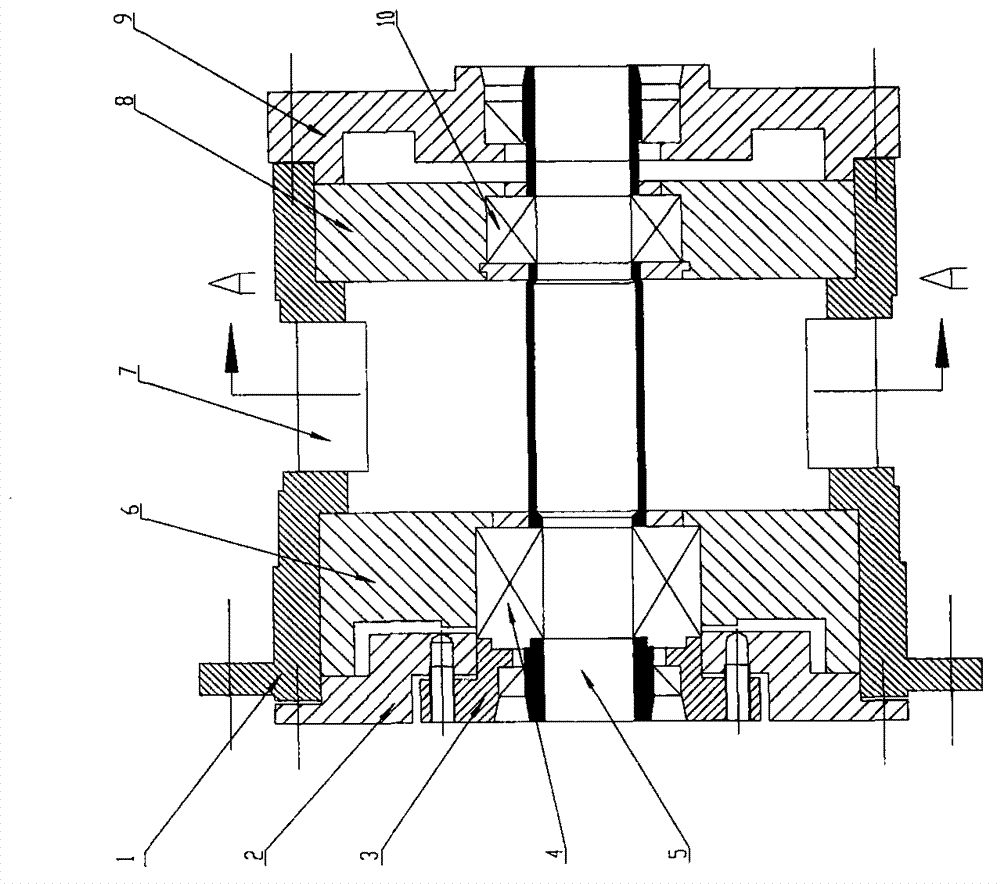

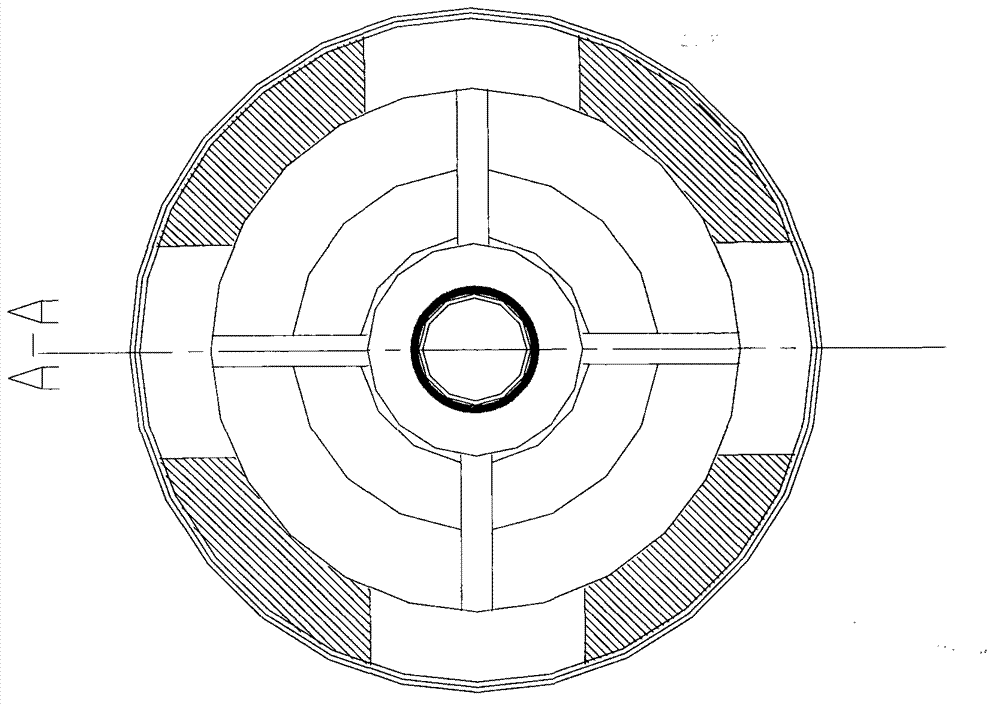

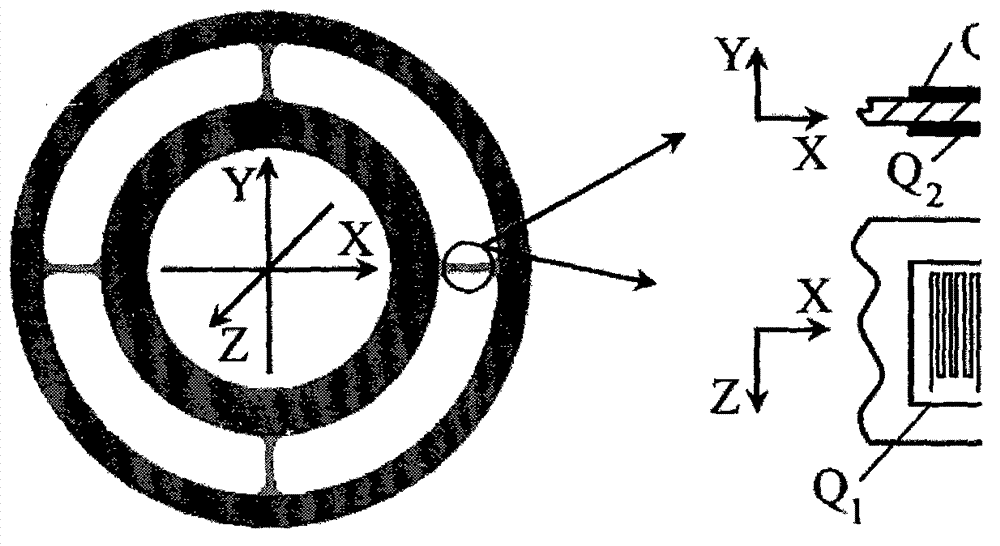

Device for measuring radial force of transient-state hydraulic power of centrifugal pump and measuring method thereof

ActiveCN102901598ASimple structureLow priceApparatus for force/torque/work measurementForce/torque/work measurement apparatus calibration/testingTransient stateMeasurement device

The invention provides a device for measuring radial force of transient-state hydraulic power of a centrifugal pump and a measuring method thereof, and discloses a measuring device. The measuring device comprises a shell 1, a back fixed ring 2, a compaction plate 3, a tight bearing 4, a shaft cavity 5, tight bearing elastic supports 6, an operation hole 7, loosened bearing elastic supports 8, a loosened bearing 9 and a front fixed ring 10, wherein outer rings of the tight bearing 4 and the loosened bearing 9 are connected and fixed with the shell 1 of the device by four elastic supports 6 and 8 respectively; the elastic supports are distributed at intervals of 90 degrees; a longitudinal strain plate and a transverse strain plate are respectively arranged on each side; for calibration, an object of which the mass is known is placed at the front end of a pump shaft, output signals of a circuit are amplified, acquired and output in a combined mode, and data of the device in each direction are recorded. The mass of the object arranged at the front end of the pump shaft is changed and is measured for many times by using the same method, so that the calibration of the device and the conversion of a measuring value are realized.

Owner:JIANGSU UNIV

Transverse electrodisplacive actuator array

ActiveUS20050128558A1Reduce interface stressRelieve pressureMirrorsSolid-state devicesSurface mountingPhase change

A transverse electrodisplacive actuator array for controlling the optical phasing of a reflective surface includes a support structure; a plurality of electrodisplacive actuator elements extending from a proximate end at the support structure to a distal end; each actuator element including at least one addressable electrode and one common electrode spaced from the addressable electrode and extending along the direction of said proximate and distal ends along the transverse d31 strain axis; a reflective member having a reflective surface and a mounting surface mounted on the actuator elements; and a plurality of addressable contacts and at least one common contact for applying voltage to the addressable and common electrodes to induce a transverse strain in addressed actuator elements to effect an optical phase change in the reflective surface at the addressed actuator elements.

