A Pressure Control System for Engine Nozzle Test

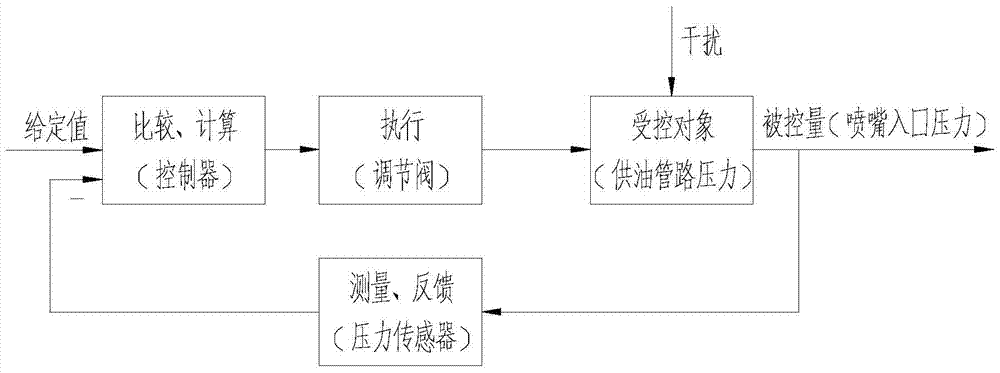

A nozzle test and pressure control technology, applied in the direction of electric fluid pressure control, etc., can solve problems such as pressure measurement interference, slow adjustment, and difficult convergence of the adjustment system, so as to reduce labor intensity, fast pressure adjustment, and improve adjustment stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

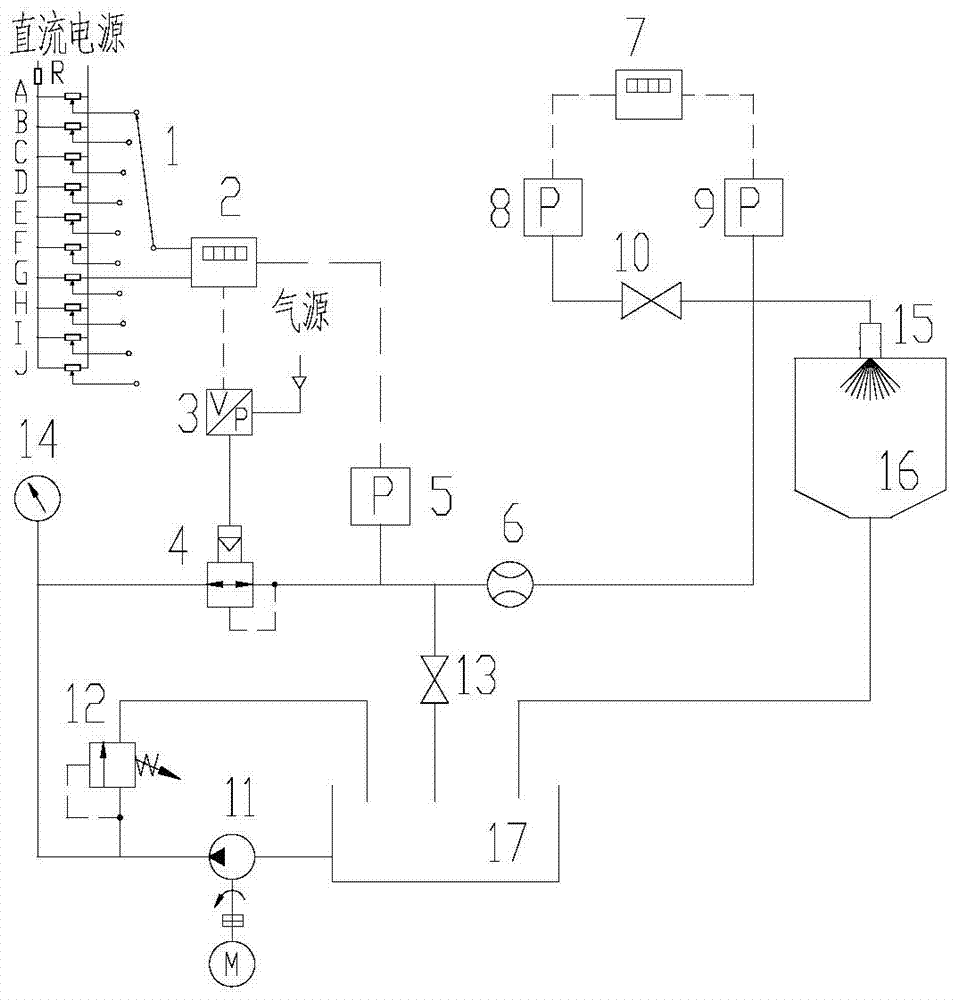

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

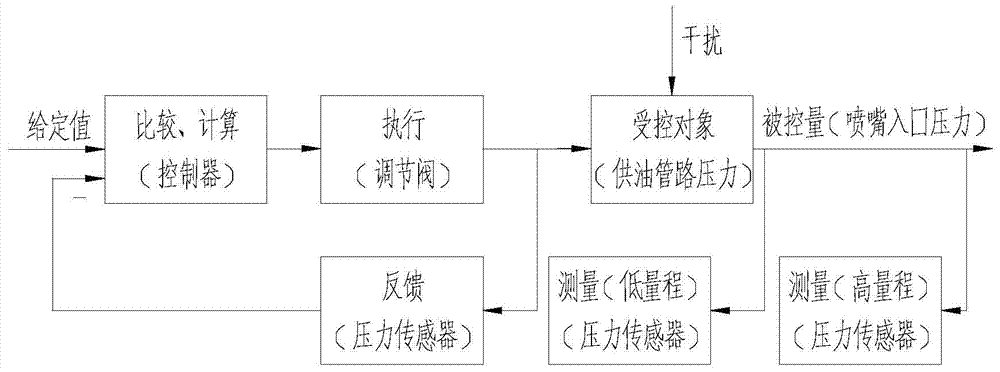

[0023] Such as figure 2 As shown, the pressure control system of the engine nozzle test of the present invention: a new feedback pressure sensor is added, and the pressure sensor is installed on the side of the nozzle behind the regulating valve and is set away from the nozzle, and the fuel pressure entering the nozzle is controlled by the pressure sensor. Measure, and feed back the measured value to the pressure controller synchronously in real time for comparison and calculation, so as to adjust the regulating valve to achieve closed-loop control, close to the nozzle by setting a low-range pressure sensor and a high-range pressure sensor for segmental measurement of nozzle inlet pressure , as a reference for the given value of the external pressure of the oil supply pipeline.

[0024] Install it on the oil supply pipeline after the regulating valve far away from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com