Patents

Literature

42 results about "Vertical Strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

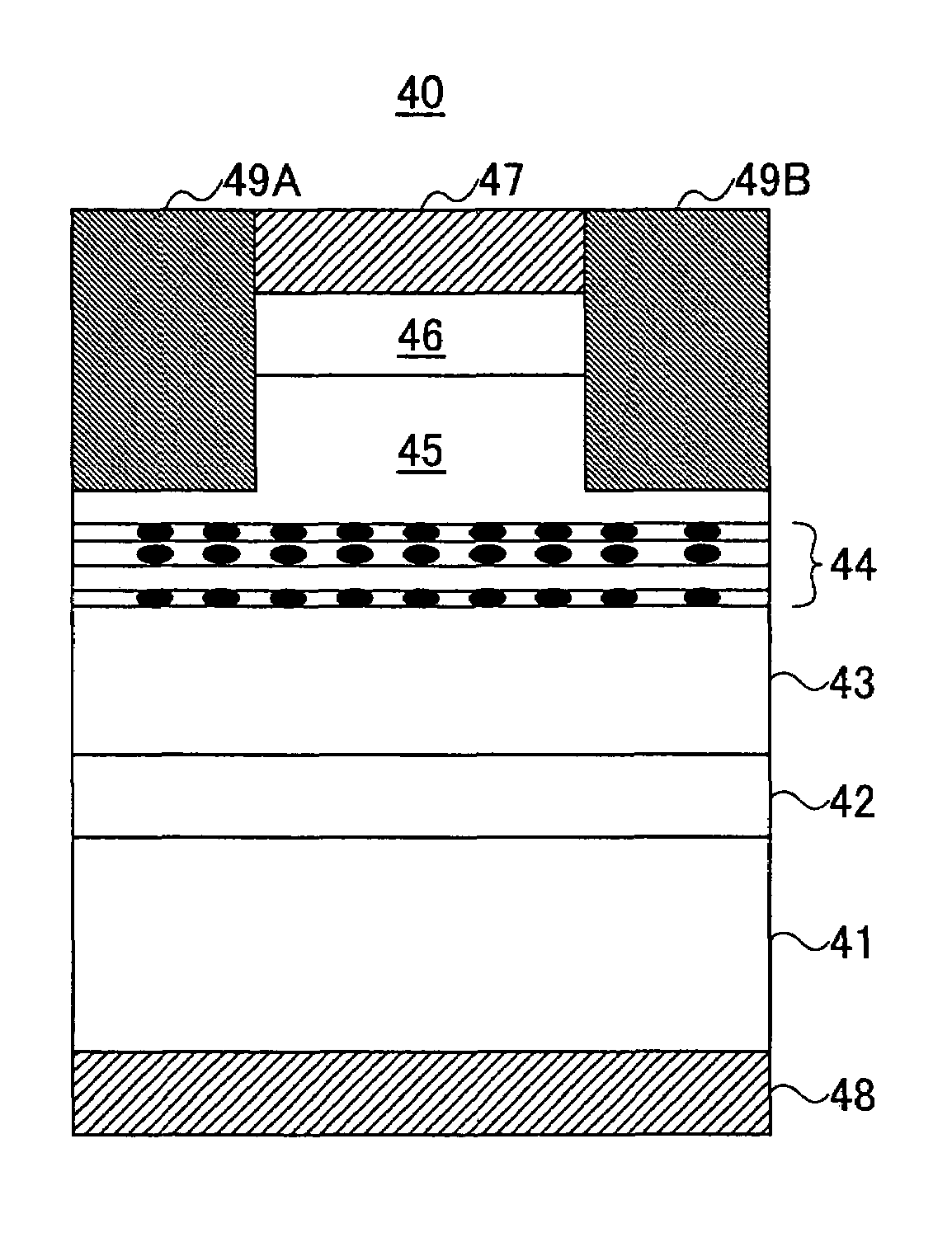

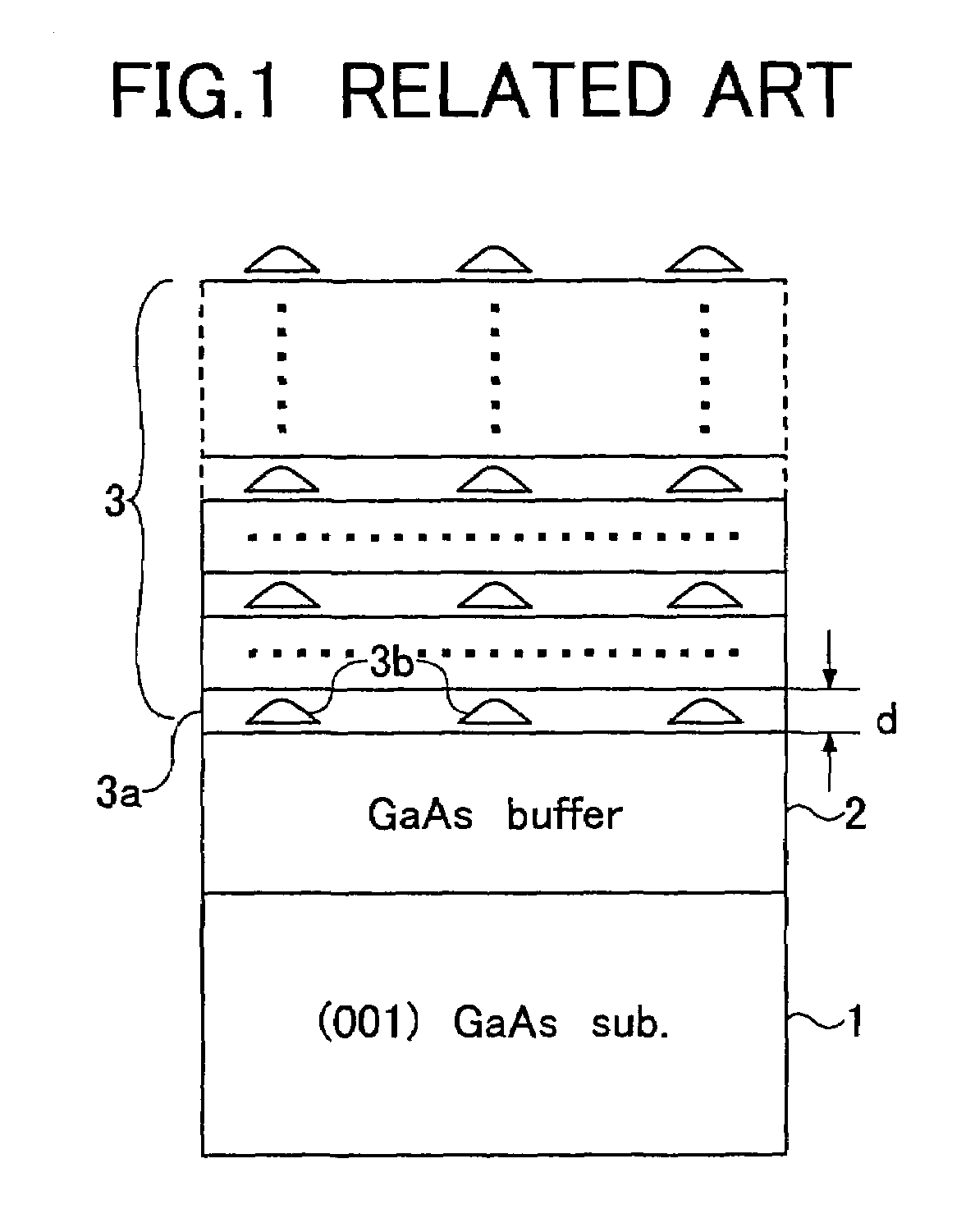

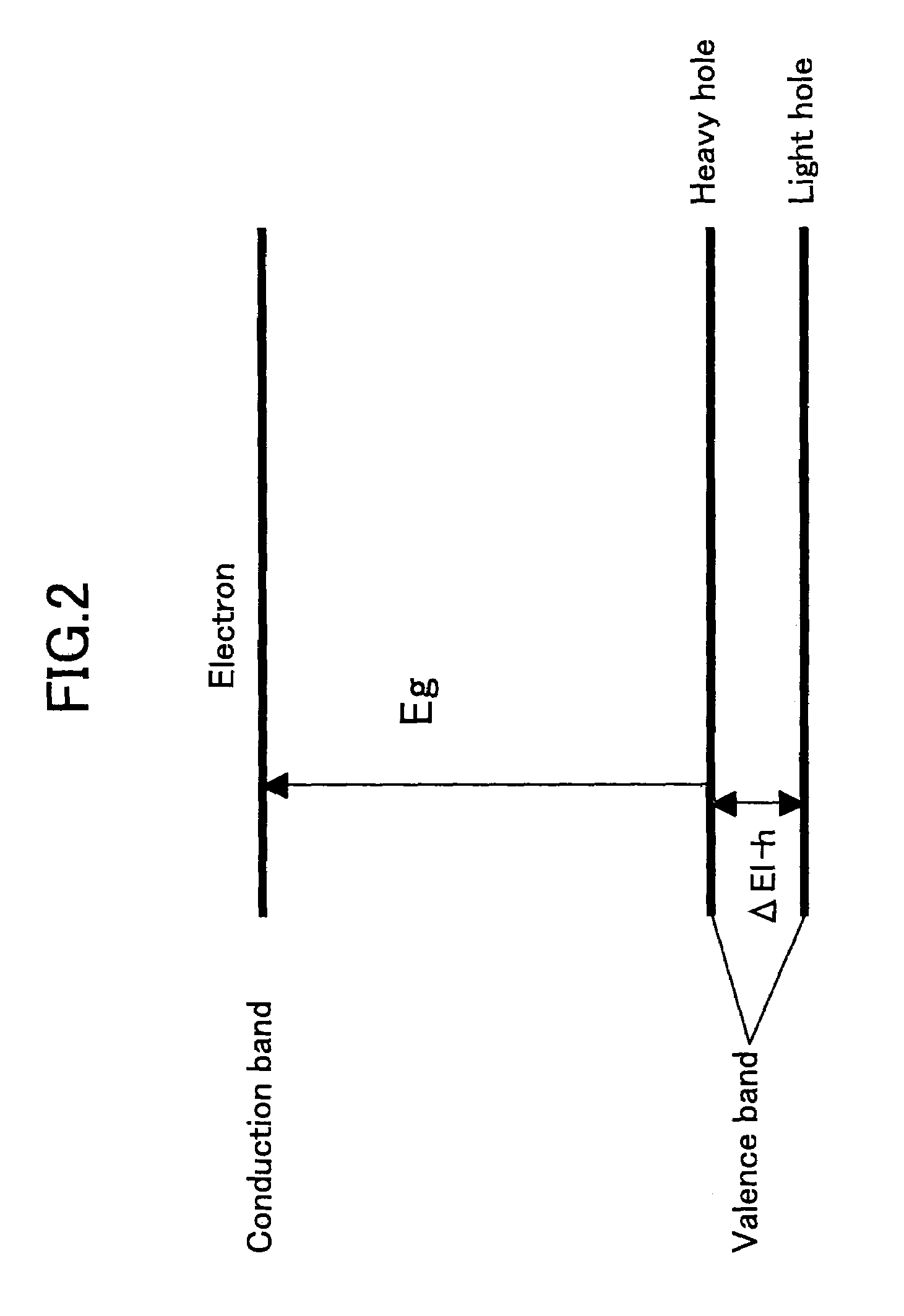

Quantum optical semiconductor device

A quantum semiconductor device including quantum dots formed by S-K growth process taking place in a heteroepitaxial system wherein the relationship between the energy level of light holes and the energy level of heavy holes in the valence band is changed by optimizing the in-plane strain and the vertical strain accumulated in a quantum dot.

Owner:FUJITSU LTD

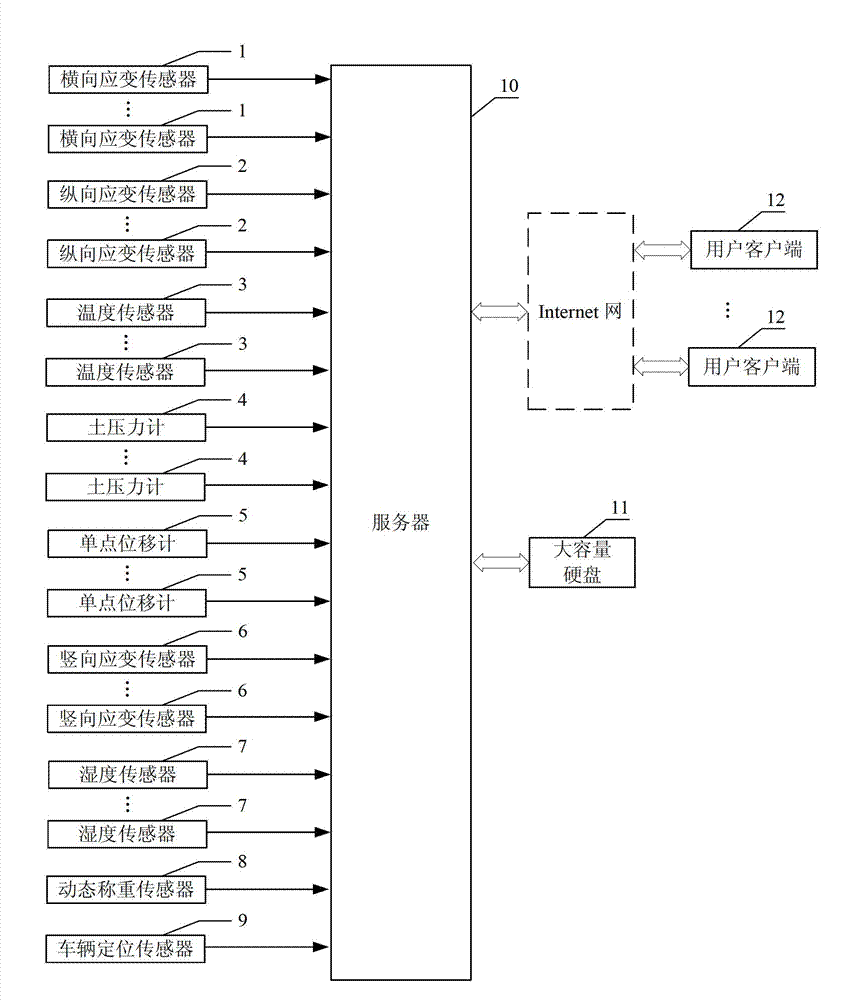

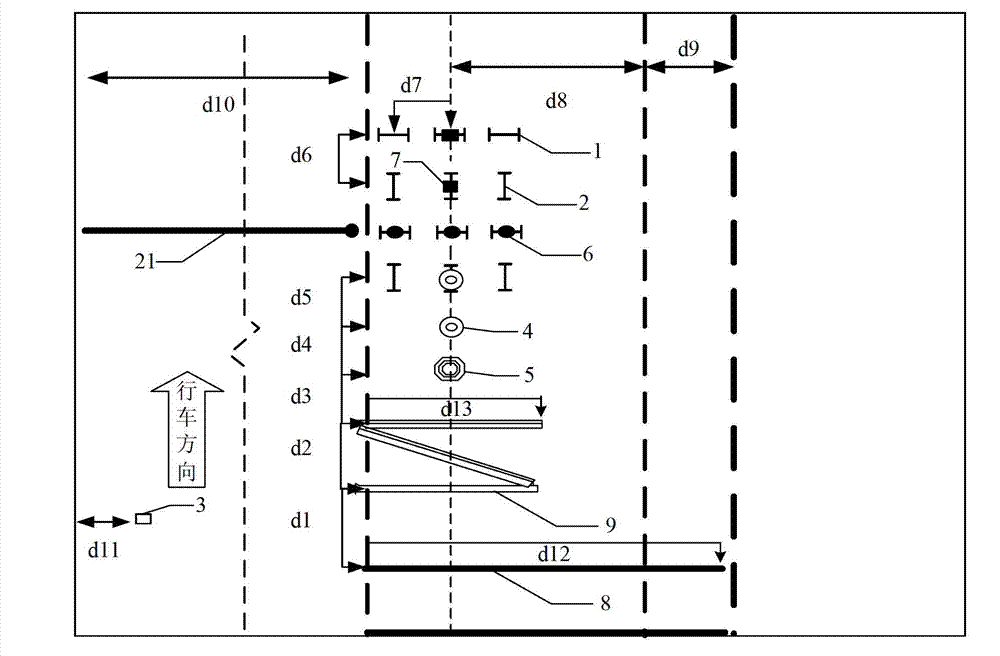

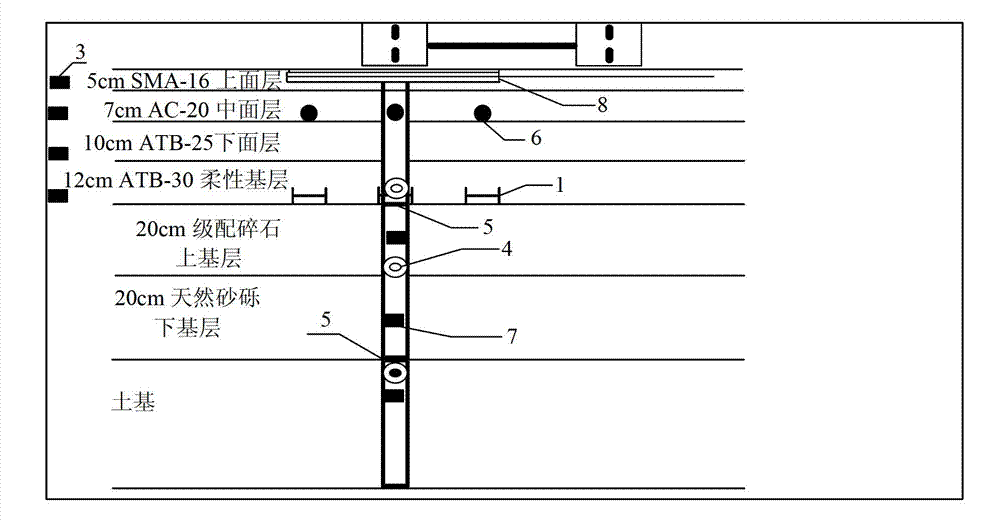

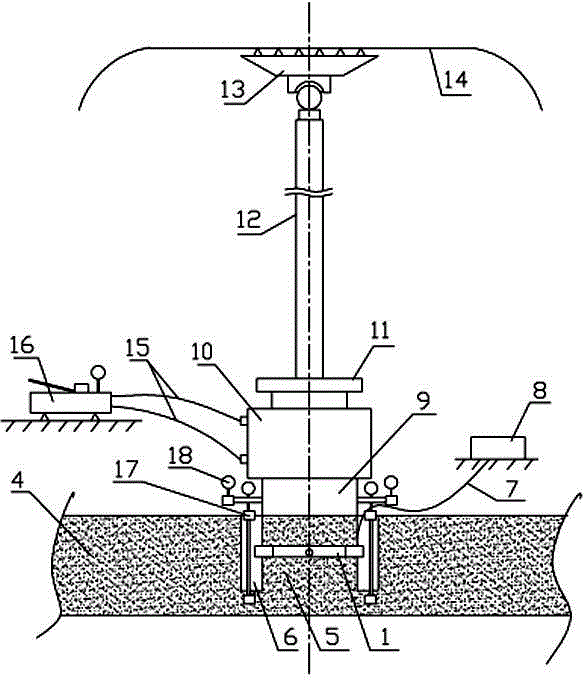

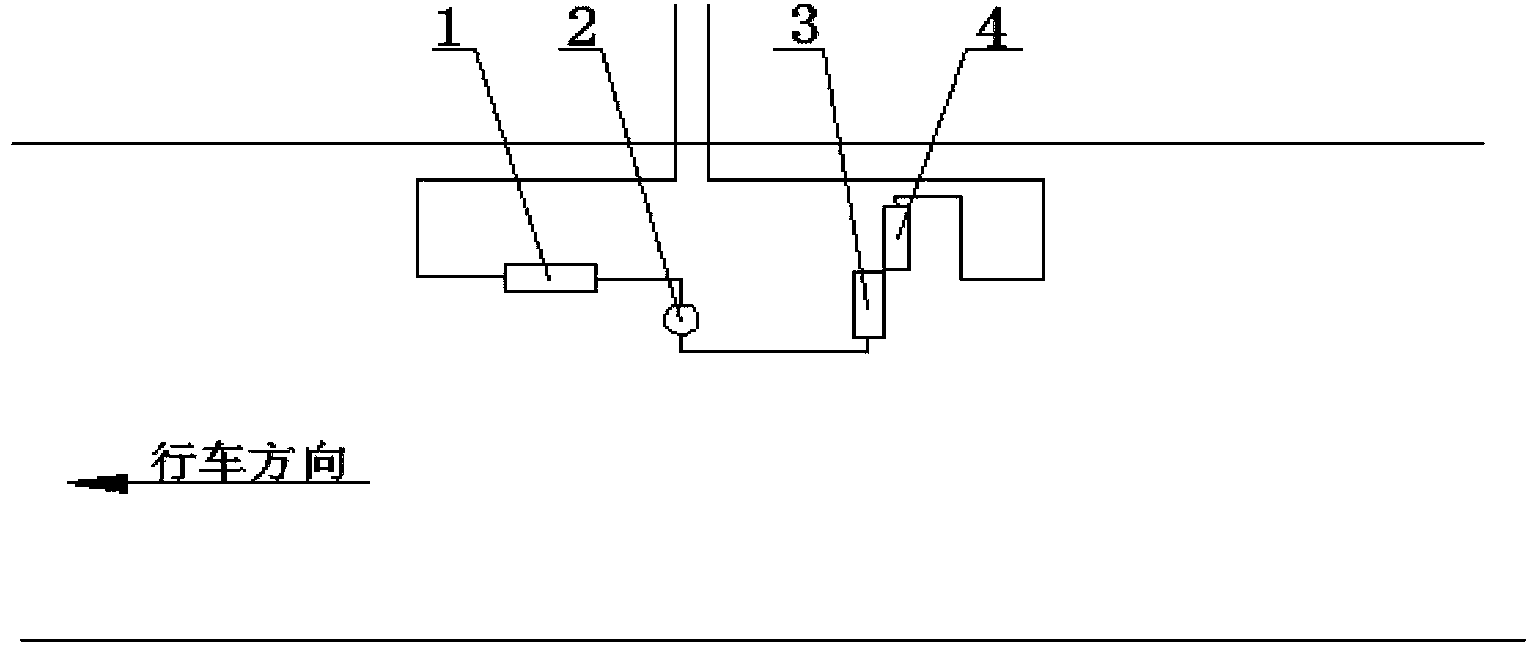

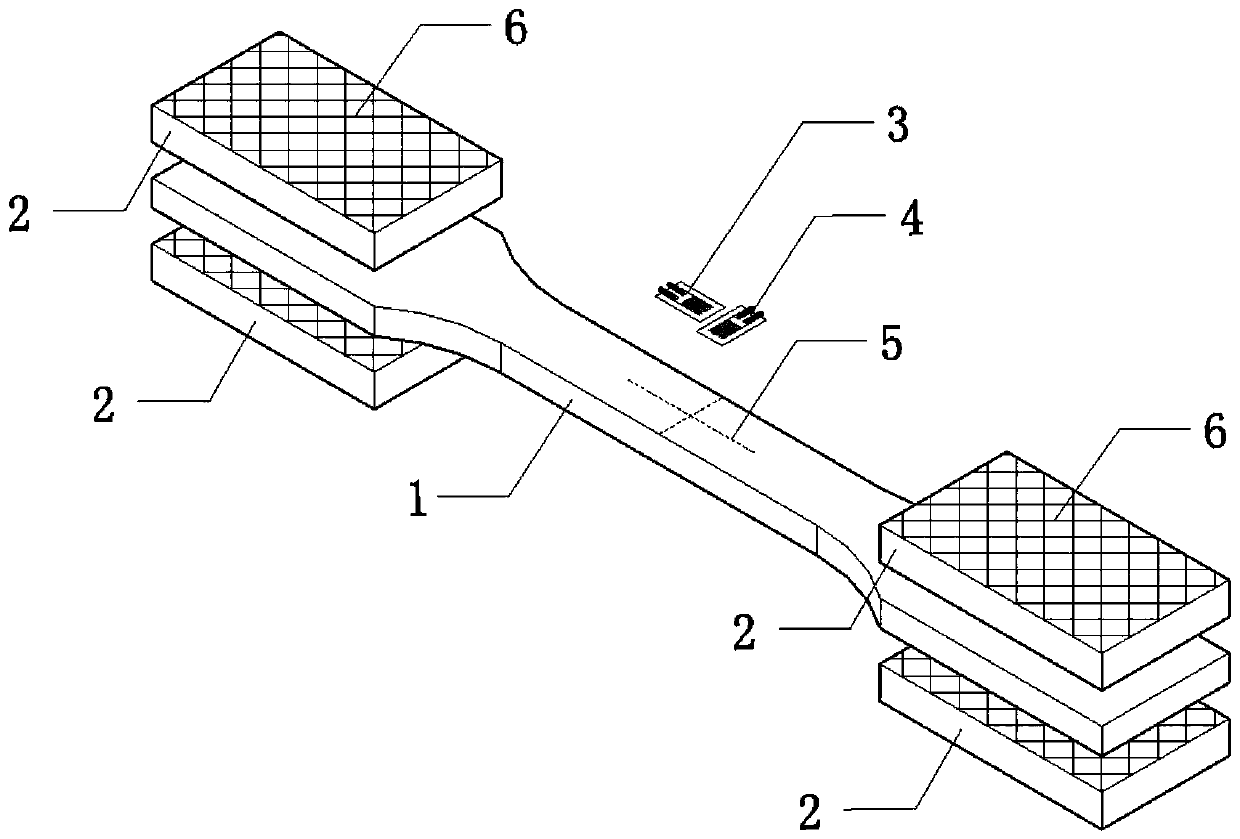

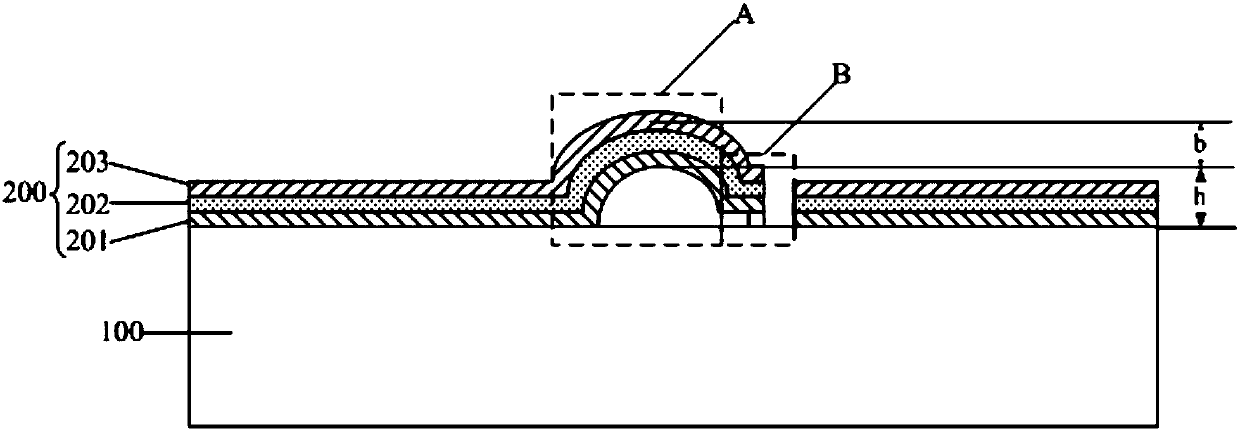

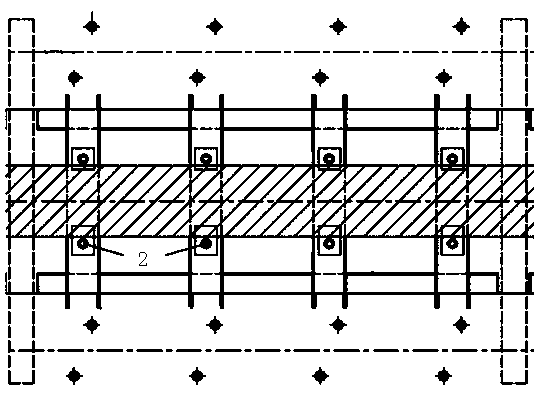

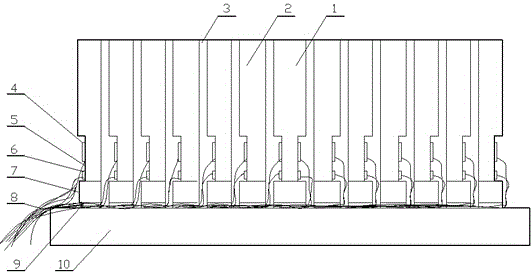

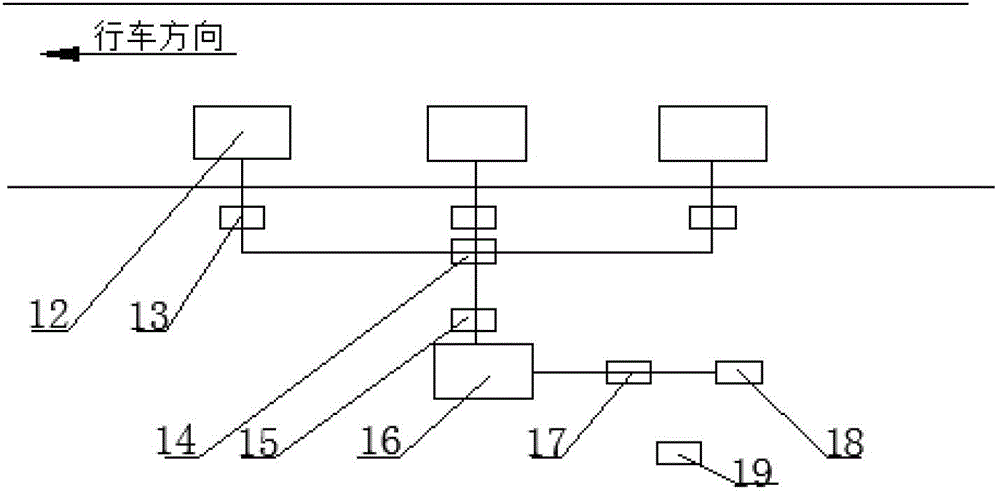

Long-term real-time monitoring system for asphalt pavement structure information based on optical fiber Bragg grating sensor

InactiveCN102900011ARealize evaluationRealize the estimateEmbedding padsRoads maintainenceGratingRoad surface

The invention discloses a long-term real-time monitoring system for asphalt pavement structure information based on an optical fiber Bragg grating sensor and relates to a long-term real-time monitoring system for the asphalt pavement structure information. The long-term real-time monitoring system meets the requirement of long-term real-time monitoring of the asphalt pavement structure information. Various data of the asphalt pavement are acquired by adopting A transverse strain sensors, B longitudinal strain sensors, C temperature sensors, D earth pressure gauges, E single point extensometers, F vertical strain sensors, G humidity sensors, a dynamic weighing sensor and a shaft position sensor and are processed by a server, and thus the long-term real-time monitoring on the asphalt pavement structure information is realized. The long-term real-time monitoring system disclosed by the invention is suitable for long-term real-time monitoring of the asphalt pavement structure information.