Owner:NORTHROP GRUMMAN SYST CORP

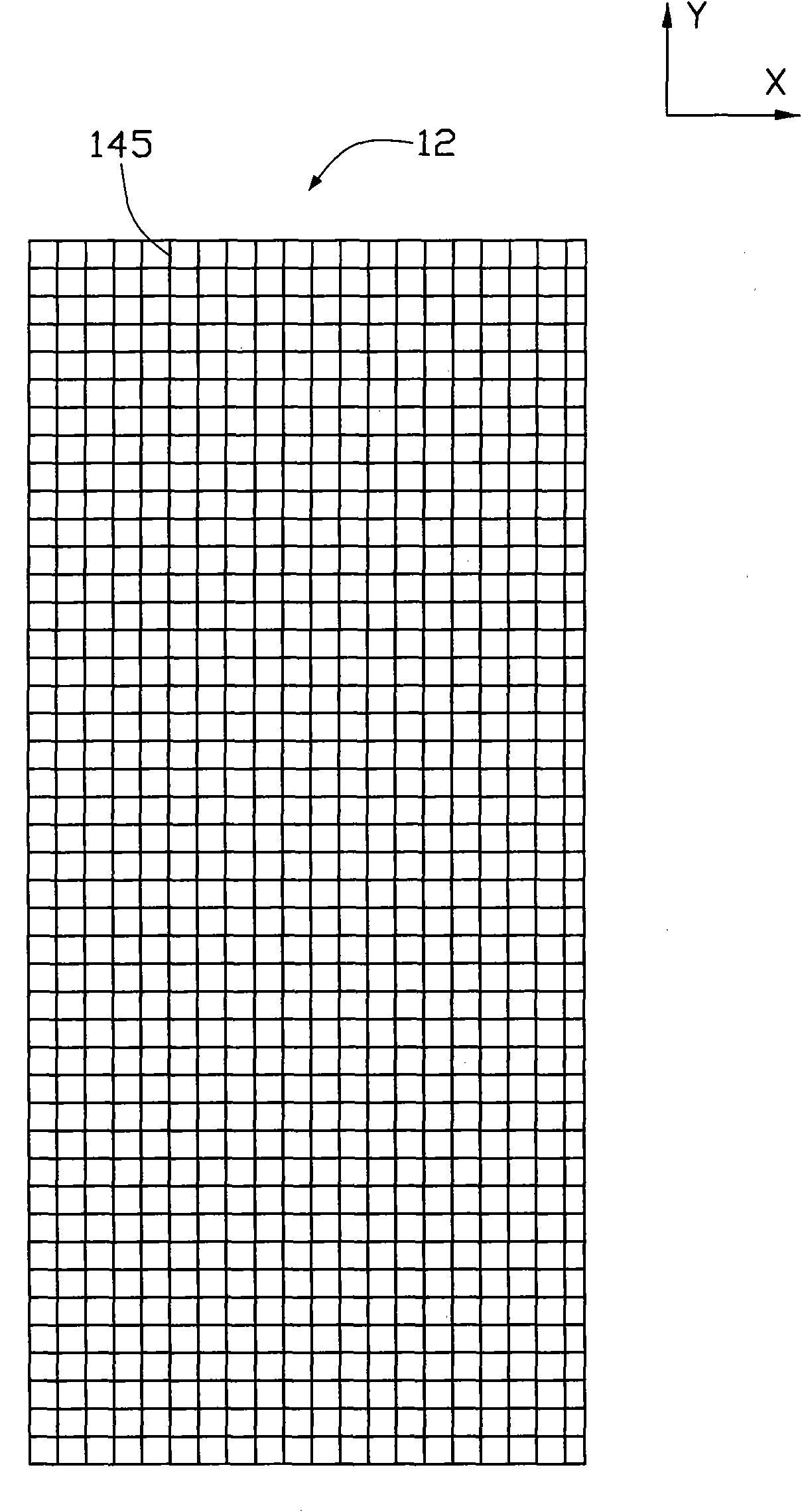

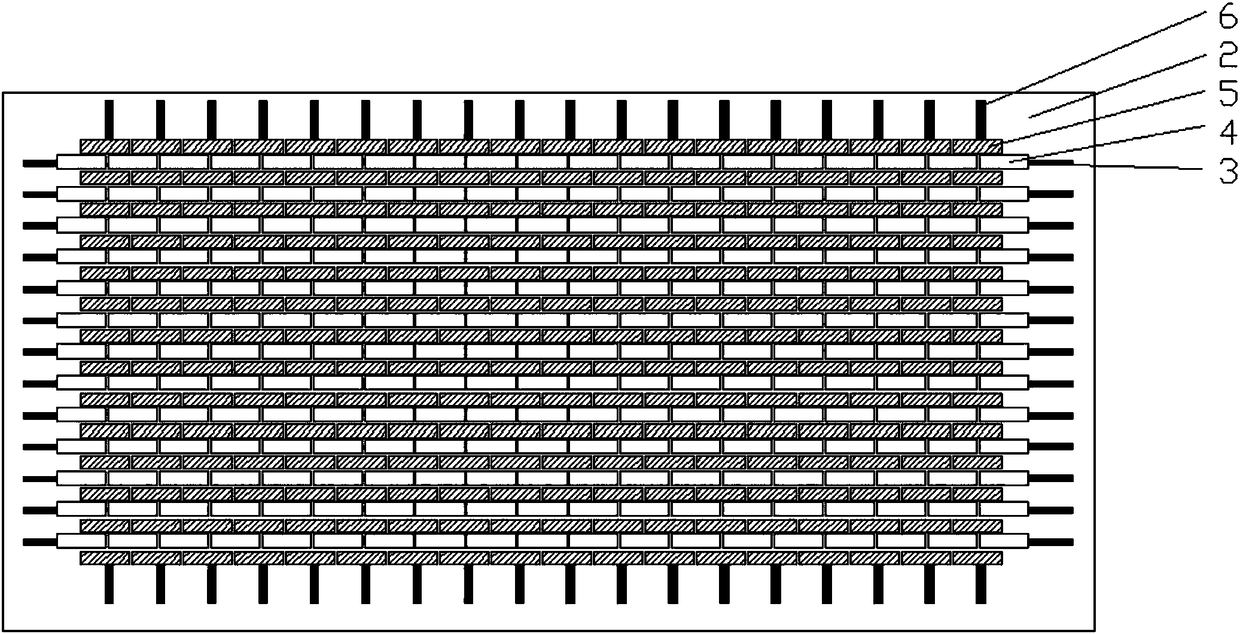

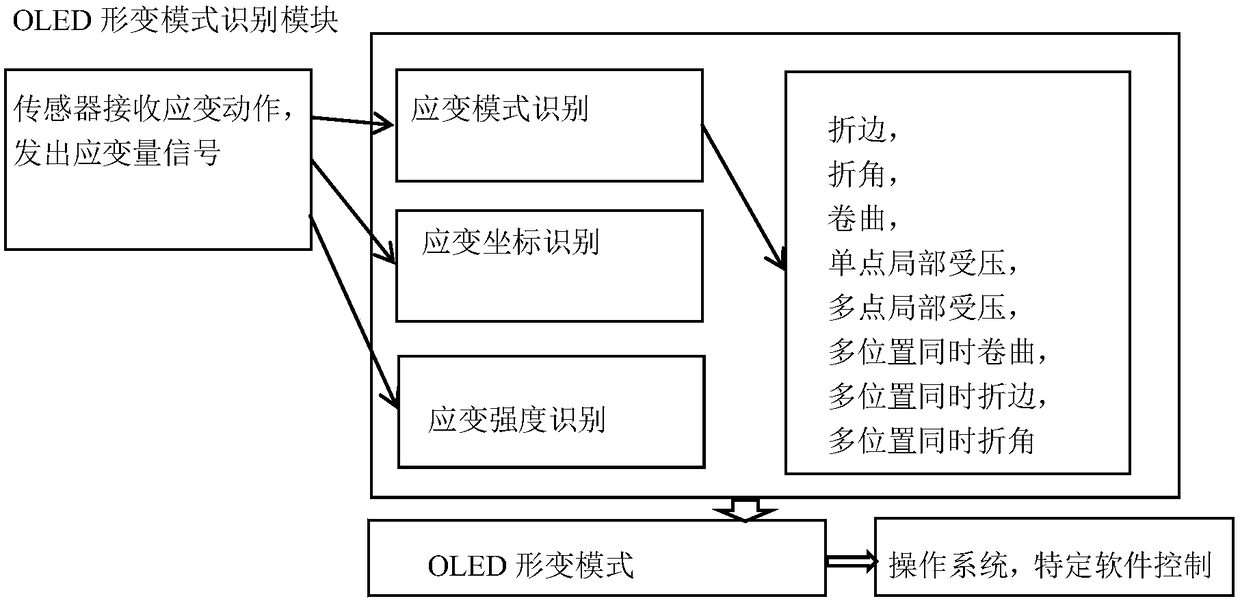

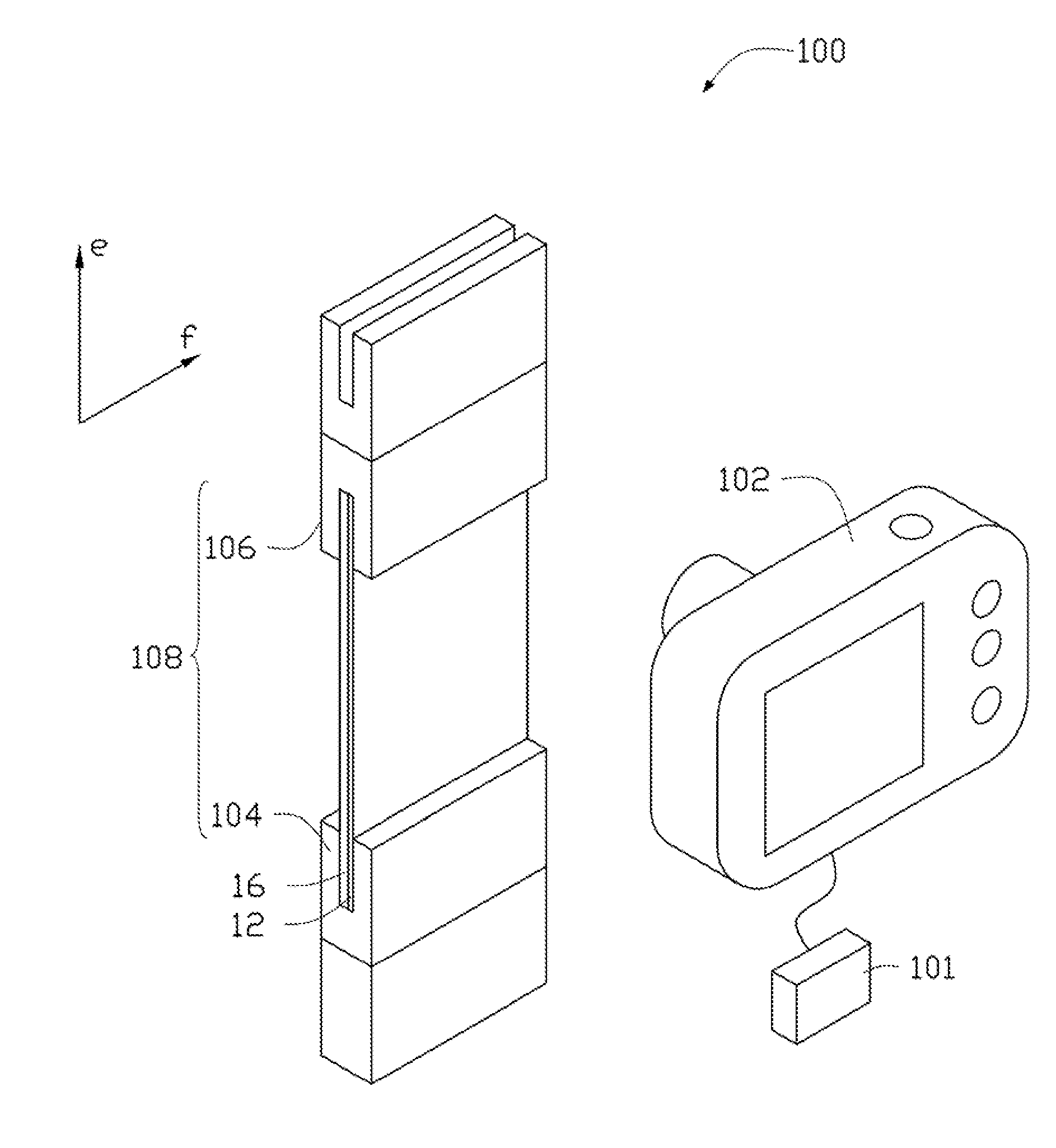

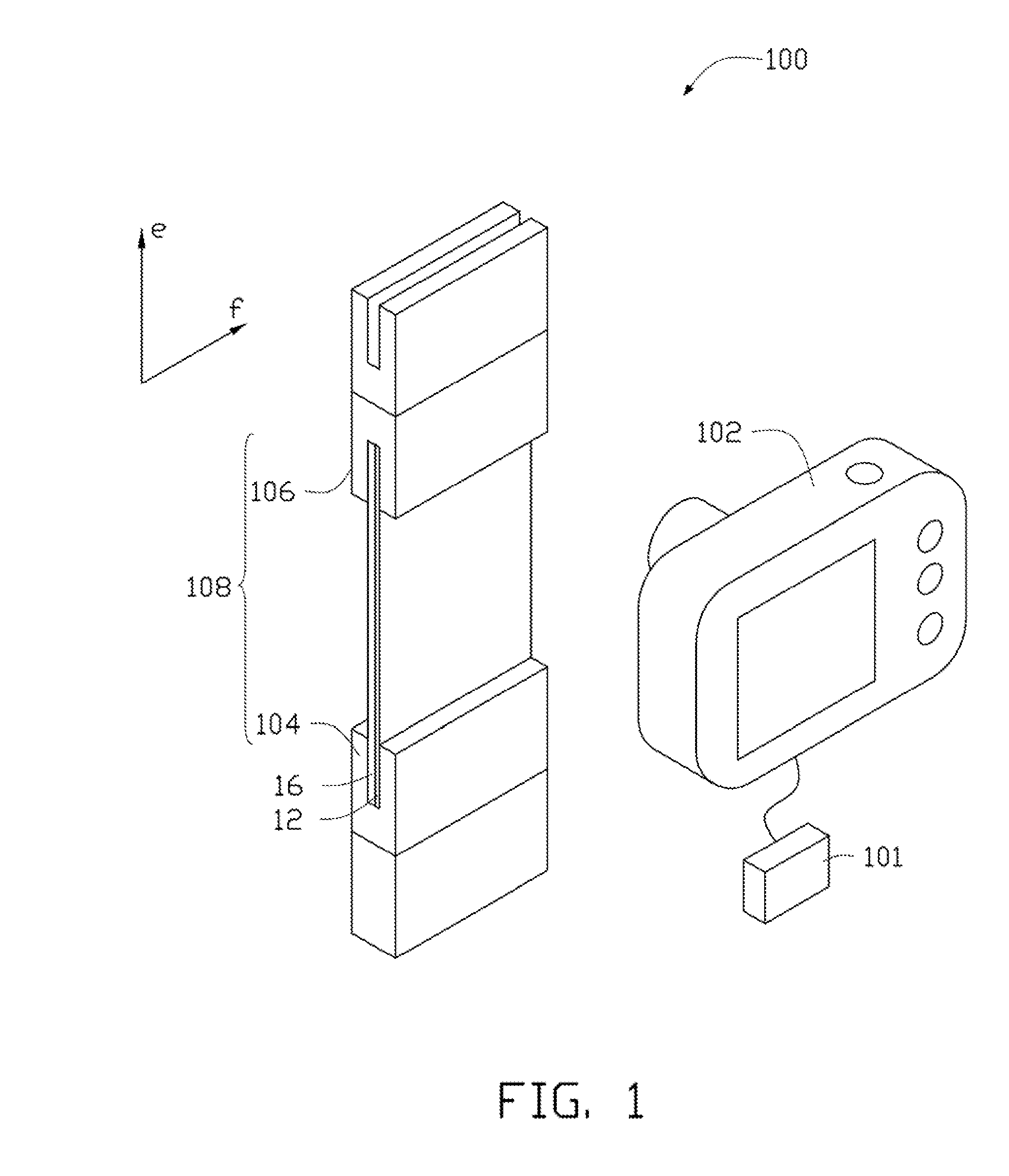

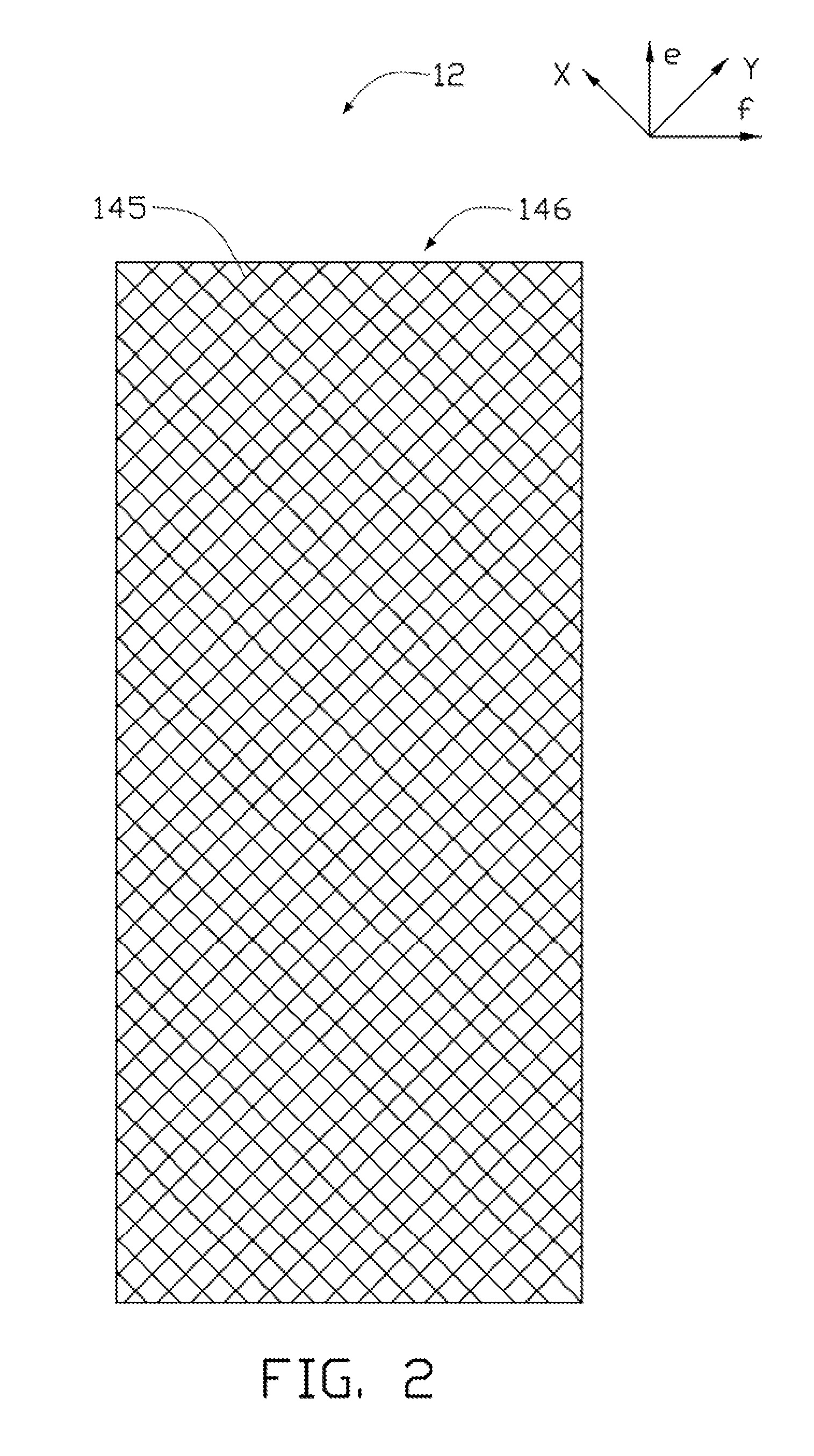

Flexible display deformation sensing system

ActiveCN108571925AElectrical/magnetic solid deformation measurementIdentification meansSensor arrayDisplay device

The invention relates to a flexible OLED (Organic Light Emitting Diode) display deformation sensing system, which comprises a sensor substrate layer attached to the back of a flexible display, whereinthe sensor substrate layer is provided with a sensor array layer, and the sensor array layer is provided with a plurality of leading-out wires. The sensor array layer comprises a strain sensor matrixformed by a transverse array and a longitudinal array, wherein the transverse array is composed of a plurality of transverse strain sensors, the longitudinal array is composed of a plurality of longitudinal strain sensors, each transverse strain sensor is provided with a transverse leading-out wire, and each longitudinal strain sensor is provided with a longitudinal leading-out wire. The transverse array sensor capture longitudinal strain point coordinates and strain values, and the longitudinal array sensors capture transverse strain point coordinates and strain values. The sensor layer cancapture a deformation mode and a deformation device of the display screen in real time. The flexible deformation action of the OLED display is captured into a digital signal so as to be used for controlling the display, a data interaction action and other control actions.

Owner:上海敏传智能科技有限公司

Strain measurement device and method of strain measurement using the same

A strain measurement device includes a strain gauge, a holding device, a transverse strain recorder, and a data processing device. The strain gauge includes at least one first and at least one second layers of carbon nanotube films, each layer of carbon nanotube films having a plurality of carbon nanotubes. The carbon nanotubes in at least one first layer of carbon nanotube film align along a first direction. The carbon nanotubes in at least one second layer of carbon nanotube film align along a second direction. The holding device is used to fasten a specimen and the strain gauge. The transverse strain recorder is used to record a transverse strain of the strain gauge. The data processing device is used to calculate an axial strain of the strain gauge.

