Novel rubber pipe extruding machine

A rubber tube and extruder technology, applied in the field of rubber production, can solve the problems of low working efficiency, waste of raw materials and labor, poor quality stability, etc., and achieve the effect of avoiding rubber hardening, improving product quality and uniform extrusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

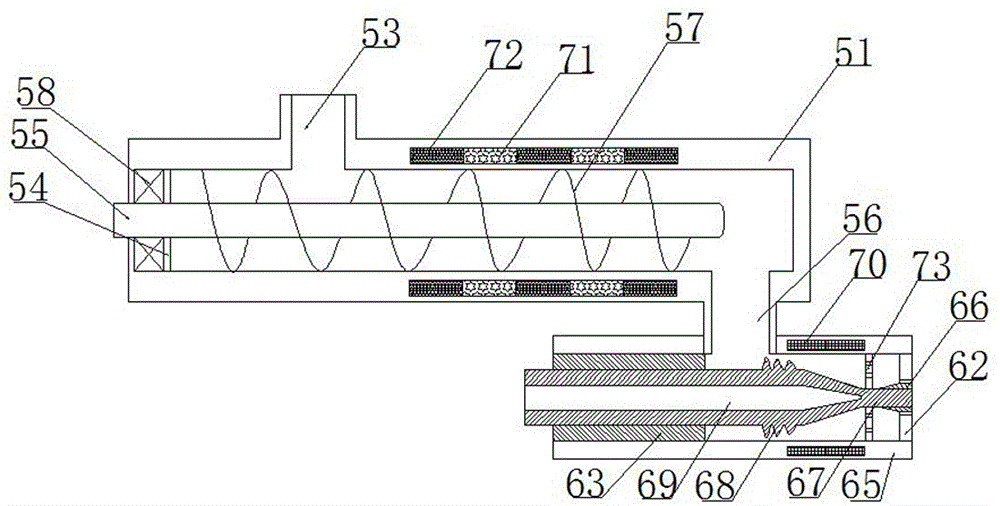

[0014] figure 1 Shown is a novel rubber tube extruder provided by the present invention, including a feed cylinder 51, a feed port 53, a rotating shaft 55, a discharge port 56, a feed thread 57, a bearing 58, a housing 65, a core sleeve 66, Mold core 67, protrusion 68, cavity 69, electric heating wire heating ring 72, infrared heater 71, hot water heat conduction layer 70, porous plate 73, annular cylinder 63 and grinding sleeve 62. The rotating shaft 55 is connected with the feed cylinder 51 through a bearing 55; one end of the feed cylinder 51 is provided with a feed port 53, and the other end is provided with a discharge port 56; the rotating shaft 55 is provided with a feeding thread 57; The feeding cylinder 51 is equipped with a heating layer, and the heating layer includes an electric heating wire heating ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com