Patents

Literature

36results about How to "Stable pressure regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

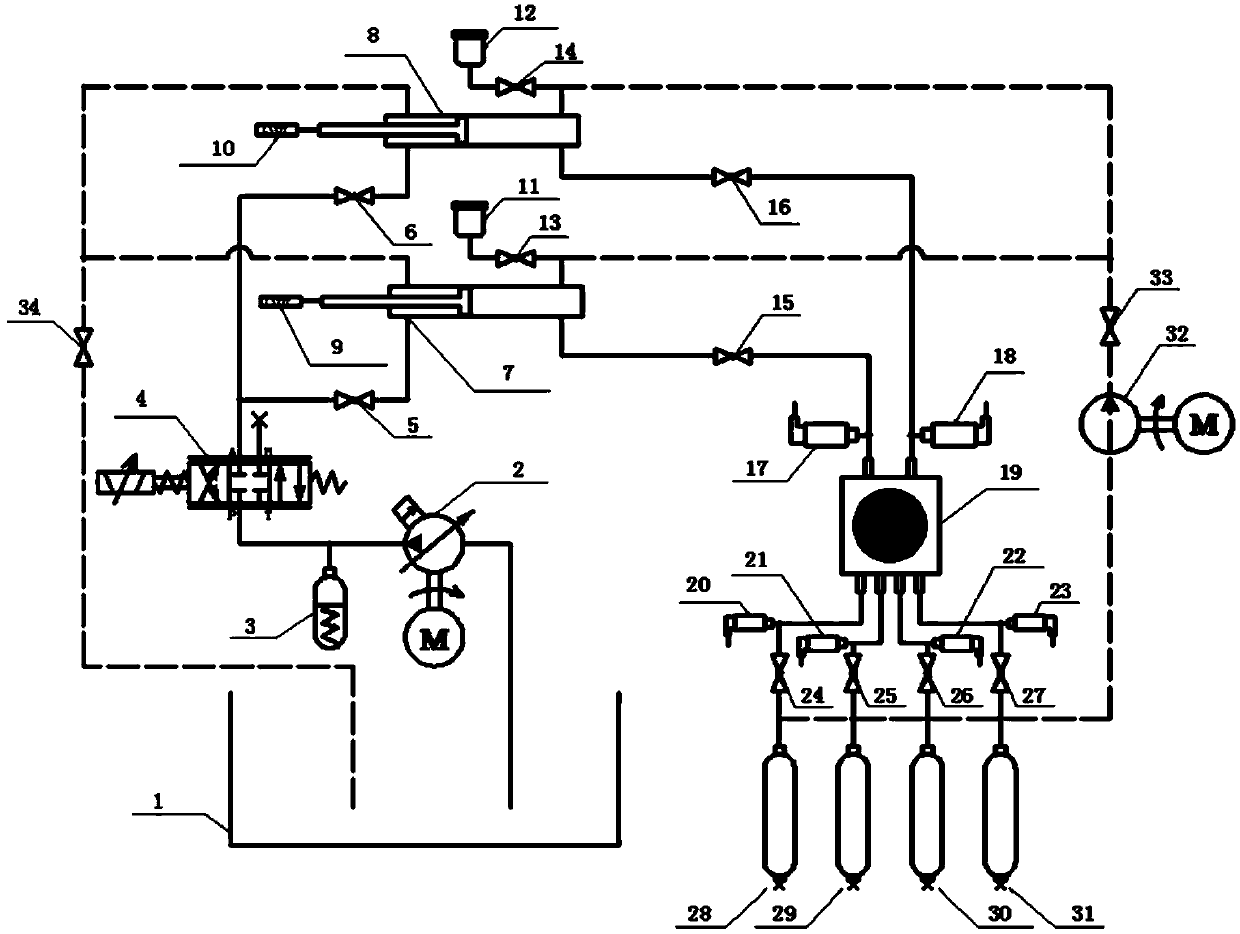

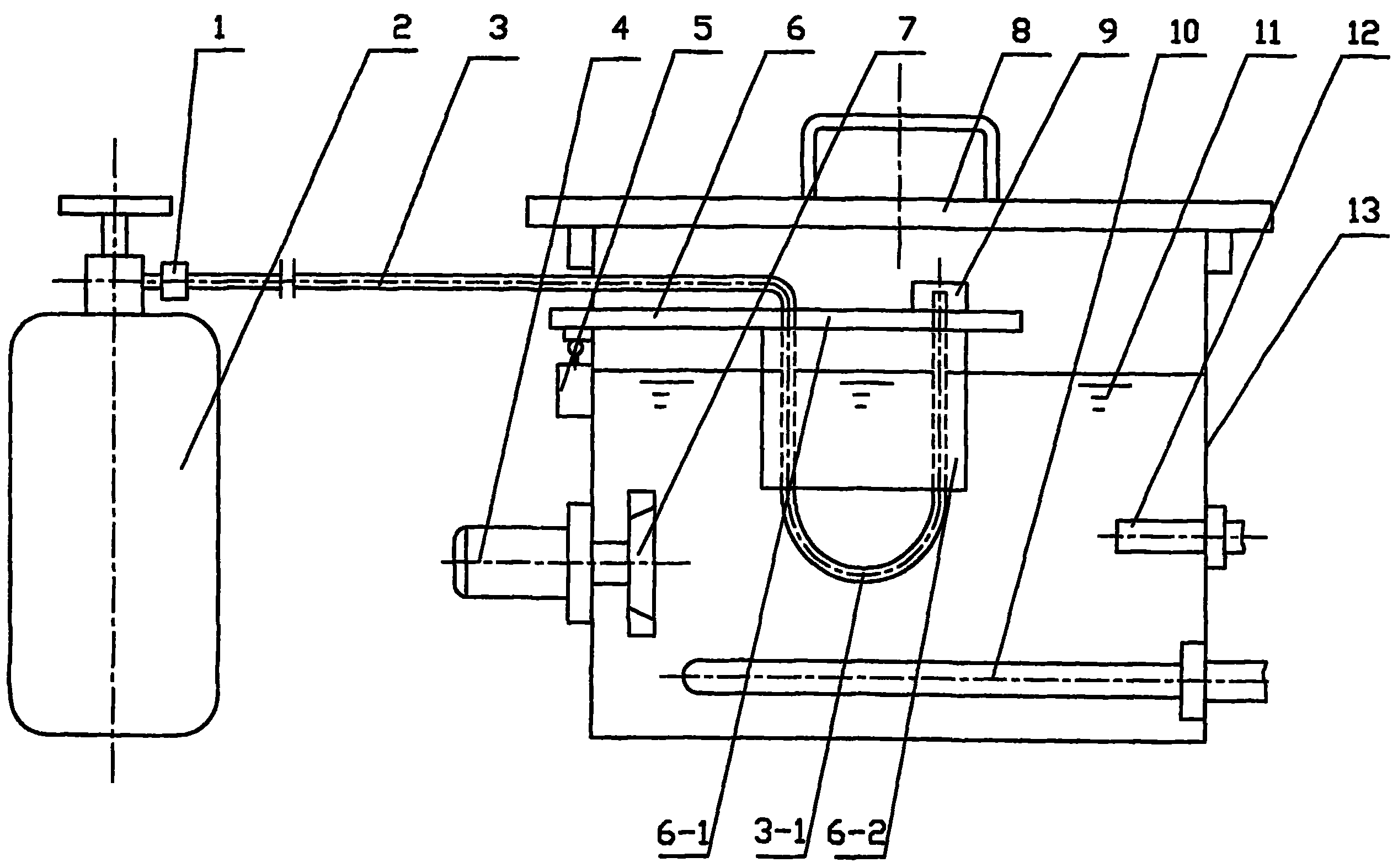

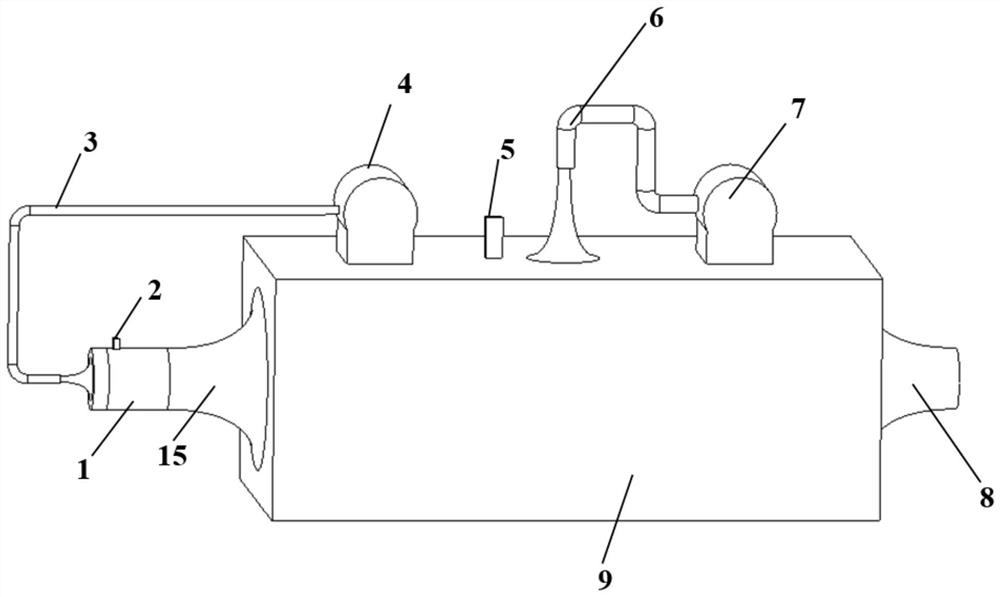

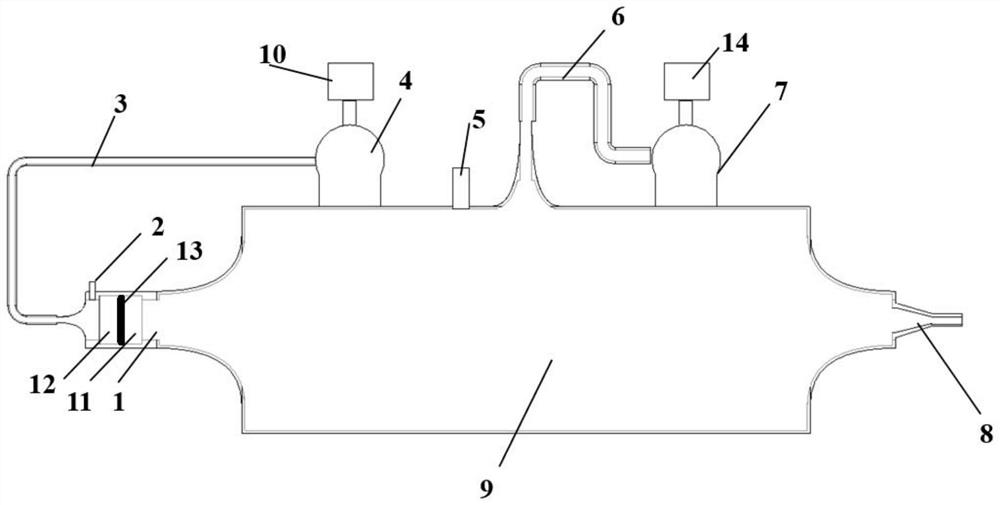

Performance test system for HCU (hydraulic control unit) in automobile brake system

ActiveCN104179752AStable pressure regulationAccurate and stable back pressureFluid-pressure actuator testingHydraulic control unitMeasurement device

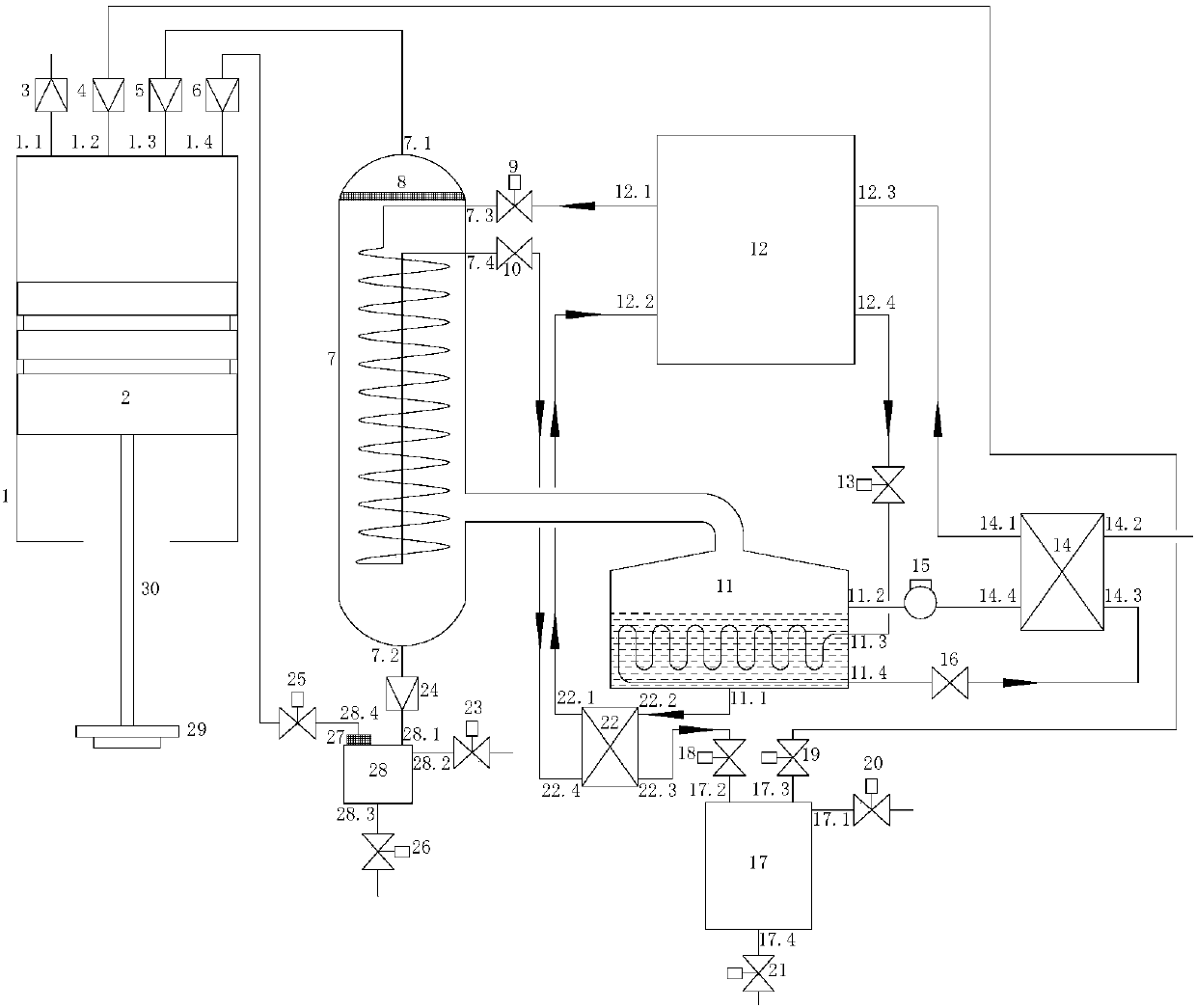

The invention relates to a performance test system for an HCU (hydraulic control unit) in an automobile brake system and belongs to the technical field of quality detection of automobile chassis dynamically-controlled parts. The test system comprises a pressure lifting device, a hydraulic pipeline system, a measurement control device and an environmental simulation device, and all parts of the test system are connected through pipelines. By means of the performance test system for the HCU in the automobile brake system, parameters such as the response speed and the sealing performance of an HCU valve, the flow and the pressurizing capacity of a plunger pump, the volume of an energy accumulator and the like can be tested accurately.

Owner:TSINGHUA UNIV

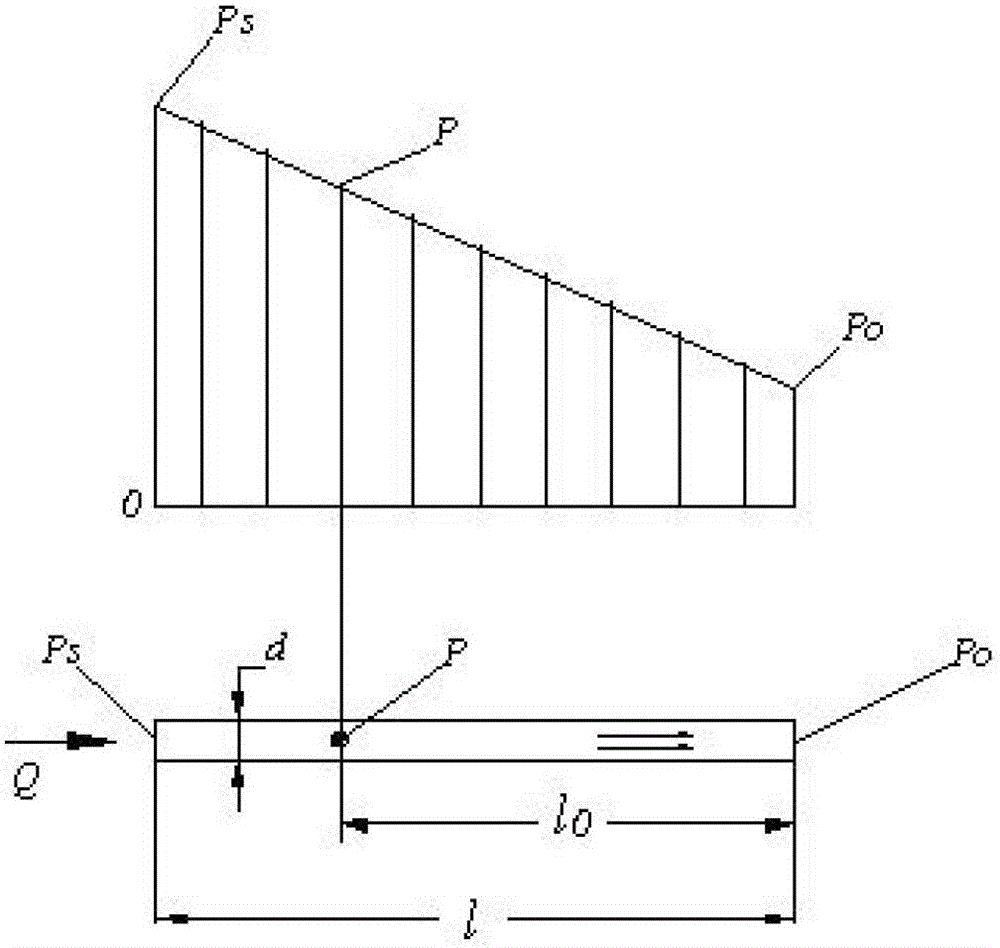

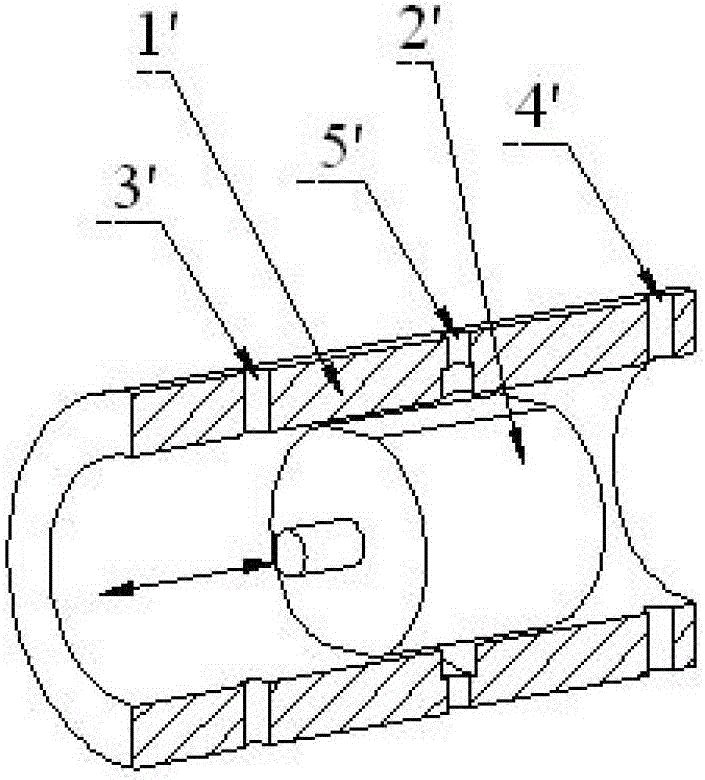

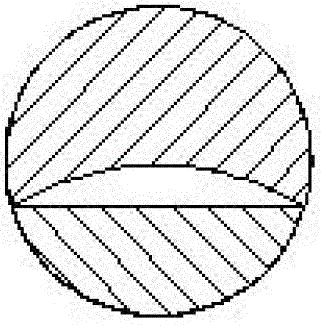

Screw extrusion melt pressure stabilizing device and method

A pressure stabilizer for the molten material extruded out by screw extruder is characterized by that a connecting body with pressure stabilizing hole on its side wall is arranged between the cylinder and head piece of extruder, and a pressure stabilizing part driven by its driver moves in said pressure stabilizing hole to apply or release the pressure to or from the extruded material which flows through the central channel of said connecting body. Its method includes sensing the pressure value of the extruded material, comparing it with its setting, and controlling the movement of said pressure stabilizing part.

Owner:BEIJING UNIV OF CHEM TECH

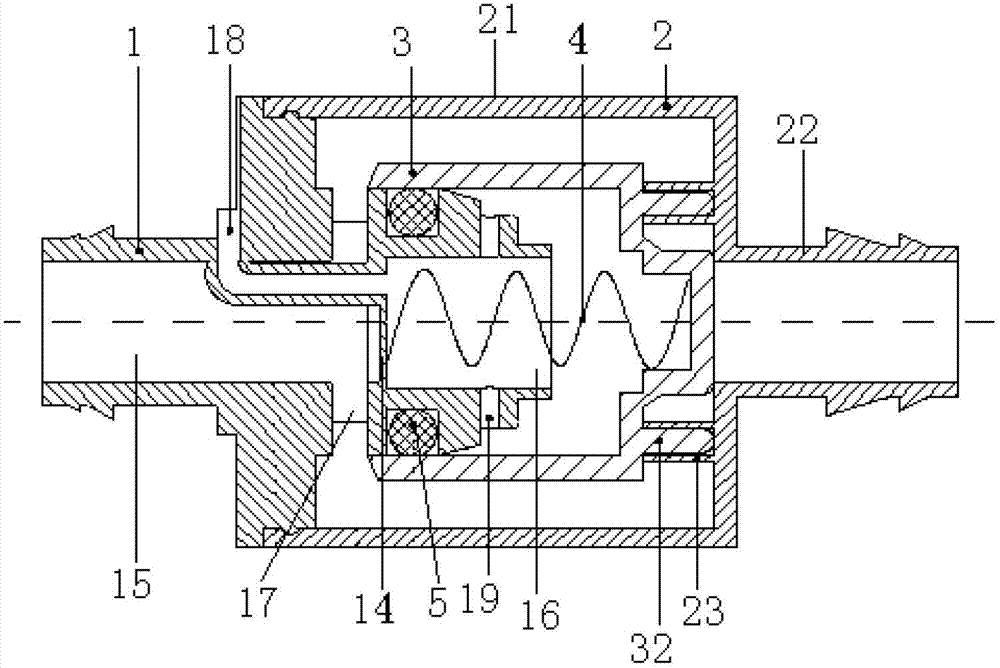

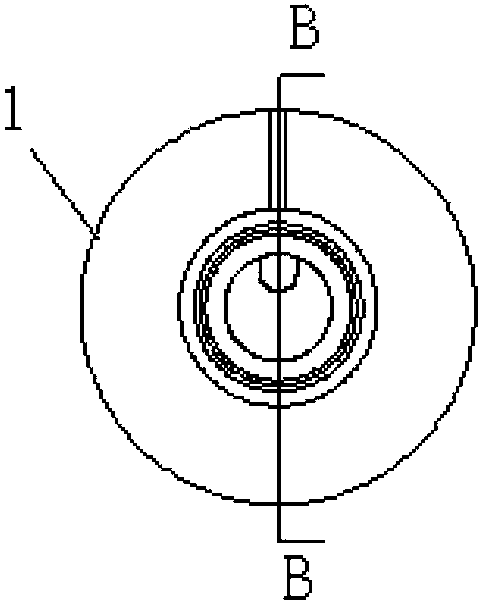

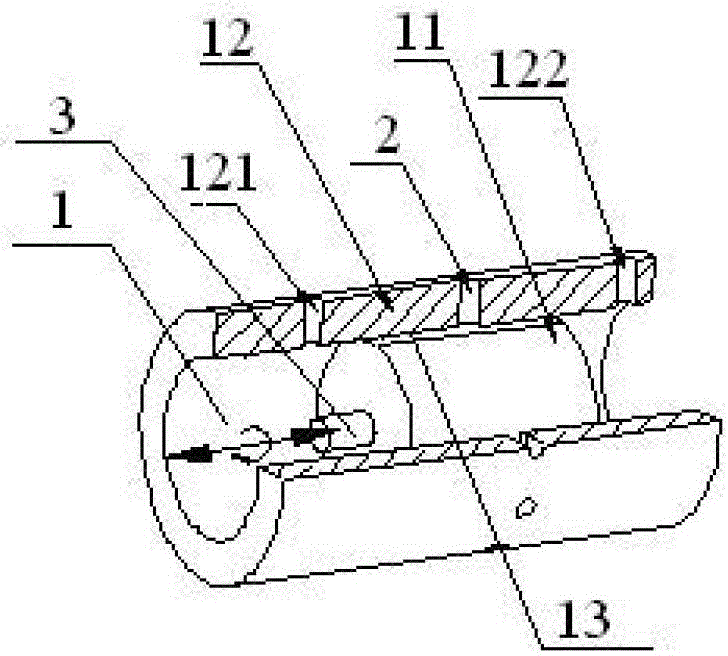

Capillary pressure regulator

ActiveCN103026948ALarge range of motionWide range of pressure regulationWatering devicesCultivating equipmentsCapillary pressureEngineering

The invention relates to a capillary pressure regulator. The capillary pressure regulator is characterized by comprising an upstream flow deflector, a downstream shell, a pressure regulating assembly and a spring, wherein a baffle for dividing interior of the upstream flow deflector into an upper cavity and a lower cavity which are not communicated with each other is arranged inside the upstream flow deflector; a water outlet hole is formed in the upper cavity; an air guiding pipe communicated with atmosphere is arranged on the lower cavity; a plurality of vent holes are also formed in the lower cavity; the downstream shell comprises a first cylinder body and a second cylinder body; the end part of the first cylinder body is connected with a shell connecting end of the upstream flow deflector; a plurality of positioning holes are formed in the side wall of the first cylinder body; the pressure regulating assembly is a cylindrical cavity with one opened side and one closed side; an outwardly-protruding spring installing groove is formed in the inner wall of a closed end; a positioning probe corresponding to the positioning holes is arranged on the outer wall of the closed end; the opened end of the pressure regulating assembly is connected with a pressure regulating assembly connecting end of the upstream flow deflector; a water stopping part is arranged between the opened end of the pressure regulating assembly and the pressure regulating assembly connecting end of the upstream flow deflector; and one end of the spring is pressed against the baffle inside the upstream flow deflector; and the other end of the spring is pressed against the bottom of the spring installing groove of the pressure regulating assembly.