Owner:TSINGHUA UNIV +1

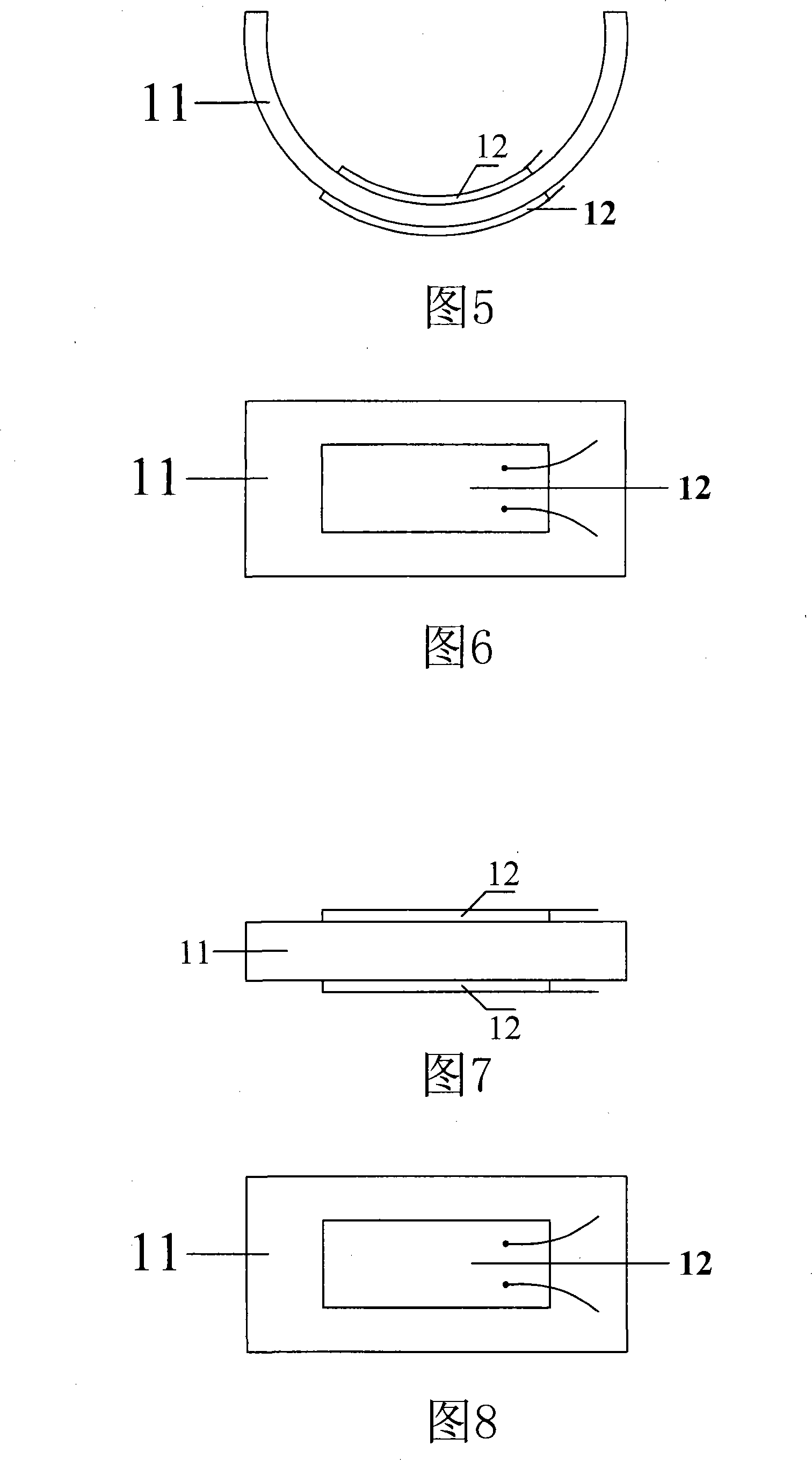

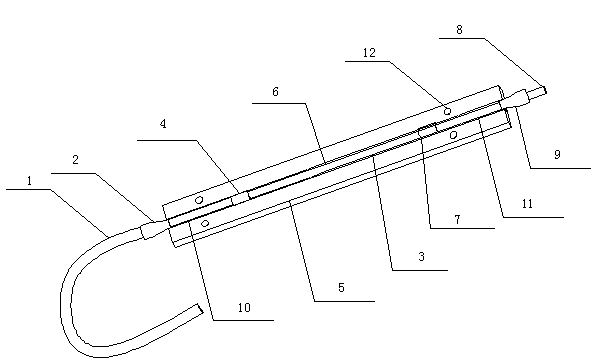

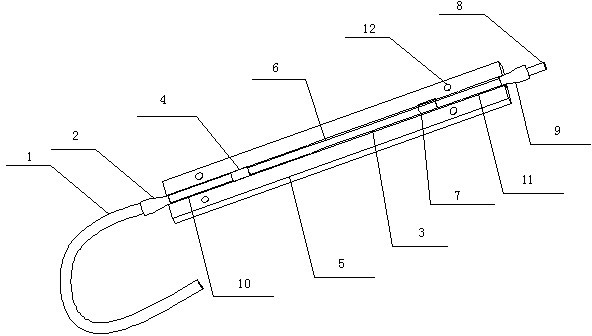

Soft rock large deformation three axis creep test transverse strain measuring extensometer and method

InactiveCN101221162AGuaranteed measurementAccurate measurementEarth material testingElectrical/magnetic solid deformation measurementEngineeringRock sample

An extensometer of the transverse strain measurement of a soft rock three-shaft creep test includes a slide ring, two pairs of supporters, two strips of extension arms, two sense elements and two springs. The inside diameter of the slide ring is larger than an outside diameter of an upper pressure head and a lower pressure head after a maximum deformation; the supporters are symmetrically arranged on two sides of the external ring surface of the slide ring; one ends of the two extension arms are hinged with one pair of supporters and the other end is provided with a contact terminal and a spring hook; one ends of the two sense elements are respectively fixed on two supporters and the other end is fixed at the end part of the hinged end of the extension arms hinged with the supporters; the two ends of the two springs are respectively connected with the spring hooks arranged on the two strips of extension arms; the hinged end between the two supporters and the two extension arms is provided with an extension arm locating hole and allocated with a locating pin. A method of the transverse strain measurement of a soft rock three-shaft creep test uses the extensometer of the structure for measuring and the quantity of the extensometer is equal to the quantity of the section to be detected of a soft rock sample.

Owner:SICHUAN UNIV

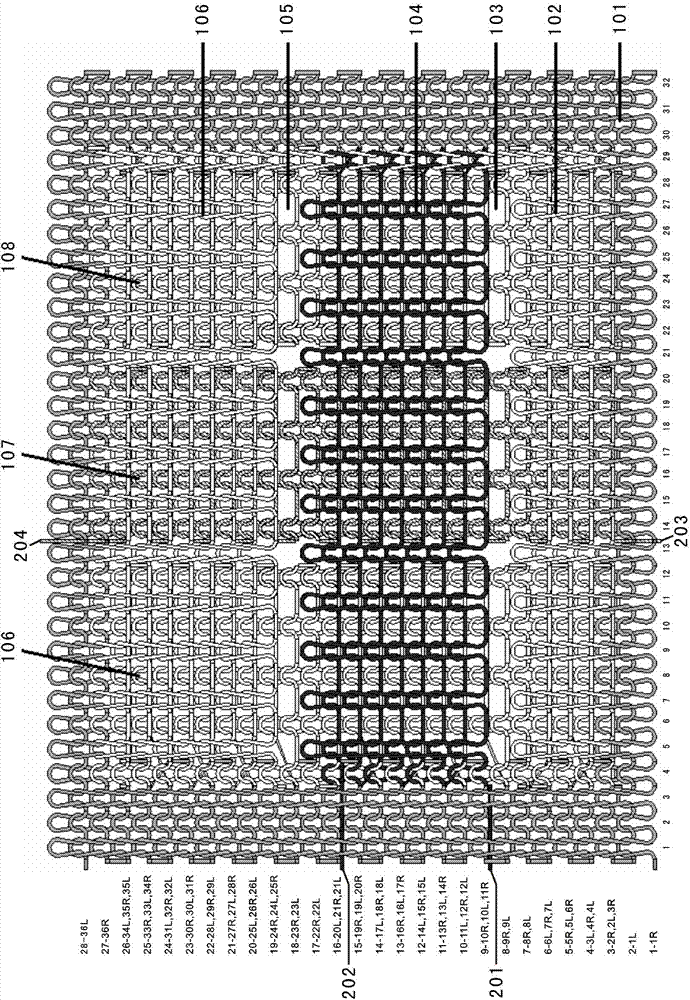

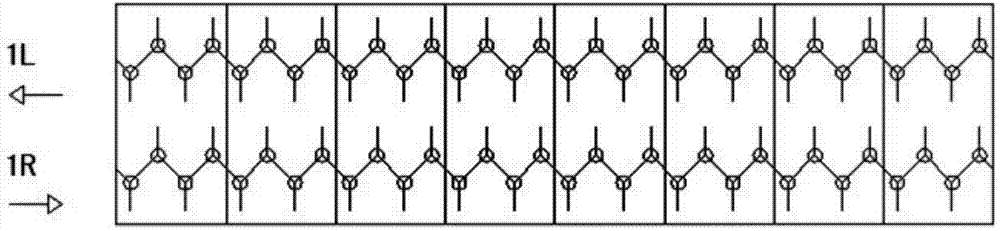

Knitted flexible sensor used for measuring two-way stretching strain and manufacturing method of knitted flexible sensor

ActiveCN103654793AReasonable structural designGood extensibilityWeft knittingMeasurement devicesEngineeringConductive yarn

The invention relates to a knitted flexible sensor used for measuring two-way stretching strain and a manufacturing method of the knitted flexible sensor. The knitted flexible sensor comprises an upper sensor layer region, a lower sensor layer region and a connection region, wherein the upper sensor layer region is composed of a sensor transverse-column region and non-sensor transverse-column regions, and the sensor transverse-column region is not connected with the non-sensor transverse-column regions in the longitudinal-row direction; the lower sensor layer region is composed of a sensor longitudinal-row region and non-sensor longitudinal-row regions, and the sensor longitudinal-row region is not connected with the non-sensor longitudinal-row regions in the transverse-column direction; the sensor transverse-column region and the sensor longitudinal-row region are composed of conductive yarns; no yarn is connected between the upper sensor layer region and the lower sensor layer region; the connection region is connected with the upper sensor layer region and the lower sensor layer region respectively. The knitted flexible sensor has the advantages of being good in structural integrity, extensibility, elastic resilience and reproducibility, and easy and convenient to manufacture, can be arranged on clothes in a knitted mode so as to measure longitudinal and transverse strain of clothes under a two-way stretching condition respectively, and can monitor postures, actions and physiological indexes such as heartbeat or respiration of the human body.

Owner:GUANGDONG RUIYUAN TECH +1

Surface fiber Bragg grating sensor with double packaging layers and manufacturing method of surface fiber Bragg grating sensor

InactiveCN102706390AEliminate the effects ofSimple manufacturing methodUsing optical meansFiberGrating

Owner:SOUTH CHINA UNIV OF TECH +1

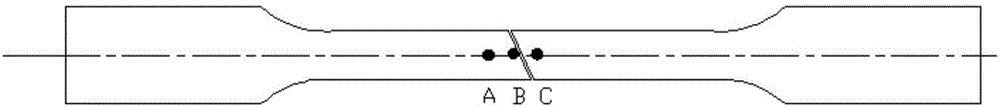

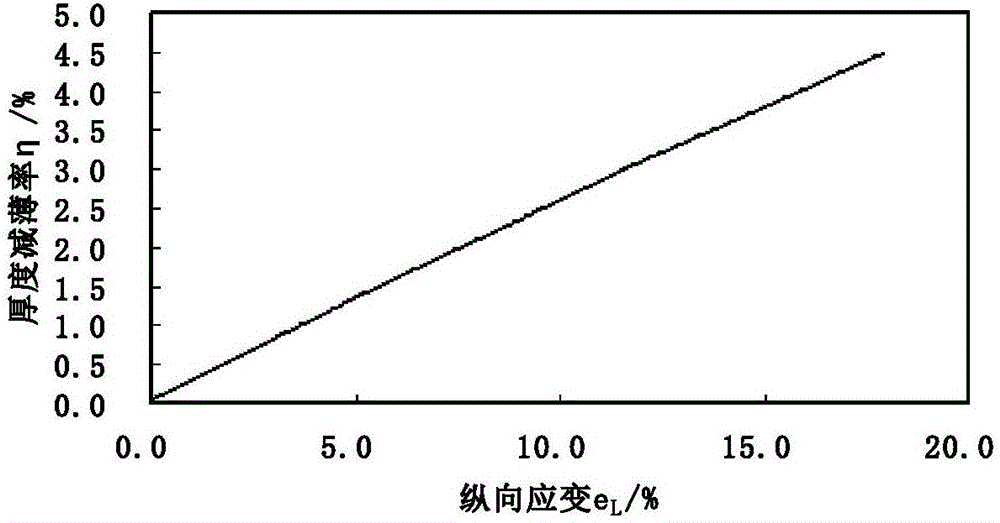

Testing method for automatically measuring thickness thinning rate by adopting tensile testing machine

InactiveCN106644712ASuitable for mass inspectionWell designedMaterial strength using tensile/compressive forcesTest sampleMicrometer

The invention discloses a testing method for automatically measuring a thickness thinning rate by adopting a tensile testing machine. The tensile testing machine is a tensile testing machine with longitudinal and transverse extensometers; the testing method comprises the following steps: 1) testing an original initial thickness a0, an initial width b0 and an initial length L0 of a test sample; 2) clamping the test sample to be tested onto the tensile testing machine with the longitudinal and transverse extensometers and recording instant sizes L and b of the test sample to be tested in a length direction and a width direction in a whole tensile testing process; solving real-time longitudinal strain eL and transverse strain eb respectively; 3) calculating the instant thickness thinning rate of the tensile test sample; 4) setting a maximum force total elongation rate Agt and a maximum force plastic elongation rate Ag, and calculating to obtain a maximum force total thinning rate and a maximum force plastic thinning rate; 5) defining a thinning rate at a fractured minimum thickness part after testing as a fractured thinning rate etau; testing a minimum thickness au of a necking region of a fractured test sample through a point micrometer; calculating the fractured thinning rate etau. The testing method disclosed by the invention is convenient and rapid and is suitable for large-batch inspection.

