Minisized piezoelectric ultrasonic energy transducer and manufacturing method therefor

A piezoelectric ultrasonic and manufacturing method technology, which is applied in the directions of loudspeakers, sensors, electrical components, etc., can solve the problems of low electromechanical coupling coefficient of transducers, improve the electromechanical coupling coefficient, improve energy conversion efficiency, and reduce working energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

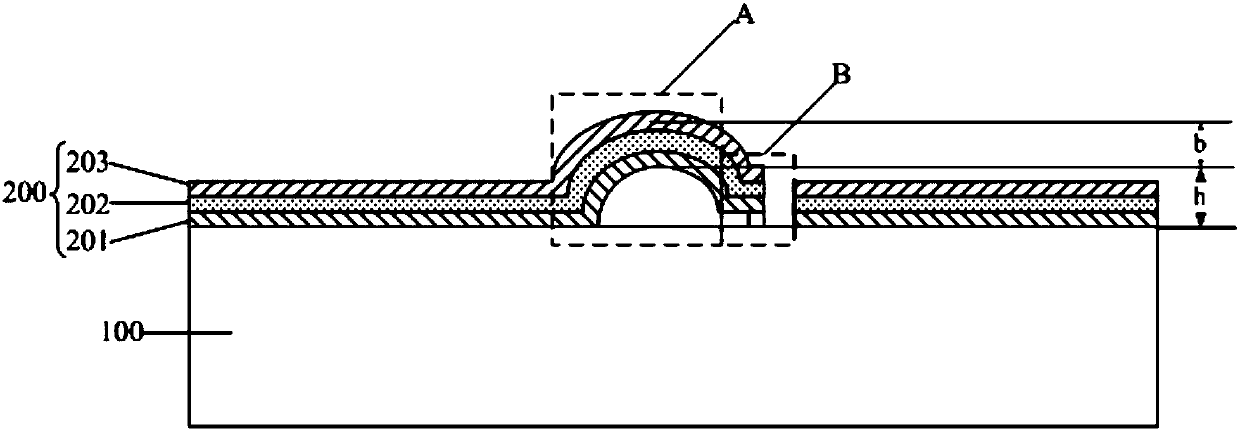

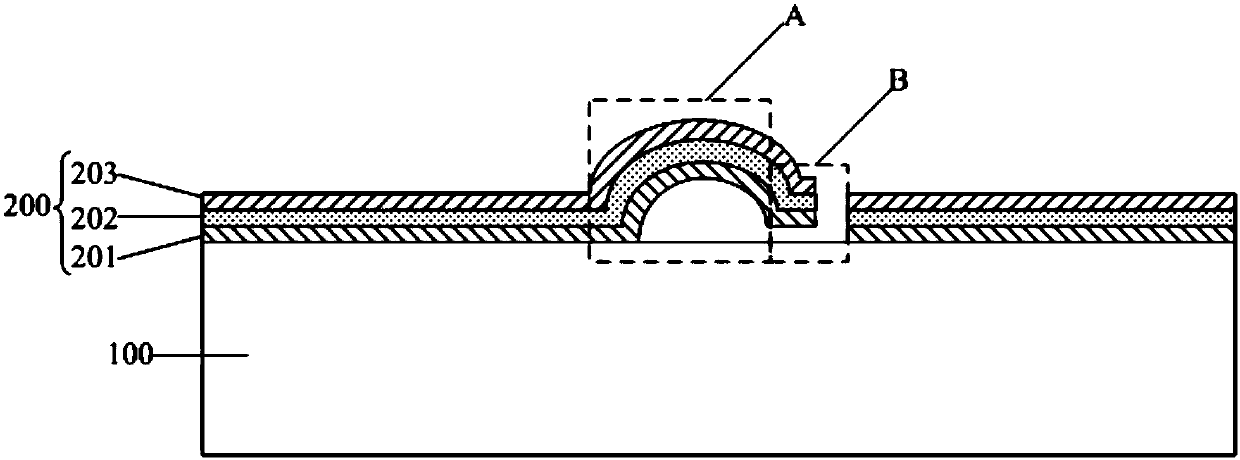

[0038] The specific implementation of the micro piezoelectric ultrasonic transducer provided by the embodiment of the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings.

[0039] The thickness and area shape of each layer in the drawings do not reflect the real scale of the miniature piezoelectric ultrasonic transducer, and the purpose is only to illustrate the content of the present invention.

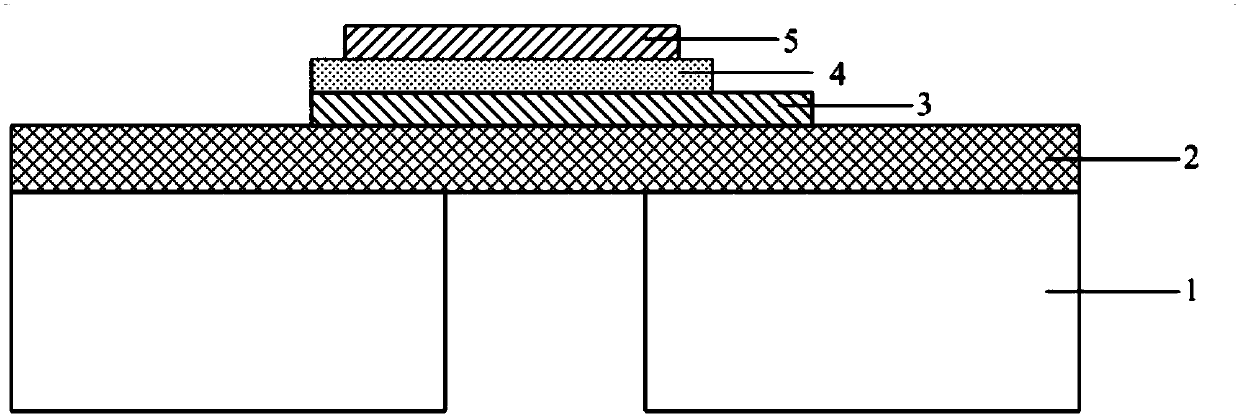

[0040] A kind of miniature piezoelectric ultrasonic transducer provided by the invention, such as figure 2 As shown, it includes: a silicon substrate 100, at least one diaphragm structure 200 disposed on the silicon substrate 100, the diaphragm structure 200 consists of a hollow structure A protruding from the silicon substrate 100 and a hollow structure A protruding from the outside of the hollow structure A At least one trailing structure B of the surface constitutes.

[0041] The above-mentioned miniature p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com