Extrusion molding machine head for aluminum profile

A technology of extrusion molding and aluminum profiles, applied in the field of mechanical devices, can solve the problems of difficult disassembly and narrow space of fixed aluminum extrusion dies, and achieve the effects of simple structure, improved production efficiency, and simple and fast positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

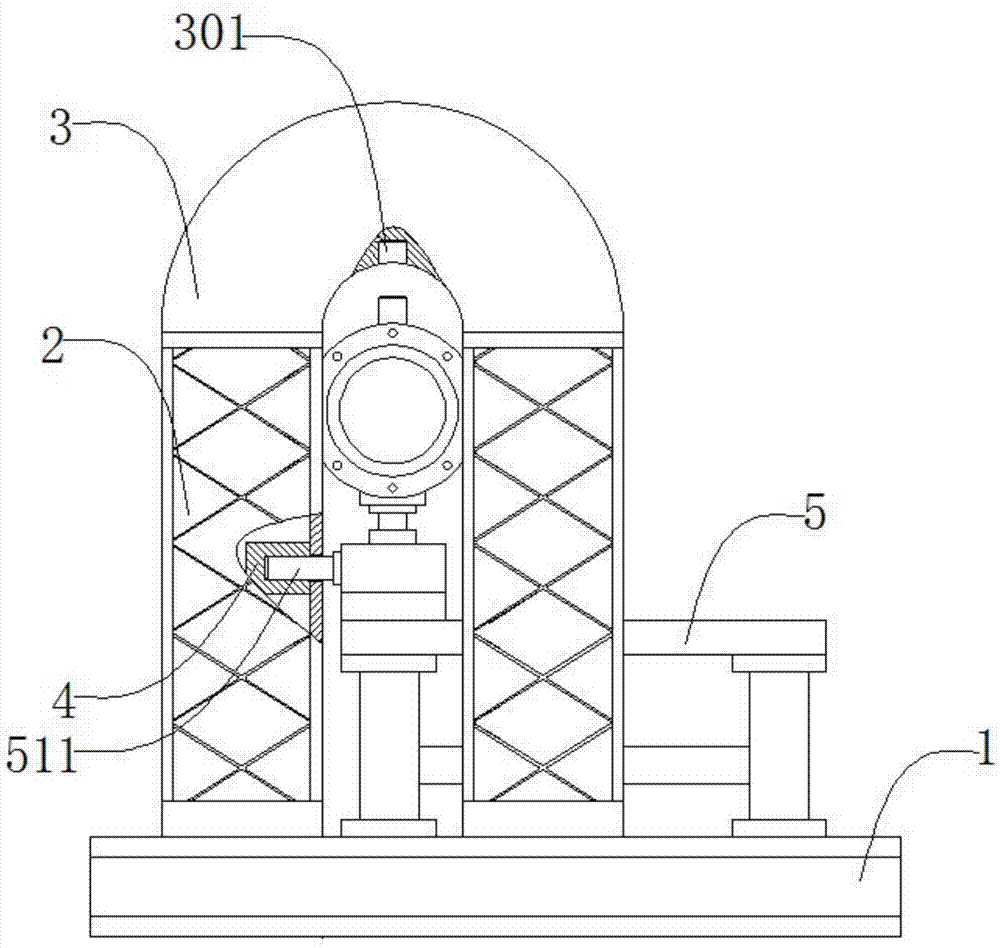

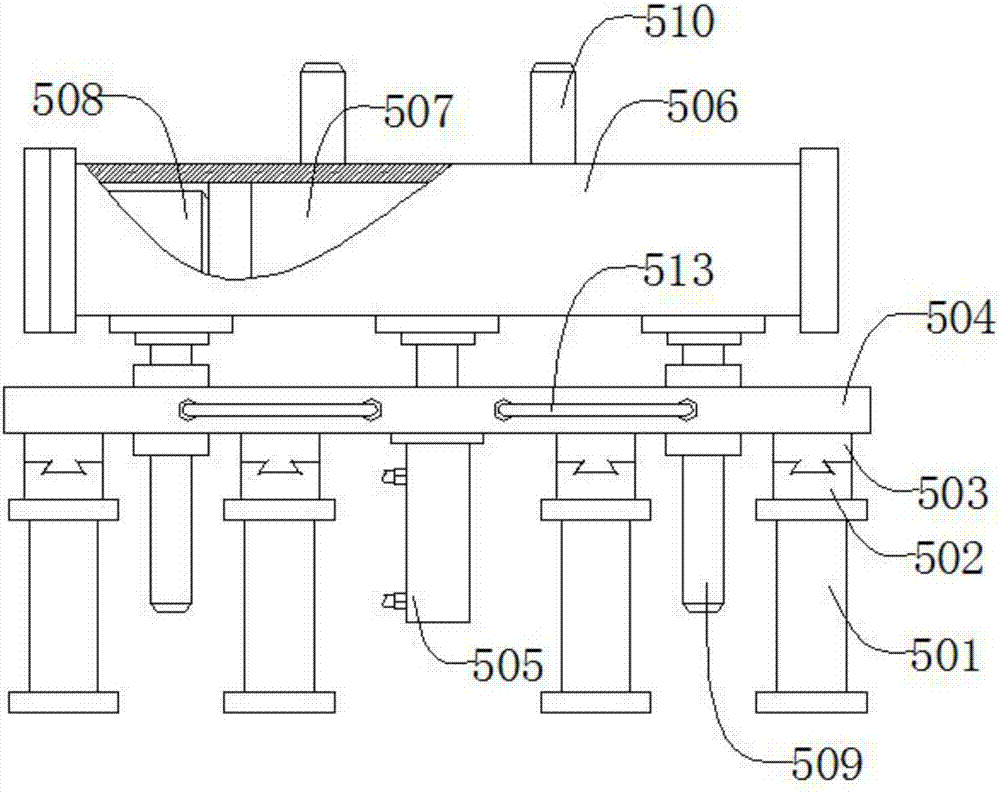

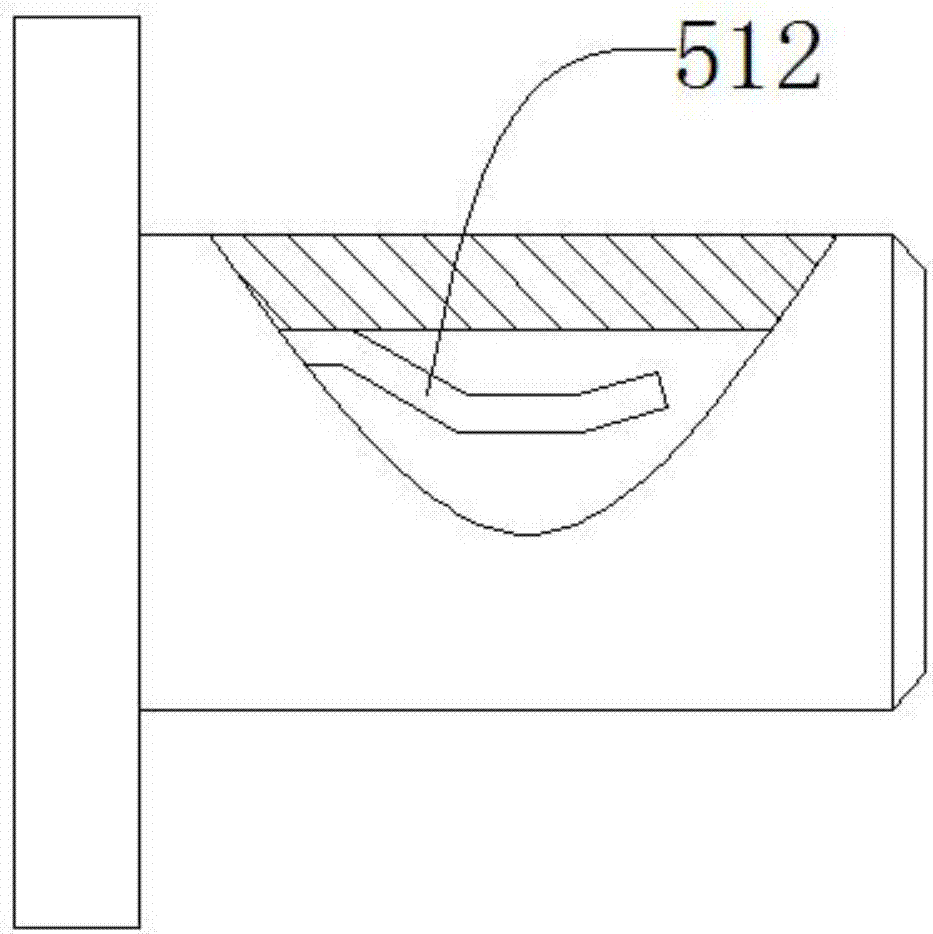

[0026] like figure 1 , figure 2 , image 3 As shown, an aluminum extrusion molding machine head, a base 1, a door frame 2, a jack 3, a limit sleeve 4, and an aluminum extrusion die mechanism 5, the door frame 2 is located at the upper end of the base 1, and the door The frame 2 is threadedly connected with the base 1, and the jacking 3 is located at the upper end of the door frame 2, and the jacking 3 is threadedly connected with the door frame 2, and the door frame 2 is also provided with a limit sleeve 4, and the limiter The bit sleeve 4 is connected to the door frame 2 by welding; the aluminum extrusion mechanism 5 also includes a support frame 501, a guide rail 502, a slider 503, a sliding plate 504, a cylinder 505, a mold barrel 506, and a number of not less than 3 pieces. Aluminum extrusion die 507, guide end cap 508, guide rod 509, first positioning pin 510 of 2 pieces, second positioning pin 511 of 2 pieces, shrapnel 512, the support frame 501 is located at the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com