Camera performance automatic test equipment and system and operation method thereof

An automatic testing equipment and camera technology, which is applied in the testing of machine/structural components, optical instrument testing, testing optical performance, etc., can solve the problem of long time-consuming shooting, low efficiency, and difficulty in ensuring the test distance, height and shooting angle of the mobile terminal camera Consistent test conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

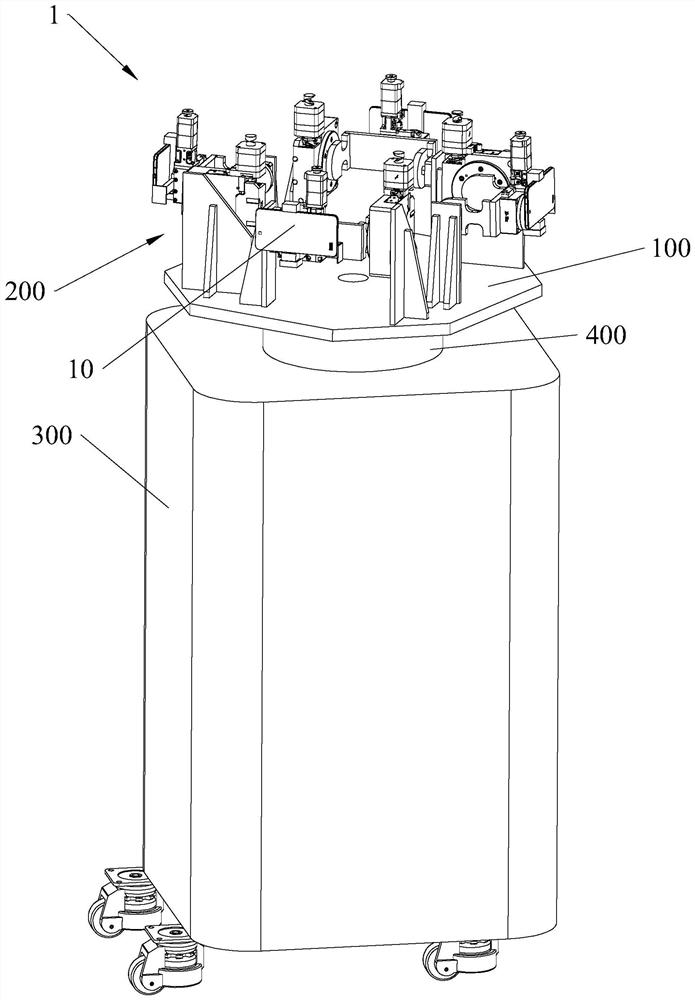

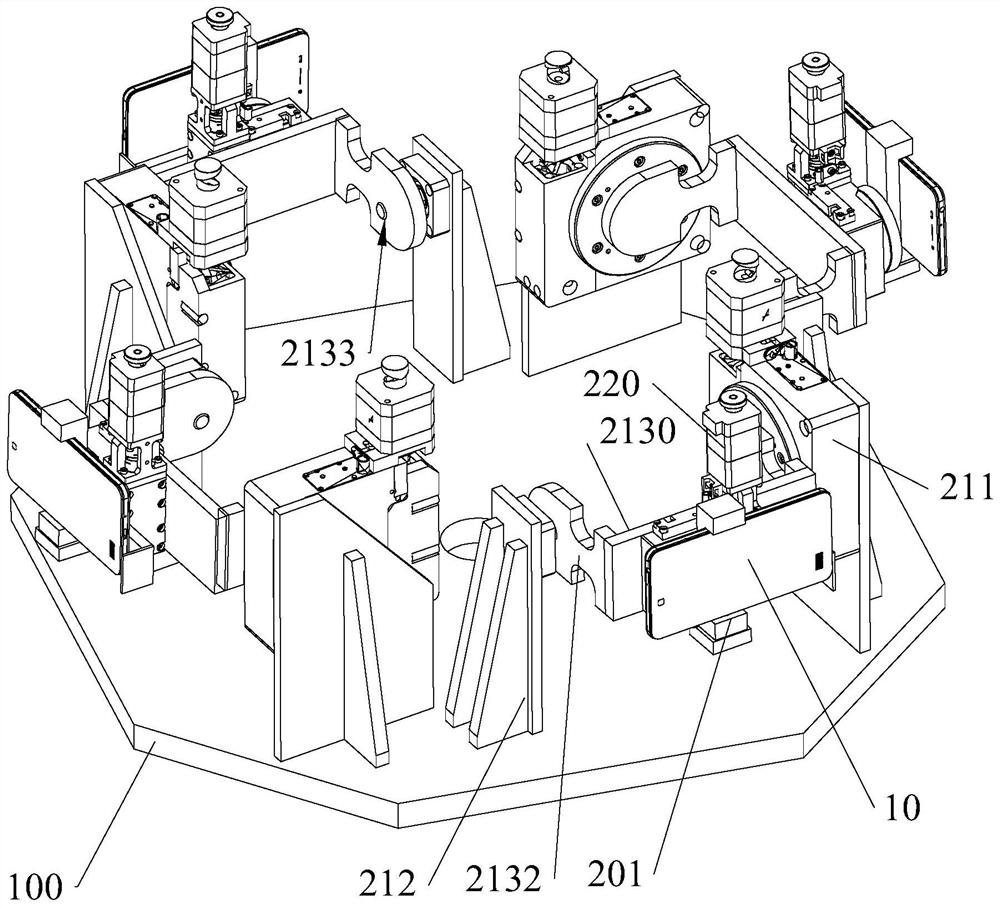

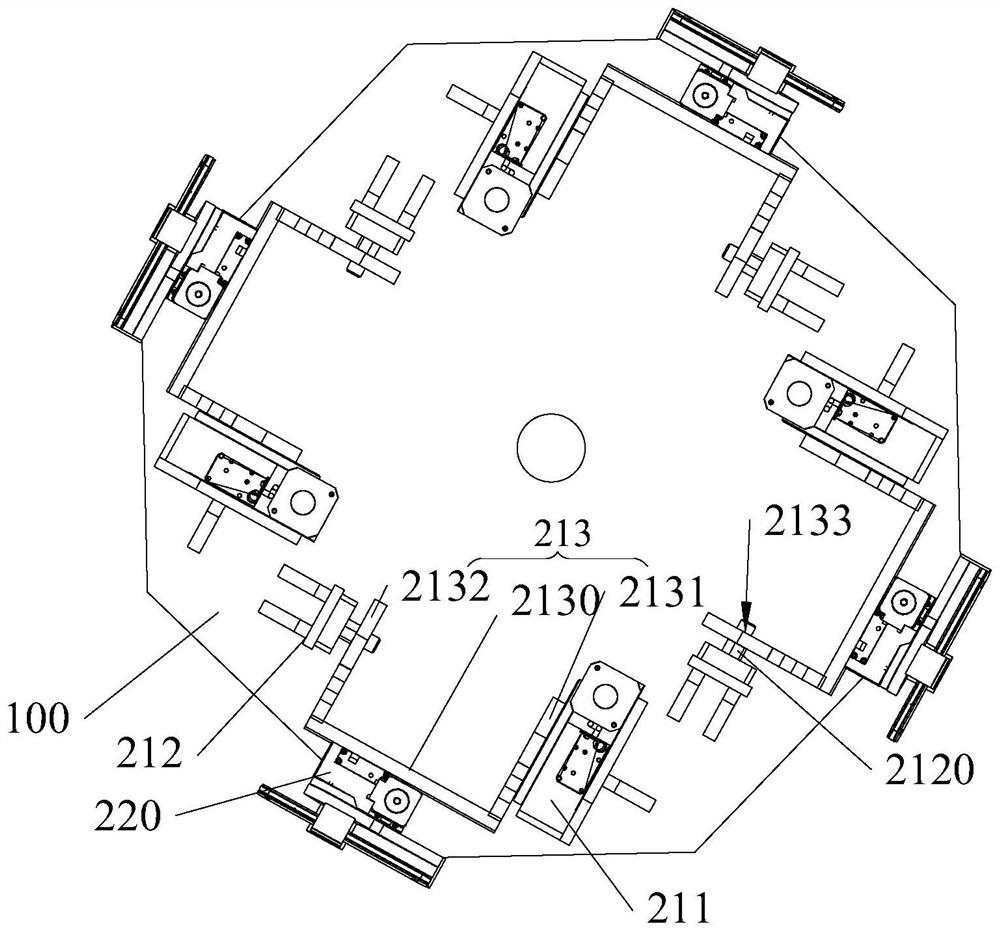

[0032] see Figure 1 to Figure 5 , the present invention discloses a camera performance automatic testing equipment 1, which is used for performing performance testing on a camera on a mobile terminal 10. The camera performance automatic testing equipment 1 includes a rotating platform 100, a plurality of positioning devices 200 and a mobile robot 300, multiple A positioning device 200 is evenly distributed on the rotating platform 100 along the circumferential direction. The positioning device 200 includes a depression angle adjustment mechanism and a terminal clamp 201 arranged on the angle adjustment mechanism. The angle adjustment mechanism is used to adjust the angle of the terminal clamp 201 to adjust the mobile terminal. 10 camera angles....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com