Owner:武汉钢铁有限公司

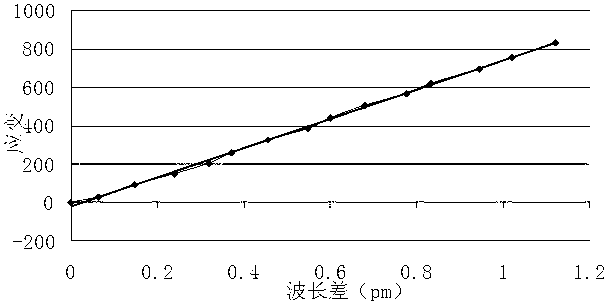

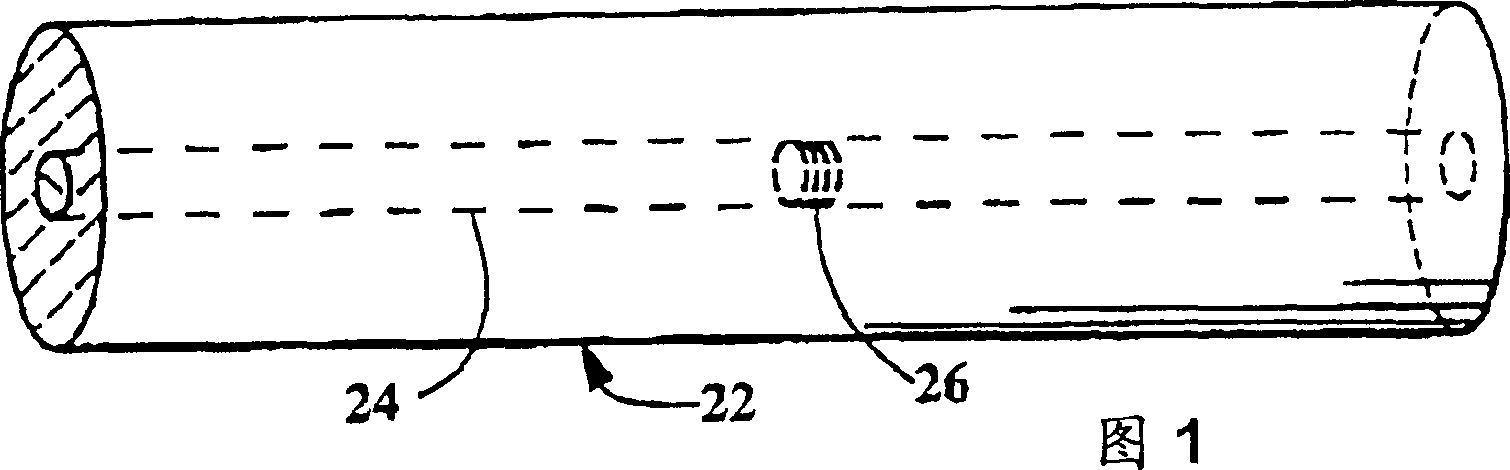

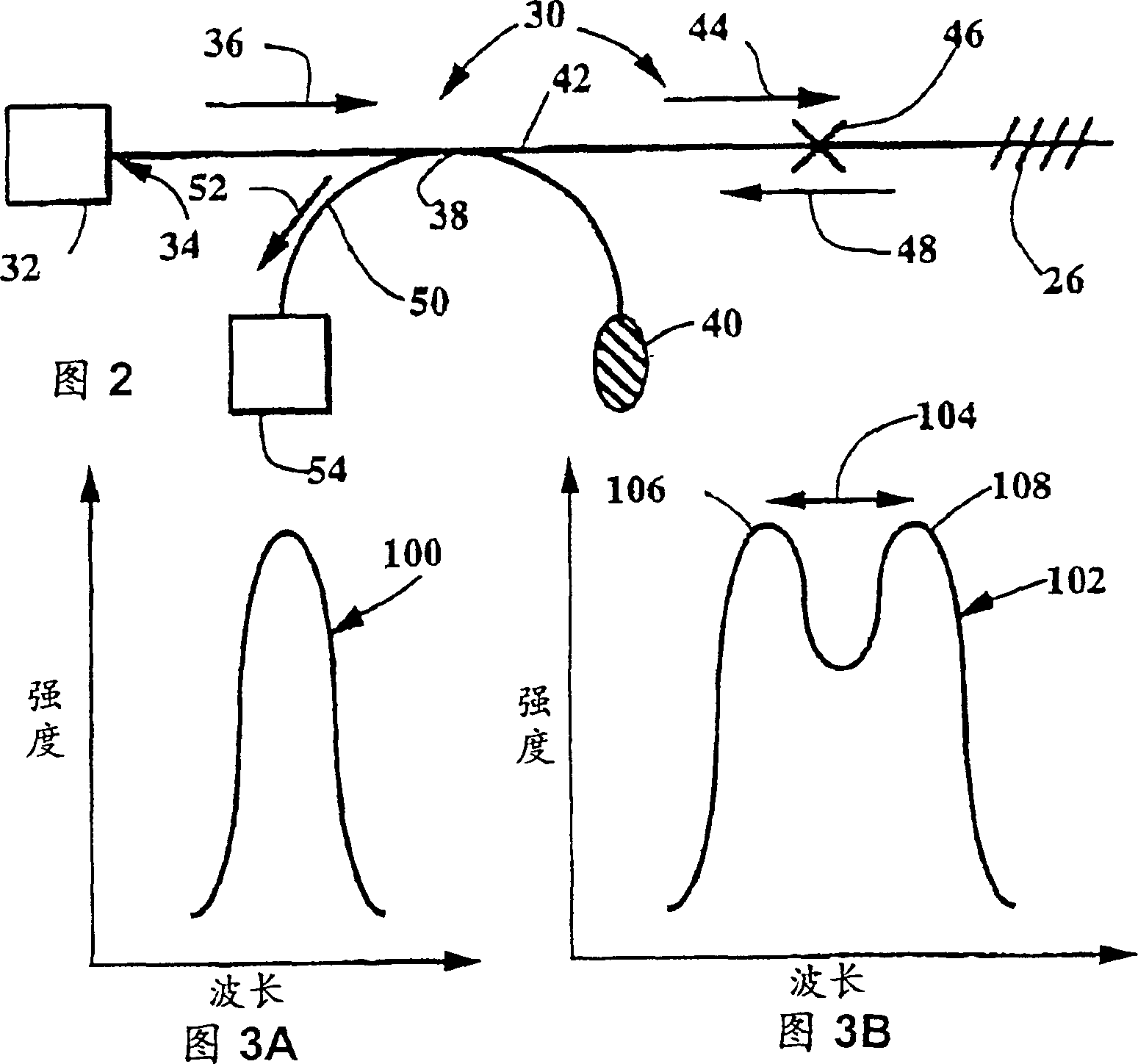

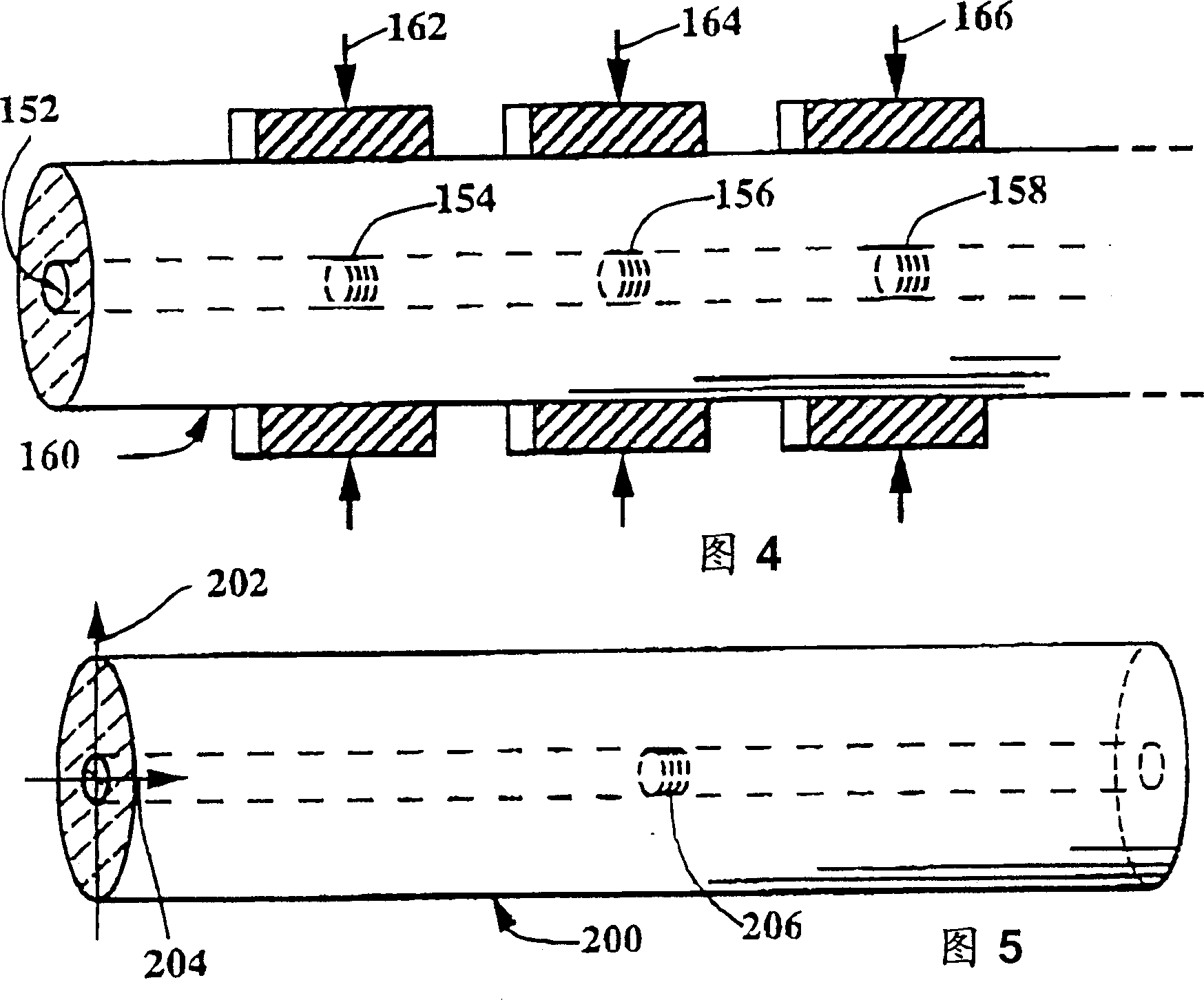

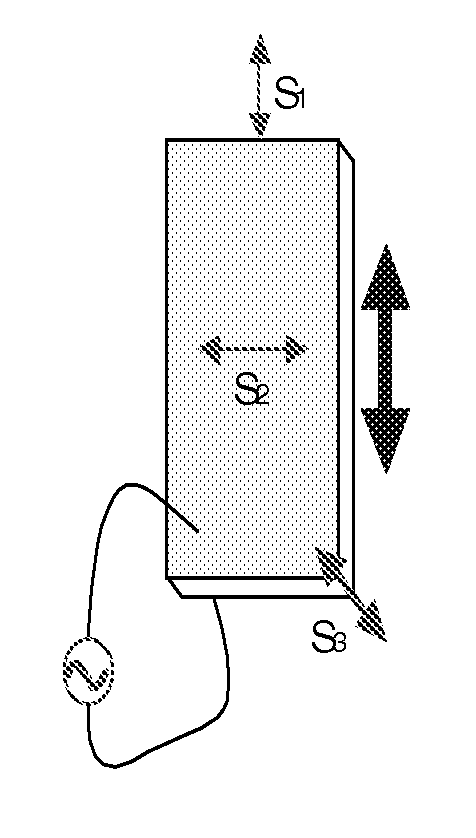

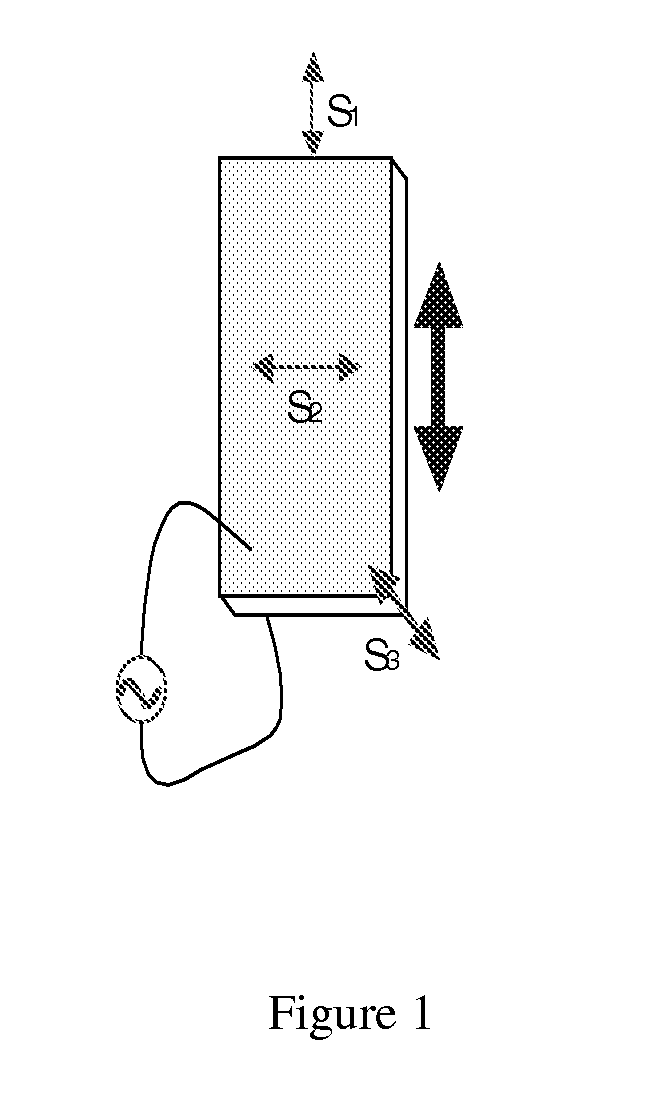

Fiber optic grating transverse strain sensor system

InactiveCN1155798CForce measurement by measuring optical property variationThermometers using physical/chemical changesFiberFrequency spectrum

A system and method to sense the application of transverse stress to an optical fiber include a light source (32) that produces a relatively wide spectrum light beam, an optical fiber (22), a grating (26) within the fiber, and a spectrum analyzer (54). The light beam is reflected off or transmitted through the optical grating in the core (24) of the optical fiber that is transversely stressed directly by exposure to pressure. When transversely stressed, the optical grating produces a reflection or transmission of the light beam that has two peaks or minimums in its frequency spectrum whose spacing and / or spread are indicative of the forces applied to the fiber. One or more detectors sense the reflection or transmission from the optical grating to produce an output representative for the applied forces. Multiple optical gratings and detectors may be employed to simultaneously measure temperature or the forces at different locations along the fiber.

Owner:SCHLUMBERGER OVERSEAS SA

Strain measurement device and method of strain measurement using the same

A strain measurement device includes a strain gauge, a holding device, a transverse strain recorder, and a data processing device. The strain gauge includes at least one first and at least one second layers of carbon nanotube films, each layer of carbon nanotube films having a plurality of carbon nanotubes. The carbon nanotubes in at least one first layer of carbon nanotube film align along a first direction. The carbon nanotubes in at least one second layer of carbon nanotube film align along a second direction. The holding device is used to fasten a specimen and the strain gauge. The transverse strain recorder is used to record a transverse strain of the strain gauge. The data processing device is used to calculate an axial strain of the strain gauge.

Owner:TSINGHUA UNIV +1

Capacitive touch sensor based on zero Poisson ratio structure

PendingCN108613758AImprove detection accuracyHigh sensitivityForce measurementTactile sensorDielectric layer

The invention discloses a capacitive touch sensor based on a zero Poisson ratio structure. The capacitive touch sensor comprises an upper electrode layer, a lower electrode layer and a zero-Poisson-ratio structural dielectric layer arranged between the two electrode layers. The zero-Poisson-ratio structural dielectric layer is formed by a plurality of cellular structures arranged in an array; a smooth flexible photosensitive resin layer for connection with the upper electrode layer is arranged on the upper surface of the top cellular structure; and a smooth flexible photosensitive resin layerfor connection with the lower electrode layer is arranged at the lower surface of the bottom cellular structure. The longitudinal cross section of each cellular structure has a convex-shaped structureand the lower bottom surface of the convex-shaped structure is recessed. An included angel between the outer cell wall of the cellular structure and the vertical direction is alpha all the time; whenpositive-pressure simulation is applied to the sensor, the alpha value is kept to be unchanged all the time and thus the transverse strain perpendicular to the load direction is always zero; and onlythe strain in a load direction is generated and the equivalent Poisson ratio is always zero.