Owner:HARBIN INST OF TECH

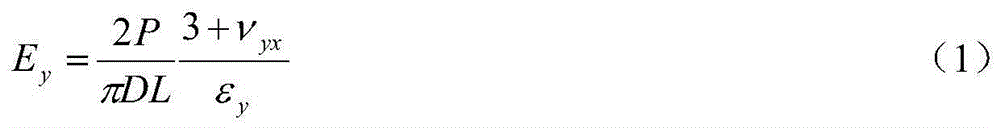

Testing method for one-time measurement of tensile modulus and compression modulus of rock

ActiveCN105158070AThe test method is simple and feasibleThe data is accurate and reliableMaterial strength using tensile/compressive forcesEngineeringRock sample

A testing method for one-time measurement of the tensile modulus and the compression modulus of rock comprises steps as follows: a horizontal strain gauge and a vertical strain gauge are pasted at centers of front and back sides of a disk sample respectively; the disk sample is placed on a press for a Brazilian disk test, the load force P is monitored by a pressure sensor, and the horizontal strain gauge and the vertical strain gauge monitor transverse strain epsilon x and vertical strain epsilon y of the centers of the disk sample respectively; the tensile modulus and the compression modulus of the rock are calculated as per the following formulas shown in the specification, wherein Ex and Ey represent the tensile modulus and the compression modulus of the rock respectively, P is the external load, D is the disk diameter, L is the disk thickness, vyx represents the x-direction transverse deformation coefficient caused by y-direction stress, and epsilon x and epsilon y represent the transverse strain and the vertical strain of the disk centers respectively. The tensile modulus and the compression modulus of the rock can be measured on the same rock sample through one test, the test method is simple and easy to implement, data are accurate and reliable, and results are more scientific.

Owner:NORTHEASTERN UNIV LIAONING

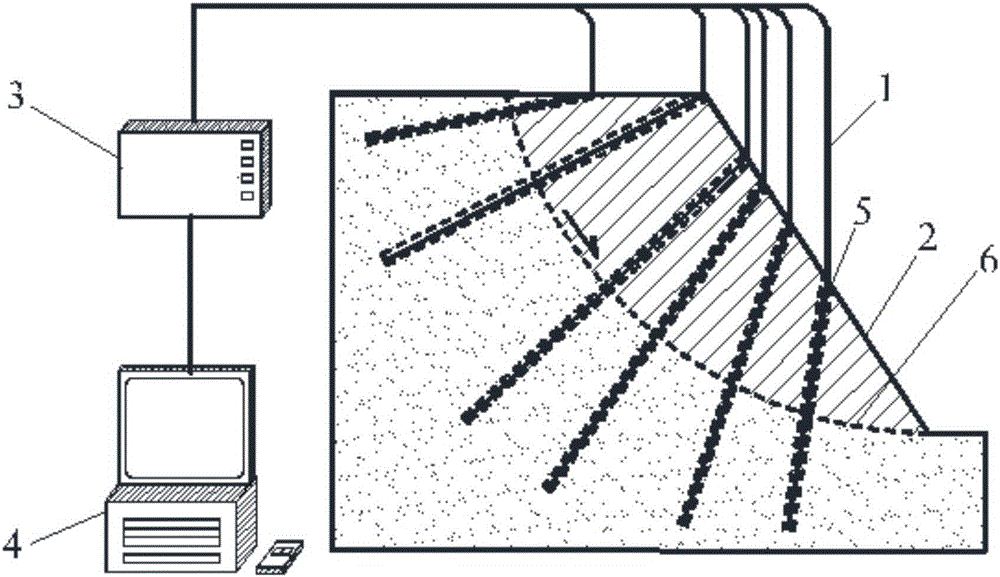

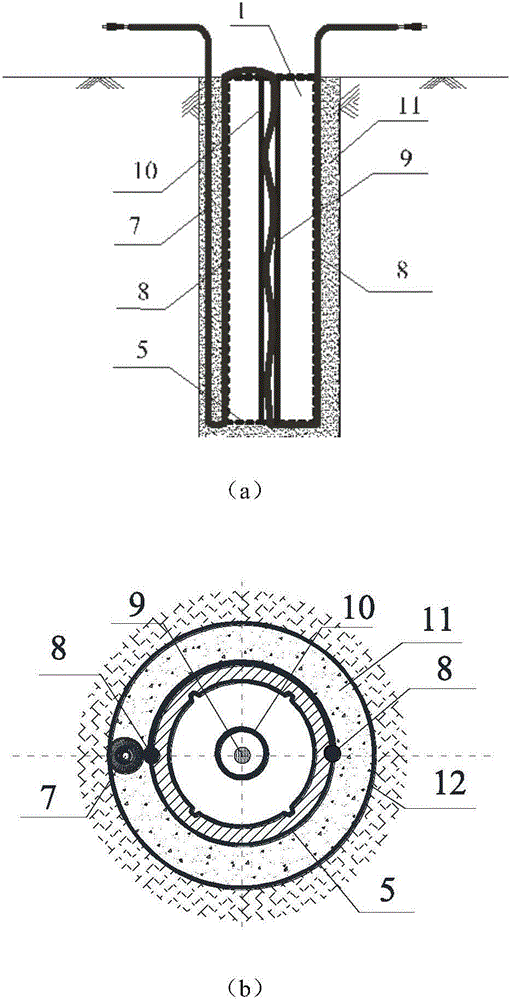

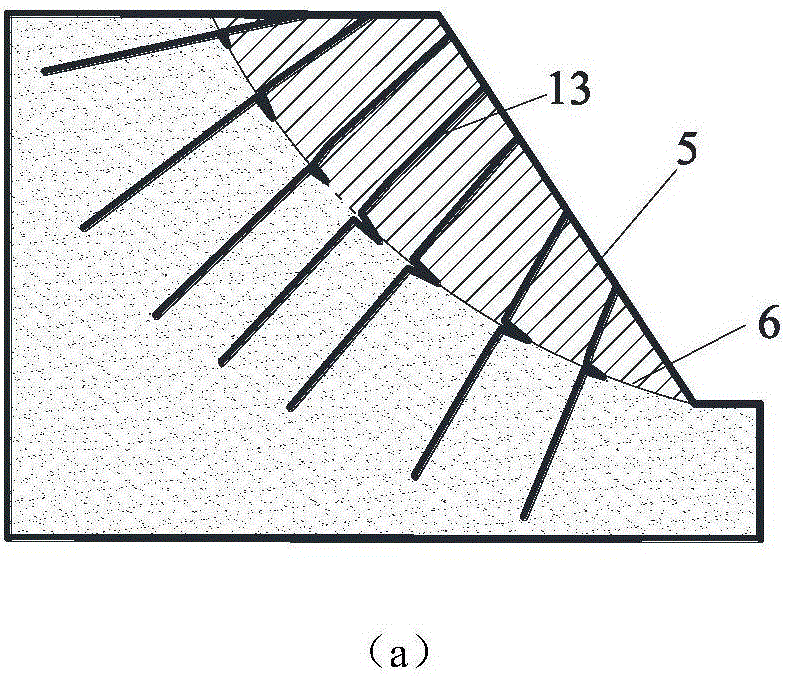

Slope stability monitoring and landslide warning and forecasting method based on all-fiber sensor network

ActiveCN106767476AHigh monitoring sensitivityAccurately identify critical safety statesMaterial heat developmentUsing optical meansFiberBedrock

The invention discloses a slope stability monitoring and landslide warning and forecasting method based on an all-optical fiber sensing network. A number of drill holes are drilled in a direction perpendicular to a potential sliding surface or a joint surface and a bedrock surface in the top and surface of a rocky soil slope. An all-optical fiber integrated gauging pipe is buried in each drill hole. All optical fibers are mutually welded to form the all-optical fiber sensing network which is connected with an optical fiber demodulator to measure the strain and temperature distribution of each optical fiber. On the basis of early monitoring results, the vertical strain eigenvalue of the slope is selected, and the safety factor of the slope is acquired. The empirical relationship between the vertical strain eigenvalue and the safety factor is acquired. According to the measured result of the vertical strain eigenvalue, the safety factor of the slope is estimated, and warning and forecasting of slope instability are realized. Based on the optical fiber monitoring data, the process of birth, occurrence and development of the potential sliding surface of the slope and the position of a multi-level potential sliding surface can be accurately identified.

Owner:NANJING UNIV

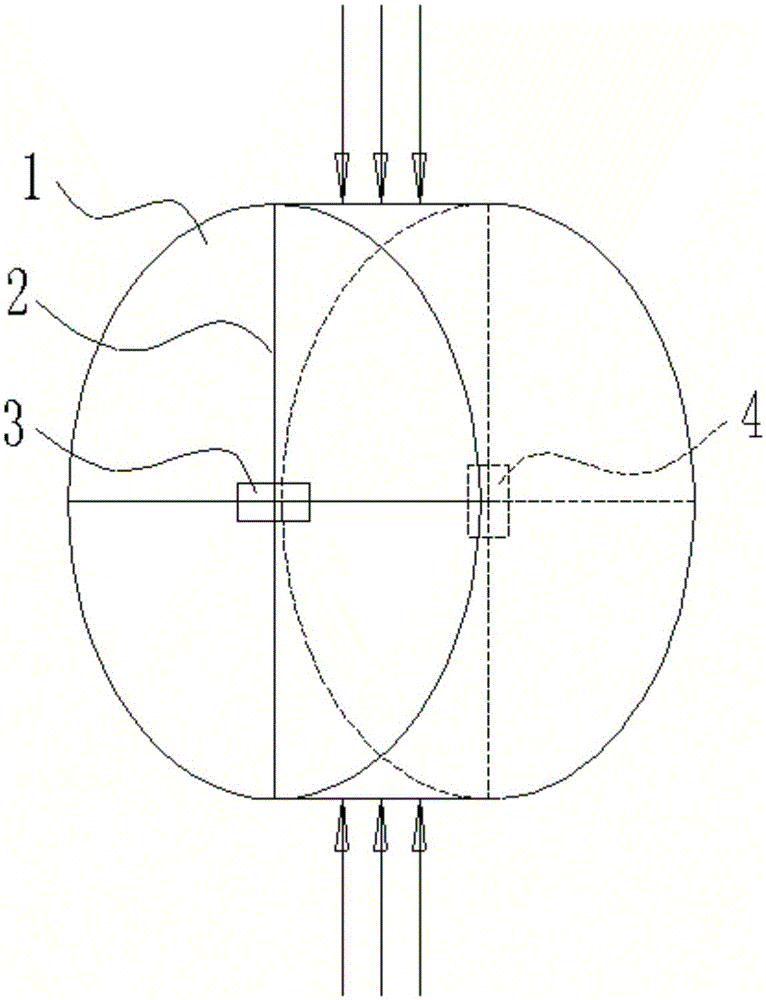

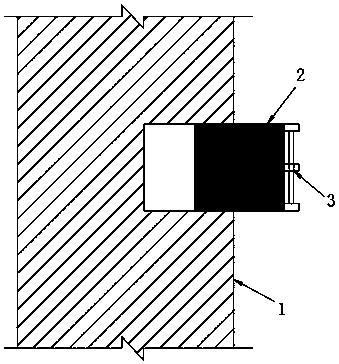

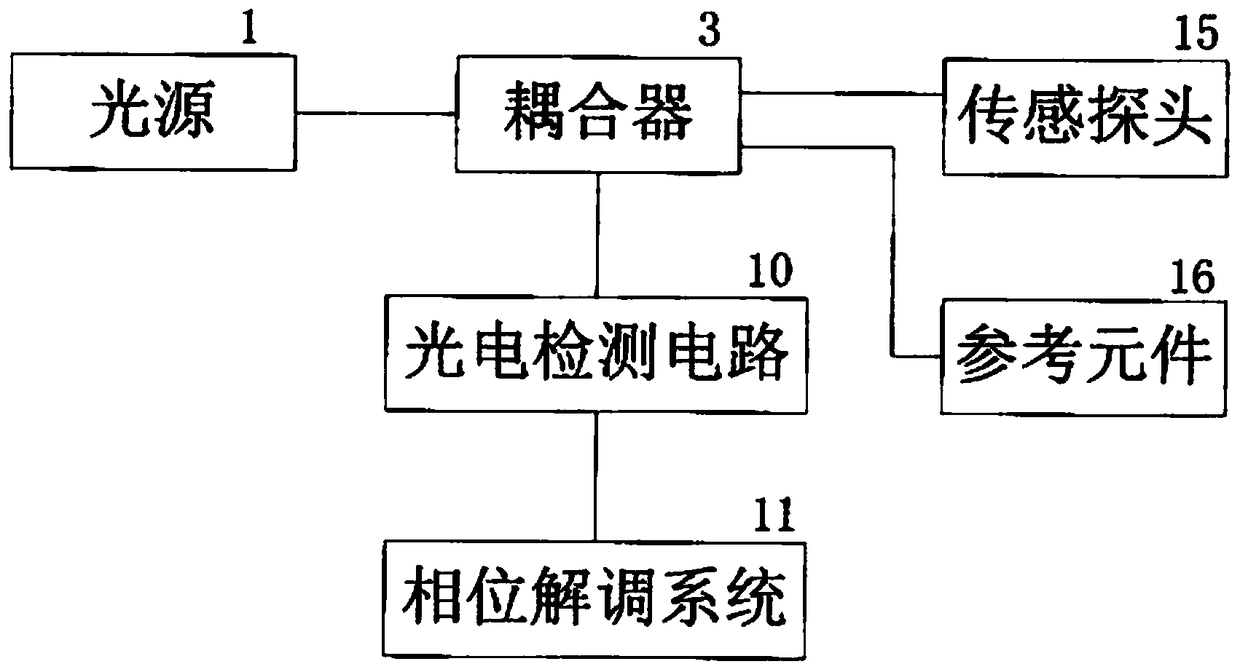

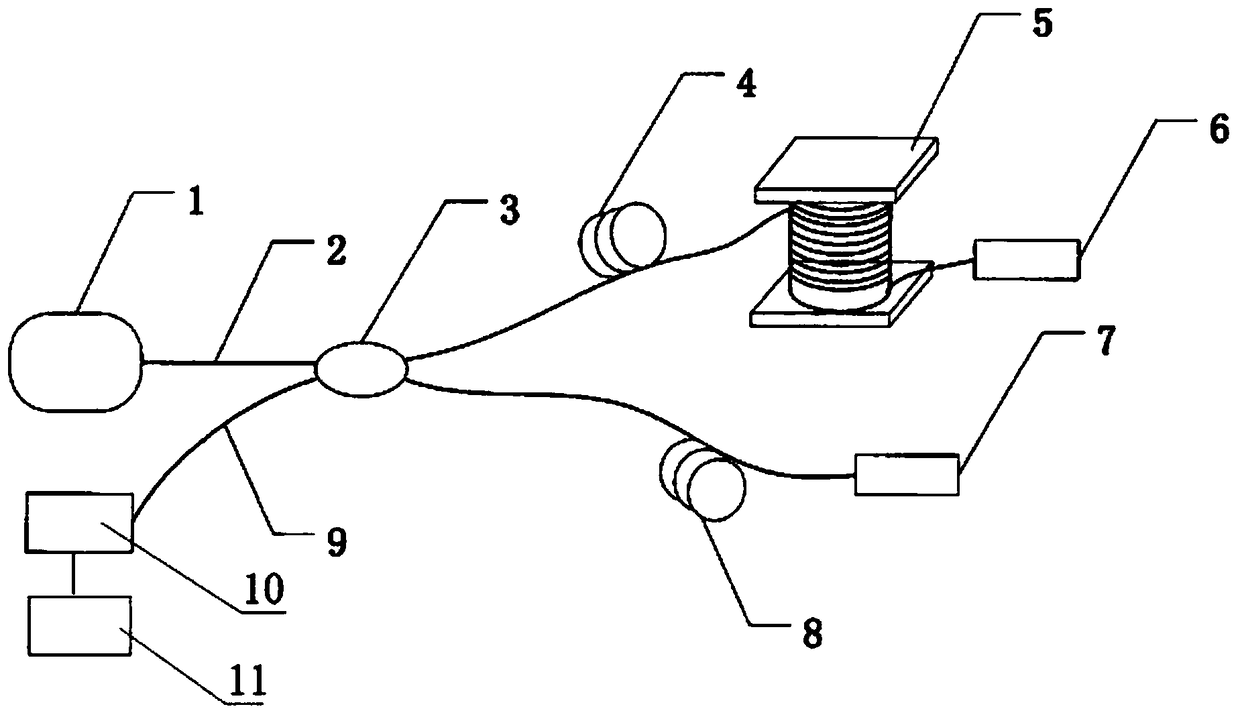

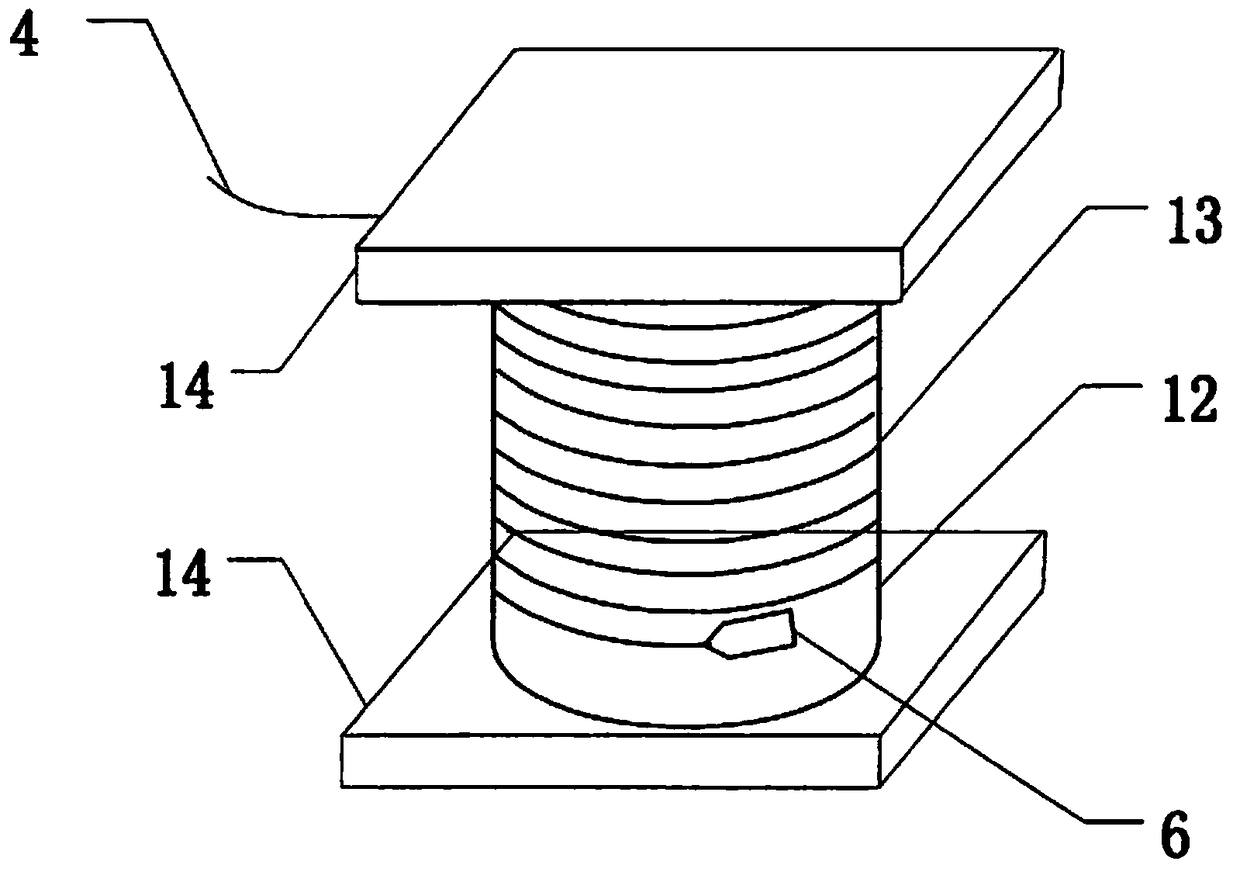

Optical fiber interference water level sensor

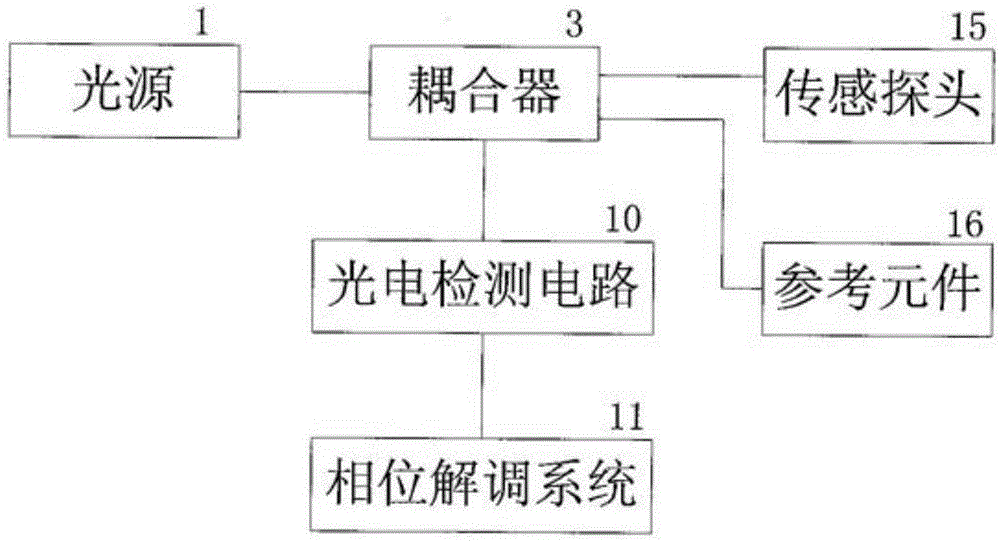

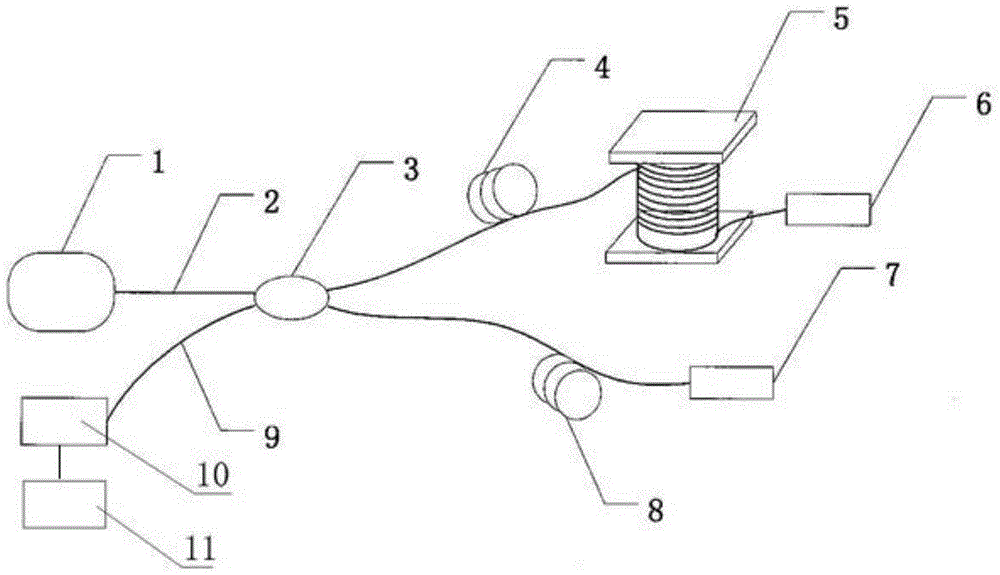

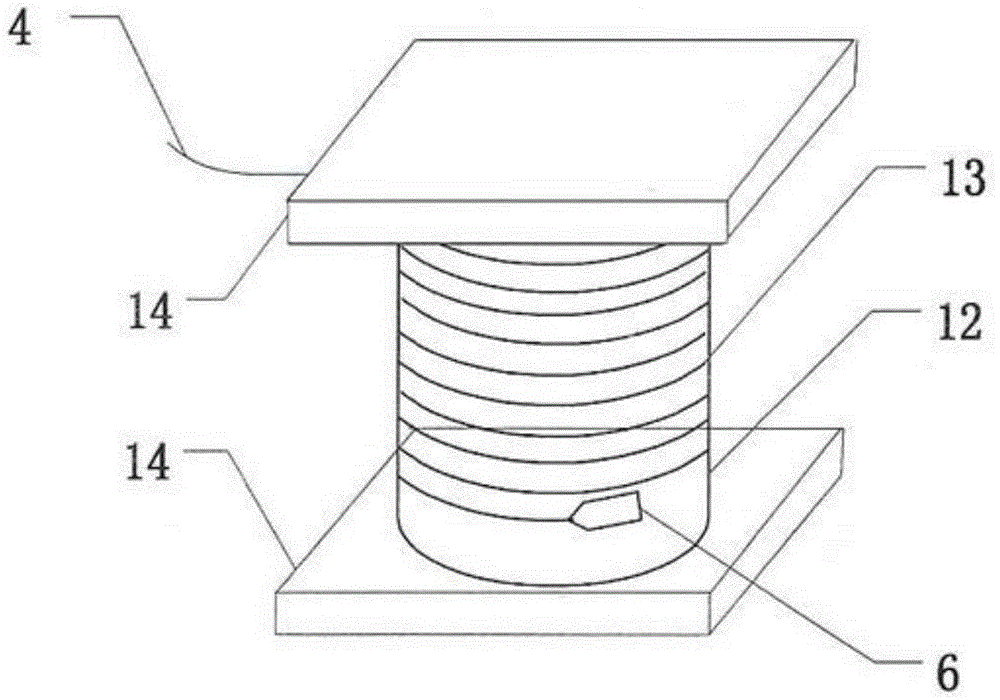

InactiveCN104697609AExquisite structureExtended service lifeMachines/enginesLevel indicatorsPhotovoltaic detectorsPhase difference

The invention discloses an optical fiber interference water level sensor. The optical fiber interference water level sensor is composed of a semiconductor laser device, a 3dB coupling device, a sensitive element, a Faraday polariscope, a light guide optical fiber, a photoelectric detector and a computer, wherein the sensitive element is a key part of the water level sensor and is used for converting the change of a water level into vertical strain and radial strain of the optical fiber so that the phase difference of two interference arms is changed; finally, the change of the water level is inverted by using the change of the phase difference. By the aid of the optical fiber interference water level sensor, the high-precision water level measurement can be realized, and the optical fiber interference water level sensor has the advantages of reliability, electromagnetic interference resistance, corrosion resistance, high sensitivity, simple and exquisite structure and the like, and is suitable for the environment needing high-precision water level monitoring.

