Die used in extrusion moulding of high-precision complex copper alloy thrust bearing seat

A thrust bearing and extrusion forming technology, which is applied in the direction of metal extrusion dies, etc., can solve the problems of workpiece retention, small shape and size of extrusion punches, and poor economy, so as to reduce labor intensity, shorten the manufacturing process, and improve material utilization. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments.

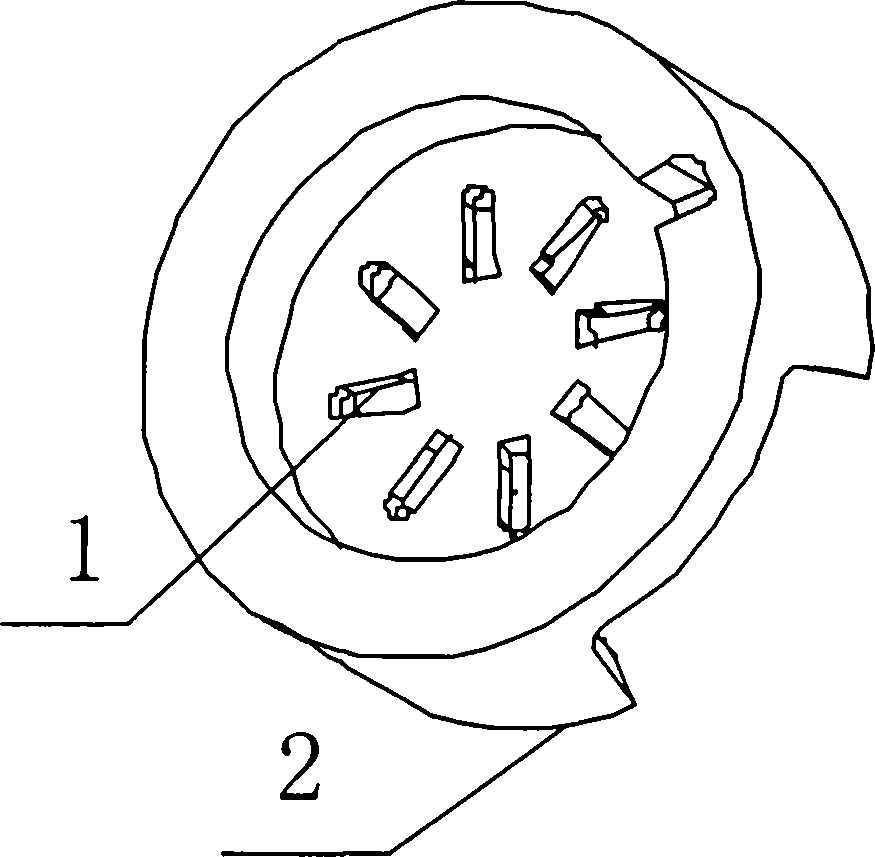

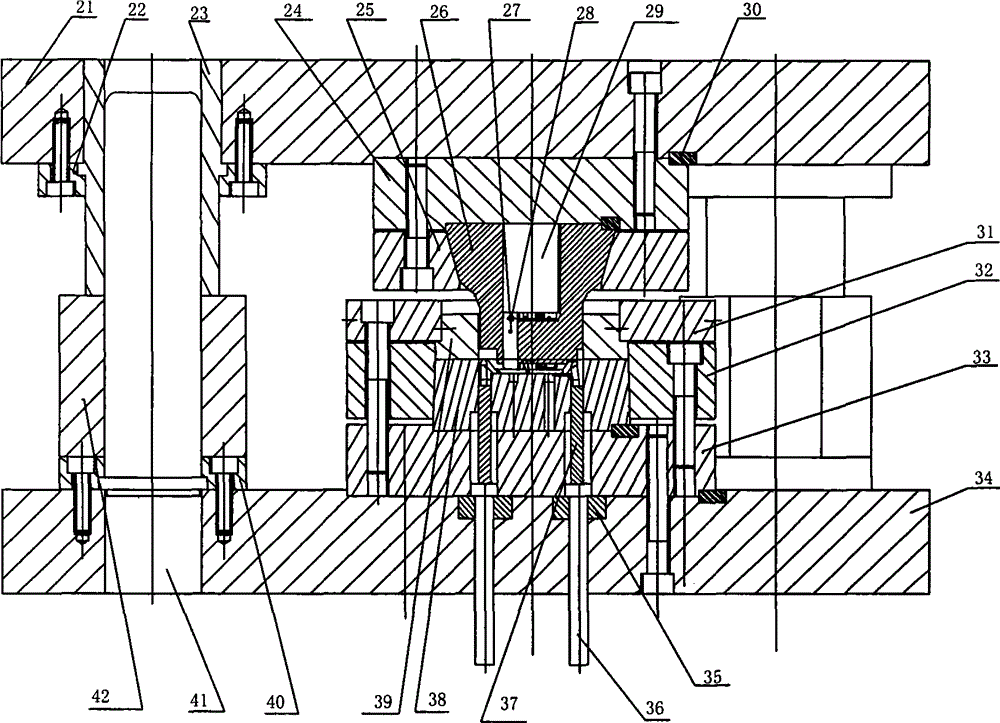

[0026] figure 2 Shown, copper alloy thrust bearing extrusion die ( figure 2 for mold clamping state). The mold includes punch parts (such as Figure 4 shown), die part (such as Figure 5 shown) and guides (such as Figure 6 shown), the ejection part ( Figure 7 Recursive ejector structure).

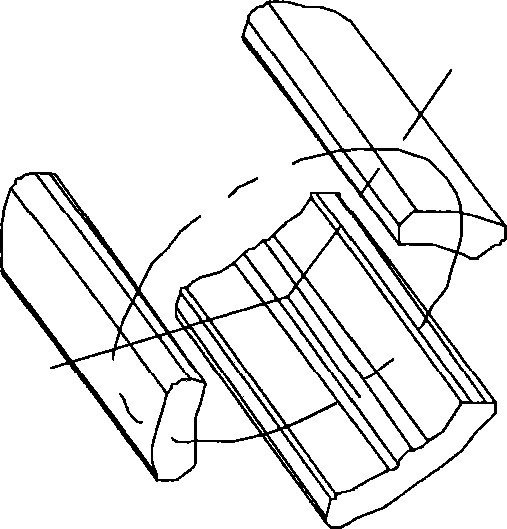

[0027] The punch part includes a punch body 26 and an oil groove punch 27 (eight in total), a hanger pin 28, a plug 29, an upper fixing plate 25, an upper backing plate 24 and an upper template 21; The upper backing plate 24 and the upper fixing plate 25 are connected together, the upper backing plate 24 is connected with the upper formwork 21, and the upper formwork 21 is connected with the press by bolts; in order to ensure that the oil groove punch 27 is quickly changed after wear and tear, the punch part is designed as Inlaid type, the oil groove punch 27 is fixed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com