High-precision dropper extrusion device for medical assay

An extrusion device and high-precision technology, which is applied in the field of high-precision dropper extrusion devices for medical testing, can solve the problems of affecting the accuracy of the output, easy to extrude, and the extrusion volume cannot be controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

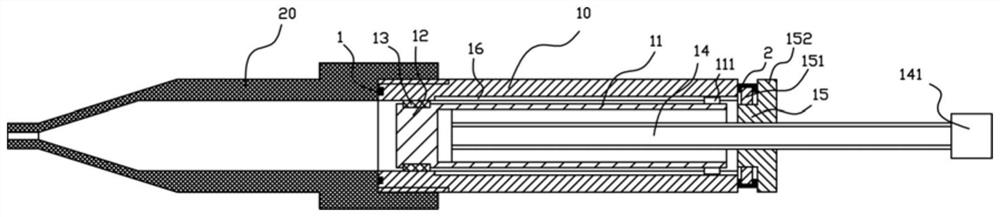

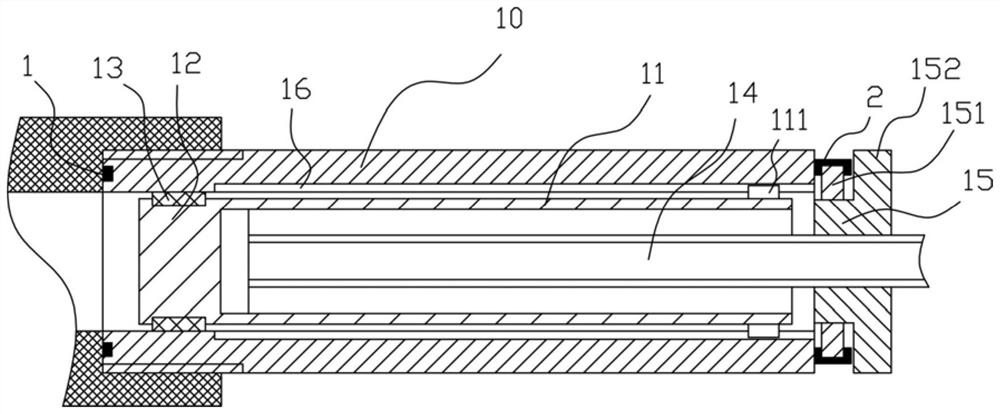

[0017] Example: see Figure 1 to Figure 2 As shown, a dropper extrusion device for high-precision medical testing includes a main connection sleeve 10, the left end of the main connection sleeve 10 is connected with an extrusion dropper 20, and the middle part of the main connection sleeve 10 is inserted into the sleeve There is a telescopic sleeve body 11, the left end of the telescopic sleeve body 11 is formed with a connector 12, and an annular groove is formed on the outer wall of the connector 12, and the sealing ring 13 is nested in the annular groove, thereby being fixed on the connector 13, The outer wall of the sealing ring 13 is close to the left end inner wall of the main connecting sleeve 10, and the diameter of the inner wall of the main connecting sleeve 10 is the same as the diameter of the inner wall of the main body of the extruding dropper 20;

[0018] The middle part of the right side wall of the connecting head 12 is fixed with a connecting screw 14, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com