Owner:JILIN UNIV

Field rock mass poisson ratio test method

InactiveCN104483199AFully reflect the real stateLow costMaterial strength using tensile/compressive forcesElectrical/magnetic solid deformation measurementElectrical resistance and conductanceBedrock

The invention discloses a field rock mass poisson ratio test method. The method comprises the steps of firstly digging a test flat hole in a mountain, drilling a cylindrical test piece on bedrock on the bottom surface of the test flat hole by utilizing a hollow drill bit, and symmetrically perforating test holes in the bottom of an annular groove at the periphery of the test piece; sleeving the test piece with an elastic steel lantern ring provided with a steel contact and a strain plate, connecting a strain plate test line and a resistance strain gauge, and calculating transverse deformation of the test piece by virtue of test; fixing the top surface of the test piece together with a test flat hole top plate sequentially through a pressure plate, a jack, a reducing connector steel plate, a combined force transfer rod and a hinge anchor, installing measuring points in bolt holes in two sides of the pressure plate and in the test holes in the bottom of the annular groove, and installing a dial indicator above the measuring point; calculating vertical deformation of the test piece after the load test; then calculating a corresponding transverse strain value and a vertical strain value, and calculating the poisson ratio of the test piece according to the transverse strain value and the vertical strain value. The field rock mass poisson ratio test method has advantages that the implementation method is simple and rapid, the measurement data is accurate and reliable, and the real condition of the rock mass can be comprehensively reflected.

Owner:YELLOW RIVER ENG CONSULTING

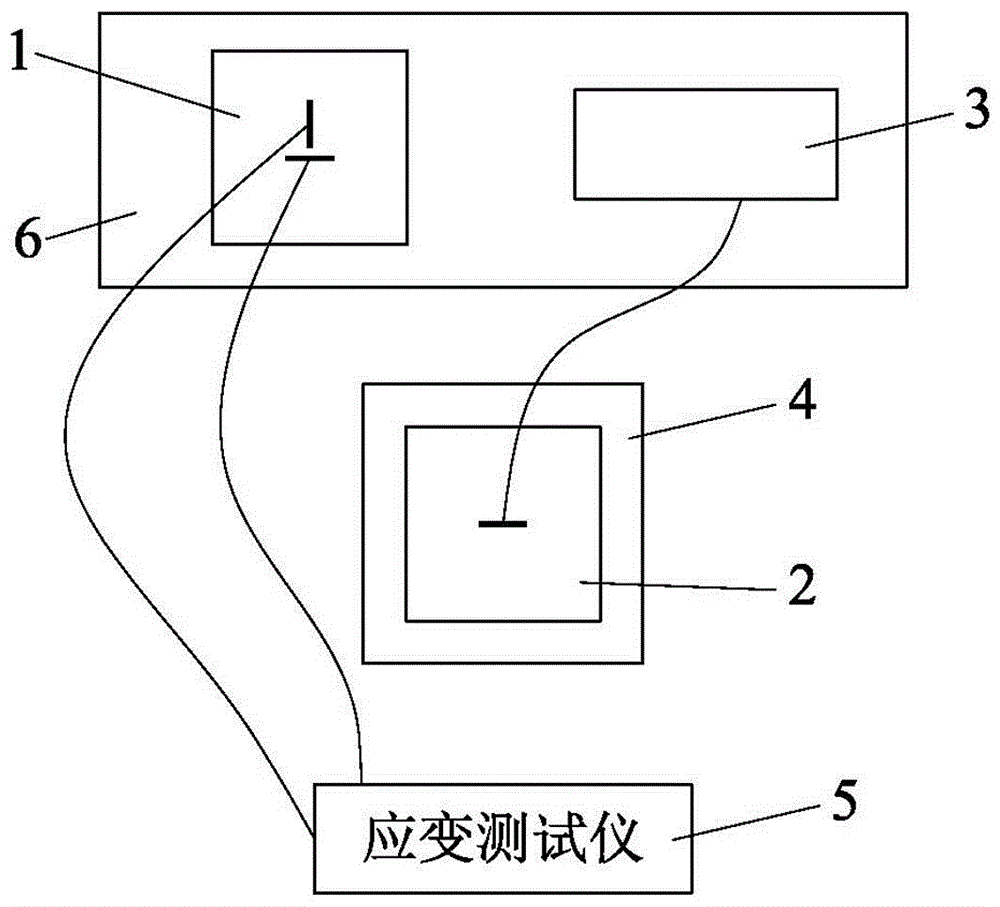

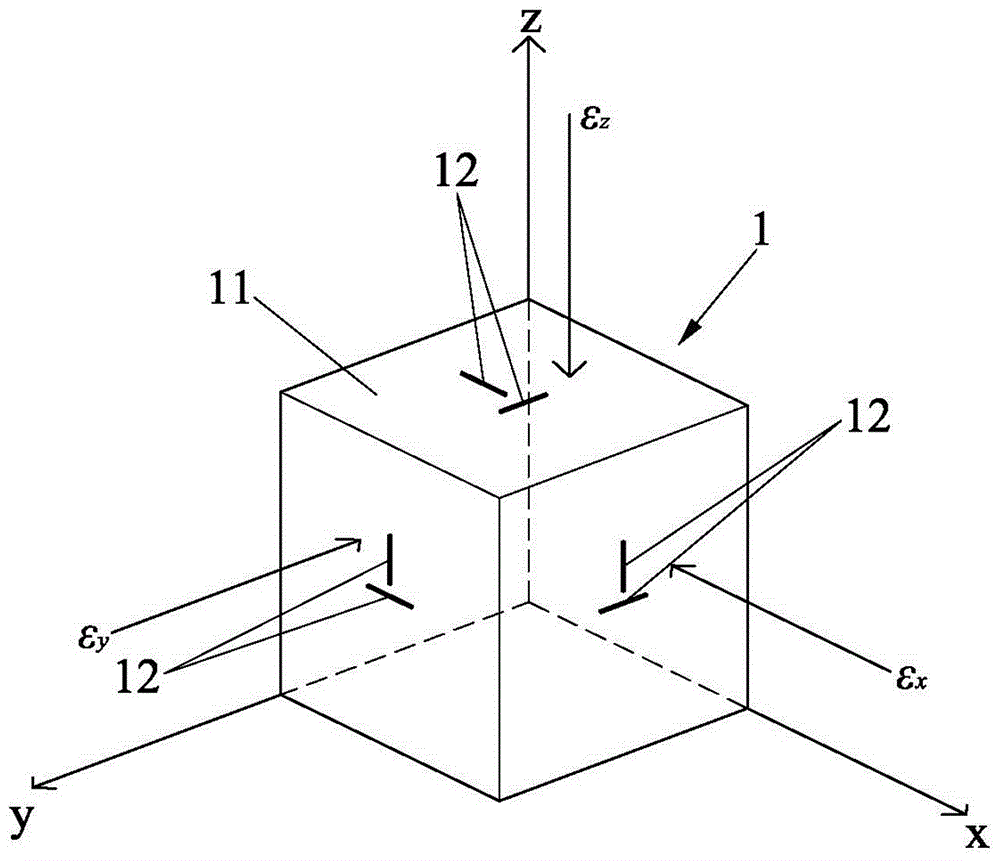

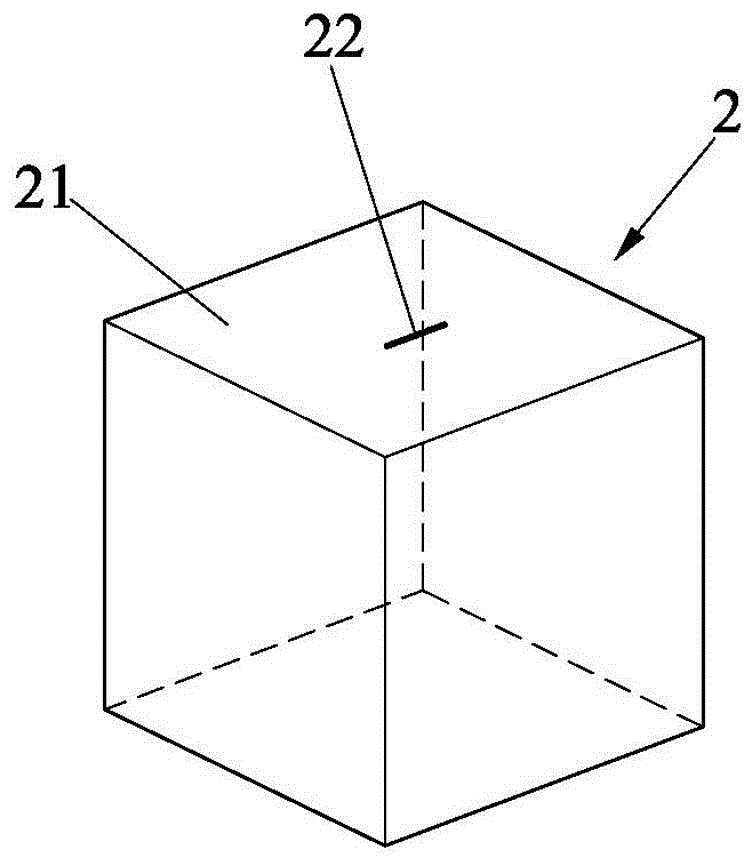

Measuring system and method for concrete non-load internal stress in concrete structure

InactiveCN106771102AImprove test accuracyEliminate the effects ofMaterial testing goodsTester deviceRebar

The invention relates to a measuring system and method for a concrete non-load internal stress in a concrete structure. The system comprises a metal block sensor, a temperature compensation block, a temperature sensor, a temperature heating box and a strain tester, wherein the metal block sensor and the temperature sensor are buried in to-be-measured concrete; the temperature compensation block is placed in the temperature heating box and is located on the to-be-measured concrete; the metal block sensor comprises a metallic lumpish test block; at least three mutually vertical strain gages are adhered to the test block; the temperature compensation block comprises a metallic lumpish compensation block; one temperature strain gage is adhered to the compensation block; the strain gages and the temperature strain gage are connected with the strain tester in the manner of 1 / 4 bridging; the poisson ratio and coefficient of linear expansion of the test block and the compensation block are similar to those of the concrete; the temperature sensor is connected with the temperature heating box. According to the invention, the influences of inner temperature change of the concrete in early period of the concrete and different rebar reinforcement ratios on the internal concrete stress can be avoided and the test precision is higher.

Owner:XIAMEN UNIV OF TECH

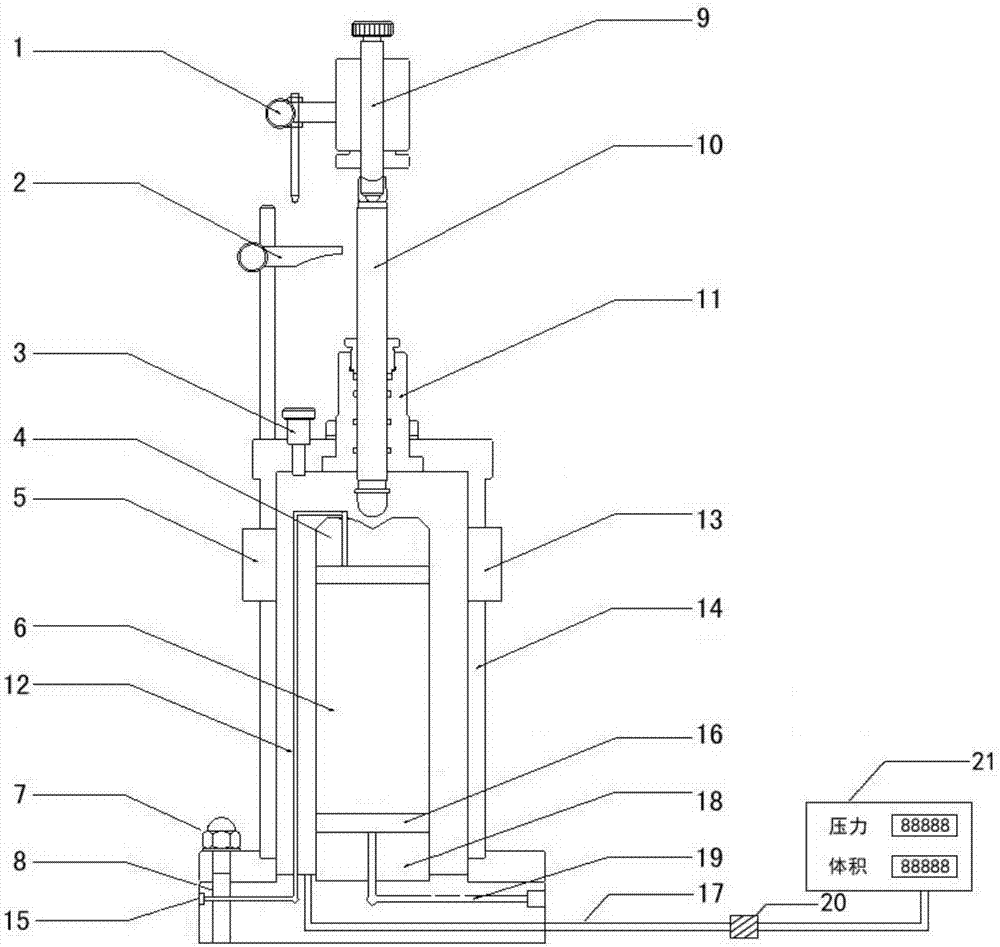

Triaxial experiment instrument pressure chamber for measuring rock specimen volume strain and operation method thereof

PendingCN107991170AConstant pressureAvoid subjective influenceStrength propertiesWater sourceEngineering

The invention discloses a triaxial experiment instrument pressure chamber for measuring rock specimen volume strain and an operation method thereof. The triaxial experiment instrument pressure chambercomprises a base and a pressure cabin arranged on the base, wherein the pressure cabin is a confining pressure sealed accommodating cavity; a precise volume pressure controller and a pressure sensorconnected in the pressure cabin jointly act; the pressure in the cabin is enabled to be strictly invariant by regulating the water inlet and outlet quantity, so that the water outlet quantity is the volume strain of a rock specimen; finally, the conversion is performed with vertical strain to obtain Poisson's ratio. The condition that errors caused by subjective influence of operators during the position selection in a traditional strain gage pasting method is avoided; the phenomenon of liquid leakage caused by strain gauge conducting wires is also avoided; meanwhile, all parameters can be obtained through once experiment; the data non-unified errors caused by many time of experiments are avoided; the experiment operation process is greatly simplified; the experiment efficiency is improved; the confining pressure is provided through water injection from water inlet holes. Compared with traditional method using oil pressure, the method has the advantages that the water sources are wide;high economic performance is realized; the control is easy.

