Screw extrusion melt pressure stabilizing device and method

The technology of a voltage stabilizer and a molten material is applied in the field of adjusting the fluctuation of extrusion pressure and the voltage stabilizer on the screw extruder, which can solve the problems of pressure fluctuation, large interference of continuous flow of materials, and inability to meet precision extrusion processing. To achieve the effect of reliable sealing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

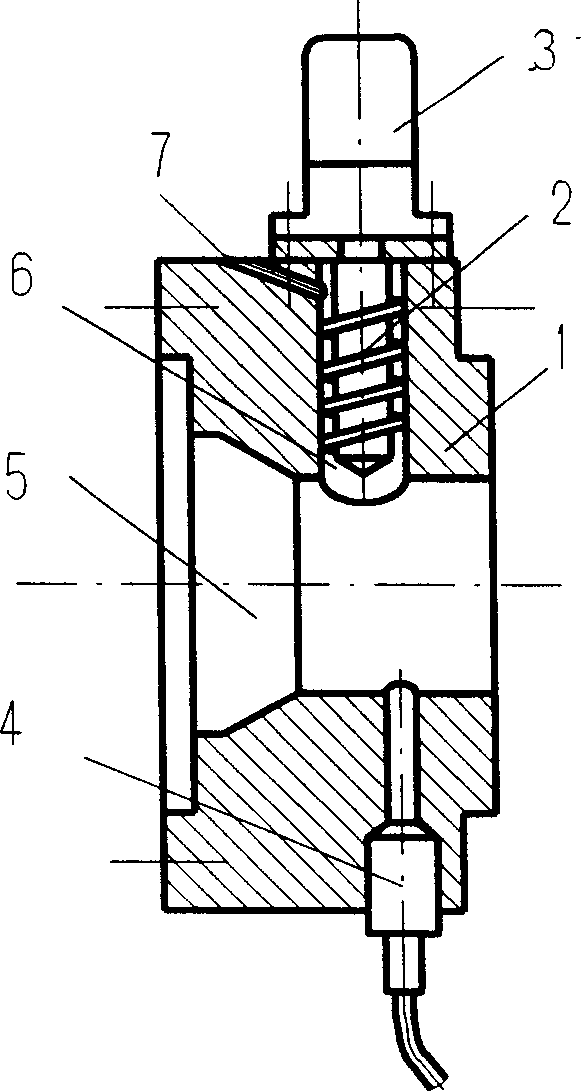

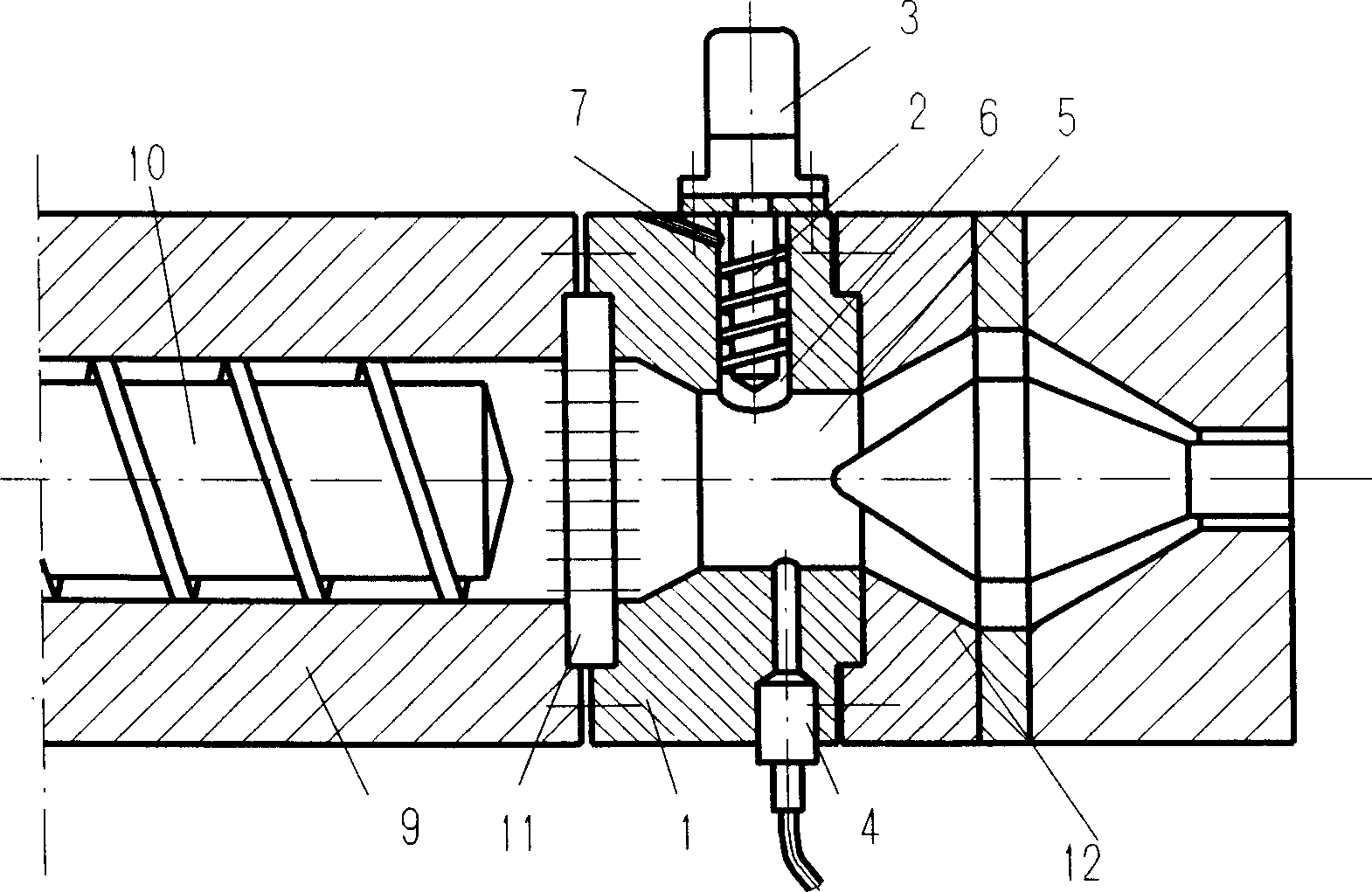

[0017] Such as figure 1 As shown, the voltage stabilizing member in this embodiment is a voltage stabilizing device with a screw structure. It consists of a connecting body 1, a small screw 2, a driving device 3 and a pressure sensor 4. There is a material channel 5 in the middle of the connecting body 1, and a pressure stabilizing hole 6 is opened on the side wall of the channel 5, and the screw 2 is set in the stabilizing hole 6. , the small screw 2 is driven by the driving device 3 (for example: a common motor and a reducer) to rotate in the pressure stabilizing hole, and the overflow hole 7 is located at the sidewall of the stabilizing hole at the thread end of the small screw 2 . The pressure sensor 4 (ordinary pressure sensor) communicates