Test device and method for parallel-to-grain tensile properties of ancient building wood materials

A technology of ancient buildings and wood materials, which is applied in the field of testing devices for tensile properties along the grain, can solve problems such as inaccurate compressive or bending properties, increased demand for raw materials, and reduced material utilization, and achieve test results Reliable, simple test operation, and the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The testing device for the along-grain tensile properties of ancient building wood materials provided by the embodiments of the present invention can realize the simultaneous testing of ancient building wood tensile strength, elastic modulus and Poisson's ratio under the premise of ensuring maximum saving of raw materials, and the wood The sample processing is simple and the material utilization rate is high.

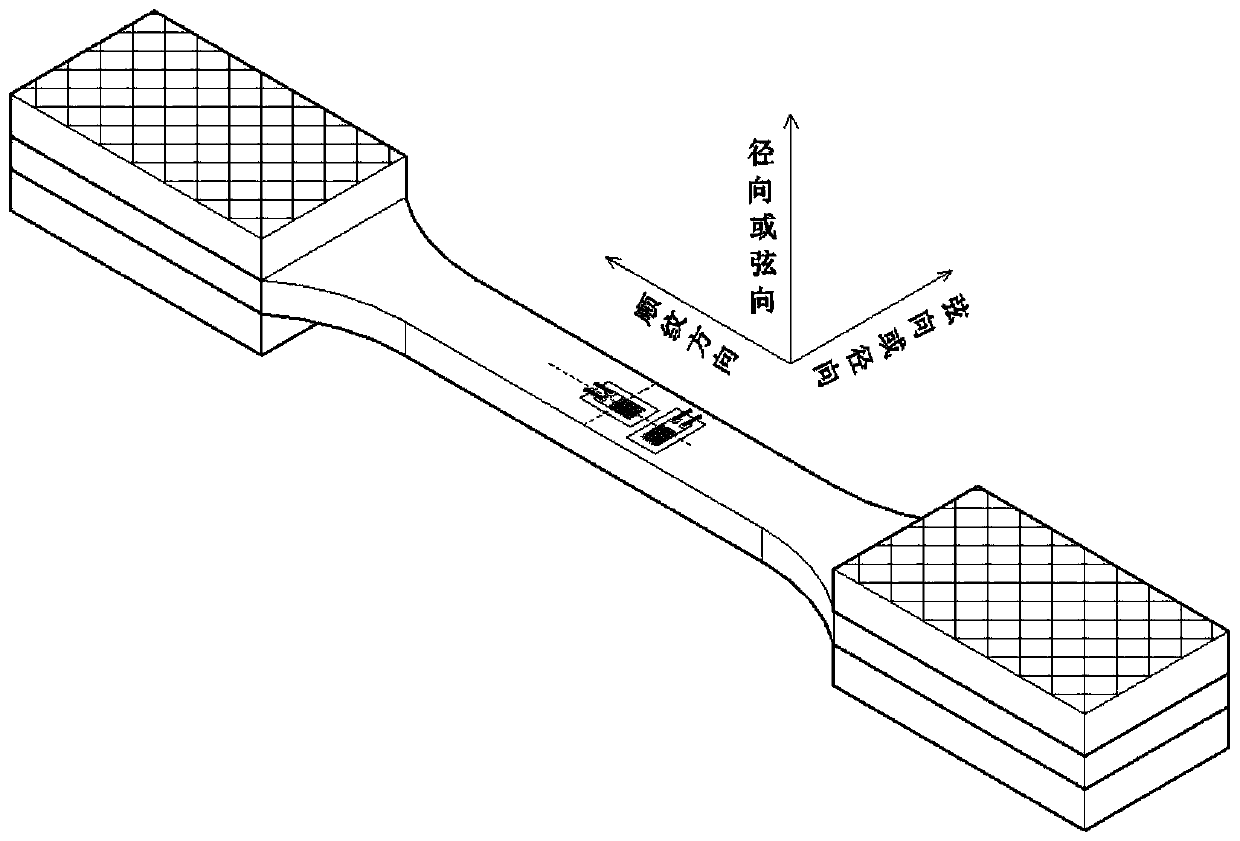

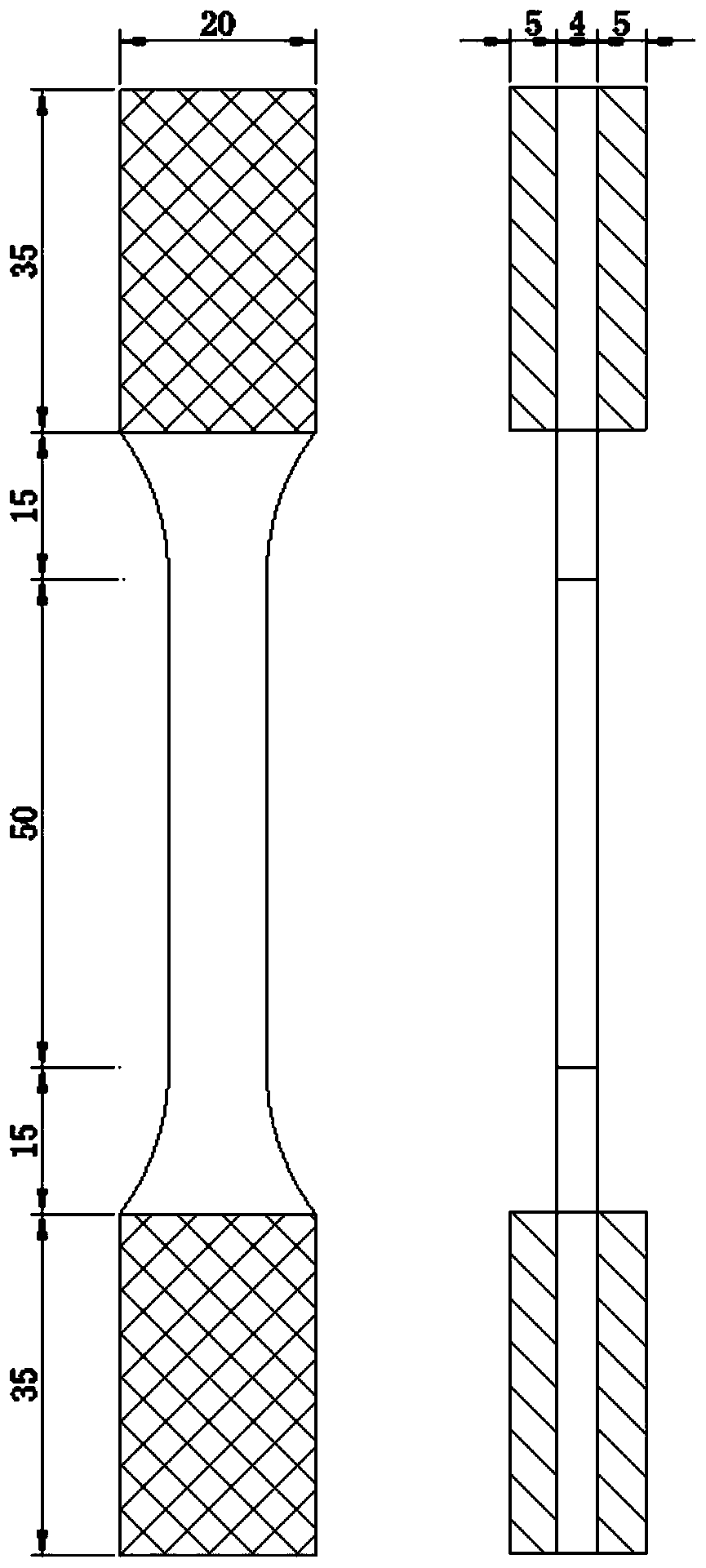

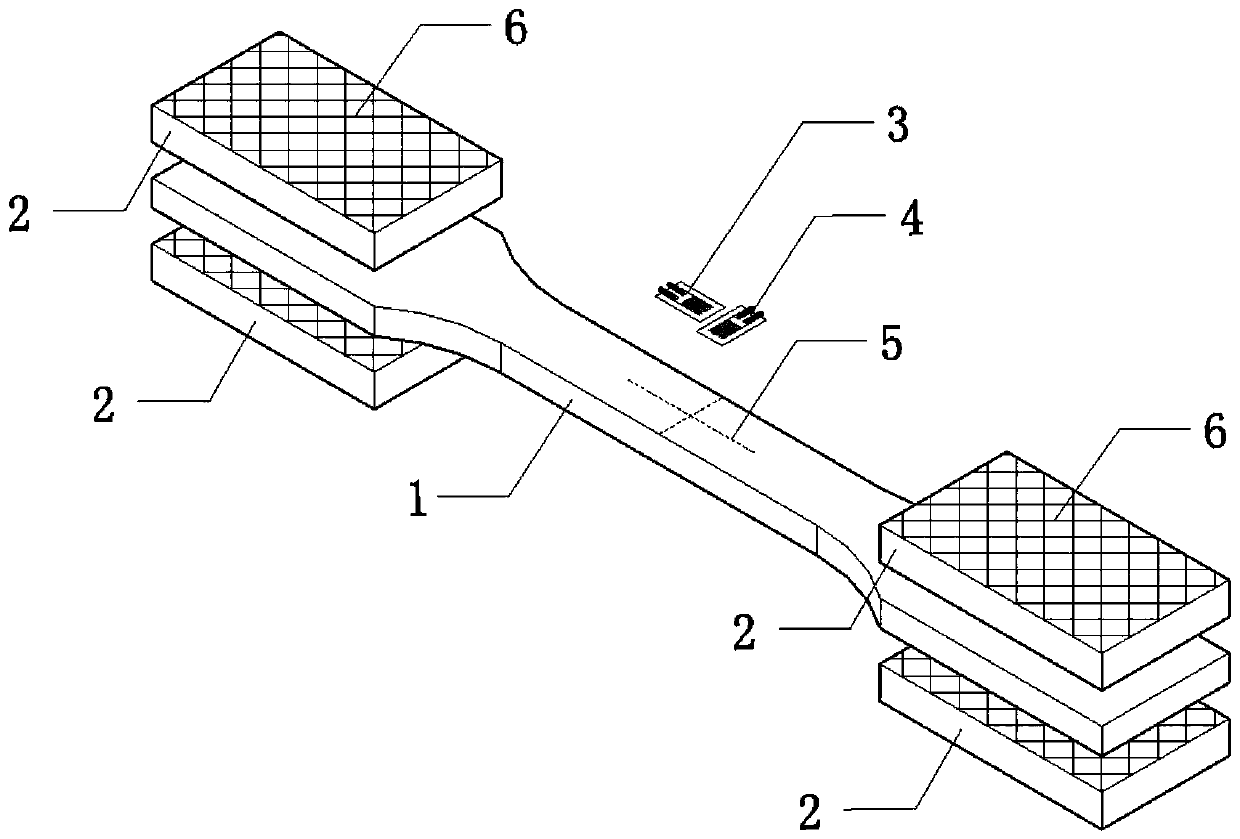

[0043] The structural diagram of a test device for the along-grain tensile properties of an ancient building wood material provided in an embodiment of the present invention is as follows: figure 1 as shown, figure 2 A schematic diagram of the size of a test device for the along-grain tensile properties of an ancient building wood material provided by an embodiment of the present invention; image 3 It is a schematic diagram of the positional relationship and numbering of the parts of the test device, Figure 4 A schematic diagram of each part of the test devi...

Embodiment 2

[0059] The preparation and testing method of a kind of ancient building wood material tensile property test timber sample that this embodiment provides comprises:

[0060] 1. Wood Specimen Preparation

[0061] Such as image 3 As shown, the wood sample includes ancient building wood raw material 1, hardwood gasket 2, vertical resistance strain gauge 3 and horizontal resistance strain gauge 4, according to figure 2 Dimensions of processed wood samples. Among them, the transition arc surface between the clamping part of the wood sample and the testing part should be smooth and symmetrical with respect to the center line of the wood sample.

[0062] The ancient building wood material raw material 1 should be sampled on ancient building replacement components or raw materials with the same chemical composition and state, wherein the length direction of the wood sample is the direction along the grain of the wood material, and the two directions of the transverse grain are respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com