Owner:CHANGAN UNIV

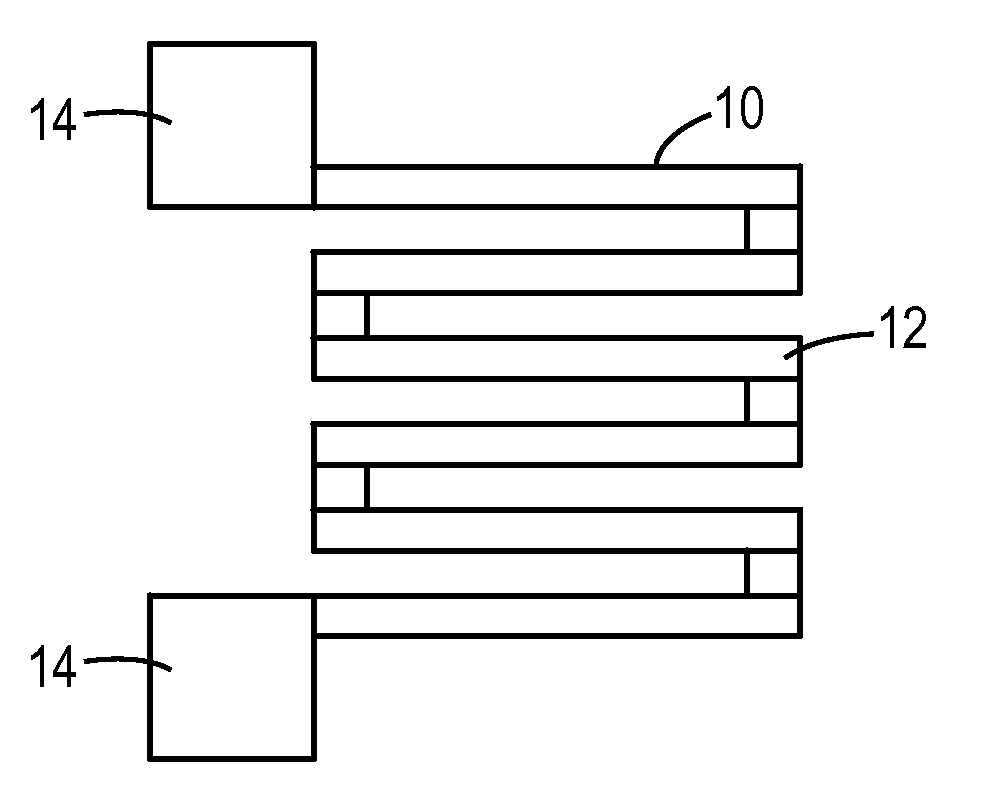

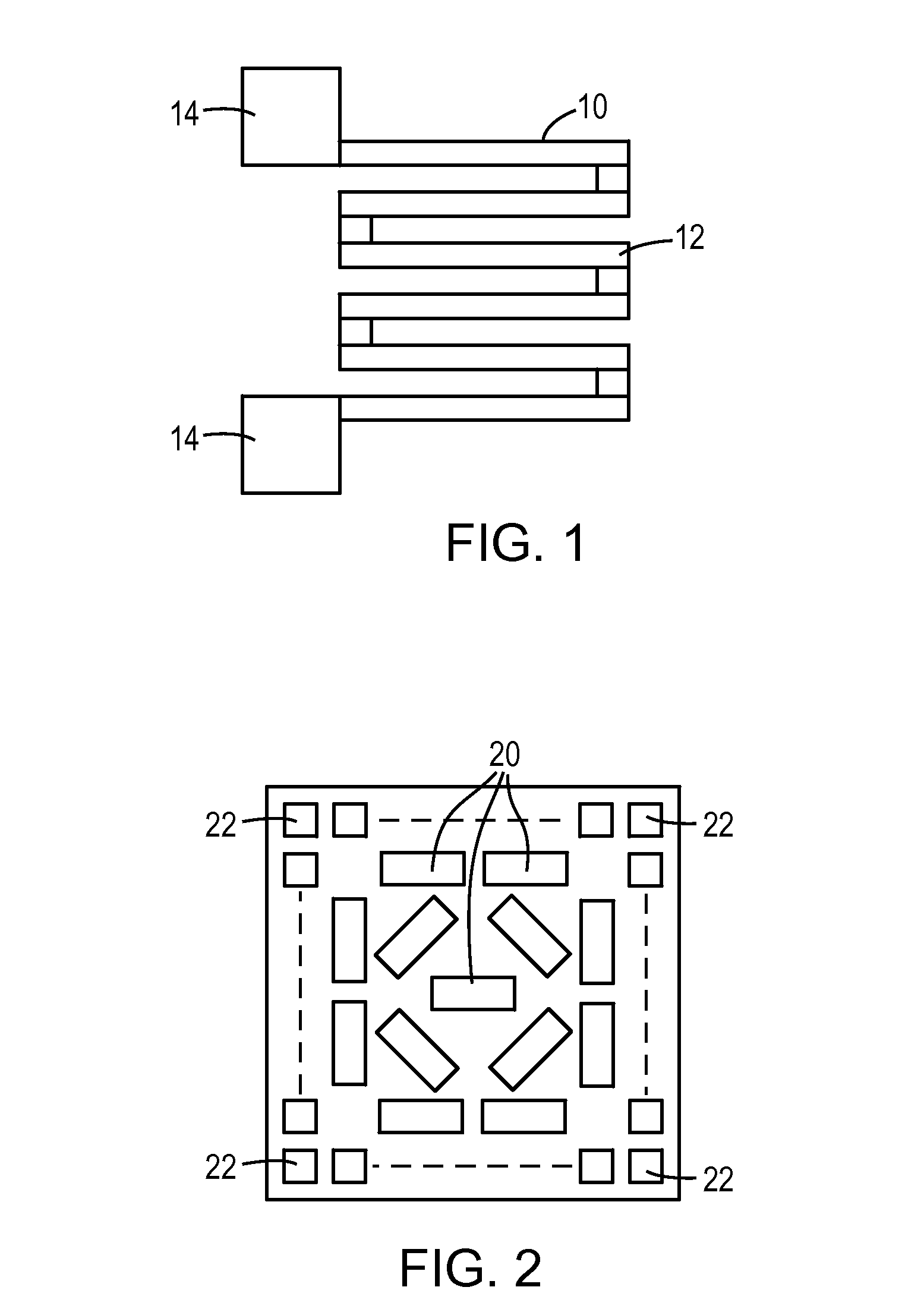

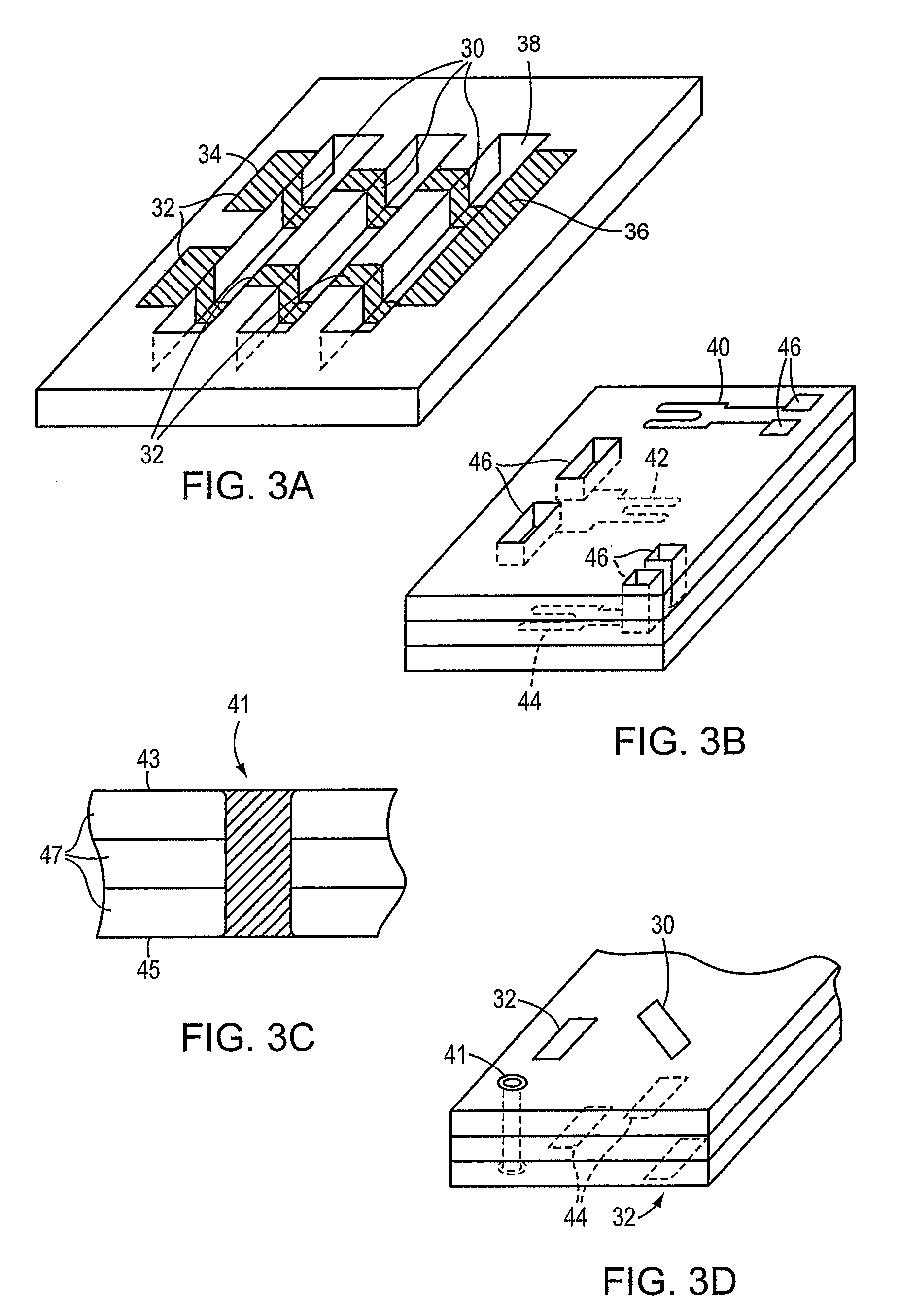

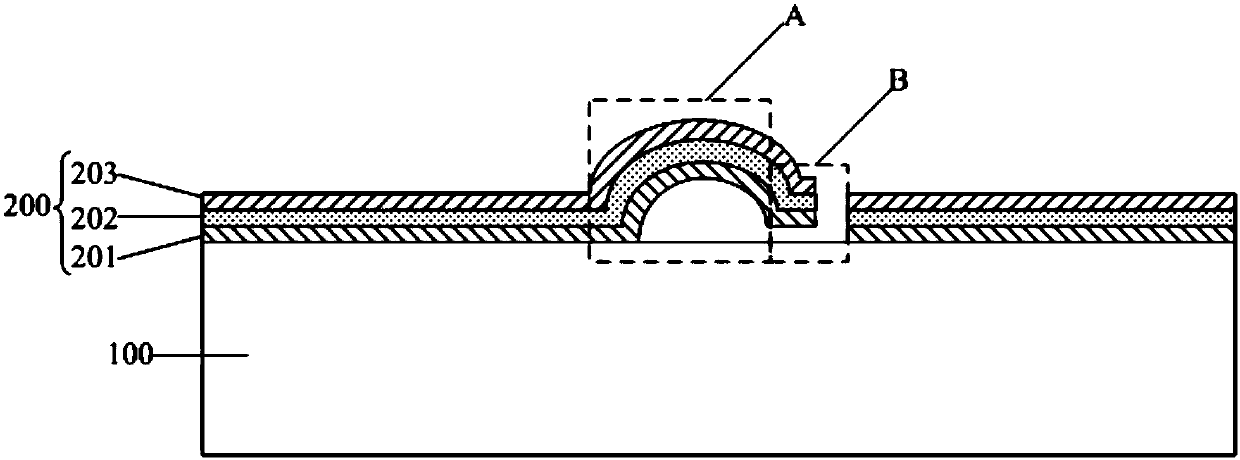

Die scale strain gauge

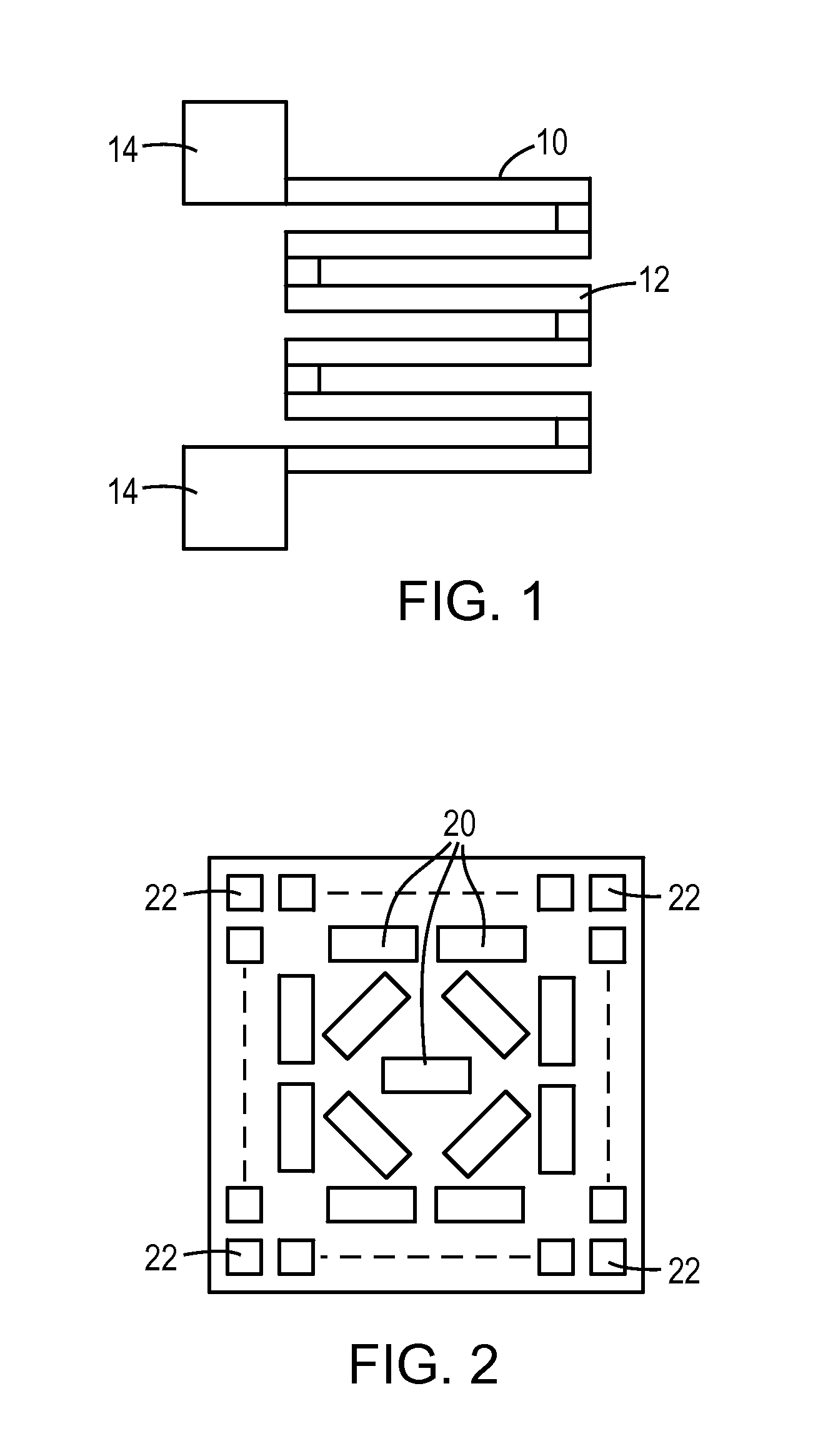

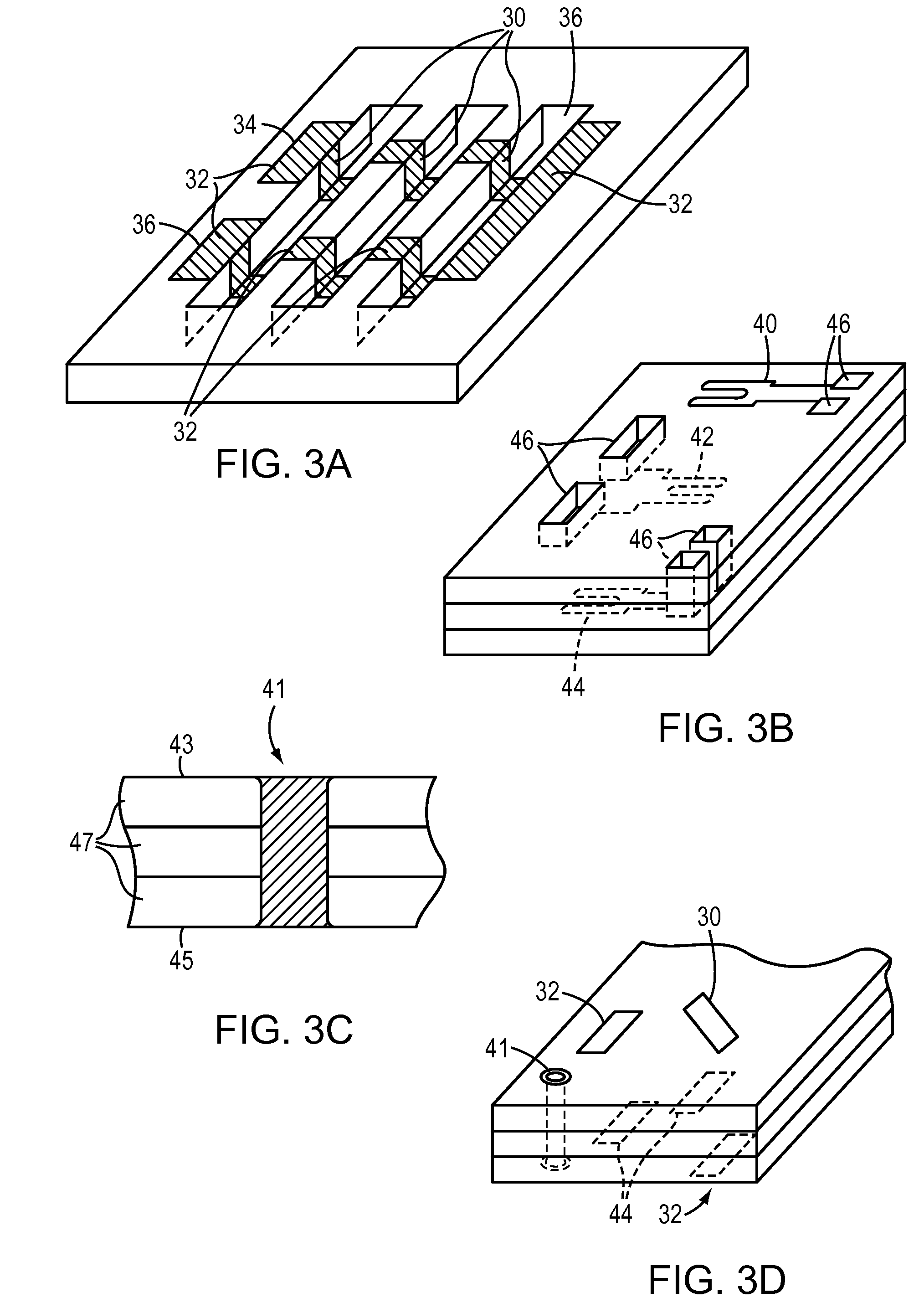

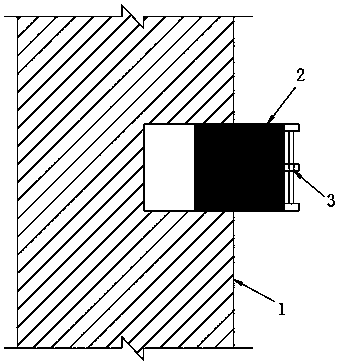

ActiveUS7934430B2Fluid pressure measurement using ohmic-resistance variationForce measurementElectrical resistance and conductanceVertical edge

A chip with resistive, metallic strain gauges distributed on surfaces on and buried within the chip. Also, vertically arranged vias and vertical thin film resistive strain gauges are described. The resistive strain gauges can be multiplexed wherein strain can be measured across the topology of the chip in each of the top, bottom and buried layers and any vertical strain. The resistive strain gauges may be in serpentine patterns and may be arranged on via or on vertical edges of grooves that extend from an upper or lower surface of the chip to buried layers. In this fashion, the distributed strain gauges may be used to map the strain throughout the body of a chip. A Kelvin bridge may be used to measure the strain, but other such measuring techniques and devices may be used.

Owner:SEMICON COMPONENTS IND LLC

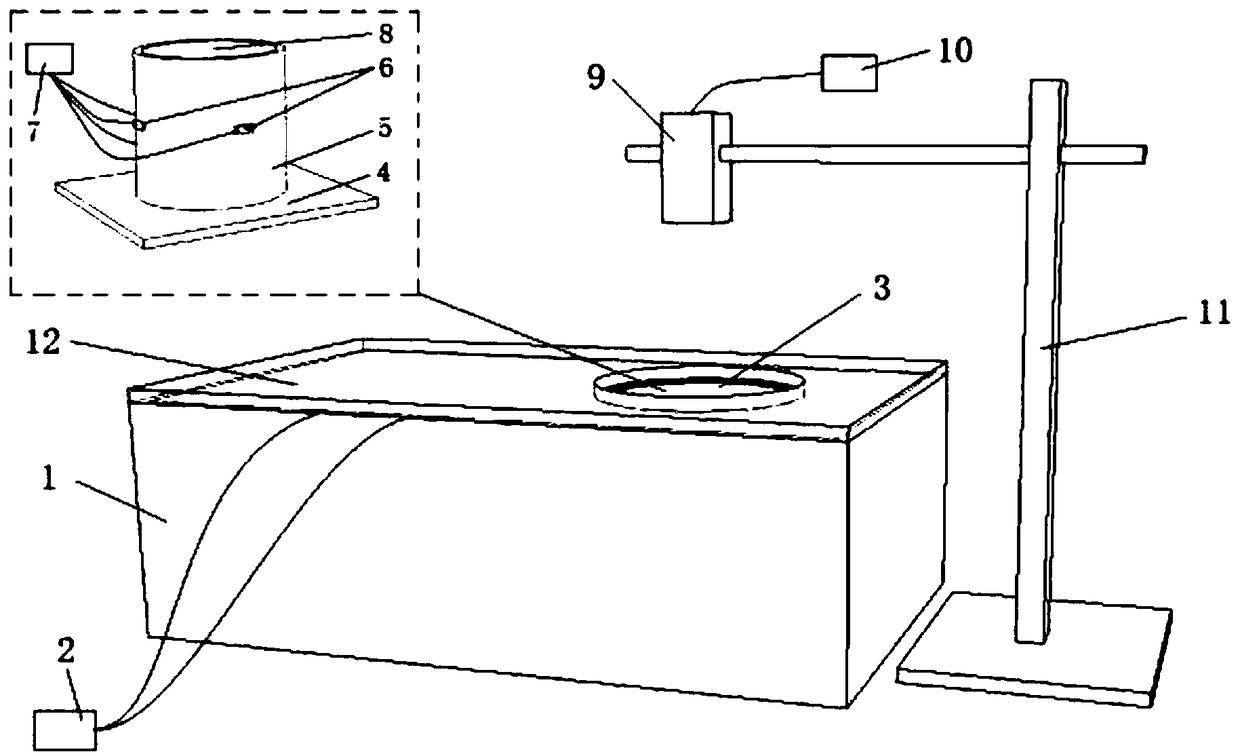

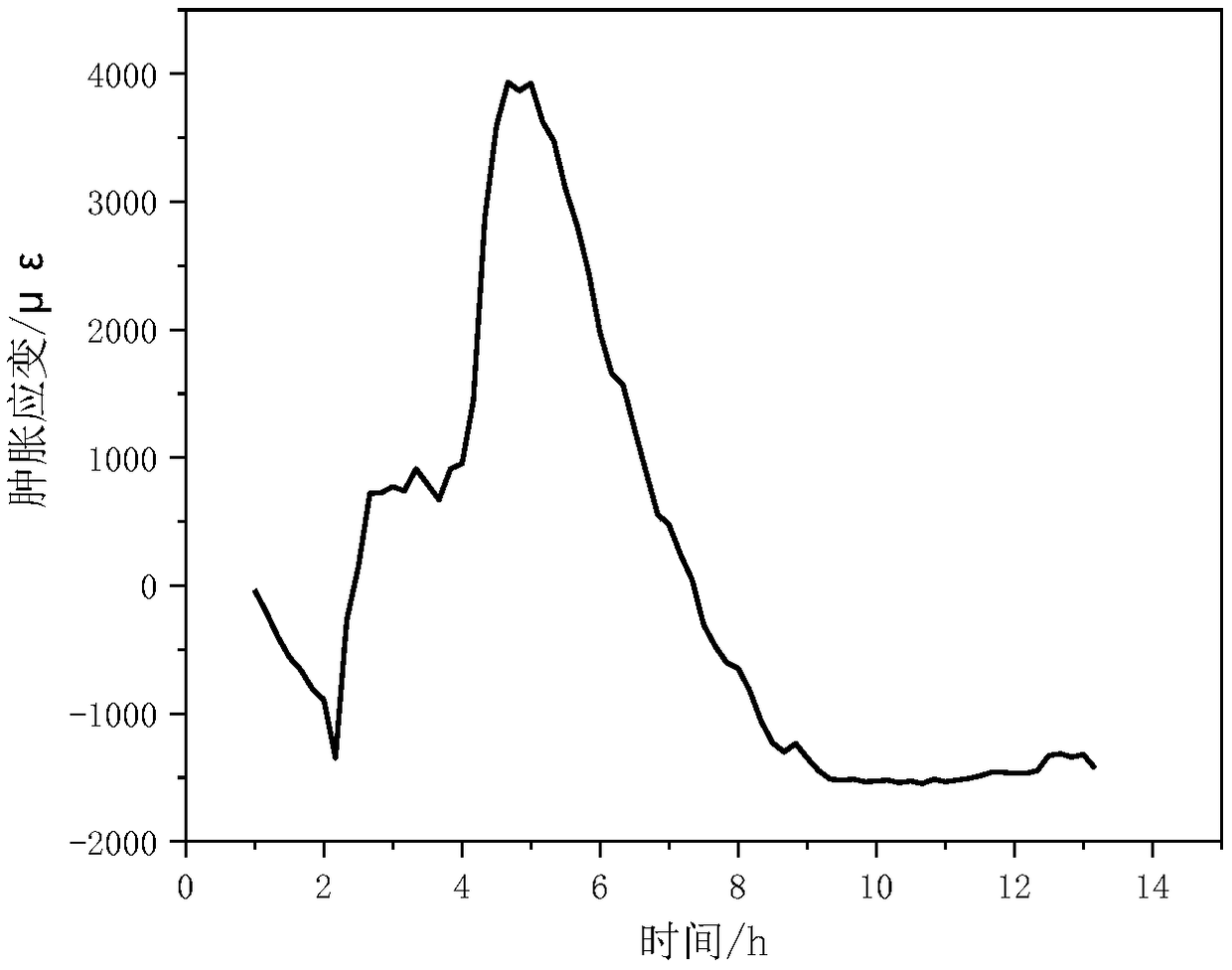

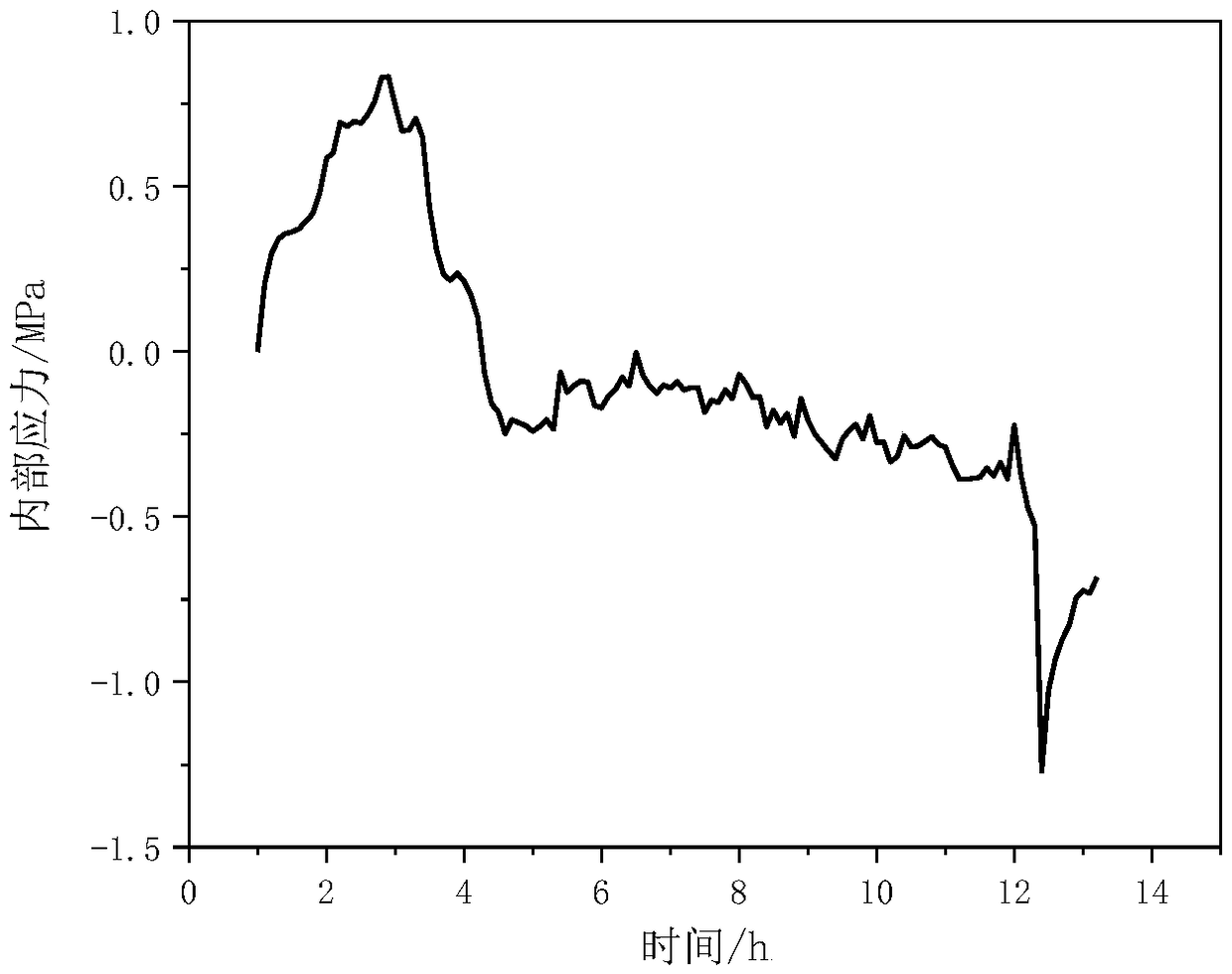

Device and method for monitoring deformation and stress of cement-based material in steaming and maintaining process

ActiveCN109238376AMonitor and calculate deformation featuresQuality improvementMeasurement devicesWater bathsData acquisition

The invention relates to a device and a method for monitoring deformation and stress of a cement-based material in a steaming and maintaining process and belongs to the technical field of test of civil engineering materials. The device comprises a water bath temperature control heating system, a steel ring restraint system, a swelling deformation test system and a stress test system; the water bath temperature control heating system is composed of a rectangular double-layer heat preservation box and a water temperature control system; the swelling deformation test system is composed of a laserdisplacement sensor and a displacement data acquisition instrument; the laser displacement sensor is fixed on a bracket and directly above a test piece; the internal stress test system is composed ofa strain gauge and a strain data acquisition instrument; the strain gauge is attached to the middle of the outer side of a steel ring; and the strain gauge is connected with the strain acquisition system. According to the device and the method for monitoring deformation and stress of a cement-based material in the steaming and maintaining process in the invention, based on volume deformation characteristic of the steamed concrete in the steaming and maintaining process, the swollen steamed cement-based material is restrained through the external steel ring; the internal stress of the concretein the steaming and maintaining process is obtained through calculation by testing strain of the steel ring; and vertical strain is obtained by testing the change in vertical displacement.

