Method for producing super high molecular weight polyvinyl products by screw extruder

An ultra-high molecular weight, screw extruder technology, applied in the polymer field, can solve the problems of long operation time, high production cost, small friction coefficient, etc., and achieve the effect of uniform material distribution, reduced production cost and increased plasticization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

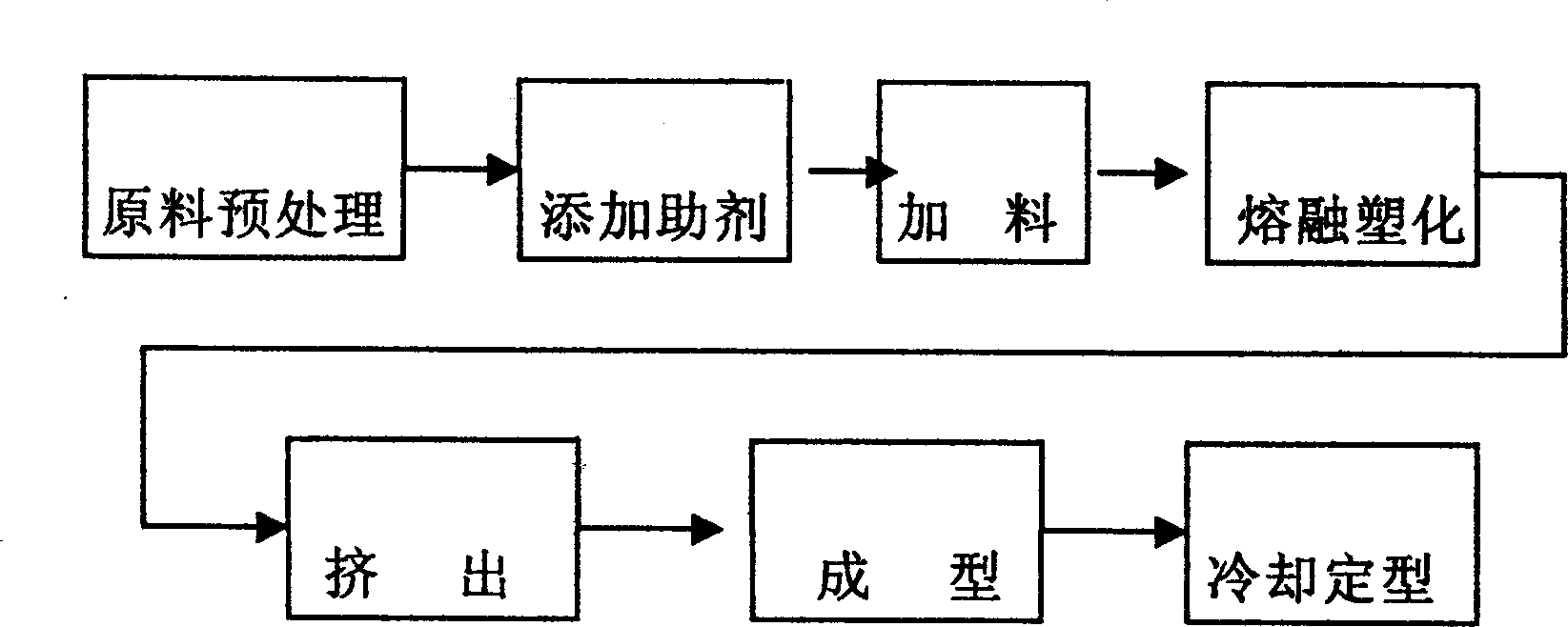

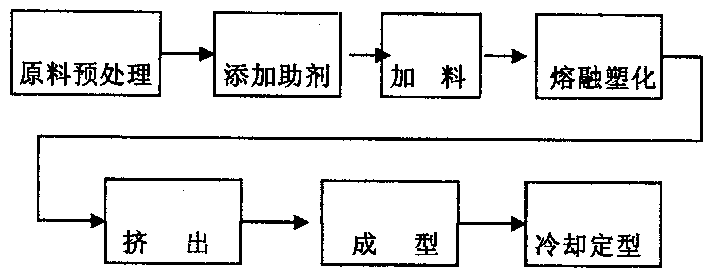

Image

Examples

Embodiment 1

[0025] a. Raw material pretreatment, using a high-speed mixer to stir the ultra-high molecular weight polyethylene, so that the powdery raw materials will generate heat due to friction, and remove the moisture in the raw materials.

[0026] b. Add additives, add modifying additive liquid crystal polymer LCP to the raw material ultra-high molecular weight polyethylene to form a mixture, wherein the ultra-high molecular weight polyethylene is 95%, and the liquid crystal polymer LCP is 5%;

[0027] c, feeding, adding the above mixture into the feeding port of the twin-screw extruder;

[0028] d. Melting and plasticizing, using a twin-screw extruder to melt and modify the above mixture. The aspect ratio of the twin-screw is 27. The axes of the two screws are approximately parallel and rotate in the same direction. The temperature of the barrel is set to 4 sections. Stage 1: 115°C, Stage 2: 180°C, Stage 3: 260°C, Stage 4: 260°C;

[0029] e. Extrude, put the above-mentioned molten ...

Embodiment 2

[0033] a. Raw material pretreatment, using a high-speed mixer to stir the ultra-high molecular weight polyethylene, so that the powdery raw materials will generate heat due to friction, and remove the moisture in the raw materials.

[0034] b. Add additives, add modifying additive liquid crystal polymer LCP to the raw material ultra-high molecular weight polyethylene to form a mixture, wherein the ultra-high molecular weight polyethylene is 85%, and the liquid crystal polymer LCP is 15%, the unit is percentage by weight;

[0035] c, feeding, adding the above mixture into the feeding port of the twin-screw extruder;

[0036] d. Melting and plasticizing, using a twin-screw extruder to melt and modify the above mixture. The twin-screw length-to-diameter ratio is 23. The axes of the two screws are approximately parallel and rotate in the same direction. The temperature of the barrel is set to 4 sections. Stage 1: 80°C, Stage 2: 130°C, Stage 3: 220°C, Stage 4: 220°C;

[0037] e. E...

Embodiment 3

[0041] a. Raw material pretreatment, using a high-speed mixer to stir the ultra-high molecular weight polyethylene, so that the powdery raw materials will generate heat due to friction, and remove the moisture in the raw materials.

[0042] b. Add additives, add modifying additive liquid crystal polymer LCP to the raw material ultra-high molecular weight polyethylene to form a mixture, wherein the ultra-high molecular weight polyethylene is 90%, and the liquid crystal polymer LCP is 10%, the unit is percentage by weight;

[0043] c, feeding, adding the above mixture into the feeding port of the twin-screw extruder;

[0044] d. Melting and plasticizing, using a twin-screw extruder to melt and modify the above mixture. The twin-screw length-to-diameter ratio is 25. The axes of the two screws are approximately parallel and rotate in the same direction. The temperature of the barrel is set to 4 sections. Stage 1: 95°C, Stage 2: 155°C, Stage 3: 240°C, Stage 4: 240°C;

[0045] e. Ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com