Owner:HEBEI UNIV OF TECH

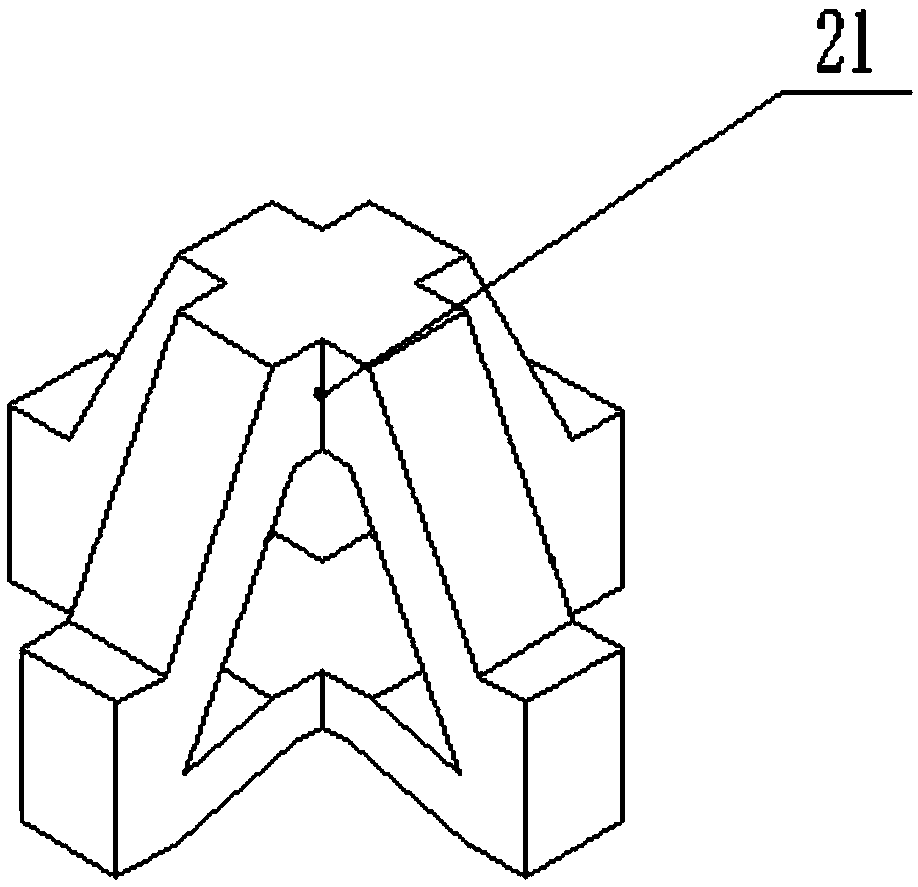

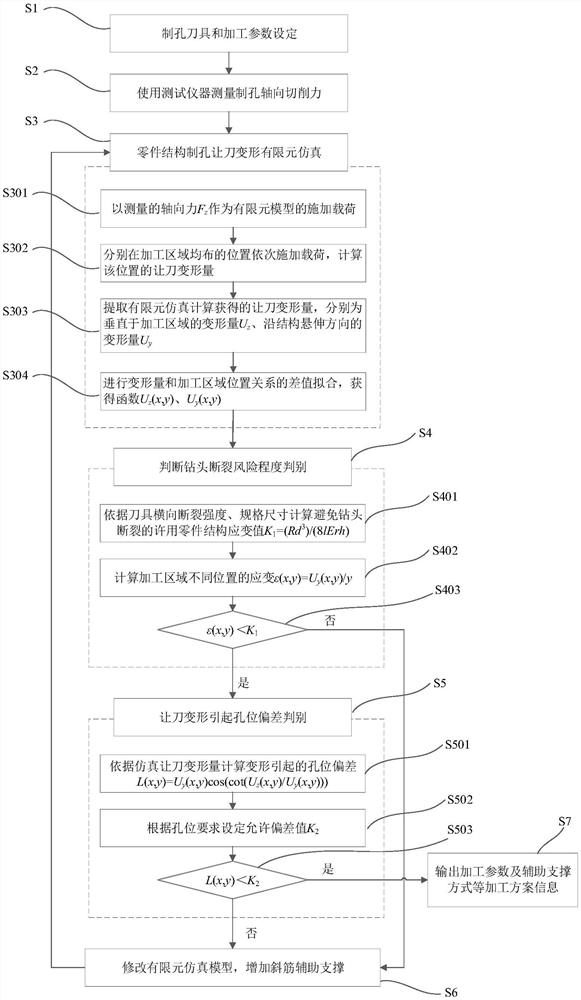

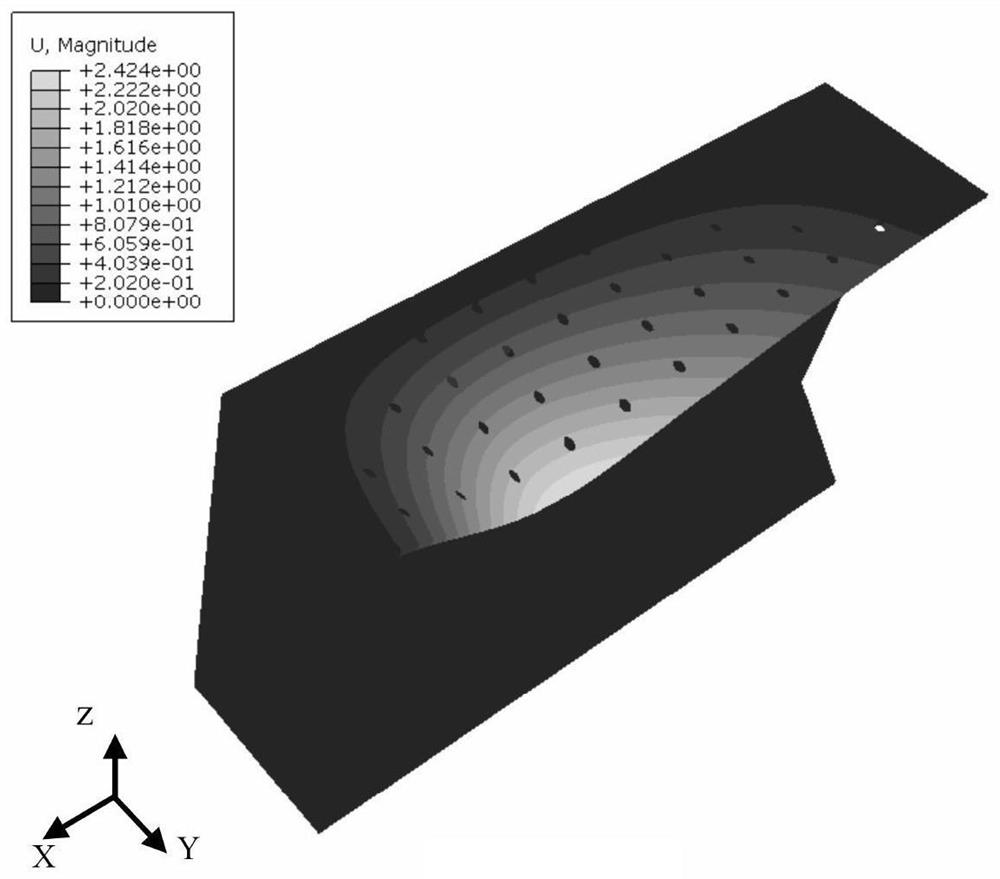

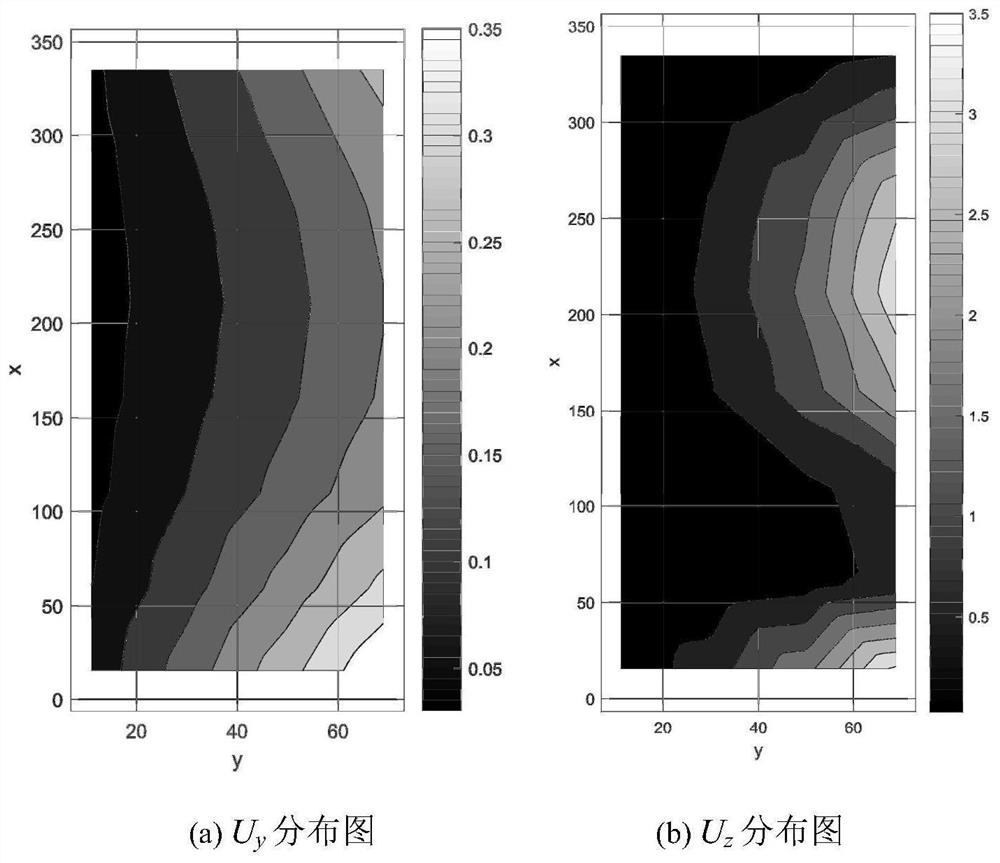

Method for controlling drilling hole sites of aircraft structural parts

ActiveCN112036057AAvoid quality problemsGeometric CADDesign optimisation/simulationNumerical controlClassical mechanics

The invention relates to the field of aircraft structural part numerical control machining, in particular to a method for controlling drilling hole sites of aircraft structural parts, which comprisesthe steps of selecting a part drilling cutter and cutting parameters, measuring drilling axial force, performing finite element simulation of part weak-rigidity structure drilling cutter relieving deformation to acquire relationships Uy (x, y) and Uz (x, y) between deformation and a machining area position, judging the fracture risk degree of the drill bit, calculating an allowable structure strain value, judging whether the transverse strain of a machining area is within an allowable range or not, judging hole site deviation caused by cutter relieving deformation, calculating the caused holesite deviation, and judging whether the hole site deviation caused by deformation meets the hole site requirement or not; if the hole site deviation caused by transverse strain or deformation does notmeet the allowable requirement, adding an inclined rib support to the part structure, carrying out simulation calculation again, setting the size and position of the inclined rib, and iterating untilthe transverse strain and deformation hole site deviation meets the requirement, so as to realize the effective control of the hole site of the hole in the weakly rigid region of the aircraft structural member. A quality problem that the drilling position is out of tolerance is avoided.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

FBG-based train dynamic weighing sensor and installation method thereof

InactiveCN108593073AReal-time measurementHigh precisionWeighing apparatus using elastically-deformable membersWeighing auxillary devicesFreight trainsEngineering

The invention discloses an FBG-based train dynamic weighing sensor and an installation method thereof, and relates to the technical field of sensors. The sensor comprises a plurality of clamps arranged on a rail and an FBG strain sensor fixed between the two clamps; each clamp comprises a plurality of U-shaped clamping blocks and a supporting seat; the two sides of the supporting seat are respectively fixed on the base of the rail through a pair of U-shaped clamping blocks; and a connecting plate is fixed between every two adjacent U-shaped clamping blocks; and the two ends of the FBG strain sensor are fixed on the supporting seat along the linear direction of the rail. By designing a high-stability FBG strain sensor, the FBG strain sensor realizes the real-time measurement of the load onthe rail through integrated stable, firm, fatigue-resistant clamps, and the sensor has the advantages of being high in precision, simple in structure and convenient to operate; the FBG strain sensor is sensitive to axial strain and insensitive to transverse strain due to the characteristics of the FBG strain sensor. The measuring range of the sensor is designed according to the characteristic of the weight of the freight train, and the linear weighing is carried out in the range of 18-100 tons.