Owner:CENT SOUTH UNIV

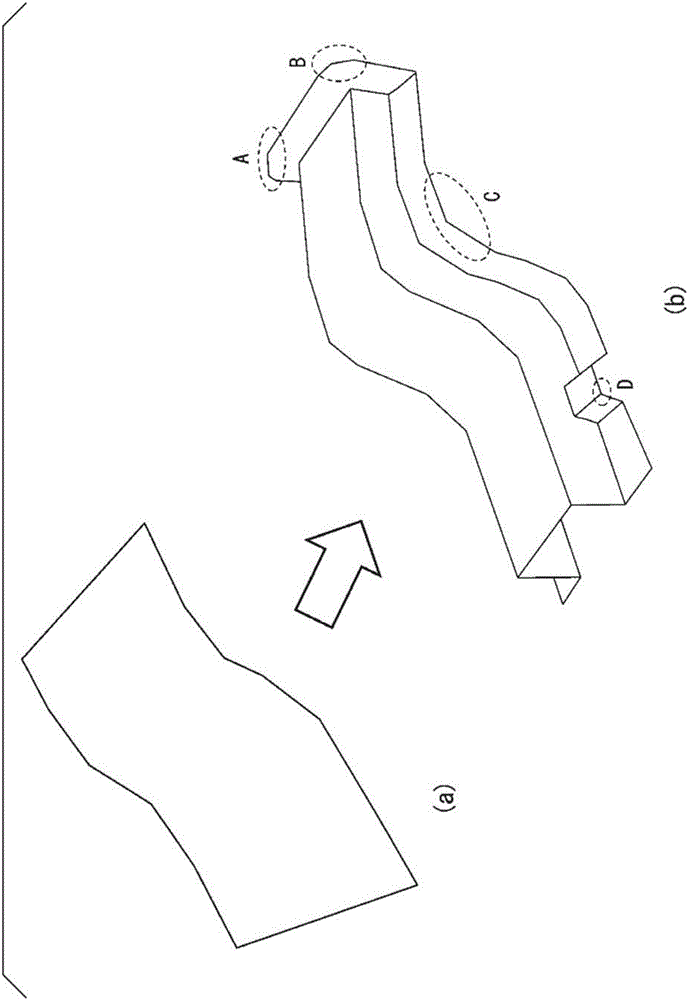

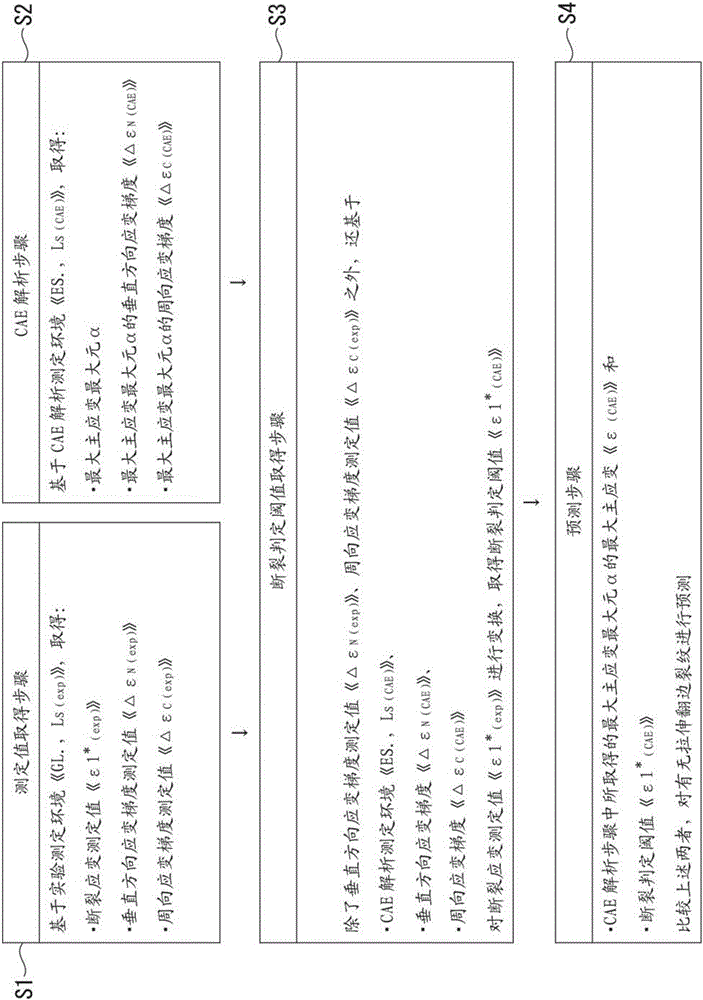

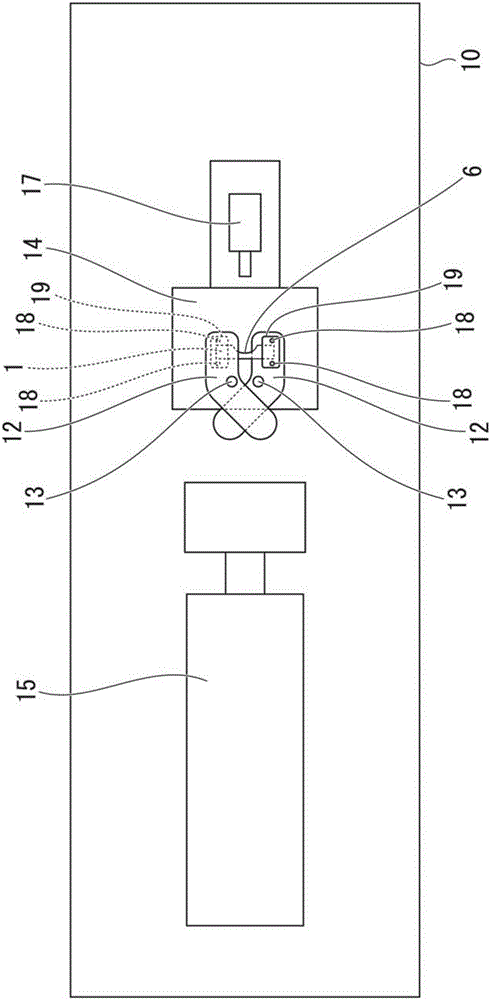

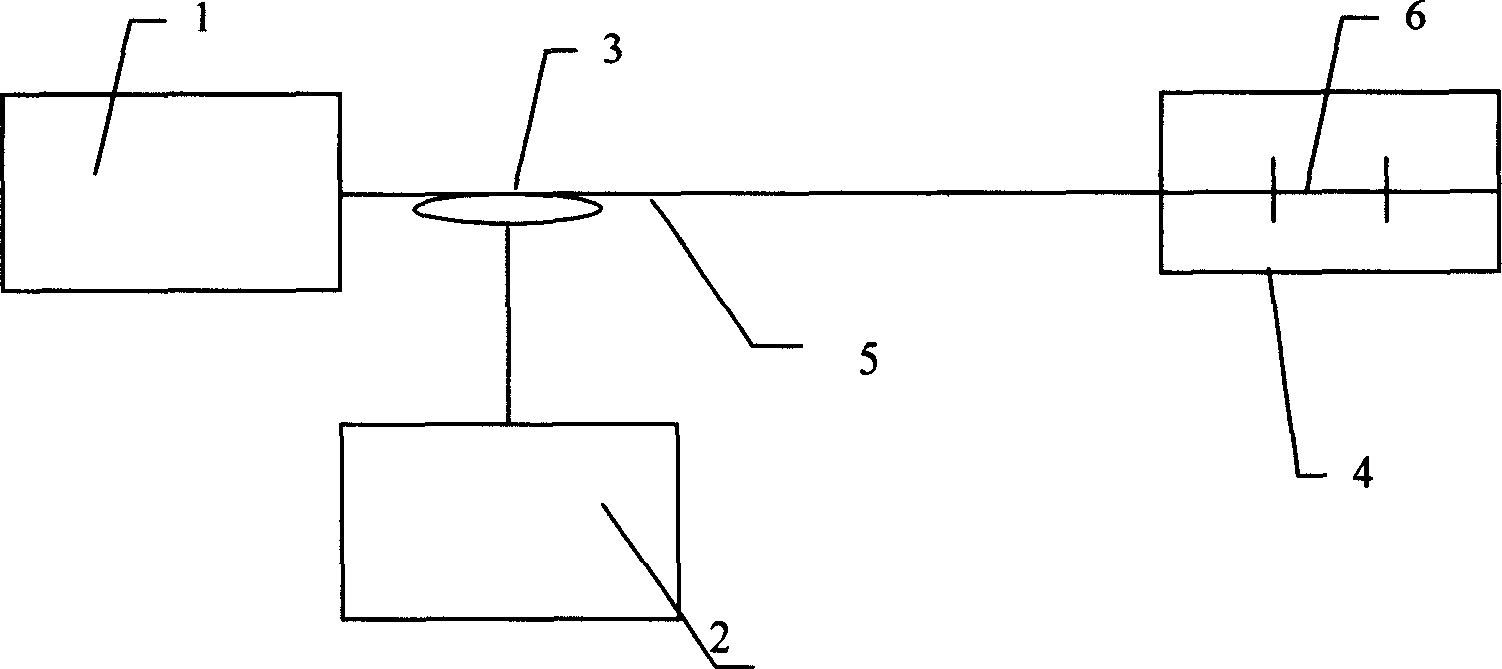

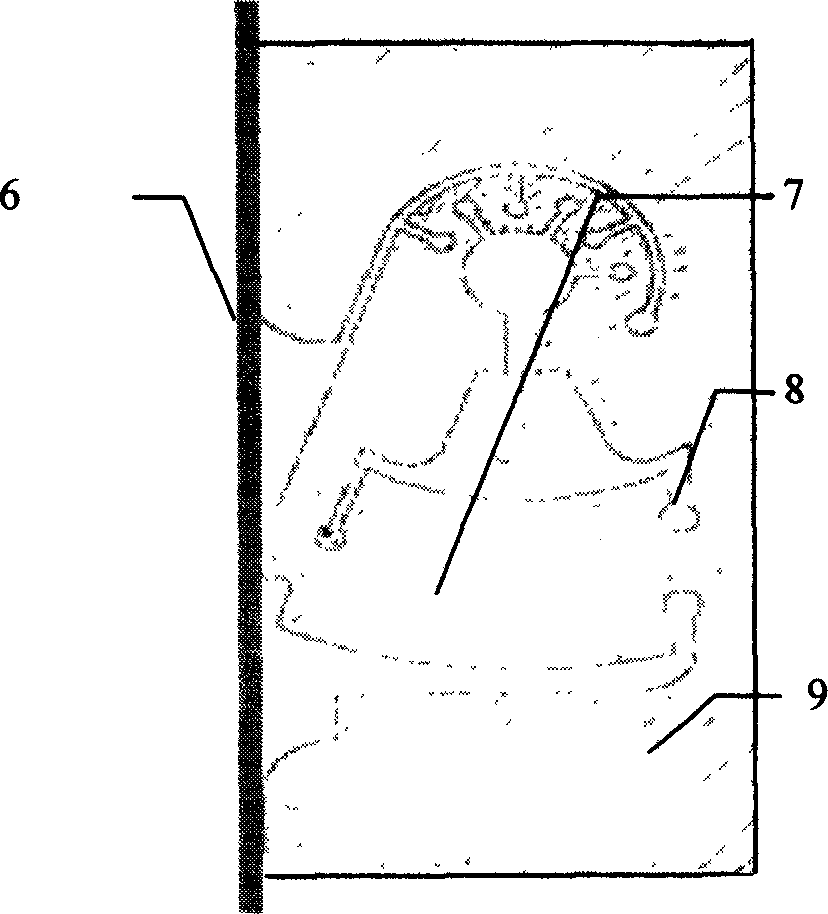

Stretch-flange crack prediction method, stretch-flange crack prediction device, computer program, and recording medium

ActiveCN106470776AAccurate predictionDesign optimisation/simulationAerodynamics improvementCircumferential strainEngineering

This stretch-flange crack prediction method for predicting occurrence of stretch-flange cracking at a flange end part when stretch-flange forming is performed on a plastic plate, wherein the method is provided with: a measured value acquisition step (S1) for acquiring a breaking strain measurement, vertical strain gradient measurement, and a circumferential strain gradient measurement for each of a plurality of plate-shape specimens; a CAE analysis step (S2) for acquiring a largest maximum principal strain element in which the maximum strain is the largest, the vertical strain gradient of the largest maximum principal strain element, and the circumferential strain gradient of the largest maximum principal strain element; a breakage determination threshold value acquisition step (S3) for converting the breaking strain measurement to acquire a breakage determination threshold value; and a prediction step (S4) for predicting the occurrence of a stretch-flange cracking when the maximum principal strain is equal to or greater than the breakage determination threshold value.

Owner:NIPPON STEEL CORP

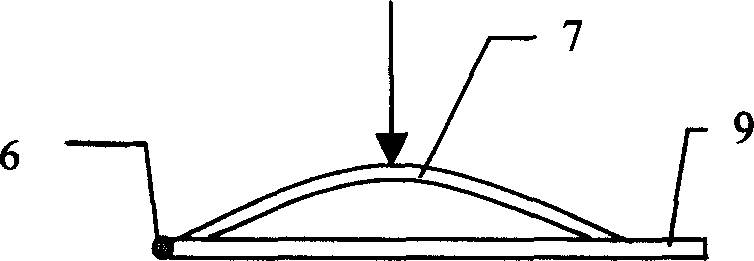

Micro pressure sensor and preparing method thereof

InactiveCN1632487AWith miniaturizationImprove resolutionForce measurement by measuring optical property variationOptical light guidesFiberTransverse force

It is a micro pressure sensor, which comprises fiber Brag grating and pressure deformation. Its process method is as following: according to the conditions to design the deformation size; to compute the flexible gemel and elastic design parameters; to process deformation; to fix the grating on the side of deformation. When the elastic plate of the invention suffers transverse force, the PEG generates vertical strain force with its two ends fixed on the rigid thin plate to convert the transverse force into vertical pressure direction. The force is exerted in the PBG to generate vertical strain force to cause the reflection wavelength change to make the transverse pressure and reflect wavelength react together to achieve the measurement.

Owner:WUHAN UNIV OF TECH

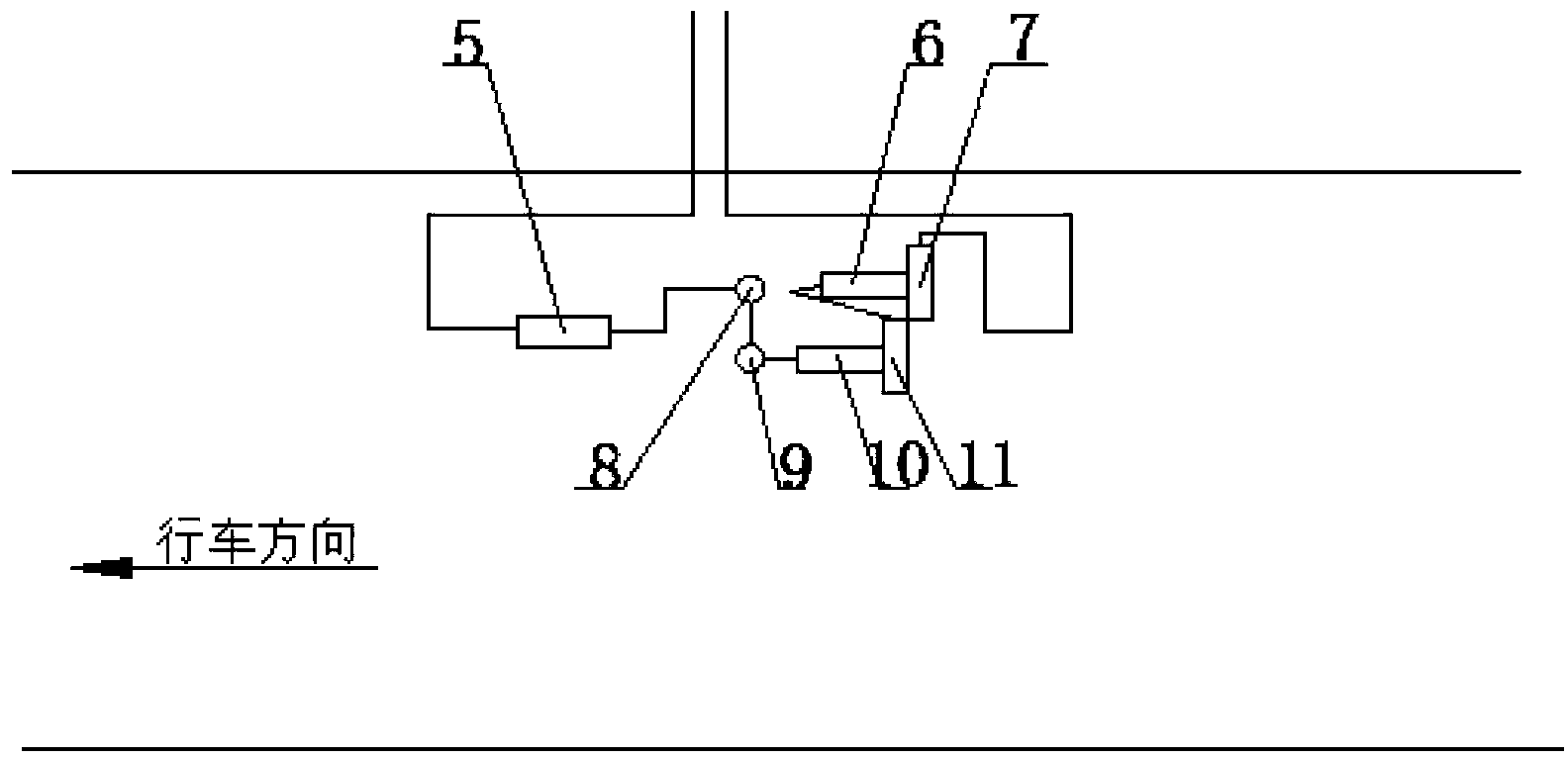

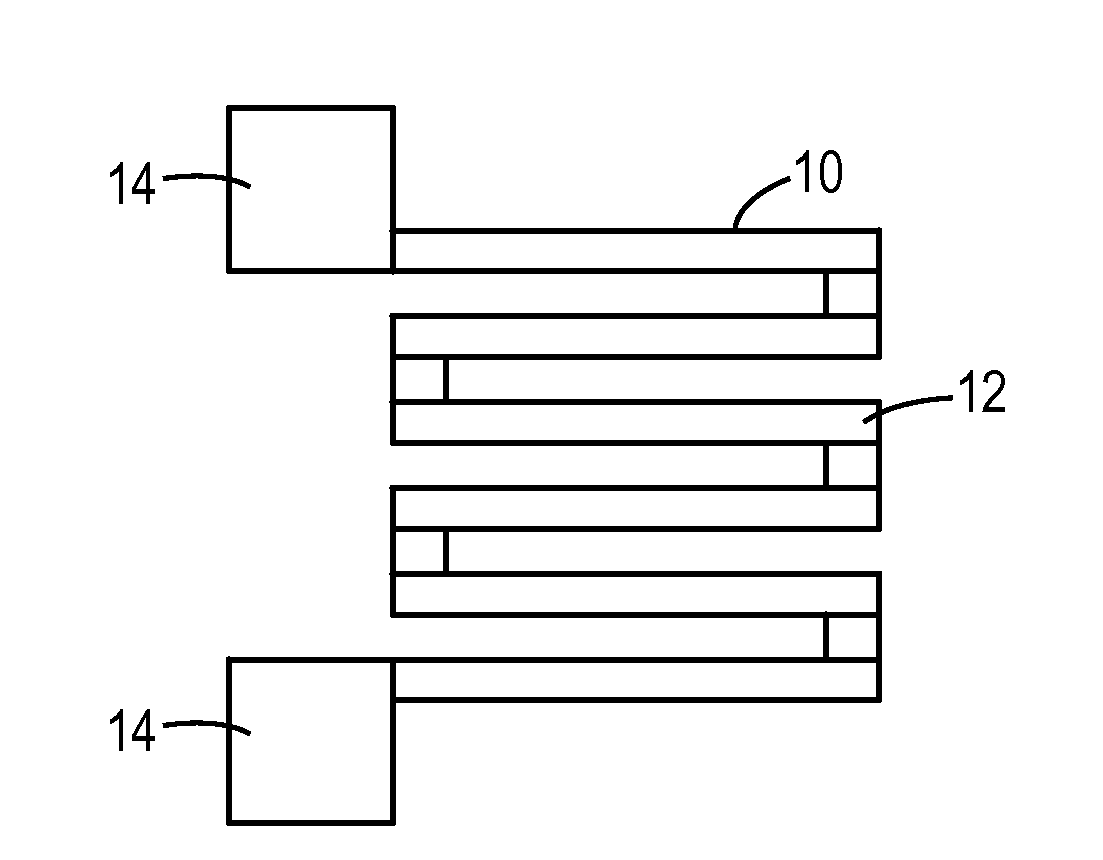

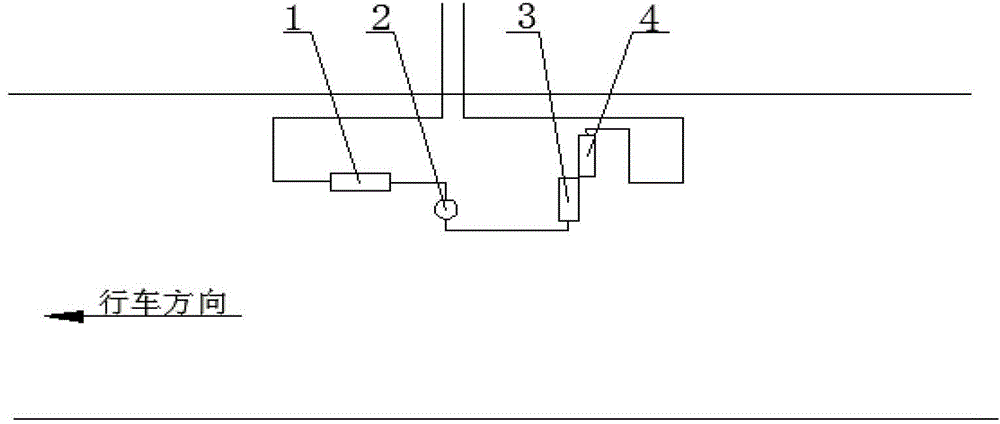

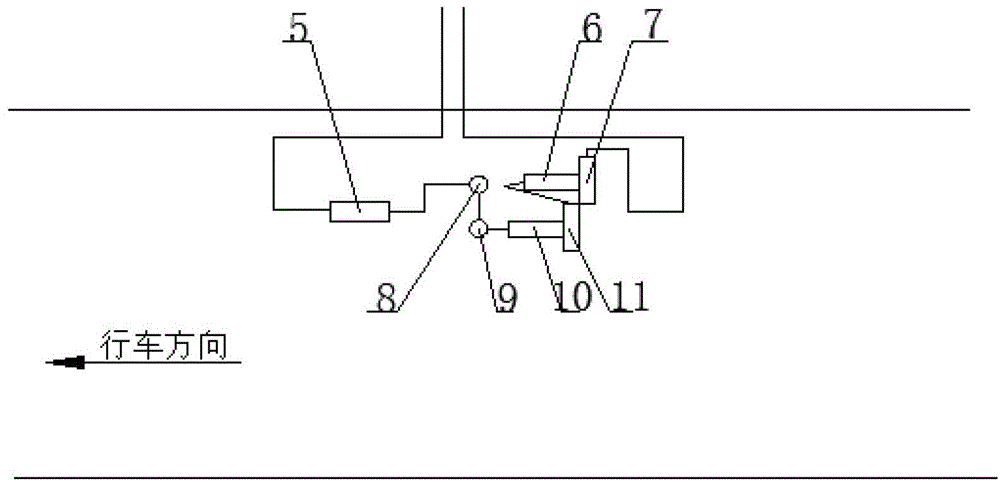

Underground sensor network used for expressway life monitoring and deployment method thereof

InactiveCN103353280AReal-time long-term dynamic monitoringLow costTransmission systemsNetwork topologiesFiberGrating

The invention discloses an underground sensor network used for expressway life monitoring and a deployment method thereof. The underground sensor network comprises sensing measuring devices, a raster demodulating device, fiber-optic connecting devices, and communication and storage devices. The sensing measuring devices mainly comprise a horizontal strain sensor, a vertical strain sensor, a temperature sensor, and a soil pressure gage. The raster demodulating device comprises a fiber bragg grating demodulation instrument. The fiber-optic connecting devices comprise a fiber junction box, a fiber terminal box, and outdoor optical cables. The communication and storage devices comprise a computer, and a GPRS module. Through embedding fiber bragg grating sensors inside each structural layer of a road, road structure is monitored in a dynamic manner in real time, so that problems that dynamic response of each structural layer of the road on traffic load are solved, difficulties of former monitoring are overcome, and real-time monitoring of road structural information is realized.

Owner:CHANGAN UNIV

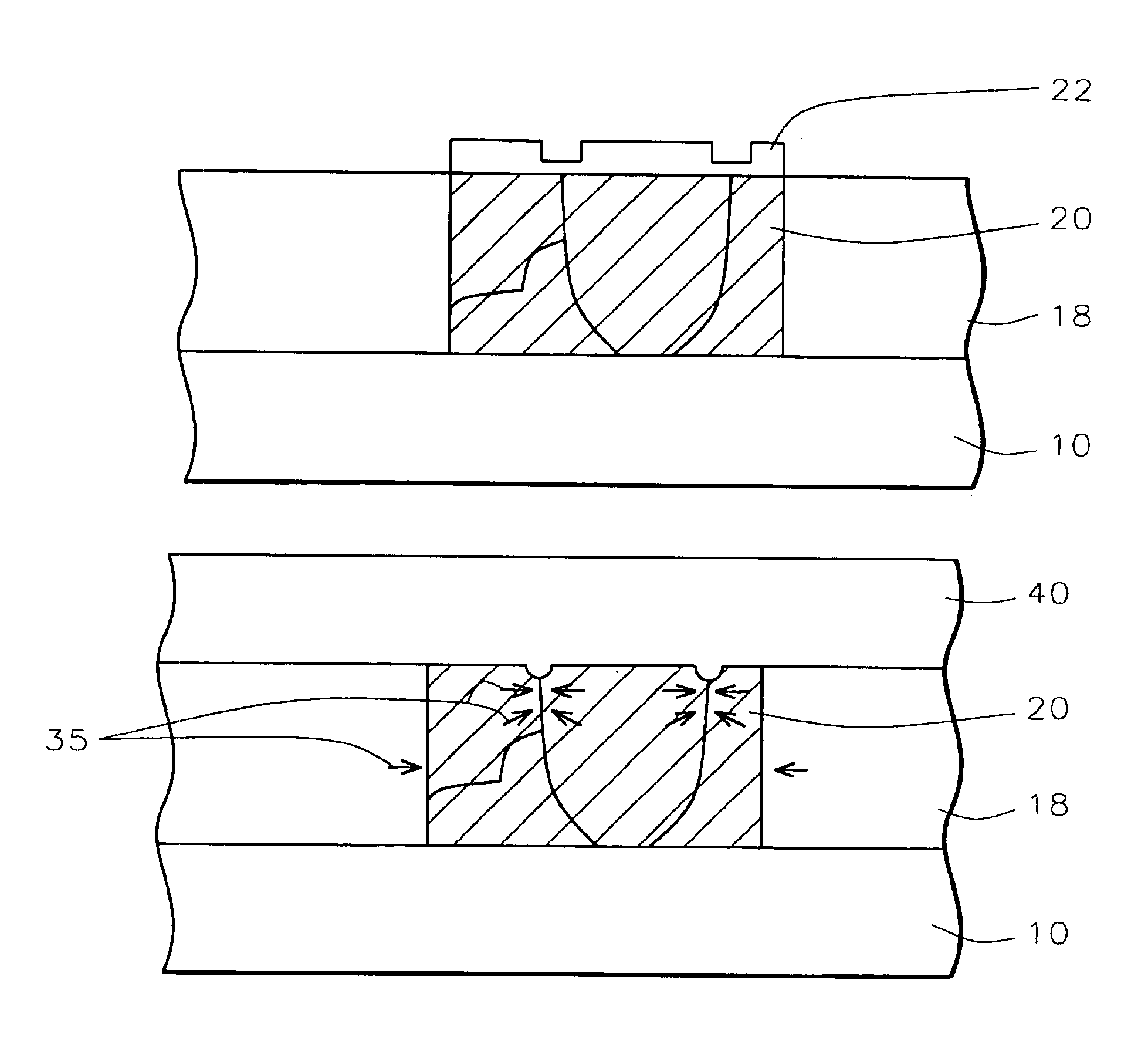

Solution for copper hillock induced by thermal strain with buffer zone for strain relaxation

ActiveUS6897147B1Reduce decreaseInhibition formationSemiconductor/solid-state device manufacturingSemiconductor devicesCopper oxideDielectric layer

A method of reducing copper hillocks in copper metallization is described. An opening is made through a dielectric layer overlying a substrate on a wafer. A copper layer is formed overlying the dielectric layer and completely filling the opening. The copper layer is polished back to leave the copper layer only within the opening. Copper hillocks are reduced by applying F ions to the copper layer to form a buffer zone on a surface of the copper layer and in-situ depositing a capping layer overlying the copper layer. The F ions remove copper oxide naturally formed on the copper surface and the buffer zone transfers thermal vertical strain in the copper to horizontal strain thereby preventing formation of copper hillocks.