with the material channel of the connecting body, and the pressure sensor controls the driving device 3 to control the rotating speed of the small screw 2 through a general control method. The pressure regulation method of the pressur...

Embodiment 2

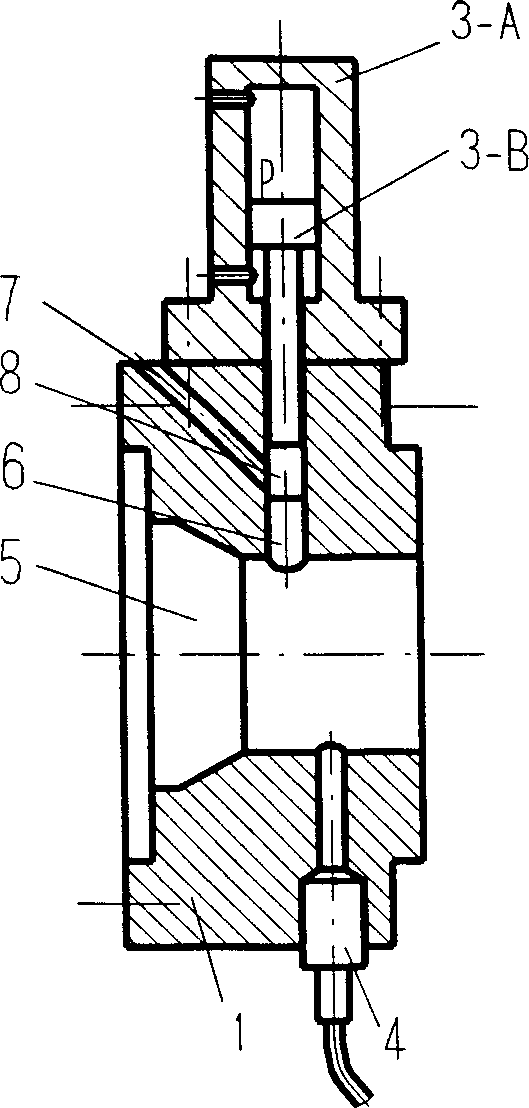

[0019] Such as figure 2Shown: The pressure stabilizing device in this example is a pressure stabilizing device with a piston structure, and the voltage stabilizing device is composed of a connecting body, a piston assembly, a driving device and a pressure sensor. There is a material channel 5 in the middle of the connecting body 1, and a pressure stabilizing hole 6 is opened on the side wall of the channel 5. The piston pressurizing rod 8 is set in the stabilizing hole 6, and a piston 3-B is connected to its end, and the piston is installed in the connection. In the piston cylinder outside the body, it is driven by power to advance or retreat, and the piston pressure rod is driven to move axially in the pressure stabilizing hole 6. The driving device can be as follows: figure 2 The shown cylinder 3-A drives the piston 3-B of the cylinder to push the reciprocating motion of the piston pressurizing rod 8 through the pumping station. The cylinder 3-A can also be a hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com