Owner:李俊

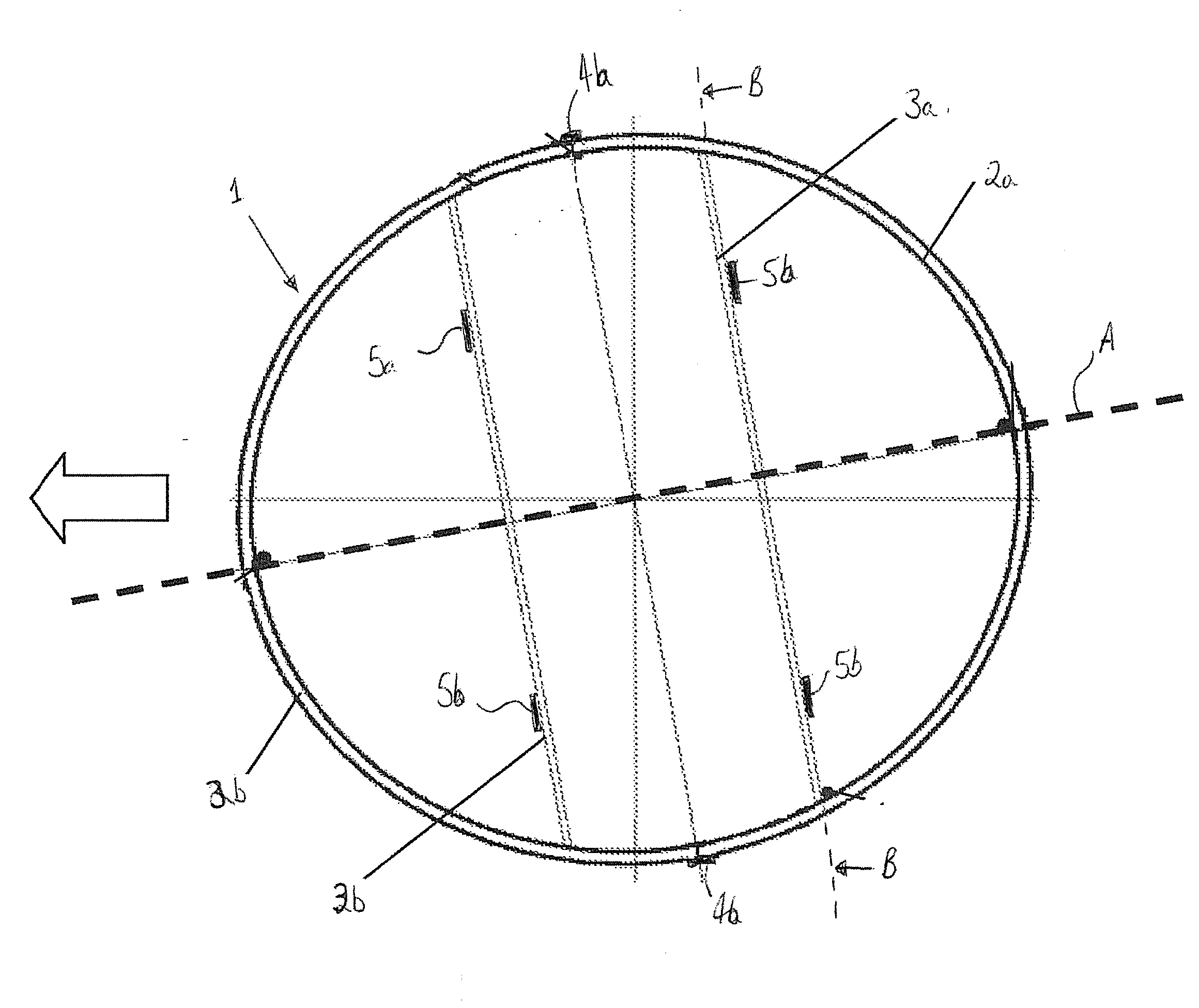

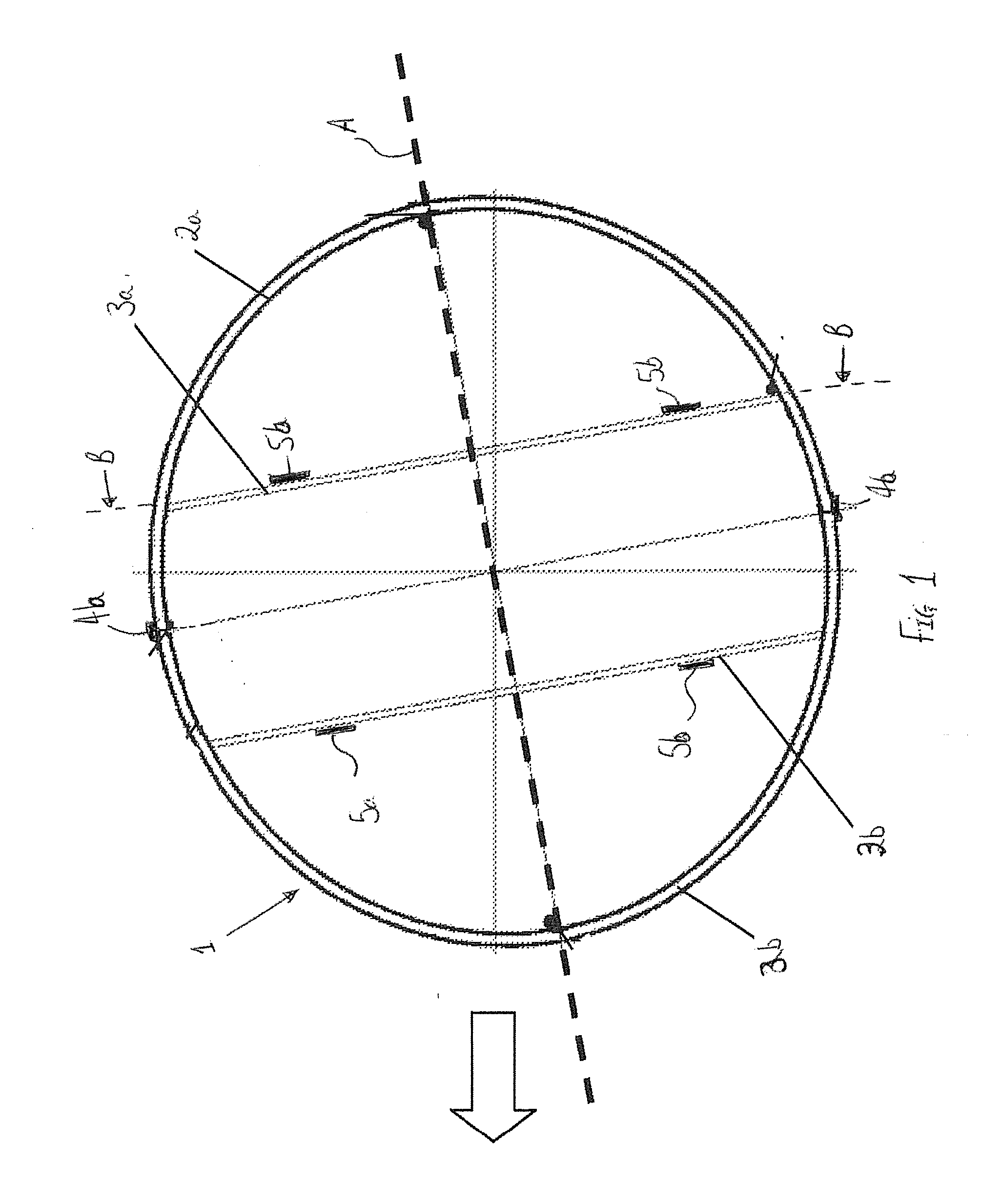

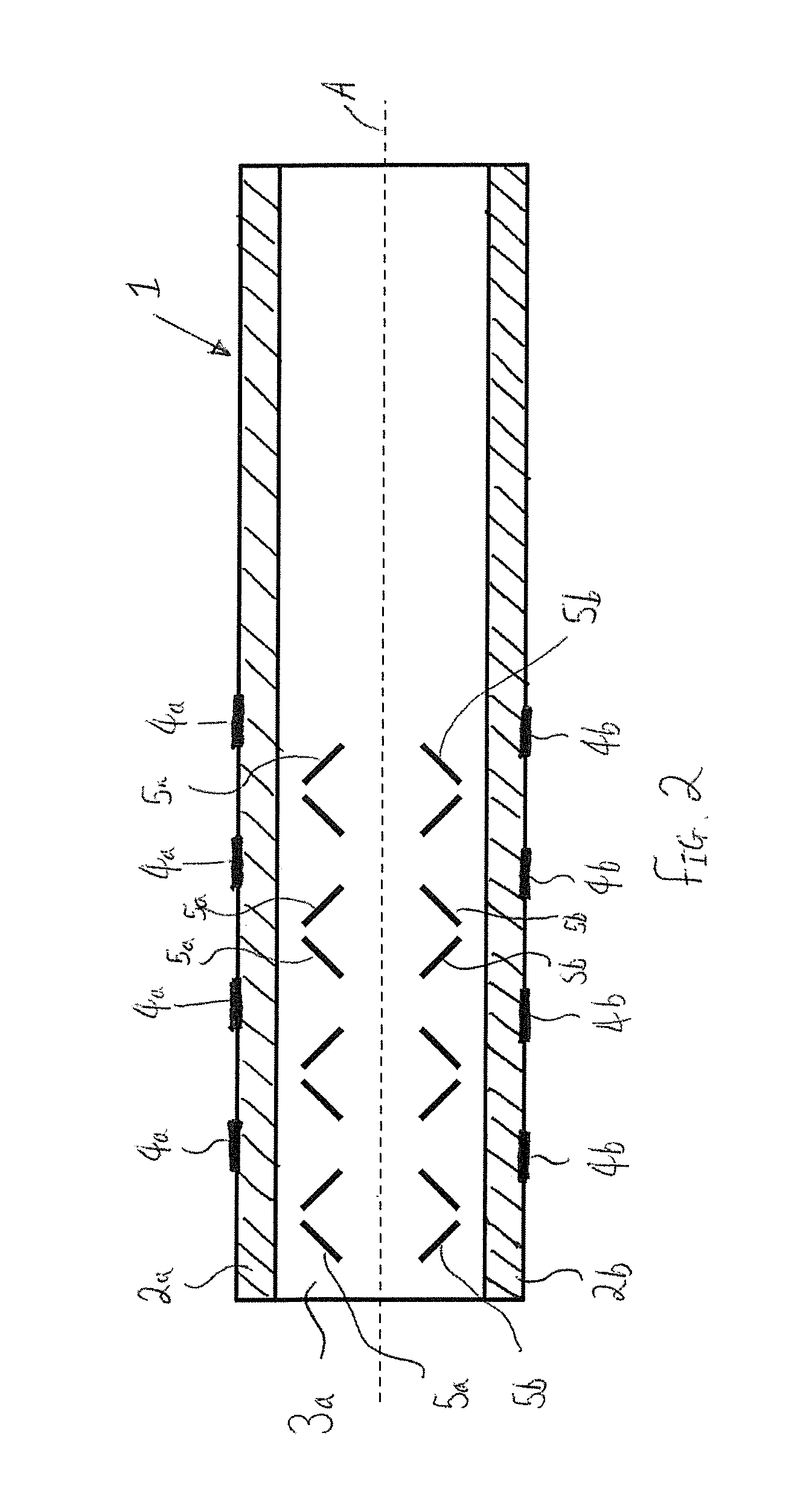

Monitoring the structural integrity of a wind turbine blade

A method of monitoring the structural integrity of a wind turbine blade 1 is disclosed. The blade 1 has at least two shell portions 2a, 2b, forming the outer surface of the turbine blade 1. At least one web member 3a, 3b connects the shell portions 2a, 2b in a transverse direction. The method comprises measuring a bending moment on the turbine blade 1 in a plane containing the longitudinal and transverse directions, measuring the transverse strain on the web member 3a, 3b at least one location, and comparing the measured transverse strain to an expected value for the transverse strain at the measured bending moment to provide an indication of debonding between the web member 3a, 3b and at least one shell portion 2a, 2b.

Owner:MOOG INSENSYS

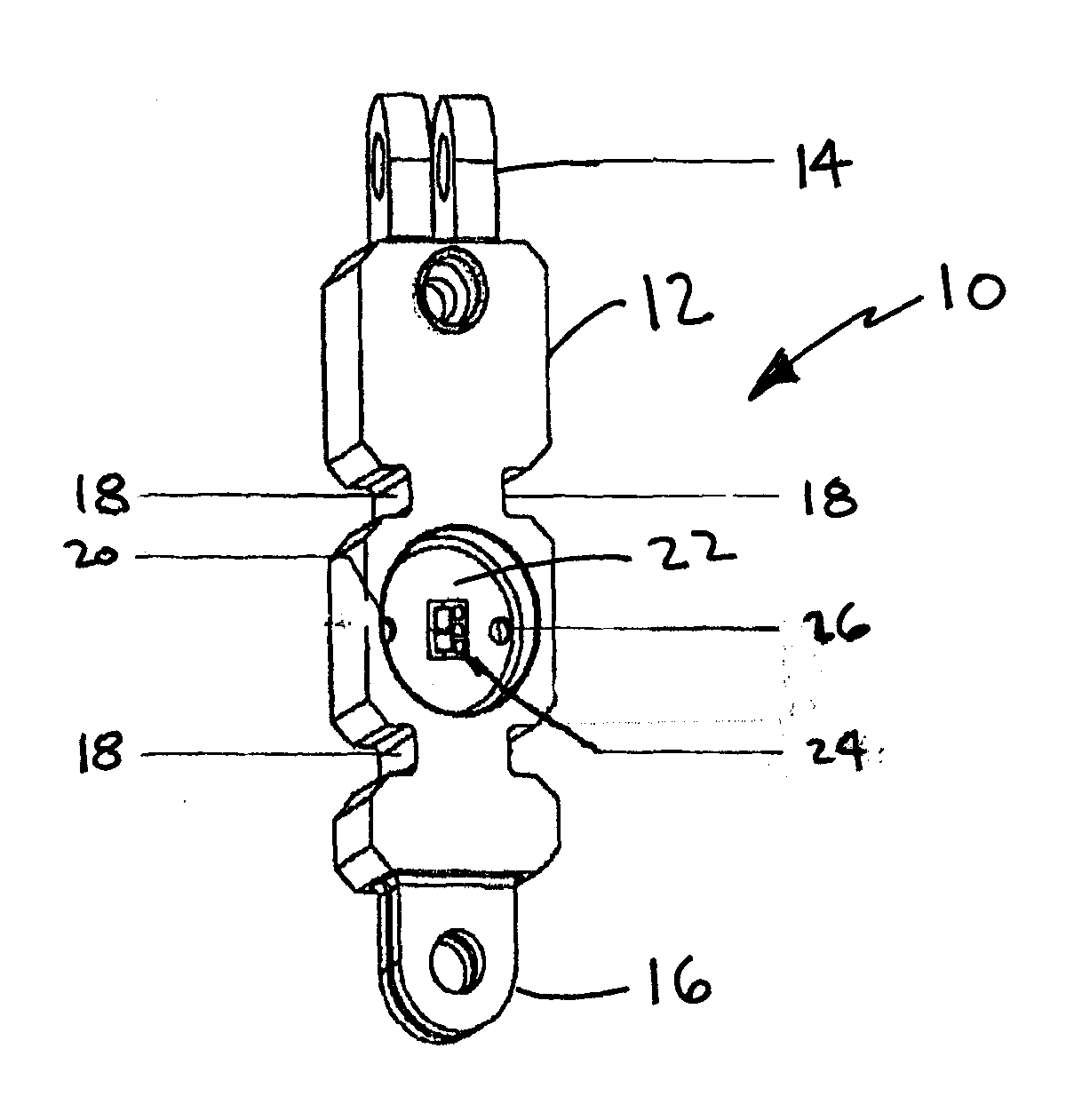

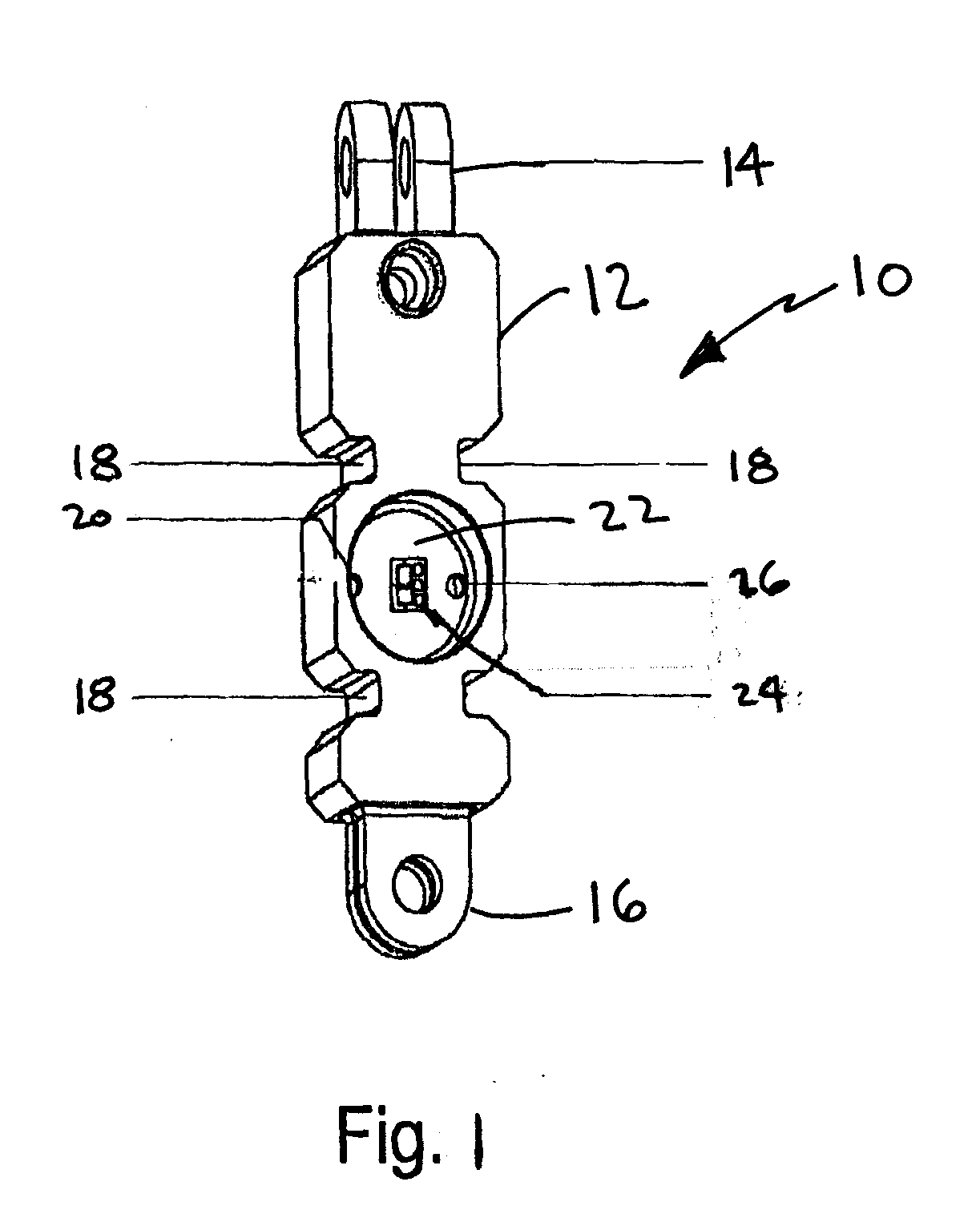

Strain measuring device

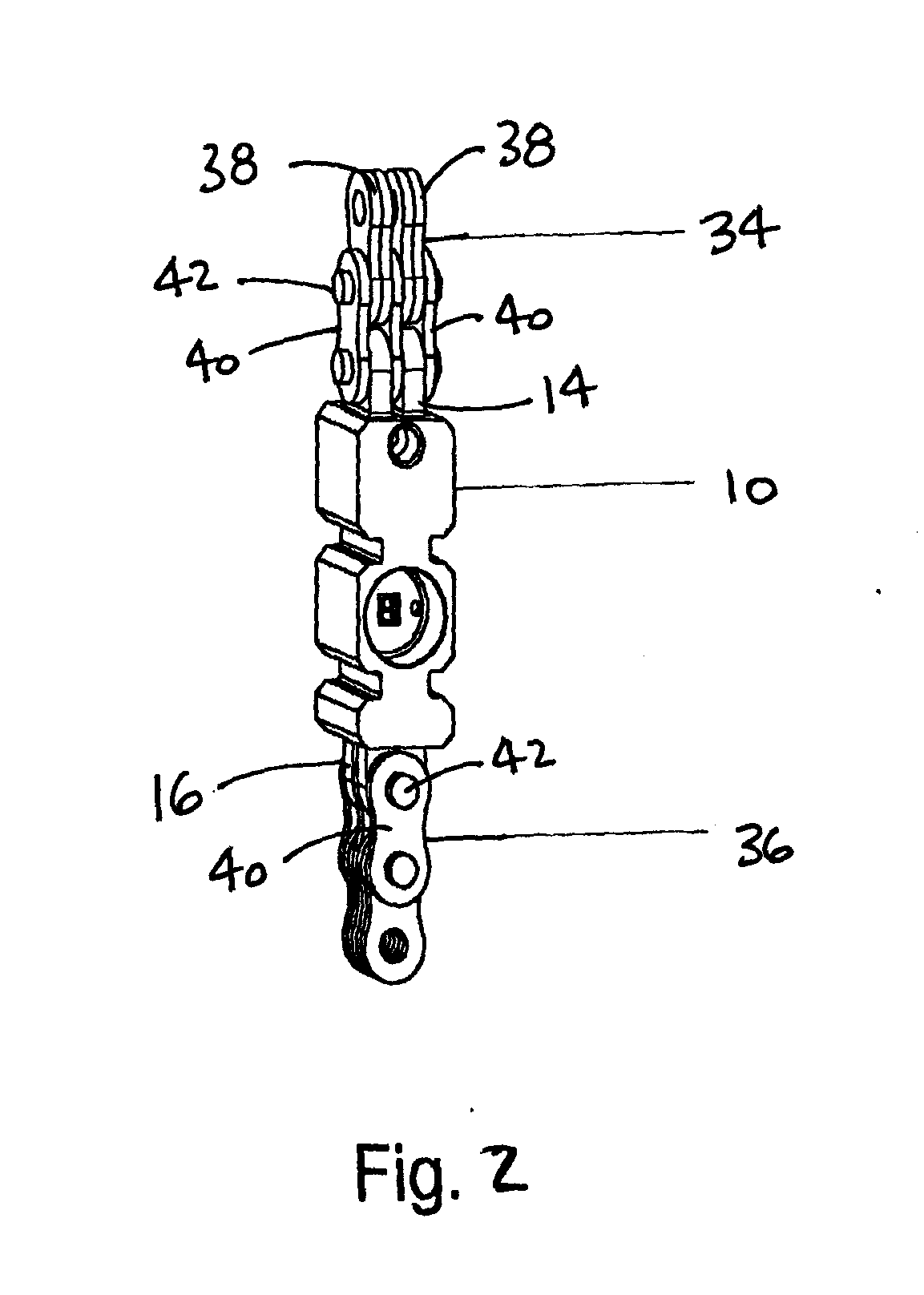

InactiveUS20070245837A1Improve linearityFavorable temperature transient behaviorApparatus for force/torque/work measurementForce measurement by elastic gauge deformationEngineeringRoller chain

A tensile force measuring device provides improved linearity and temperature transient behavior. A column load cell (10) in the device is connected at its ends to a first and a second roller chain portion (34, 36), which are in turn connected to the tensile force, to dispose the column load cell to the tensile force between the chain portions. The roller chain portions are connected to the load cell in mutually perpendicular orientation. The load cell has notches (18) formed in the side thereof to equalize the strain thereupon when tensile load is applied. Longitudinal and transverse strain gages (20) are positioned longitudinally intermediate to the notches, and may be on a gaging web (22).