Owner:TAIWAN SEMICON MFG CO LTD

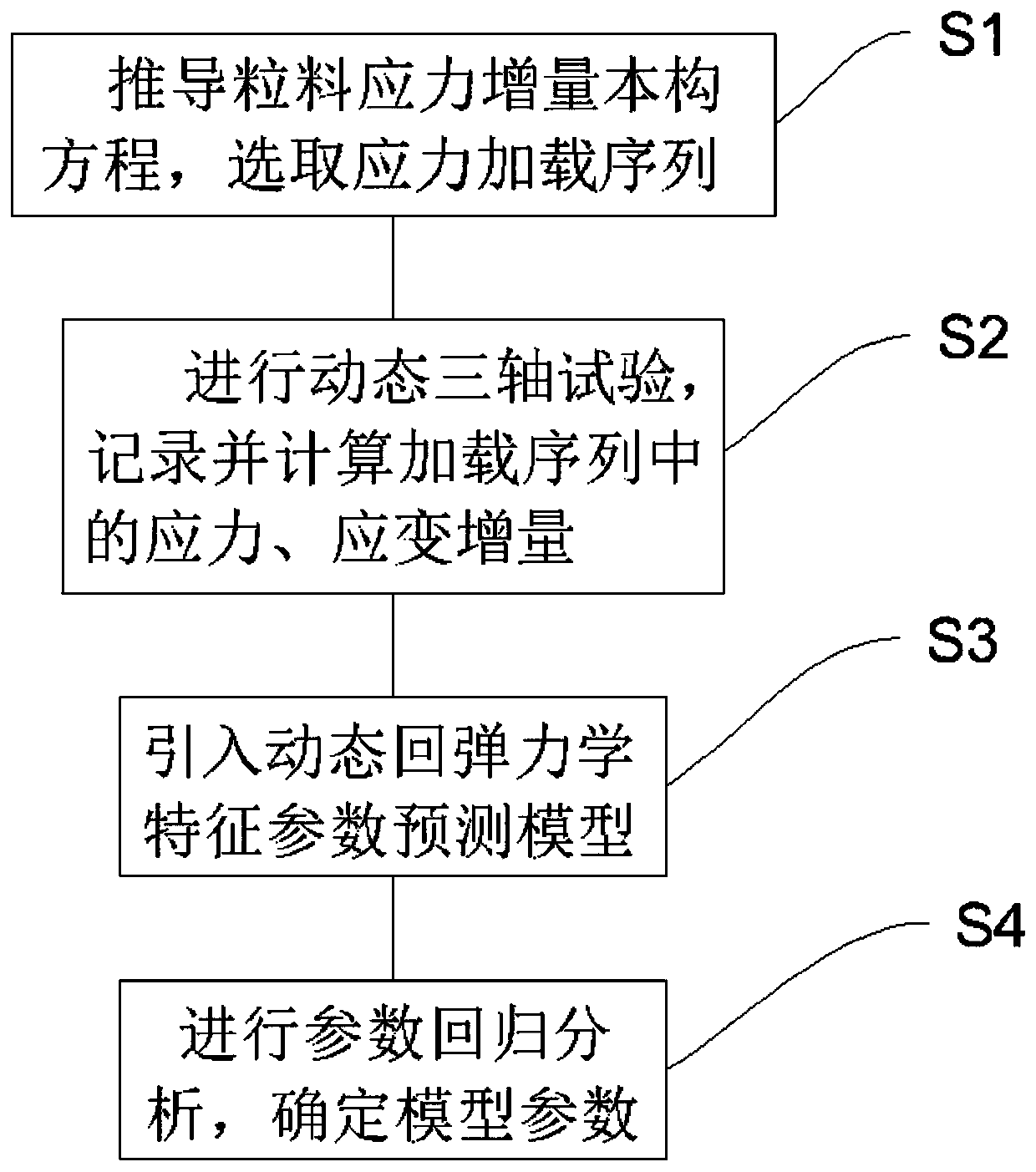

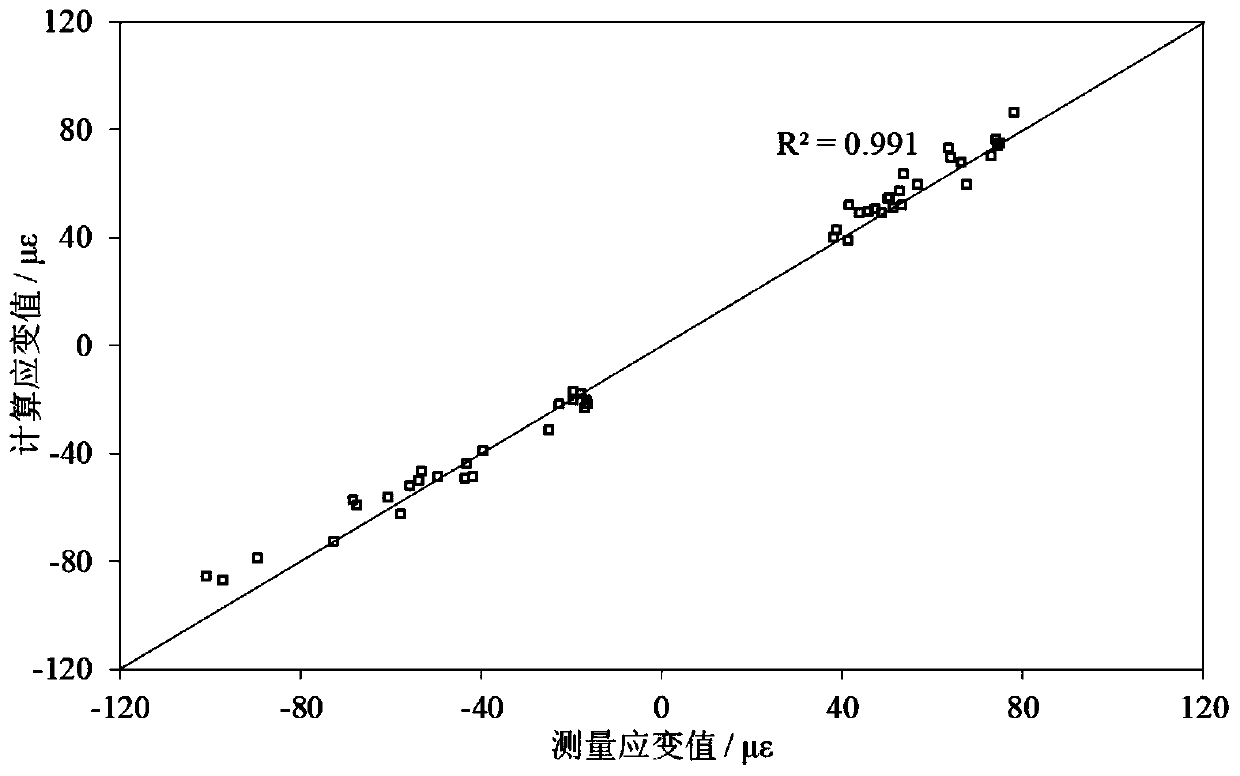

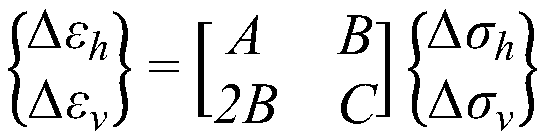

Method for obtaining dynamic resilience mechanical characteristic parameters of aggregates

The invention relates to the field of civil engineering, and discloses a method for acquiring dynamic resilience mechanical characteristic parameters of aggregates, which comprises the following steps: 1) deriving a stress increment constitutive equation of the aggregates, and determining a stress loading sequence according to the equation; 2) performing a dynamic triaxial test on the granules according to the stress loading sequence, recording the stress level, the stress increment, the corresponding horizontal deformation and the corresponding vertical deformation of the test, and calculating the horizontal strain increment and the vertical strain increment; 3) introducing a stress dependence model of dynamic resilience mechanical characteristic parameters; and 4) performing parameter regression analysis, and determining model parameters to obtain a nonlinear dynamic resilience mechanical characteristic parameter prediction model including dynamic resilience modulus, Poisson's ratioand orthotropic parameters. According to the method, the model for predicting the dynamic resilience mechanical characteristic parameters of the aggregate under different stress states can be established, the dynamic resilience mechanical characteristic parameters under various stress states can be conveniently and accurately obtained, and the requirements of engineering construction are met.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

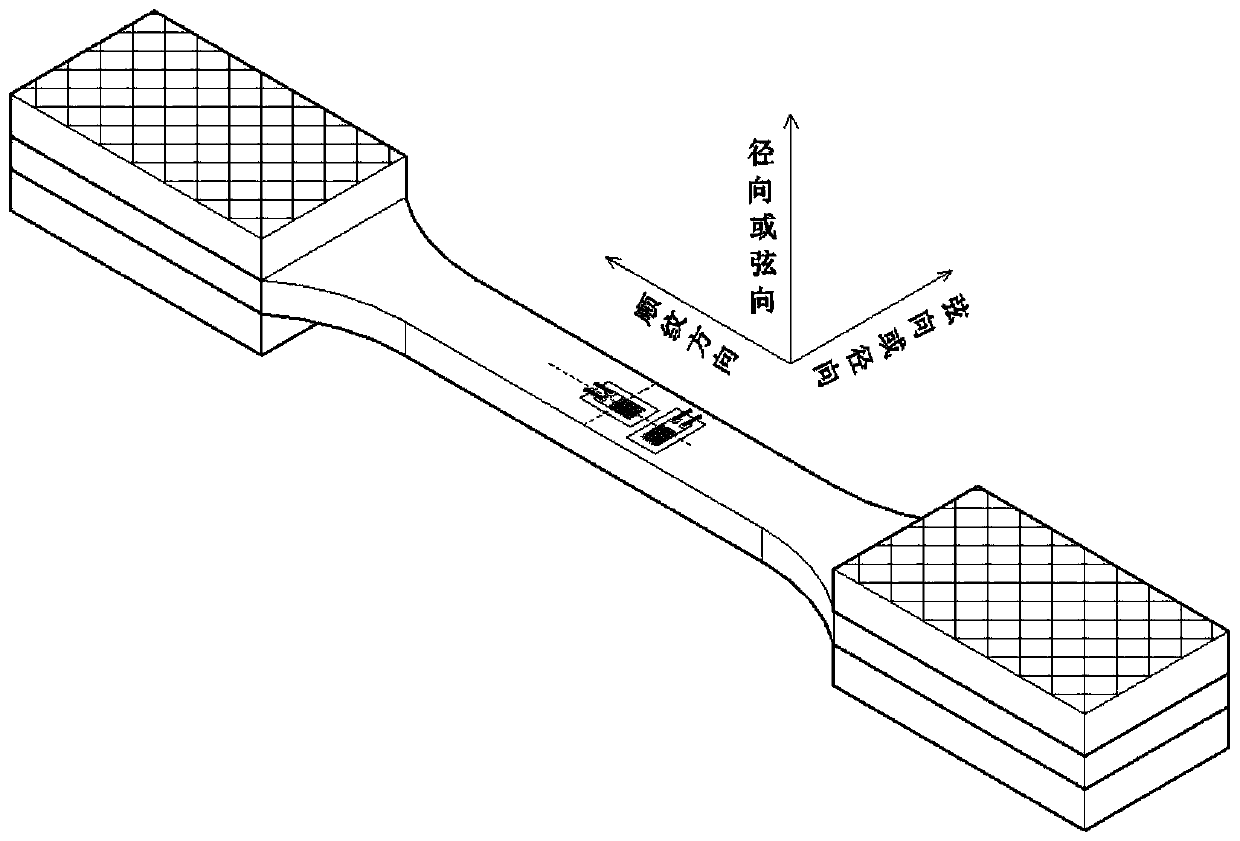

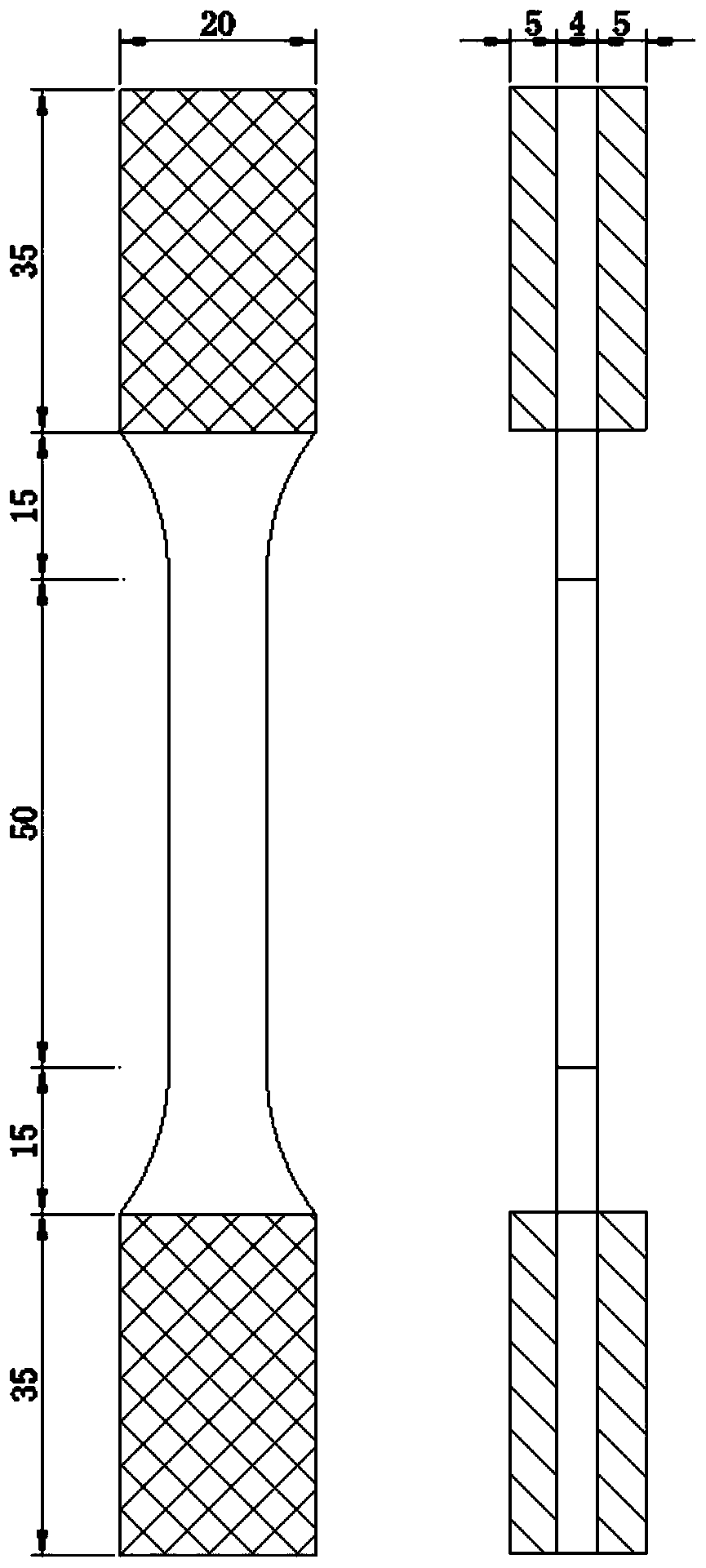

Test device and method for parallel-to-grain tensile properties of ancient building wood materials

InactiveCN110044706AEasy to processReduce instances of premature failureMaterial strength using tensile/compressive forcesTest efficiencySimple sample

The invention provides a test device and method for parallel-to-grain tensile properties of ancient building wood materials. The device comprises a test sample composed of an ancient building wood rawmaterial, hardwood gaskets and a resistance strain gauge, wherein the portions with a wider section at both ends of the test sample are clamping portions, the portion with a narrower section in the middle is a test portion, and all the portions are transitioned through circular arcs; the tester is clamped at both ends of the sample by a horizontal clamp and applies a tensile force. The method comprises the following steps of fabricating and processing the ancient building wood raw material, pasting the hardwood gaskets processed with meshes on both sides of the clamping portions by glue, drawing a cross in the middle of the test portion for positioning, pasting a vertical strain gauge, pasting a strain gauge below, causing the strain gauges at both sides in the same direction to be at thesame height, and clamping the gasket with the horizontal clamp to ensure that the longitudinal axis of the sample is in the same direction as the tensile force. The test device and method provided bythe invention are suitable for the research on the tensile properties of ancient building wood materials with limited raw materials, and have the advantages of simple sample processing, simple test operation, reliable test result and high test efficiency.

Owner:BEIJING JIAOTONG UNIV

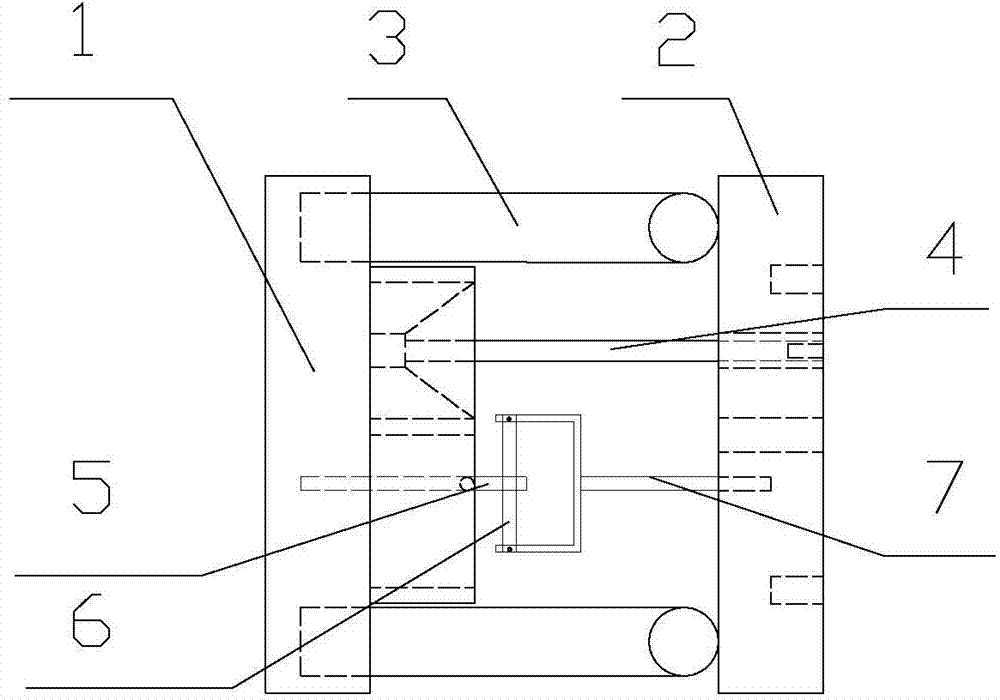

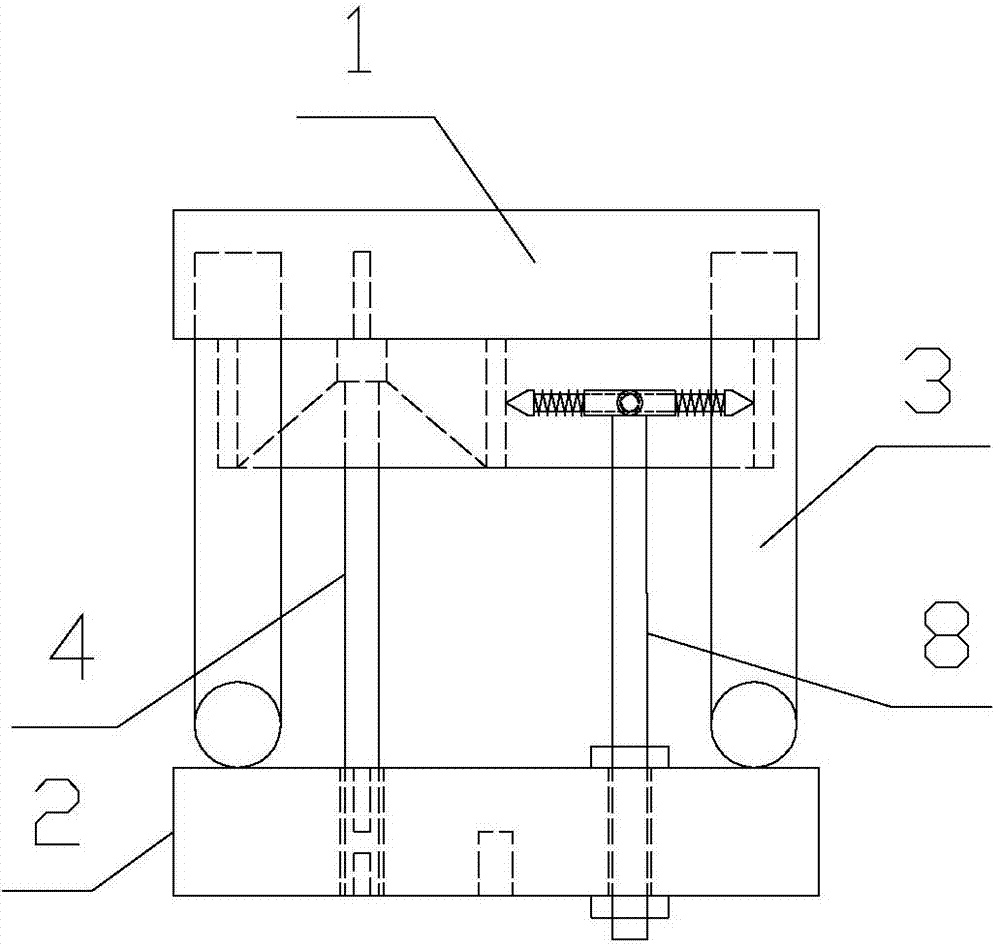

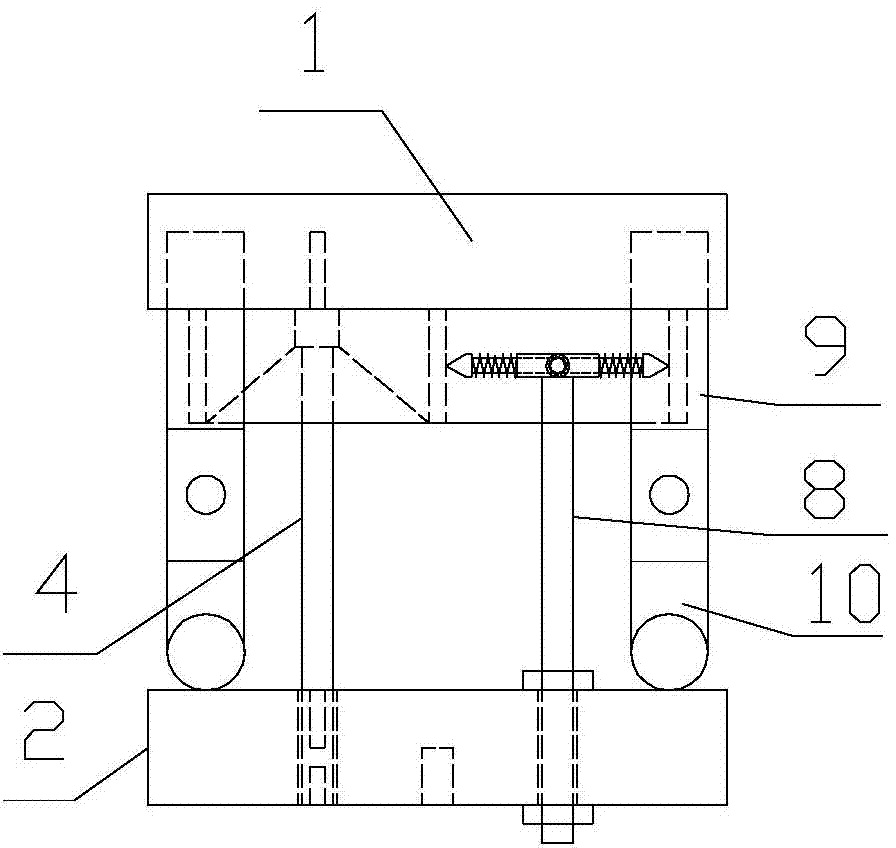

Complete plane strain similar test system capable of applying gradient strain

InactiveCN103760020AMeet the test requirementsReliable resultsMaterial strength using tensile/compressive forcesStability studyPilot system

The invention relates to a complete plane strain similar test system capable of applying gradient strain. The whole system comprises a plurality of combined modules, a detachable combined module, a horizontal gradient strain servo control system, a vertical strain servo control system, a connecting lifting control system and a data acquisition control system. Due to the adoption of the system, a more practical test condition is provided for an urban underground construction and a mining engineering; the test system can slide freely along with a rock via the modules of two sides and limits the movement in the direction vertical to a model, so as to realize the plane strain similar test. The upper pressure under a deep geological condition can be compensated by the vertical strain servo control system, and the horizontal gradient strain is applied by the horizontal gradient strain servo control system. The test condition of the test system can be well consistent with the actual engineering condition, the results of the test are more real and more reliable, and can guide the design and construction scientifically and reasonably, and therefore a scientific test condition is provided for the stability research of geotechnical engineering.