Owner:CHINA AGRI UNIV

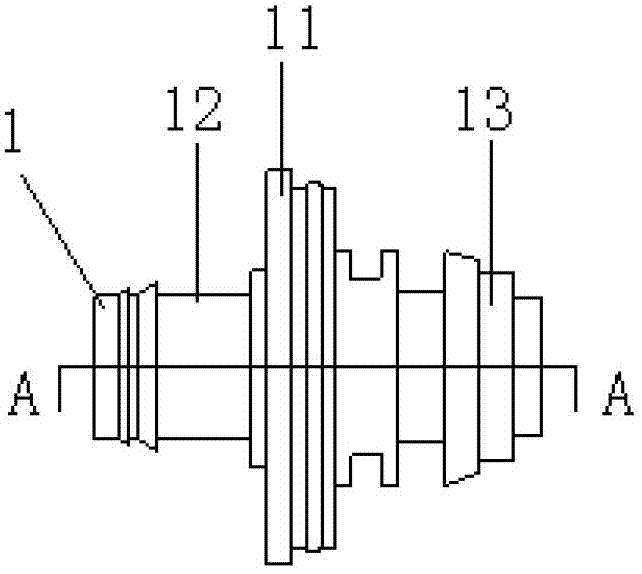

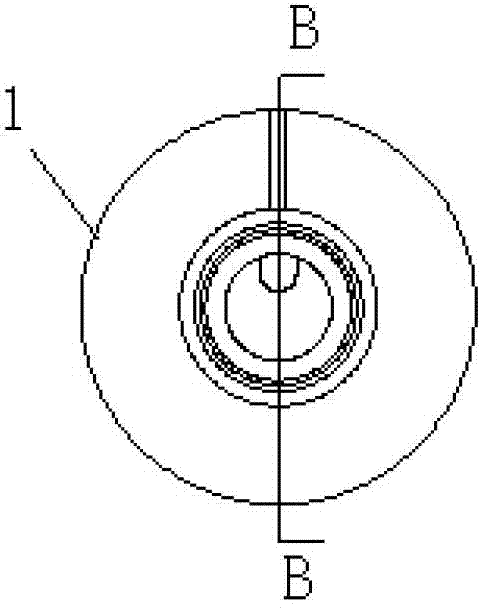

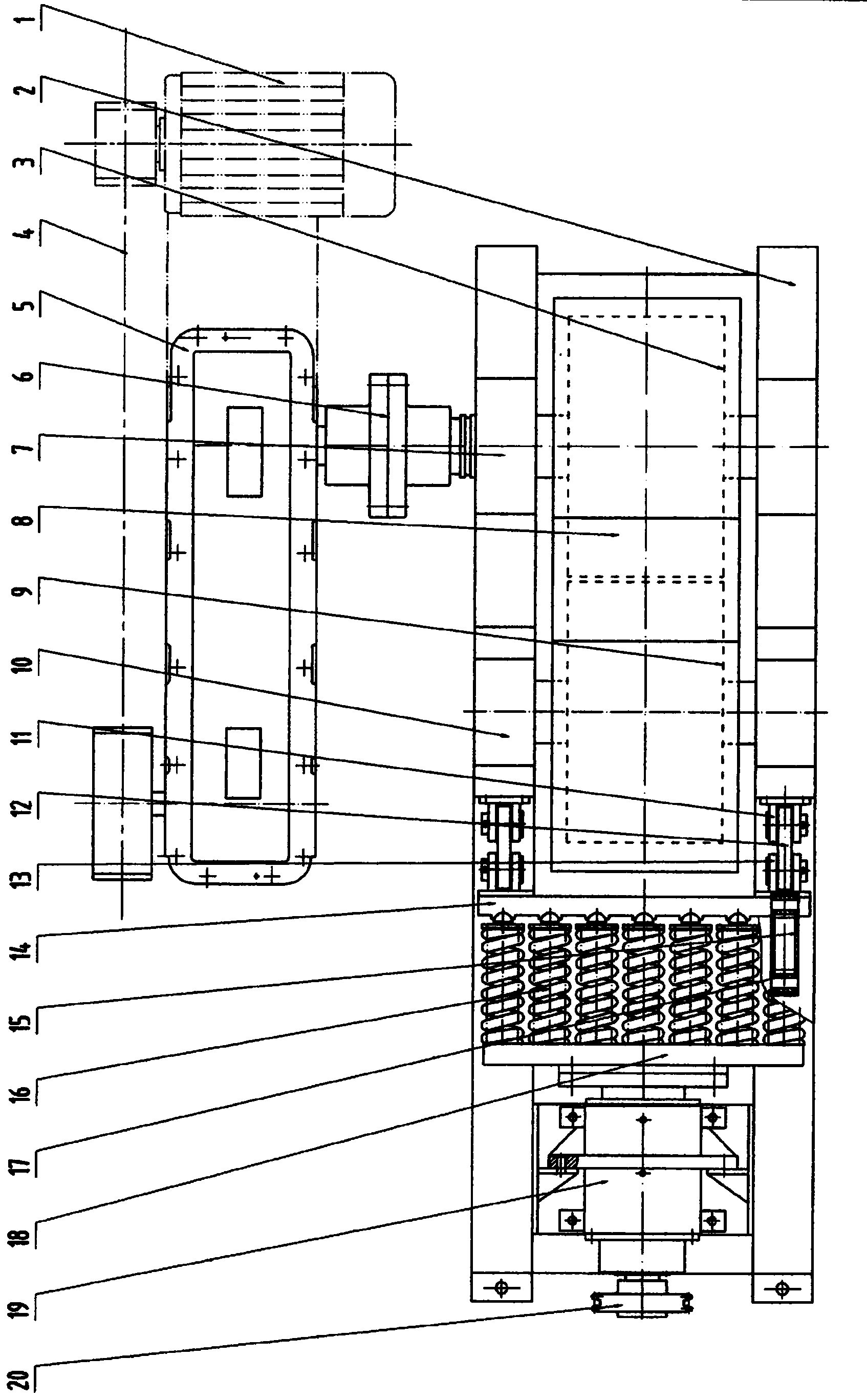

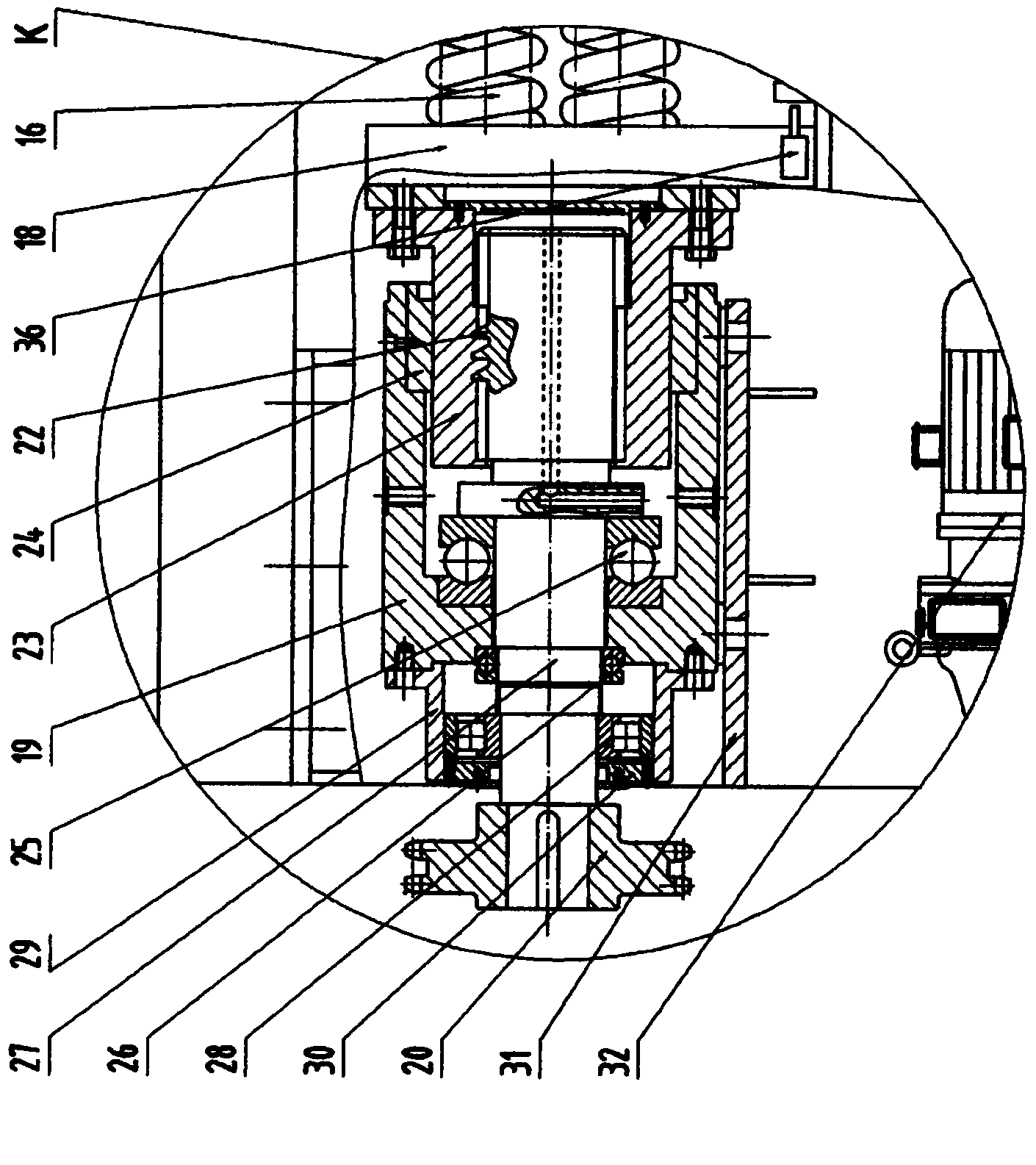

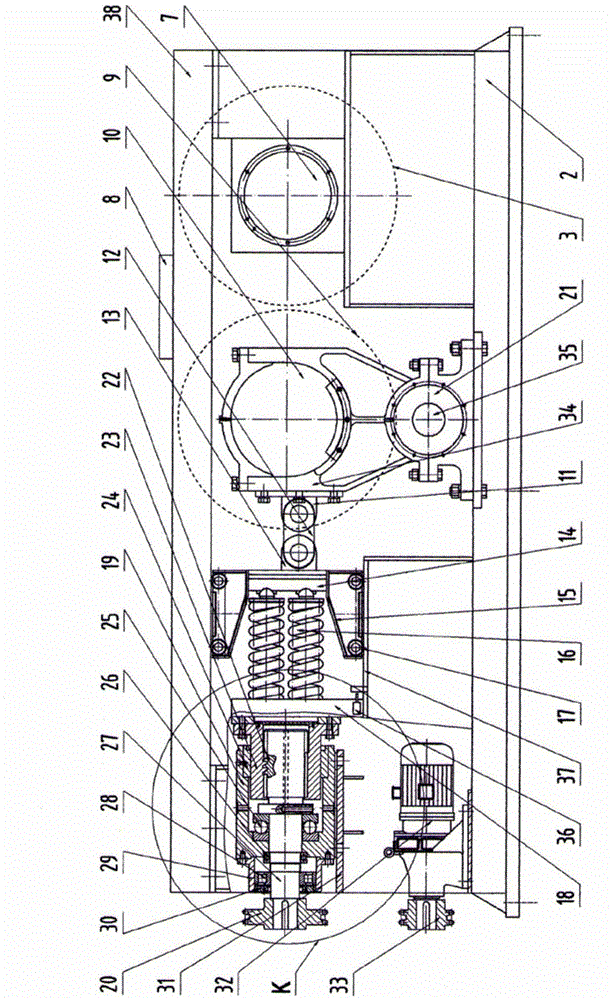

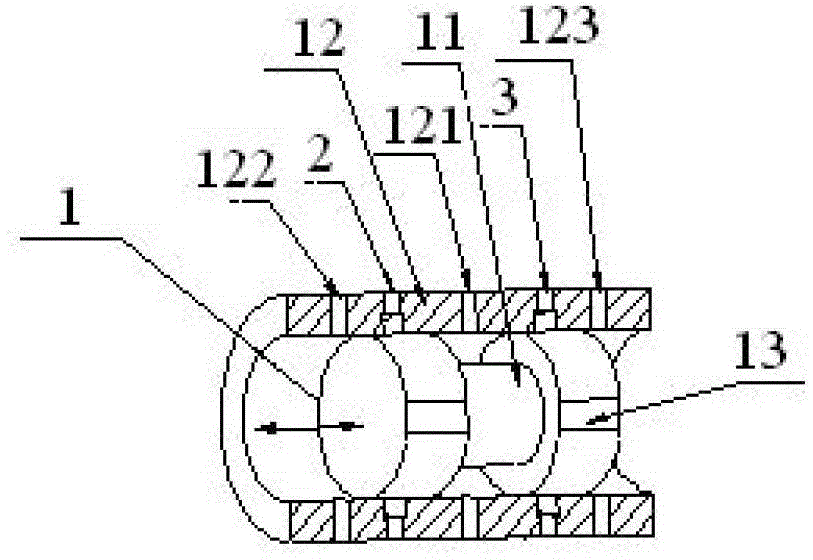

Single-driving-roller clearance-free sand maker

ActiveCN103447113AReduce powder contentIncrease sand forming rateGrain treatmentsEngineeringPower component

The invention discloses a single-driving-roller clearance-free sand maker, and relates to the technical field of crushing equipment. The single-driving-roller clearance-free sand maker is composed of a rack 2, a power device, a movable roller 9, a fixed roller, a fixed roller bearing seat 7 and a pressure regulating device; the pressure regulating device comprises a pressure regulating power component, a pressure regulating component, a pressure regulating and applying component, a pressure regulating guide component and a pressure regulating transmission component. The single-driving-roller clearance-free sand maker has the characteristics of simple structure, convenience in maintaining, low running cost, long running cycle, high sand formation rate and the like, can be used for preparing sands for construction by utilizing materials including sand stones, cobblestones and the like, also can be used for front breaking and grinding of a grinding system, and can be widely applied to the fields including construction, construction materials, mines and the like.

Owner:湖南宇晖重工机械有限公司

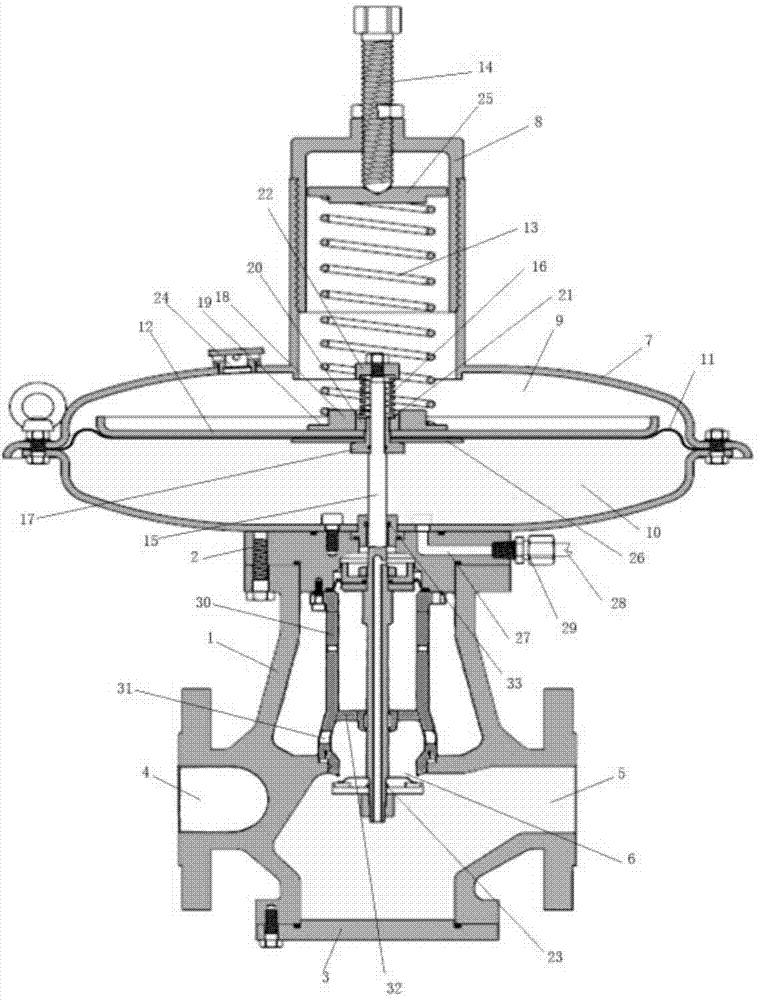

Spring-loaded pressure regulator

InactiveCN104500801AExtended service lifeWill not be damagedSpindle sealingsOperating means/releasing devices for valvesInverted tPressure regulator

The invention relates to a spring-loaded pressure regulator, which comprises a valve body and a main pressure regulation mechanism connected with the top of the valve body, a partitioning diaphragm is arranged in the main pressure regulation mechanism, a pressure regulation plate is arranged on the partitioning diaphragm, a main regulation spring seat and an auxiliary regulation spring seat are arranged on the pressure regulation plate, a main regulation spring is arranged on the main regulation spring seat, a valve rod is arranged in the pressure regulator, the upper end of the valve rod sequentially and vertically runs through the partitioning diaphragm, the pressure regulation plate and the auxiliary regulation spring seat and is then screwed in a nut, an auxiliary regulation spring and an inverted T-shaped guide sleeve sleeve the upper end of the valve rod, the upper end and lower end of the auxiliary regulation spring are respectively limited by the nut and a second annular step, the outer sidewall of the vertical part of the inverted T-shaped guide sleeve is in clearance fit with the partitioning diaphragm, the pressure regulation plate and the auxiliary regulation spring seat, and the upper surface of the horizontal part of the inverted T-shaped guide sleeve is in contact with the partitioning diaphragm. The adoption of the solution can effectively prevent the partitioning diaphragm from being damaged by the overhigh pressure of gas under the partitioning diaphragm, consequently, the service life of the pressure regulator is prolonged, and the pressure regulator can more safely supply gas.

Owner:TERRENCE ENERGY

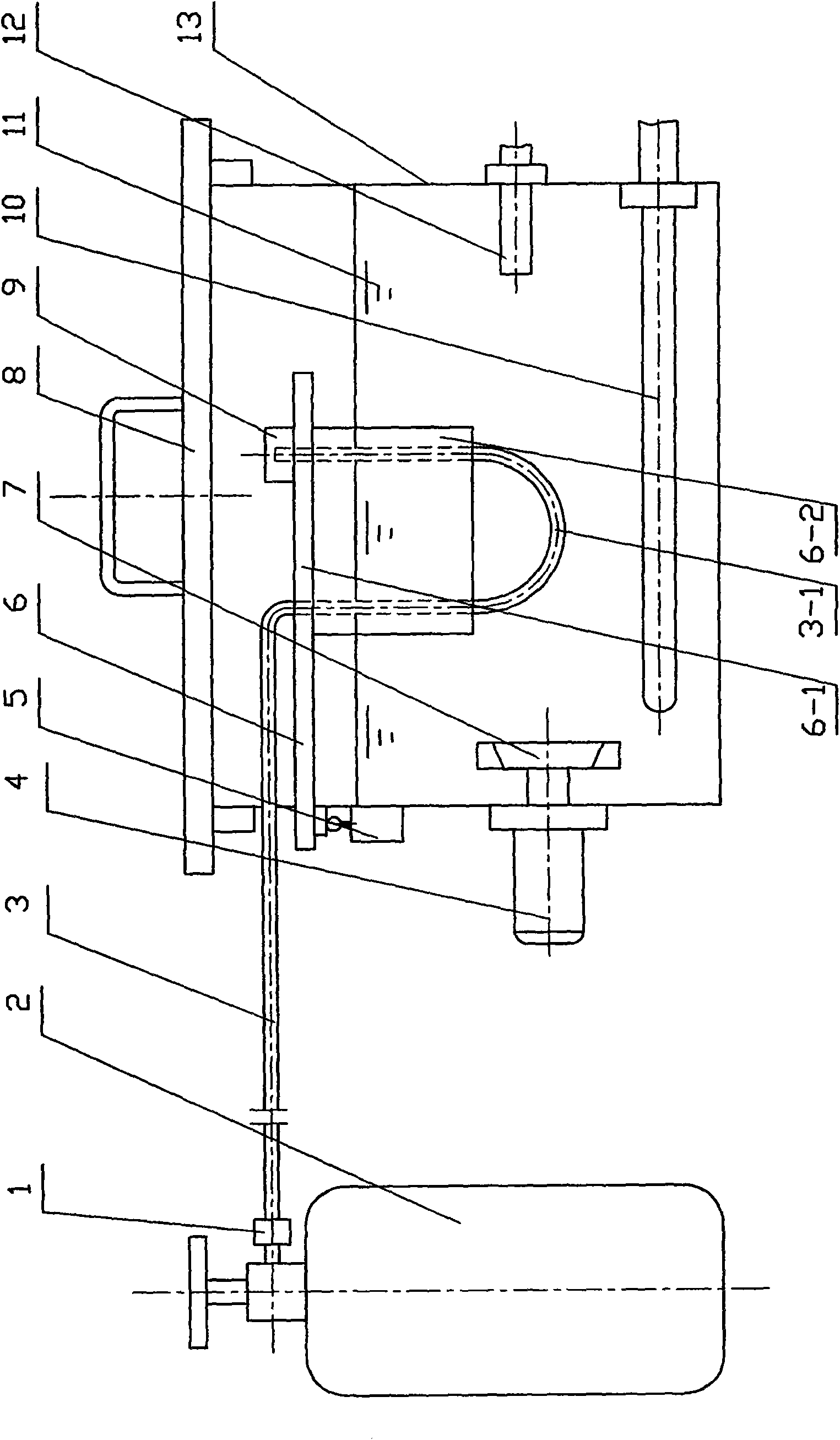

Device and method for indirectly testing performance of fire detection tube

The invention discloses a device and a method for indirectly testing the performance of a fire detection tube. A medium capable of generating high pressure gas is filled in a gas bottle of the device; one end of the tested fire detection tube is connected with the outlet of a pressure regulating valve, and the other end of the tested fire detection tube is sealed by an end connector; a test section at the center of the fire detection tube is fixed on a fixed plate; a cover plate is arranged on a test box; the fixed plate is positioned on the test box; a part of the fire detection tube on the fixed plate is soaked into the liquid medium; a timer is arranged on the lateral surface of the test box below the fixed plate; a heat source is arranged at one side of the test box and is completely soaked into the liquid medium; and a temperature testing element is arranged on the test box and is arranged in the liquid medium. The invention realizes the purpose of conveniently and accurately regulating the test pressure; when the fire detection tube is broken, gas can overflow out of the liquid medium and can not pollute the liquid medium; the indirect method which uses the liquid medium for simulating the heating environment in the working process of the fire detection tube has the advantages of high control accuracy of test temperature, simple structure, safe operation and low cost; and the device can be used as standard equipment to be popularized and used.