Owner:METTLER TOLEDO INC

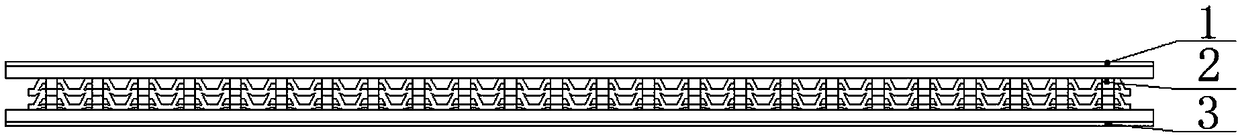

Battery separator and preparation method therefor

InactiveCN106252562AMeet the needs of the high-end marketImprove mechanical propertiesCell seperators/membranes/diaphragms/spacersAntioxidantParaffin oils

The invention discloses a battery separator and a preparation method therefor. The battery separator comprises a base material layer and a modified layer which is coated on the base material layer, wherein the base material layer is a polyolefin thin film; and the modified layer comprises the following components in parts by weight: 20-40 parts 2, 6-ditert-butyl-4-methylphenol, 15-20 parts of alkane paraffin oil, 10-20 parts of antioxidant, 5-10 parts of surface active agent and 3-8 parts of binder. The battery separator is high in mechanical performance, and the transverse strain rate and the longitudinal strain rate of the separator are both less than 1%, so that requirements of the high-end battery market can be well satisfied; it is verified that the mechanical performance of the separator can be obviously improved by the alkane paraffin oil in the modified layer; and in addition, the mechanical performance can be further optimized by banburying processing to the modified layer.

Owner:YANGZHOU YUE HENG MECHANICAL TECH CO LTD

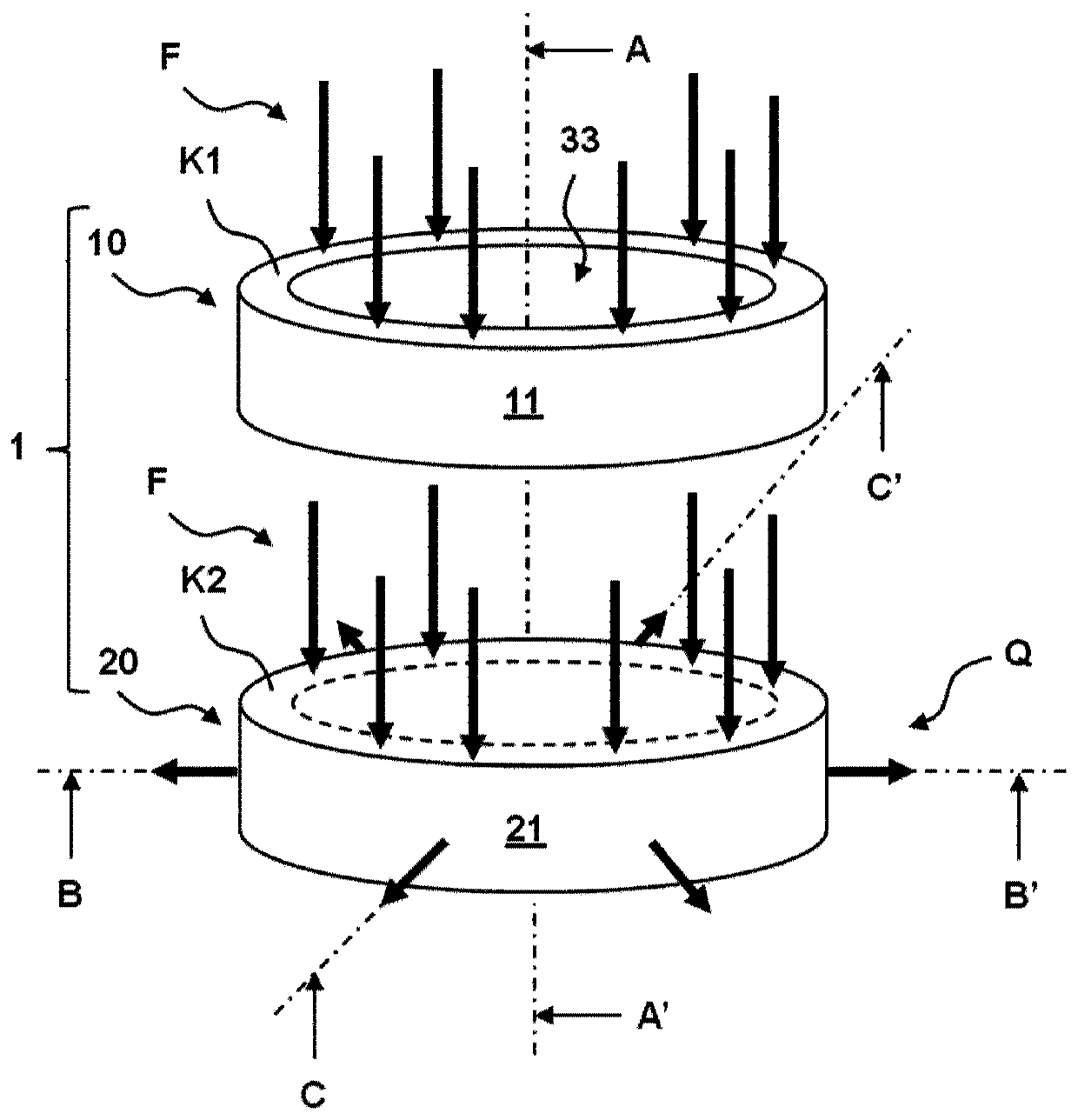

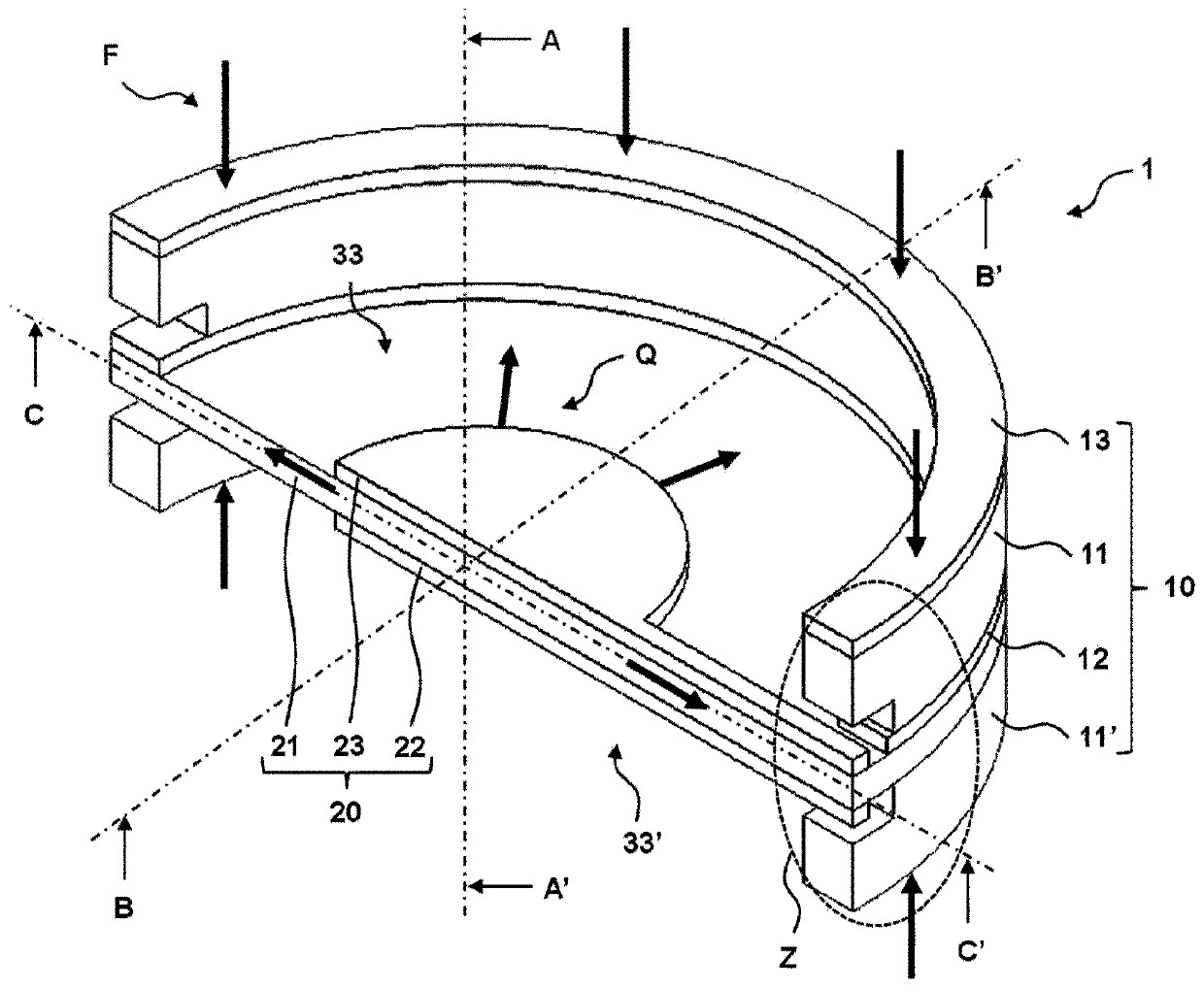

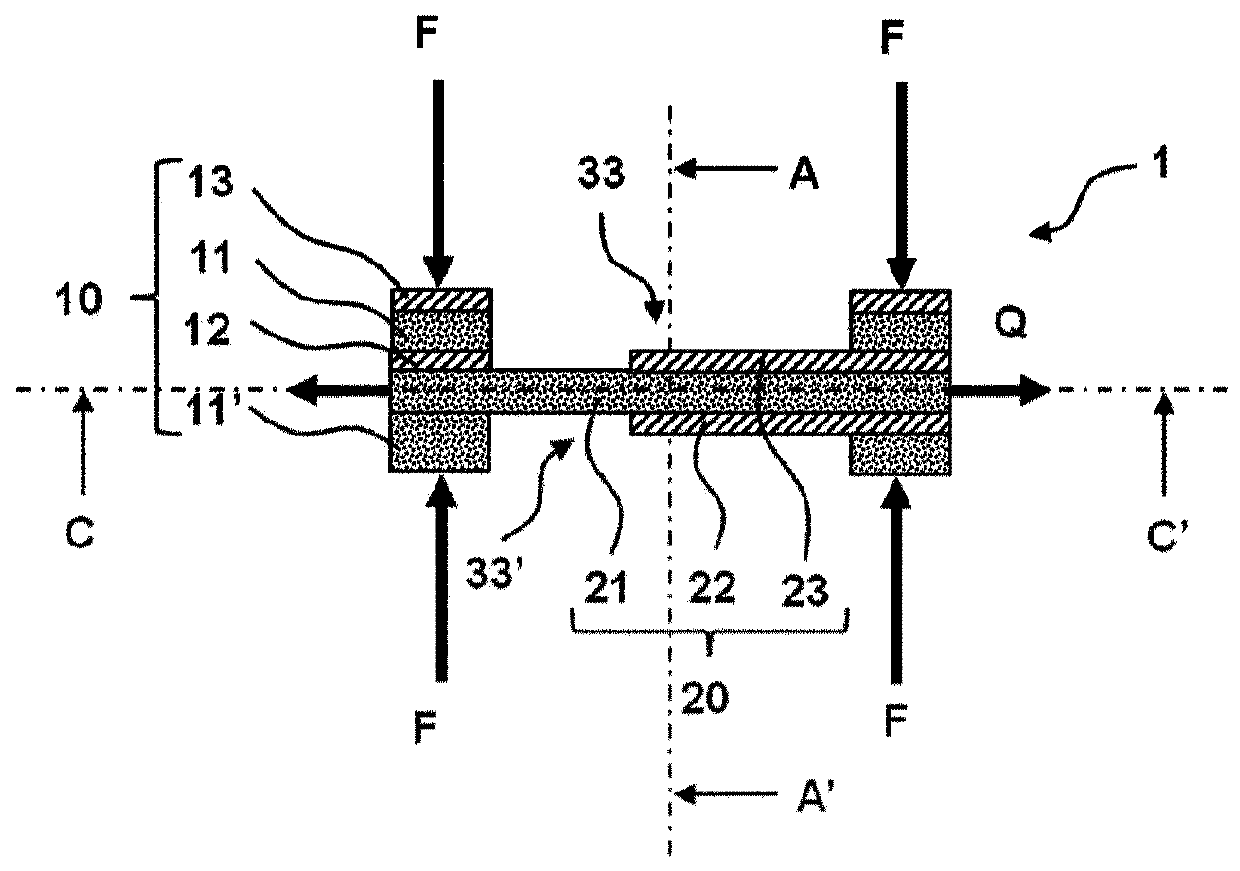

Measuring sensor for simultaneously measuring force that can be both dynamic and static

ActiveCN110036267AForce measurement using piezo-electric devicesPiezoelectric/electrostrictive/magnetostrictive devicesResonanceSoftware engineering

The invention relates to a measuring sensor (1) for simultaneously measuring a force (F) that can be both dynamic and static, comprising: at least one piezoelectric sensing element (10, 10'), whereinthe force (F) on element surfaces of the piezoelectric sensing element (10, 10') produces electrical polarization charges, a magnitude of the produced electrical polarization charges being proportional to a magnitude of the force (F); a resonator element (20), which can be excited at at least one resonance frequency (f); wherein the force (F) acts on the piezoelectric sensing element (10, 10') andon the resonator element (20) in a force direction; wherein the force (F) causes a transverse elongation (Q) in the resonator element (20), which transverse elongation (Q) occurs in the resonator element (20) in a transverse direction, which forms an angle different from zero with the force direction, a magnitude of the transverse elongation (Q) being proportional to the magnitude of the force (F); and wherein the transverse elongation produces a frequency change (Delta f) of the resonance frequency (f), which frequency change is a function of the force (F).

