Telescopic double-nozzle FDM-3D printer nozzle assembly controlled by electromagnetic

An FDM-3D, nozzle assembly technology, applied in the field of additive manufacturing, can solve the problems of complex internal structure, nozzle influence, increase in the weight of the print head, etc., to reduce control difficulty, reduce weight, and improve printing accuracy and surface accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

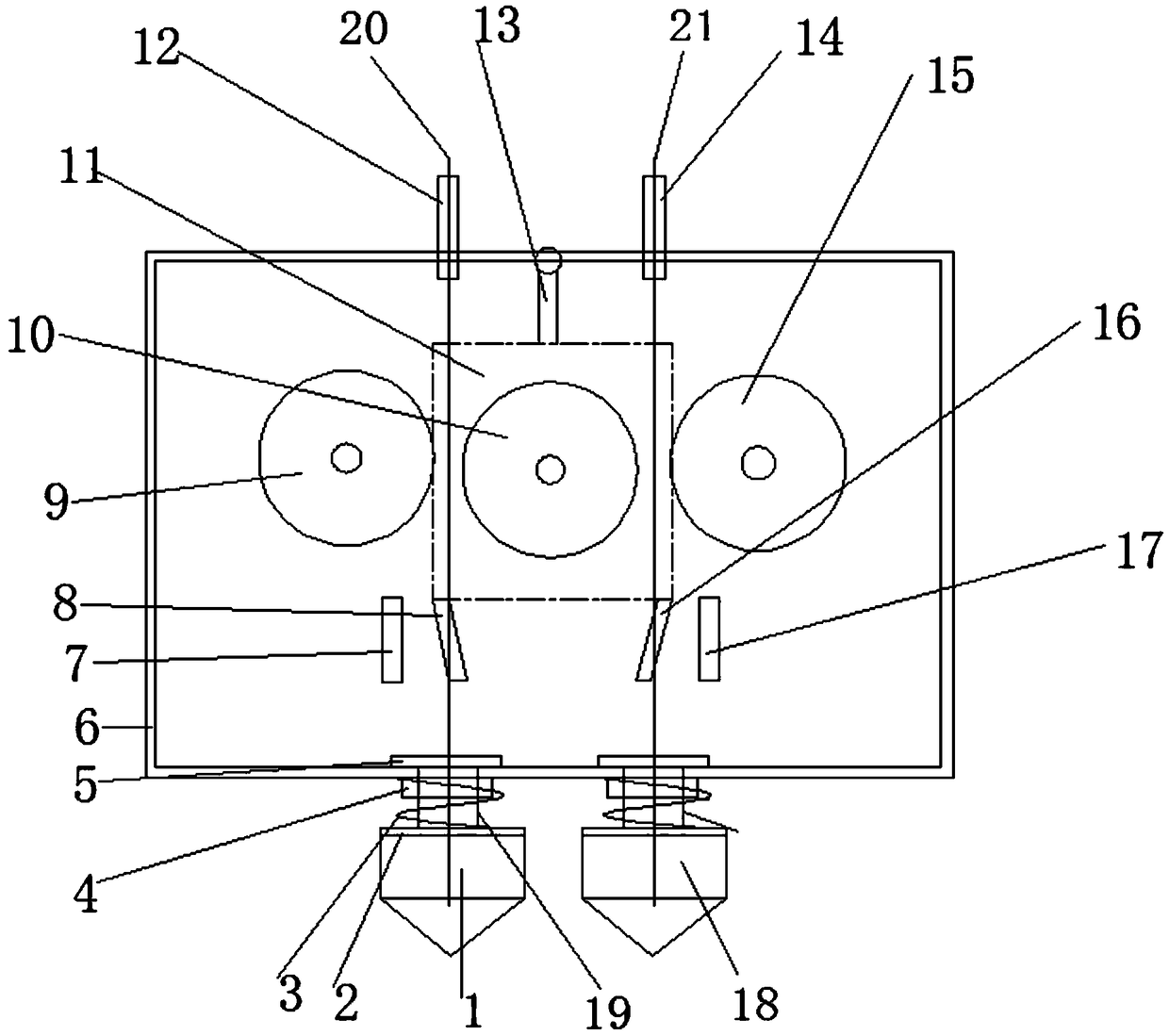

[0032] Such as figure 1 As shown, the spray head assembly of the present invention includes a fixed frame 6 , a motor 11 and a driving wheel 10 .

[0033] The first driven wheel 9 and the second driven wheel 15 are respectively symmetrically arranged on both sides of the driving wheel 10, and the end faces of the three are in the same plane. Connected so that the driving wheel 10 and the motor 11 can swing towards both sides.

[0034] Both sides of the bottom of the motor 11 are respectively symmetrically fixed with a second iron sheet 8 and a third iron sheet 16, and the outer sides of the second iron sheet 8 and the third iron sheet 16 are respectively symmetrically provided with a second electromagnet 7 and a second electromagnet fixed on the fixed frame 6. Three electromagnets 17.

[0035] The fixing frame 6 is respectively provided with a first material guide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com