Owner:BEIJING UNIV OF CHEM TECH +1

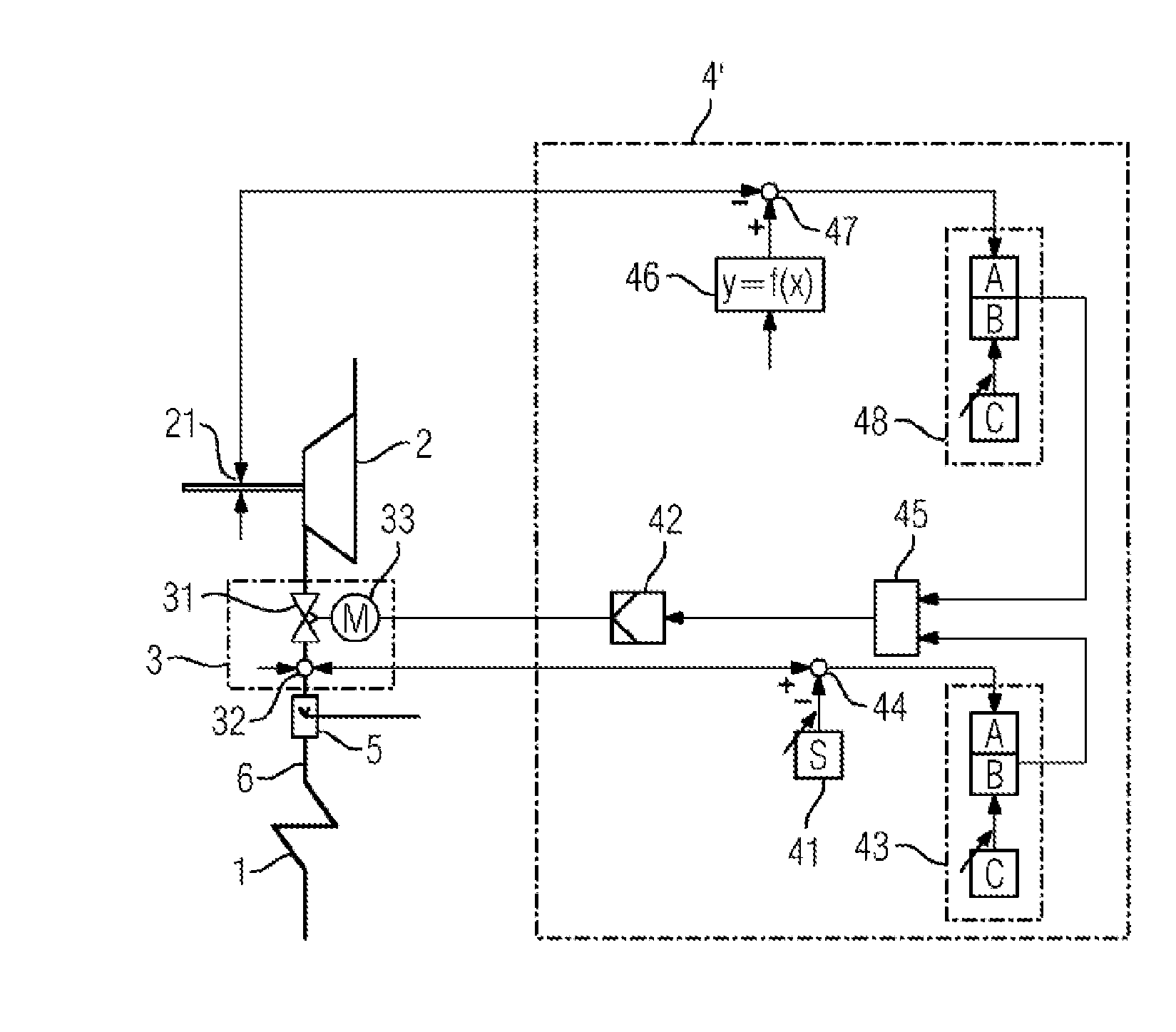

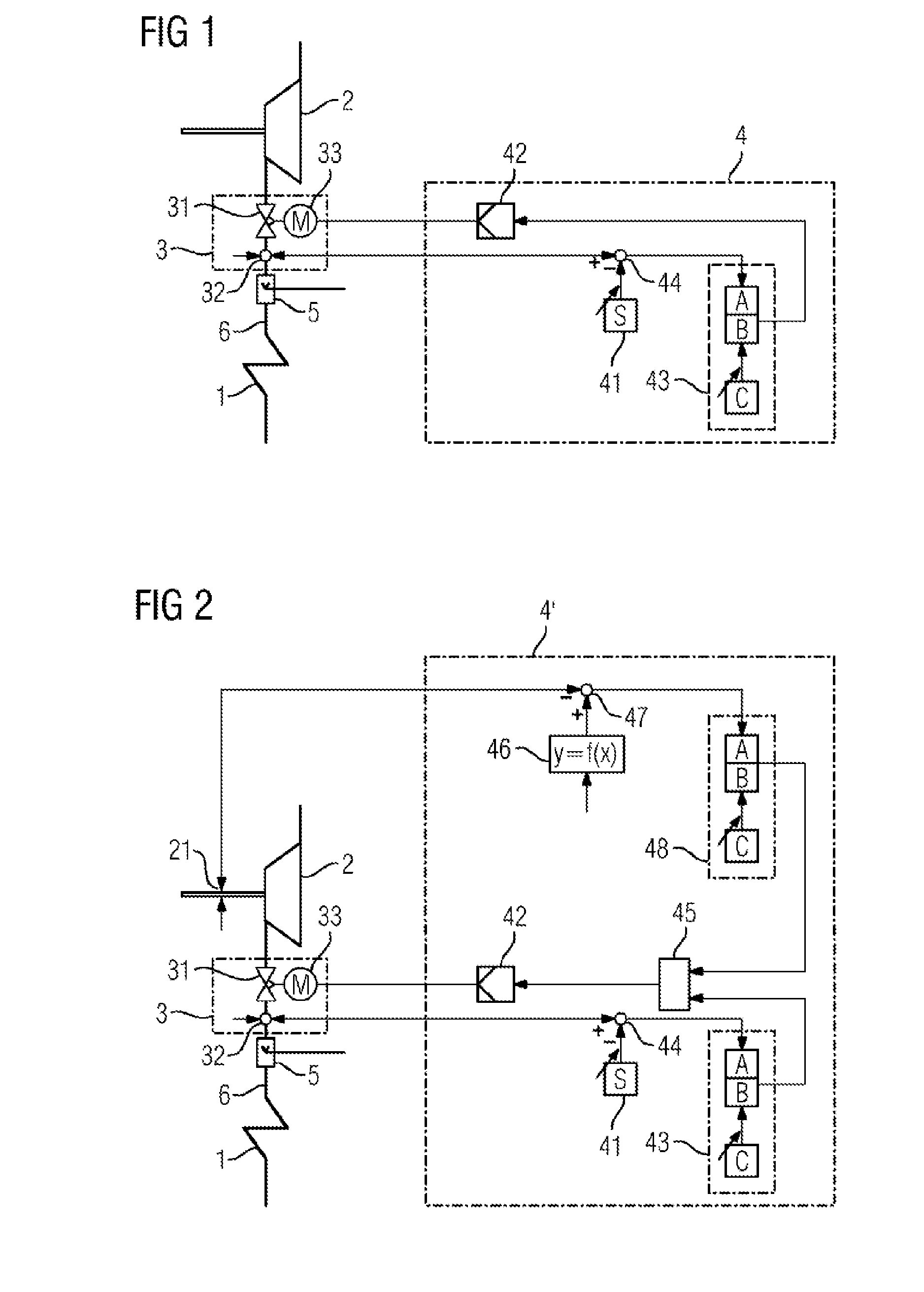

Operating method for an externally heated forced-flow steam generator

InactiveUS20160208656A1Avoid temperature fluctuationsStable pressure regulationFrom solar energyBoiler controlThermal energyTime delays

An operating method for an externally heated once-through steam generator, in particular a once-through steam generator is heated using solar thermal energy and has a steam turbine connected downstream of the once-through steam generator. A pressure regulation device, having at least one turbine valve for regulating the pressure, is arranged in the feed water-steam circuit between the once-through steam generator and the steam turbine, the pressure regulation device being controlled by a control unit in such a way that, in the event of sudden load reductions, the drop in pressure associated therewith occurs, in a time delayed manner, by throttling of the at least one turbine valve.

Owner:SIEMENS AG

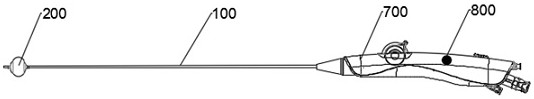

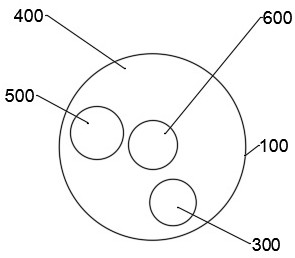

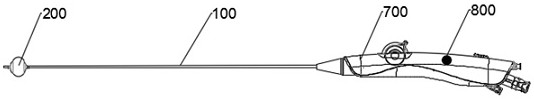

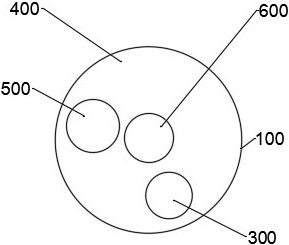

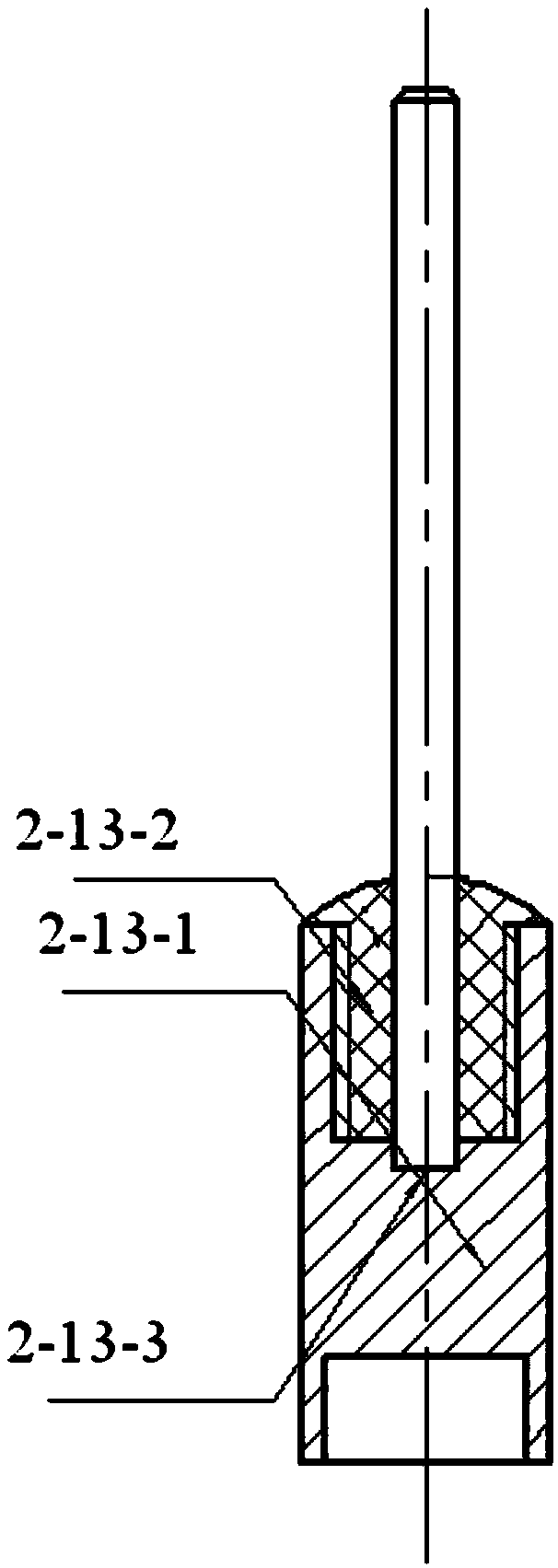

Cryoablation catheter and cryoablation system

ActiveCN112220552AImprove securityEasy to useSurgical instruments for coolingCatheterBiomedical engineering

The invention provides a cryoablation catheter and a cryoablation system. The cryoablation catheter comprises a catheter body and freezing balloons, wherein a refrigerant inlet chamber, a main refluxing chamber and a plurality of auxiliary refluxing chambers are arranged in the catheter body, the refrigerant inlet chamber, the main refluxing chamber and the auxiliary refluxing chambers all communicate with the freezing balloons, and the auxiliary refluxing chambers are used for regulating the internal pressure of the freezing balloons in an auxiliary manner. Based on the condition that cold energy of the cryoablation catheter is adjustable and controllable, the internal pressure of the freezing balloons can be stably regulated and controlled through employing a multi-chamber refluxing mode, the internal pressure of the freezing balloons of various dimensions can be in a safe use range, the clinical safe use of cryoablation catheters of various specifications is achieved, and customized / user-friendly treatment of different requirements is achieved. In addition, through additionally arranging the auxiliary refluxing chambers, the accuracy of control on flow rate can be further improved, the problem of single-chamber regulating that over regulation easily occurs is avoided, and the safety of cryoablation is improved.

Owner:SHANGHAI ARTECHMED MEDICAL TECH CO LTD

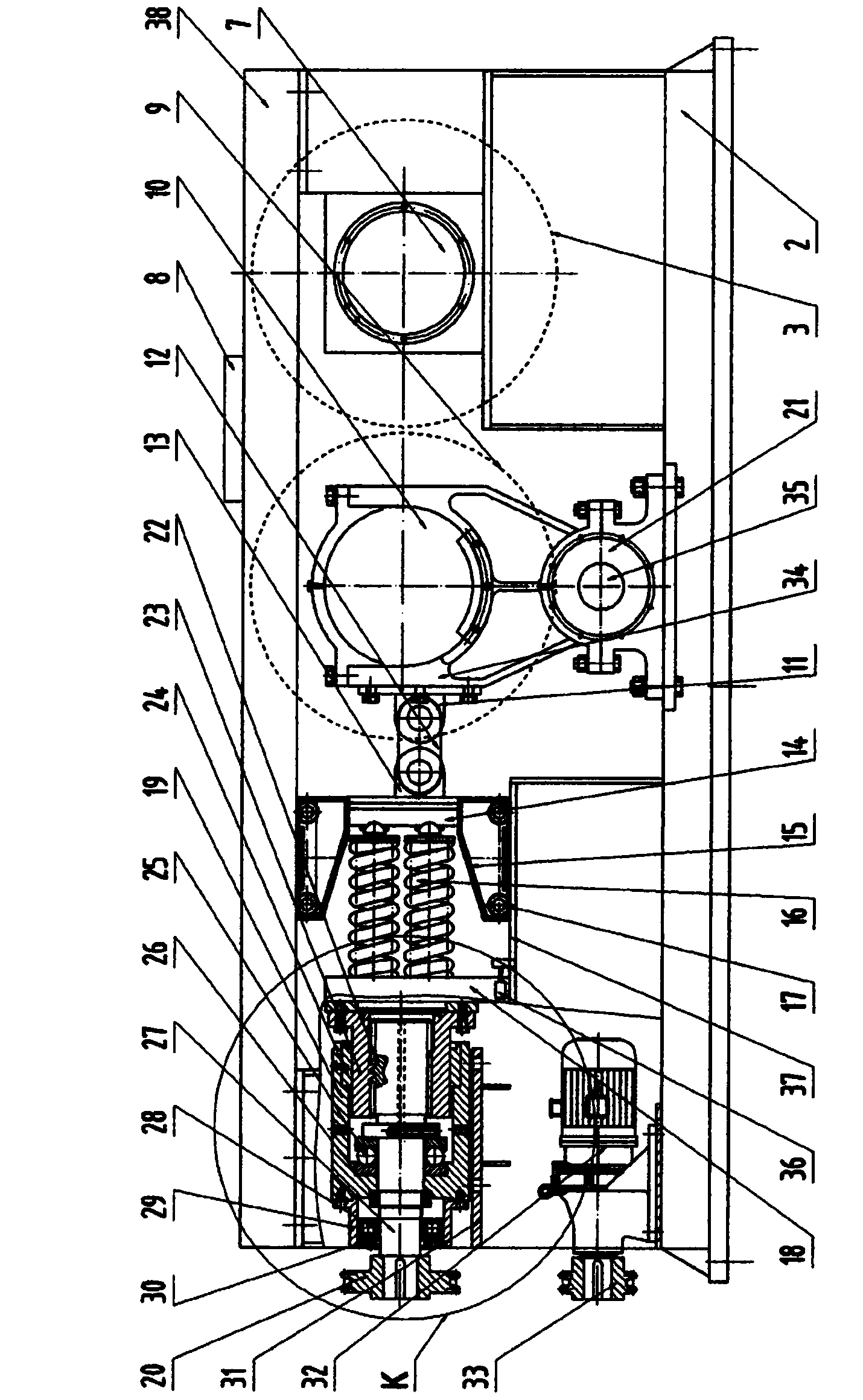

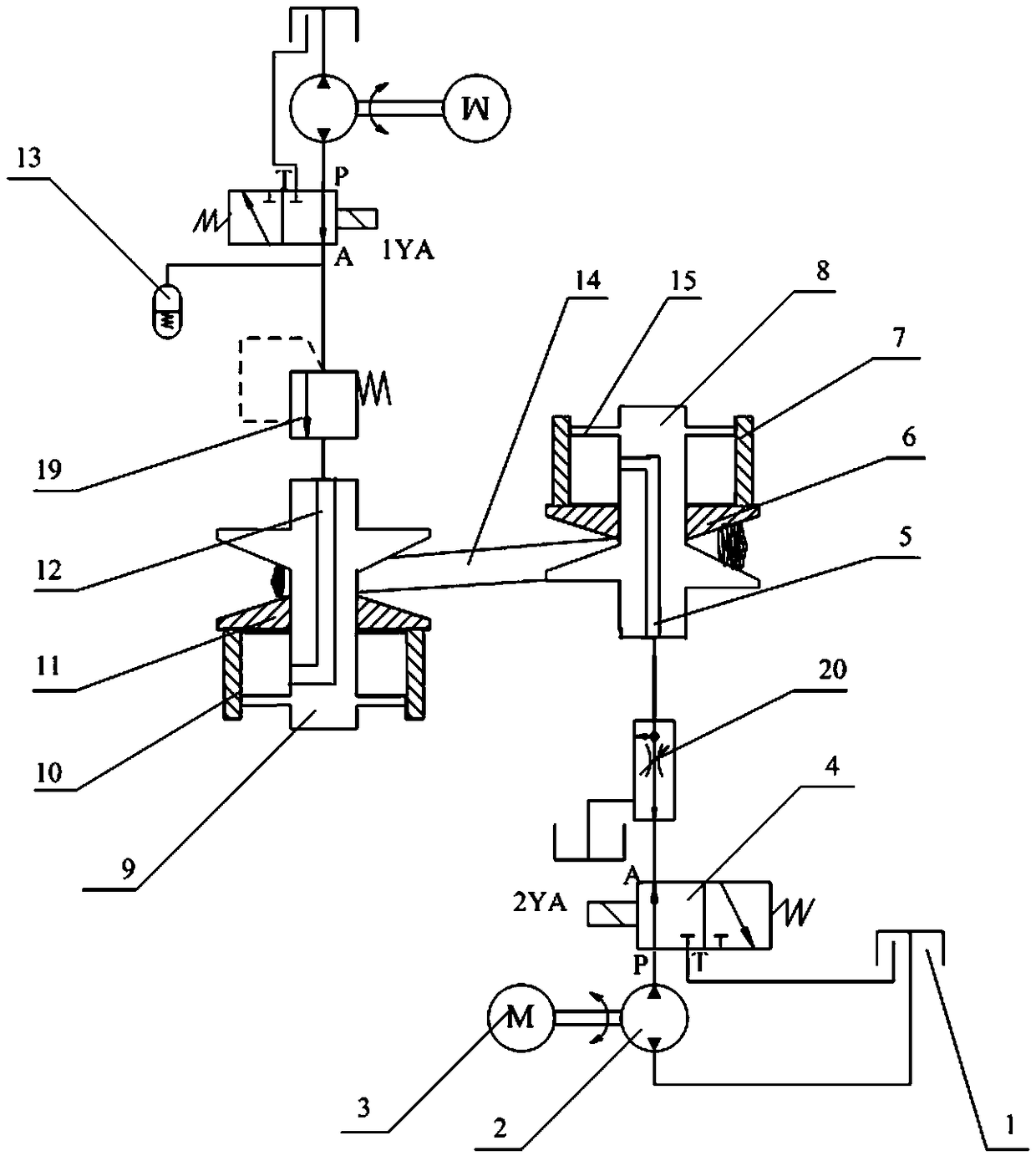

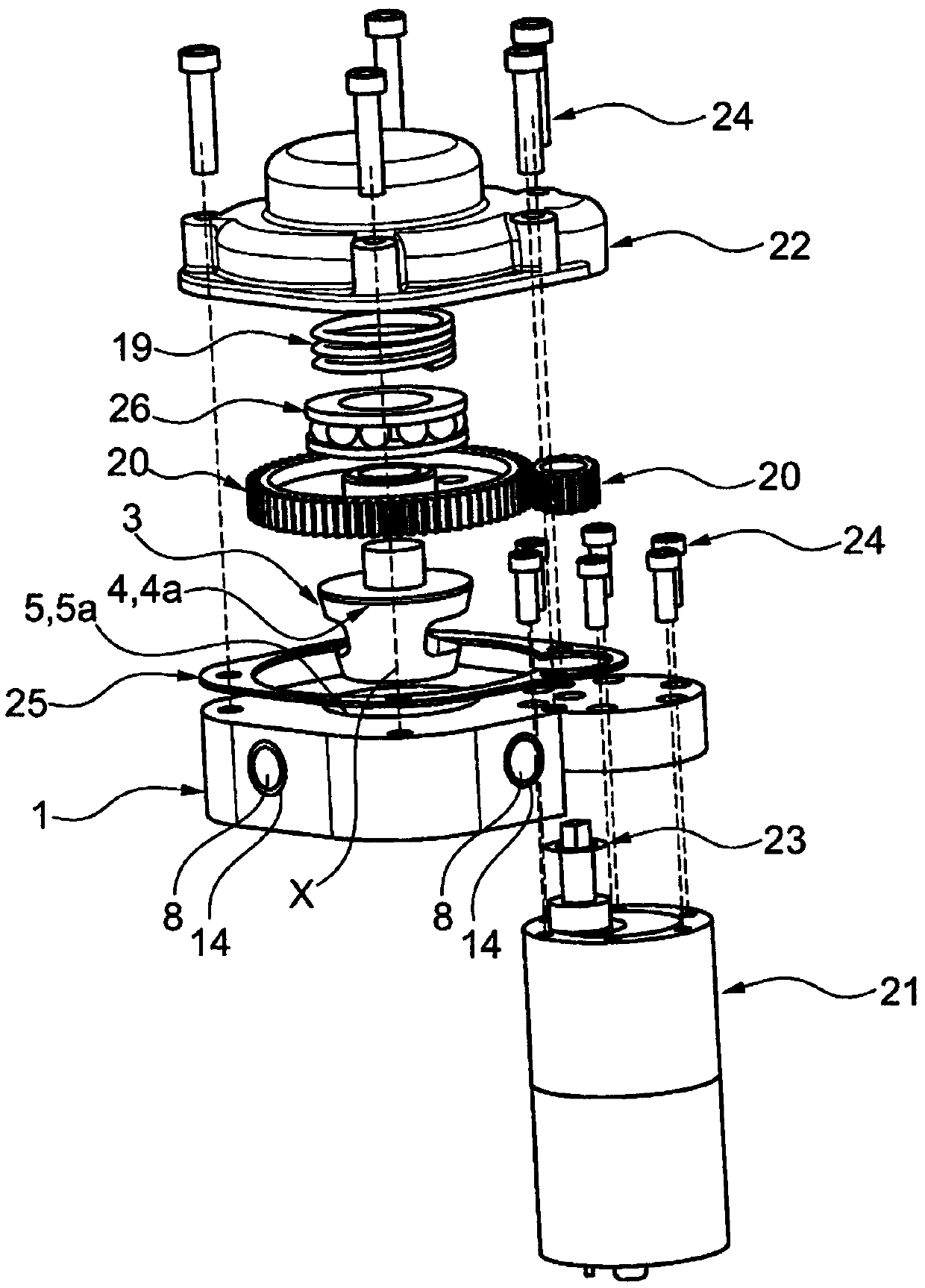

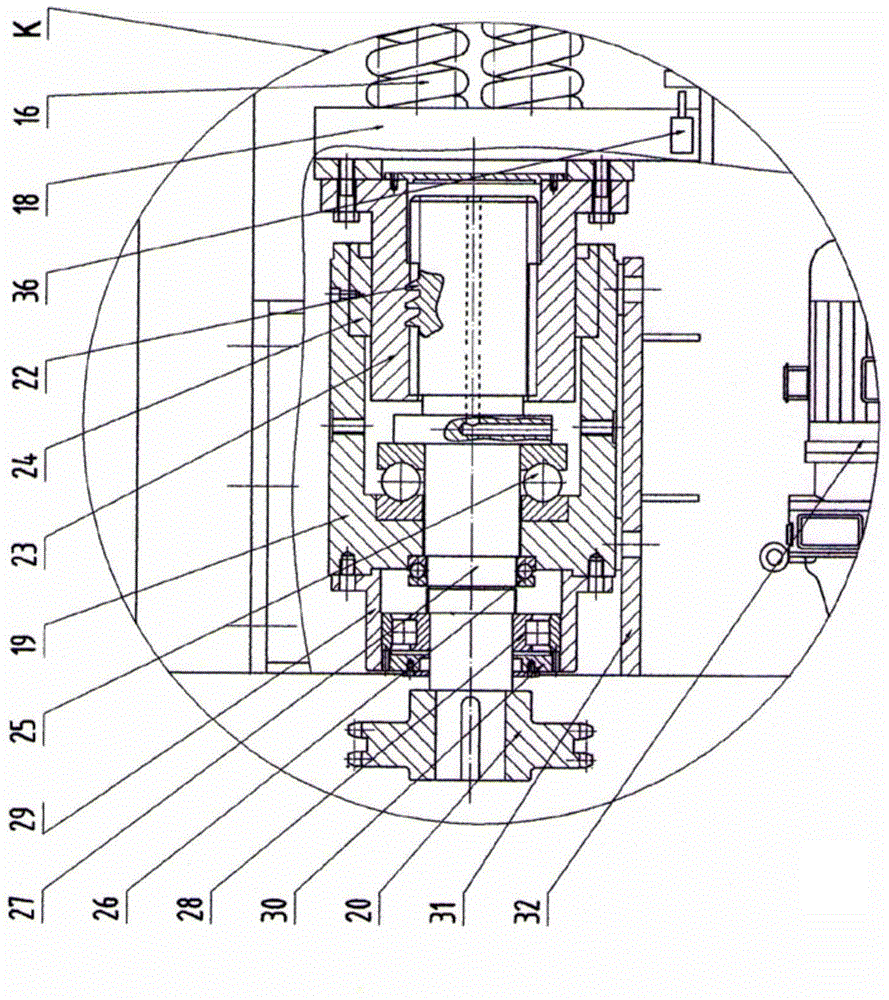

Speed ratio adjusting device of continuously variable transmission of hydraulic machinery

The invention discloses a speed ratio adjusting device of a continuously variable transmission of hydraulic machinery. The device comprises a speed ratio stepless adjusting unit and two movable conical disc pressure adjusting units; the speed ratio stepless adjusting unit comprises two movable conical discs; the two movable conical discs respectively sleeve a power input shaft and a power output shaft, and are respectively connected with a driving wheel hydraulic cylinder and a driven wheel hydraulic cylinder; oil holes on the power input shaft and the power output shaft respectively communicate with the driving wheel hydraulic cylinder and the driven wheel hydraulic cylinder; the movable conical disc pressure adjusting units comprise motors; the motors are connected with plunger pumps; oil inlets and oil outlets of the plunger pumps are respectively connected with oil tanks and P ports of high-speed switching valves; and A ports of the high-speed switching valves of the two movable conical disc pressure adjusting units are respectively connected with the oil holes on the power input shaft and the power output shaft. The device has the advantages of simple structure, stable pressure adjustment, high adjusting reliability and precision of the speed ratio and the clamping force and short acceleration time, and achieves self-protection capacity of the continuously variable transmission.

