Contrast test method for cooling effects of cooling pipes of different materials for air cooler

A technology of comparison test and cooling effect, applied in the field of mechanical design, can solve the problems of not being able to produce test data and test process, unreasonable, inaccurate, etc., to achieve the test workload is small, the test conditions are the same, and the test data is accurate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

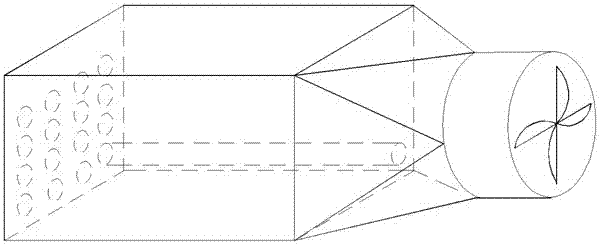

[0013] As shown in the accompanying drawings, a specific embodiment of the method for comparing the cooling effects of cooling tubes made of different materials for air coolers according to the present invention, wherein: the right end is an independent fan, and the cooling tubes placed vertically and horizontally have 4 rows and 4 columns, and the actual number is far more than The number shown is 300 to 800 pieces. The test was carried out on the same motor. Viewed from the left end of the motor cooler, all the cooling pipes were laid out in layers at equal intervals instead of W-shaped or M-shaped. The length of cooling pipes made of different materials, The diameter and wall thickness of the tubes are exactly the same for easy comparison of cooling effects. Viewed from the left end of the motor cooler, place two aluminum tubes at about 1 / 3 of the width of the air cooler counting from the left. The distance between the two aluminum tubes is 1 / 3 of the height of the air coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com