Single-driving-roller clearance-free sand maker

A gapless, single-drive technology, applied in grain processing and other directions, can solve the problems of small adjustment range, high maintenance cost, large wear, etc., and achieve the effect of reducing the number of maintenance, reducing operating costs, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

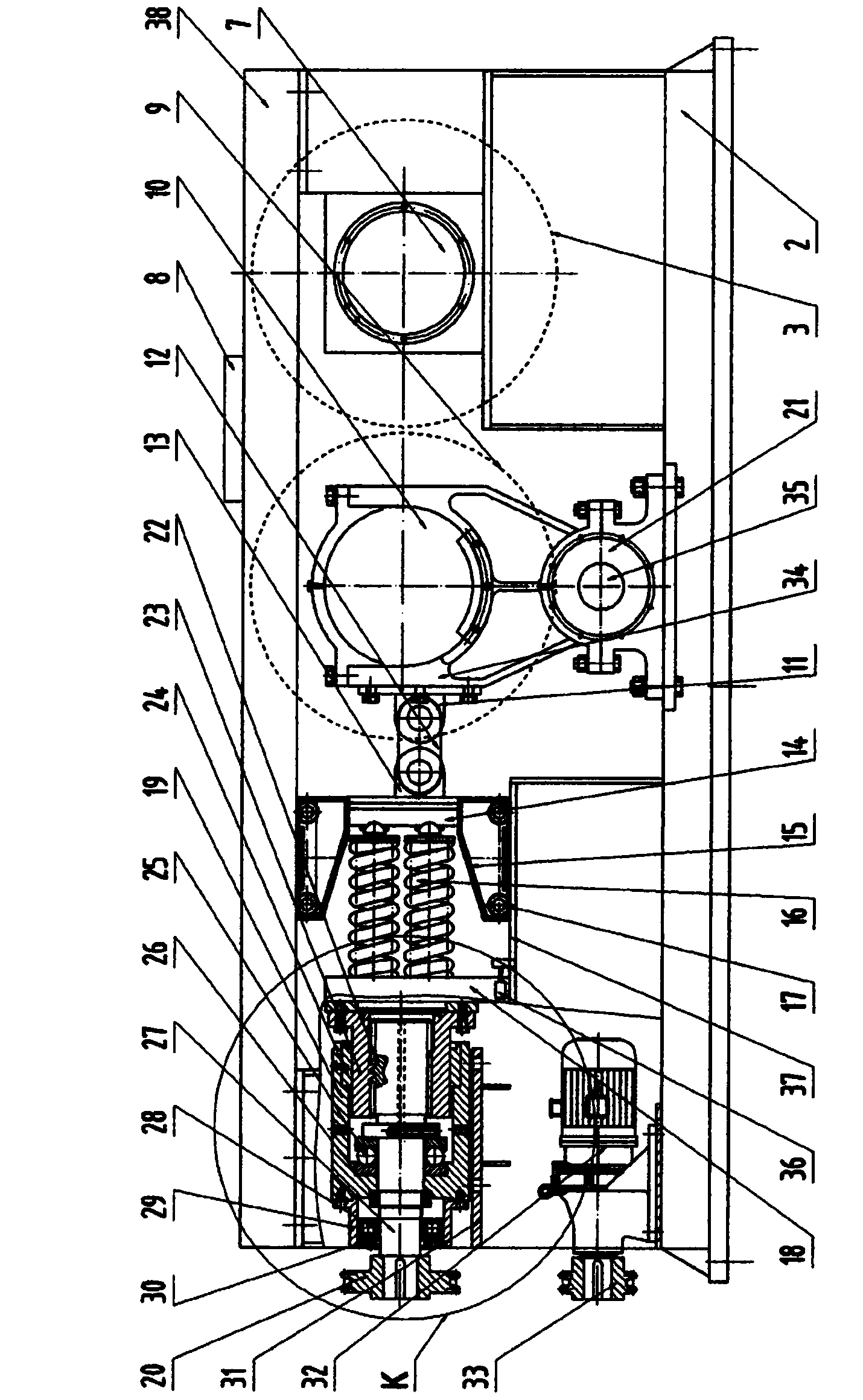

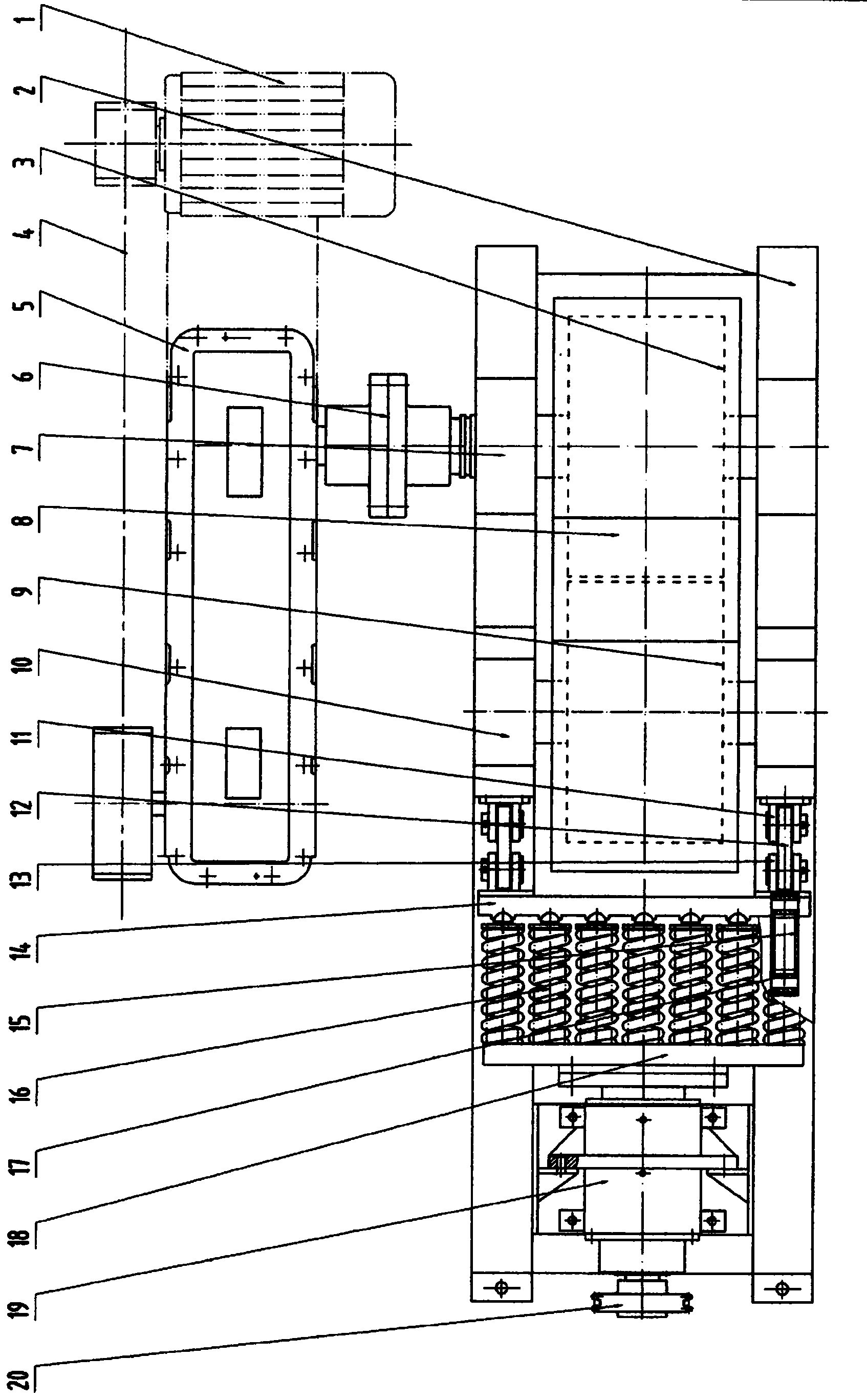

