Film bulk acoustic resonator based on phase change actuation effect of anti-ferroelectric material

A thin-film bulk acoustic wave, antiferroelectric technology, applied in electrical components, impedance networks, etc., can solve problems such as poor repeatability, frequency limitation, and increased internal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

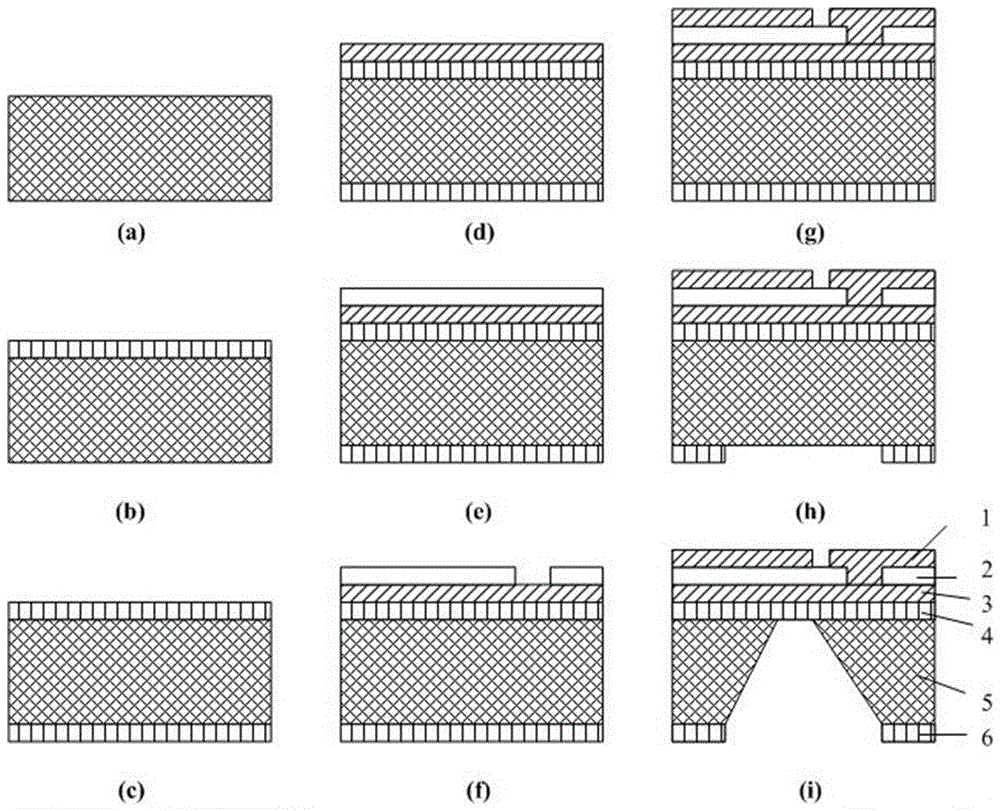

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] A thin-film bulk acoustic resonator based on the actuation effect of the phase transition of antiferroelectric materials, such as Figure 4 , 5 As shown, it includes a silicon substrate 5, the silicon substrate 5 covers the front oxide layer 4 and the back oxide layer 6 up and down; the lower electrode layer 3 grows on the front oxide layer 4, and the upper surface of the lower electrode layer 3 grows antiferroelectric The PLZT thin film layer 2 is made of material, and the upper electrode layer 1 is grown on the PLZT thin film layer 2 .

[0031] Among them, the preparation method of the colloidal raw material of the PLZT thin film layer 2 is as follows: 4.9~5.1g of lead acetate trihydrate, 0.07~0.08g of lanthanum acetate and 12~15mL of acetic acid are mixed and stirred at 85-100°C (preferably 90°C). After it is cooled to room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com