Special air pressure regulating device for extrusion forming of sealing strip

A technology of extrusion molding and pressure regulating device, applied in the field of polymer extrusion molding, can solve the problems of outlet pressure fluctuation, poor precision and low precision, and achieve the effects of constant pressure, impact prevention and convenient pressure regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

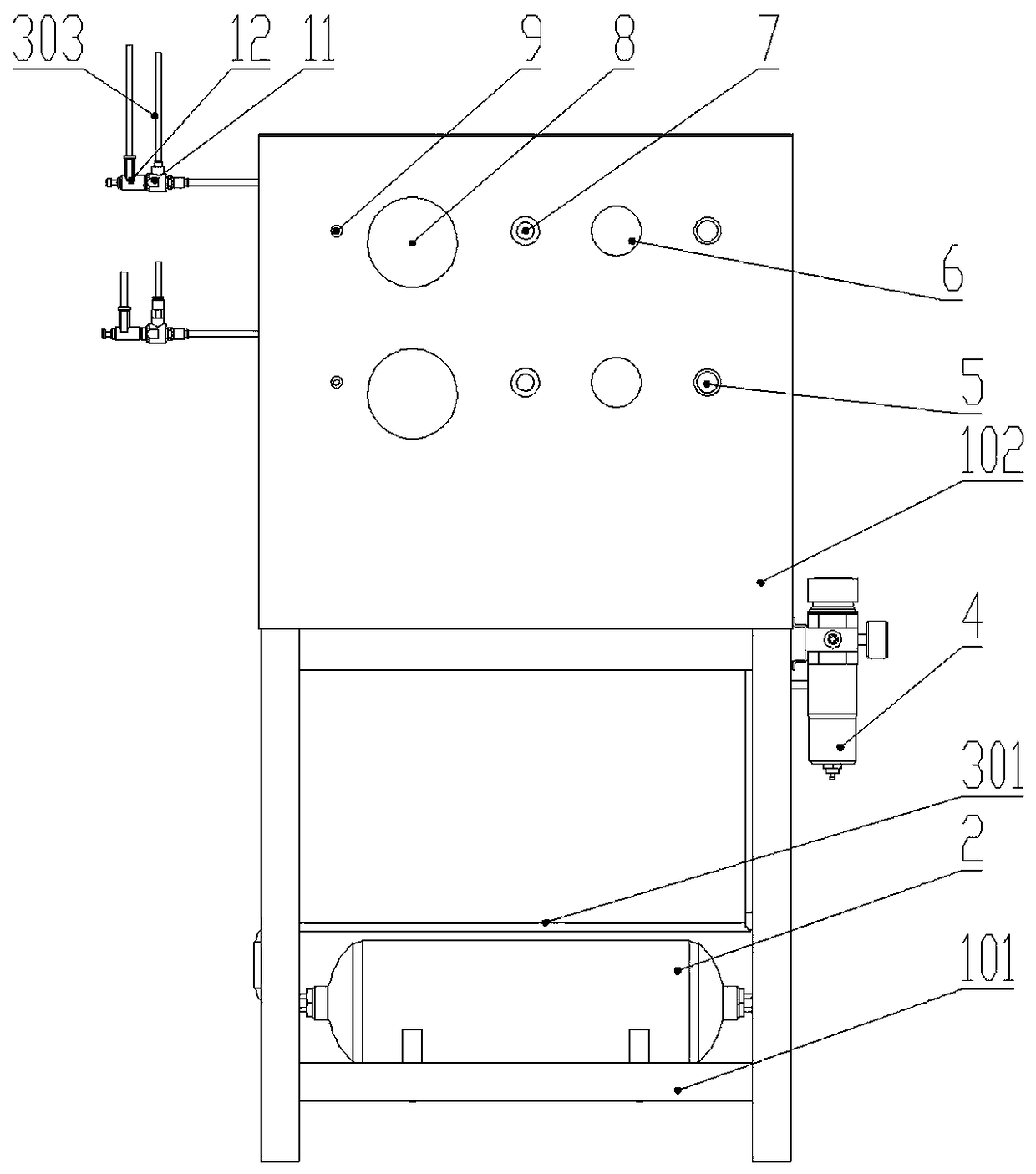

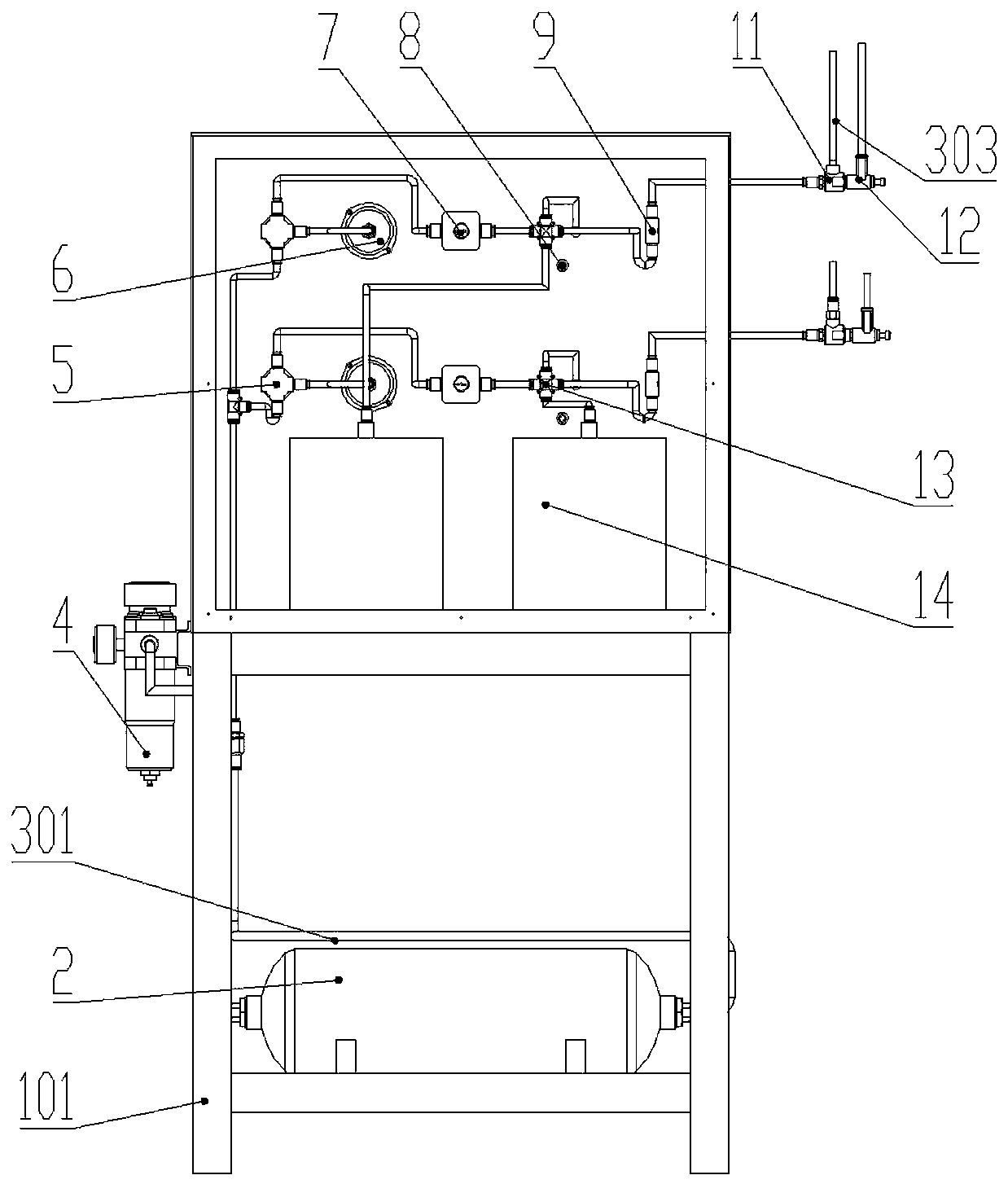

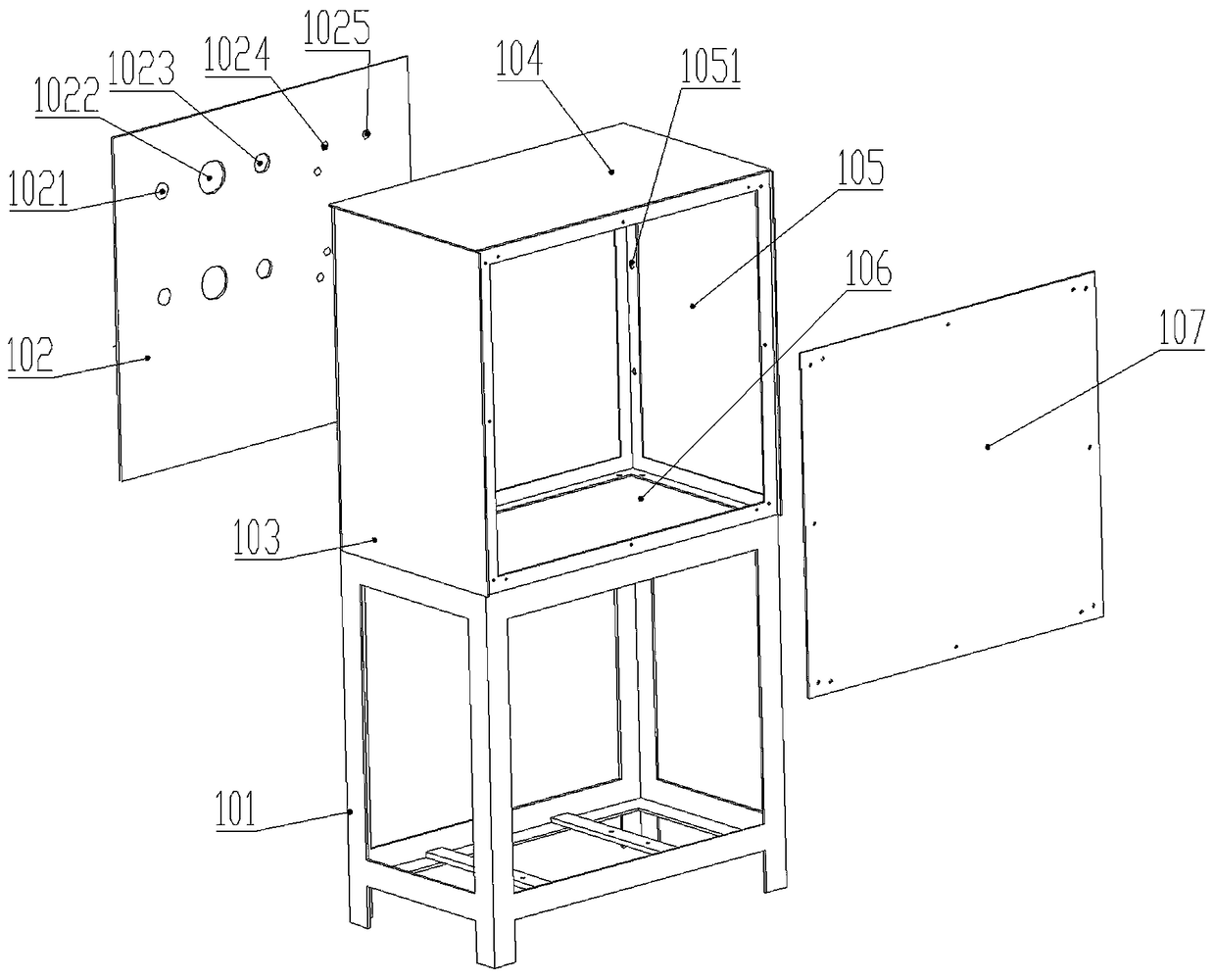

[0023] like Figure 1-4 As shown, a special air pressure regulating device for sealing strip extrusion molding, which includes a control box, the control box includes a bracket 101 and a mounting plate, the bracket 101 is welded by several angle steels, and the bracket 101 is divided into two parts by transverse