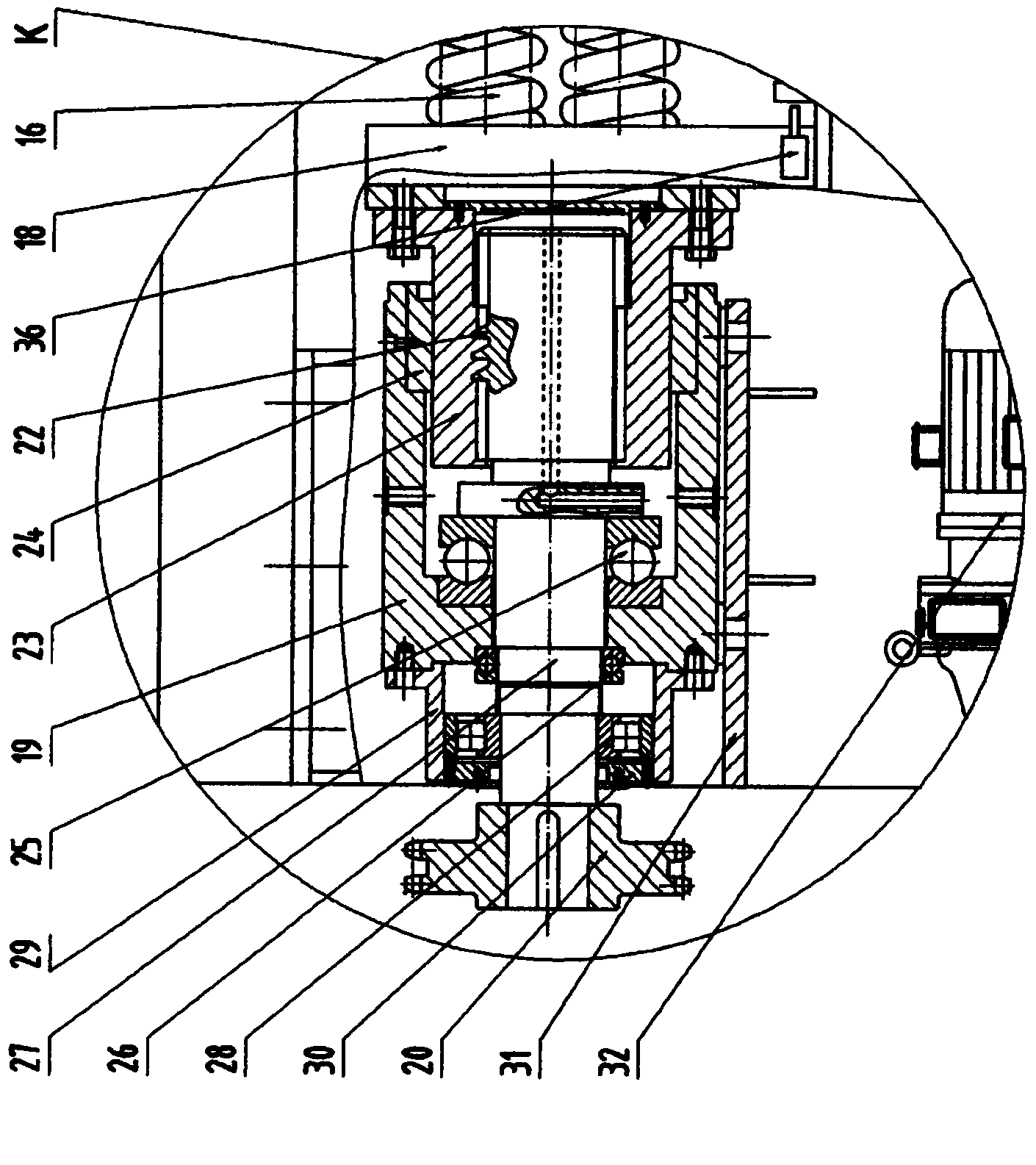

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

[0021] The present embodiment is made of frame 2, power unit, movable roller 9, fixed roller 3, fixed roller bearing seat 7 and pressure regulating device.

[0022] The power device includes a prime mover 1, a reduction device 5 and a fixed roller shaft coupling 6. The output end of the prime mover 1 (a motor, an engine or other prime movers can be used, and an electric motor is used in this example) is connected to the reduction device through a belt 4 The input end of 5 and the output end of reduction device 5 are connected to fixed roller 3 through fixed roller coupling 6 (drum-shaped gear coupling is used in this example, other types of couplings can also be used).

[0023] Fixed roller 3 is installed in the upper right p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com