Owner:XIANGTAN UNIV

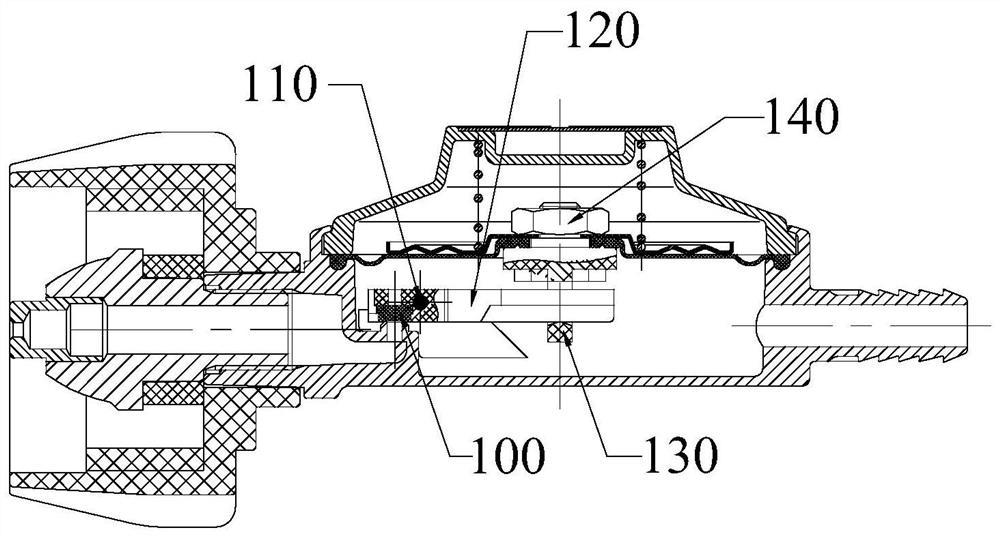

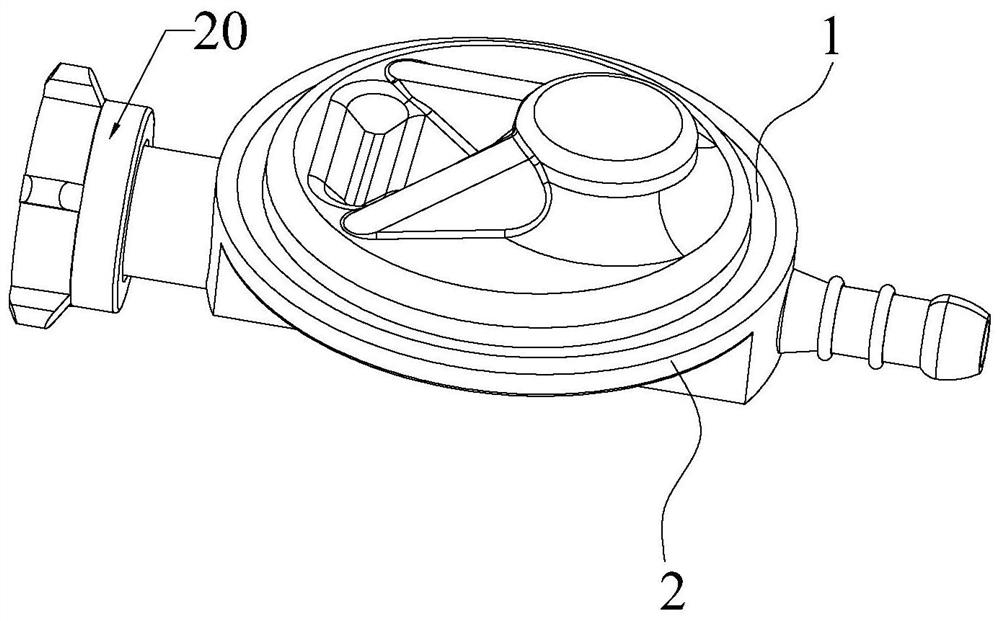

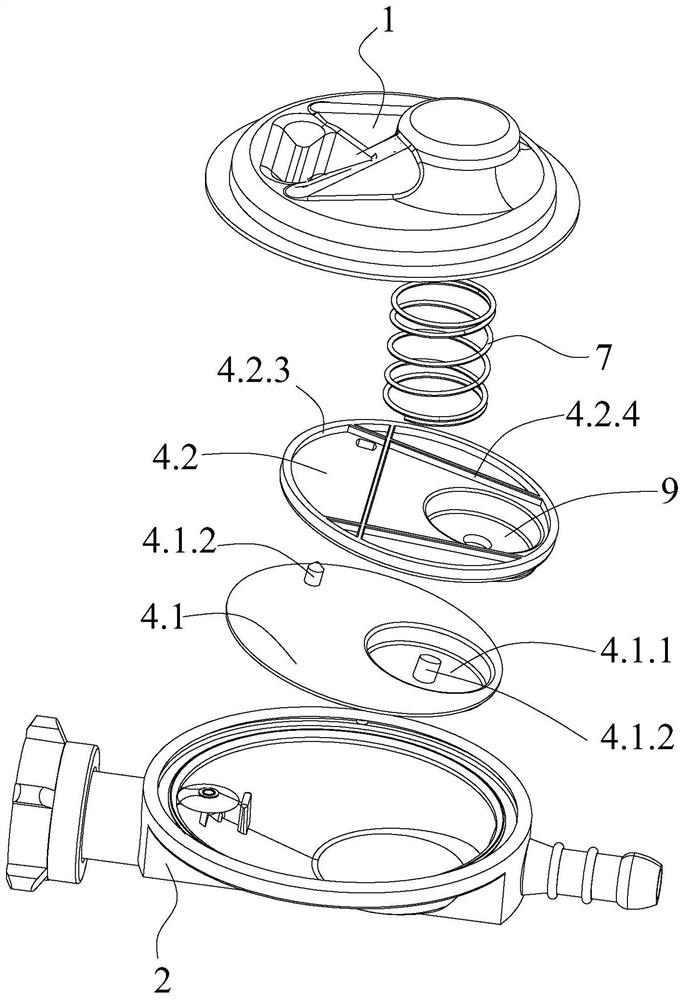

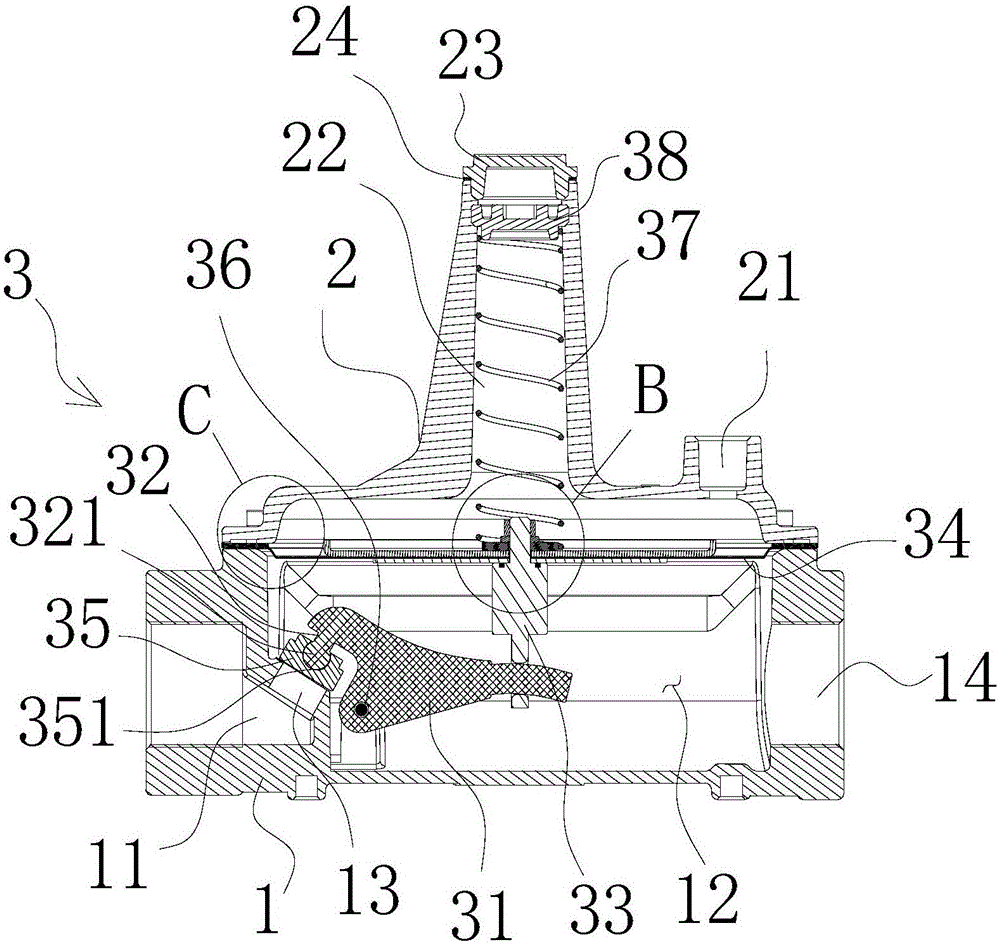

Fuel gas pressure adjusting device

PendingCN113090798AReduce assembly processLow costDiaphragm valvesEngine diaphragmsEngineeringFuel gas

The invention discloses a fuel gas pressure adjusting device which comprises an upper shell, a lower shell, a pressure adjusting cavity and a diaphragm assembly, one end of the lower shell is provided with a gas inlet and a valve port used for communicating the gas inlet with the pressure adjusting cavity, the other end of the lower shell is provided with a gas outlet, the lower shell is provided with a first fulcrum, and the upper shell is correspondingly provided with a second fulcrum. One end of the diaphragm assembly penetrates through a channel between the first fulcrum and the second fulcrum and is connected to the side wall of one end of the pressure regulating cavity, and the other end of the diaphragm assembly is connected to the side wall of the other end of the pressure regulating cavity. The diaphragm assembly can rotate around the first fulcrum or the second fulcrum so that the opening degree of the valve port can be adjusted, and an elastic reset piece is arranged between the other end of the diaphragm assembly and the upper shell. The fuel gas pressure adjusting device is simple in structure, the number of parts is small, the risk of unsafe conditions such as product leakage caused by part failure can be effectively reduced, and the stable pressure adjusting performance is effectively guaranteed.

Owner:NINGBO WANAN

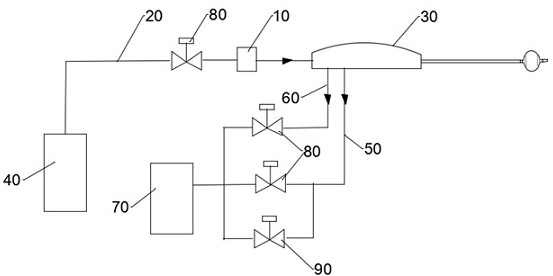

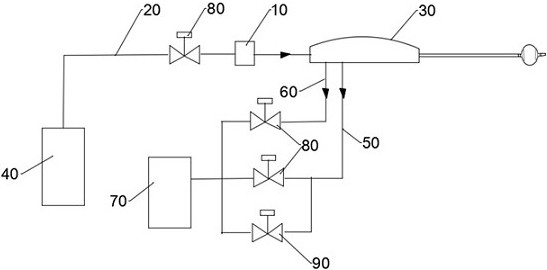

A vacuum pump simulation loading system

ActiveCN109630383BImplement Negative Feedback ControlStable gas supplyEngine testingPump installationsNegative feedbackAir pump

The invention provides a vacuum pump analog loading system. The vacuum pump analog loading system comprises a measuring and controlling end, an gas-supplementing gas pump and a pressure-regulating gaspump; a pressure balancing module is arranged at the measuring and controlling end, a left cavity, a right cavity and a membrane located between the left cavity and the right cavity are arranged in the pressure balancing module, and the membrane deforms and deviates in the corresponding cavity according to the vacuum degree difference between the left cavity and the right cavity; the gas-supplementing gas pump provides supplementing gas from the outside to a vacuum tank, the pressure-regulating gas pump is in gas connection with the left cavity and provides or extracts the gas in the left cavity according to the vacuum degree in the left cavity, and the right cavity is in gas connection with the vacuum tank. Negative feedback control over the vacuum degree in the vacuum tank is achieved,and continuous and stable gas supplementing and pressure regulating are achieved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

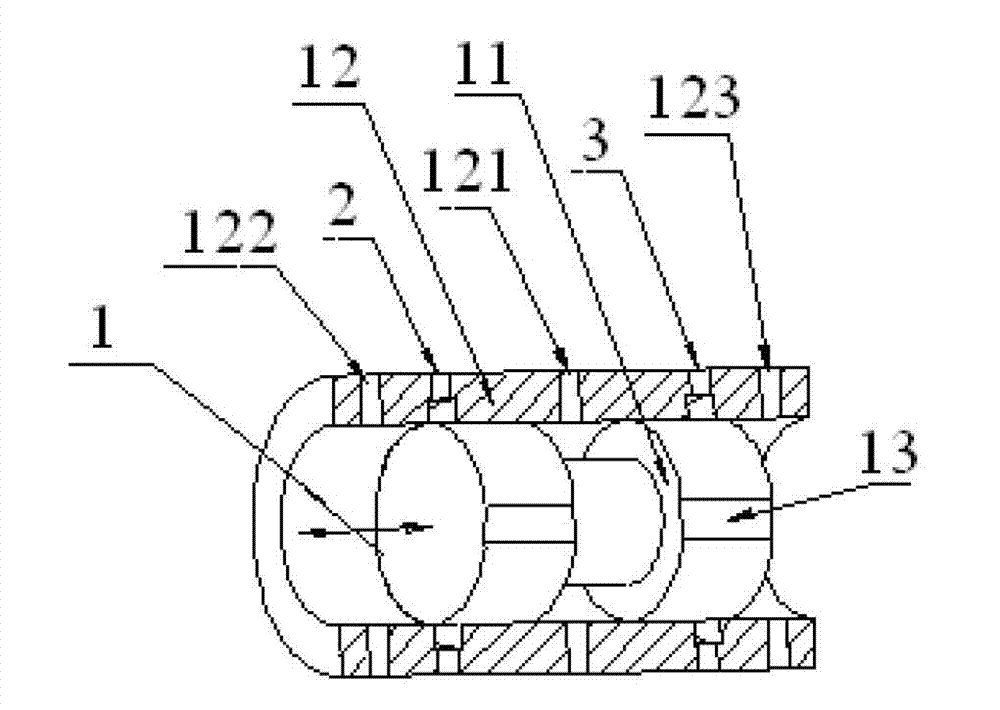

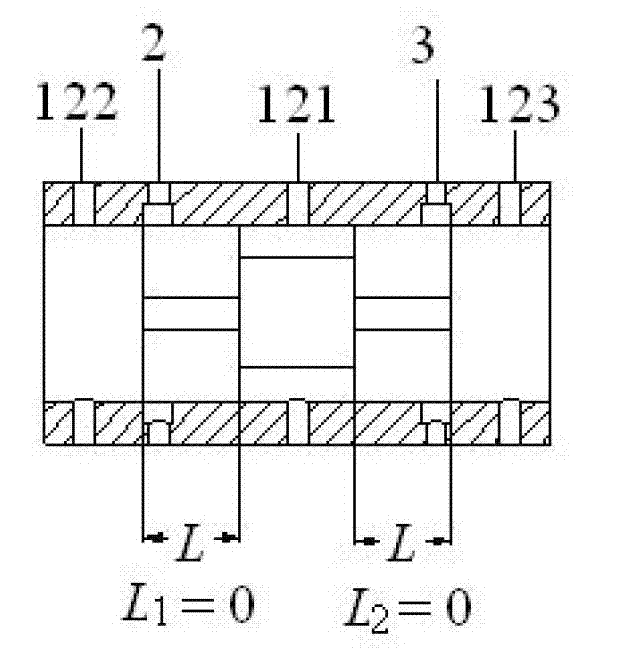

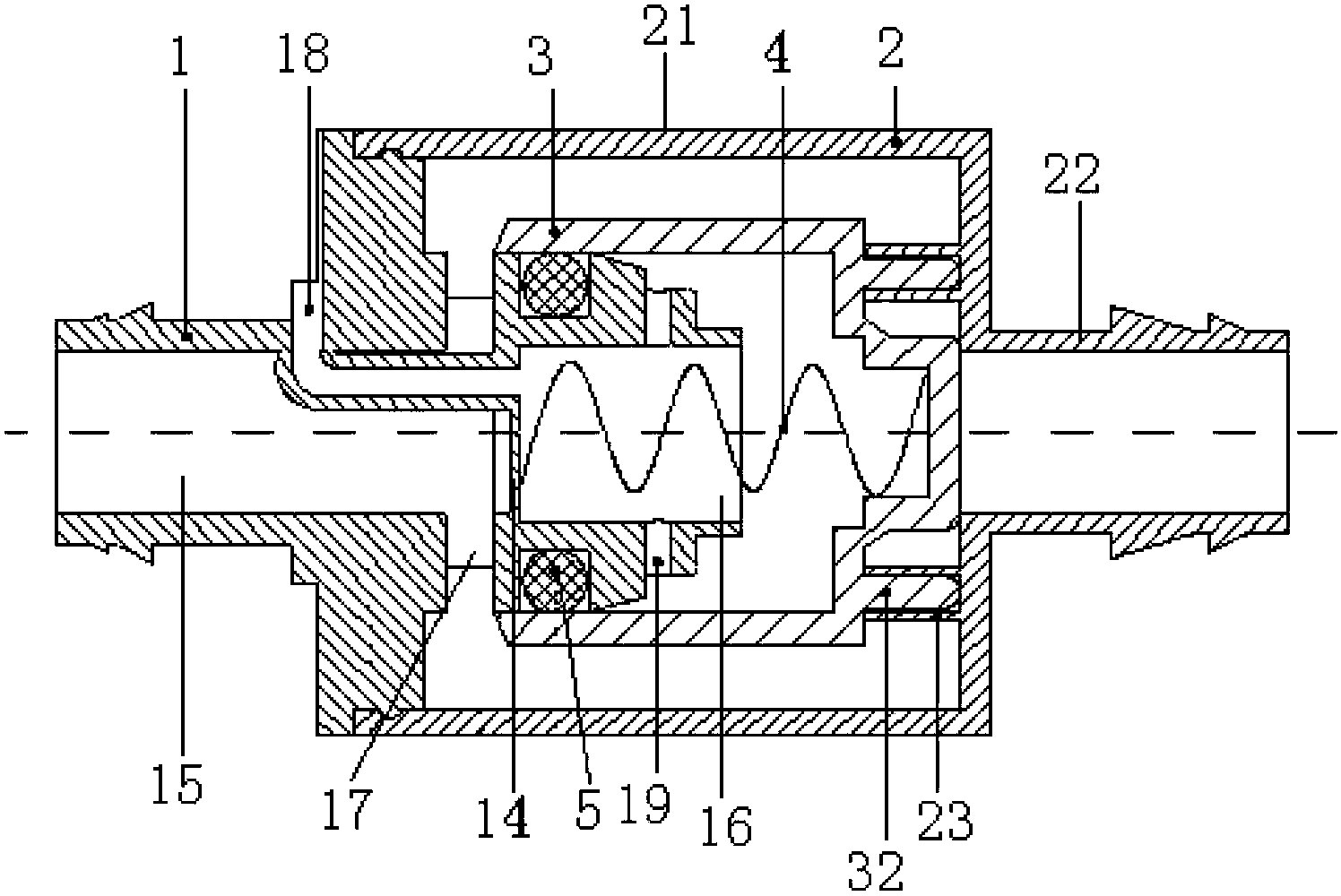

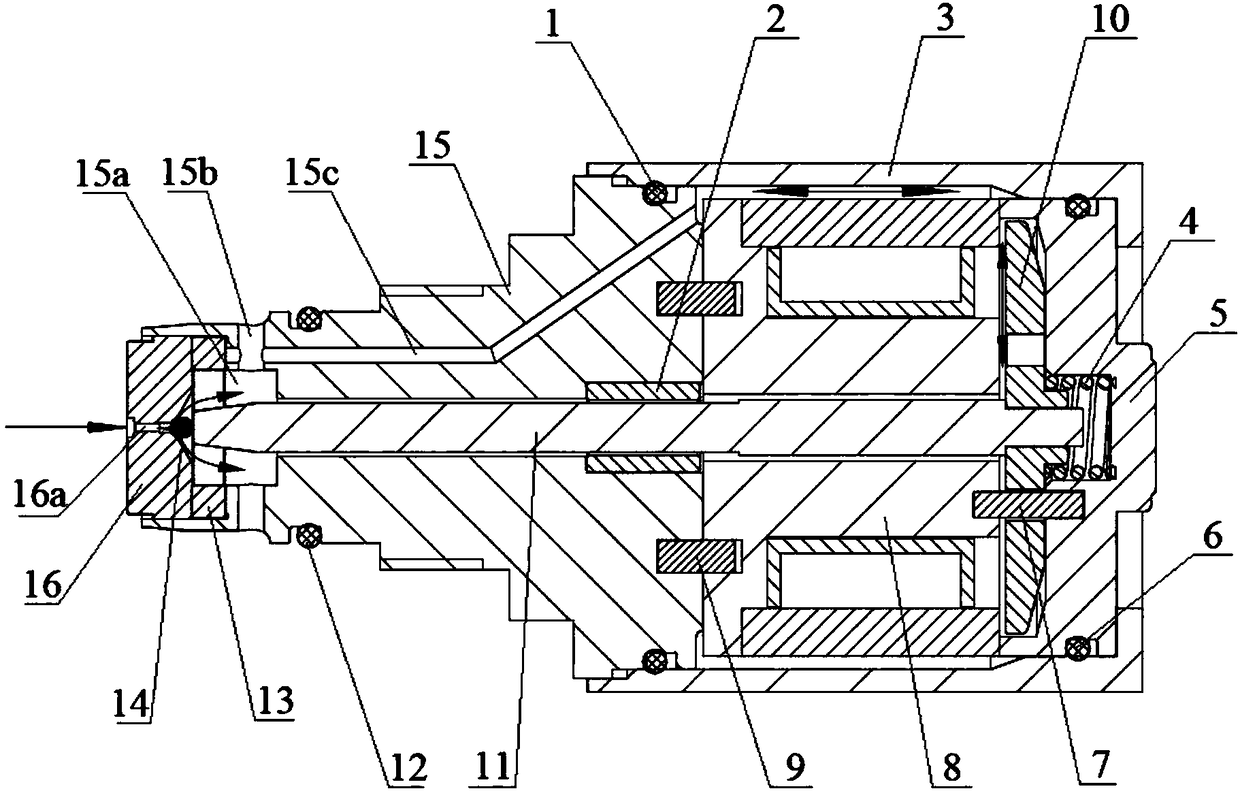

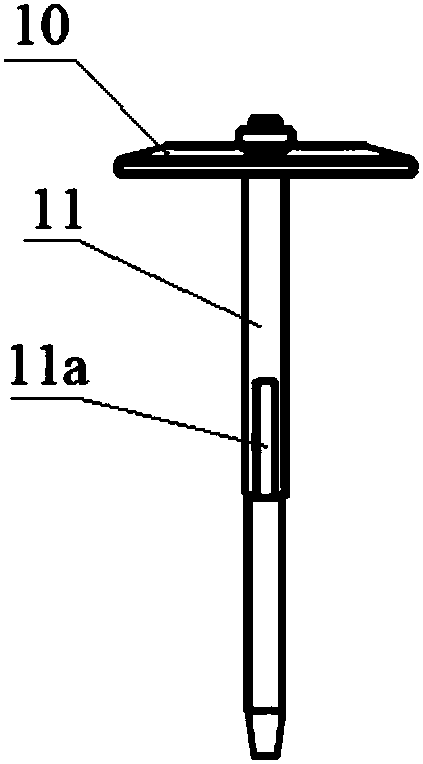

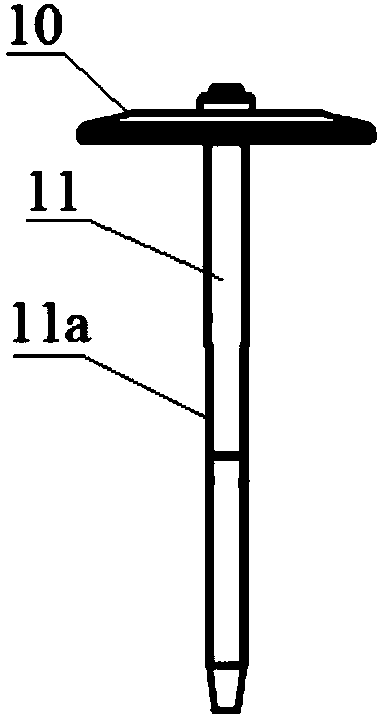

Bidirectional proportional pressure regulating mechanism

ActiveCN103161791AIncrease pressureStable pressure regulationFluid dynamicsEngineeringMechanical engineering

A bidirectional proportional pressure regulating mechanism comprises a fluid laminar flow implementing mechanism, a first pressure measuring point, a second pressure measuring point and a pressure measuring point position regulating mechanism. The fluid laminar flow implementing mechanism comprises a valve core and a valve sleeve, wherein an oil inlet, a first oil outlet and a second oil outlet are formed in the valve sleeve, and the oil inlet is arranged between the first oil outlet and the second oil outlet. Working steps matched with the inner diameter of the valve sleeve are arranged at two ends of the valve core, and the clearances of the working steps of the valve core and the valve sleeve are communicated with the oil inlet, the first oil outlet and the second oil outlet. The first pressure measuring point and the second pressure measuring point are both pressure measuring holes penetrating through the valve sleeve, and the pressure measuring holes are communicated with the clearances. The pressure measuring point position regulating mechanism comprises the valve core and a pushing component pushing the valve core to move inside the valve sleeve, and the movement of the valve core enables an L1 and an L2 to change between 0 and L. The bidirectional proportional pressure regulating mechanism has the advantages that bidirectional rectilinear motion is adopted to achieve bidirectional differential-motion proportional stable pressure regulating, and control sensitivity is high.

