Method for selecting strain gage distribution radius of radials force measuring wheel pair

A technology for measuring force wheel sets and patch radius, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve the problems of poor accuracy and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

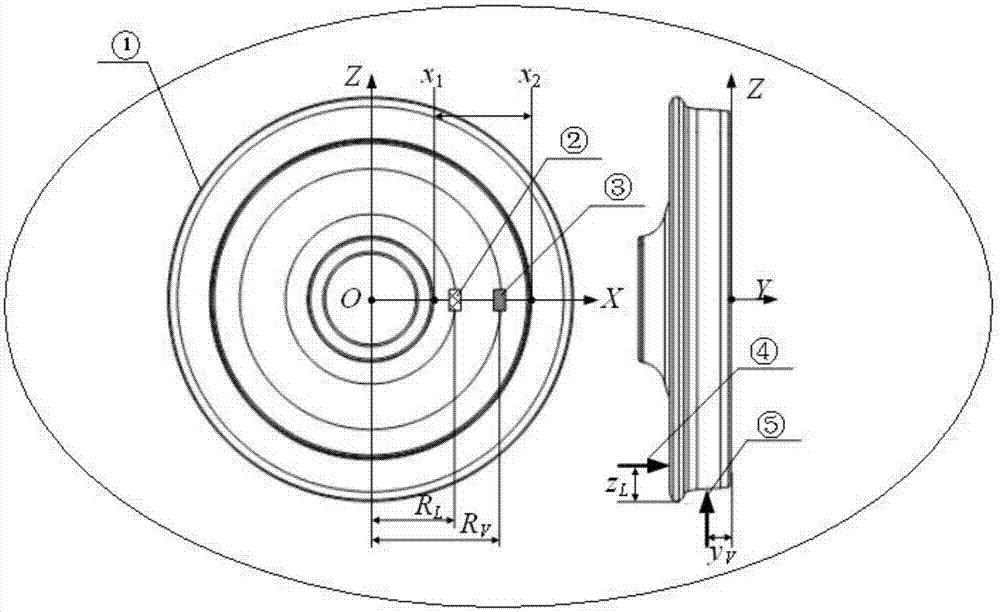

[0030] Such as figure 1 The simulation analysis model of wheel-rail contact relationship shown includes wheel 1, transverse bridge strain gauge 2, vertical bridge strain gauge 3, lateral force 4, vertical force 5; transverse bridge strain gauge 2 and vertical bridge strain gauge 3 It is located between the inner and outer webs, and the radii of the fabrics are R L with R V Indicates that the variation range of the patch radius is [x 1 ,x 2 ]; Lateral force 4 in F L Indicates that the distance between the point of action and the bottom of the rim is z L ; Vertical force 5 in F V Indicates that the distance between the point of action and the outer end face of the wheel is y V .

[0031] The selection method and working principle of the present invention are specified below:

[0032] 1. Use PROE software to build a three-dimensional wheel model, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com