Measuring system and method for concrete non-load internal stress in concrete structure

A technology of concrete structure and measurement system, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of temperature interference, influence of concrete internal stress, large compensation error, etc., and achieve the effect of high test accuracy and accurate internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

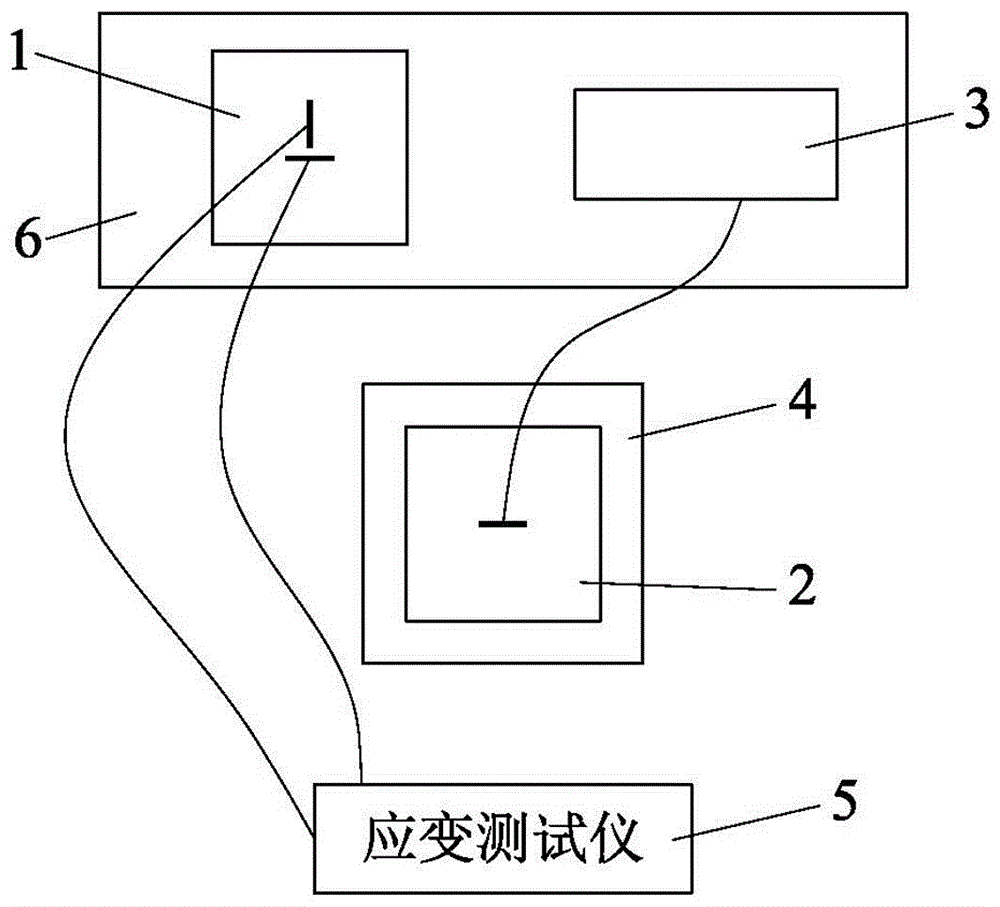

[0040] What the present invention discloses is a measurement system of concrete non-load internal stress in concrete structure, such as figure 1 Shown is a preferred embodiment of the present invention. The measurement system includes a metal block sensor 1 , a temperature compensation block 2 , a temperature sensor 3 , a temperature heating box 4 and a strain tester 5 . in:

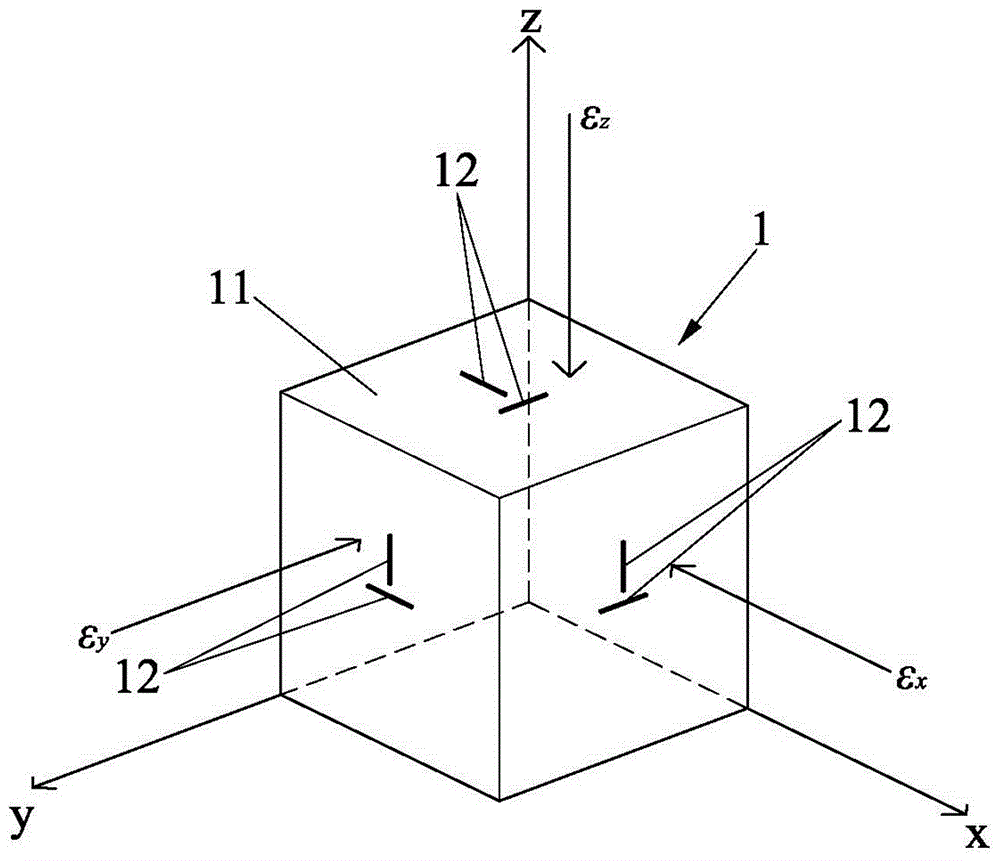

[0041] Described metal block sensor 1 (as figure 2 Shown) comprises the cubic test block 11 that metal is made, and the smaller size of test block 11 is more accurate in measurement, but size is too small to be unfavorable for arranging strain gauge, also inconvenient to use; Best, this test block 11 is not larger than The size is 20mm×20mm×20mm, and its surface is flat, and there is no requirement for surface roughness; in addition, the material of the test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com