Owner:KISTLER HLDG AG

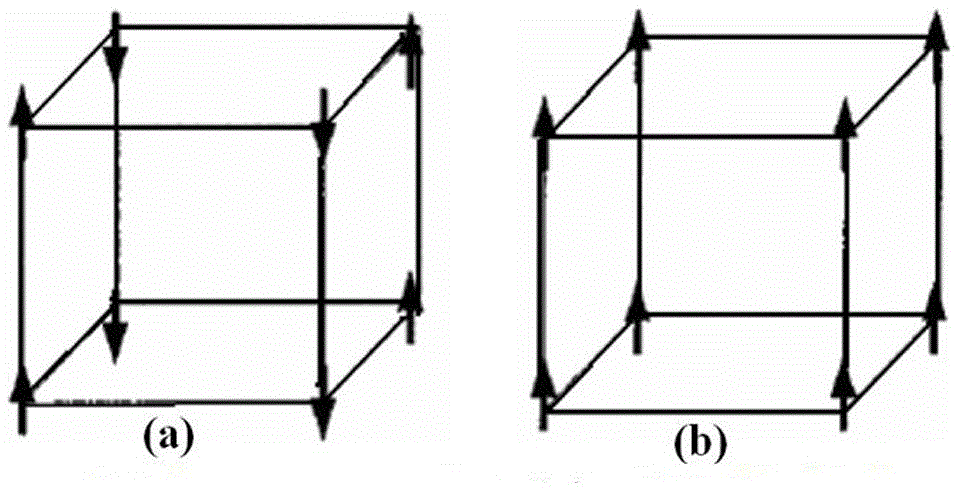

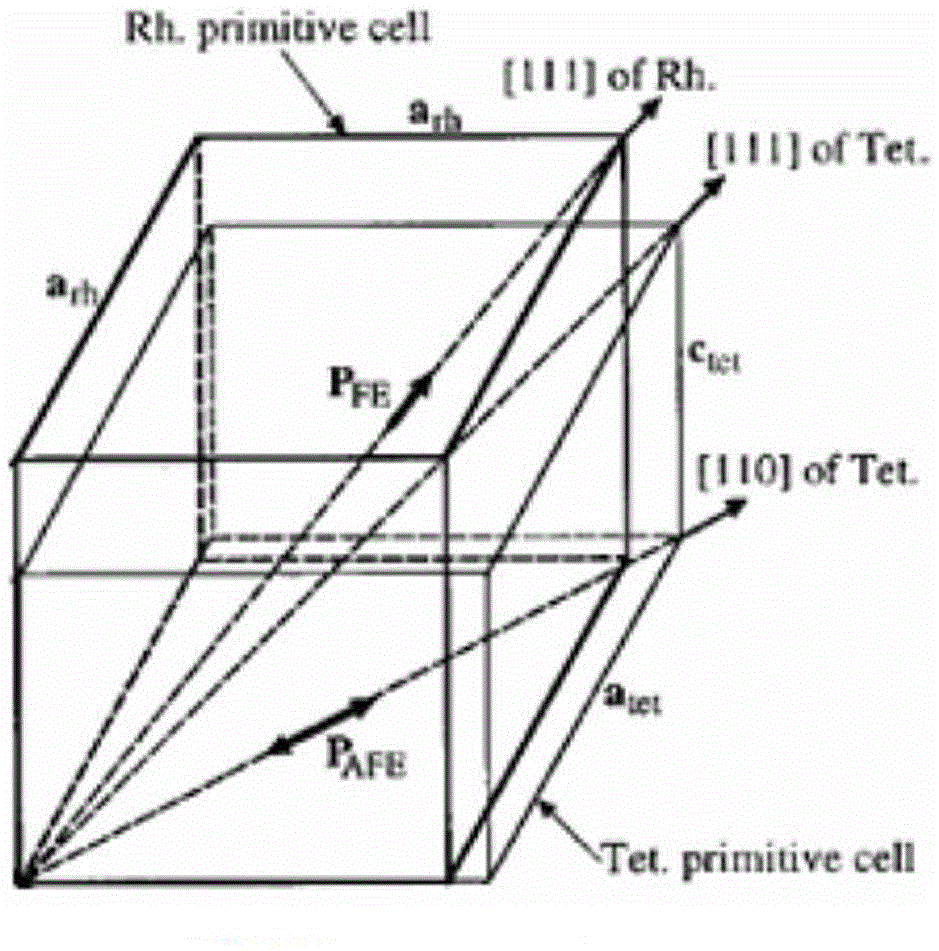

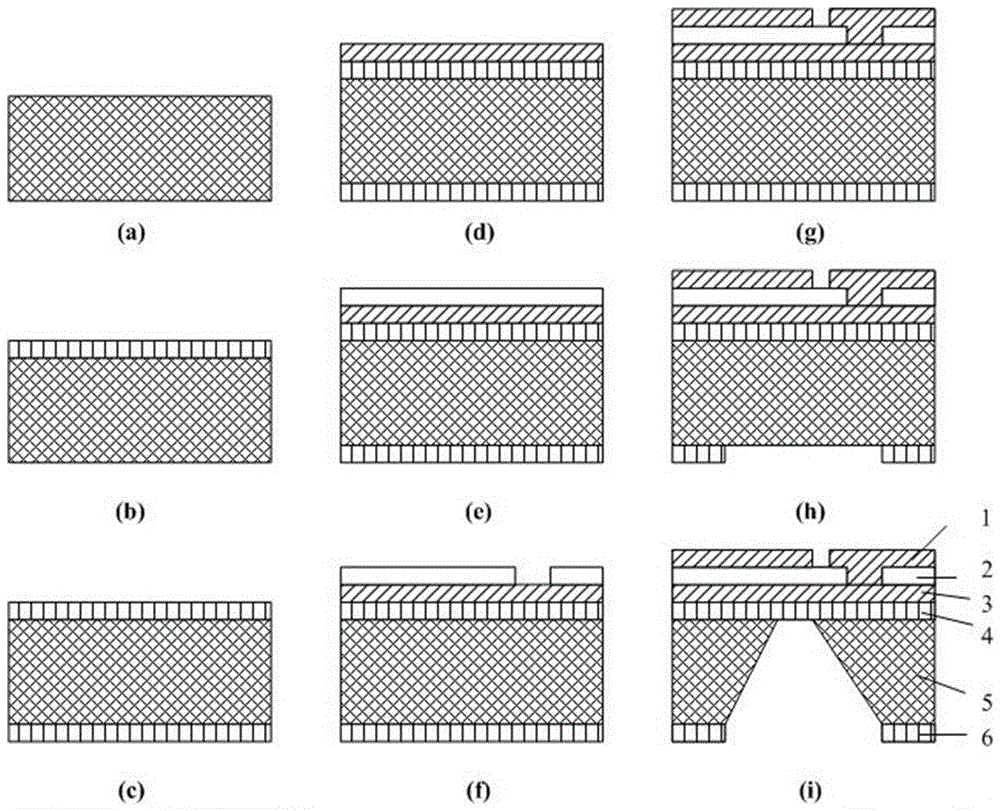

Film bulk acoustic resonator based on phase change actuation effect of anti-ferroelectric material

InactiveCN106130499AHigh Q valueRaise the resonant frequencyImpedence networksThin-film bulk acoustic resonatorMicro nano

The invention belongs to the technical fields of intelligent micro-nano devices and systems and provides a film bulk acoustic resonator (FBAR) based on a phase change actuation effect of an anti-ferroelectric material. The film bulk acoustic resonator comprises a silicon substrate (5), wherein a front oxide layer (4) and a back oxide layer (6) cover the top and the bottom of the silicon substrate (5). The film bulk acoustic resonator is characterized in that a bottom electrode layer (3) is grown on the front oxide layer (4); a PLZT film layer (2) made from the anti-ferroelectric material is grown on the upper surface of the bottom electrode layer (3); and a top electrode layer (1) is grown on the PLZT film layer (2). According to the film bulk acoustic resonator, the anti-ferroelectric PLZT film material is taken as a function layer of the FBAR, and the phase change strain effect of the anti-ferroelectric PLZT film material is utilized as a resonant device mechanism, so that the high resonant efficiency can be obtained; and meanwhile, the larger transverse strain of the material has an important significance on improvement of a Q value in a liquid state of the device.

Owner:ZHONGBEI UNIV

Corbel bracket platform for simultaneous construction of bridge piers and transverse beams and its construction method

ActiveCN103882813BRealize simultaneous constructionShorten the timeBridge erection/assemblyEngineeringCorbel

The invention discloses a corbel bracket platform for bridge pier and transverse straining beam synchronous construction. The corbel bracket platform is characterized in that the positions, with the equal height, in the middle of semicircular steel molds on the two sides of the upper portion of a pier column model (1) are respectively provided with a corbel (2) in a welding mode, jacks (3) are installed on the corbels (2), I-beams (4) are placed on the jacks (3) in the horizontal direction, the I-beams (4) on the two sides of the pier column model (1) are connected together through pulling rods (5) and fastened on the pier column model (1), and distributive beams (6) are placed between the I-beams (4) at equal intervals. The invention further discloses a construction method of the corbel bracket platform. According to the corbel bracket platform, synchronous construction of a pier column and a transverse straining beam is achieved, the construction cycle period of components below a bridge is shortened, and the bridge construction progress is accelerated. Meanwhile, compared with a traditional construction scheme, the input material cost is low, materials of the platform of the transverse training beam can be completely recycled for coping beam construction, and the circulating utilization rate of the materials is high.

Owner:CHINA RAILWAY ERJU 1ST ENG +1

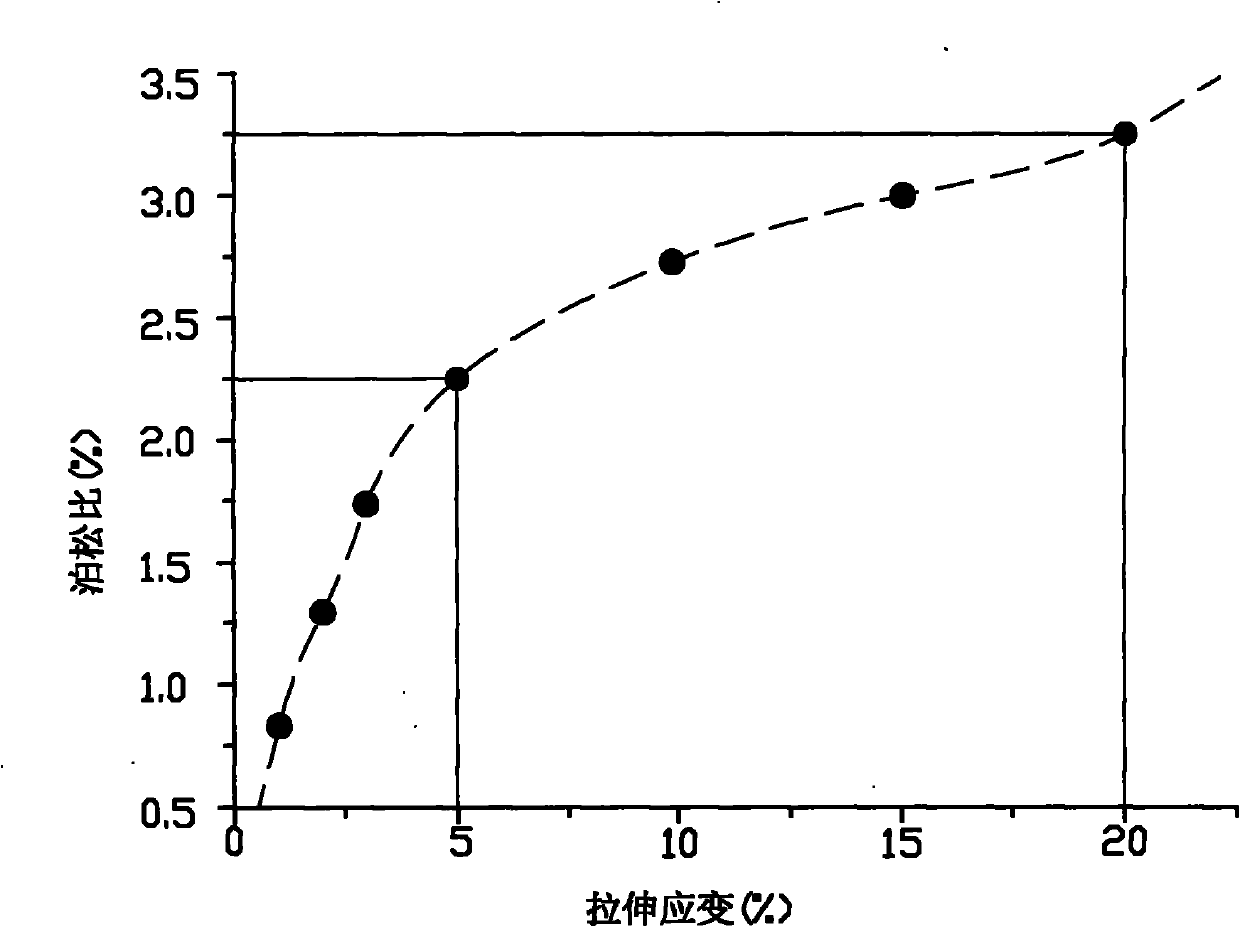

Polymer blends of electrostrictive terpolymer with other polymers

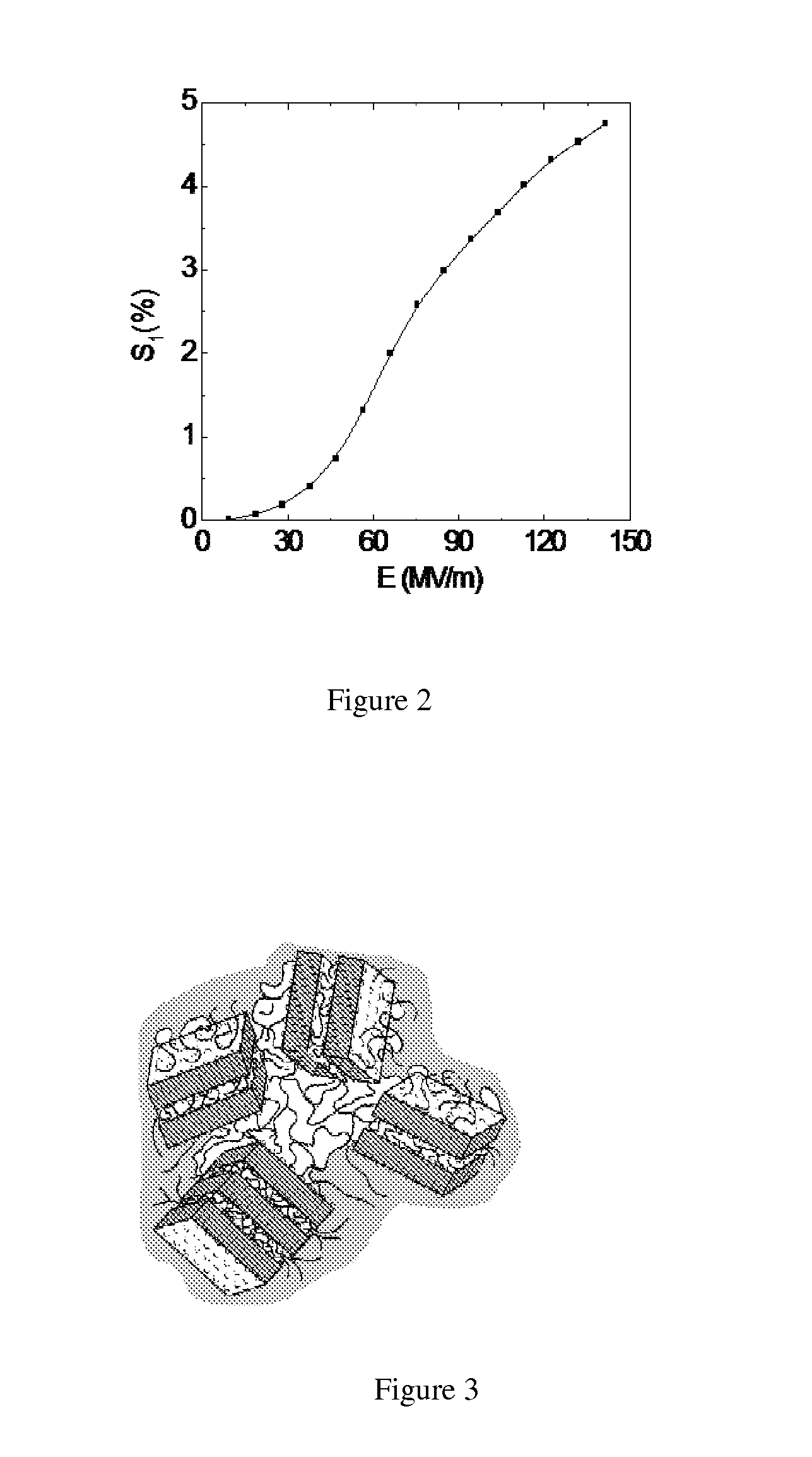

InactiveUS20150287906A1Synthetic resin layered productsPiezoelectric/electrostrictive device material selectionFluoropolymerFluoride

Polymer blends having improved electromechanical responses and mechanical properties for use in electromechanical application are disclosed. In particular, polymer blend including at least one electrostrictive terpolymer, e.g., poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) (P(VDF-TrFE-CFE)) or a derivative thereof, and at least one fluoropolymer, e.g., PVDF or derivative thereof such as PVD-TrFE are disclosed. The polymer blends advantageously have a transverse strain, i.e., a strain perpendicular to the applied electric field direction, that is about 1.5% or higher (as measured at 100 MV / m) while also having an elastic modulus of no less than about 400 MPa (as measured at 30° C. and 1 Hz by dynamic mechanical analyzer).

Owner:PENN STATE RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com