Owner:HENAN POLYTECHNIC UNIV

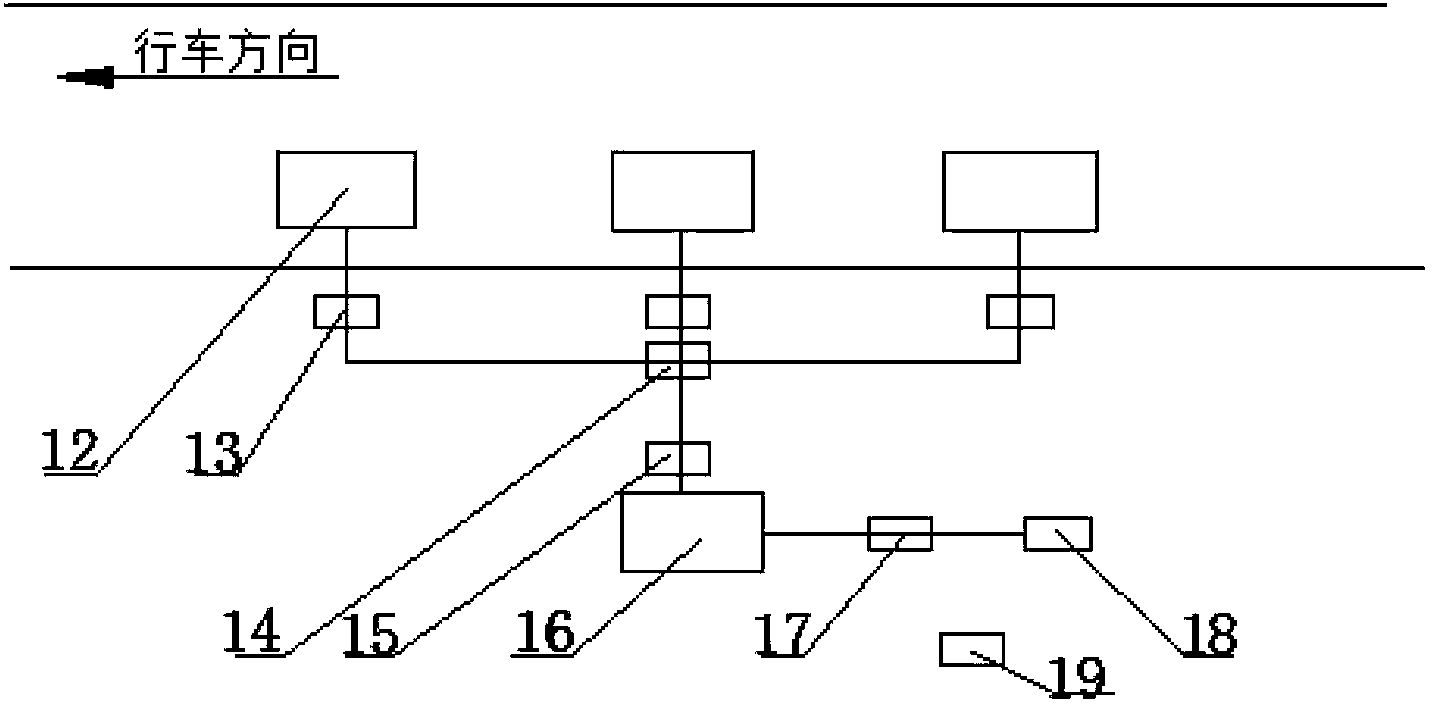

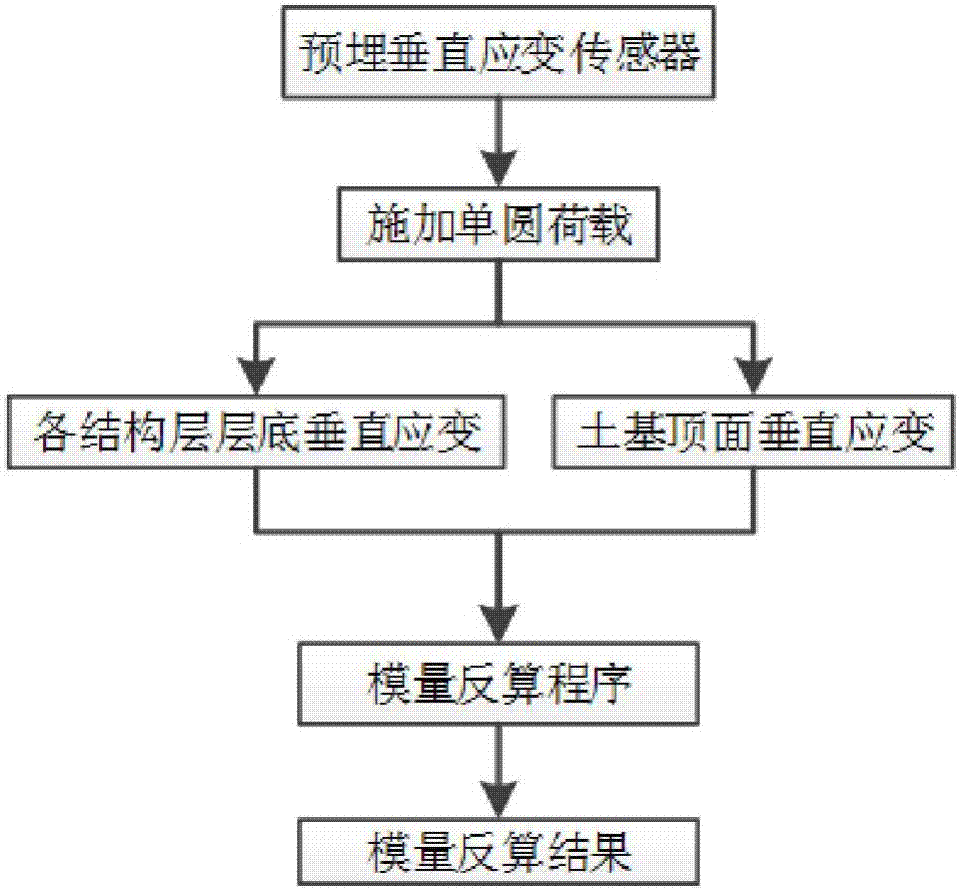

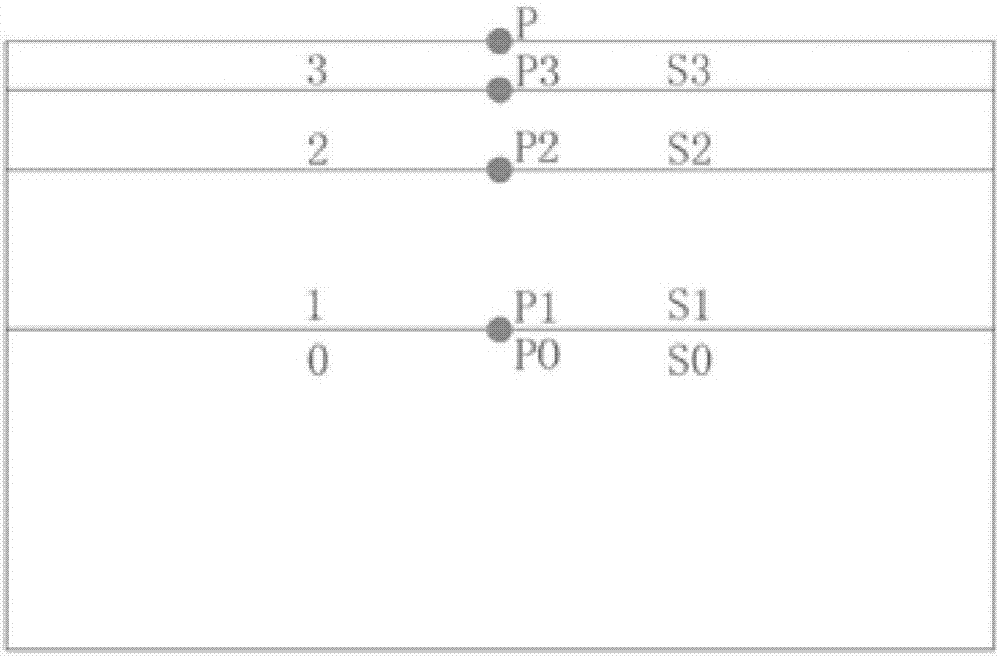

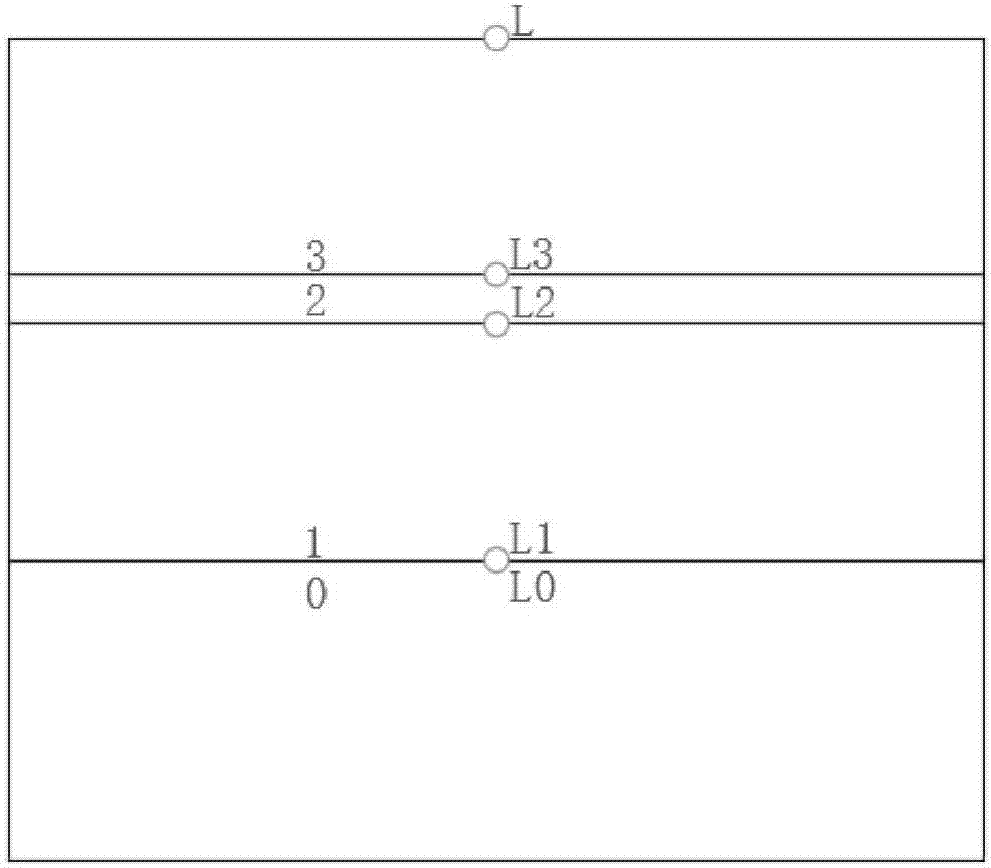

Modulus back calculation method for bituminous pavement

ActiveCN107389477AOptimize the back calculation processSolve the inverse modulusStrength propertiesMaterial typeSurface layer

The invention discloses a modulus back calculation method for a bituminous pavement. The modulus back calculation method comprises the following steps: simplifying pavement structure layers of the bituminous pavement, taking the adjacent pave3ment structure layers with same material type as simplified layers, and regarding a soil matrix as a soil matrix layer independently, wherein the modulus difference value among the structure layers contained in each simplified layer is not greater than N MPa; arranging vertical strain sensors in the soil matrix layer and each simplified layer, and guaranteeing that all the vertical strain sensors after arrangement are positioned in the same vertical direction; applying load on the surface layer of the bituminous pavement, and collecting vertical strain data of the soil matrix layer and the simplified layers through the vertical strain sensors, wherein the load is positioned over each vertical strain sensor; and taking the collected vertical strain data as back calculation parameters for carrying out modulus back calculation, wherein the value of N is 250 to 350. Through the method, the original structure is combined and simplified, so that the modulus back calculation process is optimized, and the technical problem that the back calculation modulus disaccords with the actual state is solved.

Owner:SOUTHEAST UNIV

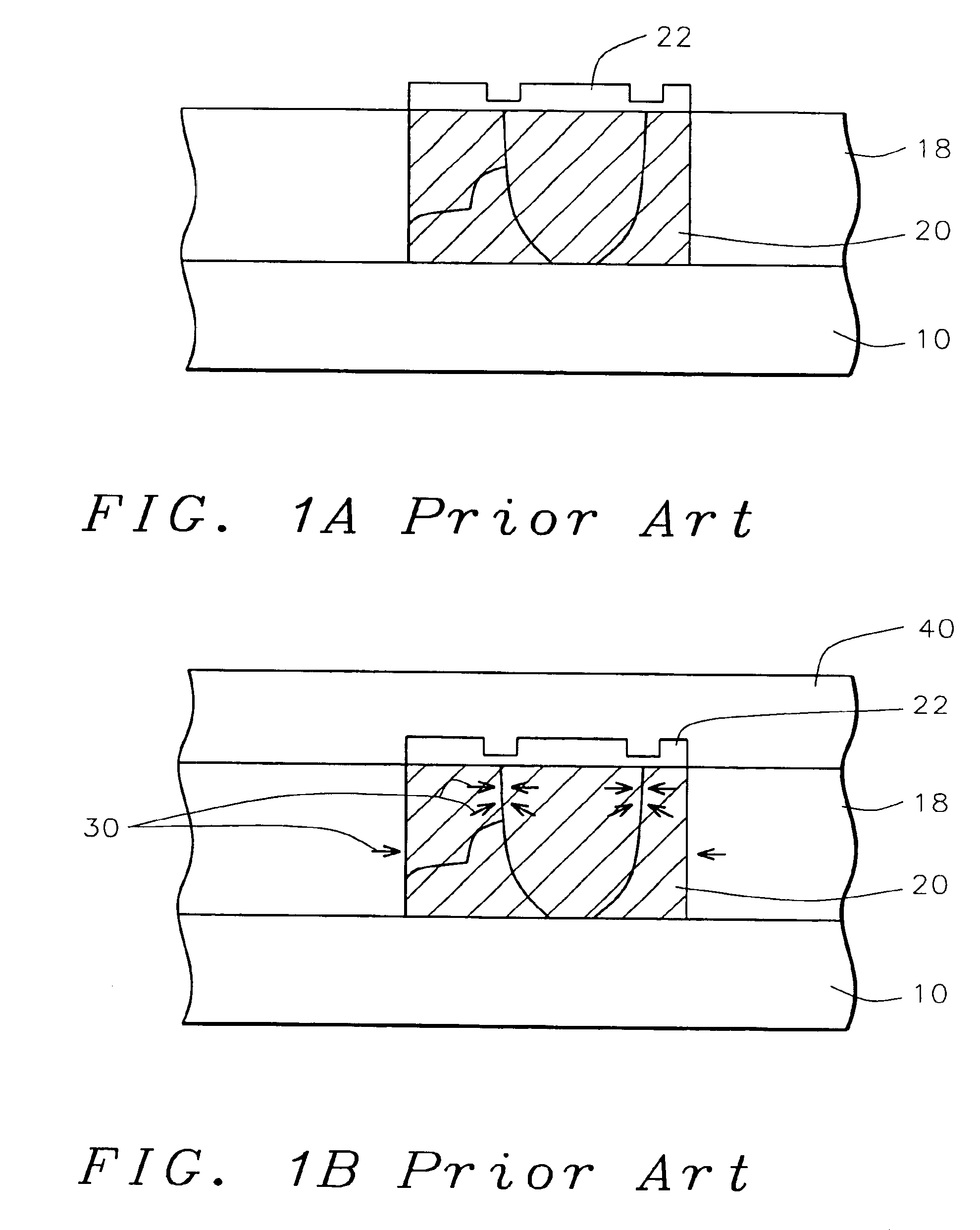

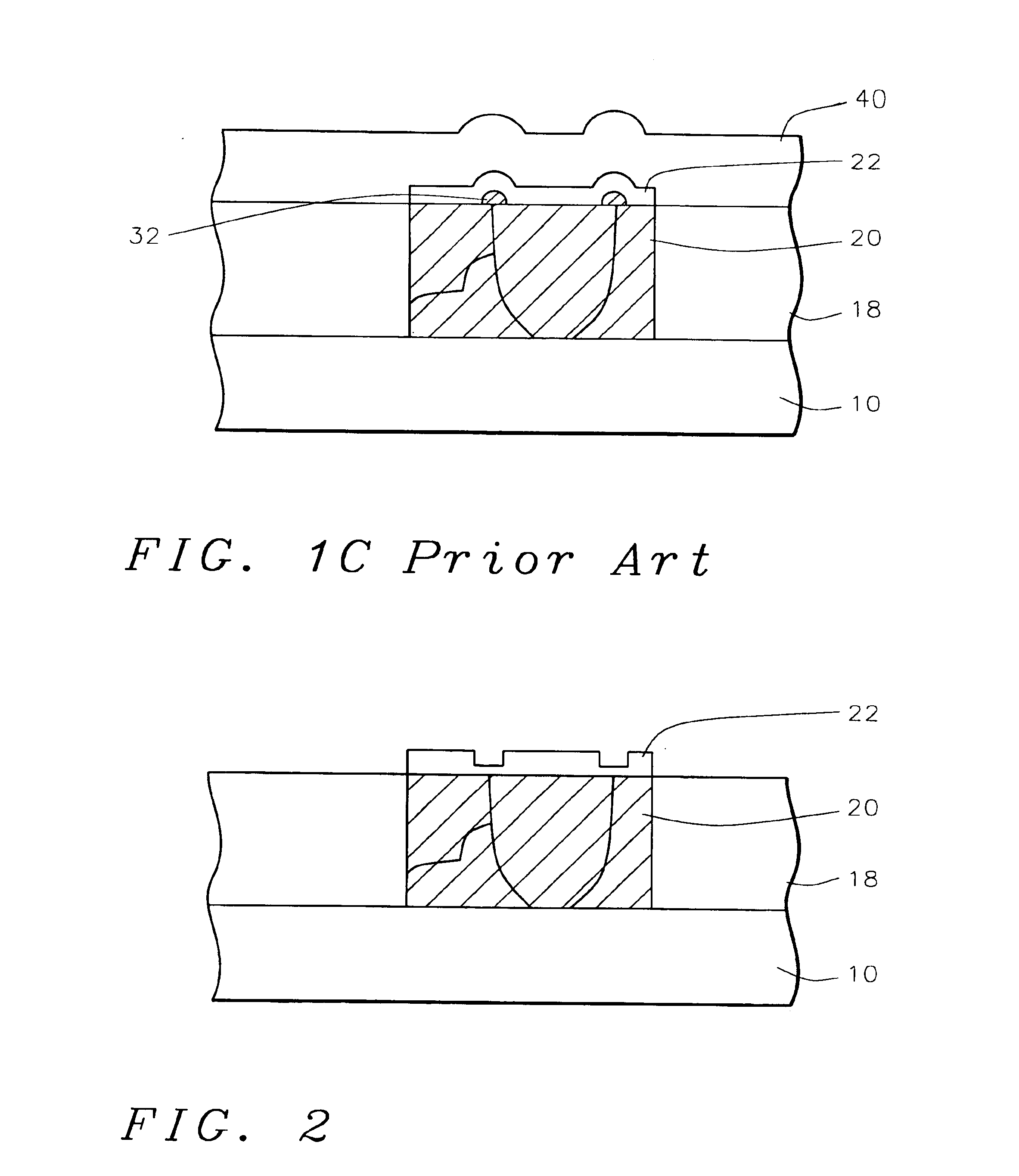

Die scale strain gauge

ActiveUS20090114030A1Fluid pressure measurement using ohmic-resistance variationForce measurementElectrical resistance and conductanceVertical edge

A chip with resistive, metallic strain gauges distributed on surfaces on and buried within the chip. Also, vertically arranged vias and vertical thin film resistive strain gauges are described. The resistive strain gauges can be multiplexed wherein strain can be measured across the topology of the chip in each of the top, bottom and buried layers and any vertical strain. The resistive strain gauges may be in serpentine patterns and may be arranged on via or on vertical edges of grooves that extend from an upper or lower surface of the chip to buried layers. In this fashion, the distributed strain gauges may be used to map the strain throughout the body of a chip. A Kelvin bridge may be used to measure the strain, but other such measuring techniques and devices may be used.

Owner:SEMICON COMPONENTS IND LLC

Method for detecting vertical structure load of existing building by intercepting concrete structure test piece

ActiveCN111175117ALess destructiveAccurate measurementUsing subsonic/sonic/ultrasonic vibration meansStrength propertiesArchitectural engineeringVibrating wire

The invention discloses a method for detecting the vertical structure load of an existing building by intercepting a concrete structure test piece. The method comprises the following steps: intercepting the concrete structure test piece from the vertical structure of the existing building, and detecting the vertical strain of the concrete structure test piece by adopting a vibrating wire strain gauge so as to calculate the magnitude of the vertical load borne by the vertical structure of the building. The concrete structure test piece is cut from the side surface of the vertical structure of the existing building, the strain of the concrete structure test piece in the vertical direction is measured through the vibrating wire strain gauge, then the vertical load of the existing building structure is calculated through the elastic modulus formula, damage to the building structure is small, implementation is convenient, the result reliability is high, and good use value is achieved in theengineering field. Meanwhile, the method provides important data support for building reinforcement design, and particularly plays an important role in building pile foundation deviation rectification and reinforcement engineering.

Owner:江苏东南特种技术工程有限公司

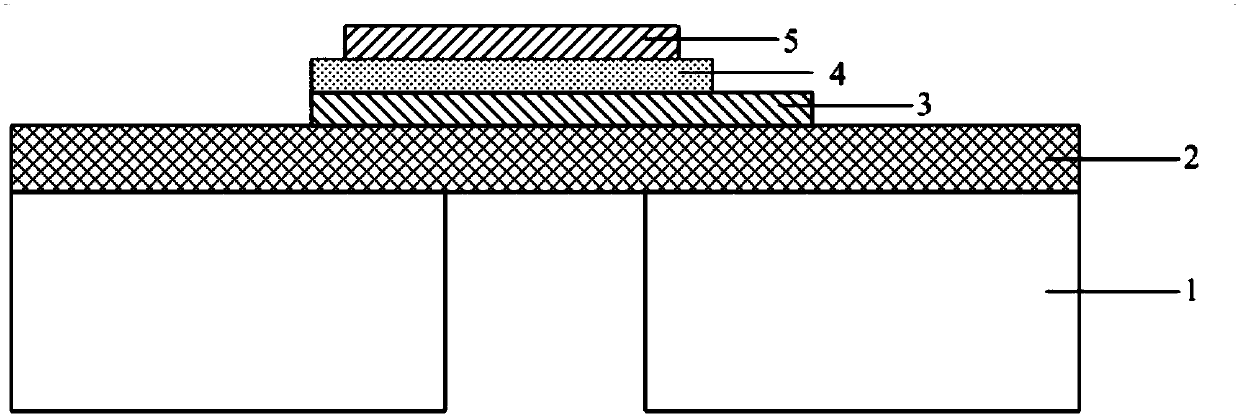

Minisized piezoelectric ultrasonic energy transducer and manufacturing method therefor

InactiveCN107920313AHigh electromechanical coupling coefficientImprove energy conversion efficiencyElectrical transducersLoudspeakersVibrating membraneShape change

The invention discloses a minisized piezoelectric ultrasonic energy transducer and a manufacturing method therefor. At least one vibrating membrane structure is arranged on a silicon substrate; the vibrating membrane structure consists of a hollow structure arranged on the silicon substrate in a protruding manner and at least one trailing structure arranged on an outer surface of the hollow structure in a protruding manner. The vibrating membrane structure is changed from a two dimensional plane structure into a three dimensional stereoscopic hollow structure, no supporting layer is needed inthe energy transducer, and ultrasonic energy transduction can be realized via the vibrating membrane structure. Because the vibrating membrane structure has a three dimensional stereoscopic curved surface, a strain direction generated via the vibrating membrane structure is changed from a transverse direction into a direction of dip that forms a certain angle with the transverse direction when theenergy transducer is in operation, strain generated via the vibrating membrane structure can be used for directly bringing about shape change and vibration in a direction vertical to the silicon substrate, a conversion process of converting transverse train into vertical strain is not needed, an electromechanical coupling coefficient of the minisized piezoelectric ultrasonic energy transducer canbe improved, energy conversion efficiency of the energy transducer can be improved, and work energy consumption can be lowered.

Owner:深圳市诺维创科技有限公司

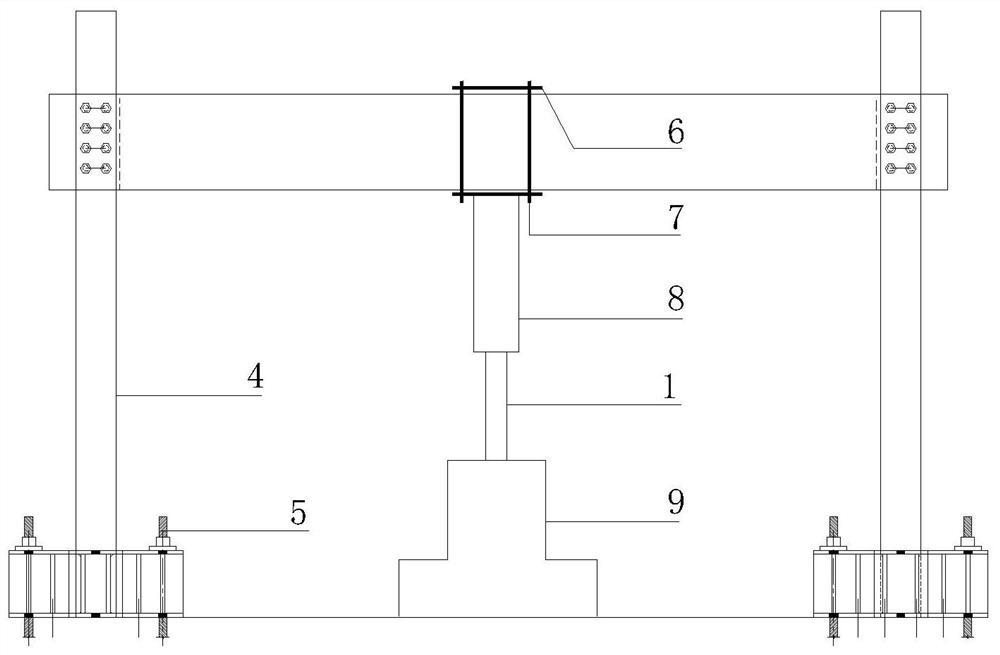

Method for detecting vertical force of linear motor based on vertical strain of bolts

InactiveCN108981997AAccurate determination of vertical forceApparatus for force/torque/work measurementForce measurement by elastic gauge deformationNon destructiveField tests

The invention provides a method for detecting vertical force of a linear motor based on vertical strain of bolts. The method includes the following steps: manufacturing force measuring bolts, and calibrating the force measuring bolts through a mechanical testing machine; on a sensing steel plate, fixing the force measuring bolts on steel plate on a concrete substrate through a pinch plate, and respectively arranging measuring points on each bolt; grinding each measuring point and the corresponding position, and wiping up by using alcohol; setting four strain gauges symmetrically on the same circumferential side surface of each bolt, wherein the adjacent two strain gauges are perpendicular to each other, and the strain gauges are tightly closed by silica gel; performing assembling of a testbridge circuit on the attached strain gauges; accessing the bridge circuit assembled at each measuring point to a strain collector system, and collecting the strain of the bolts when a train passes through the area; and inverting the vertical force of the linear motor by using the relationship between the force and the strain obtained through calibration by a laboratory. The method for detectingvertical force of a linear motor based on vertical strain of bolts is a non-destructive testing method, and the detecting process does not affect the stability of the track structure, and more accurate vertical force of the linear motor can be obtained through the field test.

