Device and method for indirectly testing performance of fire detection tube

A technology of testing device and fire detection tube, which is applied in fire rescue and other fields, and achieves the effect of large market demand, high testing accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

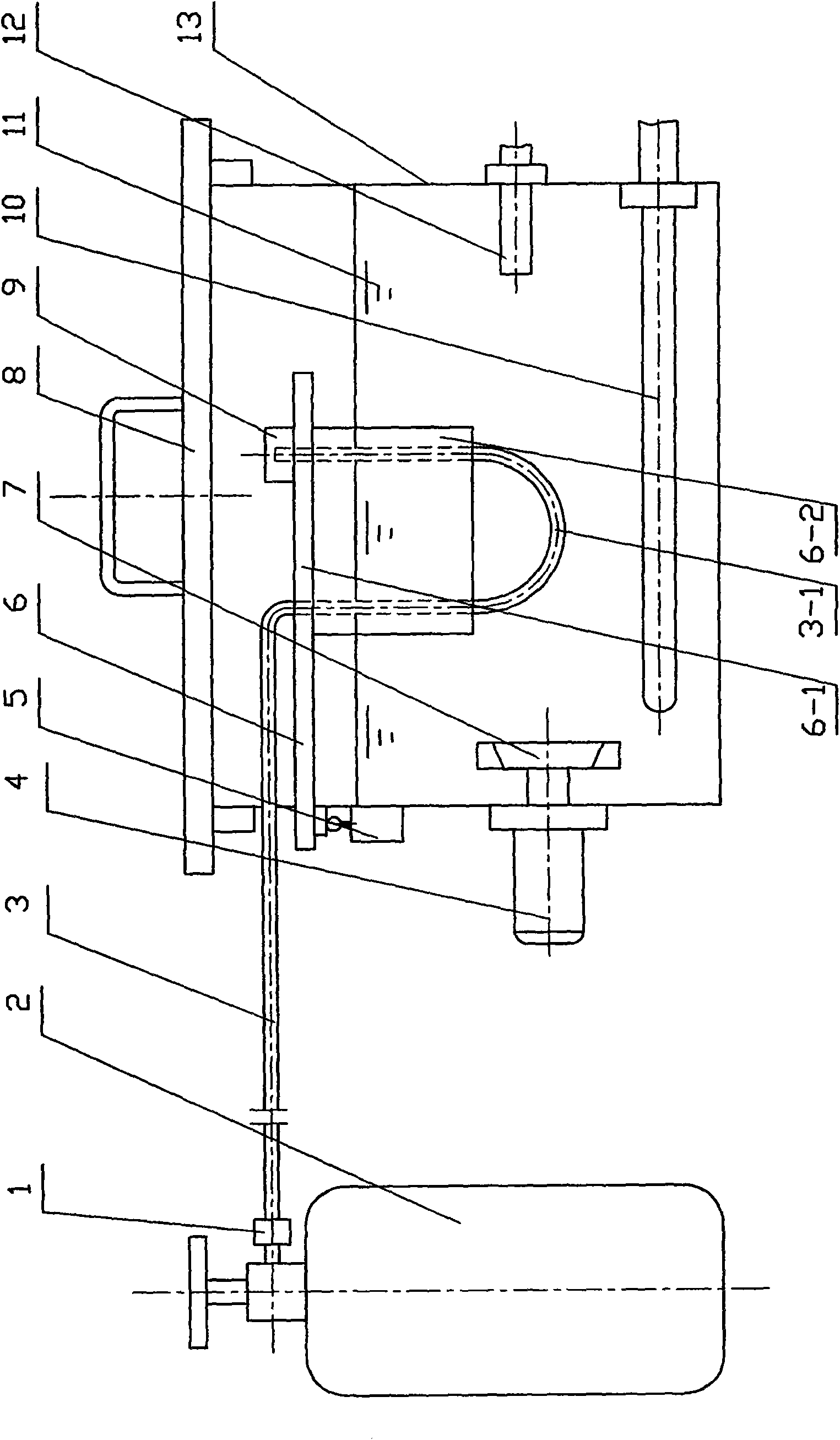

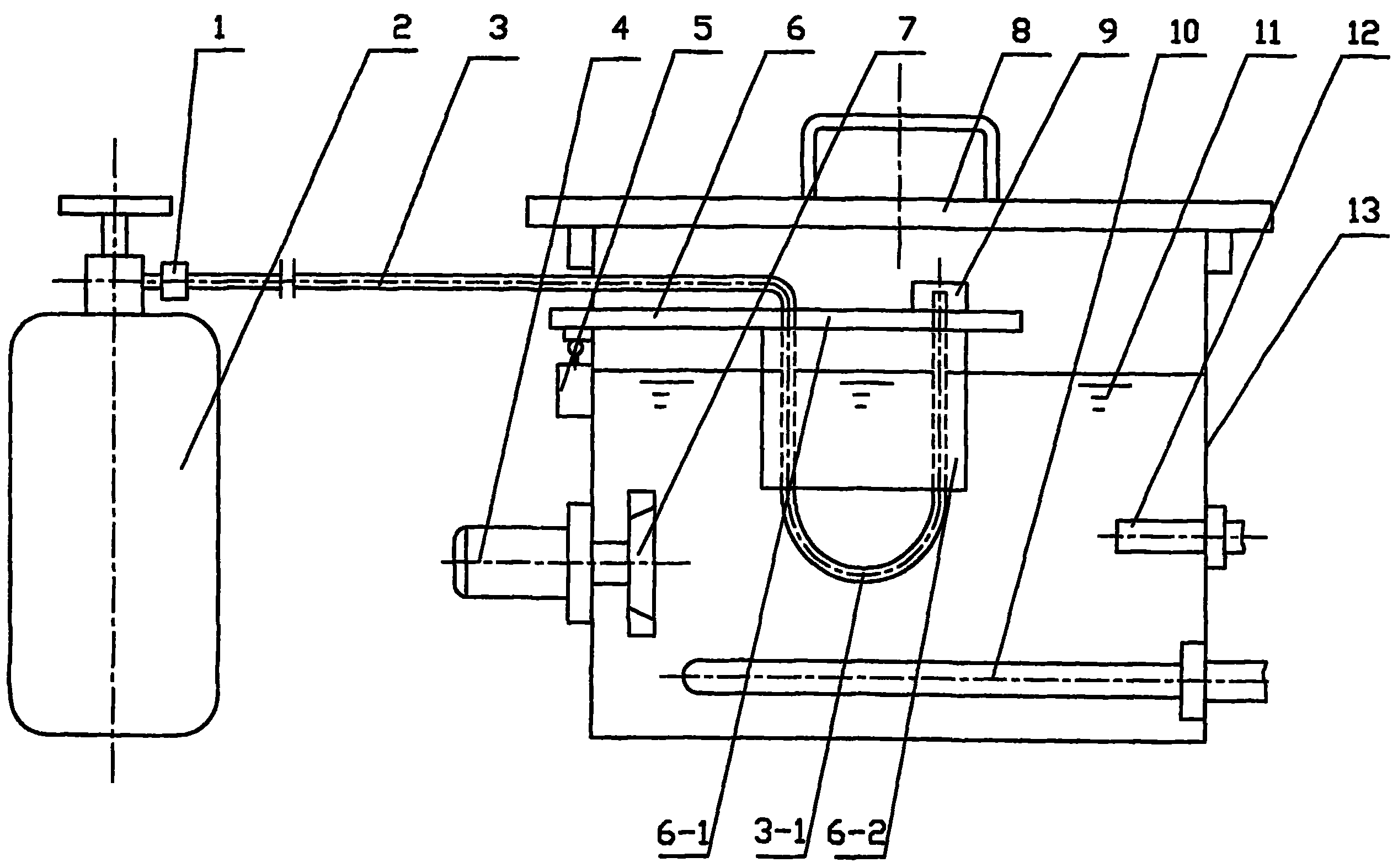

Image

Examples

Embodiment 1

[0027] Embodiment 1, using the method for testing the fire detection tube performance indirect testing device of the present invention, a fire detection tube 3 made of polymer is tested, the test temperature range is 40-300 °C, and the test pressure range is 0-300 °C. 5MPa, the inner diameter of the fire detection tube 3 tested in this embodiment is 4mm, the outer diameter is 6mm, the test temperature is set to 175°C, the test pressure is set to 1MPa, the test liquid medium 11 is silicone oil, the gas cylinder 2 The gas is nitrogen, the heat source 10 is an electric heating rod, and the temperature measuring element 12 is a thermocouple. The tested fire detection tube 3 ruptured in 18s, and the average test time was 10 minutes, which is mainly used for temperature constant of the liquid medium. In this example, the operation is simple, fast and safe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com