Wood plastic physical micro-foaming squeezing type injection molding machine and molding process

An injection molding machine and micro-foaming technology, which is applied in the field of wood-plastic material production equipment, can solve the problems of uneven pore size, high brittleness of product molding, and poor compactness, and achieve simple structure, high brittleness, and poor bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

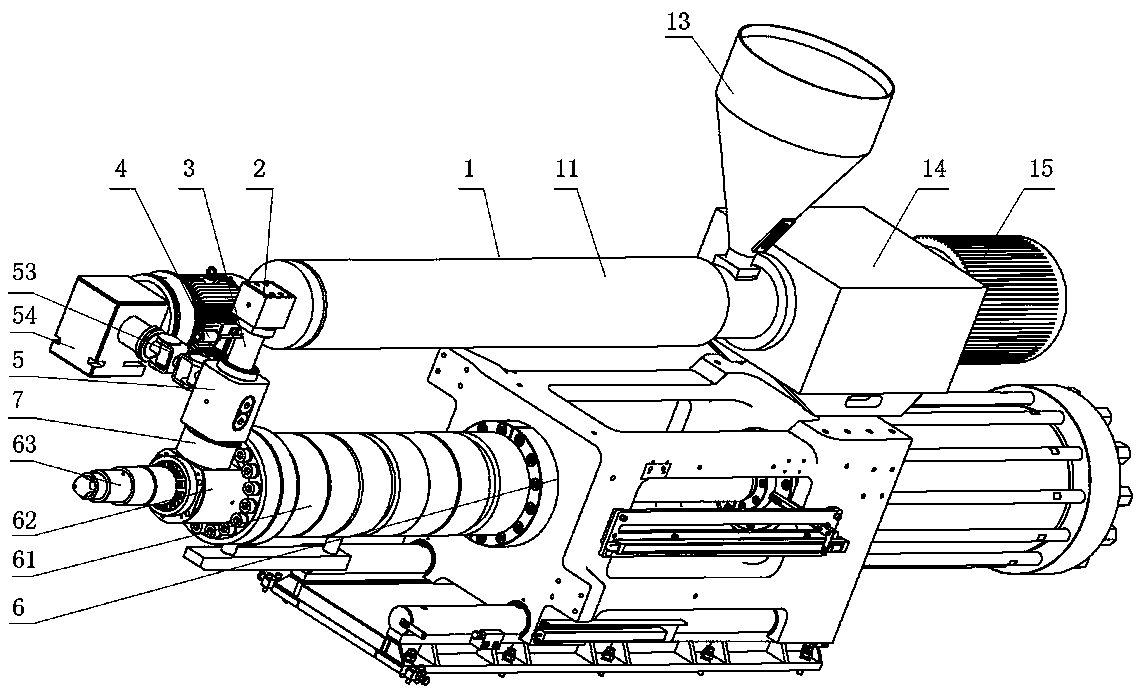

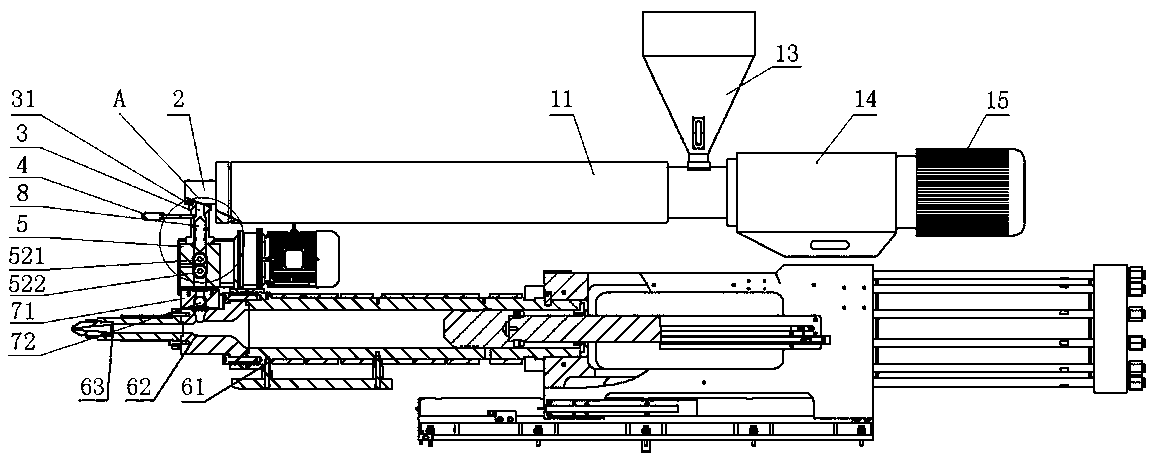

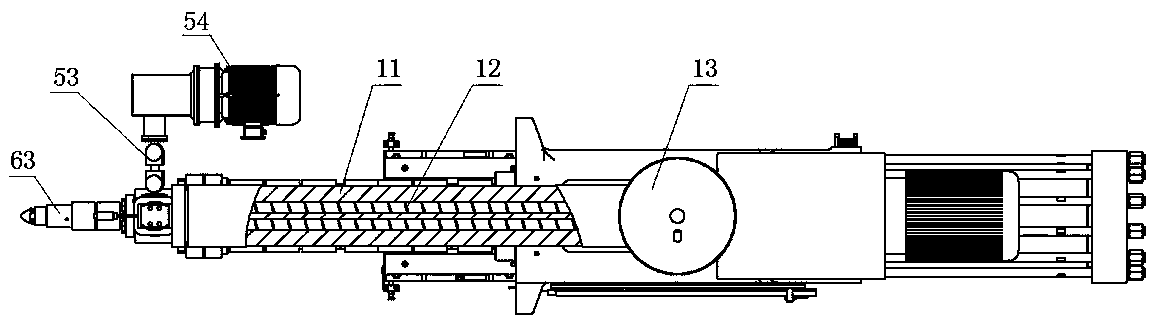

[0038] As shown in the figure, a wood-plastic physical micro-foaming extrusion injection molding machine in this embodiment includes a twin-screw extruder 1 and an injection mechanism 6. The twin-screw extruder 1 includes a barrel 11, and the barrel 11 Two screw rods 12 are arranged inside, and the two screw rods 12 are arranged in parallel and meshed with each other. The two screw rods 12 are connected with the driving motor 15 through the reduction box 14 at the front end. The input end of the material barrel 11 is provided with a hopper 13, and the output A barrel precursor 2 is arranged at the end of the barrel, and a connecting body 3 is arranged under the barrel precursor 2, and a supercritical fluid inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com