Testing method for one-time measurement of tensile modulus and compression modulus of rock

A technique of tensile modulus and compressive modulus, applied in the direction of applying stable tension/compression to test material strength, etc., can solve the problem of inability to obtain the same sample tensile modulus and compressive modulus, technical difficulties, test failures, etc. problems, to achieve the effect that the test method is simple and feasible, and the data is accurate and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

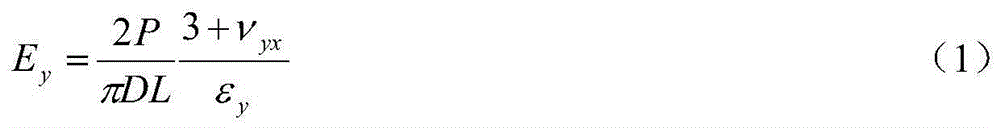

[0025] Such as figure 1 and figure 2 , the test method of disposable measurement rock tensile modulus and compressive modulus of the present invention comprises the following steps:

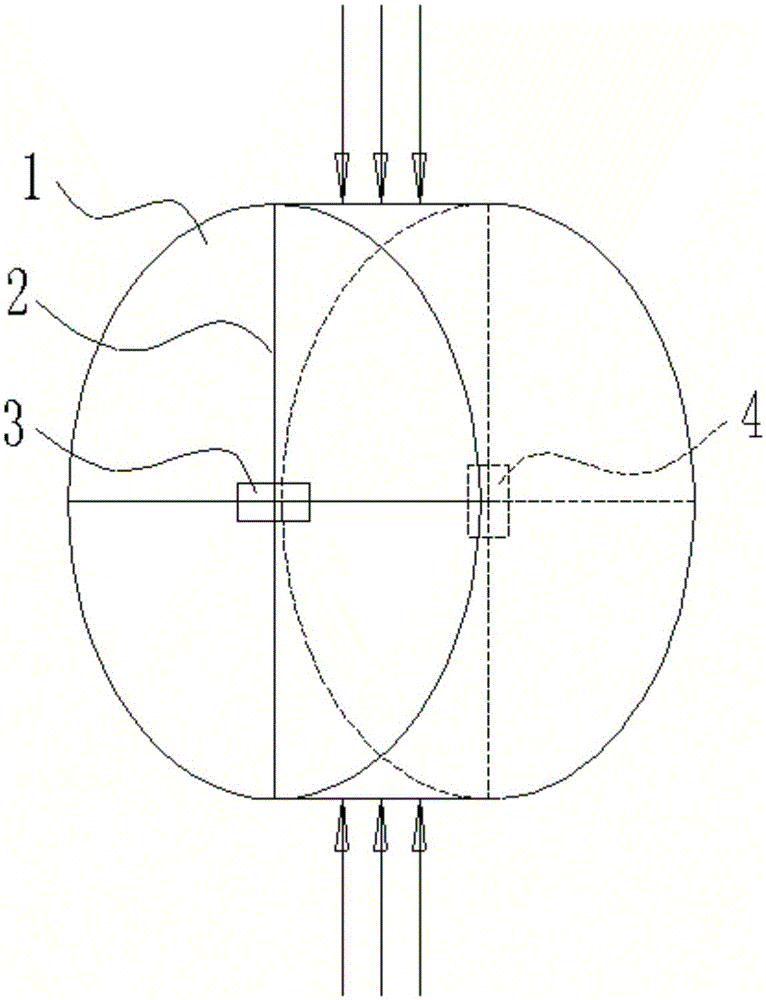

[0026] Step 1: draw two mutually perpendicular baselines 2 along the radial direction of the disk rock 1, and the intersection of the two baselines 2 is the center of the rock;

[0027] Step 2: Paste the horizontal strain gauge 3 and the vertical strain gauge 4 on the center of the front and back of the disc rock 1 respectively, and connect them to the strain acquisition instrument;

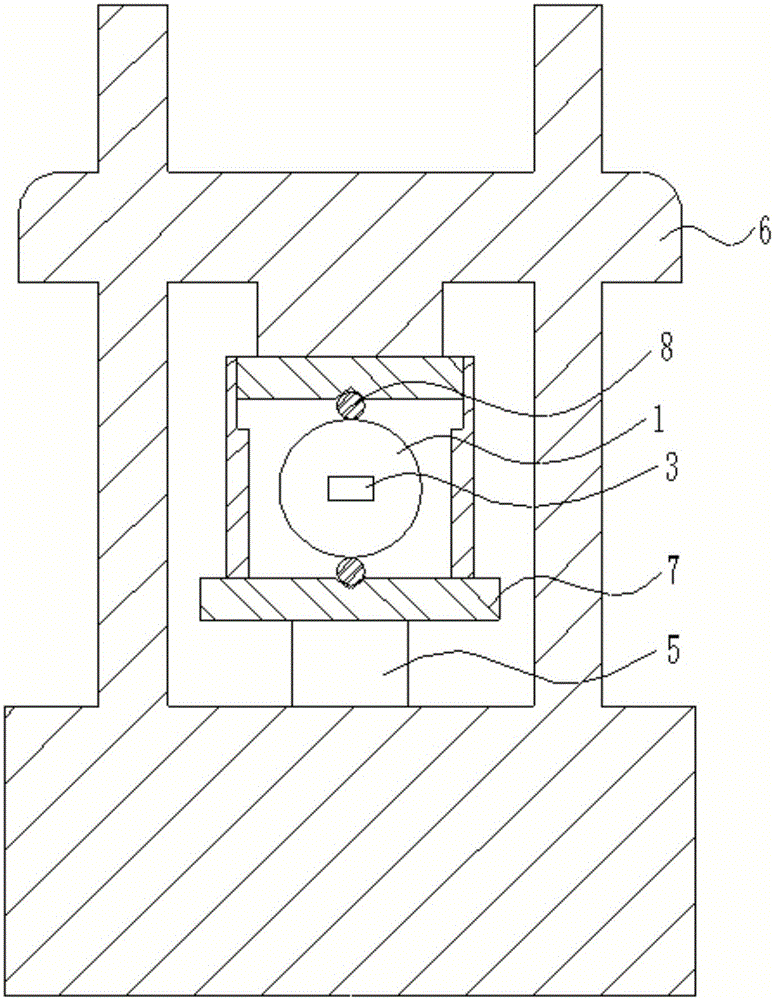

[0028] Step 3: Place the pressure sensor 5 under the pressure plate 7 of the press 6 and connect it to the strain collector;

[0029] Step 4: Place the disc rock 1 between the upper and lower bearing plates 7 of the press 6, and place a steel spacer 8 with a diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com