Owner:ZHEJIANG UNIV OF TECH

Flow control valve

Flow control valve, comprising a housing forming a number of internal passages and an internal cavity in fluid communication with each of the internal passages; and a flow direction block disposed inthe internal cavity, the flow direction block having an outer face encircled by an inner face of the internal cavity, wherein the flow direction block comprises two clearances extending through a portion of the flow direction block, wherein each of the two clearances is adapted to selectively connect one pair of the four internal passages of the housing when the flow direction block is rotated around a rotation axis relative to the housing, thus forming a first flow passage and a second flow passage.

Owner:EATON INTELLIGENT POWER LTD

High-power pressure reducing valve of pipeline

InactiveCN106090370ASimple structureImprove securityEqualizing valvesSafety valvesInlet channelSize change

A high-power pressure reducing valve of a pipeline comprises a valve seat, a valve deck combined on the valve seat and a pressure regulating actuating mechanism, wherein the valve deck is provided with an air release opening; an air inlet chamber and an air regulating chamber are arranged inside the valve seat; an air inlet channel is arranged between the air inlet chamber and the air regulating chamber; the pressure regulating actuating mechanism comprises a movable warping plate pivoted to the valve seat; one end of the movable warping plate is connected with a valve rod; the other end of the movable warping plate is connected with a movable piece; the movable piece is connected with a flexible membrane; the flexible membrane responds to the intake pressure changes so as to drive the movable piece; the valve rod is provided with a valve element portion used for being in movable fit with an intake channel so as to change the opening of the intake channel; the flexible membrane drives the movable piece to act vertically under the air pressure changes; and the movable warping plate bounces through the movable piece so as to swing around a pin shaft, and accordingly the valve element portion drives the volume of the pressure regulating chamber to change relative to the size changes of the opening of the intake channel. The high-power reducing valve of the pipeline is simple in structure, good in safety performance, low in manufacturing cost, stable in driving, long in service life and stable in pressure regulation.

Owner:虞上海

Capillary pressure regulator

ActiveCN103026948BLarge range of motionWide range of pressure regulationWatering devicesCultivating equipmentsCapillary pressureEngineering

The invention relates to a capillary pressure regulator. The capillary pressure regulator is characterized by comprising an upstream flow deflector, a downstream shell, a pressure regulating assembly and a spring, wherein a baffle for dividing interior of the upstream flow deflector into an upper cavity and a lower cavity which are not communicated with each other is arranged inside the upstream flow deflector; a water outlet hole is formed in the upper cavity; an air guiding pipe communicated with atmosphere is arranged on the lower cavity; a plurality of vent holes are also formed in the lower cavity; the downstream shell comprises a first cylinder body and a second cylinder body; the end part of the first cylinder body is connected with a shell connecting end of the upstream flow deflector; a plurality of positioning holes are formed in the side wall of the first cylinder body; the pressure regulating assembly is a cylindrical cavity with one opened side and one closed side; an outwardly-protruding spring installing groove is formed in the inner wall of a closed end; a positioning probe corresponding to the positioning holes is arranged on the outer wall of the closed end; the opened end of the pressure regulating assembly is connected with a pressure regulating assembly connecting end of the upstream flow deflector; a water stopping part is arranged between the opened end of the pressure regulating assembly and the pressure regulating assembly connecting end of the upstream flow deflector; and one end of the spring is pressed against the baffle inside the upstream flow deflector; and the other end of the spring is pressed against the bottom of the spring installing groove of the pressure regulating assembly.

Owner:CHINA AGRI UNIV

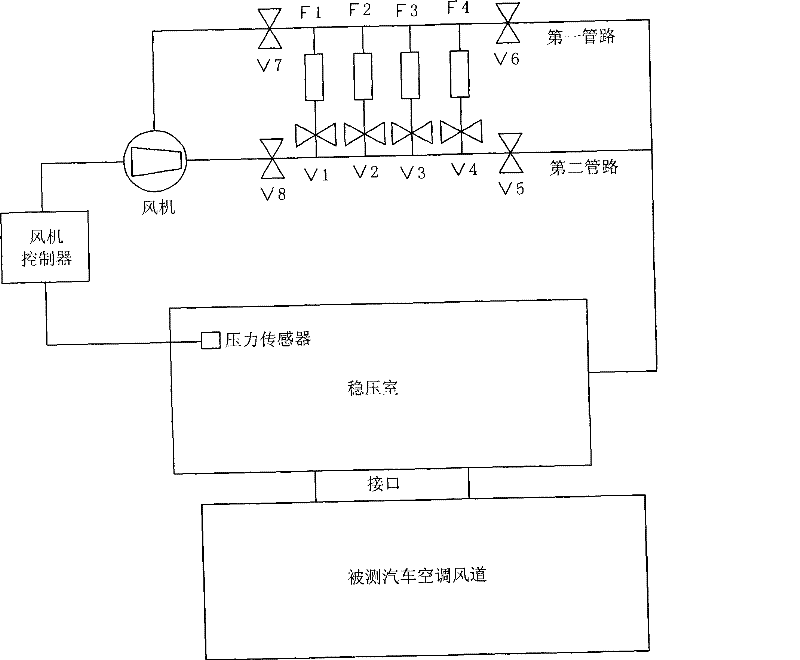

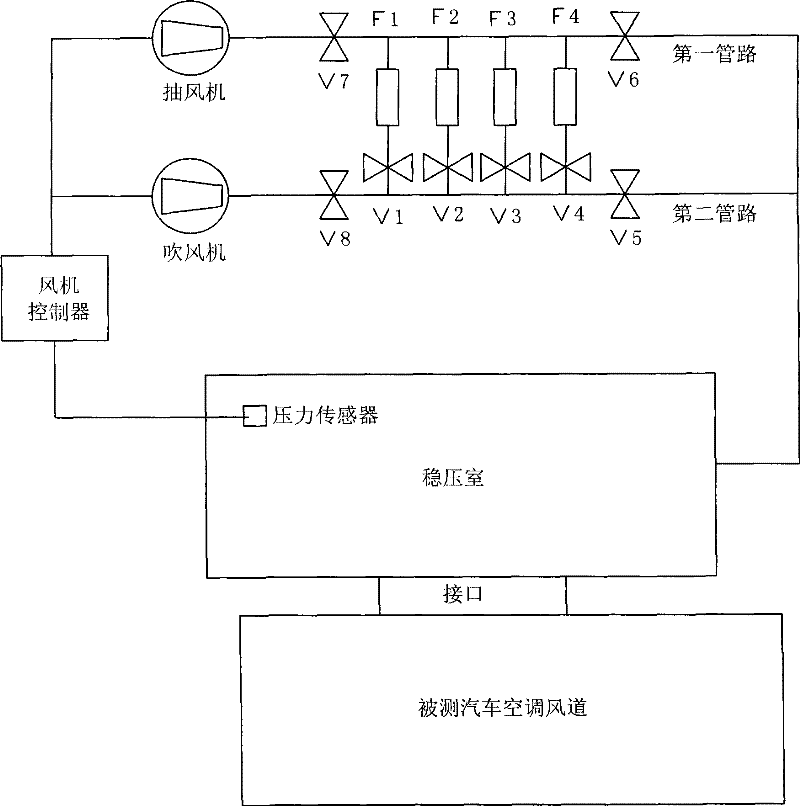

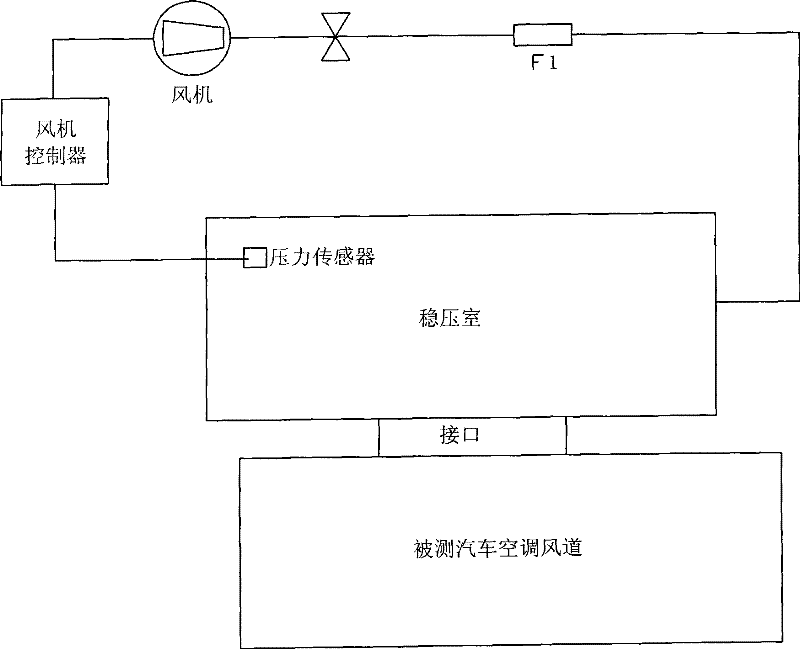

Testing bench used for detecting air leakage of automobile air conditioner ventiduct

ActiveCN101368833BImprove detection accuracyCases where switching is not repeated frequentlyStructural/machines measurementVolume/mass flow by differential pressureSolenoid valveAtmospheric air

The invention relates to a test bed for detecting the automotive air conditioning duct air leakage, comprising a regulator room, a pressure sensor arranged in the regulator room, a flow sensor, a solenoid valve, a computer, a blower, a blower controller and a pipeline; the blower is controlled by the blower controller; the regulator room is connected with the blower through the pipeline on which the flow sensor is arranged; the regulator room is provided with an interface for connecting the automotive air conditioning duct under detection; and the output end of the pressure sensor is connected with the blower controller. The test bed is provided with a relatively stable pressure room at the upstream of the automotive air conditioning duct under detection, so that a relatively stable pressure difference can be formed between the automotive air conditioning duct and the atmosphere; the automotive air conditioning duct air leakage caused by the effect of the pressure difference is equal to the air flow sent (or pumped under negative pressure) by the blower at the upstream of the regulator room; therefore, the air flow measured by the flow sensor is also the air leakage generated under the effect of the pressure difference by the automotive air conditioning duct.

Owner:武汉经开科创运营有限公司

Cryoablation catheter and cryoablation system

ActiveCN112220552BImprove securityEasy to useSurgical instruments for coolingCatheterBiomedical engineering

The present invention provides a cryoablation catheter and a cryoablation system. The cryoablation catheter includes a catheter body and a cryoballoon. The catheter body is provided with an inlet refrigerant chamber, a main return chamber and several auxiliary return chambers. The refrigerant inlet cavity, the main return cavity and the auxiliary return cavity are all in communication with the cryoballoon, and the auxiliary return cavity is used to assist in regulating the pressure in the cryoballoon. On the basis of realizing the adjustable and controllable cold capacity of the cryoablation catheter, by adopting the form of multi-cavity reflux, the internal pressure of the cryoballoon is regulated and stabilized, ensuring that the internal pressure of cryoballoons of various sizes is within the safe use range , to achieve the safe use of cryoablation catheters of various specifications in clinical practice, and to meet the personalized treatment of different needs. In addition, by adding an auxiliary recirculation chamber, the control accuracy of the flow rate can be improved, the problem of easy overshoot when adjusting a single chamber can be avoided, and the safety of cryoablation can be improved.

Owner:SHANGHAI ARTECHMED MEDICAL TECH CO LTD

Single-driving-roller clearance-free sand maker

ActiveCN103447113BReduce powder contentIncrease sand forming rateGrain treatmentsEngineeringPower component

Owner:湖南宇晖重工机械有限公司

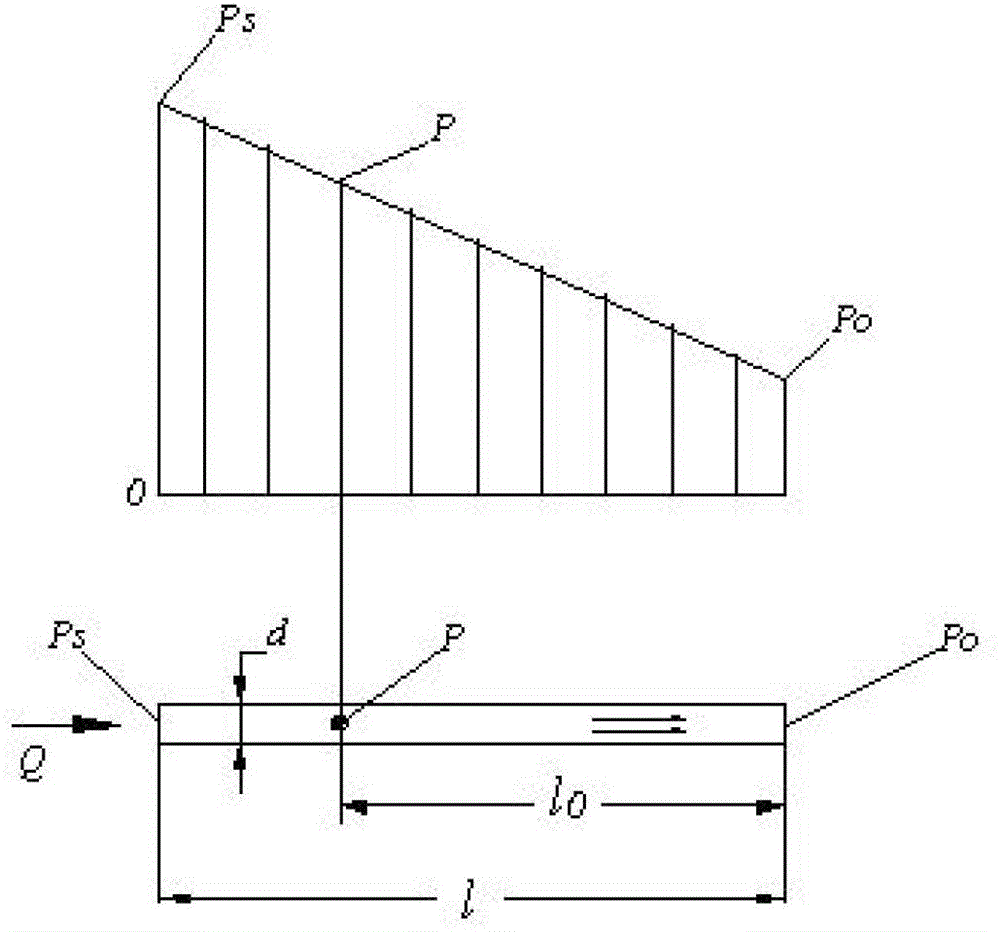

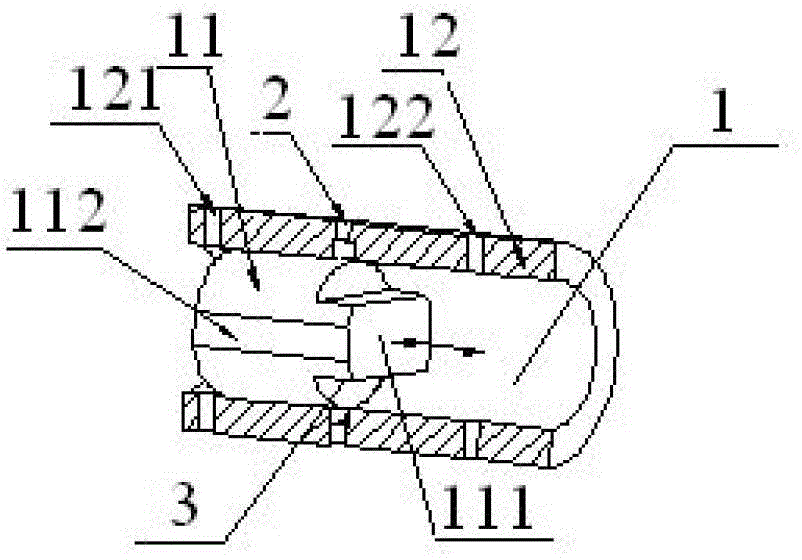

Pressure regulating mechanism with two freedom degrees

ActiveCN103161793BRealize the function of steady voltage regulationEasy to useFluid dynamicsMultiple pointEngineering

A pressure regulating mechanism with two freedom degrees comprises a fluid laminar flow implementing mechanism, a plurality of pressure measuring points connecting with different pressure regulating mechanisms and a freedom degree regulating mechanism. The fluid laminar flow implementing mechanism comprises a valve core and a valve sleeve. A plurality of through grooves penetrating through the head and the tail of the valve core are axially formed in the side wall of the valve core, clearances formed by the through grooves and the valve sleeve are communicated with an oil inlet and an oil outlet, the flow of the fluid in the clearances is of a laminar flow state, and the pressure distribution of the oil inlet and the oil outlet is of stable linear distribution. The pressure measuring points are pressure measuring holes penetrating through the valve sleeve, and the pressure measuring holes are communicated with the clearances. The pressure measuring point position regulating mechanism comprises the valve core and a pushing component pushing the valve core to move inside the valve sleeve at two freedom degrees of a straight line mode and a rotating mode. The pressure regulating mechanism with the two freedom degrees has the advantages that the valve core has the motions of two freedom degrees of the straight line motion and the rotating motion simultaneously, the plurality of pressure measuring points can be connected with different pressure regulating mechanisms, the plurality of through grooves can regulate the range of the pressure regulating, and therefore the pressure regulating mechanism is enabled to be wide in application range, capable of being controlled in multiple points, stable in pressure regulating, and convenient to use.

