Micro pressure sensor and preparing method thereof

A pressure sensor and pressure technology, applied in the field of sensing, can solve the problems of increasing the complexity of the sensing system, no product development and application, difficult to improve the measurement accuracy, etc., to achieve high resolution, short response time, and miniaturized devices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

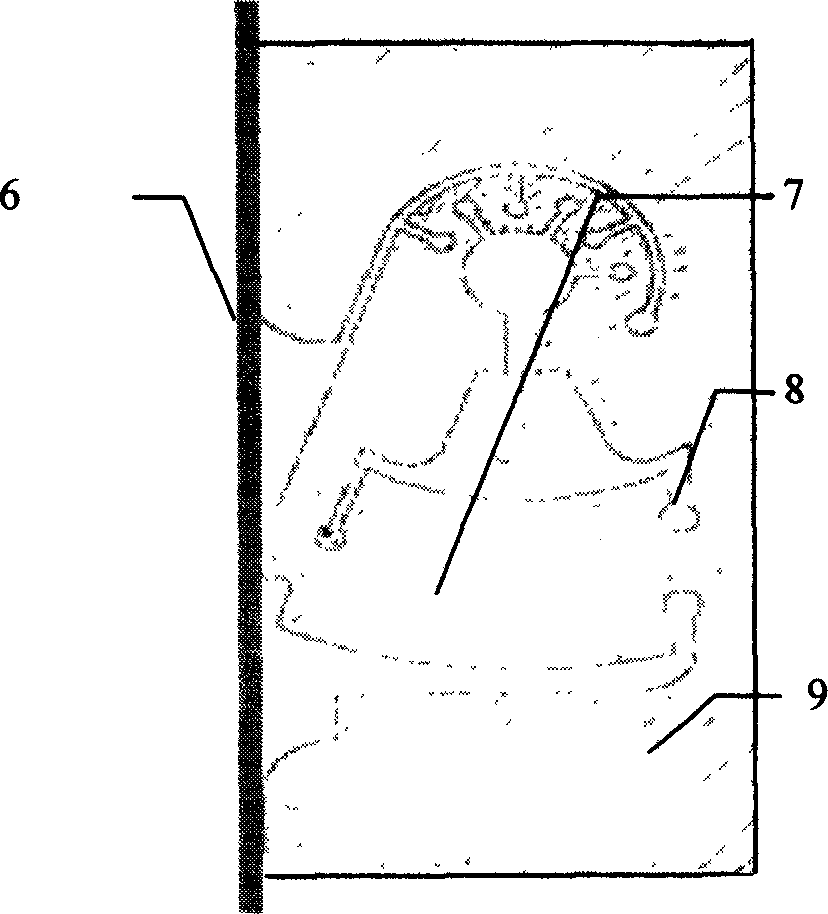

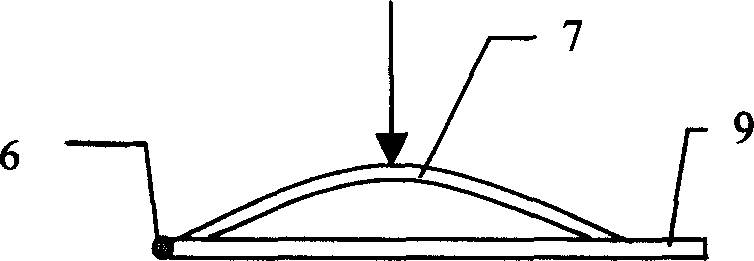

[0030] Such as figure 2 , 3 As shown, the elastic sheet 7, the flexible hinge 8 and the rigid sheet 9 form a deformation body, and the two ends of the fiber Bragg grating (FBG) 6 are closely pasted on the side of the rigid sheet 9, and the middle part is fixed together with the elastic sheet 7; the rigid sheet 9 The middle part of the shrapnel 7 is bent into an arc shape. When the protruding part of the shrapnel 7 is subjected to lateral pressure, the shrapnel 7 will be deformed and straightened. The movable end of the shrapnel 7 pushes to the center of the FBG6 sideways, so that it generates tension along the longitudinal direction, so that The transverse pressure of the optical fiber is effectively converted into a force perpendicular to the pressure direction. This force is applied to the FBG6 to cause longitudinal strain, which makes the reflection wavelength of the FBG6 move. By detecting the wavelength change, the pressure condition can be known. FBG6 can be arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com