Owner:EAST CHINA JIAOTONG UNIVERSITY

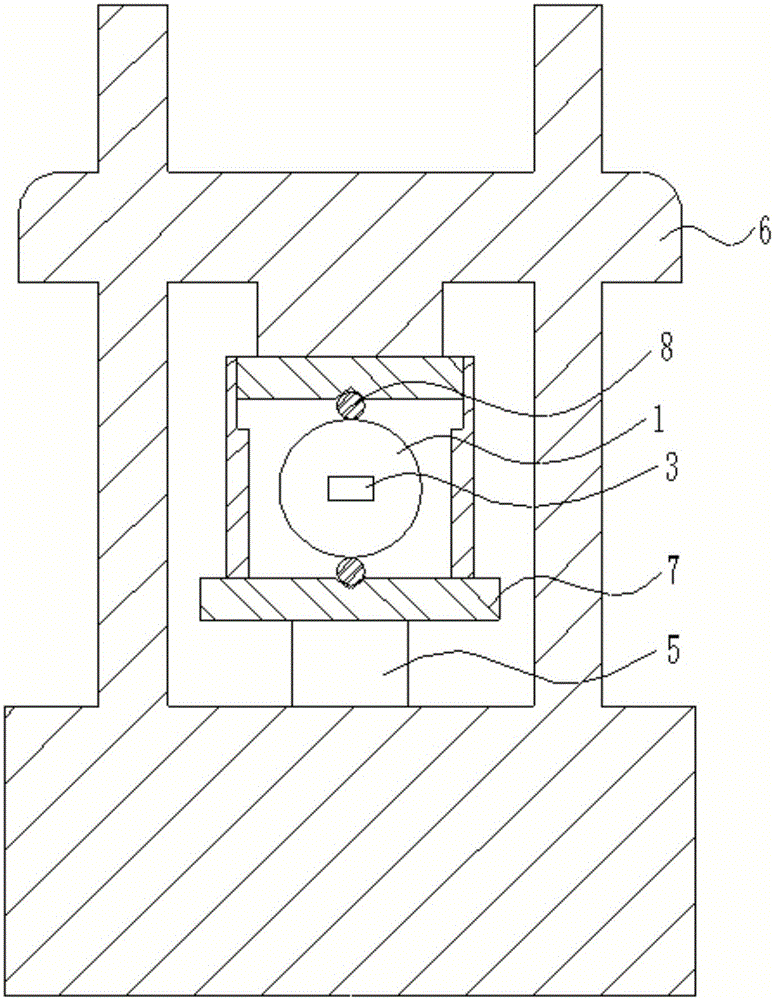

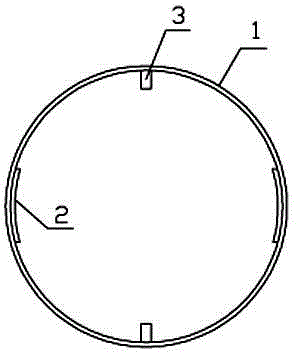

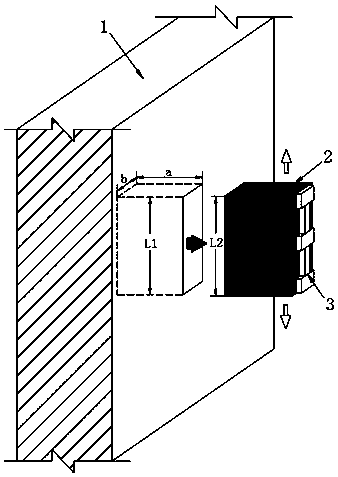

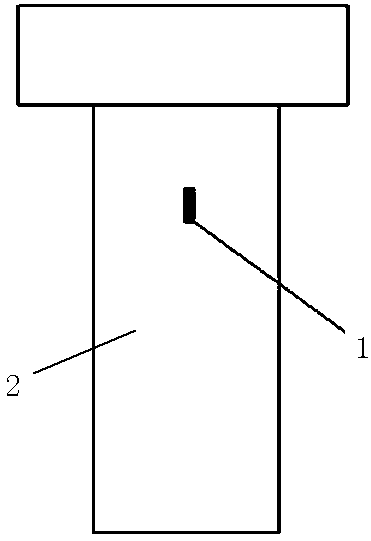

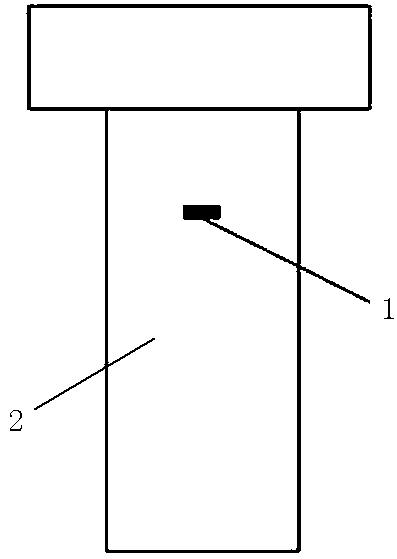

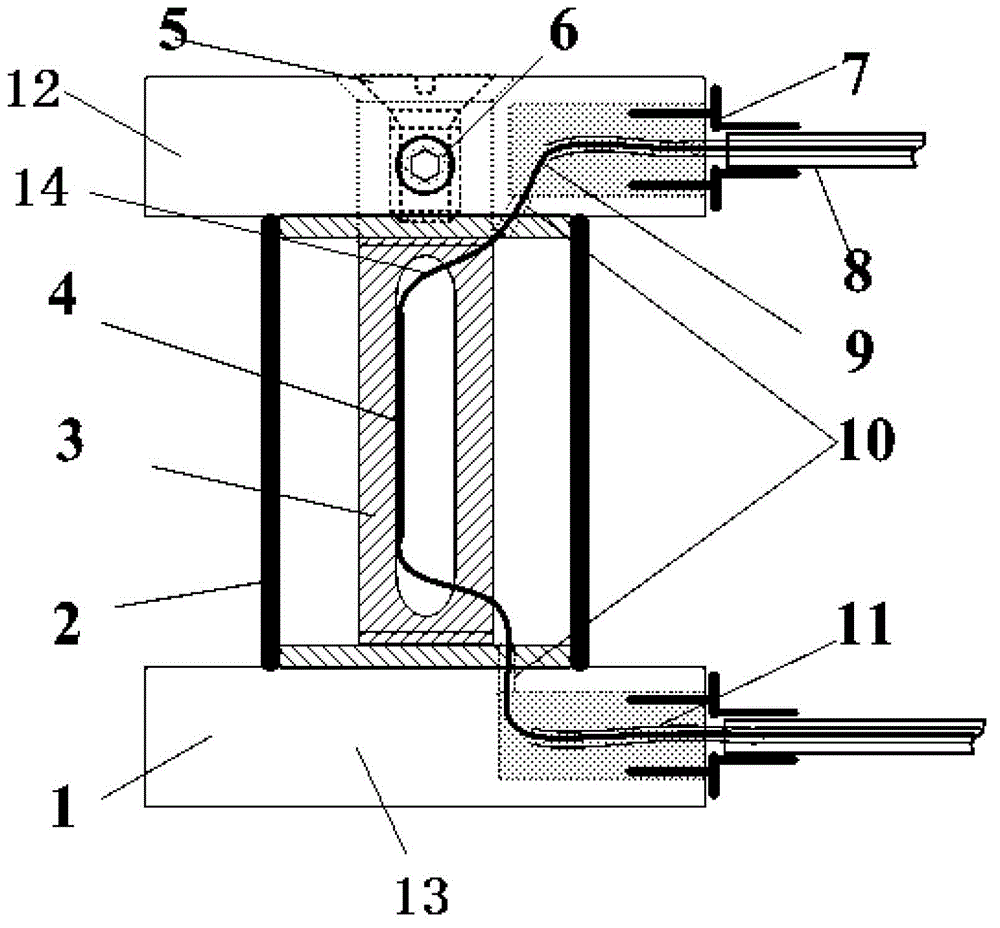

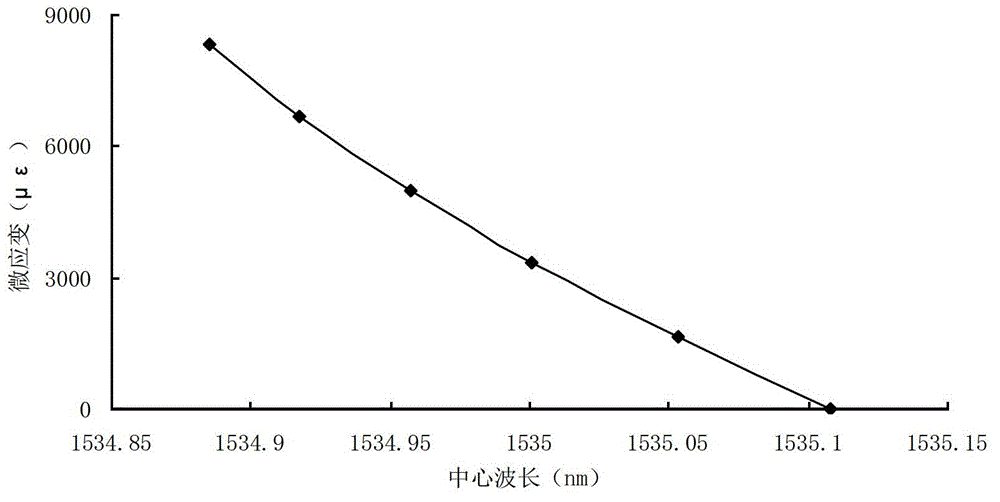

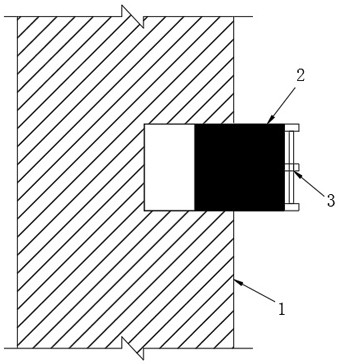

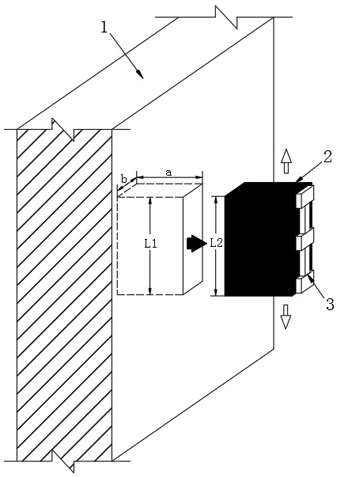

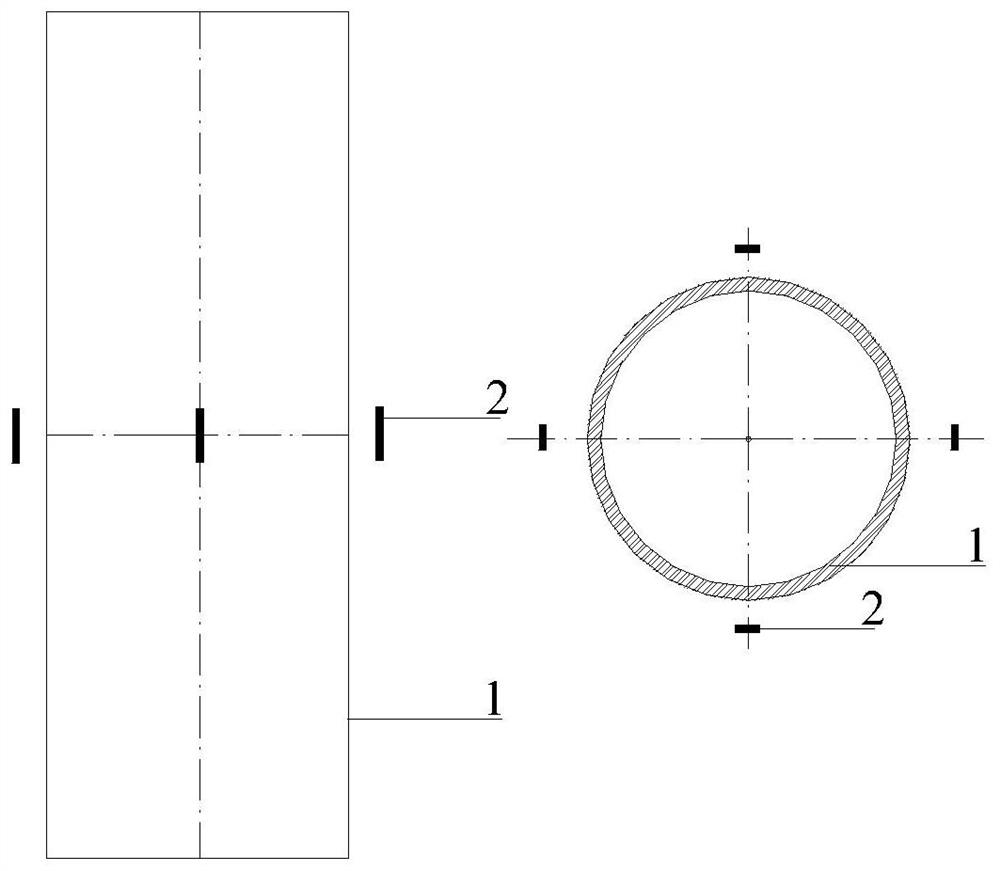

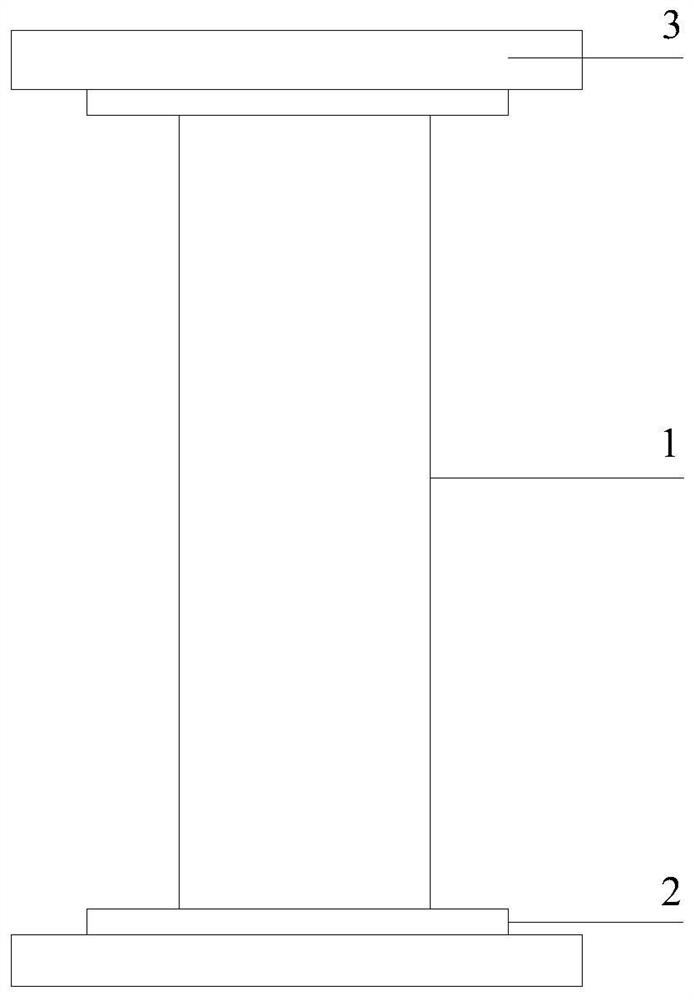

Fiber grating vertical strain sensor

The invention particularly discloses a fiber grating vertical strain sensor, which comprises a fixed base, a hollow supporting column, optical fibers and a sensitive grating, wherein the fixed base comprises an upper base and a lower base, the hollow supporting column is arranged between the upper base and the lower base, the sensitive grating is arranged on the optical fibers and is bonded on the inner wall of the hollow supporting column, the optical fibers enter from the side surface of the upper base, run through the hollow supporting column and go out from the side surface of the lower base, temperature compensation gratings are arranged on the optical fibers which penetrate through the upper base and the lower base, and the two ends of the optical fibers are connected with fiber grating demodulators. The fiber grating vertical strain sensor has the advantages that the similarity between the material of the sensor and the material of an environment is realized through the hollow supporting column, the change of material strain distribution of the base due to embedment of the sensor is effectively avoided, and the measurement of vertical strain of roadbed materials under the effect of external acting force is realized.

Owner:SHANDONG UNIV

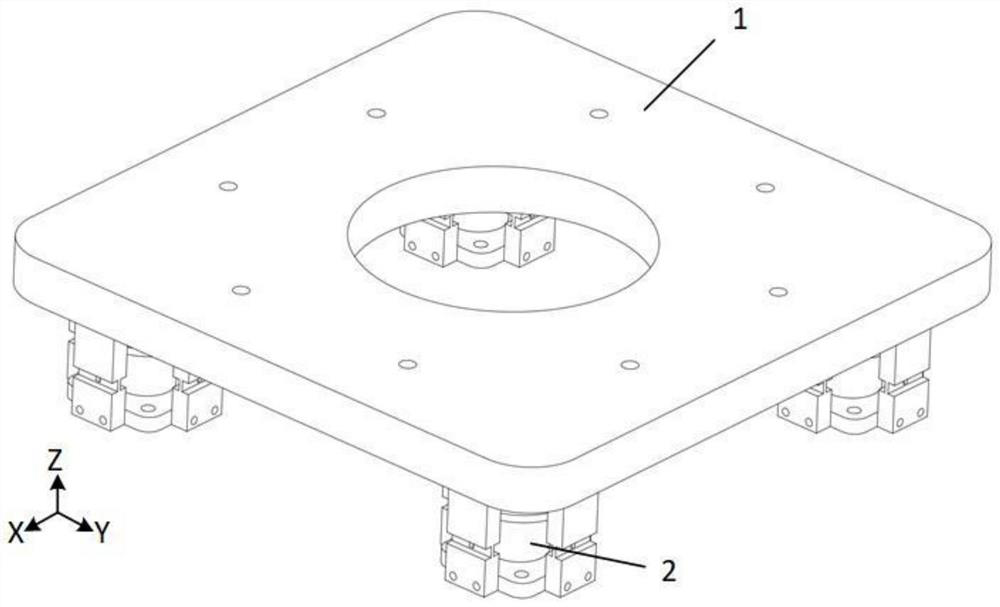

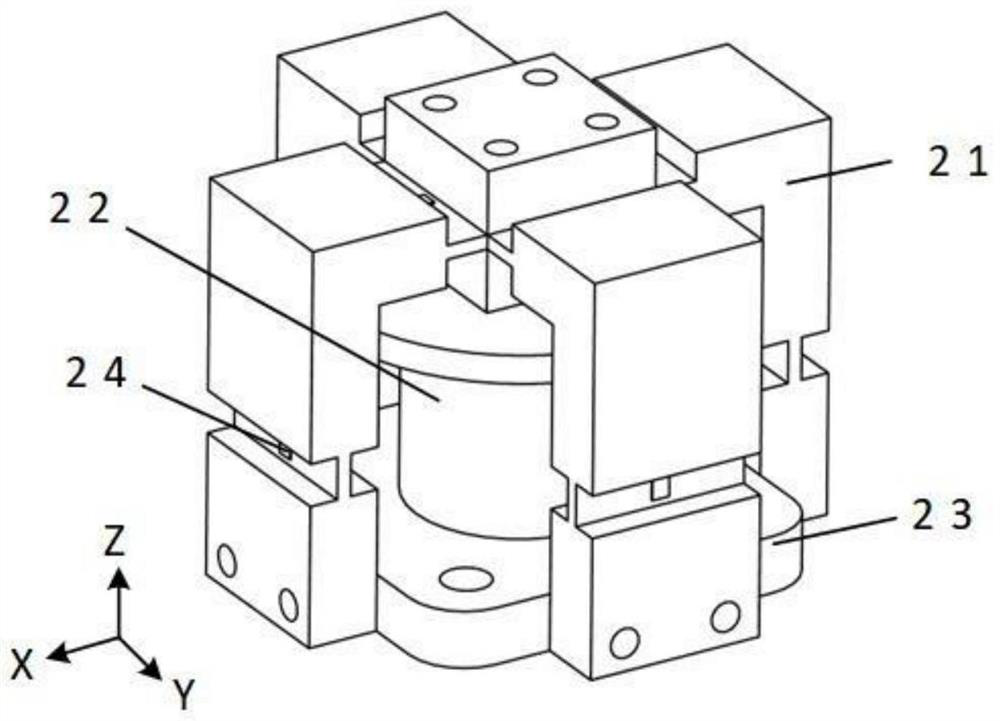

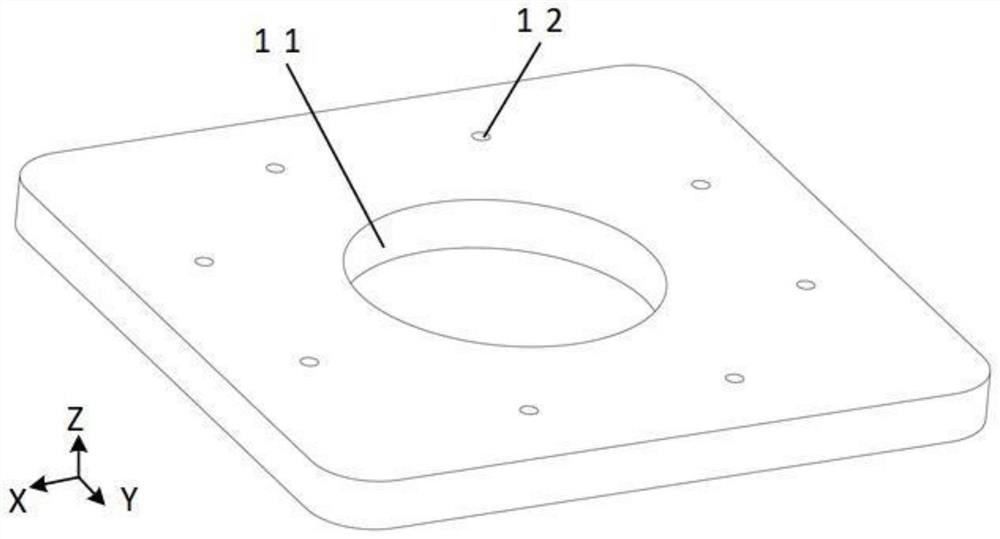

Strain foot structure and torque measuring platform

PendingCN114778043AHigh measurement accuracyGood low frequency dynamic characteristicsMeasurement of force componentsVibration testingCouplingClassical mechanics

The invention discloses a strain foot structure and a moment measurement platform, the moment measurement platform comprises a plurality of strain foot structures and a placement table, the placement table is supported by the plurality of strain foot structures, and the load capacity of the placement table is improved. Each strain foot structure comprises a loading block, a connecting block and a fixing block; the connecting block comprises a horizontal connecting part and a vertical connecting part, the horizontal connecting part and the vertical connecting part are vertically arranged, and the horizontal connecting part is connected with one side of the loading block through the horizontal strain beam; and the fixed block is arranged below the vertical connecting part and is connected with the bottom surface of the vertical connecting part through the vertical strain beam. Through the horizontal strain beam and the vertical strain beam arranged in the strain foot structure, the inter-dimensional coupling is reduced, the measurement precision of the torque measurement platform is improved, and the strain gauges are respectively arranged on the horizontal strain beam and the vertical strain beam, so that the torque measurement platform has a relatively good low-frequency dynamic characteristic.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Bearing plate collecting vertical stress of each point on coal-rock mass end face in real time

InactiveCN104897322AAvoid end effectReduce the effects of frictionForce measurementUniaxial compressionRock sample

A bearing plate collecting vertical stress of each point on a coal-rock mass end face in real time mainly comprises a bearing rod, bearing rings, vertical strain gauges, horizontal strain gauges, a line and a pedestal; the features are that the bearing rod is arranged in the center and sleeved by a plurality of bearing rings; the number of the bearing rings correspondingly changes according to the size of a measured rock sample; a compensation gap is arranged between adjacent bearing rings; a middle lower portion of the bearing rod and bearing rings is provided with an annular slot; the horizontal strain gauges and vertical strain gauges are arranged in the annular slot, arranged in pairs and connected with the line; one side on the lower portion of the bearing ring is provided with a line concentration slot; the downmost end of the bearing ring is provided with a horizontal groove; the line concentration slot and the horizontal groove are on a same vertical line and mutually matched so as to output the line; the bottom of the bearing rod and the bearing rings is provided with the pedestal. The bearing plate is strong in adaptability and good in technical effect, can remove test piece end face effect in a single shaft compression process, and can realize the test piece end face vertical stress collection.

Owner:CHINA UNIV OF MINING & TECH

Optical Fiber Interference Water Level Sensor

InactiveCN104697609BExquisite structureExtended service lifeMachines/enginesLevel indicatorsFiberPhotovoltaic detectors

The invention discloses an optical fiber interference water level sensor. The optical fiber interference water level sensor is composed of a semiconductor laser device, a 3dB coupling device, a sensitive element, a Faraday polariscope, a light guide optical fiber, a photoelectric detector and a computer, wherein the sensitive element is a key part of the water level sensor and is used for converting the change of a water level into vertical strain and radial strain of the optical fiber so that the phase difference of two interference arms is changed; finally, the change of the water level is inverted by using the change of the phase difference. By the aid of the optical fiber interference water level sensor, the high-precision water level measurement can be realized, and the optical fiber interference water level sensor has the advantages of reliability, electromagnetic interference resistance, corrosion resistance, high sensitivity, simple and exquisite structure and the like, and is suitable for the environment needing high-precision water level monitoring.

Owner:JILIN UNIV

A method for testing the vertical structural load of existing buildings by intercepting concrete structure specimens

ActiveCN111175117BLess destructiveAccurate measurementUsing subsonic/sonic/ultrasonic vibration meansStrength propertiesArchitectural engineeringVibrating wire

The invention discloses a method for detecting the vertical structure load of an existing building by intercepting a concrete structure test piece. The longitudinal strain can be used to calculate the vertical load carried by the vertical structure of the building. The invention intercepts the concrete structure test piece from the side of the vertical structure of the existing building, measures the strain of the concrete structure test piece in the vertical direction through the vibrating wire strain gauge, and calculates the existing building structure through the elastic modulus formula The vertical load is less destructive to the building structure, and it is easy to implement, the result is reliable, and it has good use value in the engineering field. At the same time, the invention provides important data support for building reinforcement design, especially plays an extremely important role in building pile foundation deviation correction and reinforcement engineering.

Owner:江苏东南特种技术工程有限公司

Underground Sensor Network and Its Deployment Method for Highway Life Monitoring

InactiveCN103353280BHigh detection costLabor intensiveTransmission systemsNetwork topologiesFiberMeasurement device

The invention discloses an underground sensor network used for expressway life monitoring and a deployment method thereof. The underground sensor network comprises sensing measuring devices, a raster demodulating device, fiber-optic connecting devices, and communication and storage devices. The sensing measuring devices mainly comprise a horizontal strain sensor, a vertical strain sensor, a temperature sensor, and a soil pressure gage. The raster demodulating device comprises a fiber bragg grating demodulation instrument. The fiber-optic connecting devices comprise a fiber junction box, a fiber terminal box, and outdoor optical cables. The communication and storage devices comprise a computer, and a GPRS module. Through embedding fiber bragg grating sensors inside each structural layer of a road, road structure is monitored in a dynamic manner in real time, so that problems that dynamic response of each structural layer of the road on traffic load are solved, difficulties of former monitoring are overcome, and real-time monitoring of road structural information is realized.

Owner:CHANGAN UNIV

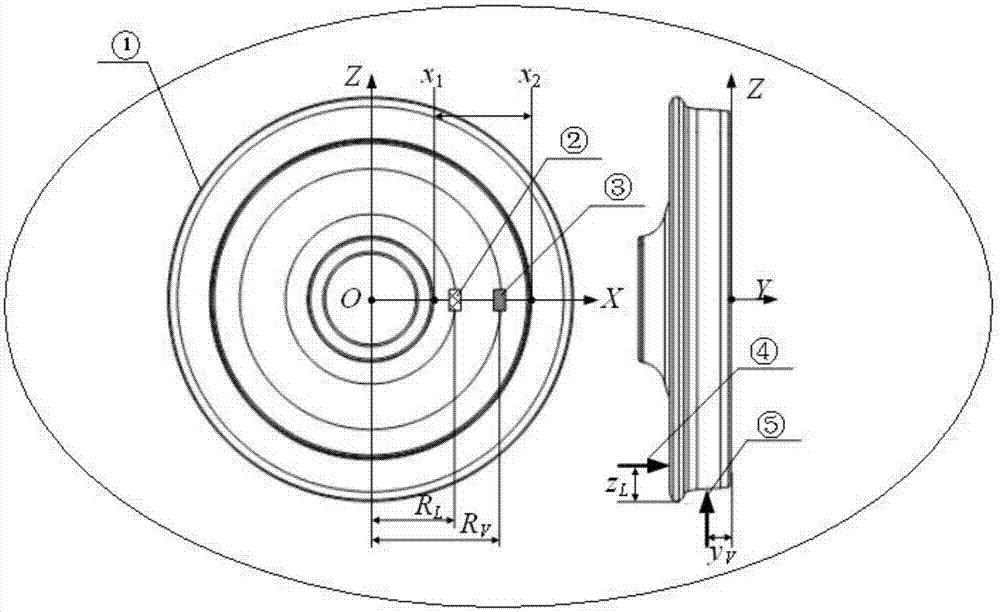

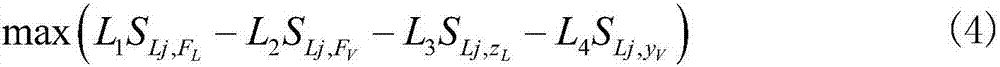

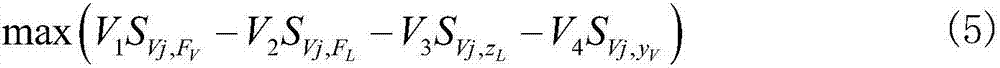

Method for selecting strain gage distribution radius of radials force measuring wheel pair

PendingCN107239638AExact Sensitivity Calculation ResultsGeometric CADDesign optimisation/simulationSurrogate modelEngineering

Provided is a method for selecting the strain gage distribution radius of a radials force measuring wheel pair. The method includes the steps of based on a surrogate model technique, obtaining the global sensitivity of radials strain values at the positions of different radii of a vehicle wheel relative to a wheel-rail force and the positions of action points of the wheel-rail force, comprehensively comparing the global sensitivity of the radials transverse and vertical strain values relative to the wheel-rail force and the positions of the action points of the wheel-rail force; finally selecting the maximum of the global sensitivity as the strain gage distribution radii of a transverse bridge and a vertical bridge. According to the global sensitivity analysis method, the global sensitivity and individual sensitivity of the vehicle wheel radials strain values relative to the wheel-rail force and the positions of the action points of the wheel-rail force can be accurately described; according to the principle that interference is as large as possible and crosstalk is as small as possible, the global sensitivity of the radials transverse and vertical strain values relative to the wheel-rail force and the positions of the action points of the wheel-rail force is comprehensively compared, and the method has a theoretical foundation, and makes the test results of the wheel-rail force more reliable.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

A method for calibrating hydraulic jacks by using axial pressure steel pipes

ActiveCN111189657BEasy to operateSave on calibration costsStructural/machines measurementAxial pressureAxial compression

The invention discloses a method for calibrating a hydraulic jack in the technical field of civil engineering structure testing, which comprises the following implementation steps: making two short steel pipes with completely identical parameters; pasting vertical strain gauges in the middle of the steel pipes; on a long-axis testing machine, Carry out the axial compression test of a steel pipe to measure the force and strain of the steel pipe in the elastic stage; carry out the axial compression test of another steel pipe on the hydraulic jack to measure the force and strain of the steel pipe in the elastic stage; The correction coefficient of the hydraulic jack can be obtained by comparing the force of the steel pipe under the same strain in the elastic stage. This method uses the existing instruments and equipment to calibrate the hydraulic jack. This method utilizes the force characteristics of the steel pipe in the elastic stage, has the advantages of high measurement accuracy and accurate correction coefficient, and can meet the measurement requirements of building structure tests and actual engineering.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com