Owner:ZHEJIANG UNIV OF TECH

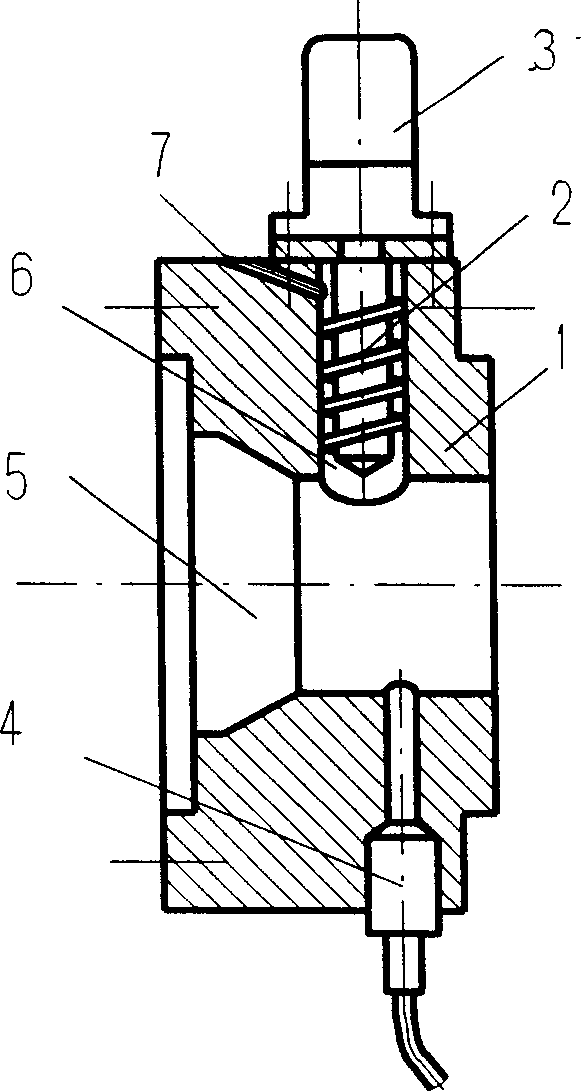

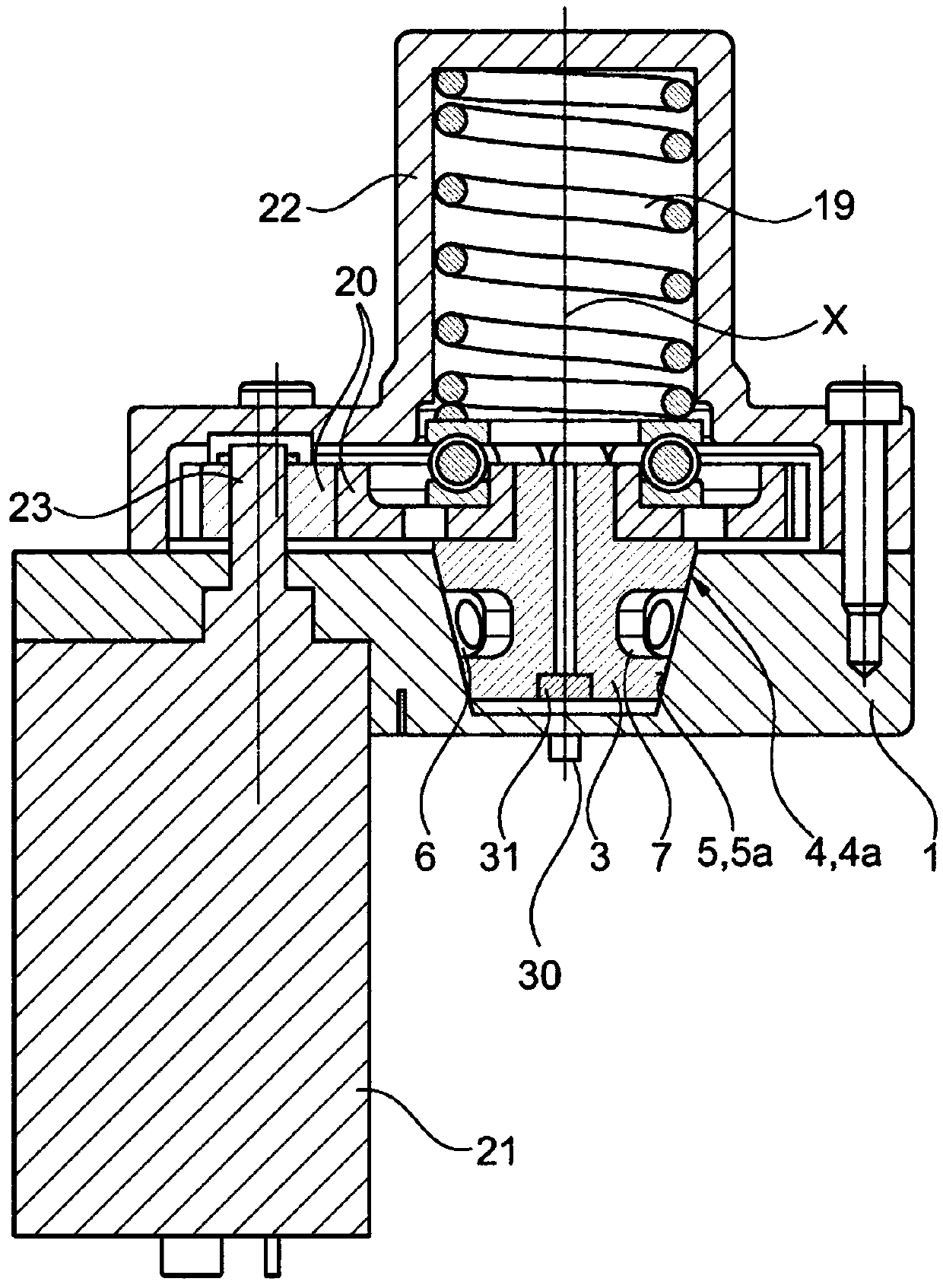

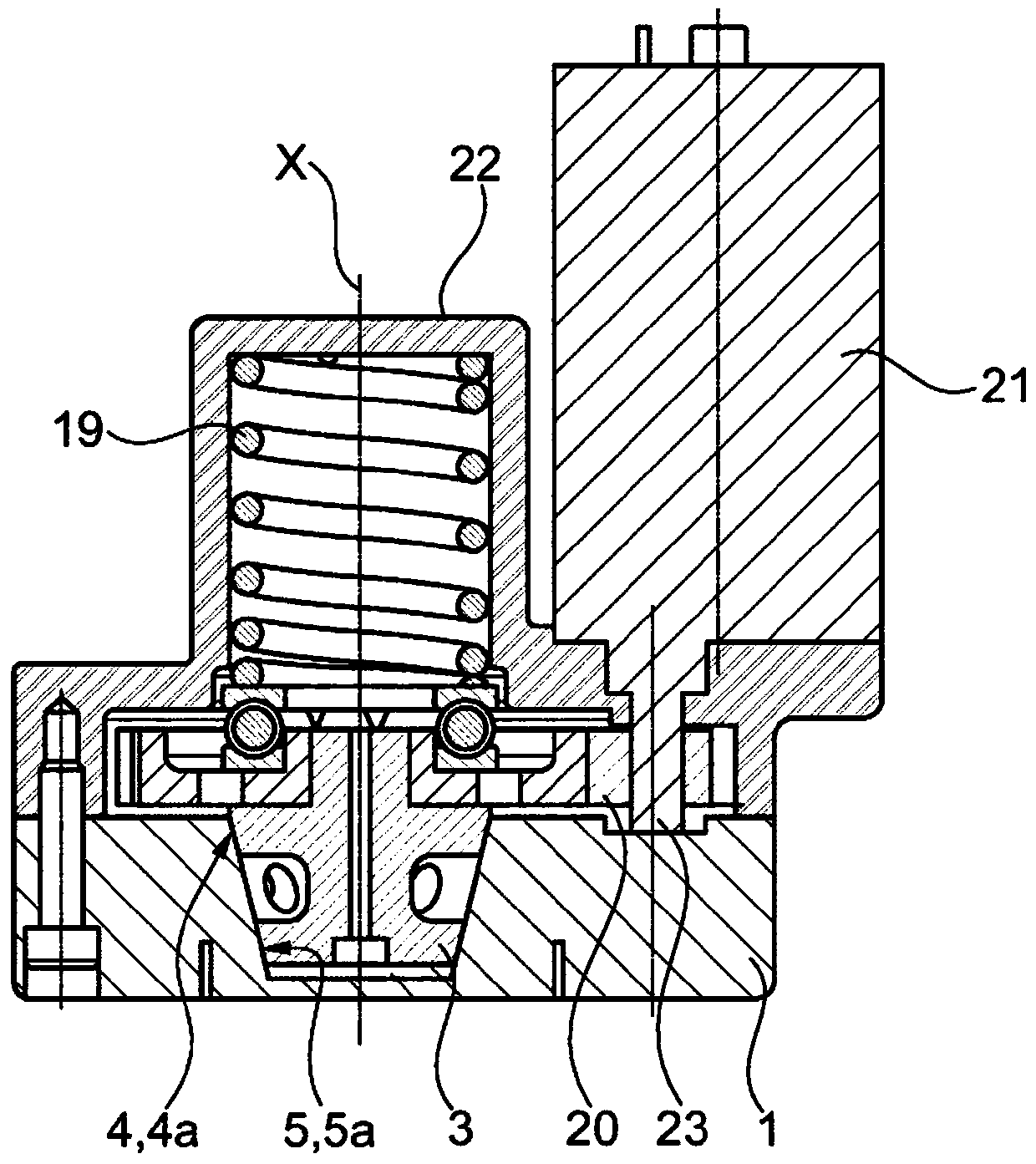

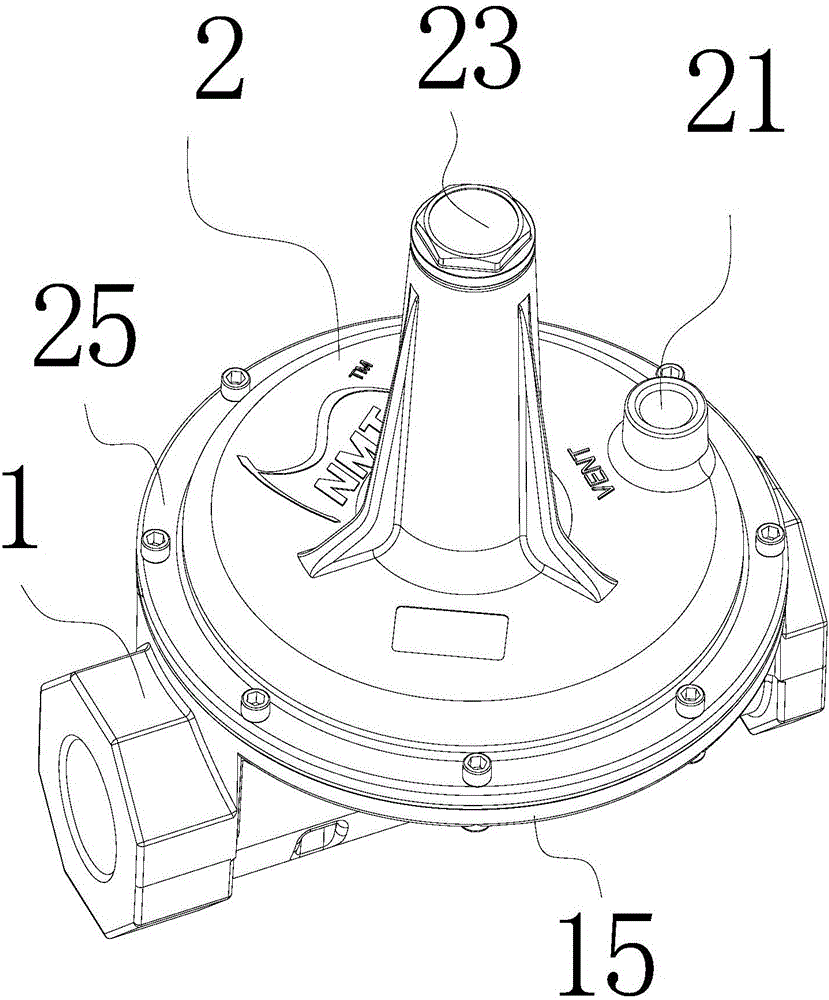

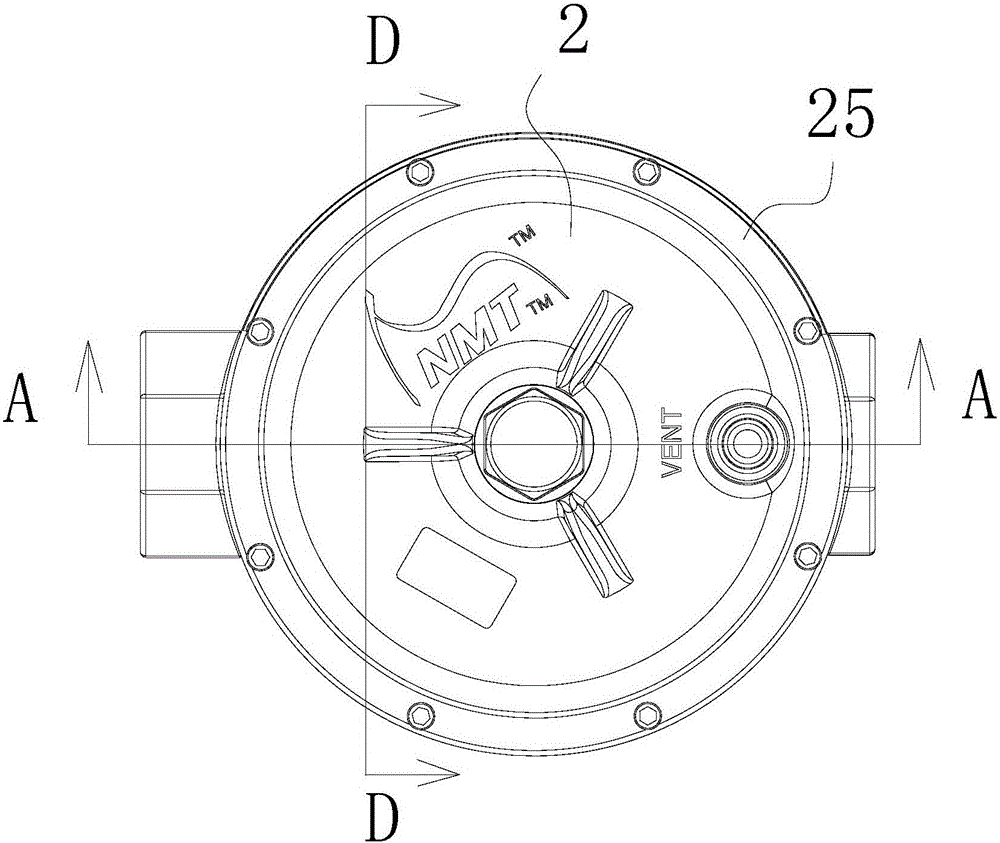

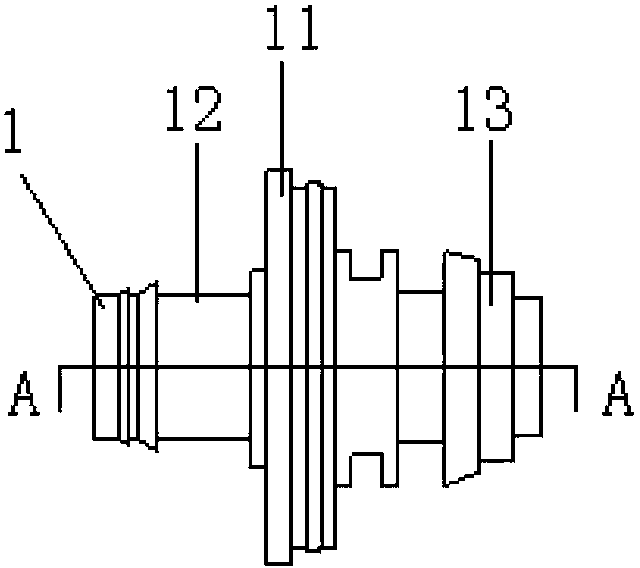

Solenoid Pressure Regulating Valve

ActiveCN106594357BStable pressure regulationLower working temperatureOperating means/releasing devices for valvesFluid pressure control using electric meansOil canSolenoid valve

The invention relates to an electromagnetic type pressure regulating valve which comprises a tightening cap, a valve body, an armature component, an electromagnet and a valve seat. The electromagnetic type pressure regulating valve is characterized in that a through hole is formed in the valve body; one end of the through hole communicates with peripheral space of the electromagnet; the other end of the through hole communicates with an oil outlet; circulation gaps are formed between an armature lever and the electromagnet and between the armature lever and a center hole of the valve body; a guide sleeve is in interference forced fit with the center hole of the valve body; the armature lever penetrates through the guide sleeve and is in tight sliding fit with the guide sleeve; a flat station is processed on the inner wall of the guide sleeve or on the outer wall of a matching section of the armature lever and the guide sleeve, and forms a circulation channel, so that the peripheral space of the electromagnet, and the peripheries of the armature and the armature lever are filled with liquid oil completely. The flat station is processed on the armature lever and the through hole is formed in the valve body, so that a liquid oil channel is formed in the electromagnetic type pressure regulating valve, air-liquid pressure fluctuation in the electromagnetic type pressure regulating valve is eliminated through liquid oil flowing, and the pressure regulating stability of the valve is ensured; in addition, the liquid oil can cool the electromagnet, and the life of the electromagnetic type pressure regulating valve can be prolonged.

Owner:CHINA FIRST AUTOMOBILE

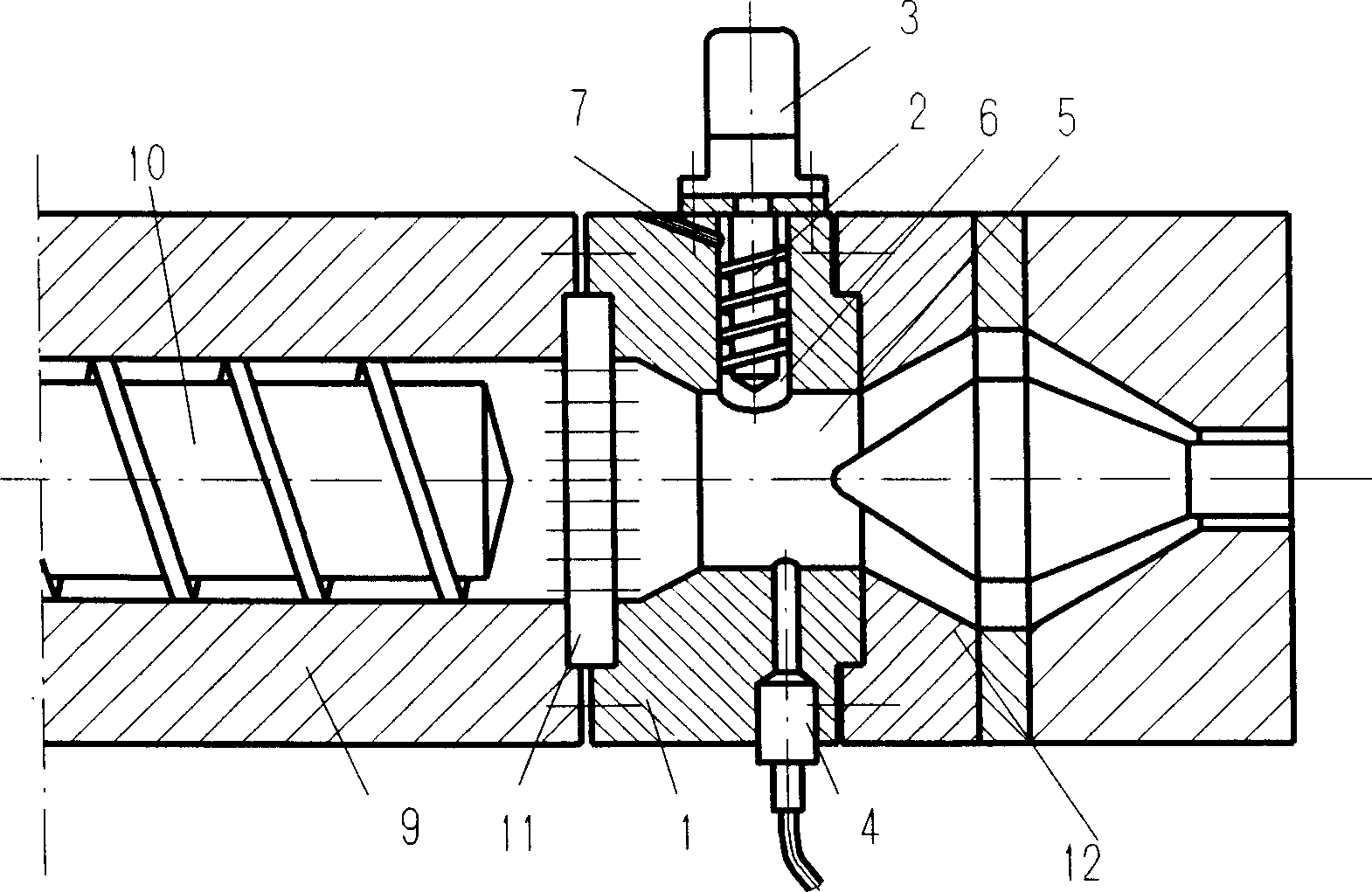

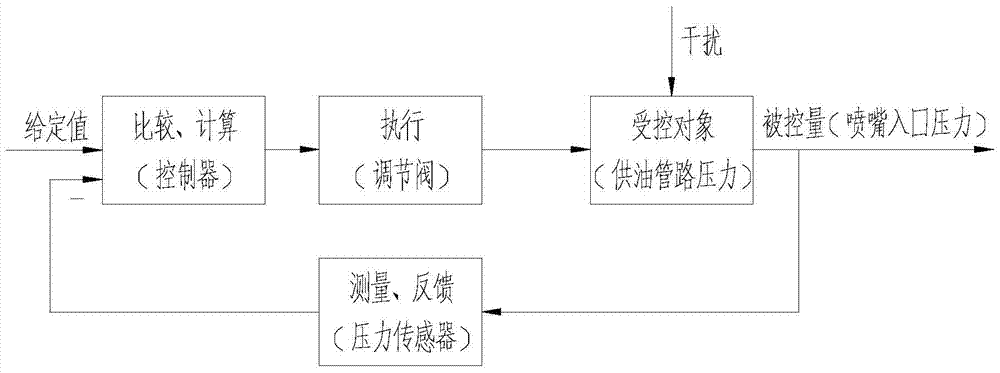

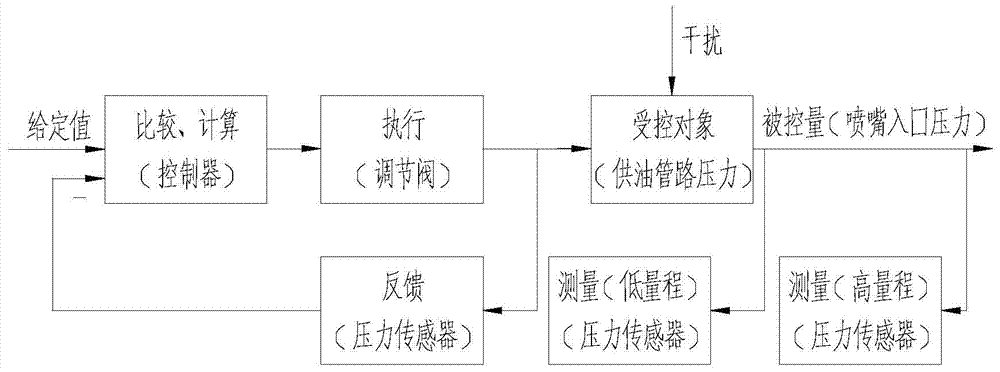

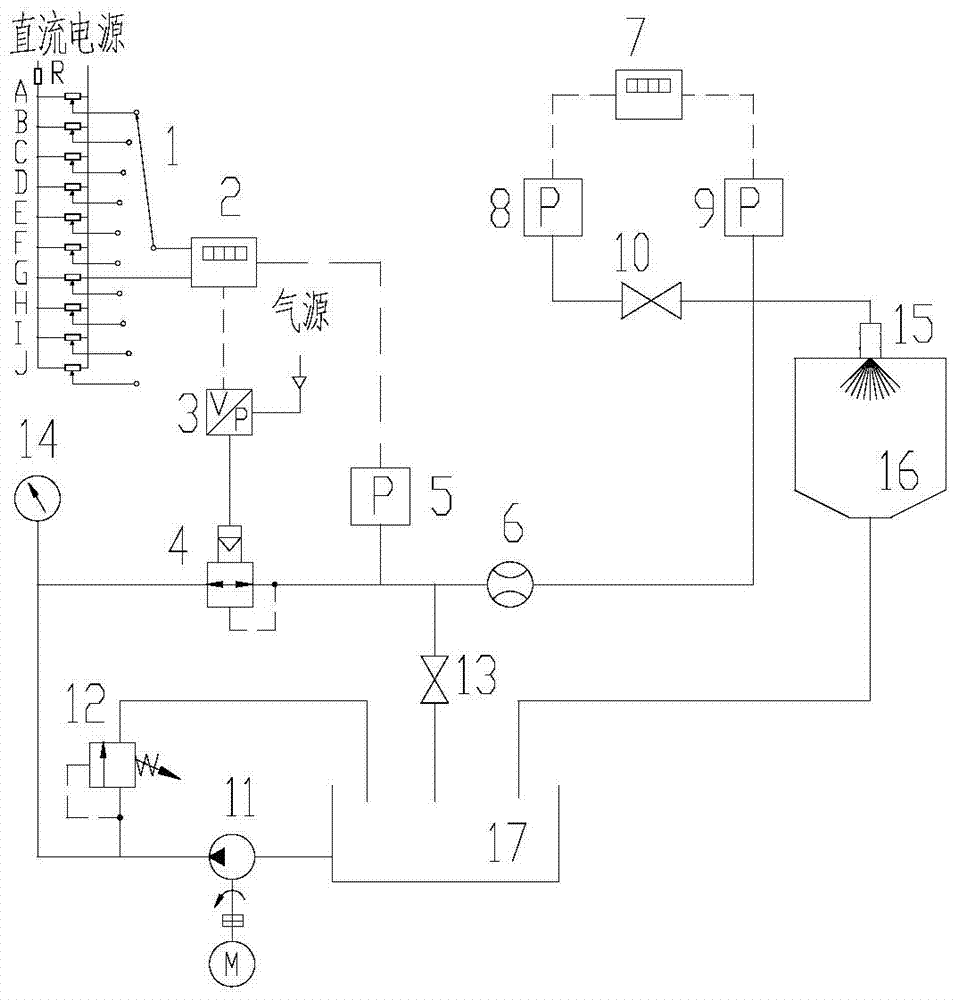

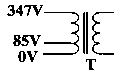

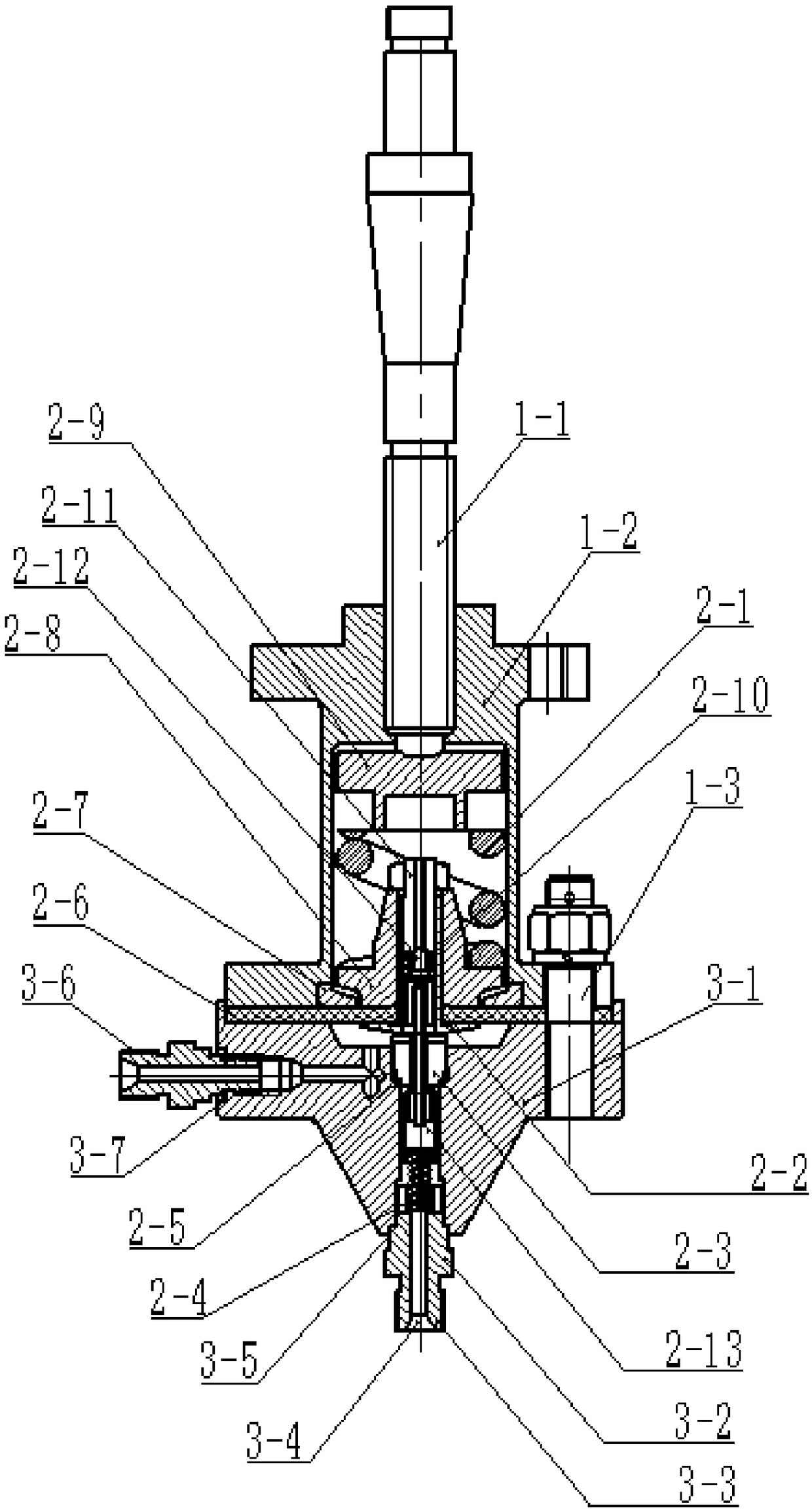

A Pressure Control System for Engine Nozzle Test

ActiveCN104375529BReduce labor intensityAvoid interferenceFluid pressure control using electric meansControl systemClosed loop

The invention provides a pressure control system for an engine nozzle test. A pressure sensor is installed on the side, adjacent to a nozzle, of the back of a regulating valve and is arranged far from the nozzle. The pressure sensor is used for measuring the pressure of fuel oil entering the nozzle and synchronously feeding back measured values to a pressure controller in real time for comparison and calculation, and therefore the regulating valve can be regulated and closed-loop control can be achieved. A low-range pressure sensor and a high-range pressure sensor are arranged close to the nozzle respectively to measure the pressure on the inlet of the nozzle in a segmented mode. The pressure sensor is installed on the side, adjacent to the nozzle, of the back of the regulating valve and is arranged far from the nozzle, the measured values can be synchronously fed back to the controller in real time, so pressure regulation is free of overregulation and overshoot, interference of fluctuation of a spring in the nozzle in pressure measurement in a feedback link is avoided, and regulation stability is greatly improved. The two high-accuracy pressure sensors, namely the low-range pressure sensor and the high-range pressure sensor, are used for measuring the pressure on the inlet of the nozzle in a segmented mode, so pressure display is accurate, and work efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