angle steel There are two layers up and down, and the installation board includes a front board 102, a back board 107, a left side board 103, a top board 104, a right side board 105 and a bottom board 106, which are installed around and around the upper bracket 101, and the above installation board surrounds the upper bracket 101 into a box body, the front plate 102 is provided with two horizontal rows (viewed from the direction shown in the figure) of mounting holes, and each row of mounting holes runs from right to left ( figure 1 Seen from the direction) are: pressure reducing valve mounting hole 1021, pressure gauge mounting hole 1022, precision pressure reducing ...

Embodiment 2

[0030] like Figure 5 As shown, a special air pressure regulating device for sealing strip extrusion molding, which includes a control box, the control box includes a bracket 101 and a mounting plate, the bracket 101 is welded by several angle steels, and the bracket 101 is divided into two parts by transverse angle steel There are two layers up and down, and the installation board includes a front board 102, a back board 107, a left side board 103, a top board 104, a right side board 105 and a bottom board 106, which are installed around and around the upper bracket 101, and the above installation board surrounds the upper bracket 101 into a box Body, the front plate 102 is provided with three horizontal rows (viewed from the direction shown in the figure) of mounting holes, each row of mounting holes from right to left is: pressure reducing valve mounting hole 1021, pressure gauge mounting hole 1022, precision pressure reducing valve mounting hole 1023, differential pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com