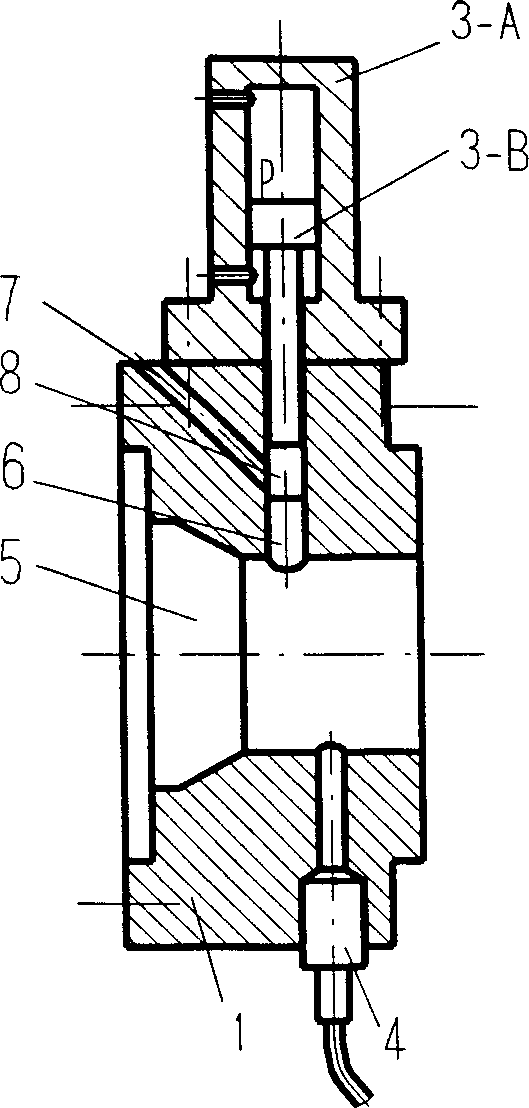

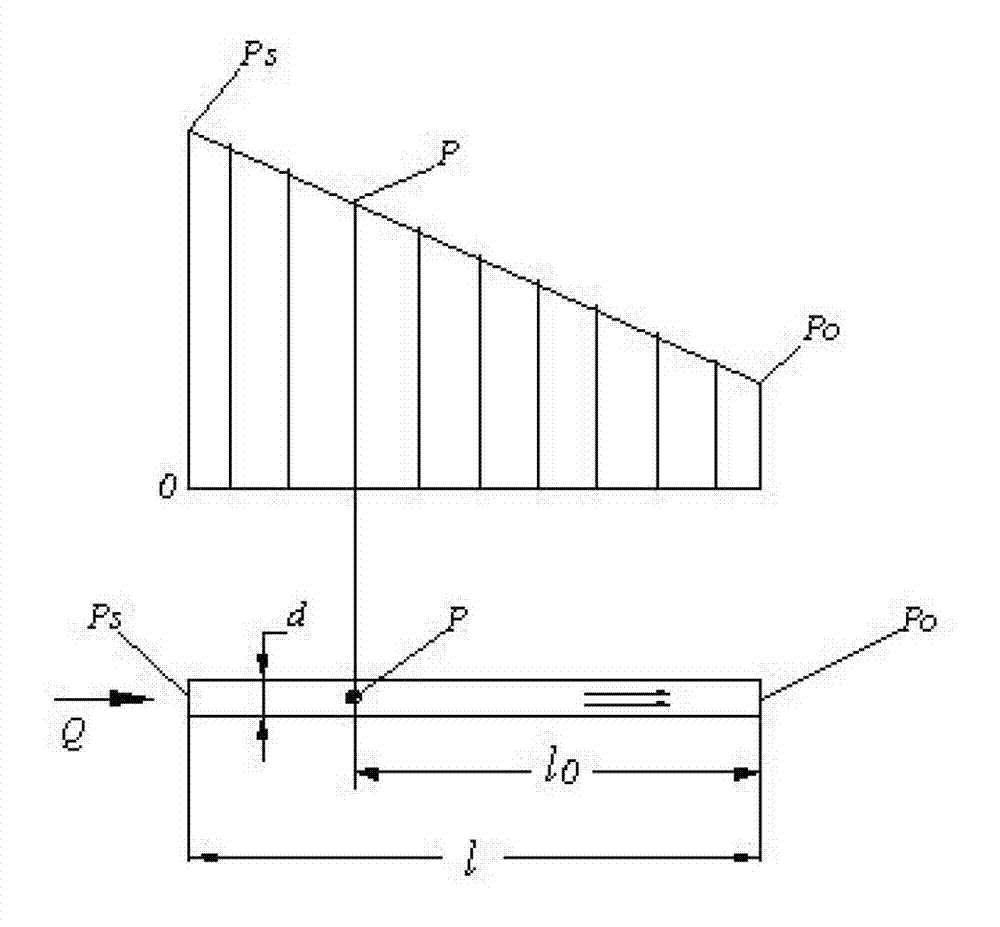

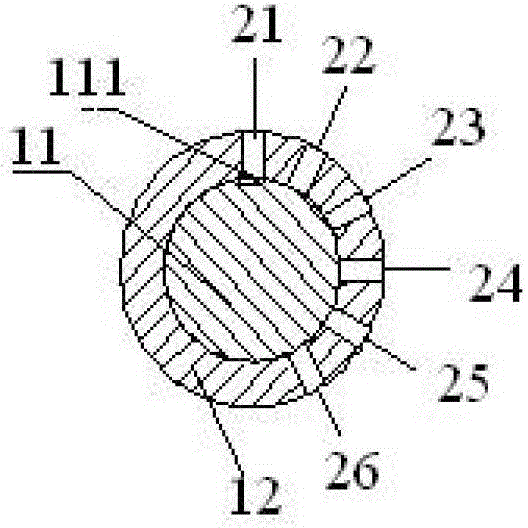

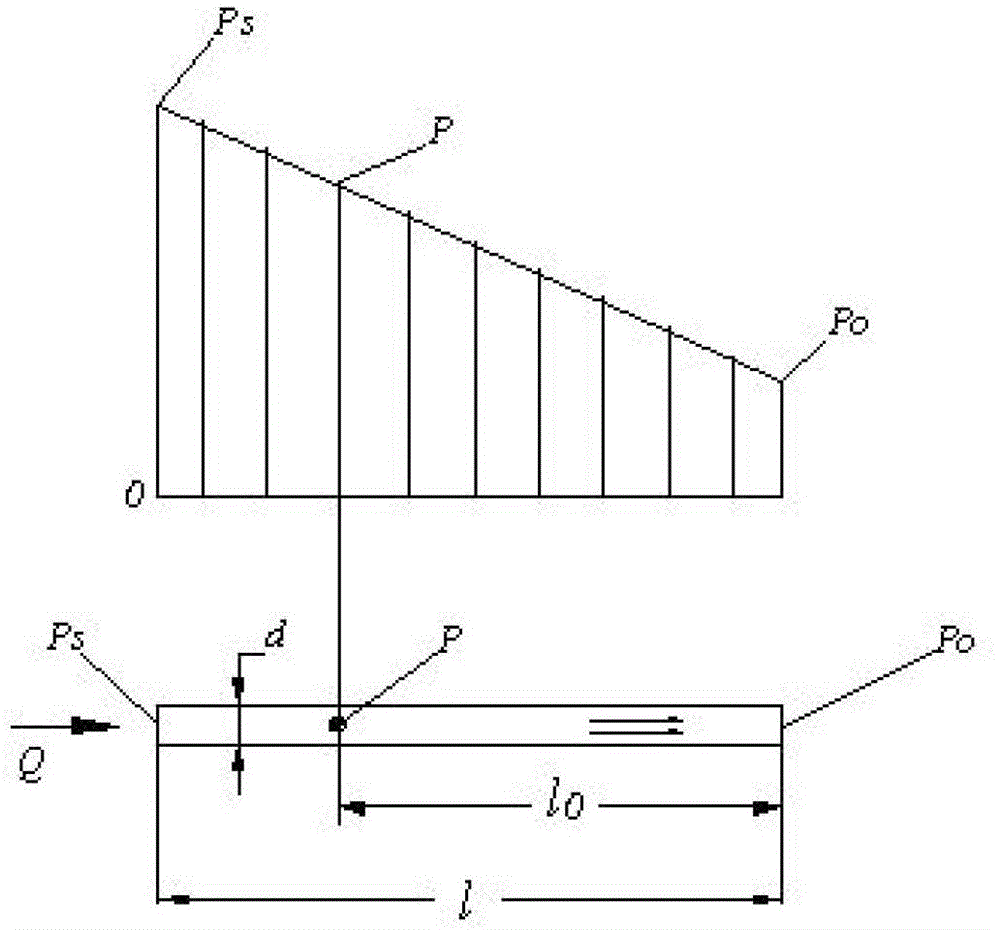

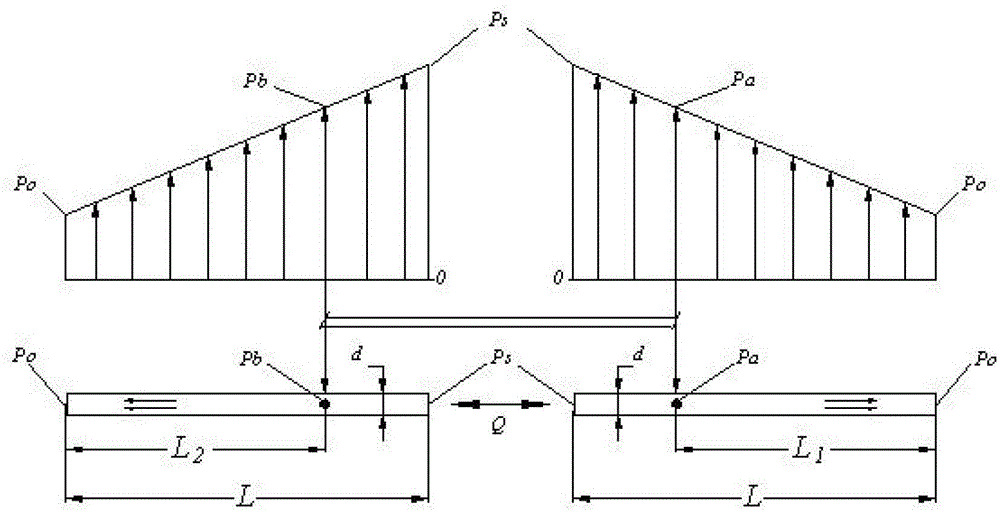

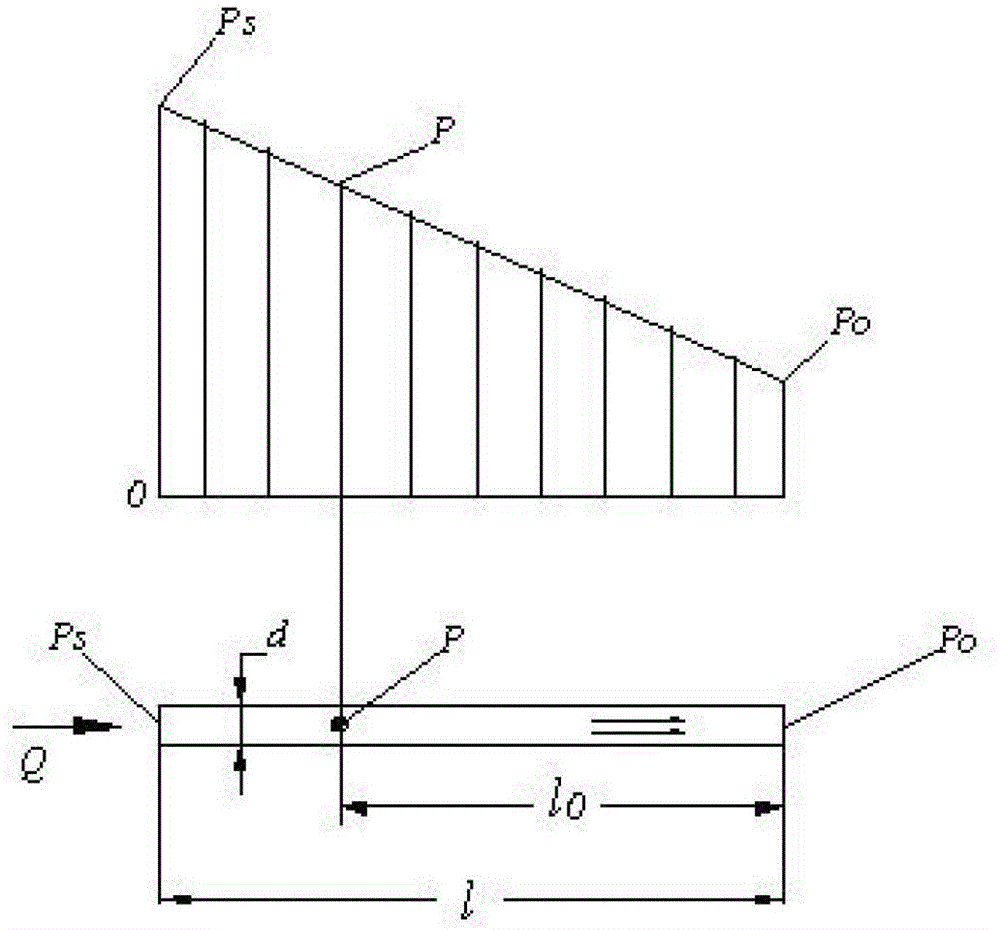

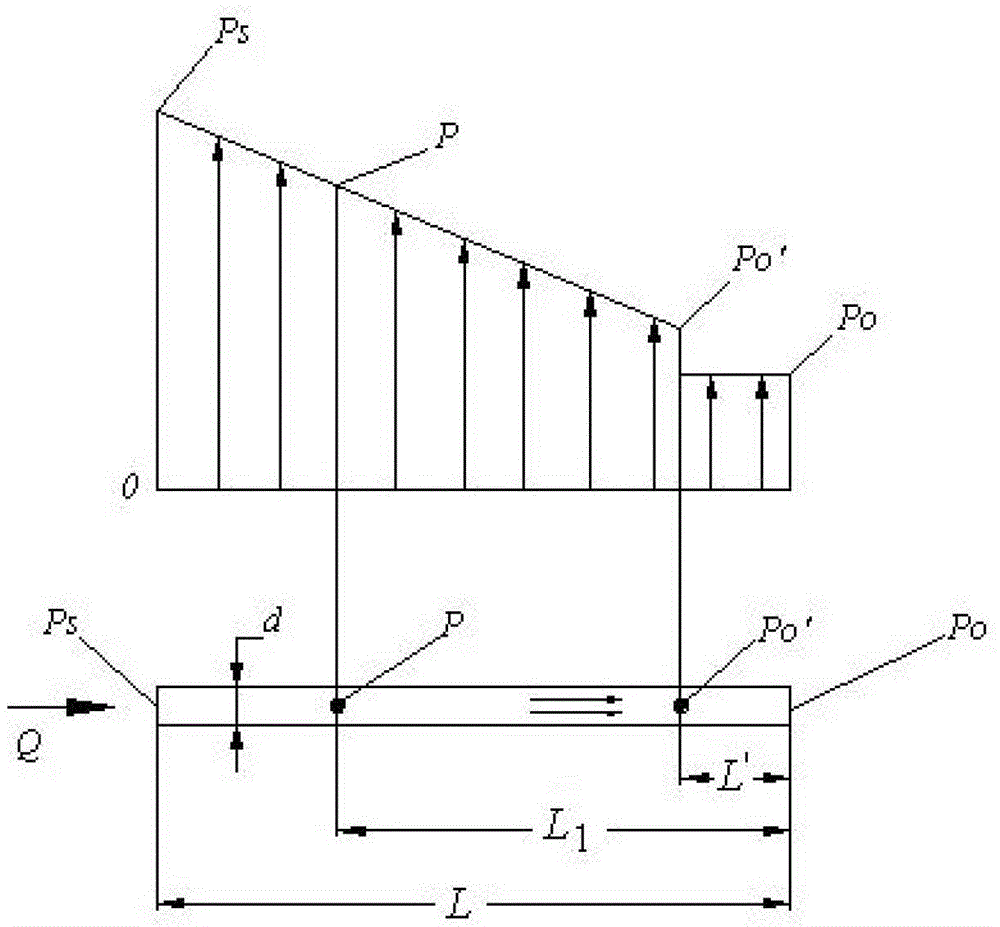

Bidirectional differential-motion proportional pressure regulating mechanism

ActiveCN103161790BStable pressure regulationHigh control sensitivityFluid dynamicsMechanical engineeringDifferential motion

A bidirectional differential-motion proportional pressure regulating mechanism comprises a fluid laminar flow implementing mechanism, a first pressure measuring point, a second pressure measuring point and a pressure measuring point position regulating mechanism. The fluid laminar flow implementing mechanism comprises a valve core and a valve sleeve, wherein an oil inlet, a first oil outlet and a second oil outlet are formed in the valve sleeve, and the oil inlet is arranged between the first oil outlet and the second oil outlet. Working steps matched with the inner diameter of the valve sleeve are arranged at two ends of the valve core, and the clearances of the working steps of the valve core and the valve sleeve are communicated with the oil inlet, the first oil outlet and the second oil outlet. The first pressure measuring point and the second pressure measuring point are both pressure measuring holes penetrating through the valve sleeve, and the pressure measuring holes are communicated with the clearances. The pressure measuring point position regulating mechanism comprises the valve core and a pushing component pushing the valve core to move inside the valve sleeve, and the movement of the valve core enables an L1 and an L2 to change between 0 and L. The bidirectional differential-motion proportional pressure regulating mechanism has the advantages that bidirectional rectilinear motion is adopted to achieve bidirectional differential-motion proportional stable pressure regulating, and control sensitivity is high.

Owner:ZHEJIANG UNIV OF TECH

Pressure regulating mechanism capable of setting initial pressure

A pressure regulating mechanism capable of setting an initial pressure comprises a fluid layer flow achieving mechanism, a pressure measuring point and a pressure measuring point position regulating mechanism. The fluid layer flow achieving mechanism comprises a valve core and a valve sleeve. A boss is arranged on an end face, towards one side of an oil outlet, of the valve core. A through groove is formed in the side wall of the valve core in the axial direction, and extends to the front end of the boss. A gap of the through groove of the valve core and the valve sleeve is communicated with an oil inlet and the oil outlet. Fluid in the gap is in a layer flow flowing state in a flowing mode. Pressure distribution of the oil inlet and the oil outlet is in a stable linear distribution. The pressure measuring point is a pressure measuring hole penetrating through the valve sleeve. The pressure measuring hole is communicated with the hole. The pressure measuring point position regulating mechanism comprises the valve core and a pushing component which pushes the valve core to move in the valve sleeve. The length of the boss can be regulated according to the actual needs and the initial pressure of the pressure regulating mechanism can also be set according to actual needs, pressure regulating is stable, control sensitivity is high, and processing difficulty is low.

Owner:ZHEJIANG UNIV OF TECH

Bidirectional dual-redundancy proportional pressure regulating mechanism

ActiveCN103161789BIncrease pressureSolve the problem of easy blockageFluid dynamicsEngineeringMechanical engineering

A bidirectional dual-redundancy proportional pressure regulating mechanism comprises a fluid laminar flow implementing mechanism, a first pressure measuring point, a second pressure measuring point and a pressure measuring point position regulating mechanism. The fluid laminar flow implementing mechanism comprises a valve core and a valve sleeve, wherein an oil inlet, a first oil outlet and a second oil outlet are formed in the valve sleeve, and the oil inlet is arranged between the first oil outlet and the second oil outlet. Working steps matched with the inner diameter of the valve sleeve are arranged at two ends of the valve core, and two notches are axially formed in the side wall of each working step. The first pressure measuring point and the second pressure measuring point are both pressure measuring holes penetrating through the valve sleeve, and the pressure measuring holes are communicated with clearances. The pressure measuring point position regulating mechanism comprises the valve core and a pushing component pushing the valve core to move inside the valve sleeve. The bidirectional dual-redundancy proportional pressure regulating mechanism has the advantages that a double-flow-passage structure is adopted, even if one of the flow passages is blocked, the pressure regulating mechanism can still work normally, the problem that a pressure regulating mechanism is easy to block is effectively solved, and pressure regulating is stable.

Owner:ZHEJIANG UNIV OF TECH

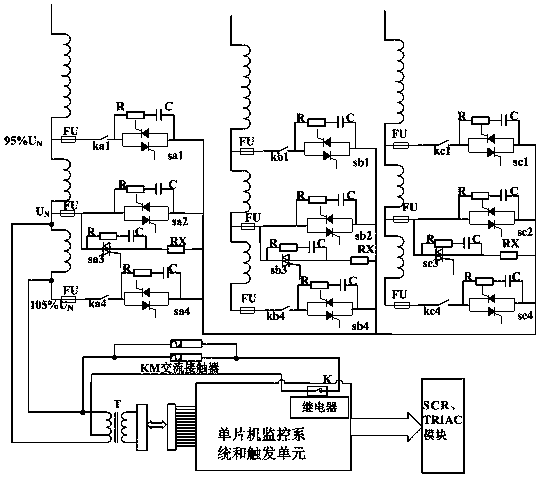

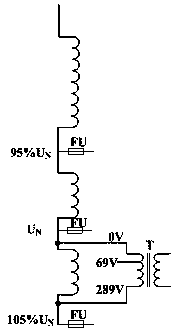

Non-contact on-load automatic voltage regulation distribution transformer and method for automatic voltage regulation

ActiveCN104579070BCompact structureLow costConversion without intermediate conversion to dcTap changerPower grid

After the reform of a power grid, the voltage quality is relatively improved but the fluctuation range of voltage still exceeds the national regulation. The invention relates to an automatic voltage control distribution transformer with contactless on-load and a method for carrying out automatic voltage control. The automatic voltage control distribution transformer with the contactless on-load comprises a distribution transformer main body, and an automatic voltage control tapping switch with the contactless on-load. The distribution transformer main body is a current energy-saving distribution transformer with various models. Three tapping joints of nominal voltage such as UN, 95 UN and 105% UN are remained on the neutral point side by a high-voltage winding. The position between each tapping point and neutral point is provided with an anti-parallel thyristor module which is regarded as a contactless tapping switch. By measuring the variation of a high-voltage terminal voltage provided by a concurrent working power transformer T, a single chip supervisory system sends a pulse which is regarded as a trigger signal of the anti-parallel thyristor module off the contactless tapping switch, and the change of a working tapping joint is carried out, and the working tapping joint is regarded as the automatic voltage control tapping switch with the contactless on-load. The automatic voltage control distribution transformer with contactless on-load and the method for carrying out automatic voltage control are applied to a contactless on-load automatic voltage control distribution transformer.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Portable small-flow precise pressure regulating device

PendingCN109506023AAccurate pressure regulationStable pressure regulationEqualizing valvesSafety valvesEngineeringStreamflow

The invention provides a portable small-flow precise pressure regulating device. The portable small-flow precise pressure regulating device comprises an upper shell assembly, a precise pressure regulating assembly and a lower shell assembly. The upper shell assembly comprises a screw, an upper shell and a screw connecting part. The precise pressure regulating assembly comprises a first spring, aninner liner, a positioning base, a lower spring, a third gasket, a diaphragm, a limiting ring, an outer liner, a check block, an upper spring, an upper valve and a lower valve. The lower shell assembly comprises a lower shell, a first filler neck, a nut, a nozzle, a first gasket, a second filler neck and a second gasket. Precise pressure regulating of multiple media under different working conditions is achieved, and the portable small-flow precise pressure regulating device has the beneficial effects that the structure is relatively simple, output pressure is stable, and regulating is precise.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

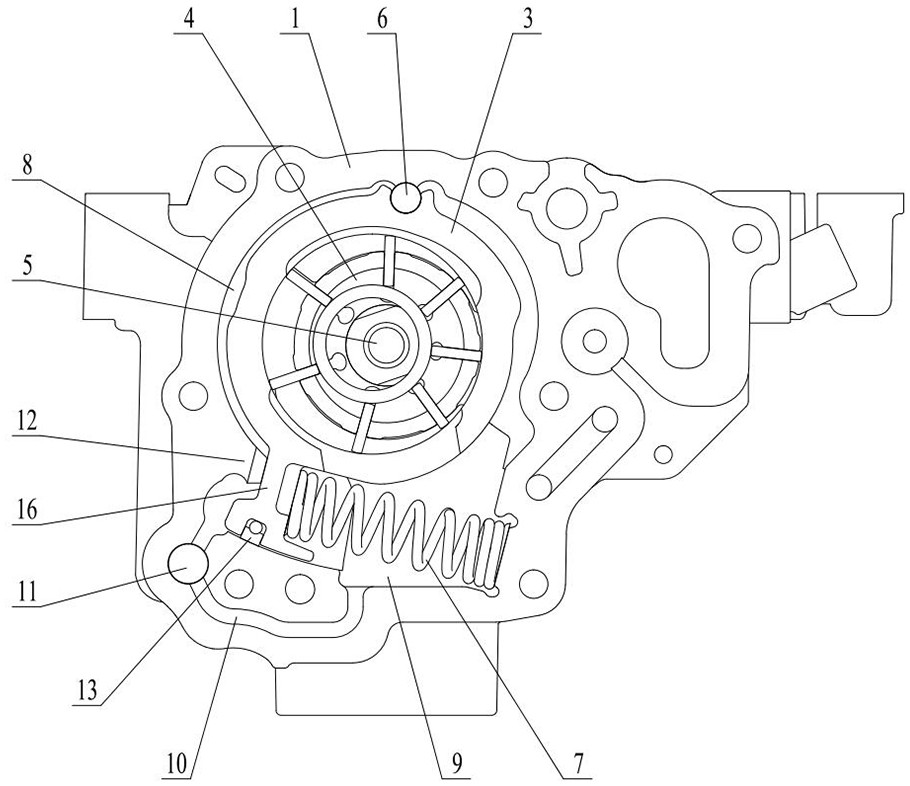

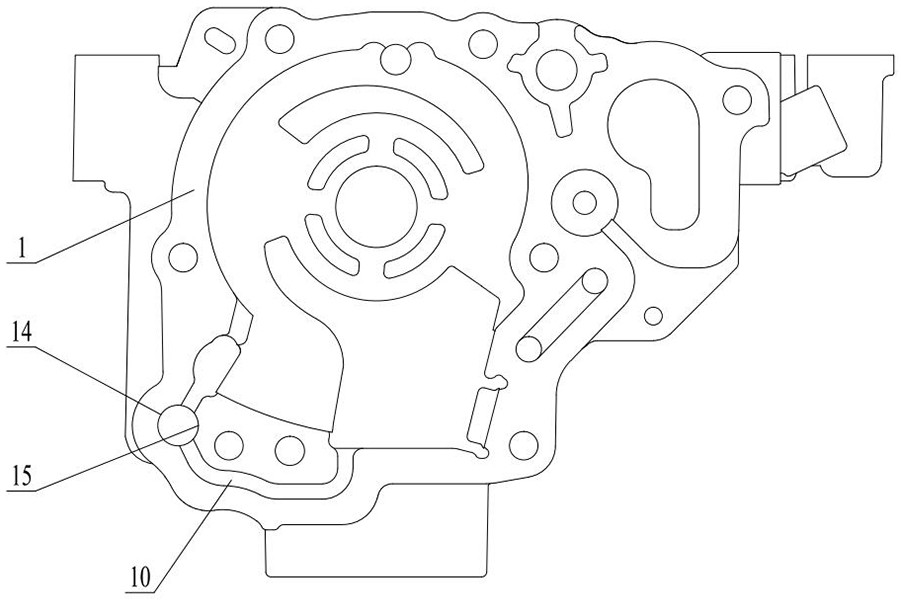

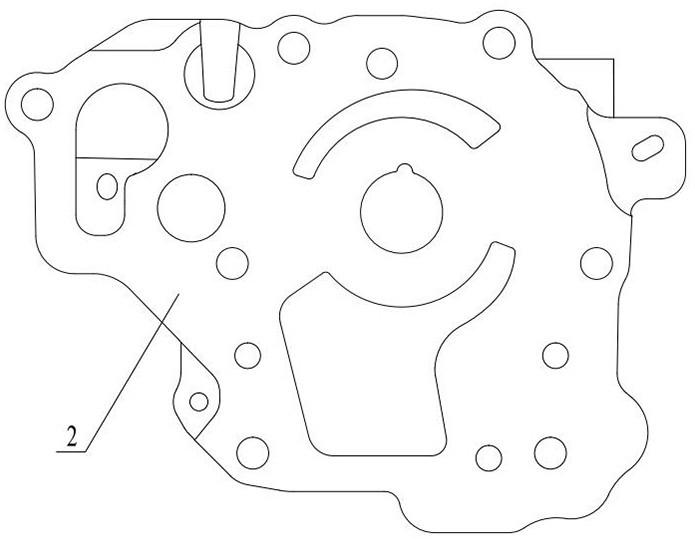

Variable displacement oil pump capable of avoiding temperature rise and pressure drop

PendingCN114215745APlay a balancing rolePrevent pressure dropRotary piston pumpsRotary piston liquid enginesMechanicsOil pump

A variable displacement oil pump capable of avoiding temperature rise and pressure drop relates to the technical field of oil pumps and comprises a pump body, a pump cover, a sliding block arranged in the pump body, a rotor, a pump shaft and the like, the front side of the sliding block is connected with the inner wall of the pump body through a rotating pin, the rear side of the sliding block is connected with the pump body through a spring, and a feedback cavity is formed between the left side face of the sliding block and the inner wall of the pump body. A low-pressure oil suction cavity is formed in the right side of the sliding block, a compensation oil channel is connected between the feedback cavity and the low-pressure oil suction cavity, a compensation pin is installed in the compensation oil channel in a clearance mode, and the compensation pin is used for guiding feedback oil to pass through the clearance between the side wall face of the compensation pin and the inner wall face of the compensation oil channel. Oil liquid in the feedback cavity is distributed, and oil liquid leaking into the feedback cavity from a high-pressure oil discharging cavity in the pump cavity under the high-temperature working condition is compensated and balanced, so that the stability of pressure adjustment of the whole system is guaranteed.

Owner:HUNAN OIL PUMP

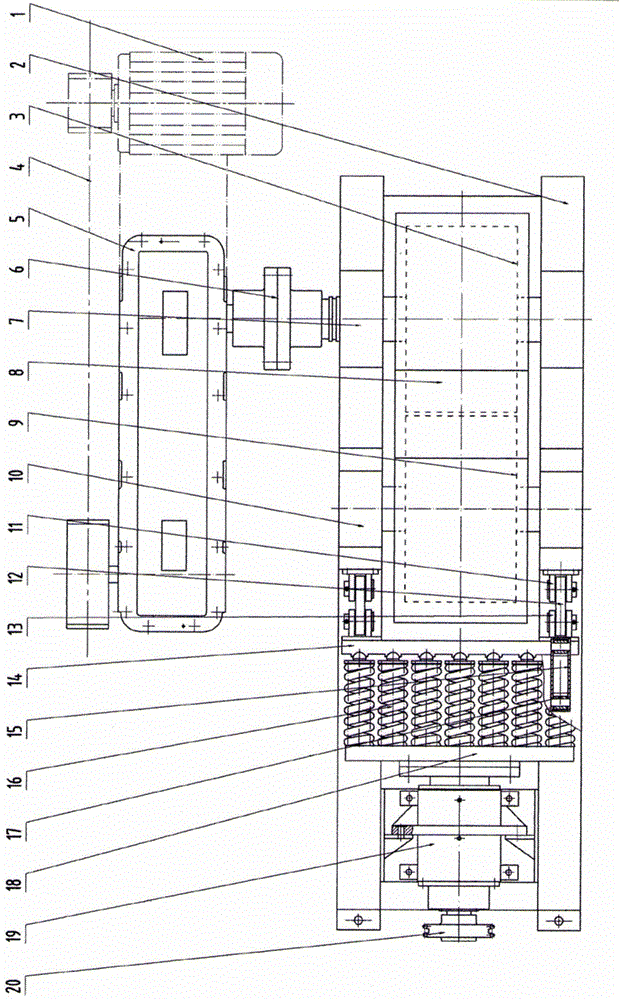

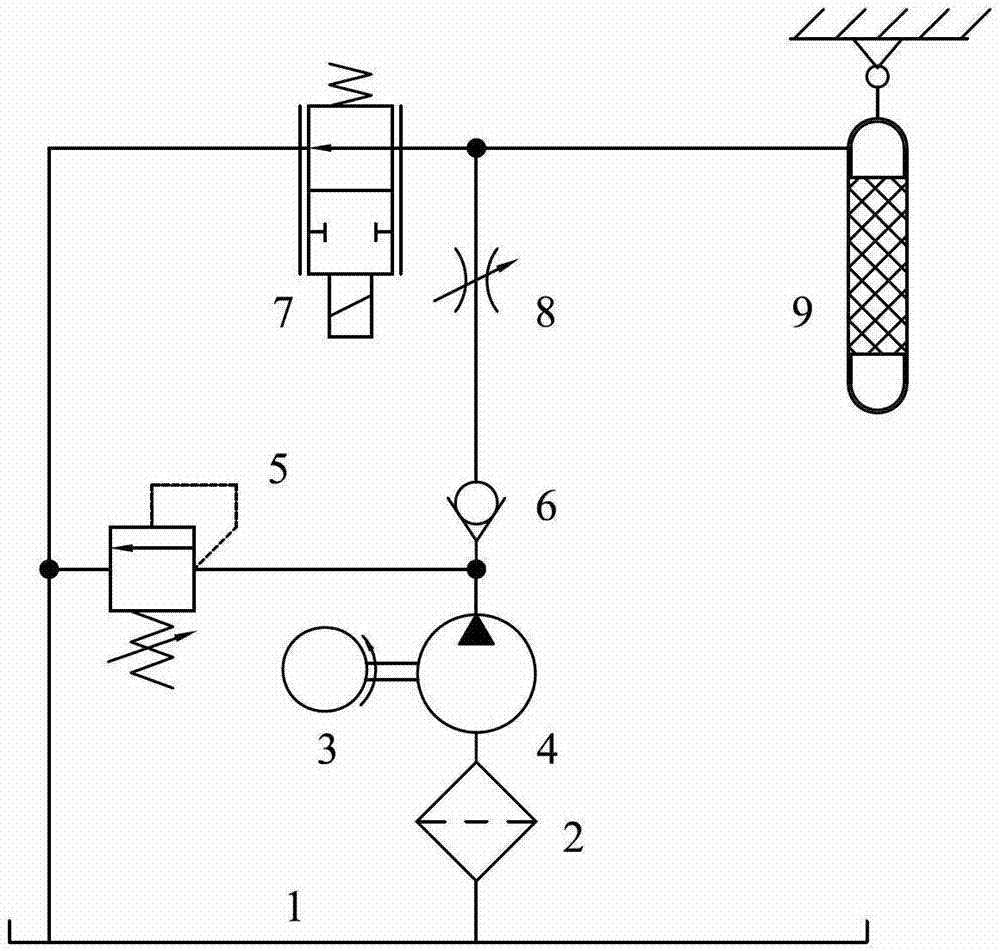

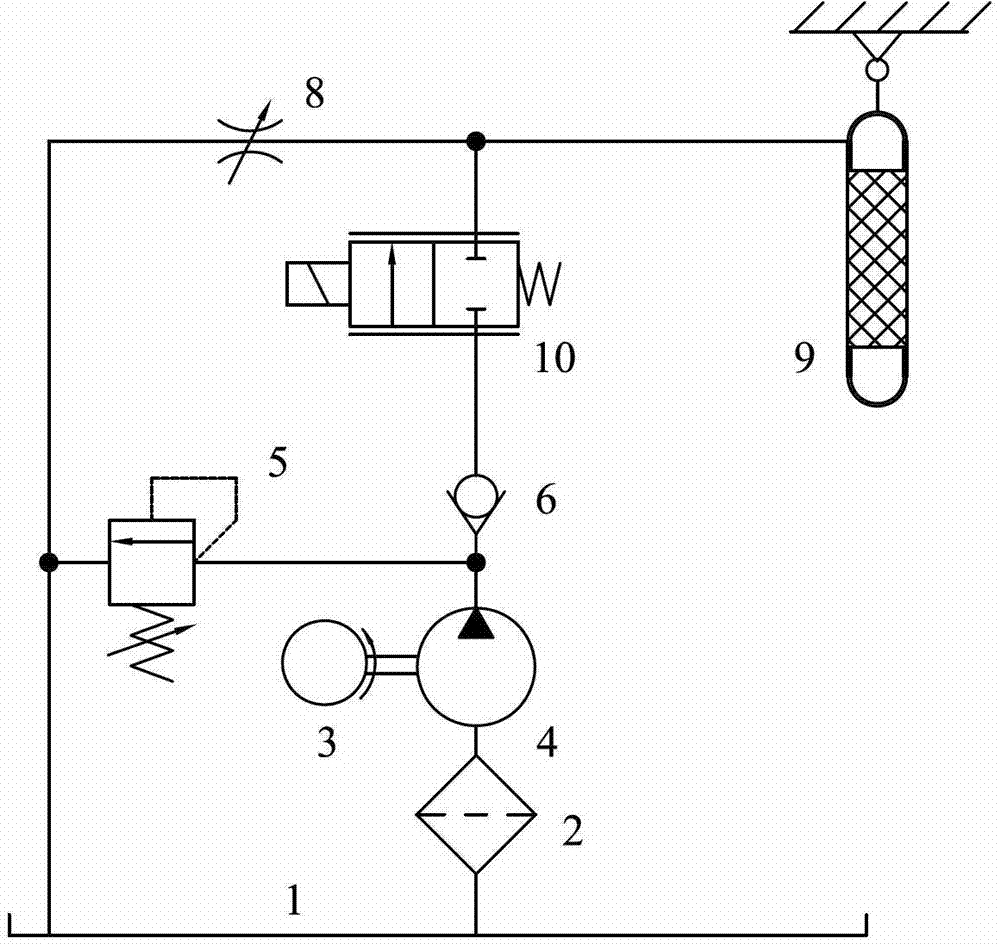

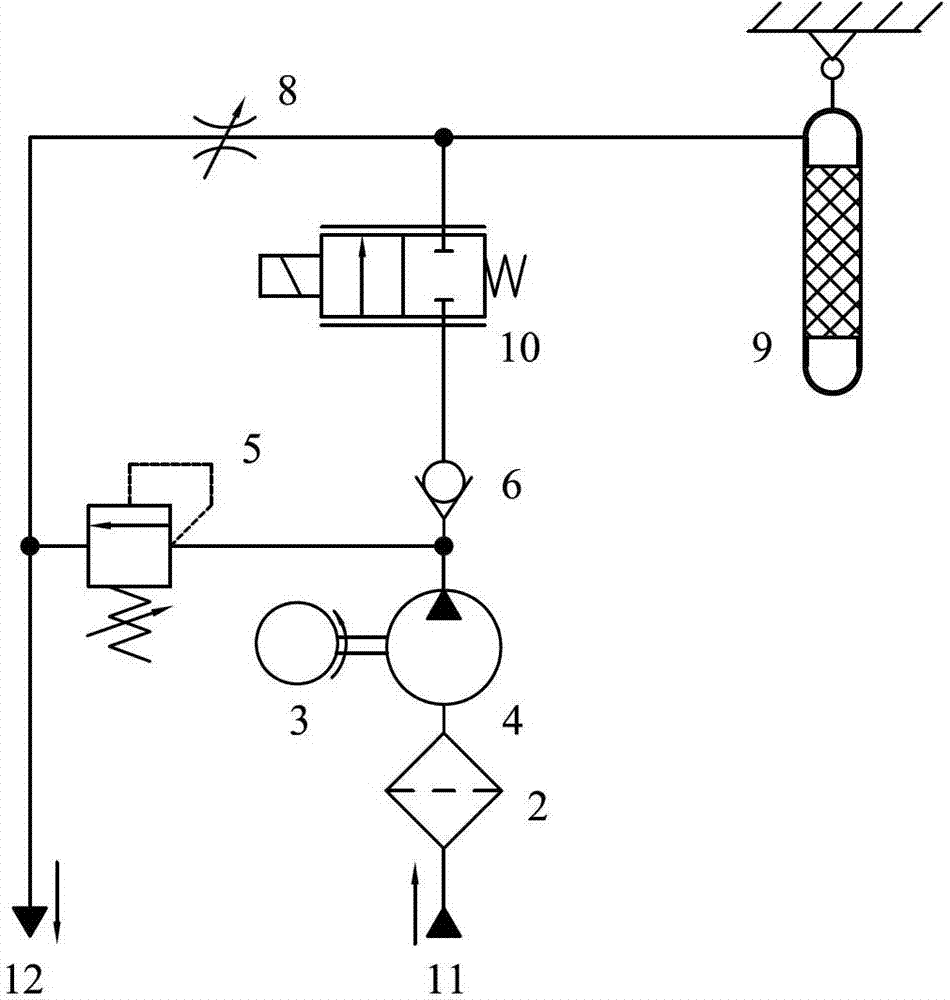

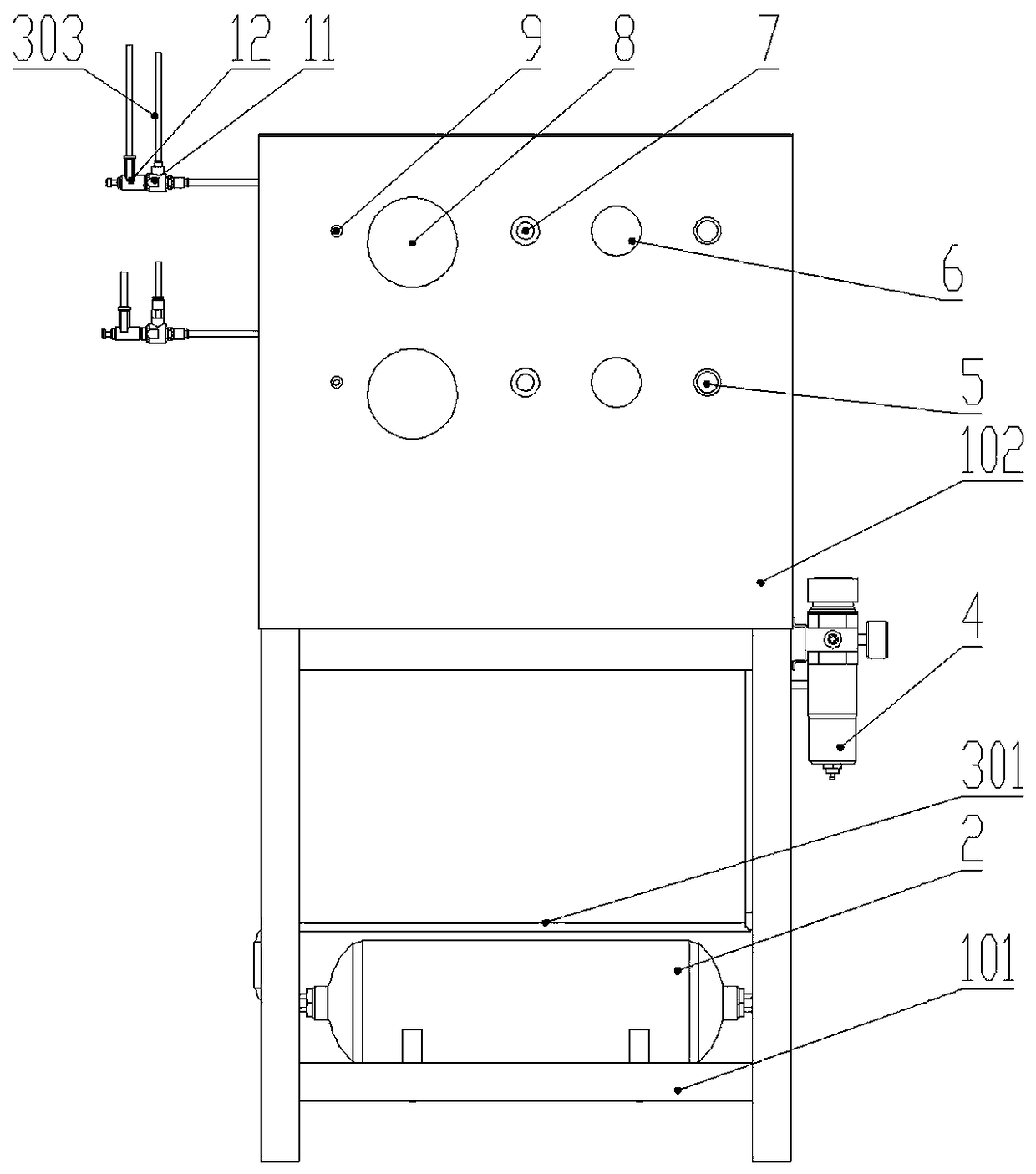

Hydraulic artificial muscle hydraulic drive and control system

ActiveCN102829009BControl displacementApplicable mechanical joint controlServomotorsControl systemHydraulic pump

The invention discloses a hydraulic artificial muscle hydraulic drive and control system, comprising a motor, a hydraulic pump, a water tank, a filter, an overflow valve, a one-way valve, a normally-open proportional throttle valve, a throttle valve and a hydraulic artificial muscle drive. The throttle valve is separately connected with the normally-open proportional throttle valve and the hydraulic artificial muscle drive, and the throttle valve together with the normally-open proportional throttle valve forms a B-shaped half bridge. Through the bridge formed by the normally-open proportional throttle valve and the adjusted throttle valve, pressure of the hydraulic artificial muscle drive being adjusted by the proportional throttle valve, the invention achieves control to the output force and placement of the hydraulic artificial muscle drive, suitable for control to a manipulator's joint driven by a hydraulic artificial muscle. The invention utilizes a hydraulic half bridge formed by a proportional throttle valve and an adjusted throttle valve to control the driving pressure of a hydraulic artificial muscle, and thereby, performance requirements to the hydraulic elements are reduced, and there's no need to install a proportional pressure-reducing valve. Furthermore, the system has the advantages of stable pressure adjustment, wide range and nice linearity.

Owner:DALIAN MARITIME UNIVERSITY

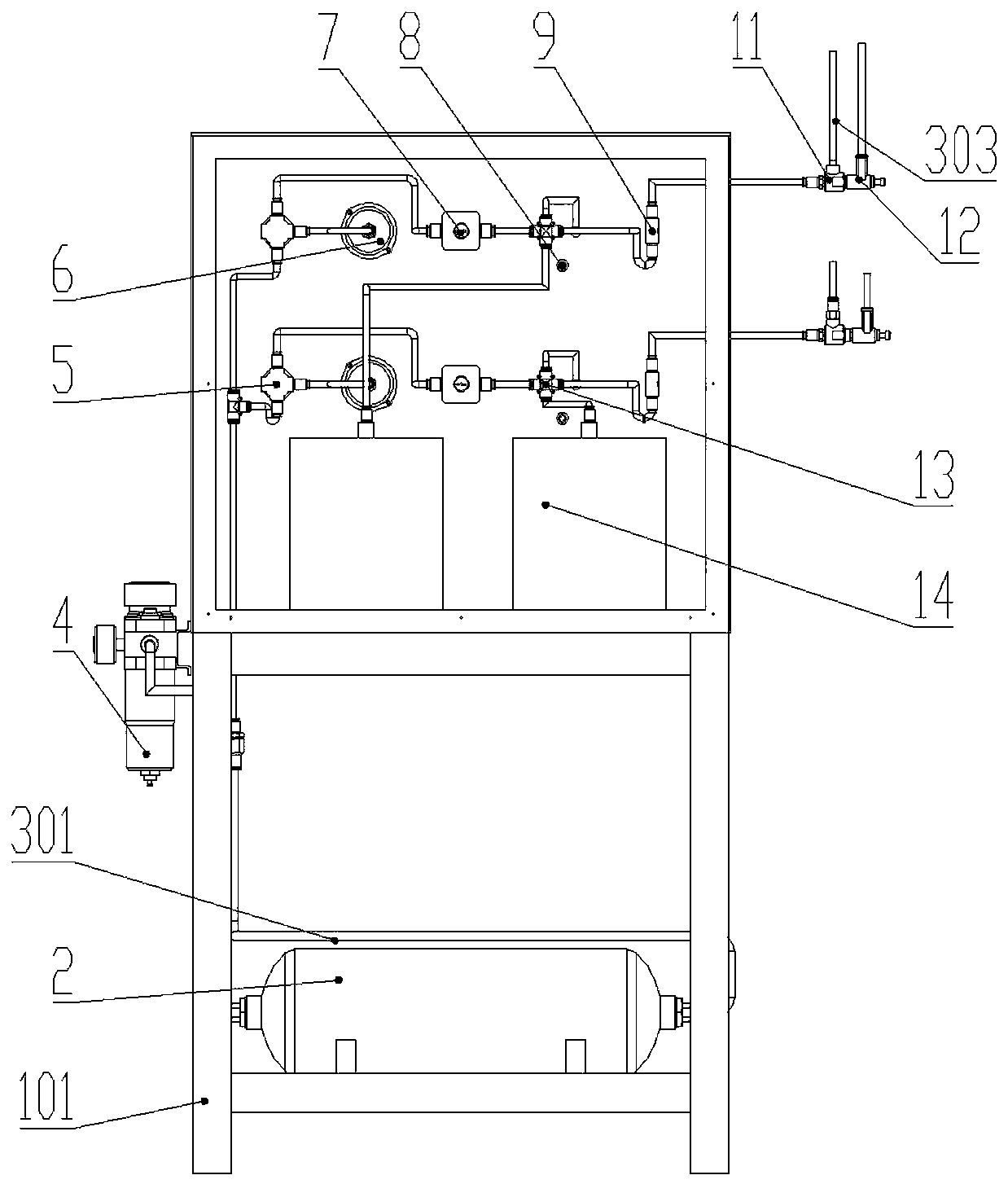

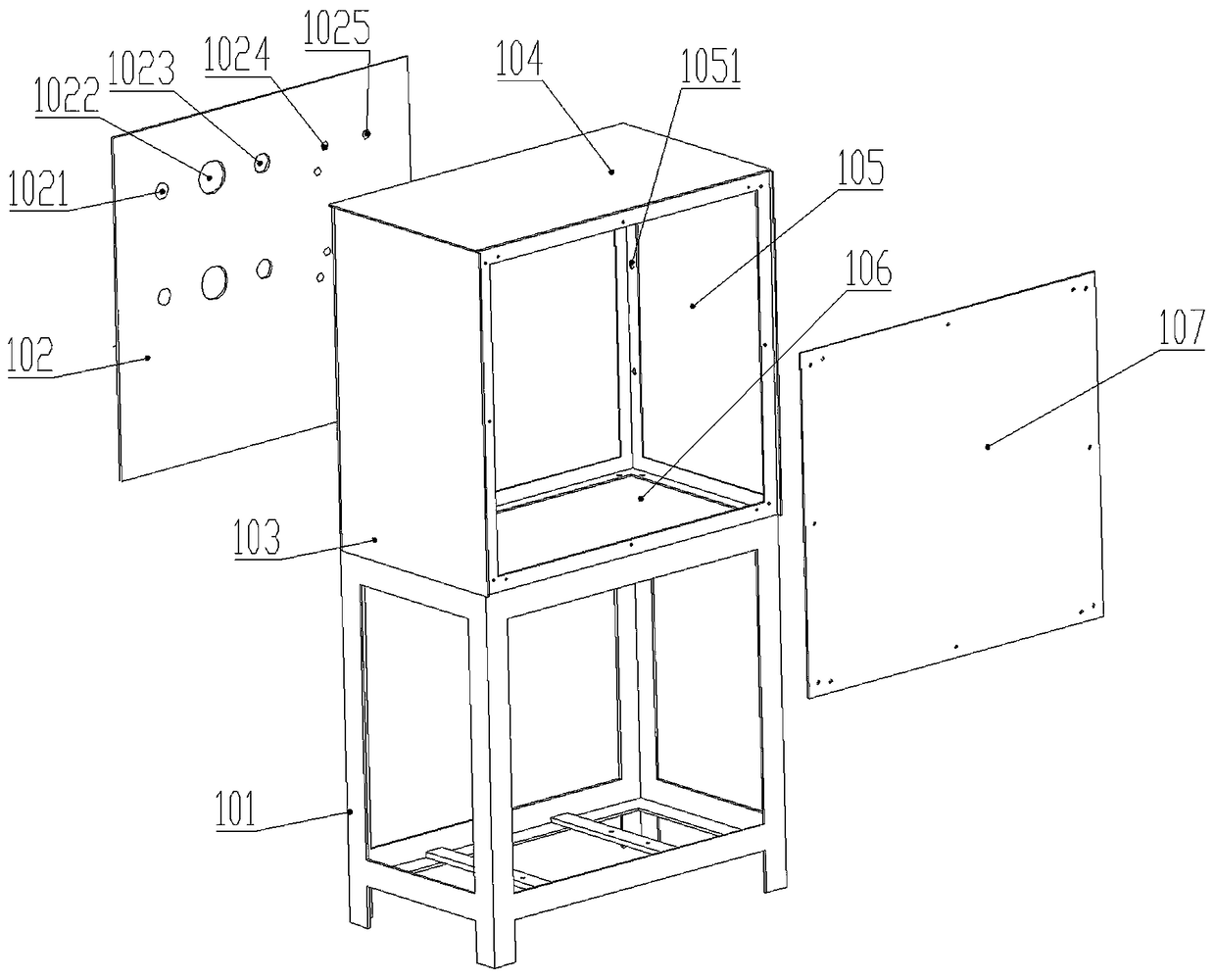

Special air pressure regulating device for extrusion forming of sealing strip

The invention discloses a special air pressure regulating device for extrusion forming of a sealing strip. The special air pressure regulating device for extrusion forming of the sealing strip comprises a control box, the control box comprises a support and a mounting plate, a box body is formed by the mounting plate and the support in an enclosed mode, an air pressure regulating system is installed in the box body, the air pressure regulating system comprises a precision pressure reducing valve, an inlet of the precision pressure reducing valve is connected with a pressure reducing valve, theother end of the pressure reducing valve is connected with an air storage tank, and the air storage tank is connected with a pneumatic triple part. An outlet of the precision pressure reducing valveis connected with a throttling valve, and an outlet of the throttling valve is connected with an extrusion die port through an air pipe. The special air pressure regulating device for extrusion forming of the sealing strip has the advantages of providing accurate and stable air pressure and achieving convenient pressure adjusting.

Owner:HUNAN TECHN COLLEGE OF RAILWAY HIGH SPEED

A vacuum-based salt solution heat pump regeneration system

InactiveCN106369706BReduce energy consumptionTake advantage ofHeat recovery systemsLighting and heating apparatusSaline solutionsEngineering

Owner:TIANJIN UNIV OF COMMERCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com